Patents

Literature

64 results about "Light clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light clay (also light straw clay, light clay straw, slipstraw) is a natural building material used to infill between a wooden frame in a timber framed building using a combination of clay and straw, woodchips or some other lighter material.

Porous ceramicite and preparation method and application thereof

InactiveCN101693631AHigh activityTo promote metabolismWater/sewage treatment by irradiationWater/sewage treatment using germicide/oligodynamic-processRare earthBiological activation

A porous ceramicite and a preparation method and an application thereof in the field of water purifying and filtering technologies, the porous ceramicite comprises the following components in percentage by weight: 2.5%-4.5% of titanium dioxide nanometer grade micro powder, 2%-4.5% of silicon dioxde nanometer grade micro powder, 2.5%-5.5% of zinc oxide nanometer micro powder, 12%-29% of polarity mineral tourmaline powder, 0.5%-1.5% of rare-earth activating agent, 1.5%-3% of ferric oxide red, 3%-10% of feldspar ores, 5%-8% of bergmeal ores, 15%-47% of light clay ores, and the other is water. The method ionizes water into negative ions through realizing infrared, cuts off hydrogen keys through resonance and splits the hydrogen keys into small water molecules (five-six), improves the activation, enables the small molecules into a body, can activate cells, prompts metabolism and acid-base balance, reduces the function of the oxidation-reduction potential ORP value of a water body, and the method can be used for processing water in cups and containers, such as tanks, tower pools, grooves and the like.

Owner:SHANGHAI JIAO TONG UNIV

Light-weight clay

The invention discloses light-weight clay, which consists of the following components in percentage by mass: 8.0 to 20.0 percent of water soluble resin, 26.9 to 85.75 percent of water, 0.05 to 0.1 percent of kathon, 1.0 to 20.0 percent of humectant, 2.0 to 10.0 percent of xanthan gum, 2.0 to 15.0 percent of light-weight padding powder, 1.0 to 8.0 percent of borax and 0.2 to 1.5 percent of colorant. Compared with the conventional clay in the prior art, the light-weight clay has the advantages of easy forming, good handfeel, no greasiness, little possibility of mildewing, long quality guarantee period, innocuity and no peculiar smell.

Owner:深圳云之彩美术工艺用品有限公司

Light clay composition and preparing method

This invention relates to a light weight clay combination, maintains hollow minuteness sphere, water, gelatinizer, humectant and tackifier. The humectant includes sorbitol, tackifier includes polyvinyl alcohol. Under the mating reaction of polyvinyl alcohol, boric acid and sorbitol, this invention has excellent film-forming properties, could execute 0.1 millimeter thick film, furthermore possess excellent tensile property, could execute different kinds of tenuity shape, especially could execute filament with 0.1 millimetric diameter. This combination also possesses excellent hydrating performance, operability and weather resisting property.

