Ultraviolet-resistant radiation-protection aqueous ultra-thin fire resistive coating for steel structure and preparation method thereof

A UV-resistant and fire-resistant coating technology, applied in fire-resistant coatings, coatings, etc., can solve problems such as poor flame retardancy, fire resistance and heat insulation performance, large release of organic volatiles, and affecting the service life of steel structures. Achieve the effects of good flame retardancy, good weather resistance and excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

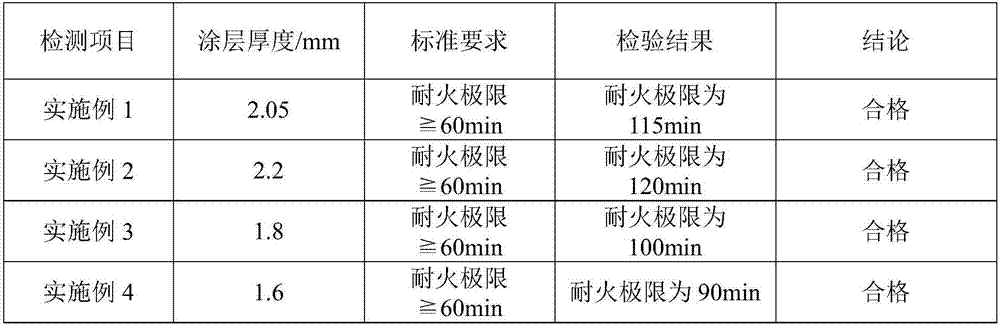

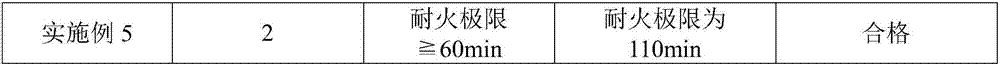

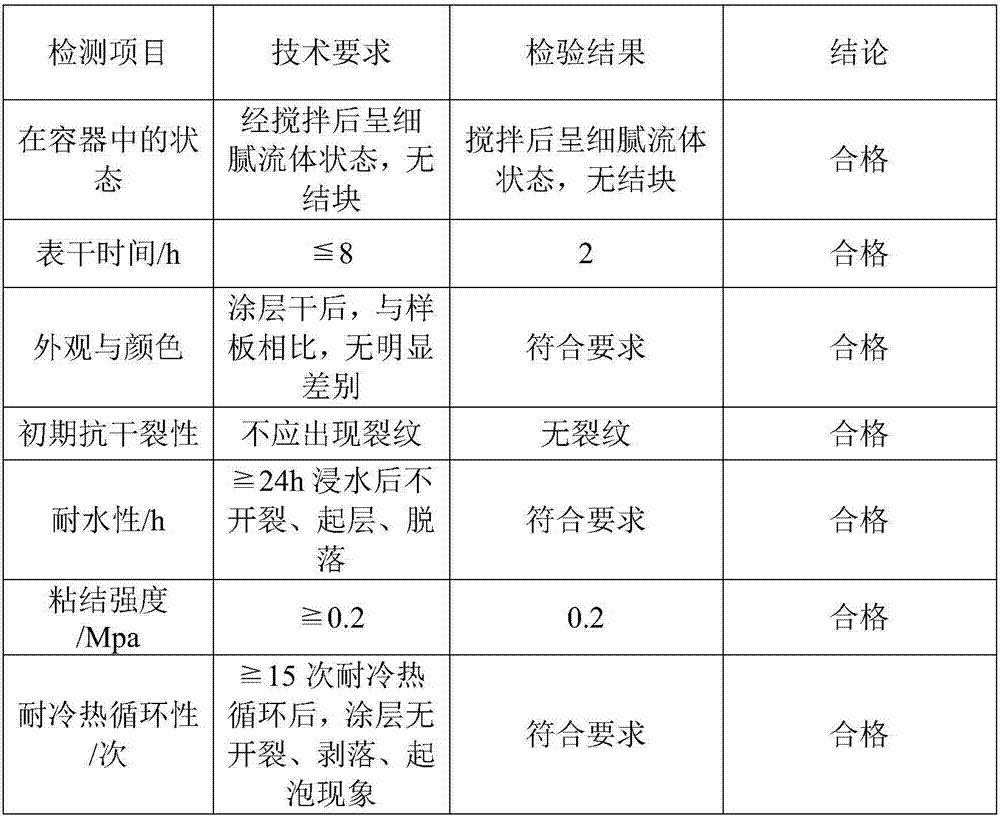

Examples

Embodiment 1

[0033] This embodiment provides a water-based ultra-thin fireproof coating for steel structures resistant to ultraviolet rays and radiation. The raw material components include:

[0034] Ethylene-vinyl acetate emulsion 707 # (viscosity is 2000MPa s, solid content is 55wt%), 6 parts by weight;

[0035] Polyvinyl acetate emulsion 235 # (viscosity is 25000MPa s, solid content is 35wt%), 15 parts by weight;

[0036] A mixture of ammonium polyphosphate with a degree of polymerization of 1000 and ammonium polyphosphate with a degree of polymerization of 30 according to a mass ratio of 2:3, 25 parts by weight;

[0037] Melamine, 12.5 parts by weight;

[0038] Pentaerythritol, 12.5 parts by weight;

[0039] Zinc borate (ZnO accounts for 38wt%, B 2 o 3 accounted for 48wt%, water of crystallization accounted for 14wt%, particle size is 325 mesh), 2 parts by weight;

[0040] Dicyandiamide, 1 part by weight;

[0041] Expandable graphite (expandable multiple of 500), 1 part by weig...

Embodiment 2

[0048] This embodiment provides a water-based ultra-thin fireproof coating for steel structures resistant to ultraviolet rays and radiation. The raw material components include:

