Super light clay machining device

A processing device, the technology of ultra-light clay, which is applied in the direction of manufacturing tools, transportation and packaging, conveyor objects, etc., can solve the problems of continuous processing difficulty, inability to control the number of box covers, and low blanking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

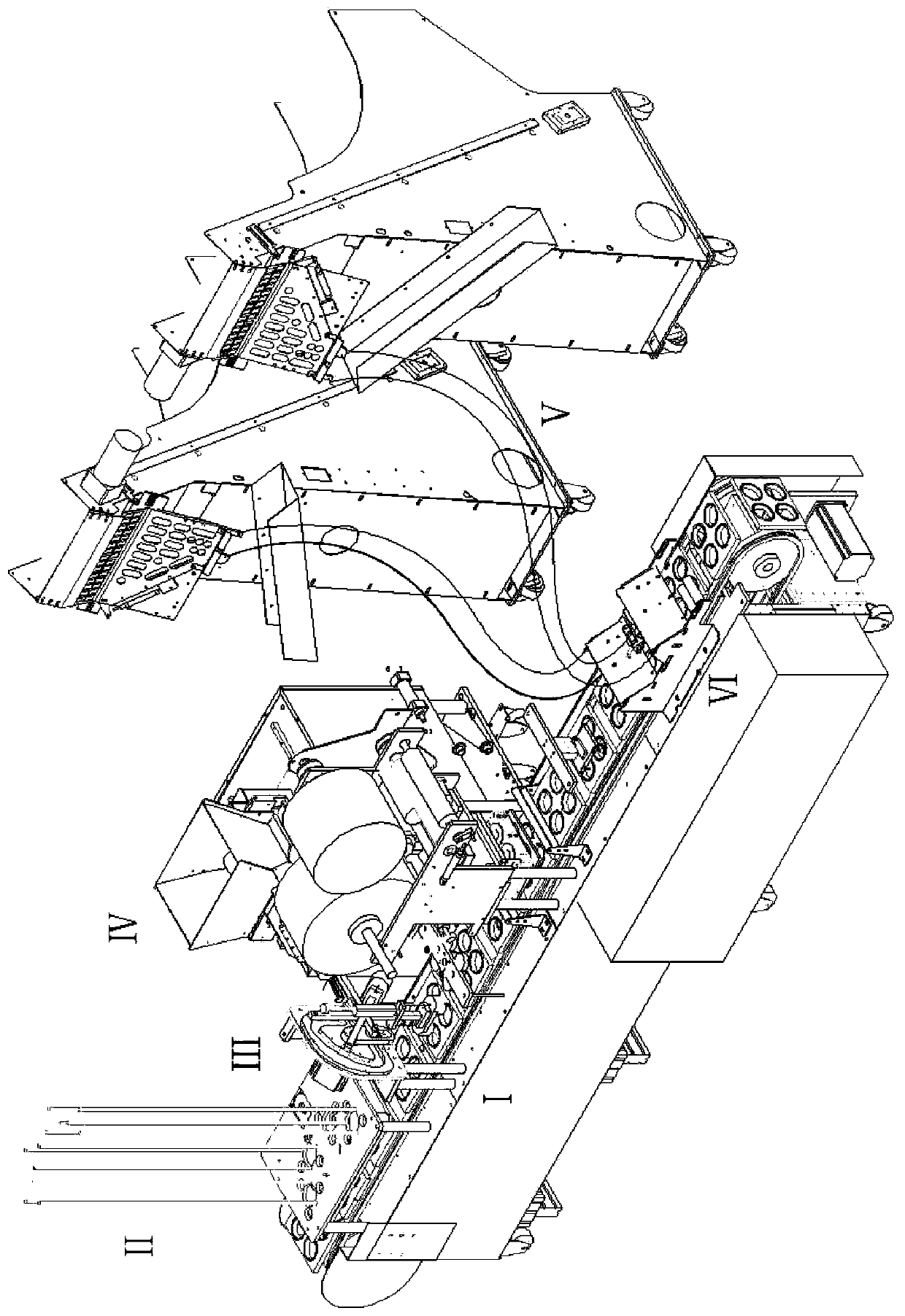

[0047] A processing device for ultra-light clay, comprising a packing box unloading device II arranged in sequence, a clay cutting device IV and a clay transfer device III correspondingly arranged, a cap unscrambling device V and a capping device VI, and a device connected to the above devices Conveyor belt I, on the conveyor belt I is provided with the opening that is adapted to the packing box; Wherein said cover unscrambling device V is two, is connected with the feeding port of capping device VI respectively; Described capping device VI is double Capping machine