Owner:童心奕阳(北京)教育科技有限公司

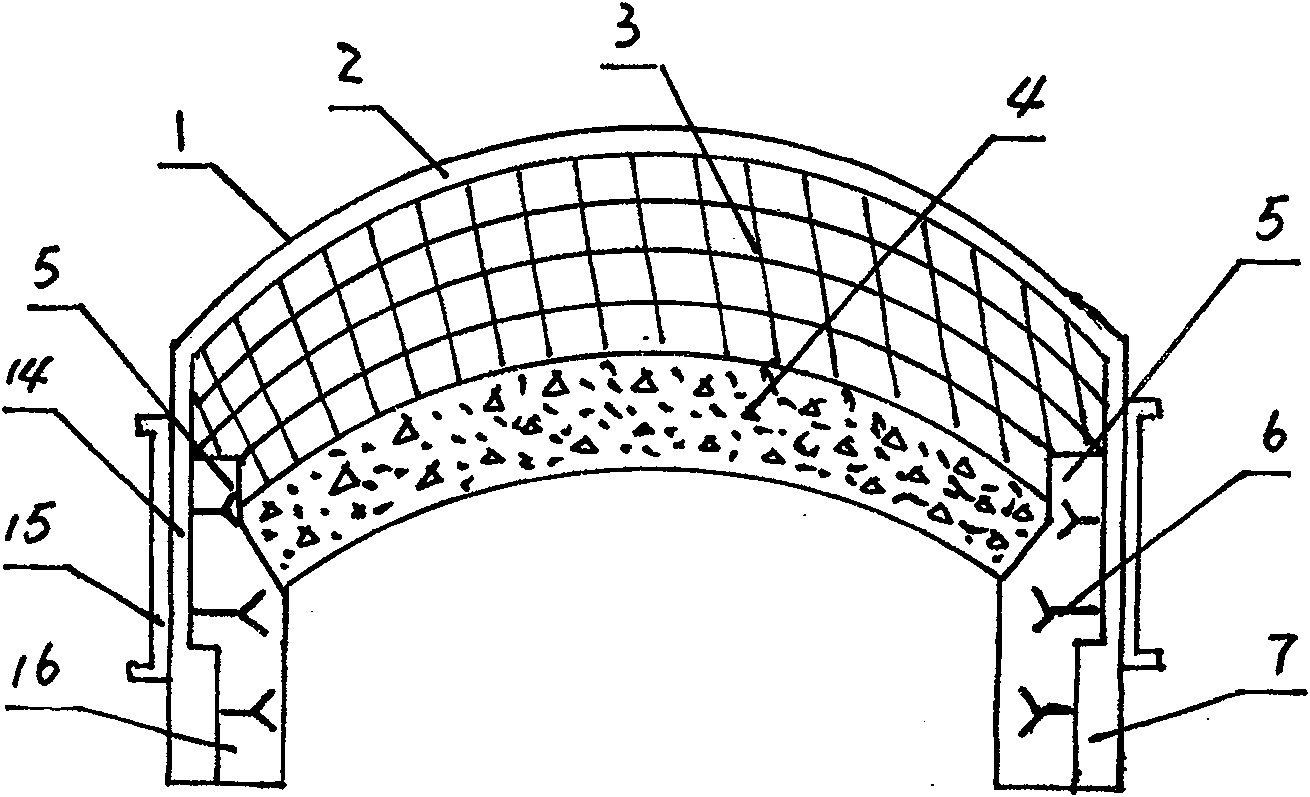

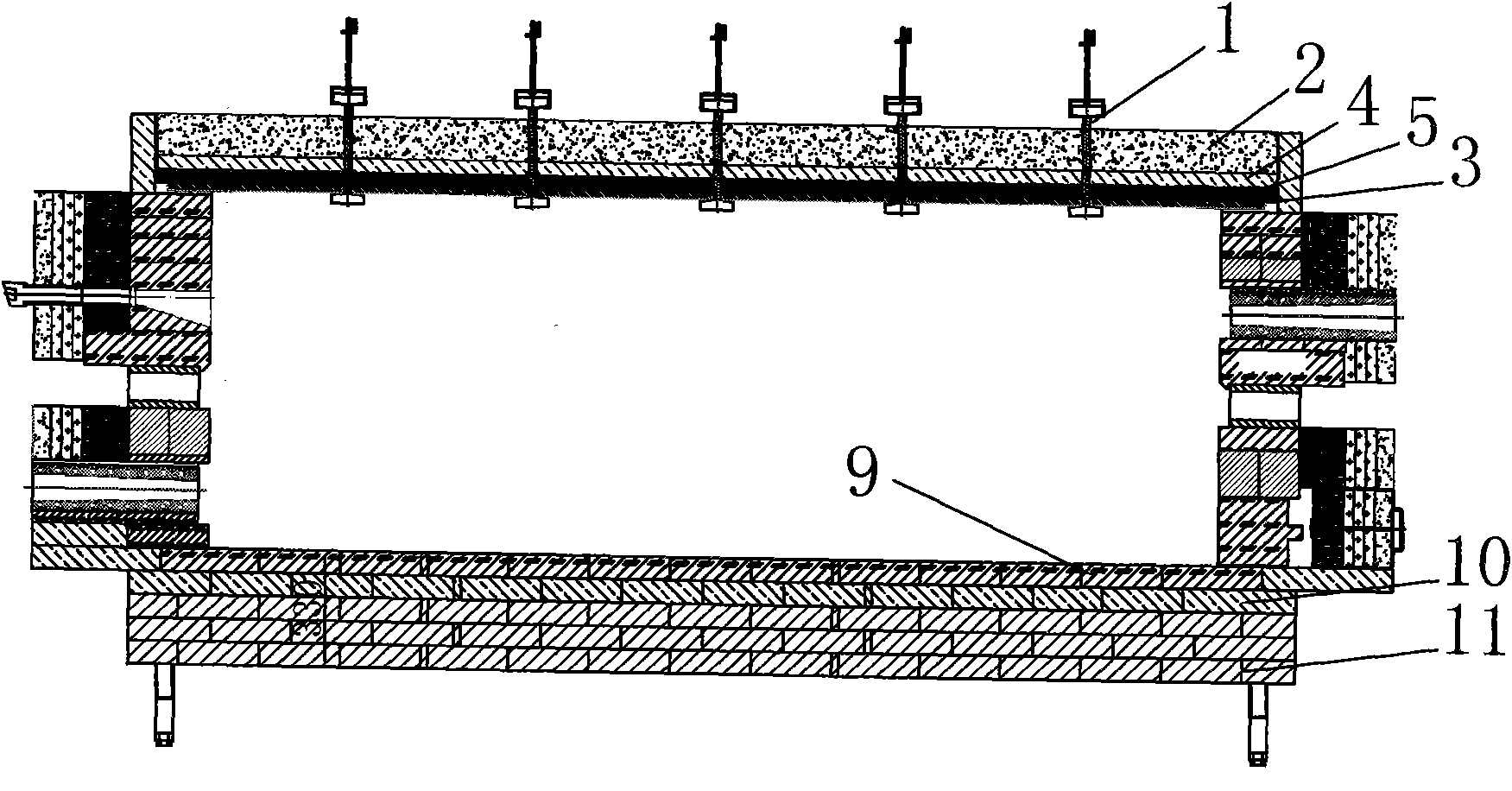

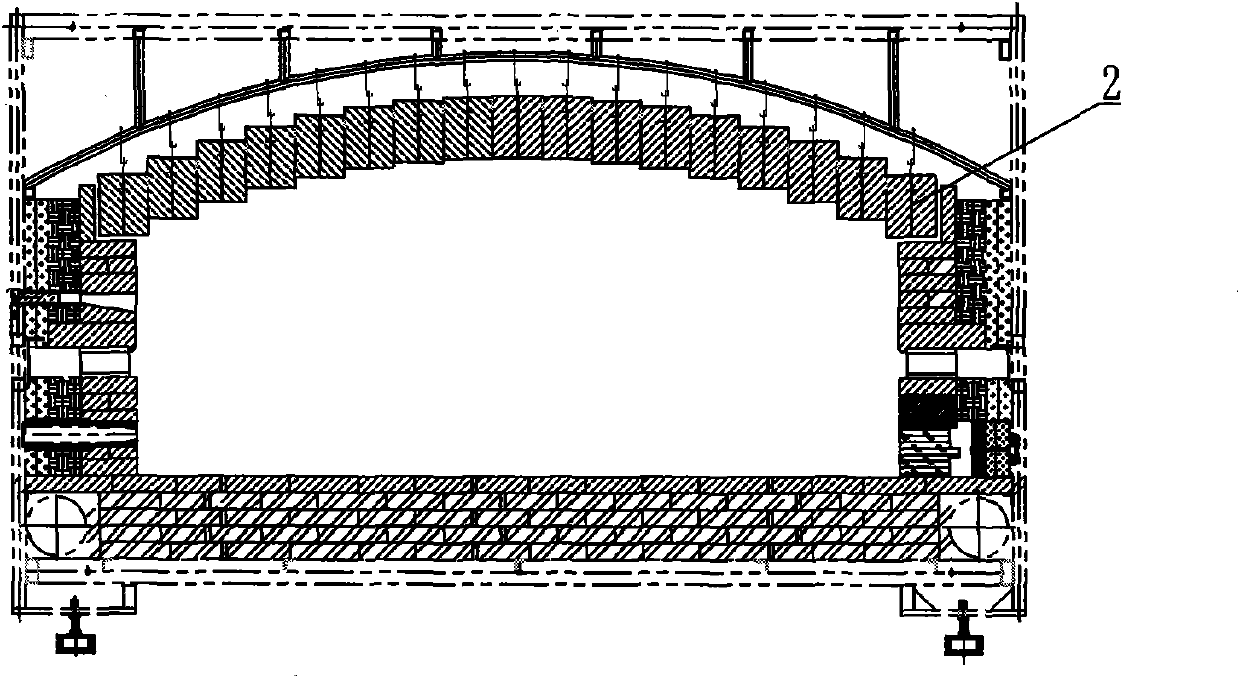

Fluidized calcining furnace ball arc furnace top and method of forming same

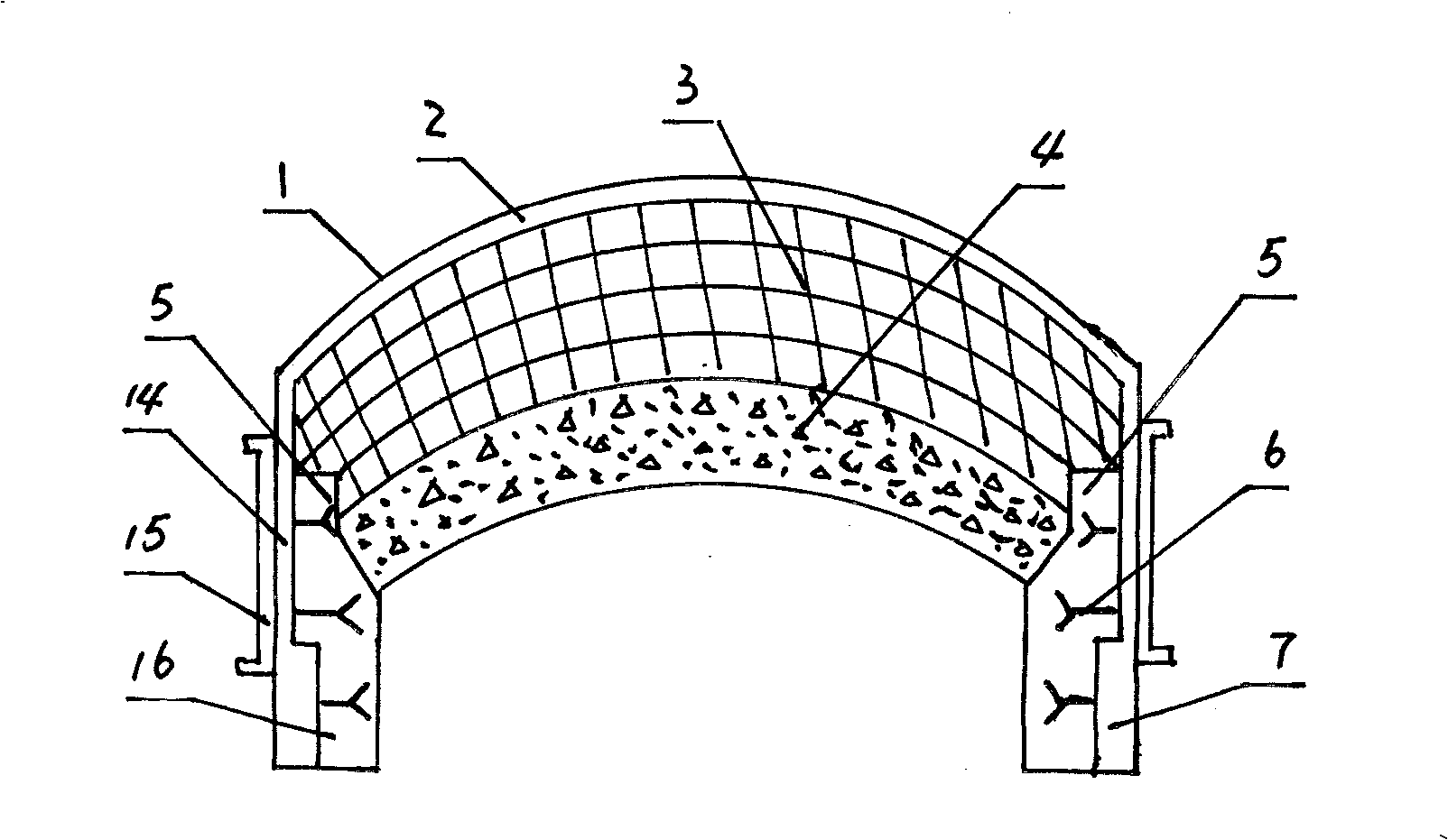

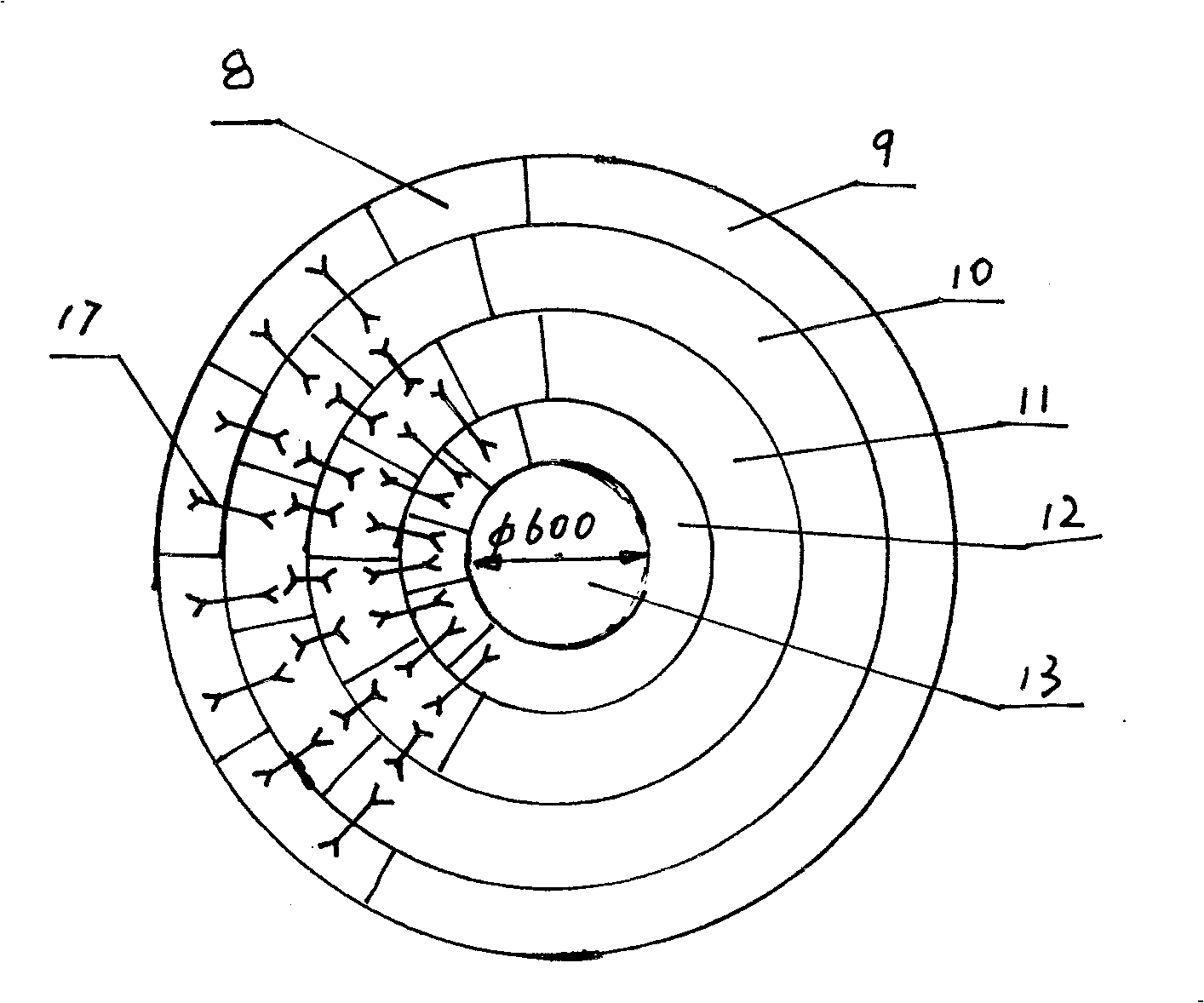

ActiveCN101261081ASolve the problem of large area damageImprove sealingFluidised-bed furnacesFurnace crowns/roofsFiberCamber angle

The invention provides a fluidizaton roasting furnace ball arch furnace top. A heavy castable layer working lining adopts a high intensity low cement castable refractory or a steel fiber reinforced castable refractory. The inside of the layer is provided with a plurality of binaural stainless steel clips widthways to connect the castable material casting by different rings and blocks into a whole. The lateral wall of a camber angle ring beam is provided with a light clay brick and a connecting rib, the outside lateral wall is provided with a lateral wall reinforcing channel steel, the inner layer is provided with a plurality groups of stainless steel clips which connect the light clay brick, the heavy castable refractory layer working lining and the lateral wall reinforcing channel steel into a whole. The forming method is as follows: (1) the center of gravity and the symmetric center of the furnace top are arranged in one line; (2) the furnace top is divided into a plurality of small blocks, the bottom arc length is less than or equal to 1.2 meters; (3) the mould is supported according to the divided small blocks; (4) a heat insulating material is arranged and the thickness of the heat insulating material is set; (5) the integral casting is performed. The fluidizaton roasting furnace ball arch furnace top has the advantages of good leak tightness, high intensity, long service life, short construction cycle and low cost, does not have any gap and does not fall off.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

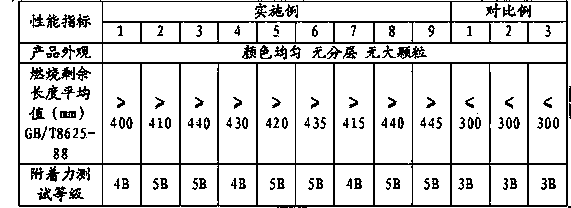

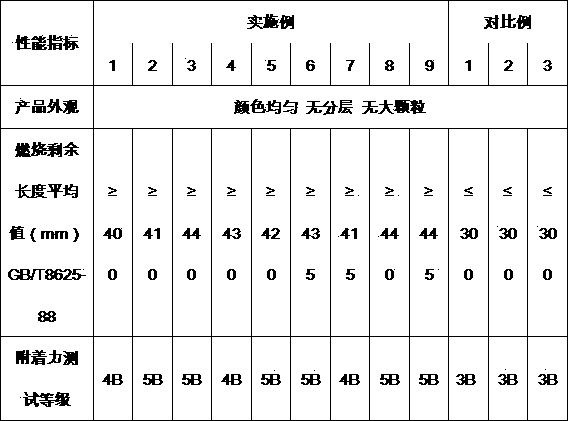

Exterior wall putty

The invention belongs to the field of construction materials and relates to exterior wall putty. The exterior wall putty comprises the following components by weight: 10-15 parts of polymer powder, 30-50 parts of light clay bricks, 10-15 parts of perlites, 6-9 parts of high-alumina cement, 12-18 parts o mullites, 10-15 parts of bentonite, 2-4 parts of szaibelyites, 1-3 parts of dextrin powder, 3-5 parts of methyl cellulose, 5-8 parts of silica powder, 5-10 parts of fibrilia or viscose, 8-18 parts of water glass, 4-6 parts of dispersable emulsion powder and 10-15 parts of aluminium oxide solutions and silicon dioxide sol composite suspension solutions combined at the mass ratio of 1:1; the polymer powder is a modified mixture of polyethylene and polypropylene; the specific modification comprises the following steps by weight: 4-9 parts of aluminium dihydrogen phosphate, 0.5-4 parts of C12H25SO3Na, 3-4 parts of EPDM, 6-8 parts of aluminium acid ester coupling agents and 2-3 parts of phosphate ester are added into a base material which consists of 30-60 parts of ultrahigh molecular weight polyethylene with the molecular weights of 4-7 million and 15-25 parts of high density polypropylene with the molecular weights of 1-1.4 million; the mixture is kneaded in an internal mixer for 40-50 min at the temperature of 110-120 DEG C. according to the invention, the exterior wall putty is excellent in adhesiveness and filling ability and can prevent walls from discoloring and falling off.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Antiseepage and water preserving method

The anti-seepage and water preserving method includes the following steps: 1. removing surface soil layer of 20-50 cm thickness and leveling and compacting the newly exposed layer; 2. mixing water, light clay and heavy clay in the ratio of 1 to 1 to 2, depositing, and making the upper layer flow into the compacted layer to form one 5-8 thick isolating layer; and 3. refilling the removed soil. The anti-seepage and water preserving method has low cost and obvious anti-seepage and water preserving effect.

Owner:王铁元 +2

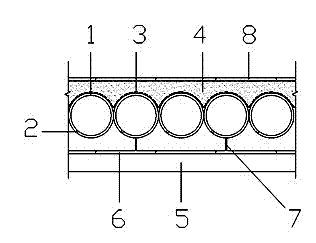

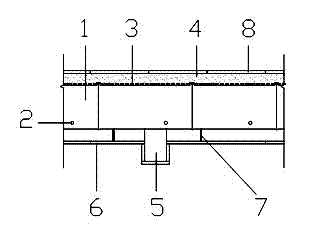

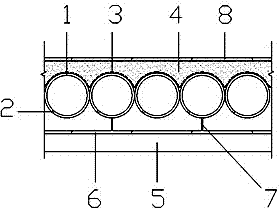

Fireproofing original bamboo floorslab

The invention relates to a fireproofing original bamboo floorslab, belonging to the technical field of building engineering. The fireproofing original bamboo floorslab comprises bamboo rafts, flexible waterproof layers, light clay layers, floor piles, a fireproofing layer, hanging bars and a floor tile layer wood floor surface layer. A plurality of original bamboo are densely arranged on the floor piles to form the bamboo rafts; the flexible waterproof layers are laid on the bamboo rafts; the light clay layers are laid on the flexible waterproof layers; the fireproofing layer is hung below the bamboo rafts through the hanging bars; and each sealed hollow cavity of the original bamboo is provided with a small pressure release hole. Compared with the traditional bamboo floorslab, the fireproofing original bamboo floorslab has the advantages of high bearing capacity, good temperature preserving and sound insulating performance, high fireproofing capacity and the like. The floor tile or wood floor can be laid on the surface of the fireproofing original bamboo floorslab, thus the indoor health sanitary condition can be greatly improved. The bamboo replaces the wood and the steel, thus the living quality of the ethnic people can be improved, the bamboo culture can be revitalized, the forest resources can be protected, and the greenhouse gas emission can be reduced.

