Patents

Literature

140results about How to "Solve many problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

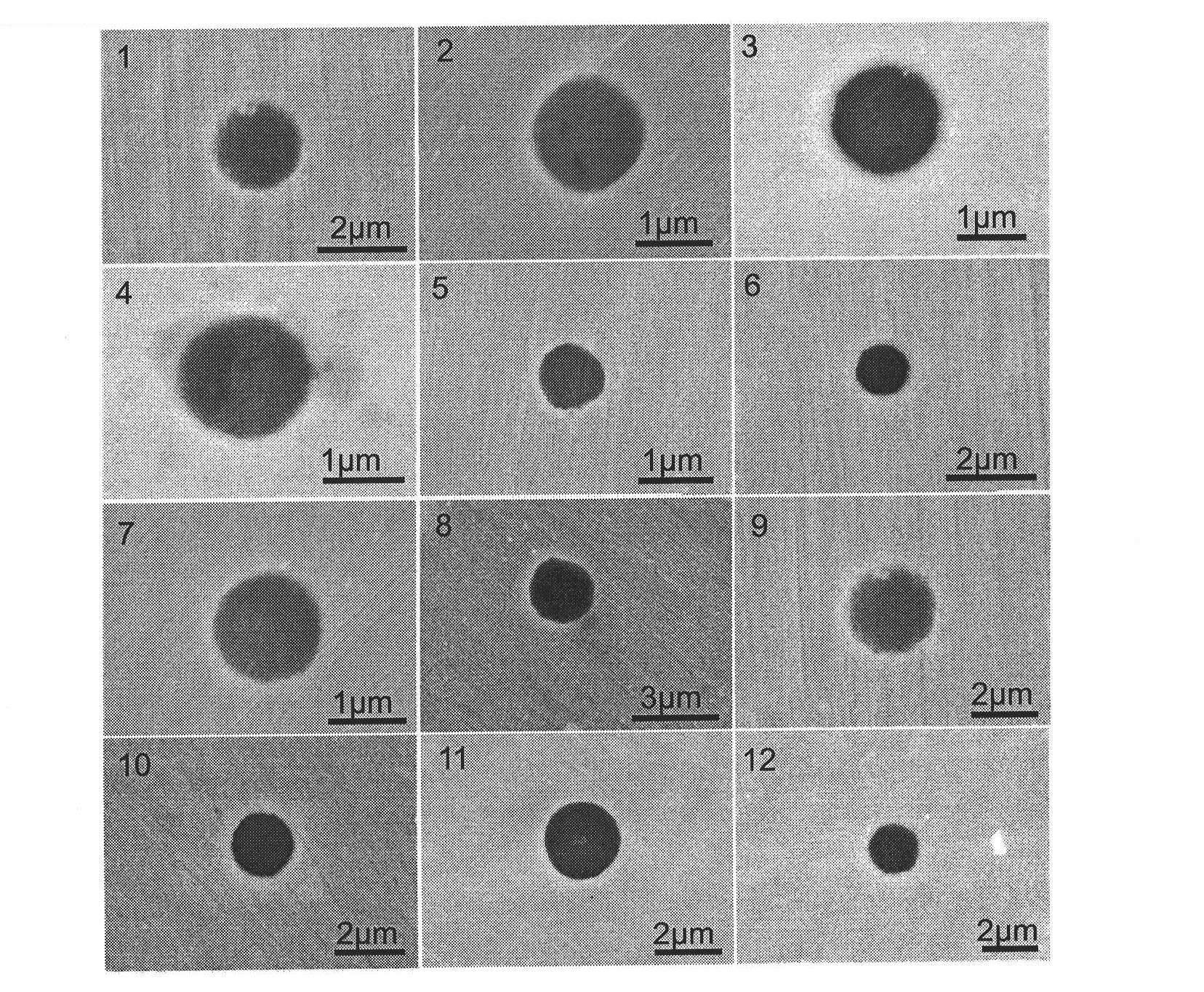

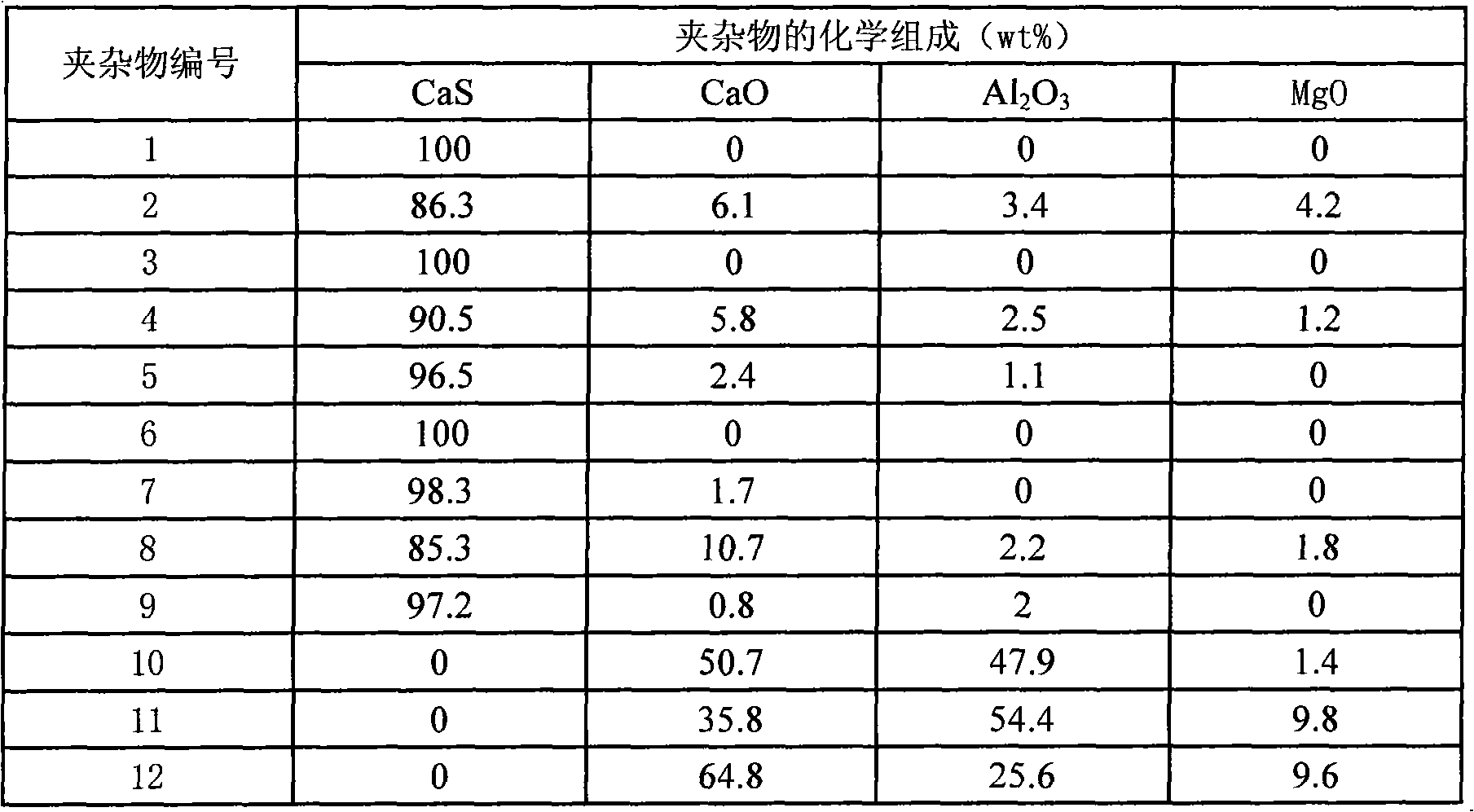

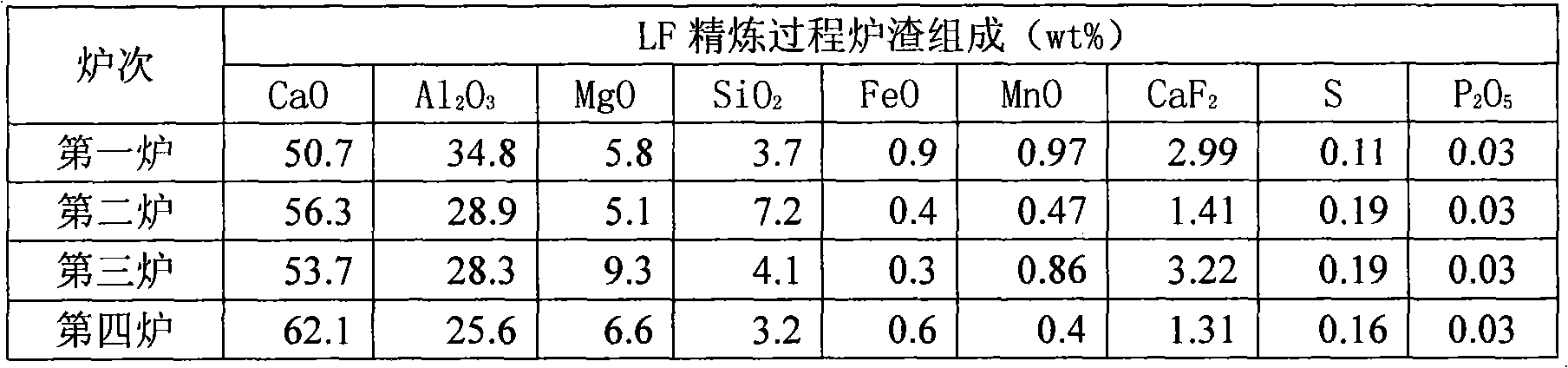

Method for controlling non-metallic inclusions in steel

ActiveCN101962702AEasy to changeExcess dischargeManufacturing convertersSteelmakingNon-metallic inclusions

The invention discloses a method for controlling non-metallic inclusions in steel, and belongs to the field of steelmaking and refining control. Two-section calcium treatment and soft blow are adopted during the refining, and the calcium treatment and the soft blow are performed at the end of LF refining and RH vacuum treatment respectively, so that the non-metallic inclusions in a casting blank are classified into two types: 70 to 90 percent of non-metallic inclusions with CaS as main components, and 10 to 30 percent of oxide type non-metallic inclusions, wherein all the non-metallic inclusions in the casting blank are spherical; the particle diameters of all the non-metallic inclusions in the casting blank are controlled within a range of 0 to 5 microns; and the number of the non-metallic inclusions with the diameter of greater than 3 microns in the casting blank is controlled within the range of 0 to 5 / cm<2>. Thus, the problem that the calcium aluminate type non-metallic inclusion produced after the calcium treatment cannot be discharged out of molten steel due to insufficient time, so the content of calcium aluminate type non-metallic inclusions in the casting blank is high is solved. The rejection rate caused by super-standard non-metallic inclusion of the low alloy structural steel is reduced.