[0049] Ethylene-vinyl acetate emulsion 707 # (viscosity is 1500MPa s, solid content is 53wt%), 5 parts by weight;

[0050] Polyvinyl acetate emulsion 235 # (viscosity is 20000MPa s, solid content is 33wt%), 10 parts by weight;

[0051] A mixture of ammonium polyphosphate with a degree of polymerization of 1200 and ammonium polyphosphate with a degree of polymerization of 100 according to a mass ratio of 1:1, 20 parts by weight;

[0052] Melamine, 10 parts by weight;

[0053] Pentaerythritol, 10 parts by weight;

[0054] Zinc borate (ZnO accounts for 37wt%, B 2 o 3 accounted for 46wt%, water of crystallization accounted for 13wt%, particle size is 300 mesh), 0.5 parts by weight;

[0055] Dicyandiamide, 0.5 parts by weight;

[0056] Expandable graphite (expandability 100), 0.5 parts by weight; ...

Embodiment 3

[0063] This embodiment provides a water-based ultra-thin fireproof coating for steel structures resistant to ultraviolet rays and radiation. The raw material components include:

[0064] Ethylene-vinyl acetate emulsion 707 # (viscosity is 2500MPa s, solid content is 57wt%), 15 parts by weight;

[0065] Polyvinyl acetate emulsion 235 # (viscosity is 30000MPa s, solid content is 37wt%), 30 parts by weight;

[0066] A mixture of ammonium polyphosphate with a degree of polymerization of 1000 and ammonium polyphosphate with a degree of polymerization of 60 according to a mass ratio of 3:5, 30 parts by weight;

[0067] Melamine, 15 parts by weight;

[0068] Dicyandiamide, 3.5 parts by weight;

[0069] Pentaerythritol, 15 parts by weight;

[0070] Zinc borate (ZnO accounts for 40wt%, B 2 o 3 accounted for 49wt%, water of crystallization accounted for 15wt%, particle size is 350 mesh), 3.0 parts by weight;

[0071] Expandable graphite (expandable multiple 1000), 3.5 parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com