Owner:KUNMING UNIV OF SCI & TECH

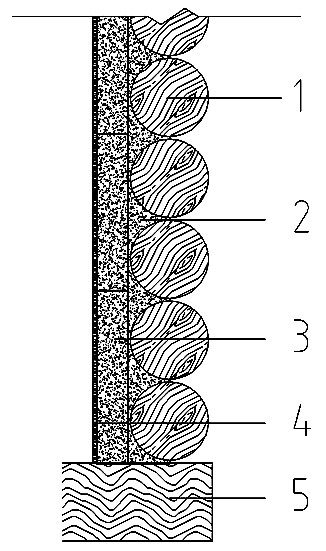

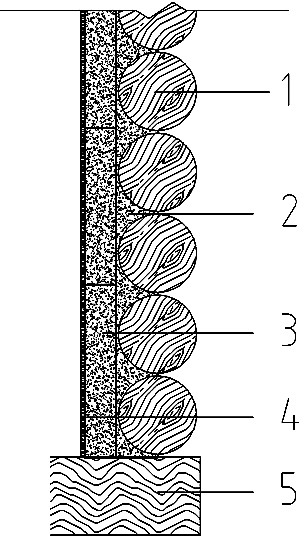

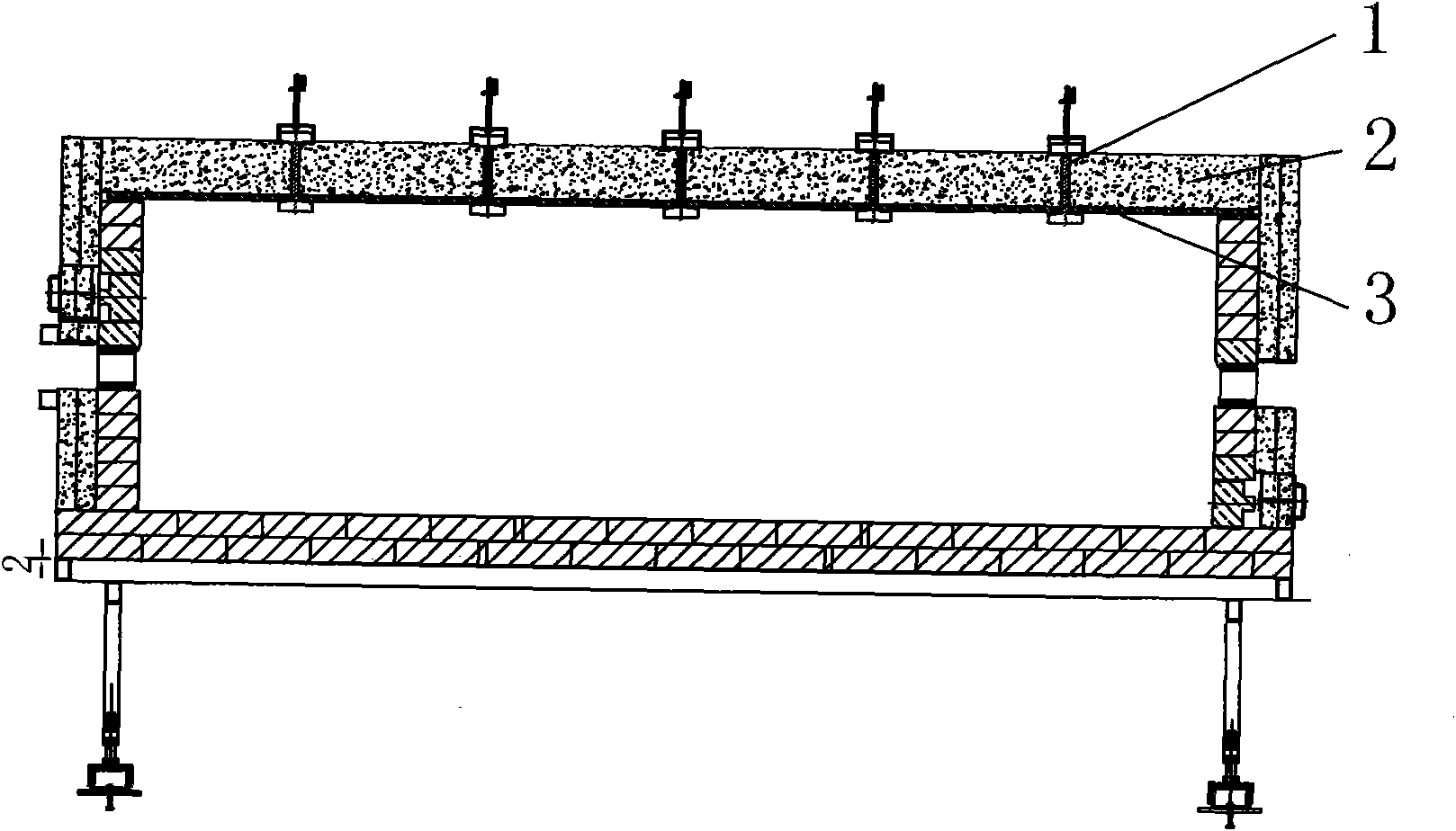

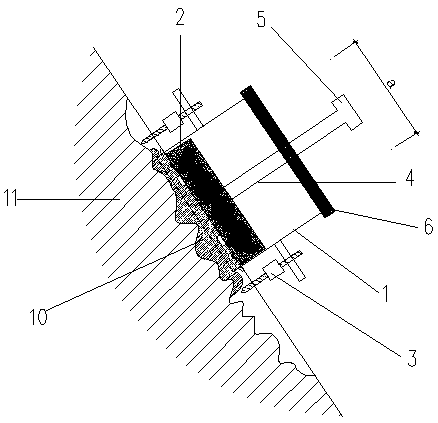

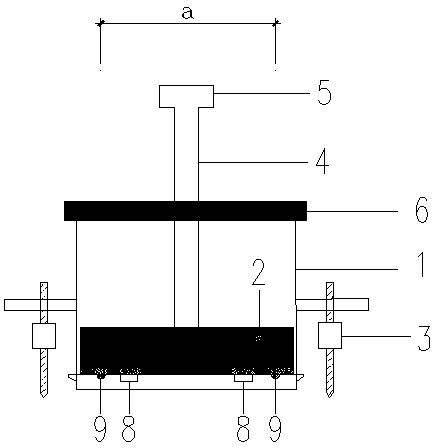

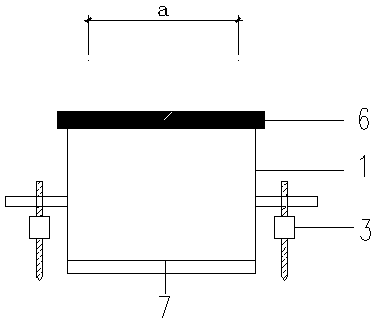

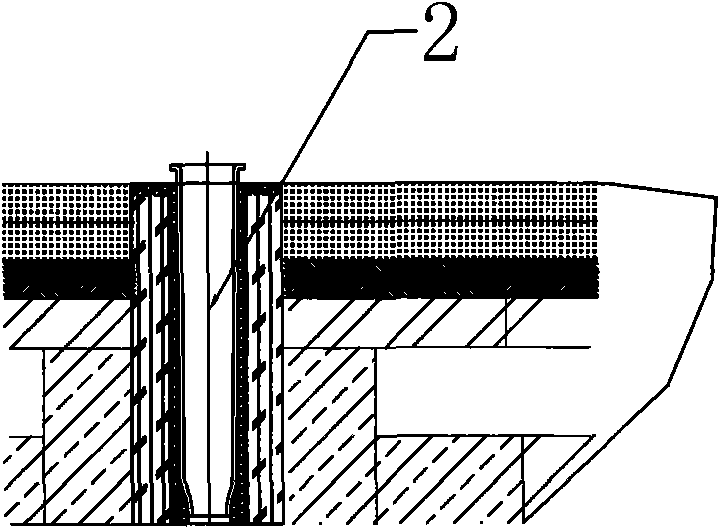

Method for enhancing thermal-insulation performance of well-frame wall body by adopting light raw soil material and composite thermal-insulation wall body

InactiveCN102505780AImprove thermal performance defectsReduce gapWallsClimate change adaptationSurface finishEnvironmental resource management

The invention provides a method for enhancing the thermal-insulation performance of a well-frame wall body by adopting a light raw soil material and a composite thermal-insulation wall body, and belongs to the technical field of buildings. The method comprises the following steps: light clay slurry formed by mixing raw soil, cement and plant fiber is used for filling slits on the well-frame wall body, so as to form a flatting layer; pre-cast light clay building blocks are built on the surface of the flatting layer; and slurry formed by mixing raw soil and cement or a surface finishing material such as board is adopted as a surface layer. The composite thermal-insulation wall body mainly comprises a beam, a wood ridge, a light clay flatting layer filled in the slits on the surface of the wood ridge, and a light clay building block thermal-insulation layer built on the surface of the flatting layer. The invention has the advantages that the materials are mainly local construction materials; the building block building method is adopted; the thickness of the thermal-insulation layer of the wall body can be designed according to local conditions; the slits in the wall body are reduced; the poor thermotechnical performance of a well-frame building is improved effectively; the construction is simple; the construction cost is low; the purpose of ecological and environmental protection is realized; and the local advantages can be played.