Owner:SHOUGANG CORPORATION

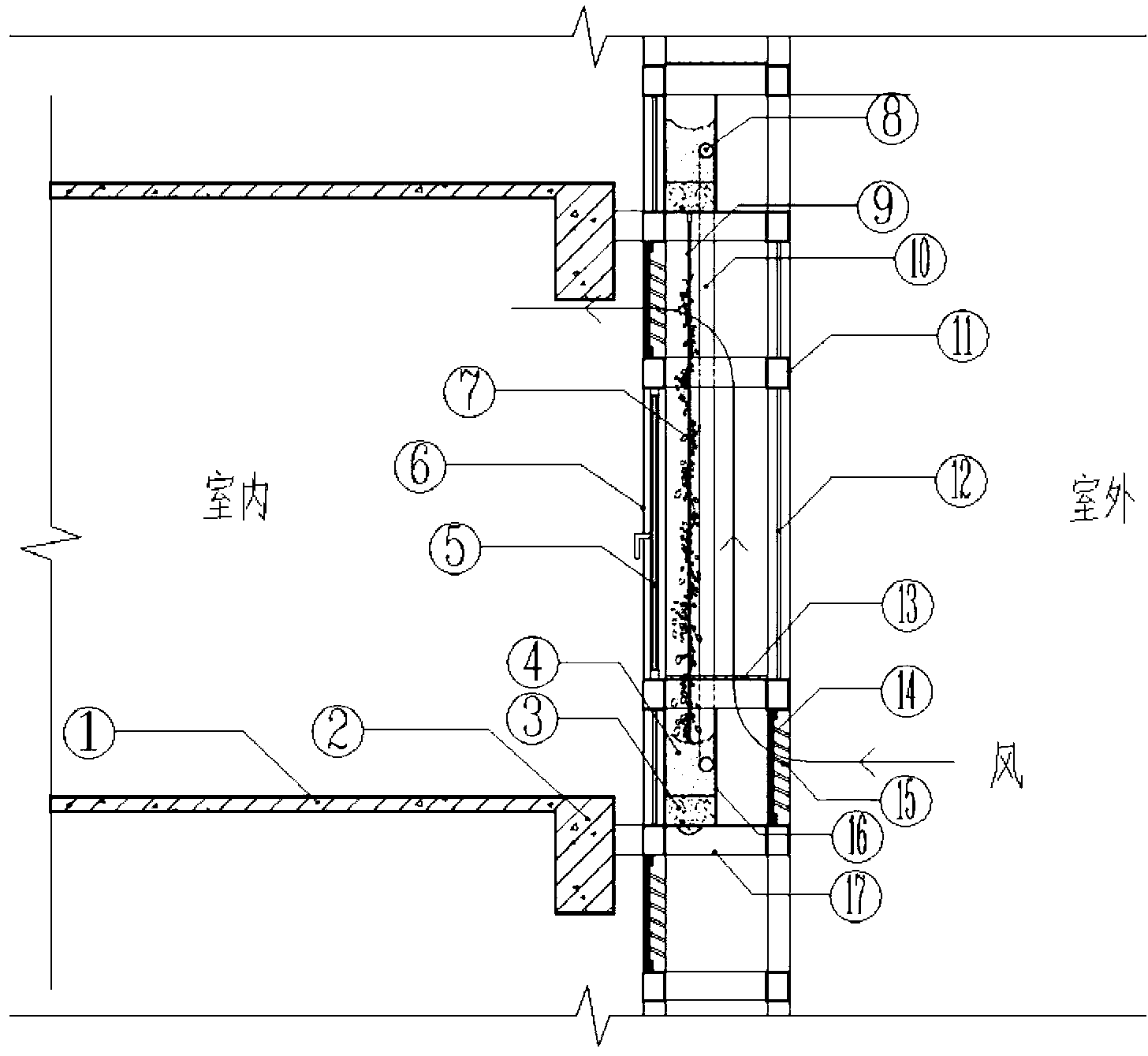

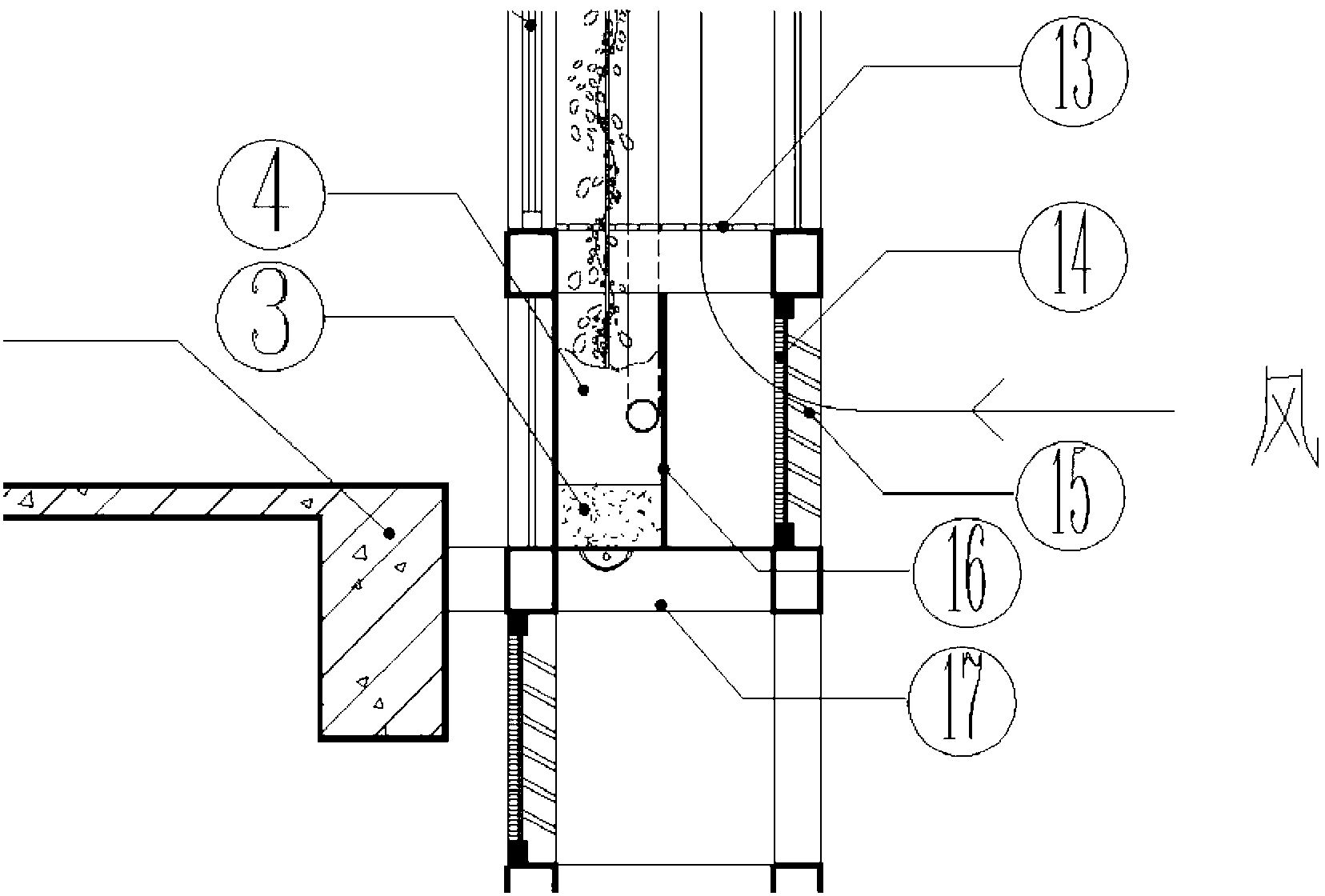

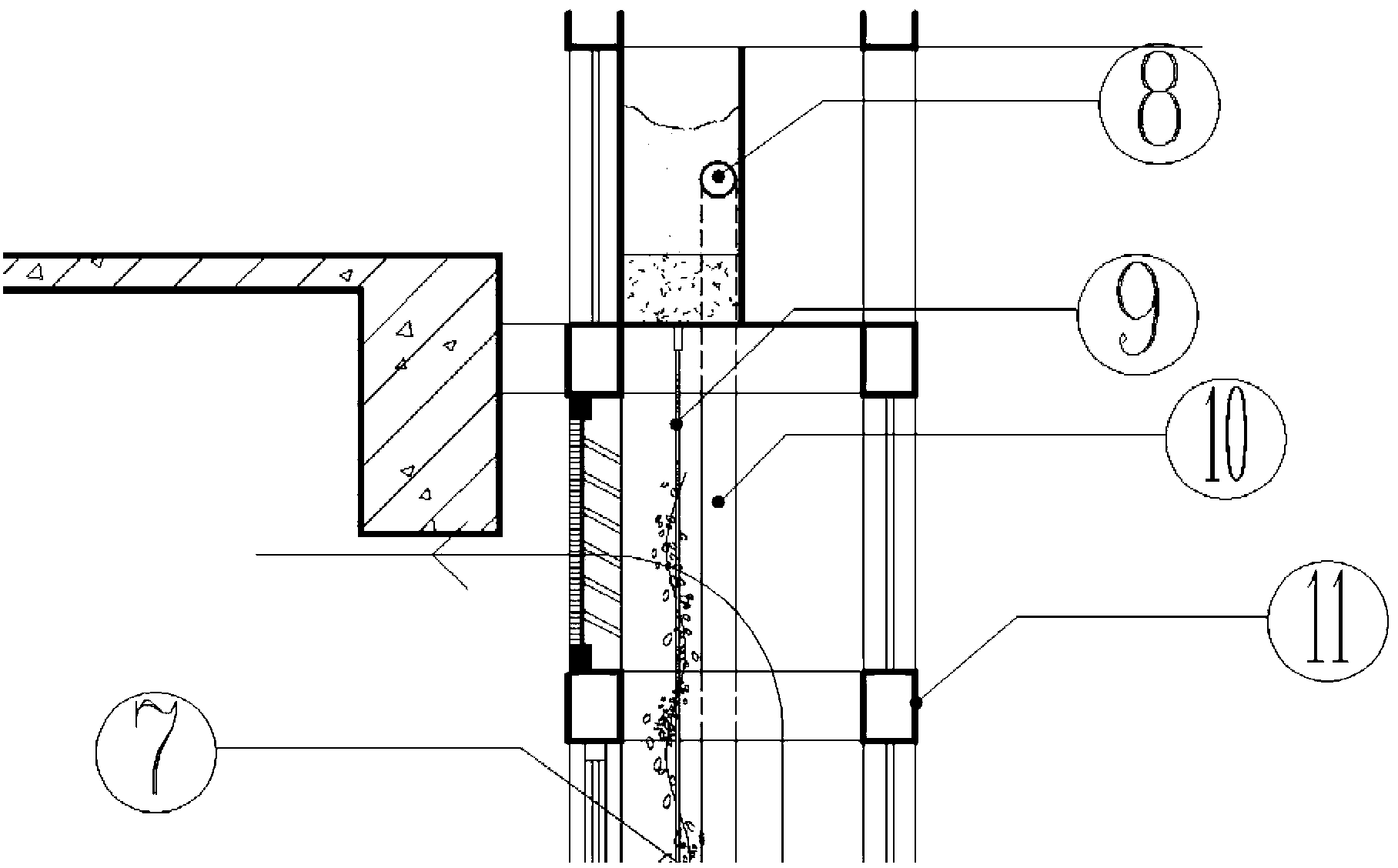

Novel environment-friendly energy-saving curtain wall

ActiveCN103015595AReduce light pollutionIncrease moistureLighting and heating apparatusWallsFiberFresh air

The invention relates to a novel environment-friendly energy-saving curtain wall, which comprises a double-layer curtain wall system and a vertical greening system. The double-layer curtain wall system comprises curtain walls which are independently arranged as an inner layer and an outer layer, wherein each curtain wall is respectively composed of an aluminum alloy frame and glass, and the two layers of curtain walls connected with the aluminum alloy frame are provided with an air cavity in the middle; the vertical greening system is positioned in the air cavity between the two layers of curtain walls; a slotted aluminum plate is arranged at the bottom of the air cavity and is connected with the aluminum alloy frames in a sealing manner; and a layer of plant fiber which prevents moisture from losing is arranged at the bottom in a slot of the slotted aluminum plate, and soil filled with fertilizers covers the plant fiber and is used for plant growth. According to the novel environment-friendly energy-saving curtain wall, the vertical greening system is smartly introduced into the double-layer curtain wall system, moisture in the air cavity is increased by utilizing the transpiration effect of plants in summer, a small greenhouse is formed in the air cavity by using the photosynthesis of the plants to resist cold air in winter, oxygen released by the plants and filtered fresh air are conveyed into rooms all the year around, and therefore multiple problems existing in the curtain wall system are solved.

