Enhanced door and window auxiliary frame and manufacturing method thereof

A production method and enhanced technology, applied to the base frame and other directions, can solve the problems of damage by insects and ants, poisonous glass fiber reinforced plastic frame, heavy weight of plastic wood frame, etc., to achieve good sound insulation effect and good impact load absorption , Good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

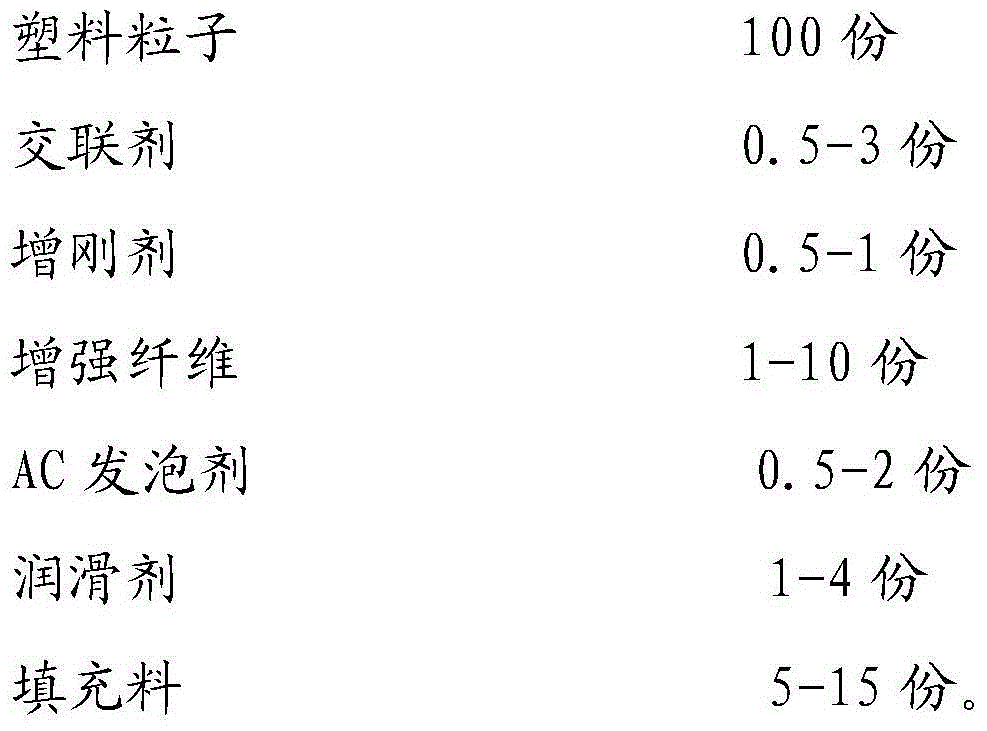

Embodiment 1

[0037] The manufacturing process of reinforced door and window frames includes the following steps:

[0038] (1) Melt 100 parts of high-density polyethylene plastic particles, 0.5 parts of crosslinking agent, 0.5 parts of rigidizer, 1 part of reinforcing fiber, and 5 parts of filler through a twin-screw extruder at high temperature and then extrude and granulate. The temperature is gradually increased from 120°C to 160°C inwards from the machine head, so that the molecular chains of the material are rearranged to obtain a premix, and each component is calculated by weight component;

[0039] (2) Add 0.5 parts of AC foaming agent and 1 part of lubricant, and at the same time, under the condition of process temperature of 60°C-80°C, stir and mix at a high speed to fully wrap the premix to obtain a new premix;

[0040] (3) The new premixed material obtained in step (2) is sent to the progressive extruder, and the temperature of the fuselage is gradually increased from 120°C to 16...

Embodiment 2

[0042] The manufacturing process of reinforced door and window frames includes the following steps:

[0043] (1) Melt 100 parts of polyvinyl chloride plastic particles, 2 parts of cross-linking agent, 0.7 parts of stiffening agent, 5 parts of reinforcing fiber, and 10 parts of filler through a twin-screw extruder at high temperature and then extrude and pelletize. Gradually increase from 120°C to 170°C inwards from the machine head, so that the molecular chains of the material are rearranged to obtain a premix, and each component is calculated by mass component;

[0044] (2) Add 1 part of AC foaming agent and 2.5 parts of lubricant, and at the same time, under the condition of process temperature of 60°C-80°C, stir and mix at a high speed to fully wrap the premix to obtain a new premix;

[0045] (3) The new premixed material obtained in step (2) is sent to the progressive extruder, and the temperature of the fuselage is gradually increased from 120°C to 170°C at the head, resu...

Embodiment 3

[0047] The manufacturing process of reinforced door and window frames includes the following steps:

[0048] (1) Melt 100 parts of FRP plastic particles, 3 parts of cross-linking agent, 1 part of stiffening agent, 10 parts of reinforcing fiber, and 15 parts of filler through a twin-screw extruder at high temperature and then extrude and pelletize. The first 120°C gradually rises inwards to 180°C, so that the molecular chains of the material are rearranged to obtain a premix, and each component is calculated by weight component;

[0049] (2) Add 2 parts of AC foaming agent and 4 parts of lubricant, and at the same time, under the condition of process temperature of 60°C-80°C, stir and mix at a high speed to fully wrap the premix to obtain a new premix;

[0050] (3) The new premixed material obtained in step (2) is sent to the progressive extruder, and the temperature of the fuselage is gradually increased from 120°C to 180°C at the head, resulting in a diameter of 0.01mm-0.5mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com