Owner:KUNMING UNIV OF SCI & TECH

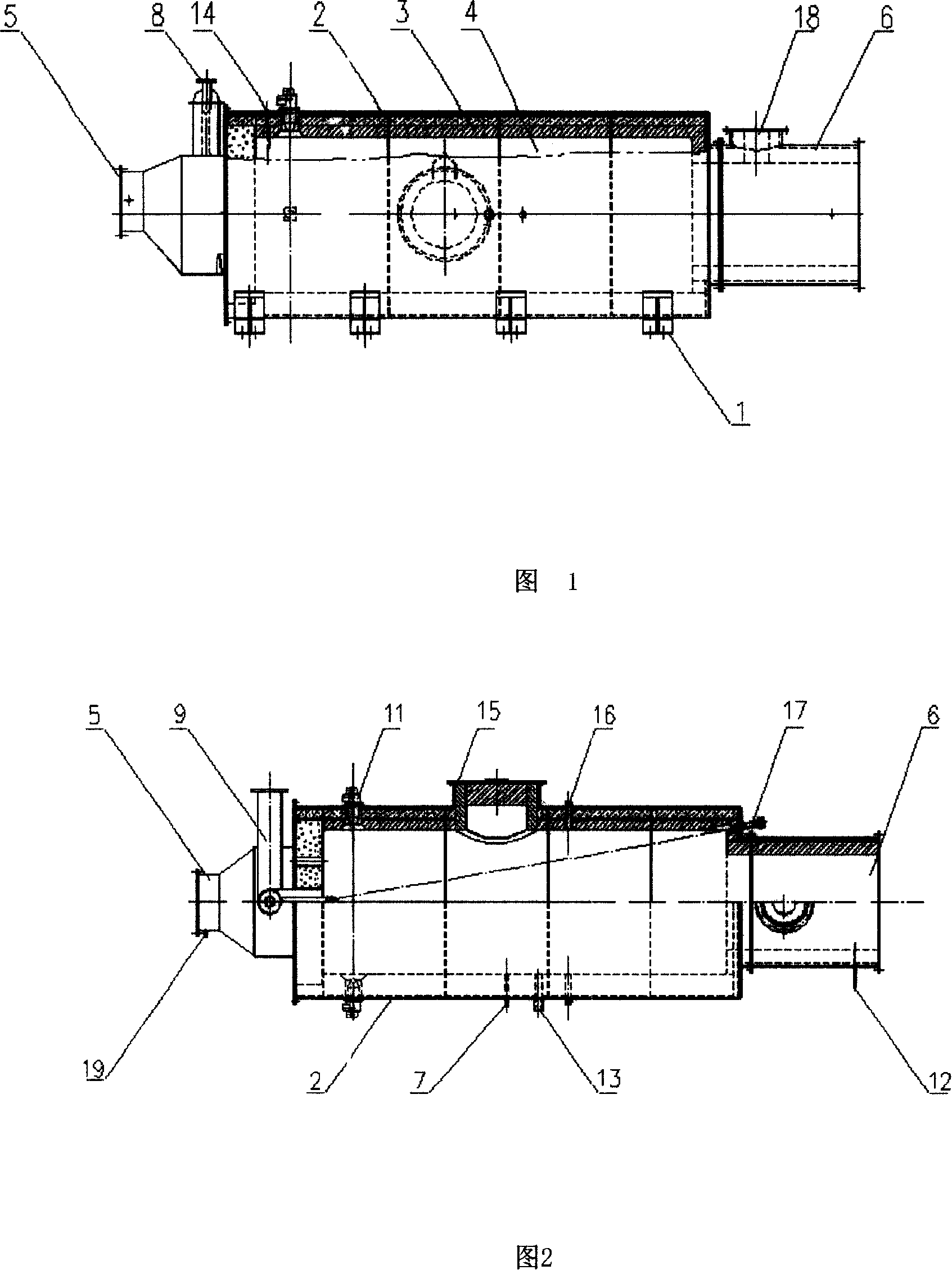

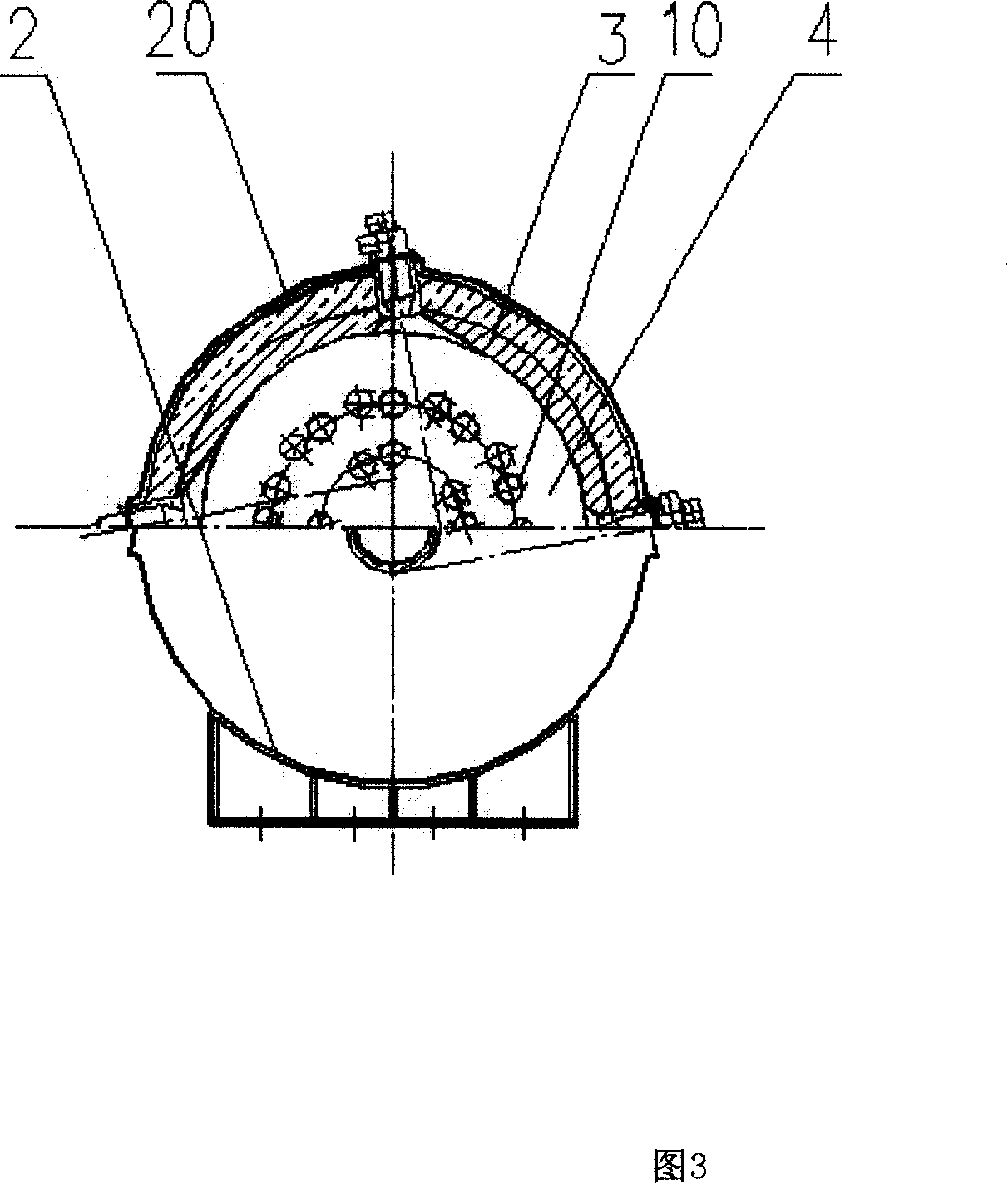

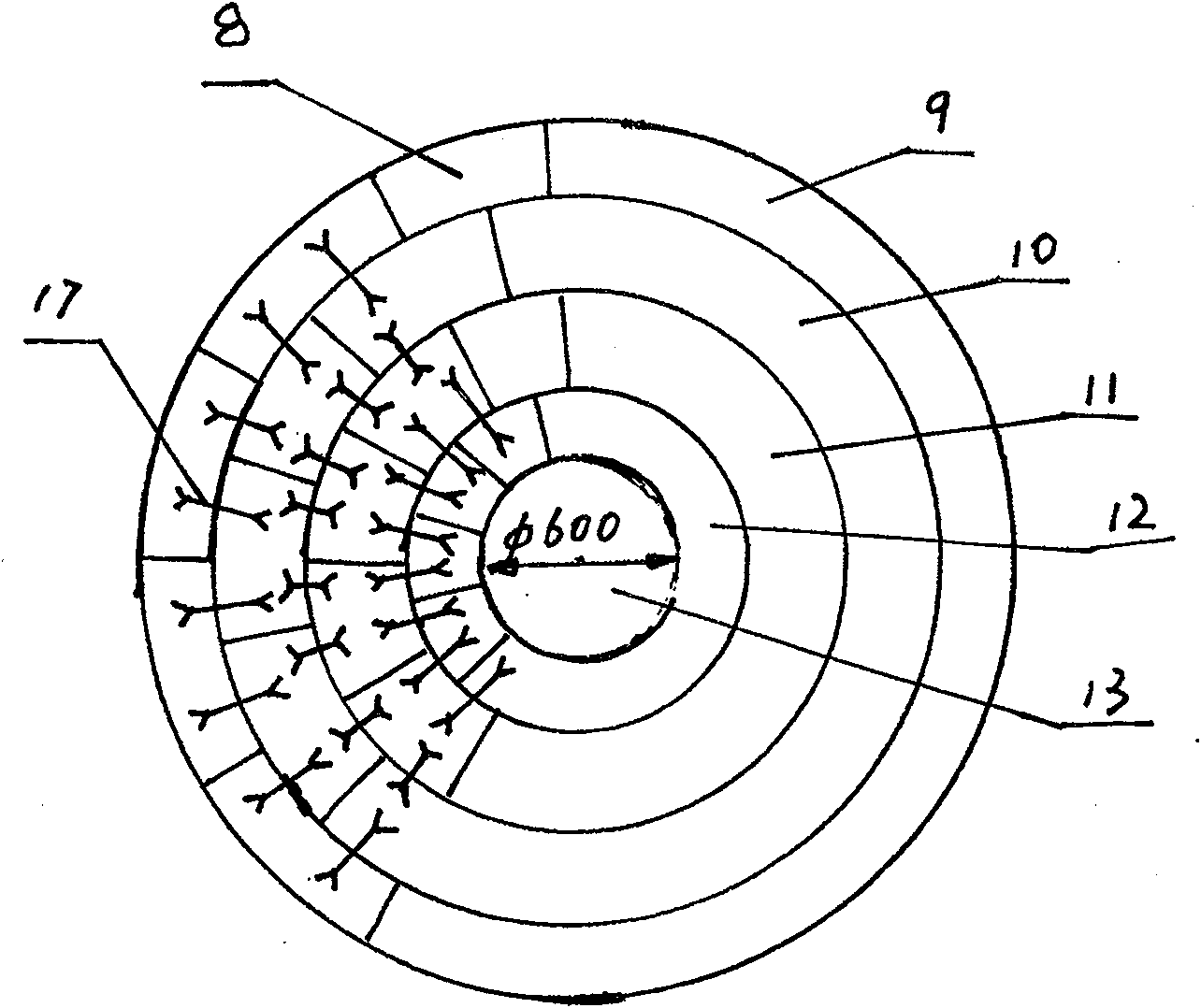

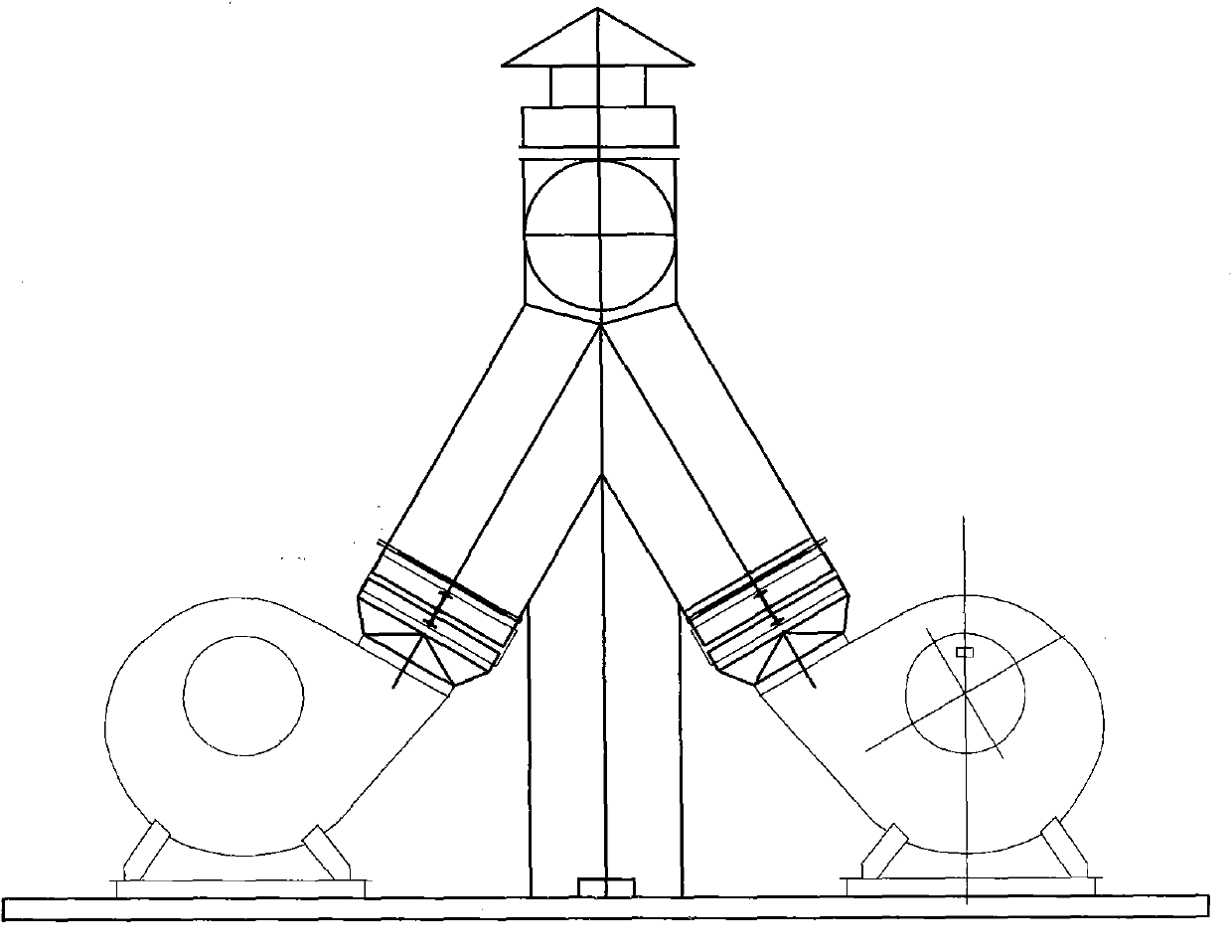

Asphalt flue gas processing method and its incinerator

PendingCN101149151ABurn fullyAdd subdivisionDispersed particle separationIncinerator apparatusEngineeringHearth

This invention discloses a asphalt smoke gas processing method and its incinerator. The asphalt smoke gas is first guided into incinerator to incinerate. Natural gas, air and asphalt gas are mixed before incinerating. Then the waster gas after incineration is discharged. The inlet pipe of asphalt smoke gas incinerator is communicated with hearth through asphalt smoke gas fine pipes. The said fine pipes are arranged at anterior end of the hearth and distributed in circle. Thus, the fully combustion of asphalt smoke gas can be fulfilled. Fire-proof bricks are used to form the barrel shaped hearth. The fire-proof brick layer forms the double layers ring structure which uses high strength light clay fire-proof bricks. This invention has perfect processing effect. It is simple and convenient.

Owner:GUIYANG AL-MG DESIGN & RES INST

Feed additive for promoting livestock growth and preparation method thereof

InactiveCN101637221APromote growthImprove immunityAnimal feeding stuffAccessory food factorsAntibiotic YOxygen

The invention relates to a feed additive for promoting livestock growth, comprising the following raw materials in parts by weight: 5-15 parts of polar mineral tourmaline micro powder, 4 to 10 parts of photocatalysis semiconductor material micro powder, 2 to 5 parts of nanometer zinc oxide micro powder, 2 to 5 parts of biotite micro powder, 2 to 5 parts of muscovite micro powder, 2 to 5 parts of feldspar micro powder, 8 to 12 parts of diatomite micro powder, 8 to 13 parts of vermiculite micro powder, and 30 to 67 parts of light clay micro powder. A preparation method for the feed additive comprises the following steps: coarse grinding, fine grinding and precision grinding. The invention has the advantages that the feed additive does not contain antibiotics, is safe to promote the livestock growth with high efficiency, resists bacterium and improves the dissolved oxygen.

Owner:平湖市畜牧兽医局 +1

Putty combination

The invention belongs to the field of building materials and relates to a putty combination. The putty combination comprises the following raw materials in parts by weight: 10-15 parts of a copolymer powder, 30-50 parts of light clay brick, 10-15 parts of perlite, 6-9 parts of high-alumina cement, 12-18 parts of mullite, 10-15 parts of bentonite, 2-4 parts of camsellite, 1-3 parts of dextrin, 3-5 parts of methyl cellulose, 5-8 parts of a silica powder, 5-10 parts of bastose or viscose, 8-18 parts of sodium silicate, 1-4 parts of a lignocellulose aerogel liquid, 4-6 parts of a dispersible emulsion powder and 10-15 parts of compound suspension consisting of aluminum oxide sol and silicon dioxide sol by a ratio by mass of 1:1, wherein the copolymer powder is a modified polyethylene and polypropylene mixture; the lignocellulose aerogel liquid is prepared by a method comprising the steps of pulverizing, purifying, freeze-thawing and solidifying regeneration. The putty combination is excellent in adhesiveness and filling ability and can prevent the wall from discoloring and falling.

Owner:湖州三利德装饰材料有限公司

Model adhesive for fused cast zircon-corundum bricks

The invention discloses a model adhesive for fused cast zircon-corundum bricks, which comprises the following raw materials by weight portions: 80-90 portions of quartz powder, 12-15 portions of soluble glass, 0.8-1.2 portions of Portland cement, 4-6 portions of light clay powder and 0.2-0.4 portions of sodium fluosilicate. The method for manufacturing the adhesive comprises the following steps: weighing the quartz powder, the Portland cement, the light clay powder and the sodium fluosilicate according the required quantities, evenly mixing on a steel plate, putting in an adhesive bucket, adding the soluble glass, and evenly stirring with a wood stick for use. According to the physicochemical properties of the corundum type, free-piece plates are adhered to form an integral shape by the adhesive according to the shape and the dimension of the product, so that the operation is simple and convenient when manufacturing and casing the model, the model strength is greatly enhanced, and thedimension of the finished product is more precise so as to ensure the dimension precision of the product, reduce the processing amount for cutting and grinding and greatly improve the internal qualityand the appearance of the product.