Owner:BEIJING NORMAL UNIVERSITY

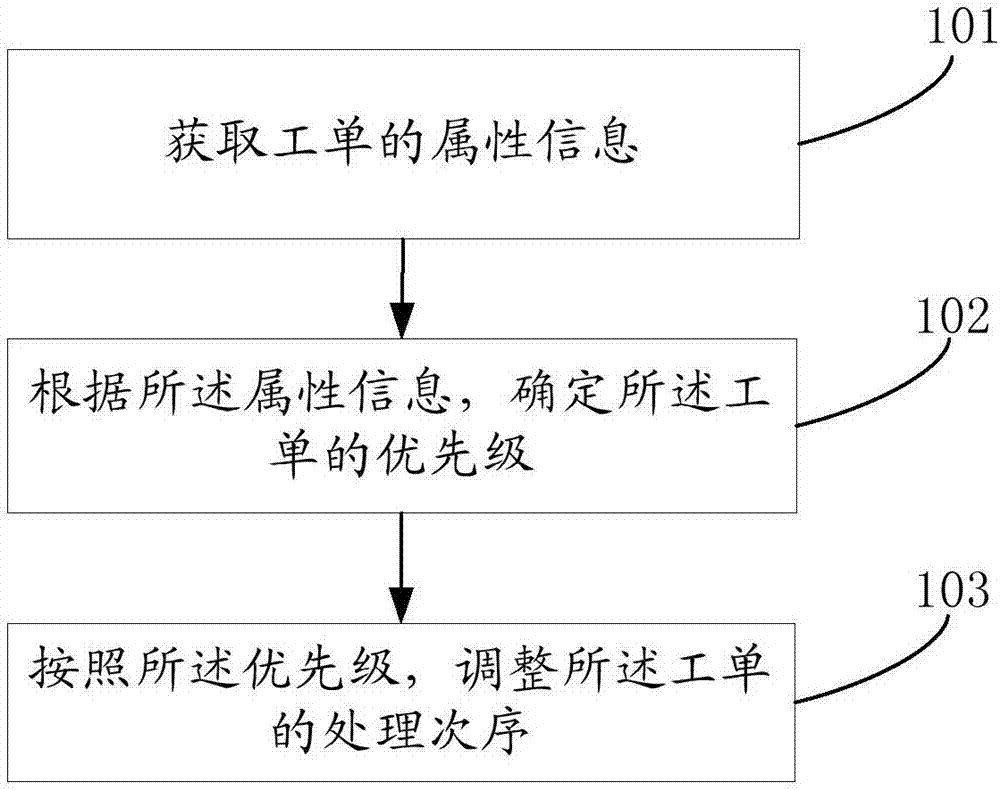

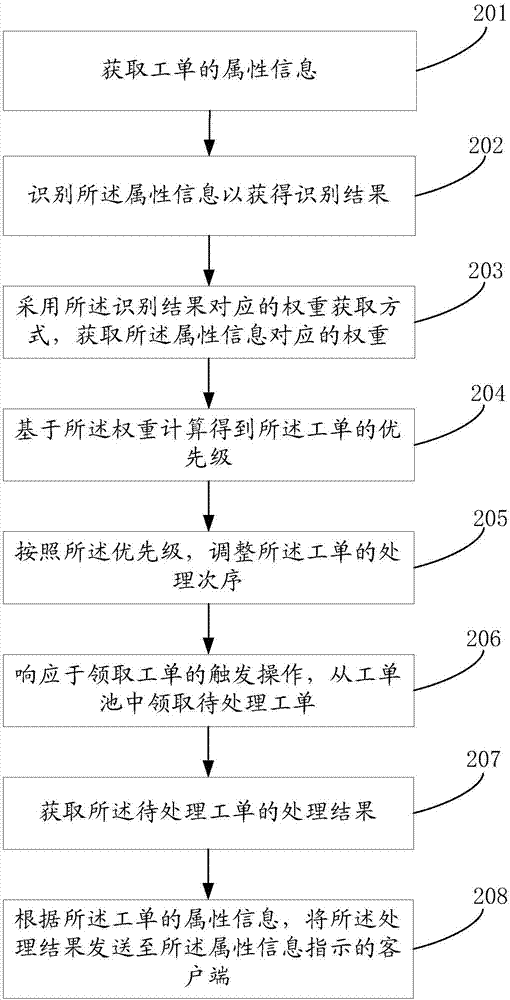

Work order processing method and apparatus

InactiveCN107094208ARaise priorityImprove satisfactionSpecial service for subscribersThe InternetOrder processing

Embodiments of the invention provide a work order processing method and apparatus, relating to the technical field of internet. The method comprises the steps of acquiring attribute information of work orders; determining priorities of the work orders according to the attribute information; and adjusting a processing sequence of the work orders according to the priorities. In the prior art, work orders are processed randomly, so that a lot of problems arise. The work order processing method and apparatus solve the problems in the prior art. Work orders of high priorities are ensured to have the process priority, and the customer service further satisfies clients.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

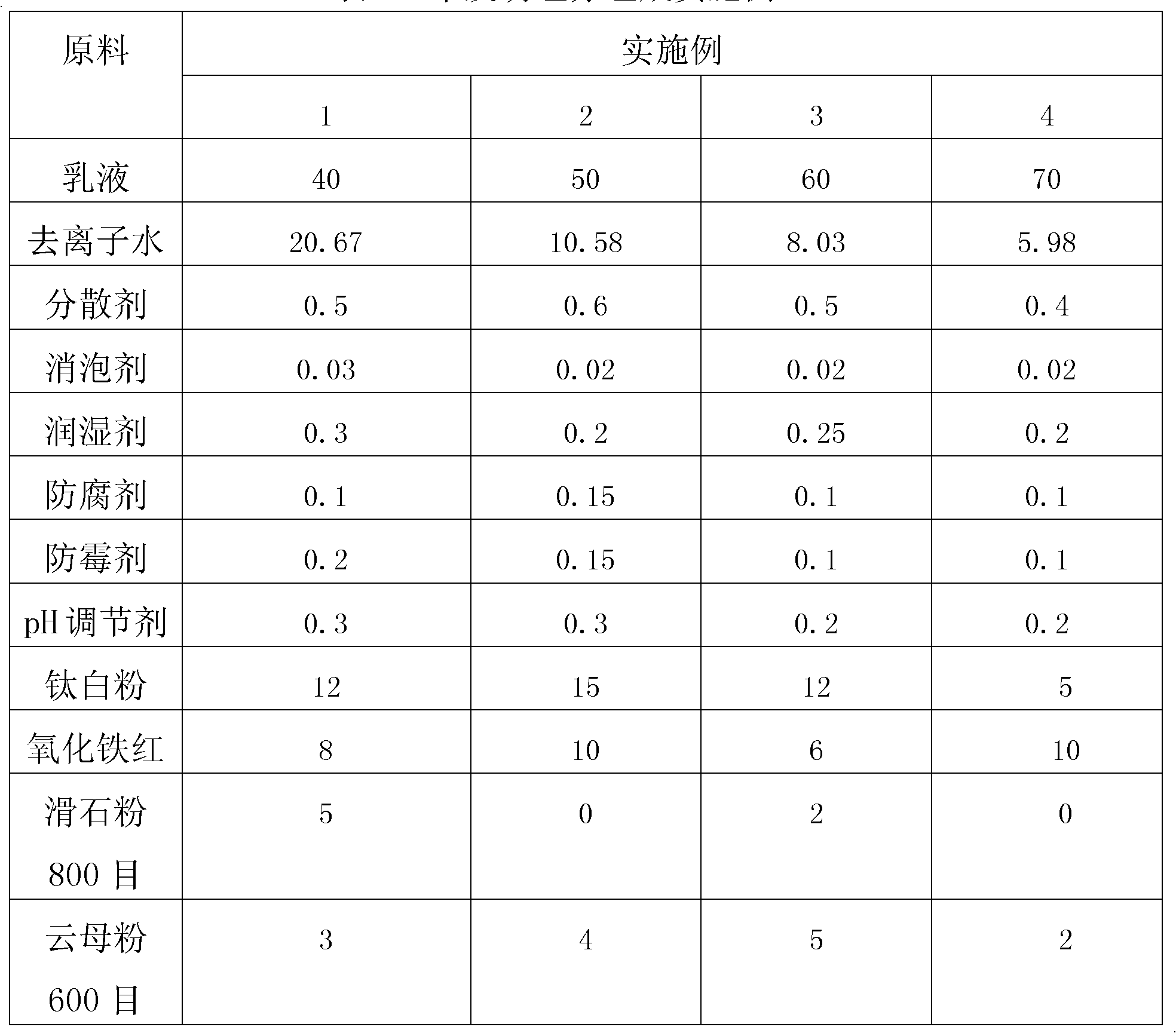

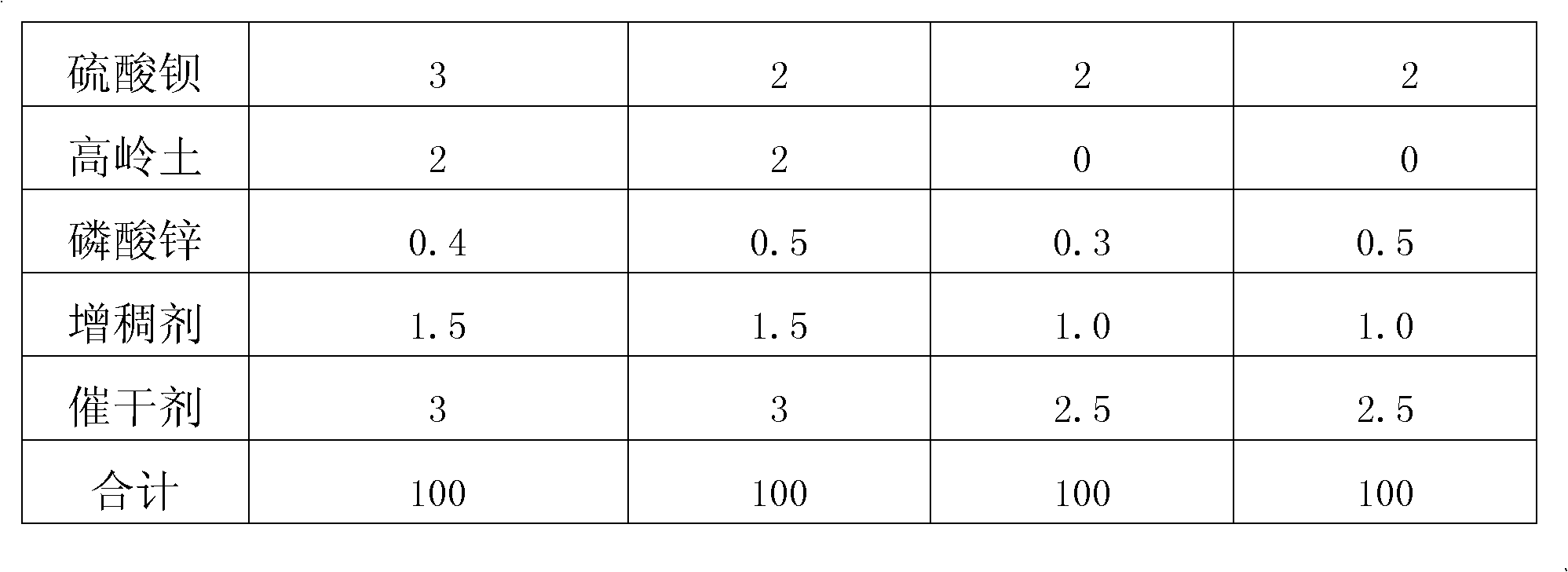

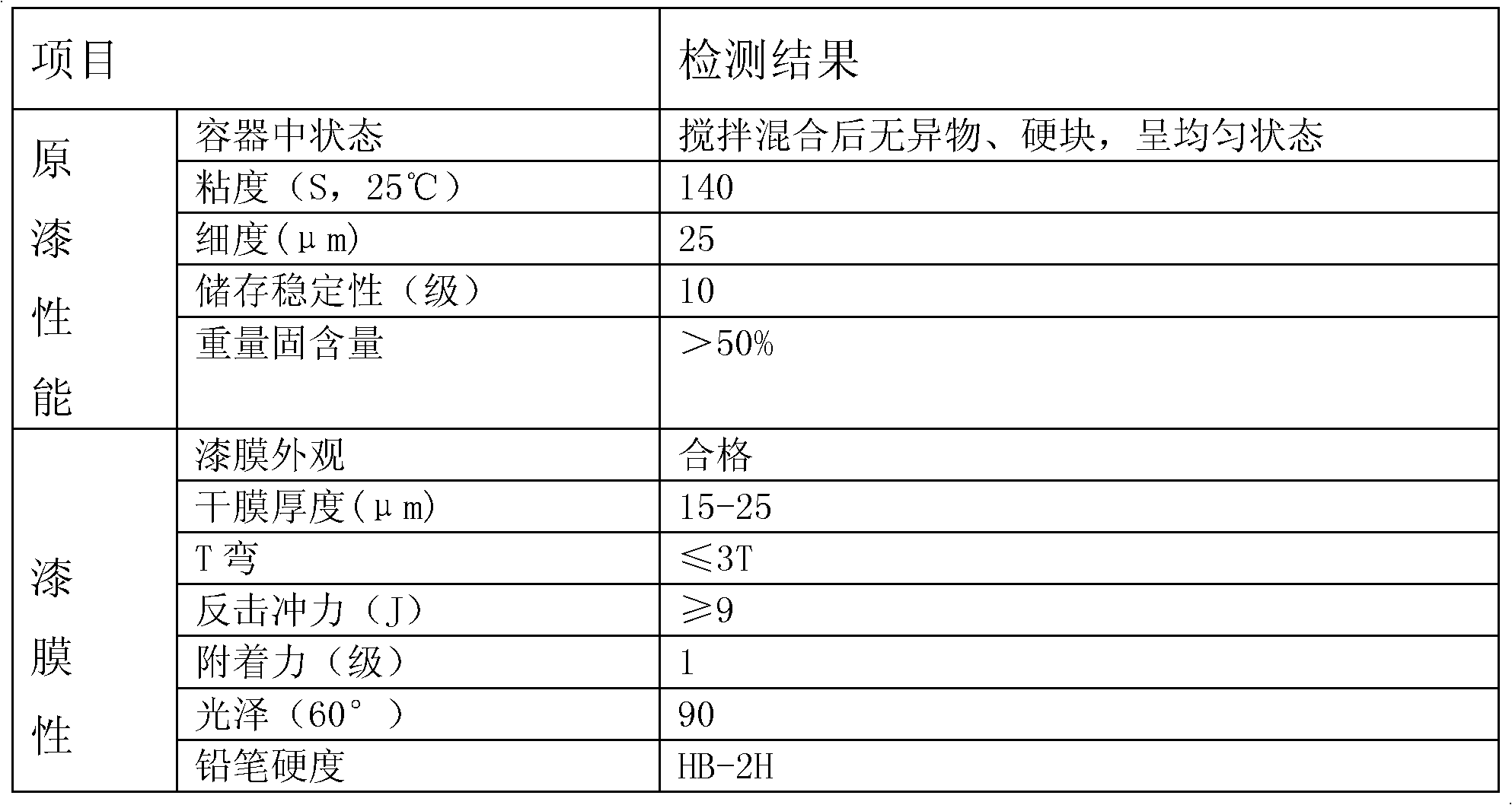

Water-based naon-sized pre-coated coil top coating and preparation method thereof

