Combined assembly type heat-insulation plate

A combined assembly and insulation board technology, applied in the direction of insulation, building components, etc., can solve the problems of thermal insulation material loss of thermal insulation effect, thermal insulation material is prone to moisture failure, simple structure of thermal insulation board, etc., to achieve strong thermal insulation effect and simple structure , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

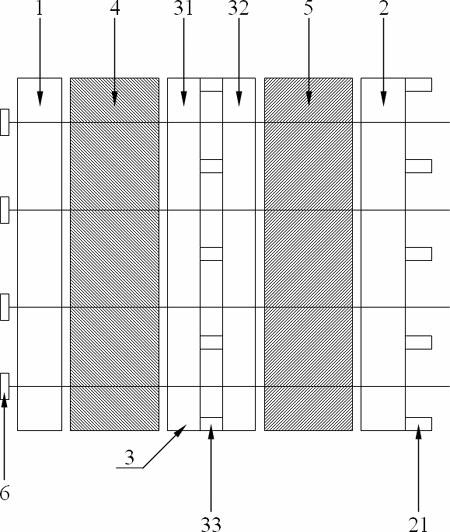

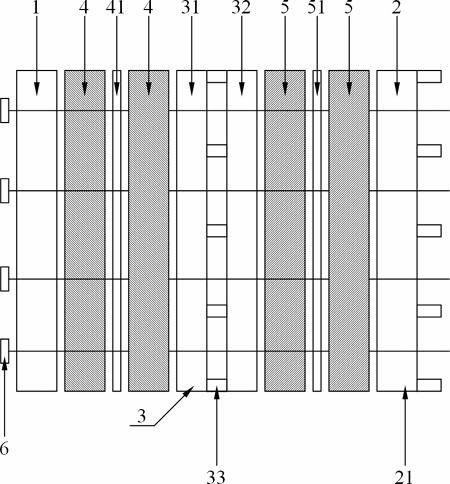

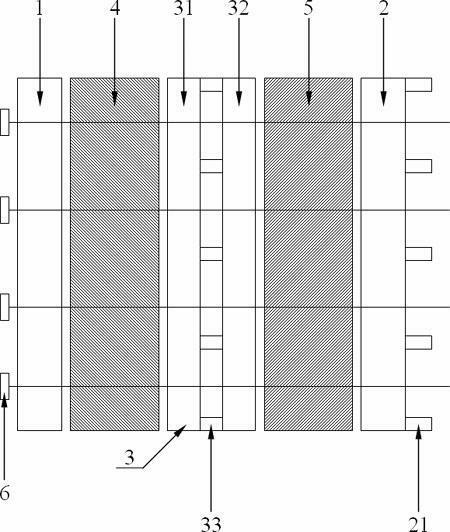

[0016] A combined assembly type insulation board, comprising an outer bracket 1, an inner bracket 2, a spacer layer 3, an outer insulation layer 4, an inner insulation layer 5 and a connecting rod 6, such as figure 1 As shown, the specific structure is: the outer support 1 is arranged on the outside of the inner support 2, the spacer layer 3 is arranged between the outer support 1 and the inner support 2, the outer heat preservation layer 4 is embedded between the outer support 1 and the spacer layer 3, and the inner heat preservation The layer 5 is embedded between the inner support 2 and the spacer layer 3, and the connecting rod 6 connects and fastens the outer support 1, the outer heat preservation layer 4, the spacer layer 3, the inner heat preservation layer 5 and the inner support 2 sequentially from the outside to the inside; the inner support 2 is also fixed with an inner boss 21 on the inner side of the inner support 2. The inner boss 21 is evenly distributed from the...

Embodiment 2

[0021] A combined assembly type thermal insulation board, comprising an outer bracket 1, an inner bracket 2, a spacer layer 3, an outer thermal insulation layer 4, an inner thermal insulation layer 5 and a connecting rod 6, the specific structure is: the outer thermal insulation layer 4 and the inner thermal insulation layer 5 are made of The thermal insulation block is composed of outer covering film, the thermal insulation block is made of glass fiber cotton, and the film is made of fiber cloth coated with fireproof material. Both the outer support 1 and the inner support 2 are composed of fibers, auxiliary materials and base materials, and the auxiliary materials and the base materials are evenly mixed and then coated on the outside of the fibers. The fibers are made of glass fibers; the base materials are made of resin; the auxiliary materials are made of quartz Powder, calcium carbonate, talcum powder, barium sulfate and fibers are uniformly mixed, and the resin is polyami...

Embodiment 3

[0024] A combined assembly type thermal insulation board, comprising an outer bracket 1, an inner bracket 2, a spacer layer 3, an outer thermal insulation layer 4, an inner thermal insulation layer 5 and a connecting rod 6, the specific structure is: the outer thermal insulation layer 4 and the inner thermal insulation layer 5 are made of The insulation block is covered with a film, the insulation block is made of foam glass, and the film is made of fiber cloth coated with waterproof material. Both the outer support 1 and the inner support 2 are composed of fibers, auxiliary materials and base materials, and the auxiliary materials and the base materials are evenly mixed and then coated on the outside of the fibers. The fibers are selected from basalt fibers; the base materials are selected from cement; the auxiliary materials are made of quartz Sand, fly ash, water reducing agent and fiber are evenly mixed, and the cement is made of high-strength cement.

[0025] Other struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com