Owner:ZHENGZHOU XINGUANGSE REFRACTORY

Water-based paint for lightweight evaporative pattern casting and enhanced by nanometer silicon carbide and preparing method of water-based paint

InactiveCN105057570AGood suspensionImprove thixotropyFoundry mouldsFoundry coresWater basedMicrocrystalline wax

The invention relates to the technical field of evaporative pattern casting, and in particular to a water-based paint for lightweight evaporative pattern casting and enhanced by nanometer silicon carbide and a preparing method of the water-based paint. Zircon sand and calcium hexaluminate serve as refractory aggregate of the paint, wherein the zircon sand and calcium hexaluminate are different from each other in particle size, so that the breathability of a coating is improved. Mixed slurry of super-light clay and sodium carboxymethylcellulose serves as a suspension agent, so that the paint is made to have good suspension performance and thixotropy. The added nanometer silicon carbide enhances the heat resistance and mechanical properties of the coating. Sand viscidity prevention of the coating can be improved through scattered microcrystalline wax, and the microcrystalline wax is melted in the casting process, so that the breathability of the coating is further improved. The paint coating prepared through the method is light and thin, tenacious and firm, good in attachment to metal liquid, high in heat stability, free of polluting metal liquid and easy to strip after casting is finished, and the quality of castings is effectively improved.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

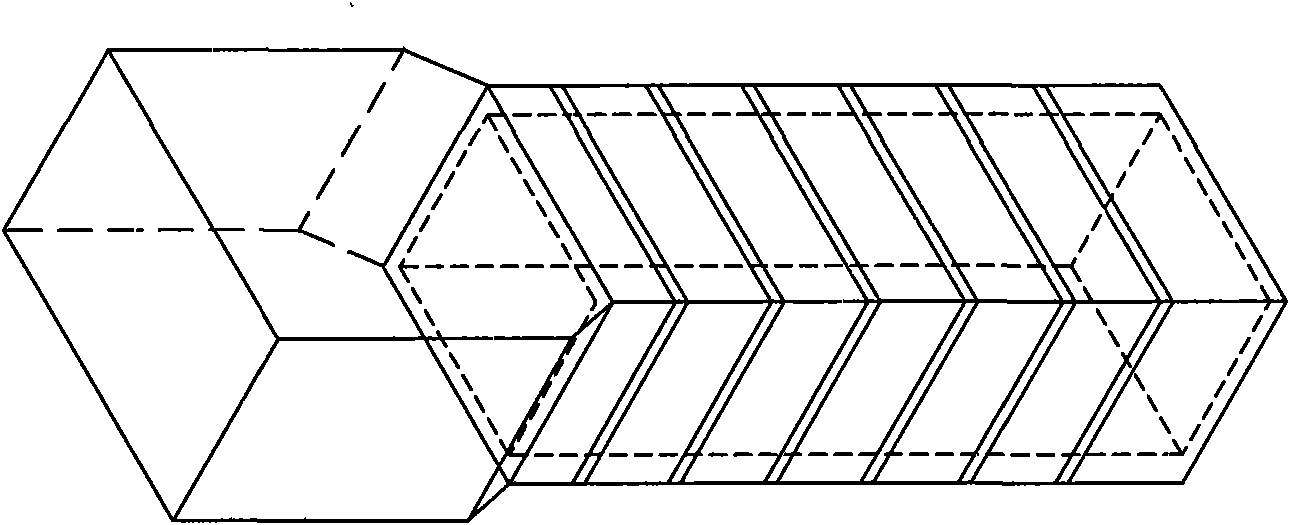

Fluidized calcining furnace ball arc furnace top and method of forming same

ActiveCN100578127CSolve the problem of large area damageImprove sealingFluidised-bed furnacesFurnace crowns/roofsRefractoryLight clay

The invention provides a fluidizaton roasting furnace ball arch furnace top. A heavy castable layer working lining adopts a high intensity low cement castable refractory or a steel fiber reinforced castable refractory. The inside of the layer is provided with a plurality of binaural stainless steel clips widthways to connect the castable material casting by different rings and blocks into a whole. The lateral wall of a camber angle ring beam is provided with a light clay brick and a connecting rib, the outside lateral wall is provided with a lateral wall reinforcing channel steel, the inner layer is provided with a plurality groups of stainless steel clips which connect the light clay brick, the heavy castable refractory layer working lining and the lateral wall reinforcing channel steel into a whole. The forming method is as follows: (1) the center of gravity and the symmetric center of the furnace top are arranged in one line; (2) the furnace top is divided into a plurality of small blocks, the bottom arc length is less than or equal to 1.2 meters; (3) the mould is supported according to the divided small blocks; (4) a heat insulating material is arranged and the thickness of the heat insulating material is set; (5) the integral casting is performed. The fluidizaton roasting furnace ball arch furnace top has the advantages of good leak tightness, high intensity, long service life, short construction cycle and low cost, does not have any gap and does not fall off.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

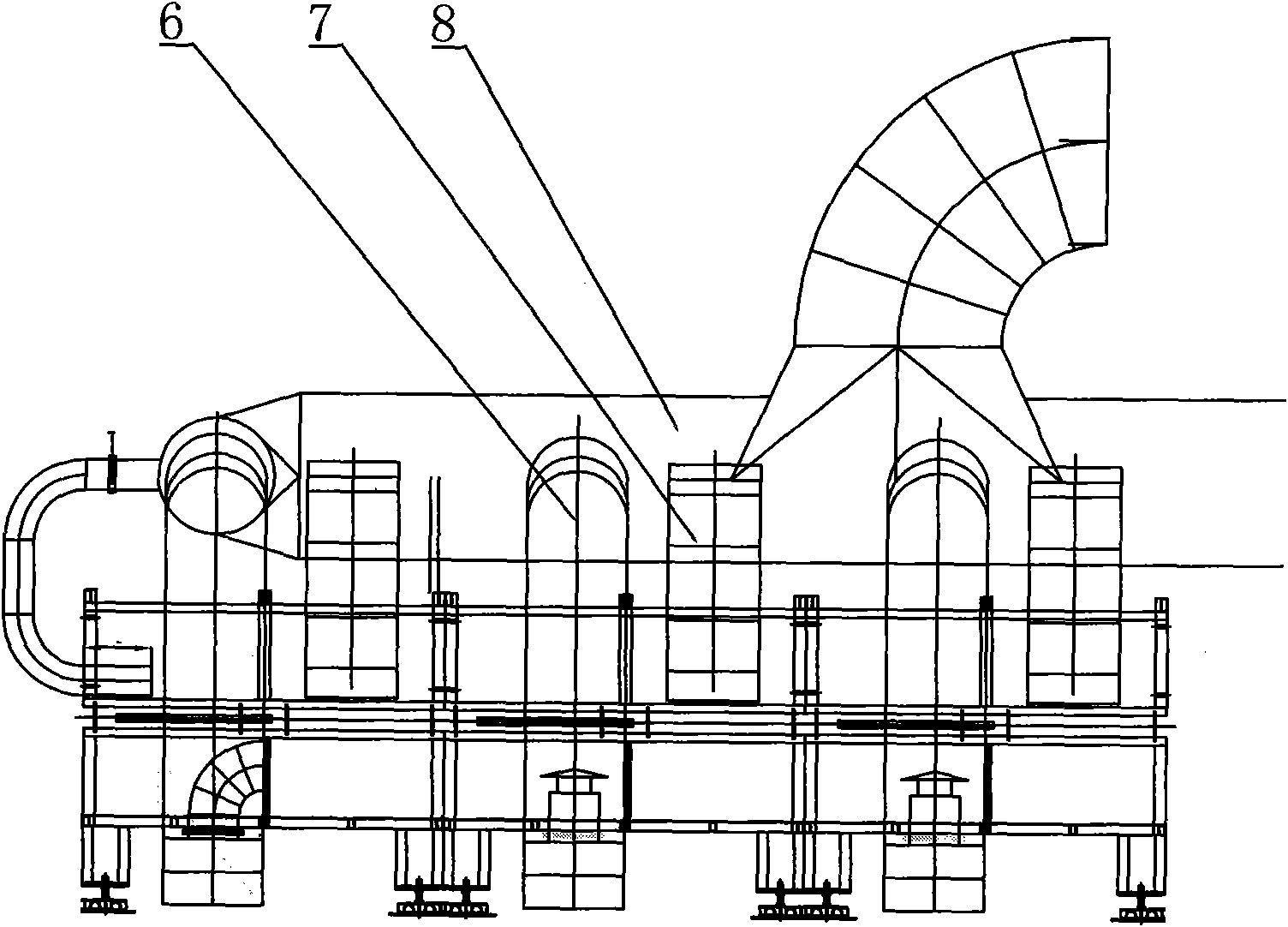

Energy-saving glazing roller kiln for producing interior wall bricks

ActiveCN101936653ASolve the defect of dirtyHeat stableFurnace typesCeramic materials productionLight clayBoard structure

The invention provides an energy-saving glazing roller kiln for producing interior wall bricks. The kiln top of the roller kiln is built by using a suspended wool board structure. The kiln bottom of a firing region consists of low-iron and high-aluminum heat reserving bricks, high-aluminum poly-light ball heat reserving bricks and light clay bricks, wherein the light clay bricks are positioned in a bottom layer at the kiln bottom of the firing region; the high-aluminum poly-light ball heat reserving bricks and the low-iron and high-aluminum heat reserving bricks are built in turn above the light clay bricks; a fume extractor is arranged in the built kiln and positioned above a smoke exhaust region of the roller kiln and comprises a top exhaust tube and a main exhaust tube; and one end of the top exhaust tube and one end of a side exhaust tube are connected to the smoke exhaust region of the roller kiln, while the other ends are connected with the main exhaust tube. In the fume extractor, top extraction and side extraction are combined, so that air stream uniformly flows towards a direction opposite to the running direction of unburned bricks, brick bodies are heated stably and glaze cracks possibly caused by non-uniform heating are avoided.

Owner:GUANGDONG CHINA KILN TECH CO LTD

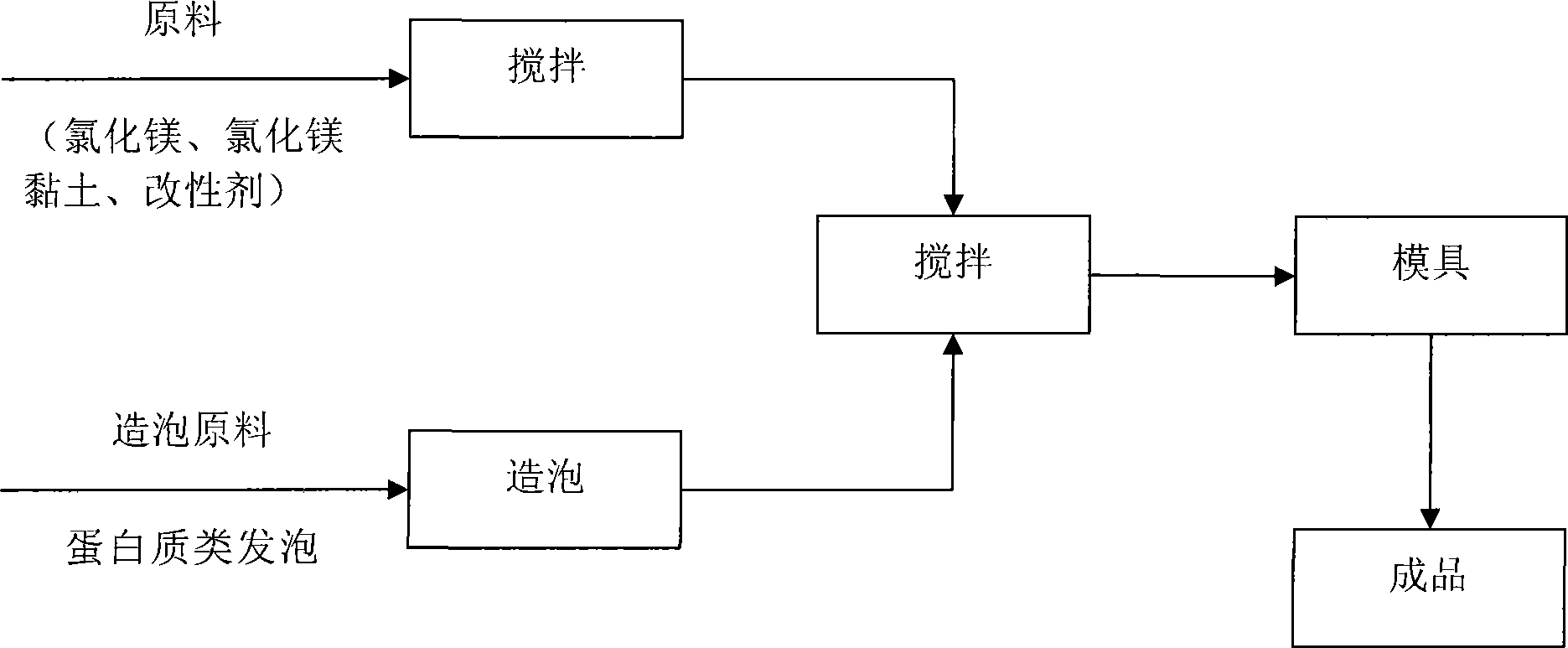

Clay baking-free light insulating brick and preparation thereof

The invention relates to a material used in the building industry, in particular to a non-burned light clay insulation brick. The insulation brick is characterized by consisting of the following raw materials based on the weight proportions: 20-28% of MgO2, 33-41% of MgCl2, 11-35% of clay, 1-2% of phosphoric acid and 4-12% of water. The preparation method of the non-burned light clay insulation brick comprises the following steps: light-burned magnesia is added to magnesium chloride; and an obtained mixture is evenly stirred, added with the clay, evenly stirred again, added with protein foam and the phosphoric acid for even stirring, pumped into a die by a slurry pump, and formed by demolding and curing after 24 hours. The preparation method is characterized in that a filling material of the non-burned light clay insulation brick is the clay with various components. As the materials required are a magnesite material and the clay, high temperature and high-pressure curing are unnecessary in production, demolding can be performed after 8 hours at normal temperature, product density is not more than 650Kg / m<3> and the heat insulation effect is obviously higher than that of the prior art. The insulation brick has the advantages of low cost, low investment and high yield, and is an environment-friendly product with low energy consumption.