InactiveCN102504694ASolve many problemsReduce surface tensionPolyurea/polyurethane coatingsWater basedWater dispersible

The invention discloses a water-based naon-sized pre-coated coil top coating and a preparation method of the water-based naon-sized pre-coated coil top coating, and belongs to the technical field of coating production. The coating contains the following ingredients in percentage by weight: 40 to 70% of a nano-polymer emulsion, 1 to 30% of pigments, 5 to 20% of inert anti-rust pigments, 0.1 to 2% of active anti-rust pigments, 5 to 20% of fillers, 0.2 to 8% of adjuvants, 0.1 to 0.5% of pH regulators and the balance of deionized water. The coating system is composed of water-dispersible nano-polymer emulsion having a particle size of less than 100 nm, deionized water, pigments, inert anti-rust pigments, active anti-rust pigments, fillers and adjuvants. The water-based nano-polymer emulsion is composed of a hydrophilic acrylate copolymer, hydrophobic polyurethane and deionized water. The novel water-based naon-sized pre-coated coil top coating has the advantages that the film coatings are dense, have high thermodynamic property and mechanical stability and is good in corrosion resistance and weather resistance, and can meet the performance requirements of coating and coating process for pre-coated coils.

Owner:DALIAN UNIV OF TECH

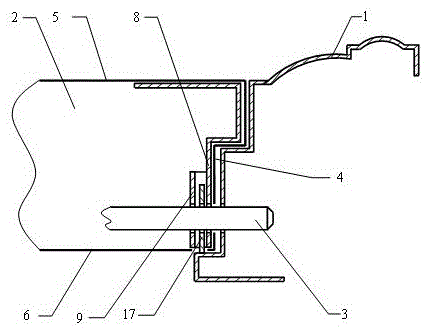

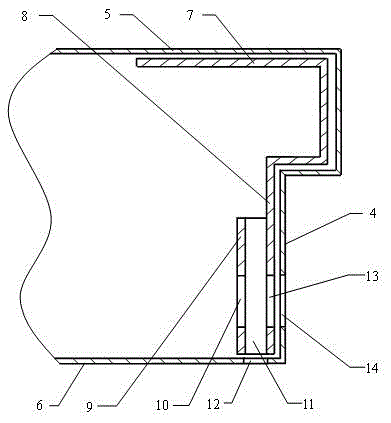

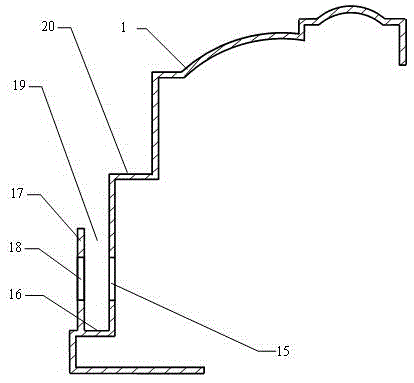

Double-insertion type antitheft door

ActiveCN105545183AImprove tamper resistanceImprove vandal resistanceBurglary protectionBuilding locksJambMechanical engineering

The invention discloses a double-insertion type antitheft door and relates to the field of antitheft safety doors. The double-insertion type antitheft door is mainly characterized in that an insertion lug is arranged at the position, corresponding to each doorframe insertion hole, of a doorframe buckled edge, an insertion lug gap is formed between each insertion lug and a doorframe, a double-insertion plate is arranged at the position, closely neighboring a door leaf side edge, inside the door leaf, the double-insertion plate is provided with liner plates in the mode that each liner plate corresponds to the corresponding insertion hole in the doorframe, a narrow-slit type insertion hole is formed between each liner plate and the double-insertion plate, the side edge of a panel inside the door leaf is provided with rectangular insertion holes in the mode that each rectangular insertion hole corresponds to the corresponding narrow-slit type insertion hole, the insertion lugs, the door leaf side edge, the double-insertion plate and the liner plates are each provided with an insertion hole in the mode of corresponding to the doorframe insertion holes, the five insertion holes which are correspondingly formed constitute a group, after the door leaf is closed, the insertion lugs are inserted into the rectangular insertion holes and the narrow-slit type insertion holes, the double-insertion plate is also inserted into the insertion lug gaps, the five insertion holes are all coaxial, lock tongues are inserted into the five concentric insertion holes correspondingly and used for locking the antitheft door, and the double-insertion type antitheft door is resistant to unclenching and damage.