[0048] In some cases, a sealing film device can also be set between the capping device, the clay cutting device and the clay transfer device, which can seal the ultra-light clay transferred into the packaging box before capping, prolonging its storage time , but this device is not necessary, but it is preferable to adopt a design with a sealing device;

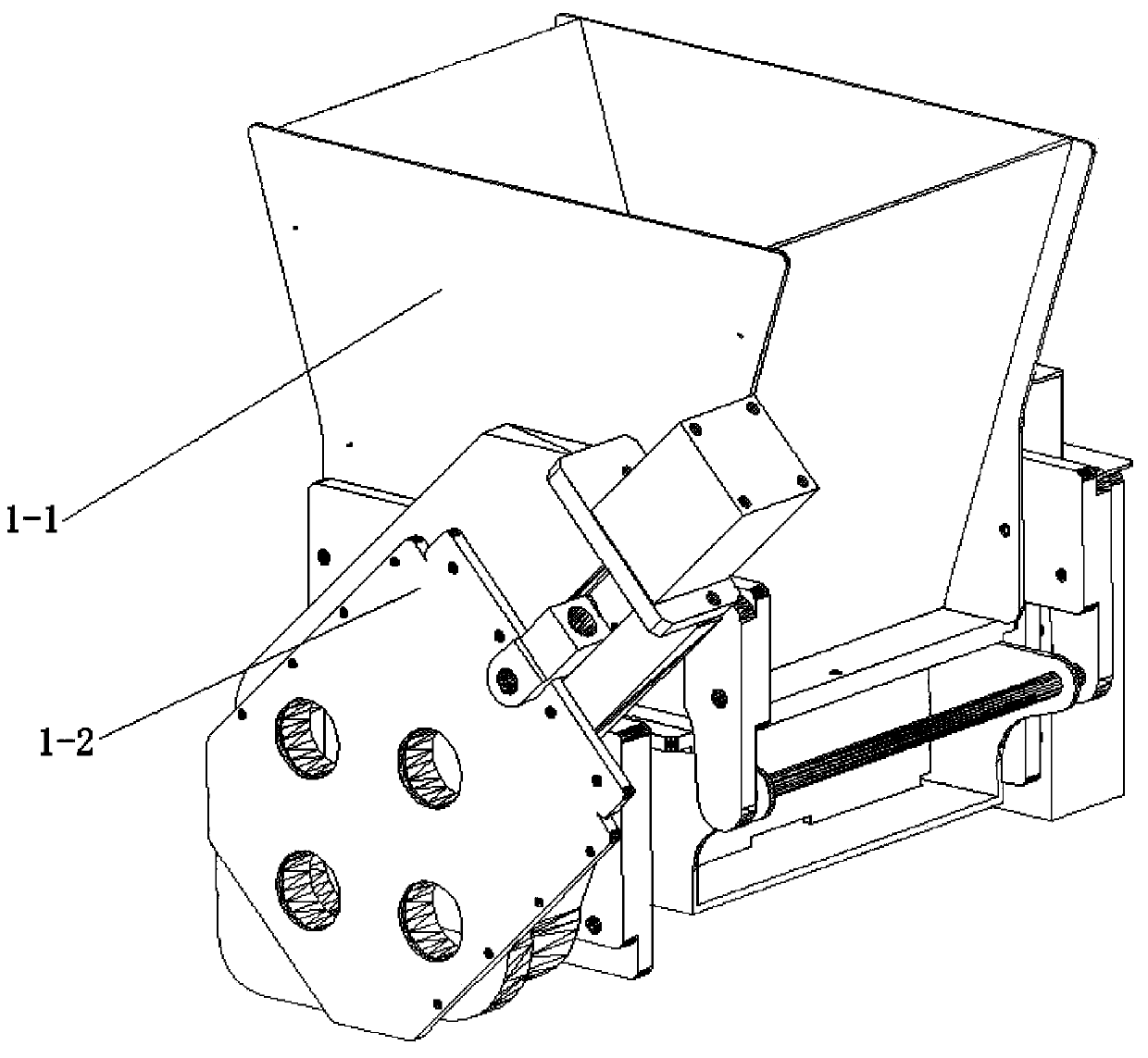

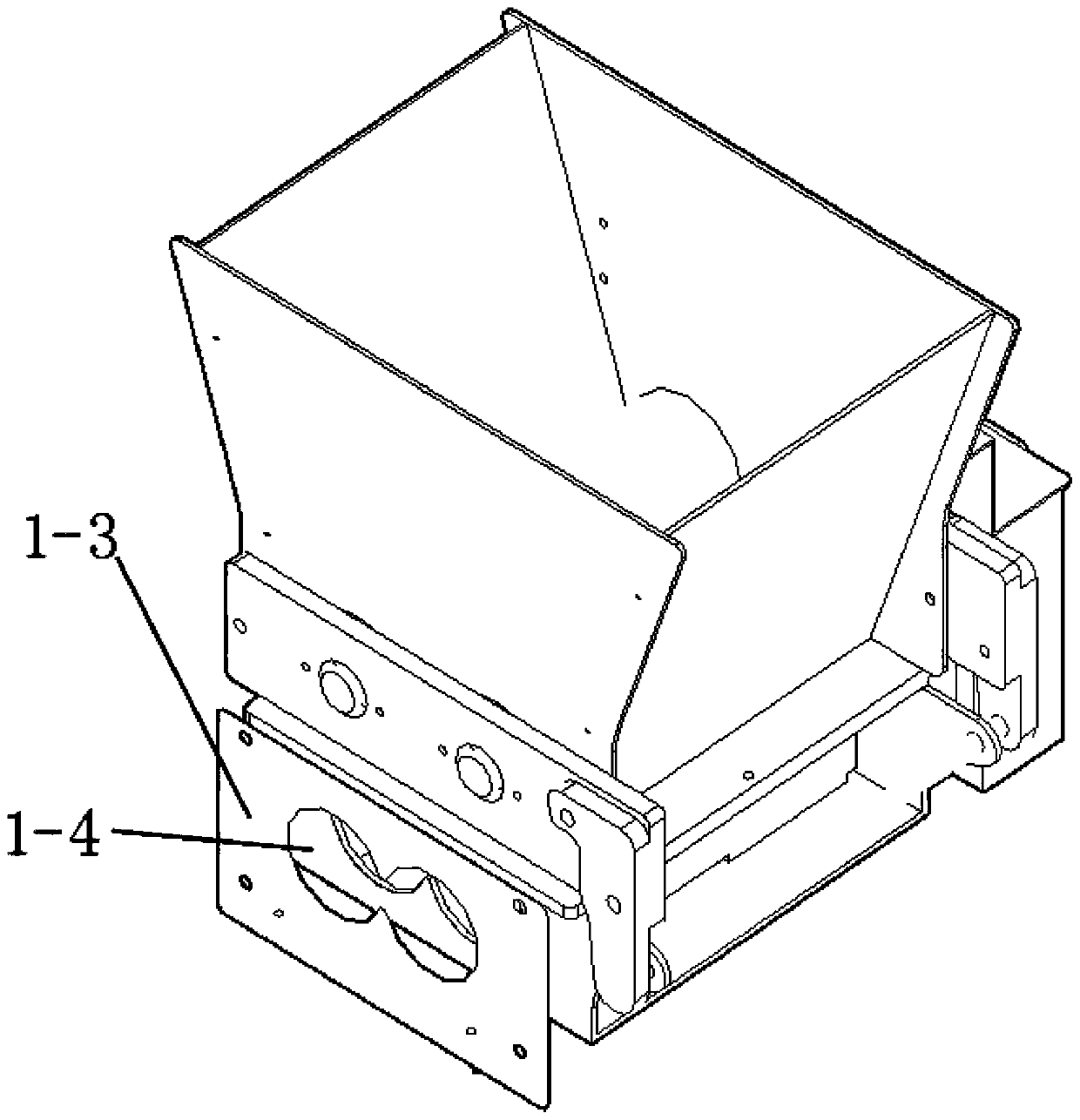

[0049] In the above technical solution, the clay cutting d...

Embodiment 2

[0067] A processing device for ultra-light clay, comprising a packing box unloading device II arranged in sequence, a clay cutting device IV and a clay transfer device III correspondingly arranged, a cap unscrambling device V and a capping device VI, and a device connected to the above devices Conveyor belt I, the conveyor belt I is provided with an opening adapted to the packaging box; wherein the cap sorting device V is one, connected to the feed port of the capping device VI, and the capping device VI is a single row Capping machine;

[0068] In this embodiment, a sealing device is provided between the capping device, the clay cutting device and the clay transfer device, which can seal the ultra-light clay transferred into the packaging box before capping, prolonging its storage time;

[0069] Apart from this, other structures of this embodiment are completely the same as those of Embodiment 1, and the inventors will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com