Owner:杜庆贵 +1

Ultra-light clay used for toys and preparation method thereof

The invention discloses ultra-light clay used for toys, which includes: 65% of glue, 2% of a powder, 6% of sorbitol, 3% of glycerin, 3% of bronopol, 2% of Casson, 1.5% of essences, 2% of borax, 9% ofwater, 4% of boric acid, and 2.5% of color slurry. A preparation method includes the steps of: 1) preparing a binder: performing carbon adsorption, filtration and ultraviolet lamp sterilization to water, pouring the water into a reaction kettle, stirring the water and slowly adding the glue, continuously stirring the mixture for 20-35 min and heating the mixture, and when the temperature of the glue reaches 100 DEG C, maintaining the temperature for 85-95 min; 2) pouring the binder, being cooled to room temperature, into a kneading machine and stirring the binder for 8-12 min, slowly adding the powder, sorbitol, glycerin, bronopol, Casson, essences, borax, boric acid, water and color slurry, stirring the mixture for 8-12 min and cooling the mixture; 3) stirring the mixture in the kneadingmachine for 15-20 min, and discharging the product through a discharge hole of the kneading machine. The ultra-light clay has simple structure and is environment-friendly and toxic-free.

Owner:佛山市盛飞文具有限公司

Preparation method of long-acting polypeptide blended fertilizer

InactiveCN104710217AImprove adsorption capacityGood sustained release effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersRoot growthPhosphate

Disclosed is a preparation method of a long-acting polypeptide blended fertilizer. The fertilizer is uniformly mixed by 500 parts by weight of urea, 130 parts by weight of monoammonium phosphate, 120 parts by weight of ammonium dihydrogen phosphate, 120 parts by weight of potassium chloride, and 45 parts by weight of light clay. The mixture is prepared into fertilizer particles containing macroelements and having average particle diameter of 2mm-3mm through a pelleting machine. Three parts of polyaspartic acid are dissolved in water, and are uniformly sprayed on the surfaces of the fertilizer particles containing macroelements, and then 42 parts of light clay are used for coating the fertilizer particles to prepare the long-acting polypeptide blended fertilizer. The invention has advantages that: the production technology is simple; light clay is taken as a coating agent, is sprayed on the surfaces of the fertilizer particles, and has a function of controlling releasing of the fertilizer, so that a fertilizer effect can be effectively developed; polyaspartic acid can prompt root growth; absorptivity of nutrients by crops is improved; the utilization rate of marcoelements of nitrogen, phosphor, and potassium by the crops is increased more than 30%; and soil hardening is reduced.

Owner:JINZHOU DADIFENG FERTILIZER IND

Environment-friendly nontoxic ultralight clay and preparation method thereof

The invention provides environment-friendly non-toxic ultralight clay and a preparation method thereof, and belongs to the technical field of toys for children. The environment-friendly non-toxic ultralight clay comprises the following components in percentage by weight: 5-20% of rubber powder, 2-8% of a thickener, 0.5-2% of citric acid, 4-8% of resin emulsion, 0.5-5% of modified ultra-fine calcium carbonate, 3-12% of foaming powder, 4-10% of glycerol, 1-5% of vaseline and the balance of water. The formula of the ultra-light clay adopts non-toxic and environment-friendly materials, the clay does not contain components harmful to human bodies, is healthy and environment-friendly and does not cause harm to children during use, the provided preparation method is simple to operate and low in production cost, citric acid is creatively used for replacing boric acid borax as a cross-linking agent, and the obtained product has good formability, is not sticky to hands, is not easy to crack after being dried and can be stored for a long time.

Owner:CRERAX SCI & TECH CO LTD

Biscuiting roller kiln used for producing interior wall tiles

ActiveCN101949641AImprove waste heat utilizationReduce energy consumptionFurnace typesWaste heat treatmentSocial benefitsSurface layer

The invention provides a biscuiting roller kiln used for producing interior wall tiles. The roller kiln comprises a smoke exhaust region, a firing region and a cooling region, wherein the smoke exhaust region and the cooling region of the roller kiln have hung ceiling structures formed by hanging high-aluminum poly light ball heat preservation bricks; a heat preservation buffer region is formed between a constructed vault and the hung ceiling by hanging the high-aluminum poly light ball heat preservation bricks; the surface layer of a kiln bottom is constructed by low-iron high-aluminum heat preservation bricks; the intermediate layer of the kiln bottom is constructed by the high-aluminum poly light ball heat preservation bricks; the bottom layer of the kiln bottom is constructed by light clay bricks; a smoke gas and afterheat composite using structure is arranged a constructed kiln; and the smoke gas and afterheat composite using structure supplies smoke gas generated in the kiln to the front part of a kiln-front drier and supplies afterheat to the back part of the kiln-front drier. The afterheat generated by the smoke exhaust region and the cooling region of the scheme is transported to the kiln-front drier by the smoke gas and afterheat composite using structure for drying green bricks without an additional drying heat source. After adopting the scheme, the biscuiting roller kiln has the characteristics of low energy consumption, high afterheat utilization efficiency, and remarkable economic benefit and social benefit.

Owner:GUANGDONG CHINA KILN TECH CO LTD

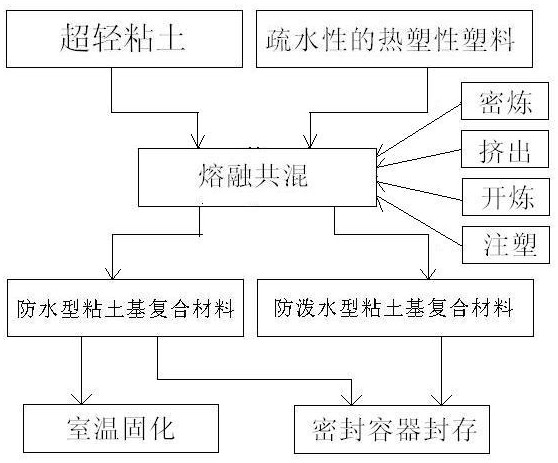

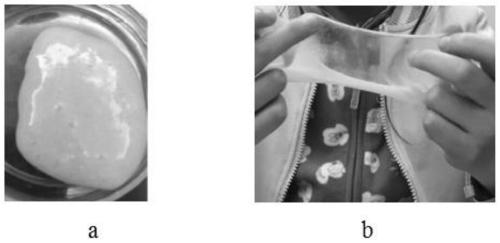

Clay-based composite material as well as preparation and use methods thereof

The invention aims to provide a clay-based composite material as well as a preparation method and a use method thereof. The composite material is prepared from the following components in parts by weight: 1 to 99 parts of ultralight clay and 1 to 99 parts of hydrophobic thermoplastic plastic, the preparation method comprises the following steps: carrying out melt blending on ultralight clay and hydrophobic thermoplastic plastic according to parts by weight, so as to prepare a clay-based composite material; according to the composite material, the ultra-light clay is prepared into the waterproof or water-repellent ultra-light clay-based composite material by utilizing the waterproof property of hydrophobic thermoplastic plastic; a product made of the composite material is molded and air-dried, the temperature of the product is increased to be above the melting point of the thermoplastic plastic, and the product with waterproof performance or water-repellent performance is formed after room temperature cooling and curing; the temperature of the product is increased to be higher than the melting point of the thermoplastic plastic for secondary processing and transformation, and the process can be repeatedly realized; the preparation method of the composite material is simple in process and suitable for industrial production; the material is an environment-friendly material.

Owner:秦皇岛砥厉科技有限公司

Non-toxic crystal mud and preparation method thereof

The invention discloses non-toxic crystal mud and a preparation method thereof. The preparation method comprises the following steps: adding 0.8-1.2 parts by mass of ultra-light clay into 6.5-7.5 parts by mass of hot water for melting; fishing out white substances floating on the water surface, discarding to obtain a clay solution, adding 3.5-4.5 parts by mass of glue into the clay solution, uniformly stirring, adding 0.2-0.4 g by mass of baking soda, and continuously stirring until forming to obtain the non-toxic crystal mud. The preparation method of the non-toxic crystal mud is simple, therequired materials are commercially available, easy to obtain and low in cost, and the prepared crystal mud is non-toxic, environment-friendly, non-sticky, good in hand feeling, bright in color and luster and very good in flowability and wire drawing effect and even can be manually drawn into filaments or elastic films.

Owner:张澜馨

Tap-hole clay for large blast furnace ironmaking and preparation method of tap-hole clay

The invention discloses tap-hole clay for large blast furnace ironmaking and a preparation method of the tap-hole clay. The tap-hole clay is prepared from the following components in parts by mass: 15-20 parts of 3-0mm brown corundum, 15-20 parts of 3-0mm light clay, 5-8 parts of 1-0mm magnesium oxide, 10-15 parts of 1-0mm sillimanite, 8-15 parts of 0.5-0mm magnesium iron oxide, 8-13 parts of meta-clay powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of strontium carbonate powder, 7-25 parts of flake graphite powder, 5-10 parts of composite carbon powder, 1-2 parts of low-temperature asphalt powder and 13-16 parts of modified tar; and 100 parts of the modified tar is prepared by blending the following substances in parts by mass: 98 parts of tar, 1 part of ethylene glycol and 1 part of N-methylpyrrolidinone. The tap-hole clay can protect an iron outlet with the pore size being stable and not liable to change, so that iron discharge is stable, and in addition, in the long-time storage process, the use performance and the serviceability of taphole loam are not lowered.

Owner:王冰

Dough-modeling material and manufacturing method of constructive model painting

InactiveCN107813643AOvercome permeabilityOvercoming Poor RenderingOrnamental structuresImage processing softwareLight clay

The invention discloses a dough-modeling material and a manufacturing method of constructive model painting. The dough-modeling material comprises light clay, paper pulp and additives. The manufacturing method of the constructive model painting comprises the following steps: first, extracting detail structures of sample painting one by one in an electronic copy of the sample painting by means of image processing software; storing and numbering the detail structures independently; and then combining a dough-modeling and carving craftsmanship with drawing by means of specific steps: manufacturing a cut template; manufacturing a hollowed template; reversing a mold; manually modeling a three-dimensional model; carrying out coloring; fixing colors; and carrying out assembling. Common painting is re-constructed and modeled and a special three-dimensional painting effect can be reflected, so that a brand new form of artistic presentation is obtained.

Owner:许可

Fired pyrophyllite silicon carbide brick and preparation method thereof

InactiveCN109020563AHas high temperature thermal conductivityReduce energy consumptionPyrophylliteLight clay

The invention provides a fired pyrophyllite silicon carbide brick, which comprises pyrophyllite raw ore (Al2O3.4SiO2.H2O), SiC, light clay, and additives. The preparation method of the fired pyrophyllite silicon carbide brick invention realizes energy consumption lowering and pollution reduction.

Owner:昆山思创耐火材料有限公司

Fluorescent glue capable of packaging white light LEDs

The invention discloses fluorescent glue capable of packaging white light LEDs. The fluorescent glue is prepared by mixing the following components in parts by weight: 50-60 parts of allochroic silicagel, 45-50 parts of water-proof silica gel, 30-40 parts of super light clay, 20-25 parts of epoxy resin glue, 5-10 parts of colorful flashlight powder, 10-12 parts of blue fluorescent powder, 10-12 parts of red fluorescent powder, 10-12 parts of green fluorescent powder, 3-5 parts of diffusion powder, 5-8 parts of light dispersing agent, 5-8 parts of electron powder and 5-10 parts of nanometer negative ion powder. The fluorescent glue capable of packaging the white light LEDs can improve the yield of the white light LEDs; compared with traditional fluorescent glue, the sedimentation rate of the fluorescent glue can be effectively controlled, the brightness of the LEDs is improved, and thus the product quality is improved.

Owner:广东赛铭照明科技有限公司

Magnolia officinalis planting method

InactiveCN107047196APrevent root rotPromote growthGeneral water supply conservationPisciculture and aquariaWater storage tankMagnolia officinalis

The invention discloses an Magnolia officinalis planting method, and belongs to the field of Magnolia officinalis planting. The Magnolia officinalis planting includes land selection and soil preparation, reproduction, field management, and harvesting and processing. In land selection and soil preparation, subacid and fertile sandy soil mixed with yellow soil and light clay is selected, a base fertilizer is applied, turning and thorough-harrowing is performed, flattening is performed, a greenhouse is built, a circular water storage tank is constructed in the greenhouse, infrared irradiation lamps are fixed on an upper end of the water storage tank, a water pump is fixed on an inner bottom of the water storage tank, beds with the width of 1.2-1.5 m are arranged on a ground surface in the water storage tank, drainage pipes are arranged between the beds, and two ends of the drainage pipes communicate with the water storage tank. In field management, water control of seedlings is performed, a rainwater collection tank is arranged on the top of the greenhouse, the rainwater collection tan communicates with the water storage tank through a water pipe, rainwater can flow to the water storage tank from the rainwater collection tank to be stored in rainy seasons; and water in the water storage tank is supplied to the drainage pipes through the water pump in drought, and bed soil can be watered. The technical scheme can effectively solve the problem that the survival rate of Magnolia officinalis planting is influenced due to rotted roots caused by waterlogging.