Owner:BEIHUA UNIV

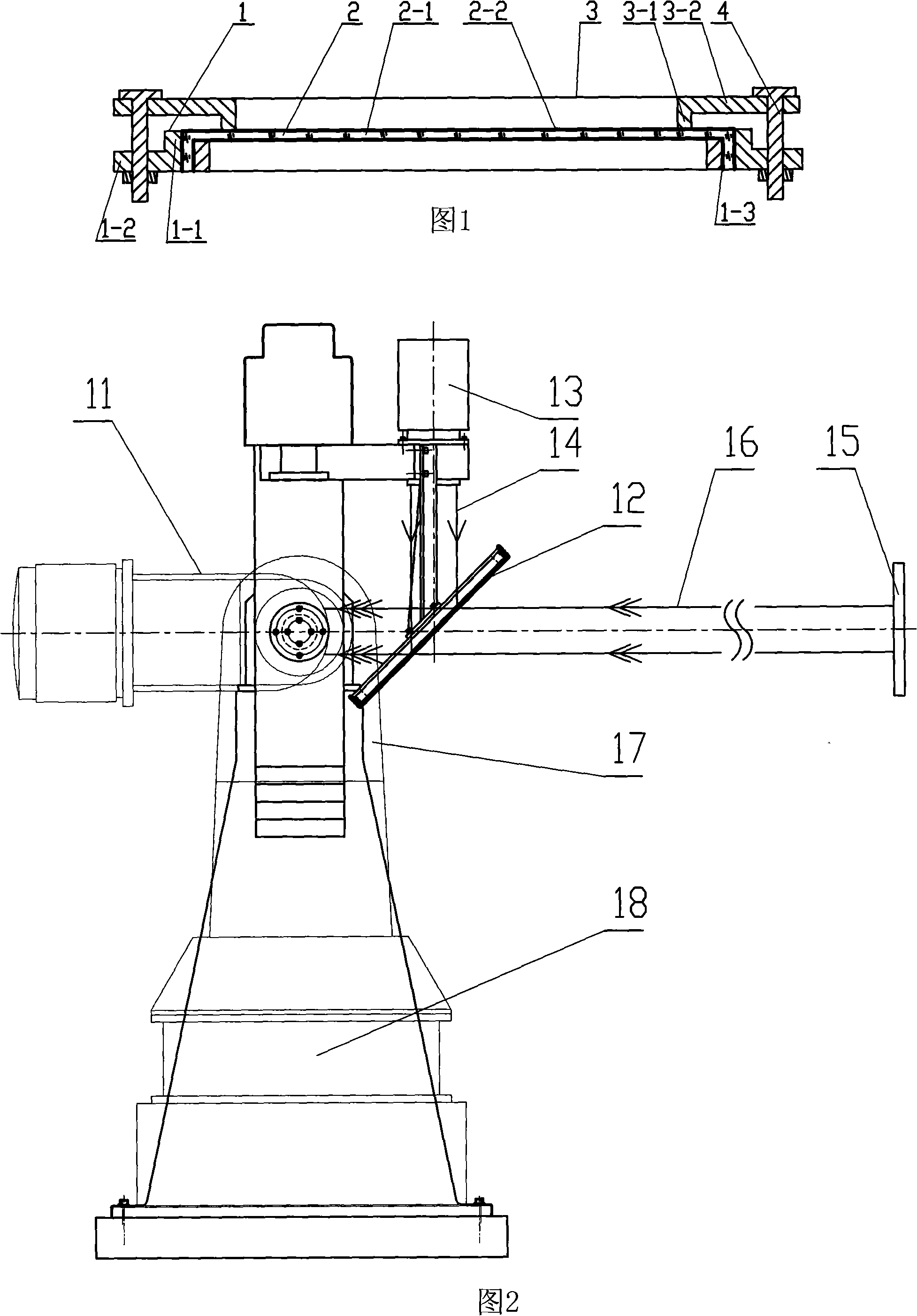

Thin film type infrared-radar beam synthesizer

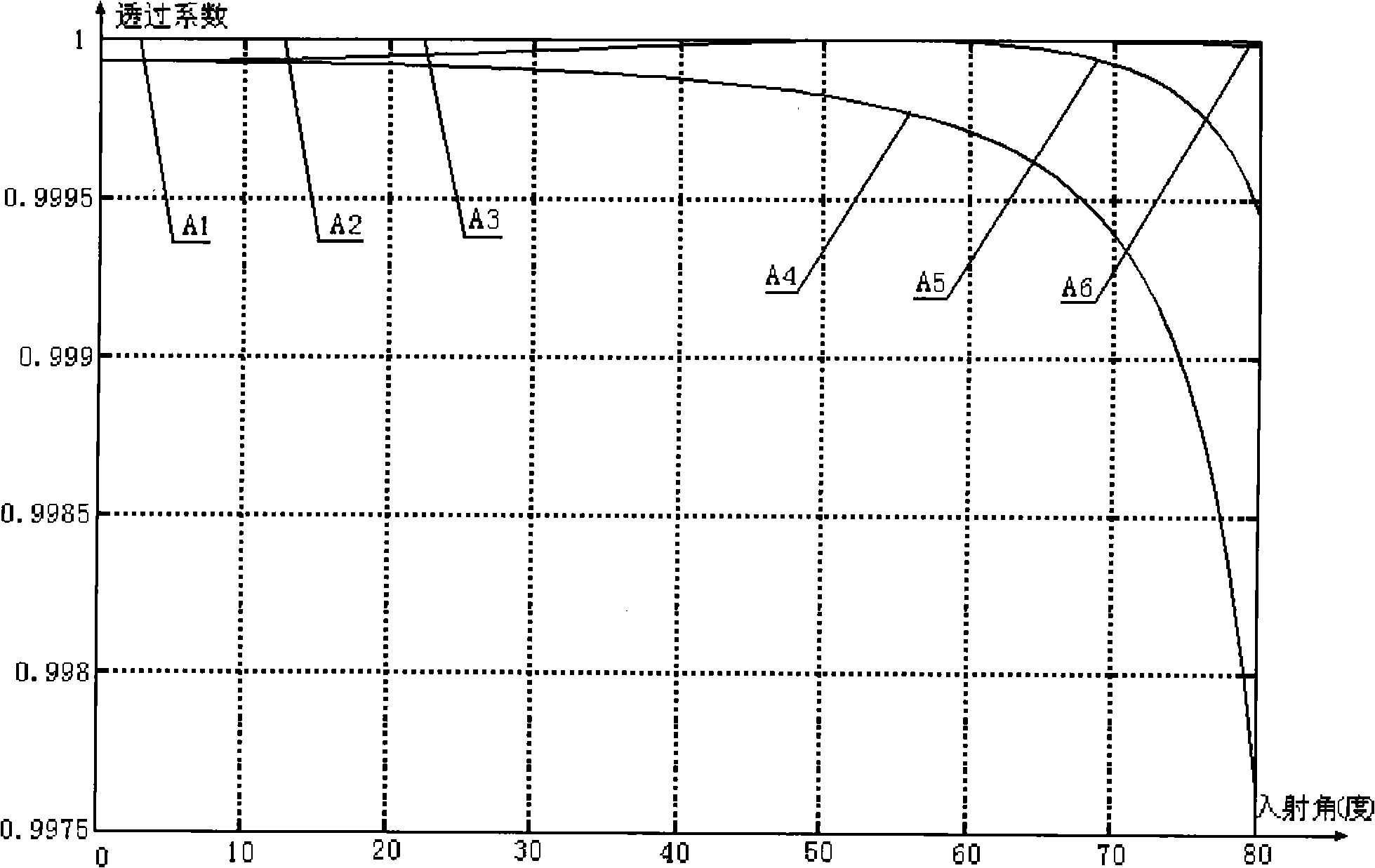

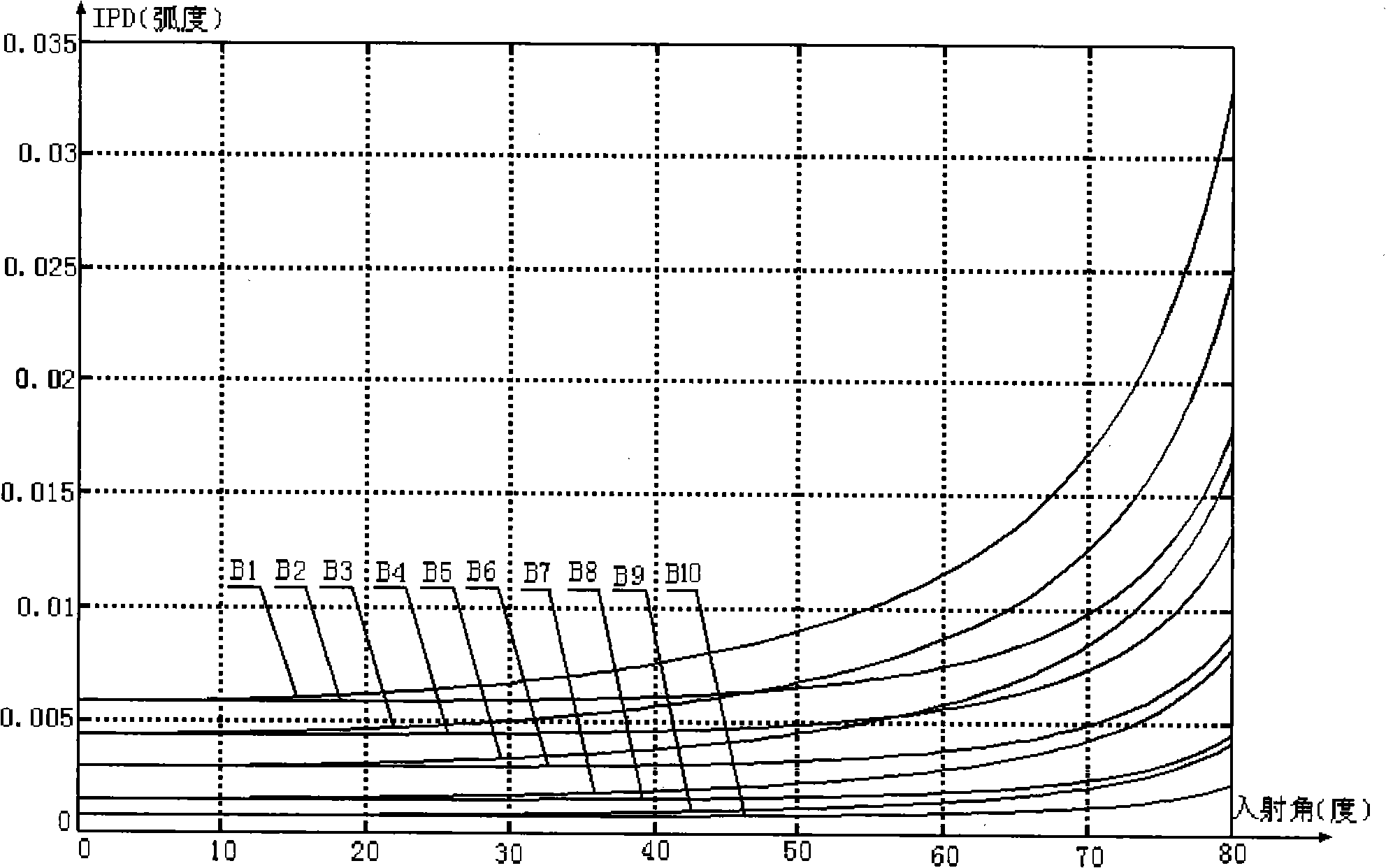

ActiveCN101303407AImprove transmittanceHigh infrared reflectivityWave based measurement systemsTransmittanceAcoustics

A diaphragm type infra-red radar beam synthesizer relates to an infra-red radar beam synthesizer. The synthesizer of the invention solves the problems that the existing beam synthesizer produces comparatively large IPD (Insertion Phase Delay) to radar wave, thus leading to an impact on the testing precision and causing the existing beam synthesizer to be incapable of moving with a simulator. The beam synthesizer of the invention consists of a fixing adjustment mechanism, a beam synthesizing film (2); the beam synthesizing film (2) is fixedly arranged on the fixing adjustment mechanism. The synthesizer of the invention produces a small amount of IPD to radar wave and can move with an infrared simulator with high radar wave transmittance rate and infrared reflectivity rate.

Owner:深圳市睿诚光电科技有限公司

High heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate and preparation method thereof

InactiveCN102558791AEasy to manufactureSimple processPolytetramethylene terephthalatePolyethylene terephthalate

The invention relates to a high heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate engineering plastic and a preparation method thereof, which solves the problem that no high heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate engineering plastic exists at present. The high heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate engineering plastic and the preparation method thereof are characterized in that the engineering plastic includes, by weight, 100 parts of the polybutylene terephthalate, 0.1-1.5 parts of main antioxygen, 0.1-1.5 parts of auxiliary antioxygen, 0.3-1.5 parts of a lubricant, 1-9 parts of flexibilizer, 0.2-1.5 parts of a nucleating agent, 0.2-1.5 parts of a crystallization accelerating agent and 0.5-3 parts of padding. The high heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate engineering plastic and the preparation method thereof have the advantages of simple formula, easiness in preparation and performances of high heat resistance, high gloss, low volatility and rapid prototyping.

Owner:新宏隆特种材料科技(苏州)有限公司

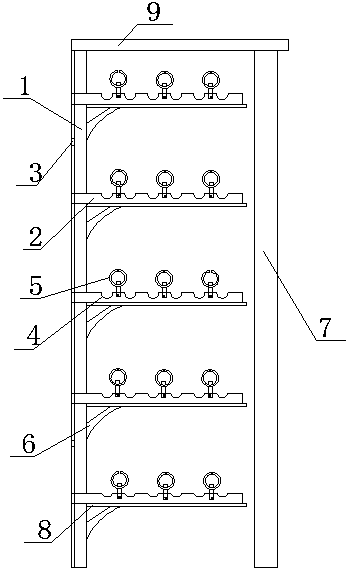

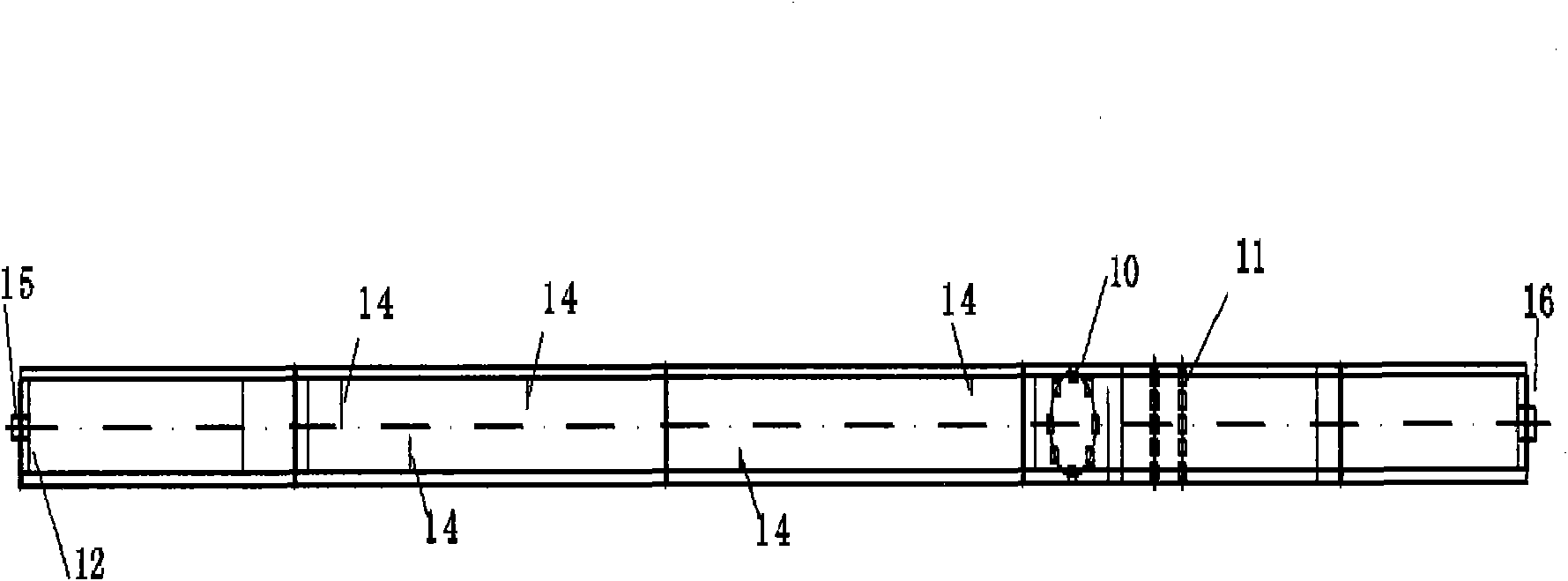

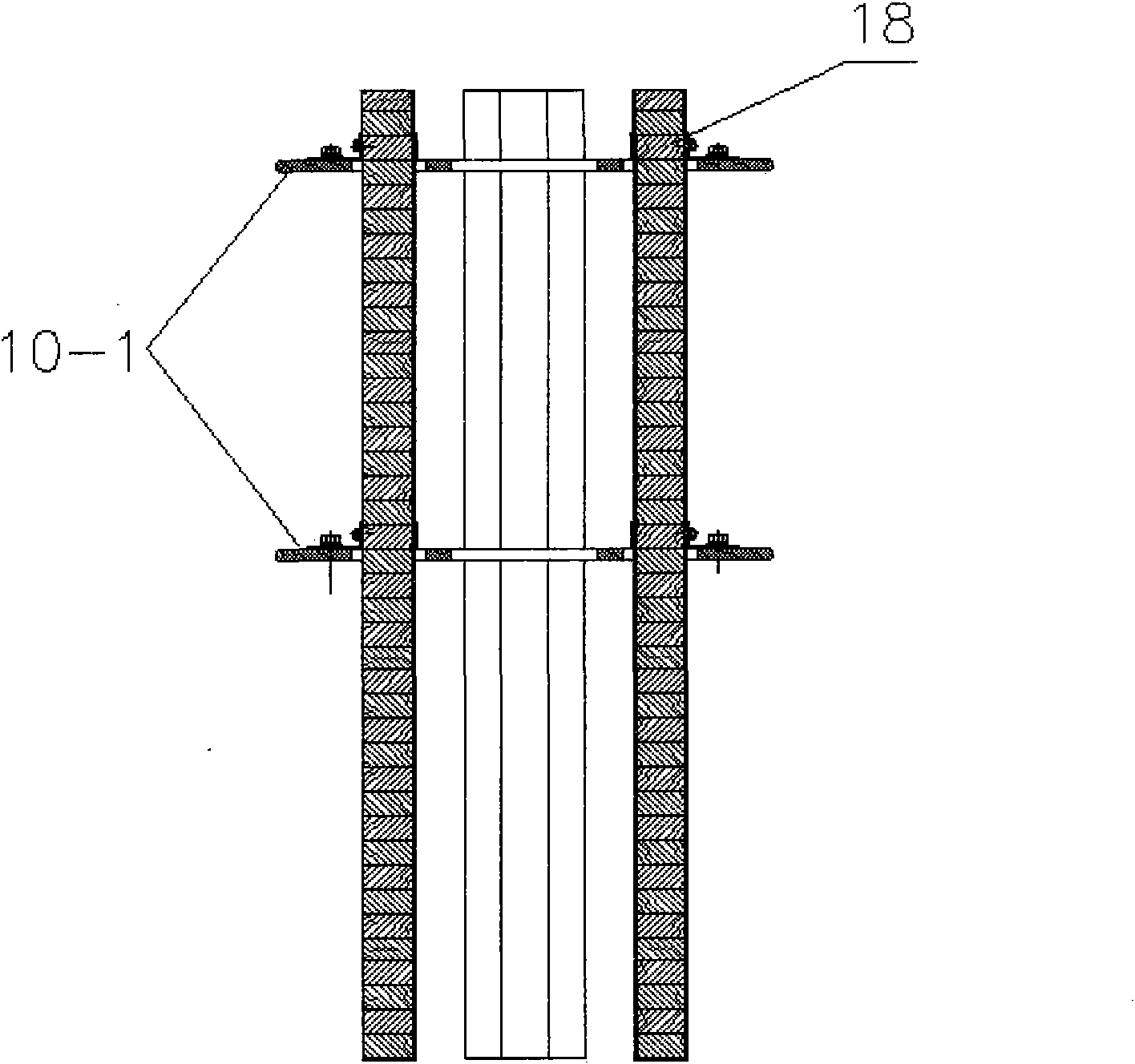

Novel manufacturing and installing method for cable holder

InactiveCN103996998AImprove installation efficiencyQuick and easy replacementElectrical apparatusEngineeringMaterial selection