Owner:道真自治县云星种植有限责任公司

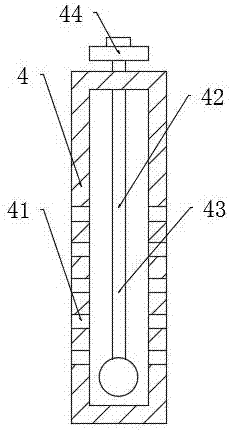

Concrete surface roughness measuring device and using method thereof

ActiveCN109323645AEasy to shapeNo lossMechanical roughness/irregularity measurementsSurface roughnessEngineering

The invention discloses a concrete surface roughness measuring device and a using method thereof. The device comprises a sleeve, a piston located in the sleeve, a piston rod connected to one side of the piston, a pressing handle connected with the other side of the piston rod, a height adjusting support located on the outer wall of the sleeve, ultra-light clay, a pressing cake detecting device, and a data analyzer, wherein the sleeve is open at one end; a limiting disk for limiting the pressing amount of the pressing handle is arranged at the other end of the sleeve; a baseline positioning line for indicating that the bottom of the piston is pressed to a lowest position is arranged on the outer wall of the open end of the sleeve; a plurality of measuring cake positioning protrusions are arranged on the bottom surface of the piston; and the pressing cake detecting device is used for detecting a concave-convex value of the ultra-light clay in a measuring area range on the surface of a pressing cake pressed and formed on the surface of concrete. The device has the characteristics of being convenient to operate and high in measurement precision.