The invention provides a novel manufacturing and installing method for a cable holder. Holes are formed in the cable holder according to a certain technological standard, cable grooves, hoops, reinforcing ribs, fireproof division plates and the like can be arranged on supporting arms of the holder as needed, reserved holes are formed in the two walls of a cable trench, and then the cable holder and the walls can be assembled and disassembled fast through expansion bolts. Through material selection, premachining, accessory addition and preliminary combination of the cable holder, the installation procedure can be achieved at one step, so that the labor and the time are saved, the cost is saved, the problem that installation, maintenance, fixation, rust prevention, fire prevention and the like of an existing cable holder are difficult is solved, and the whole cable holder is stable, scientific in design, convenient to manufacture and install, safe and practical. Thus, the novel manufacturing and installing method is worthy of popularization and application.

Owner:XICHUAN COUNTY POWER BUREAU

Novel magnetic separation sewage treatment unit

ActiveCN101913685AIncrease the proportionReduced settling timeWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationFlocculationSewage

The invention discloses a novel magnetic separation sewage treatment unit, which comprises a tank, wherein a water inlet and a water outlet are arranged at the two ends of the tank; the tank is formed by jointing tank channels; the tank is divided into a regulating and stirring tank, a partition board flocculation tank, a magnetic separation settling tank and a smoothing settling tank, wherein the regulating and stirring tank is provided with a medicament feeding system and a stirrer; an inclined plate is arranged on the bottom of the partition board flocculation tank; a funnel is arranged below the magnetic separation settling tank; and a round magnetic cylinder and a rectangular magnetic cylinder are arranged above the funnel. The device can solve the problems of high investment and low efficiency of a single water treatment technique of sewage treatment plants, can remove impurities from sewage quickly and ensures stable effluent and simple hydraulic conditions.

Owner:安徽雷克环境科技有限公司

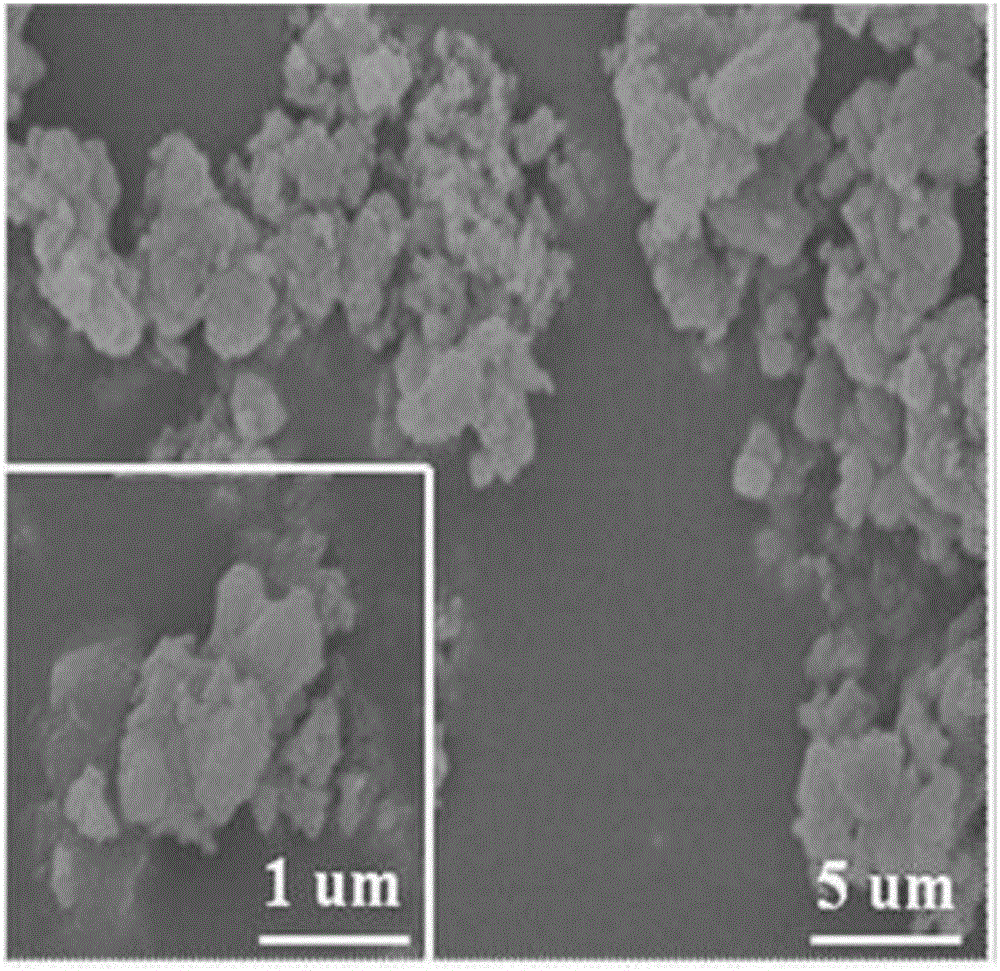

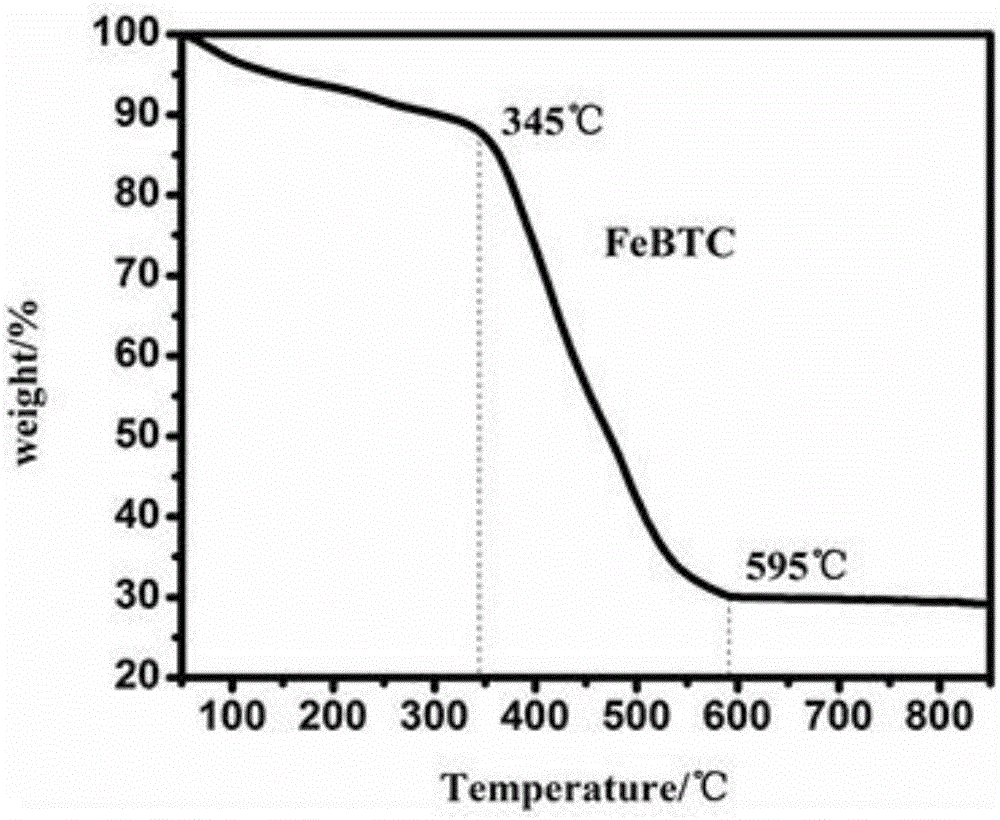

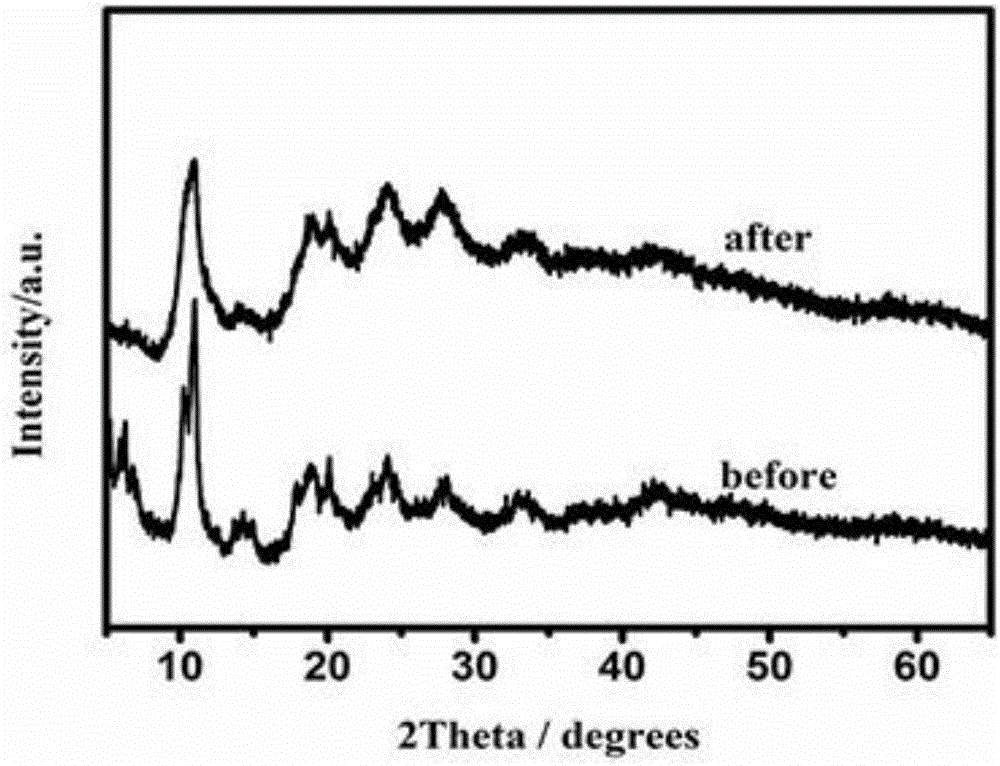

Novel preparation method of Fe-MOF (ferrous-metal oxide framework) catalyst and application thereof in desulfurizing field

InactiveCN106622381AEasy to prepareLess impuritiesGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsIonCarbon oxysulfide

The invention discloses a novel preparation method of Fe-MOF (ferrous-metal oxide framework) and an application thereof in desulfurizing field. The preparation method comprises the following steps of adopting an electrochemical method, using a metal element of Fe (iron) as an anode, and using 66.7 to 80vol% ethanol solution as an organic solvent; using an anode dissolving method to enable the dissolved-out Fe3+ ion and the H3BTC in an electrolyte solution to generate coordination reaction, so as to generate a sample; washing and drying the sample, so as to obtain the FeBTC catalyst. The preparation method has the advantages that the mixing of anion ion impurities of metal salt is avoided, the prepared sample is pure, the synthesis condition is moderate, the reaction is quick, and the reaction time is short; the prepared Fe-MOF catalyst is applied into medium-low temperature hydrolysis reaction of carbonyl sulfide, the activity and stability are good, and a novel COS (carbon oxysulfide) hydrolysis catalyst is developed.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD

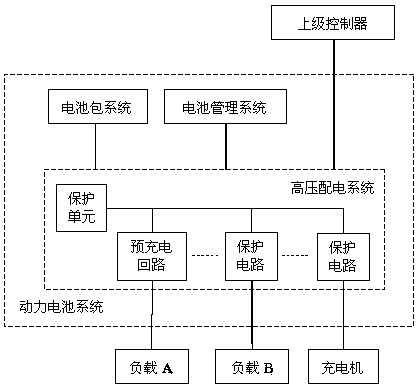

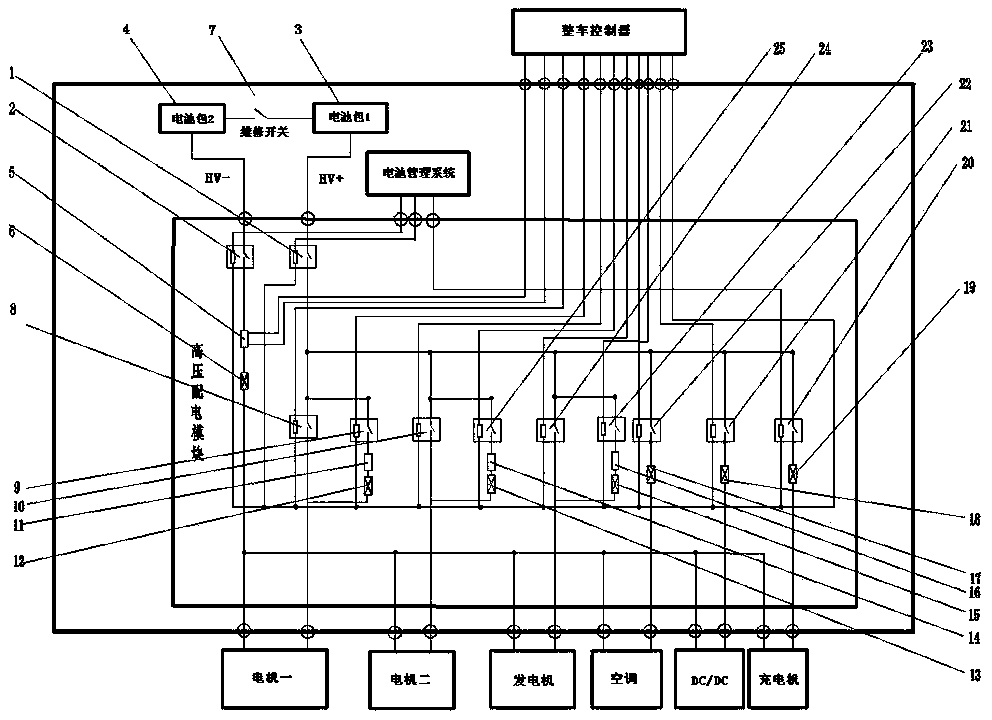

Power battery comprising high-voltage protector

InactiveCN104129316AHighly integratedReduce volumeVehicular energy storageElectric propulsionPower batteryElectrical battery

The invention discloses a power battery comprising a high-voltage protector. The power battery comprises a high voltage power distribution system, a battery management system and a battery pack system, wherein a power input of the high voltage power distribution system is connected with a power output of the battery pack system through a connector, and a power output of the high voltage power distribution system is connected with a plurality of loads through a plurality of connectors. A power control terminal of the high voltage power distribution system is connected with a power control terminal of the battery management system through a connector, and a control input of the high voltage power distribution system is connected with a control output of a superior controller through a connector. The power battery system not only comprises the battery management system and the battery pack system, but also comprises the high voltage power distribution system, so that the problem of multiple wire harnesses is effectively solved, the integration level of the power battery is improved, and the size of the power battery can be smaller. The power battery has the functions of loop protection, pre-charge, and overcurrent protection. The power battery also has a real-time maintenance switch, so that the safety of workers can be ensured during the battery maintenance.