Owner:HOHAI UNIV

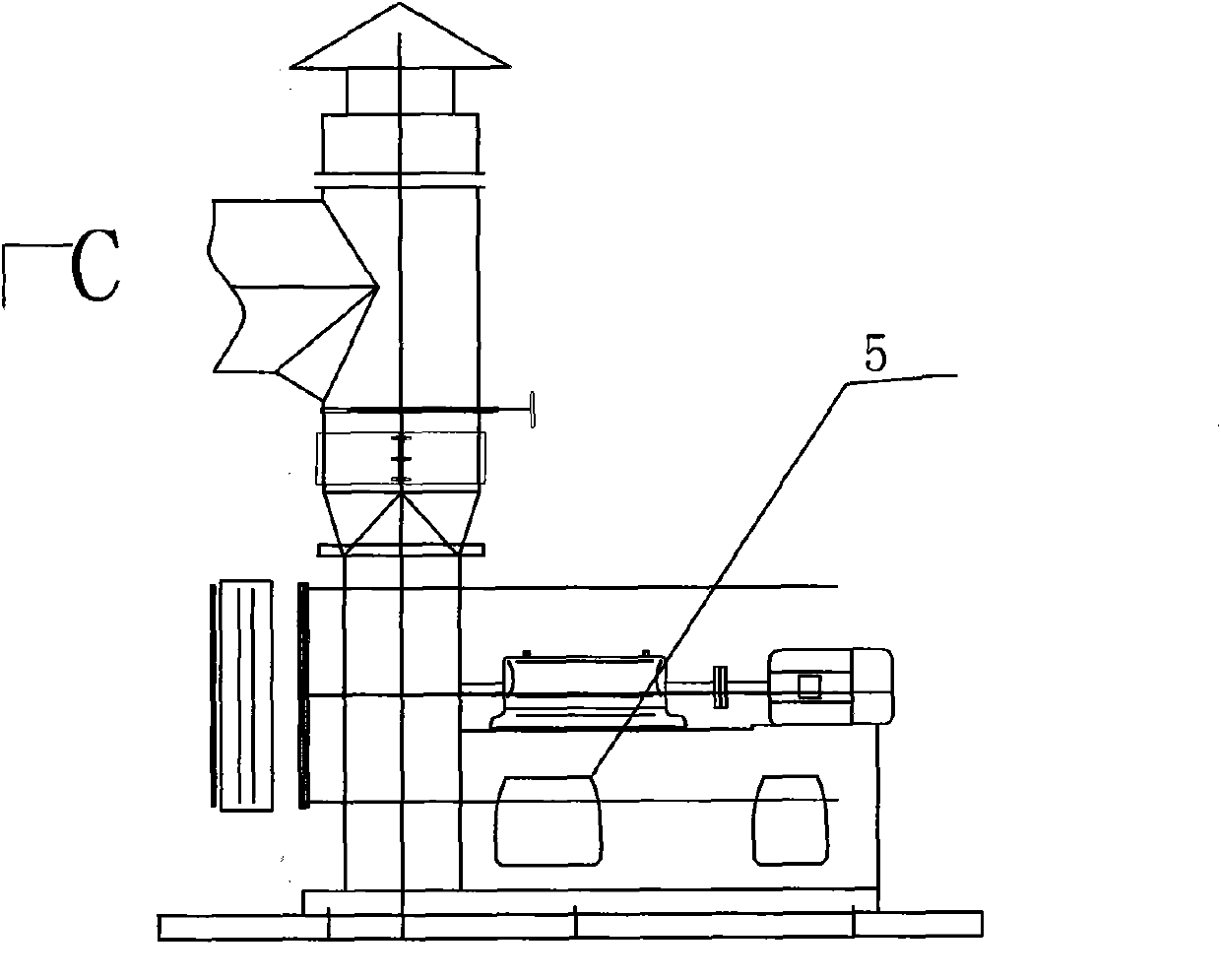

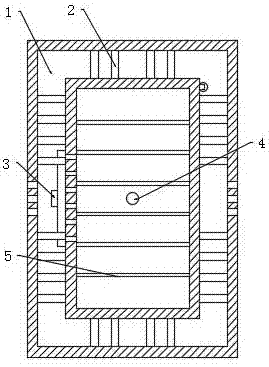

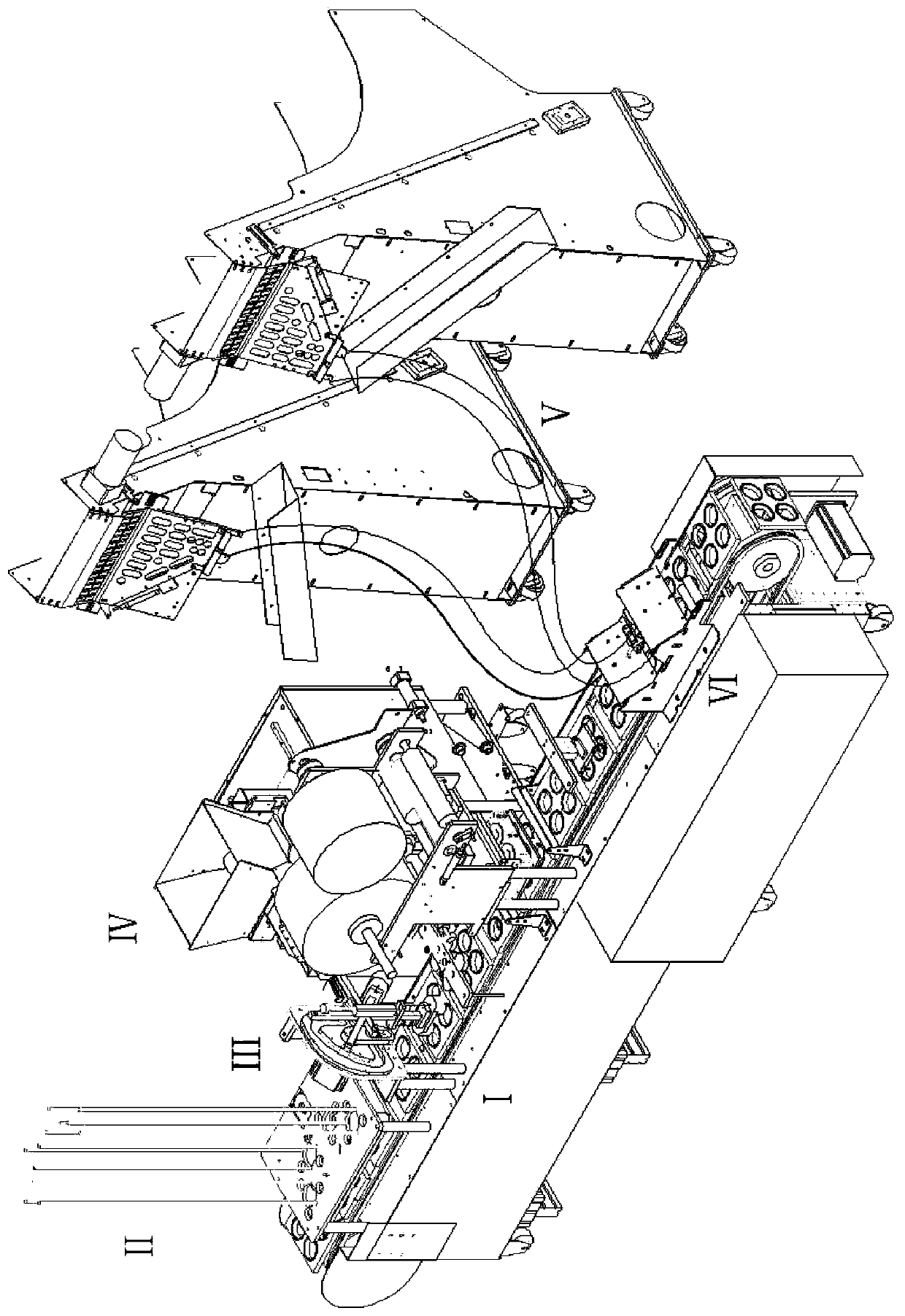

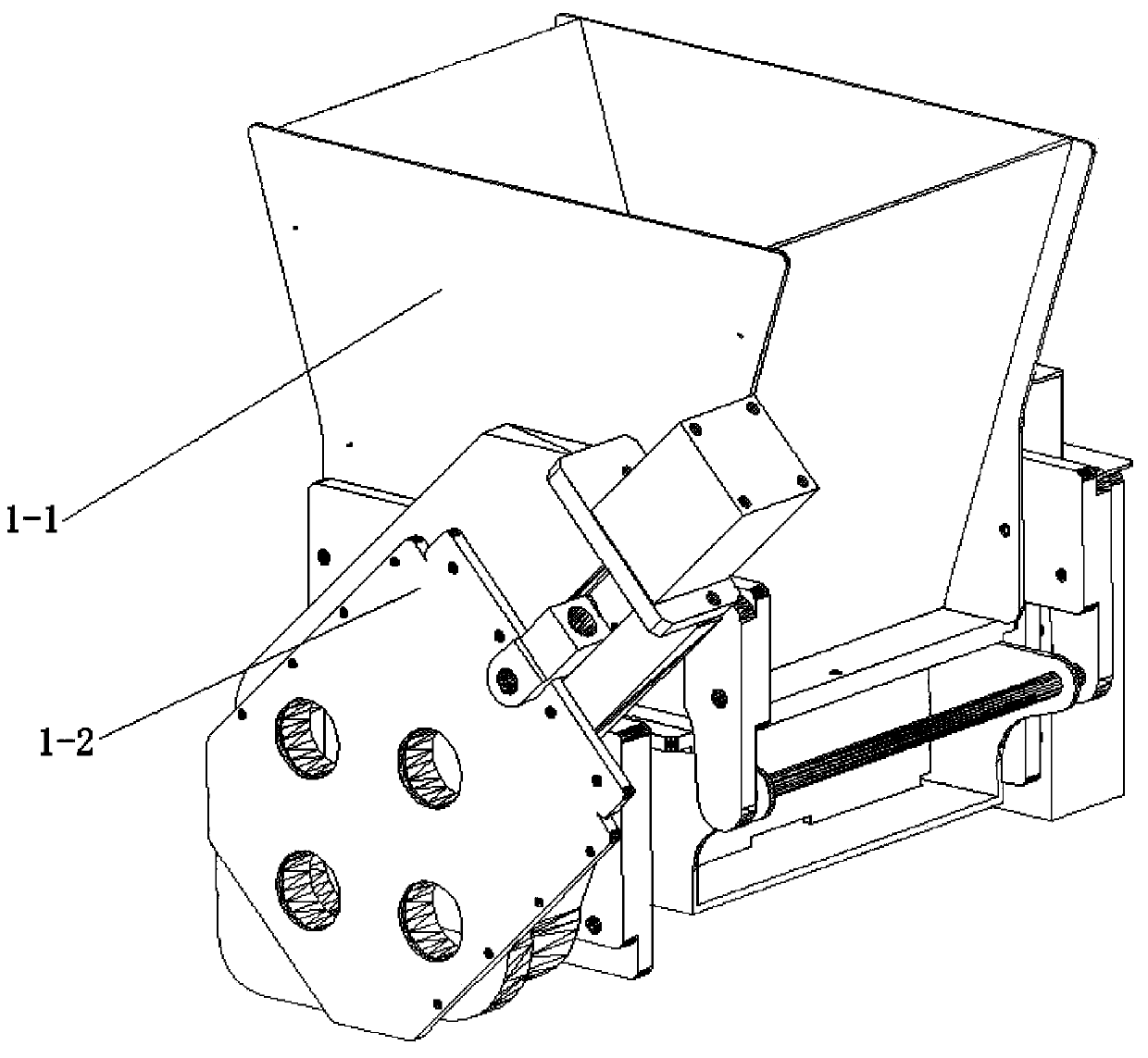

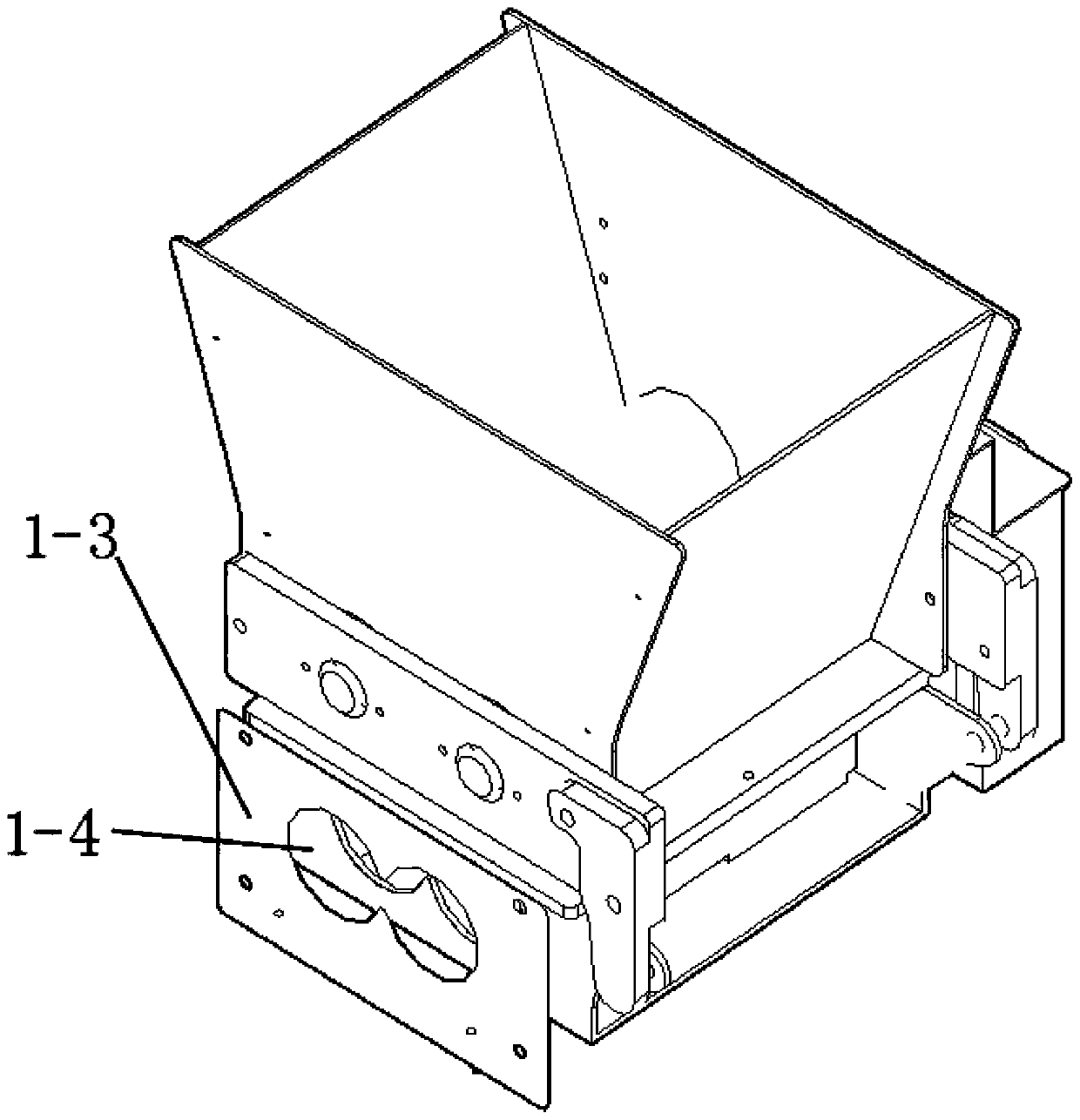

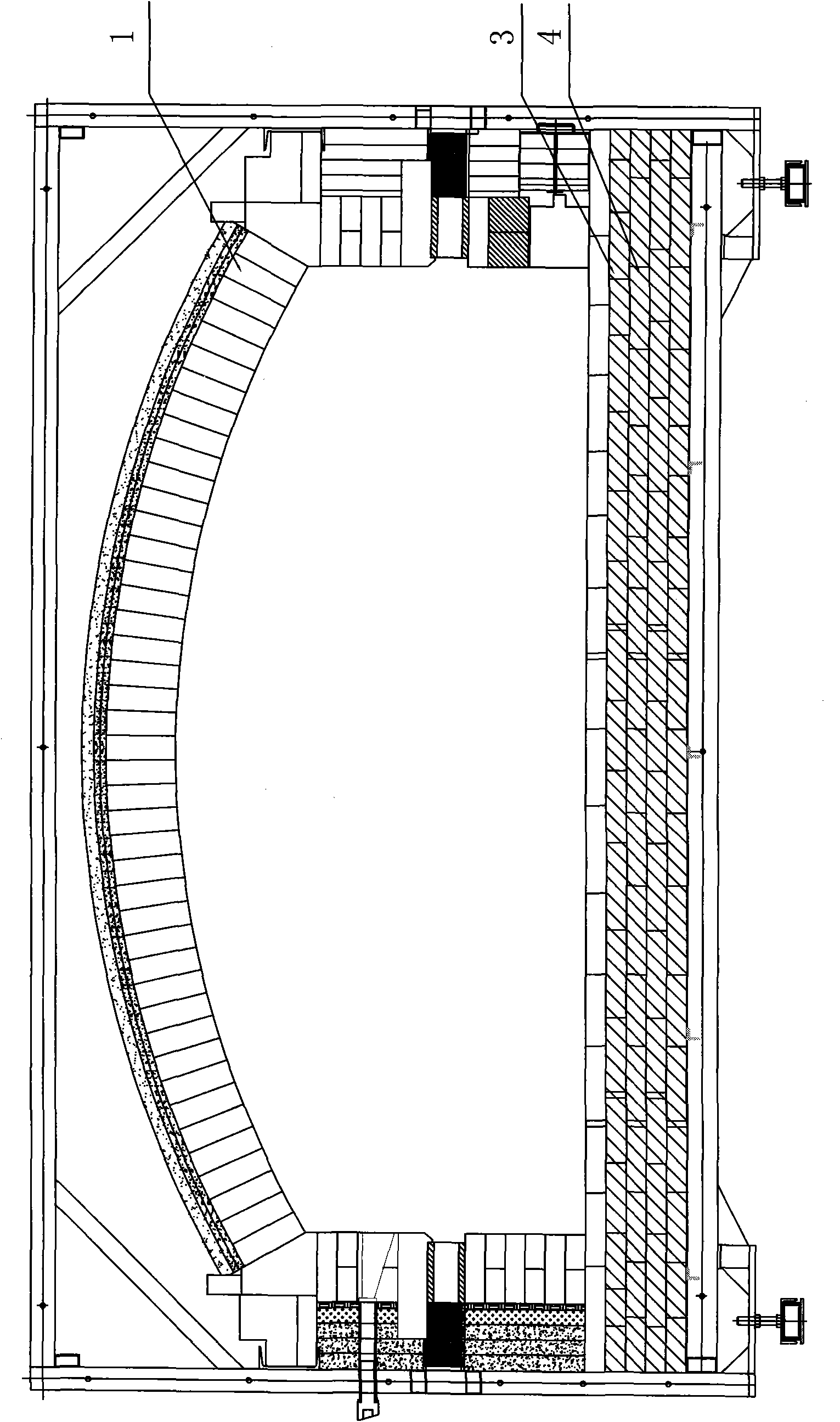

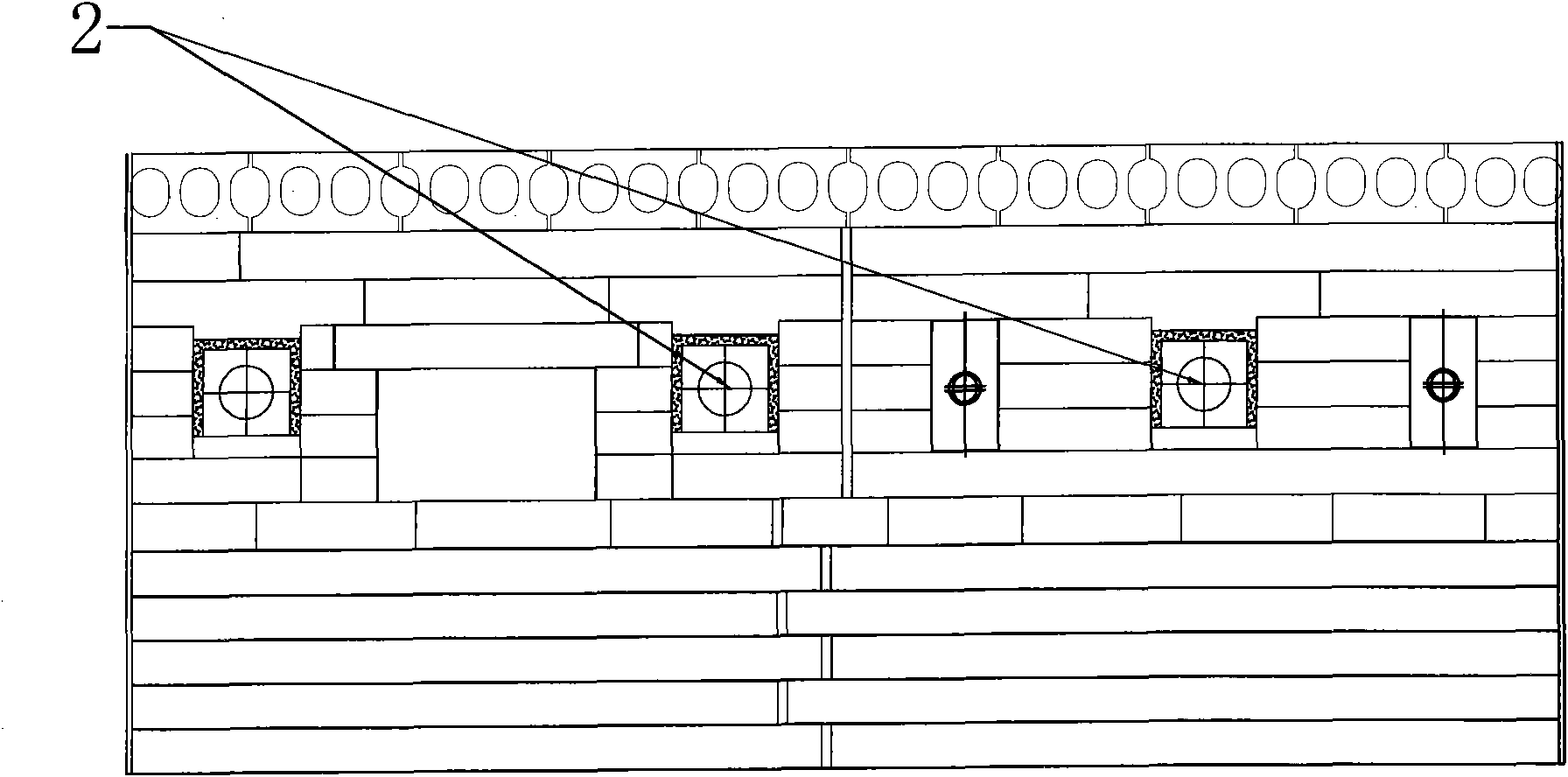

Super light clay machining device

PendingCN110625740AThe processing and packaging process is stable and reliableSolve many problemsCeramic shaping apparatusConveyor partsEngineeringLight clay

The invention provides a super light clay machining device. The device mainly comprises a clay cutting device, a clay transfer device, a cover arranging device and a cover pressing device. The devicesare connected in sequence through a conveying belt. The machining device changes vertical shearing in the prior art into horizontal cutting, during transferring, a spring rod with a limiting device is used for inserting taking of cut super light clay blocks, under driving of a rocker, transferring from the horizontal direction to the vertical direction is achieved, after the vertical direction isachieved, pressing of a press head and retraction of the spring rod are used for achieving releasing of clay blocks, the cut super light clay blocks are transferred, in the whole process, the super light clay is in the completely controllable state, product consistency is good, machining and packaging processes of the super light clay are more stable and reliable, meanwhile, the cooperation of the novel cover arranging device and the novel cover pressing device is adopted, and the yield and the machining efficiency are greatly improved.

Owner:山东博智文具有限公司

Energy-saving roller kiln for polished tiles

ActiveCN101936654ASimple structureImprove insulation effectFurnace typesCeramic materials productionEngineeringOxidation zone

The invention discloses an energy-saving roller kiln for polished tiles. Both the kiln crown and the kiln bottom of the roller kiln are built with mullite heat-preservation bricks, the built kiln crown is an arch crown and high-aluminum poly light sphere heat-preservation bricks and light clay bricks are laid under the kiln bottom in turn; holes are formed in the built kiln body for mounting a plurality of long spray gun silicon carbide sleeves and short spray gun silicon carbide sleeves alternately; and an encrypted gun is arranged in an oxidation zone in the kiln body by an encrypted gun silicon carbide sleeve. When the scheme is adopted, the uniformity of the temperature in the kiln in a section direction is improved, and the temperature difference is lowered and further controlled. After the green tiles are formed in a calcining zone, finished polished tiles at the temperature of below 60 DEG C are output from the exit of the kiln through a cooling area. The kiln adopting the scheme has simple structure, greatly improved heat preservation performance and greatly reduced energy consumption.

Owner:GUANGDONG CHINA KILN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com