Owner:成都易默生汽车技术有限公司

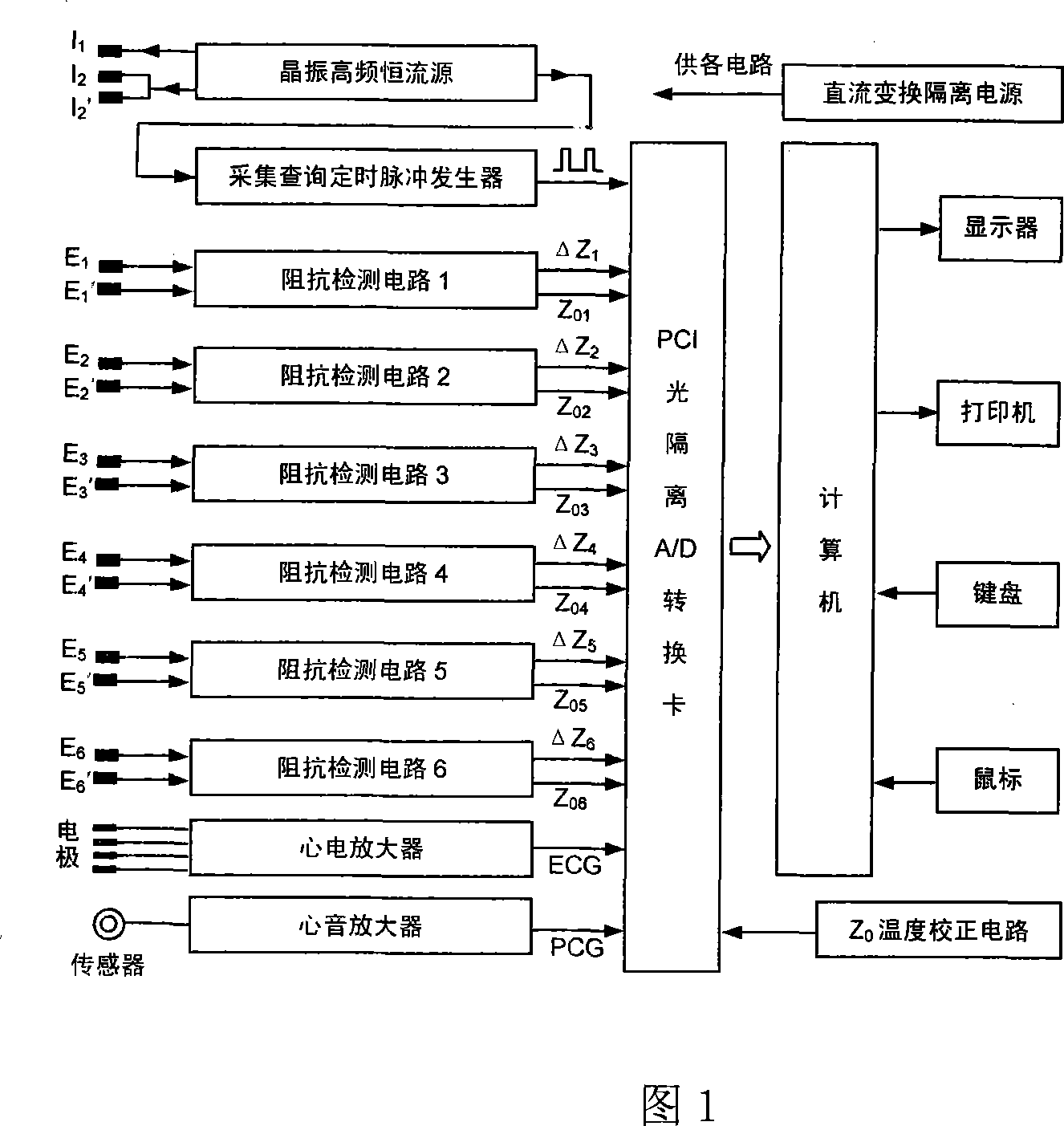

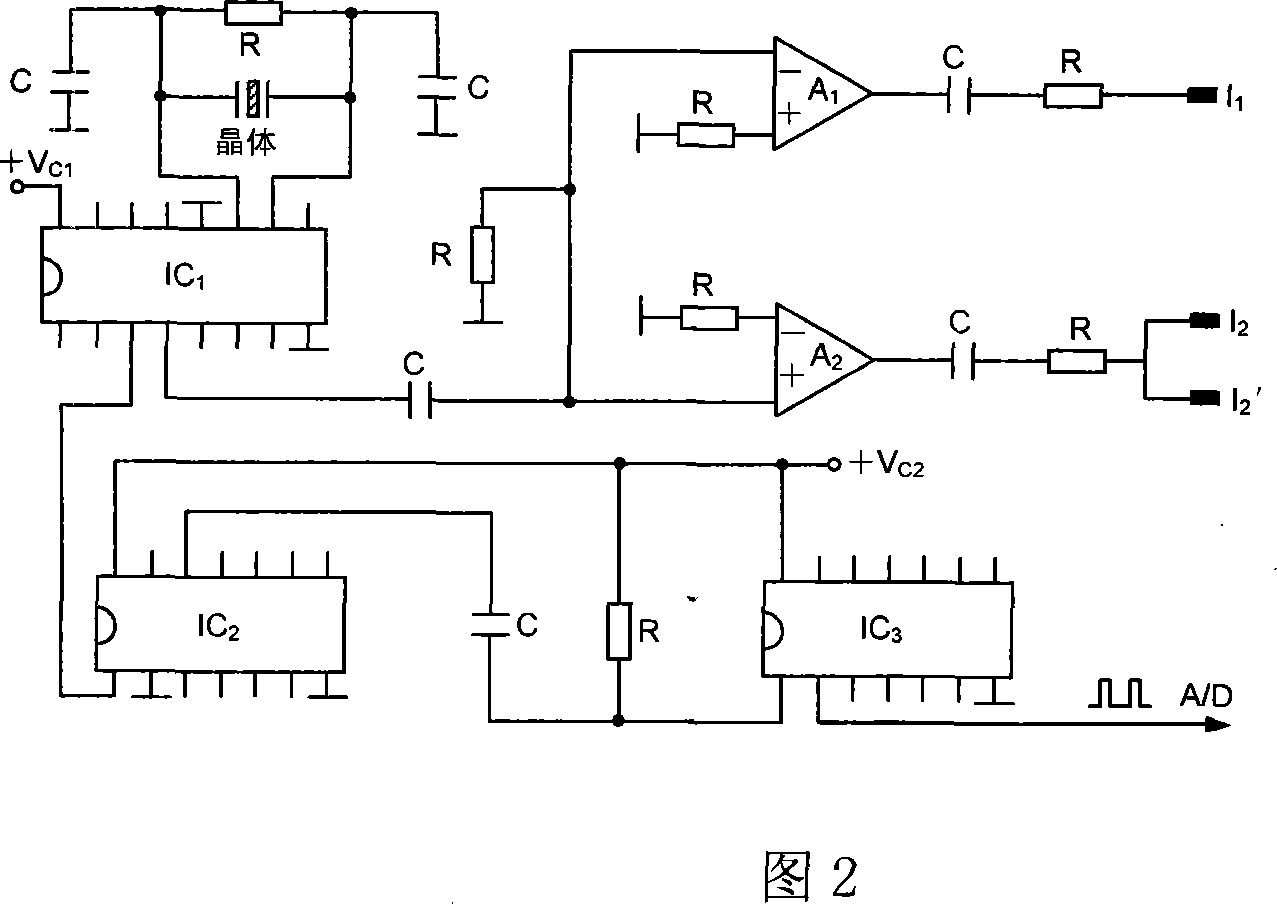

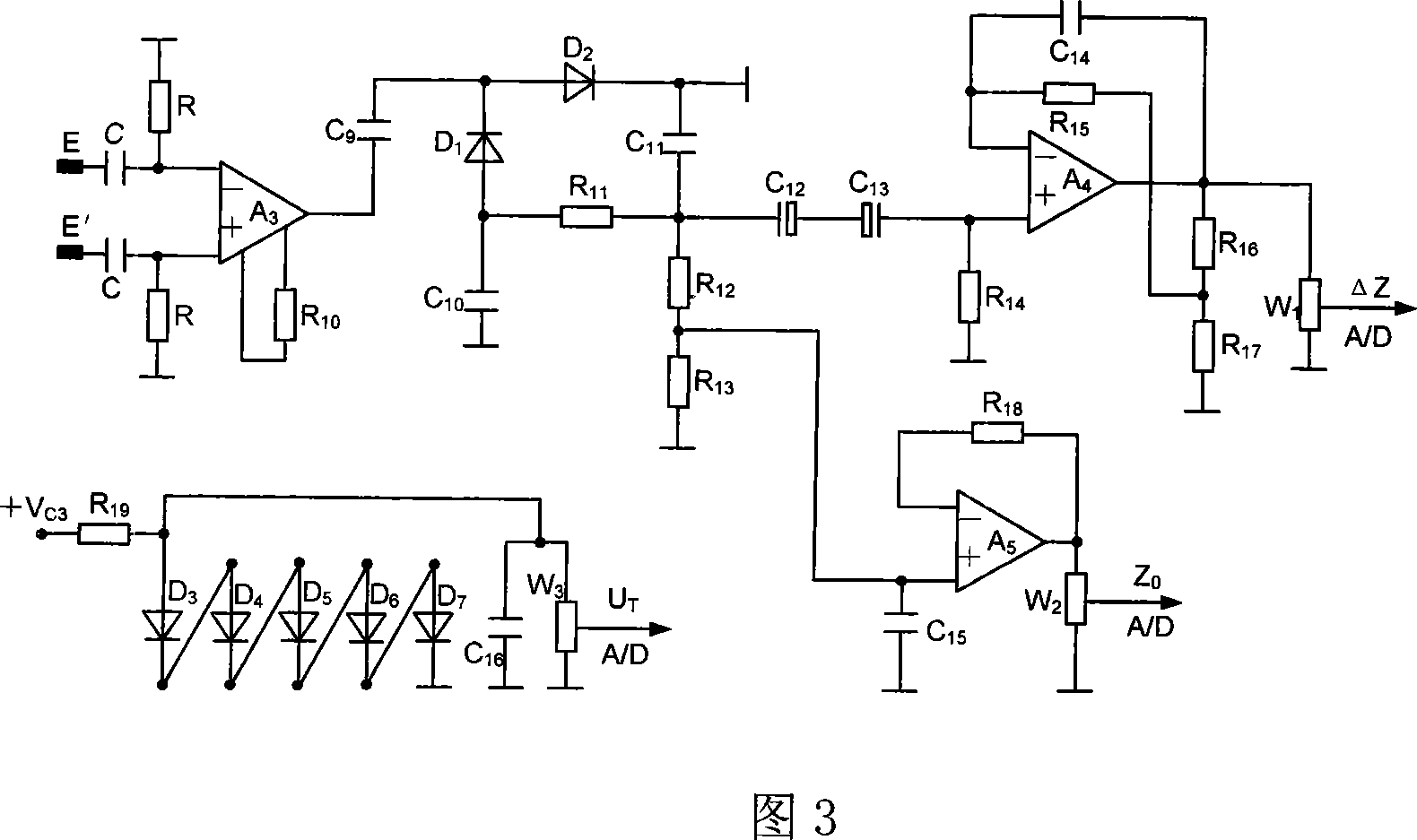

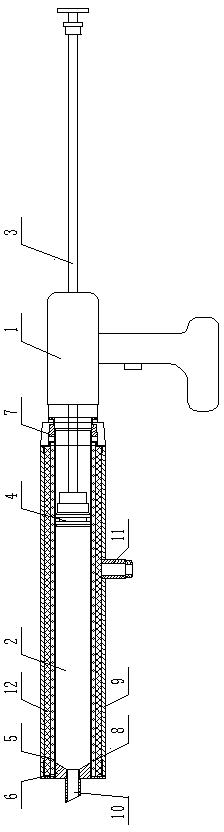

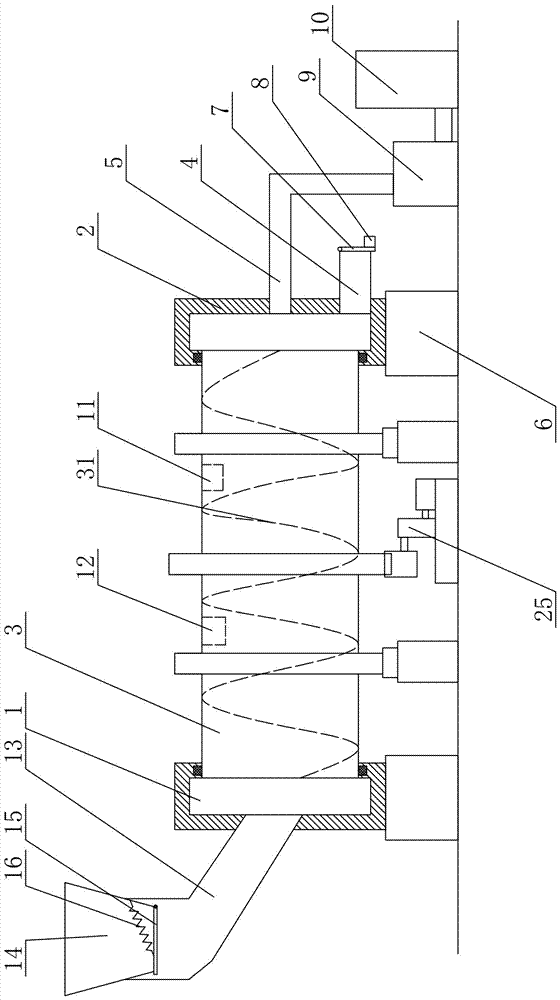

Digital reconstructing heart output instrument

InactiveCN101066207ASolve many problemsSensorsBlood flow measurementHeart soundsLeft ventricular Cardiac output

The impedance waveform reconstructing cardiac output instrument consists of a high frequency constant current source with crystal oscillator, a six-channel impedance detecting circuit, a Z0 temperature correcting circuit, a cardioelectric amplifier, a heart sound amplifier, a timing pulse generator, a A / D converting card, an isolating power source, a computer and corresponding measuring software. It can reconstruct impedance waveform, separate out different impedance components from the mixed impedance signal, draw corresponding waveform figures, measure, calculate, display and print ten cardiac function parameters automatically. The present invention is superior to available automatic cardiac function instrument.

Owner:况明星

Preparation method of composite liner

InactiveCN104911585AGuaranteed performanceReduce consumptionMetallic material coating processesManufacturing cost reductionAlloy

The invention relates to a preparation method of a composite liner, belonging to the field of composite liners. According to the preparation provided by the invention, metal or alloy powder is uniformly spread on the outer side of a liner by laser cladding while the material cladding is realized through a laser; or after the metal or alloy powder is uniformly spread on the outer side of the liner, the material cladding is realized through a laser so as to realize metallurgical bonding of the liner and the metal or alloy powder to obtain the composite liner. The problems of the existing composite liner preparation technology are perfectly solved. According to the preparation method provided by the invention, the production cost is reduced while the liner performance is guaranteed, and the thickness of the composite liner can be controlled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

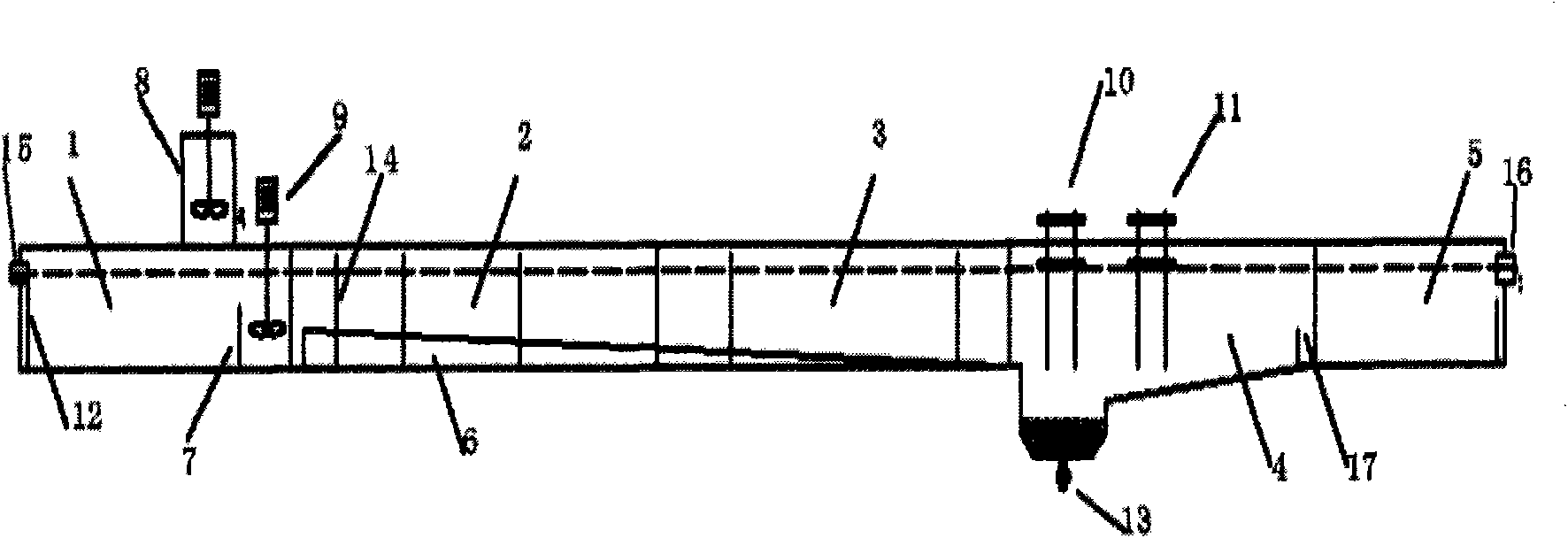

Method and device for repairing damaged conveying belt

The invention relates to a method and a device for repairing a damaged conveying belt, belongs to the technical field of conveying belt repairing, and aims to solve the technical problems by providing the method and the device for repairing the damaged conveying belt, simple in process, convenient and easy to operate, good in repairing effect and wear-resisting. The technical scheme includes putting proper meltable elastic members into a rubber barrel to be heated and melted into a meltable elastic member glue solution; polishing the surface of a conveying belt to be repaired; coating the metable elastic member glue solution onto the polished surface of the conveying belt to be repaired; cooling and condensing naturally to have repairing completed. The method for repairing the damaged conveying belt is simple, convenient and easy to operate, and mainly used for repairing the damaged conveying belt.

Owner:山西维力固科技股份有限公司 +2

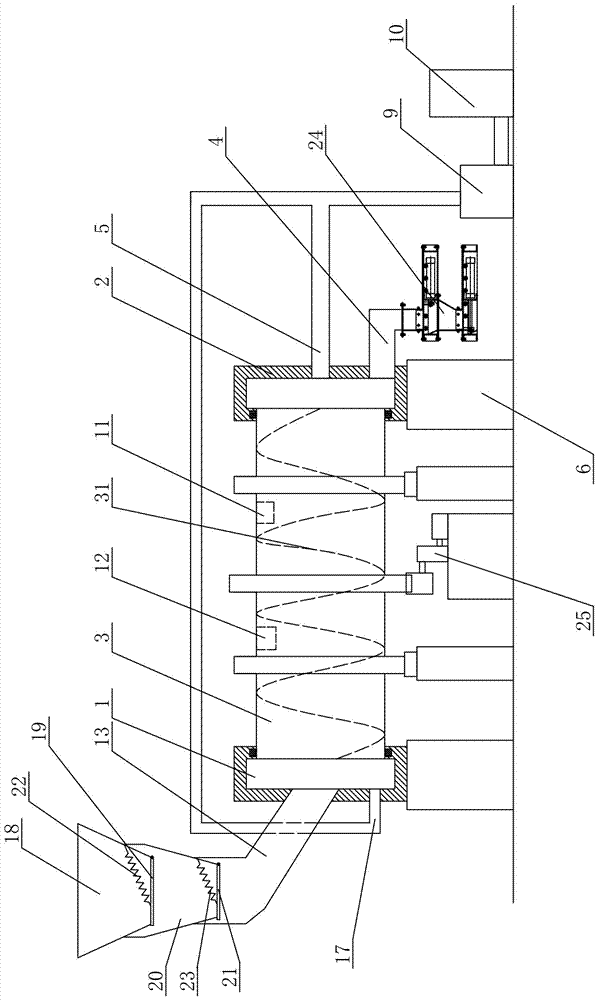

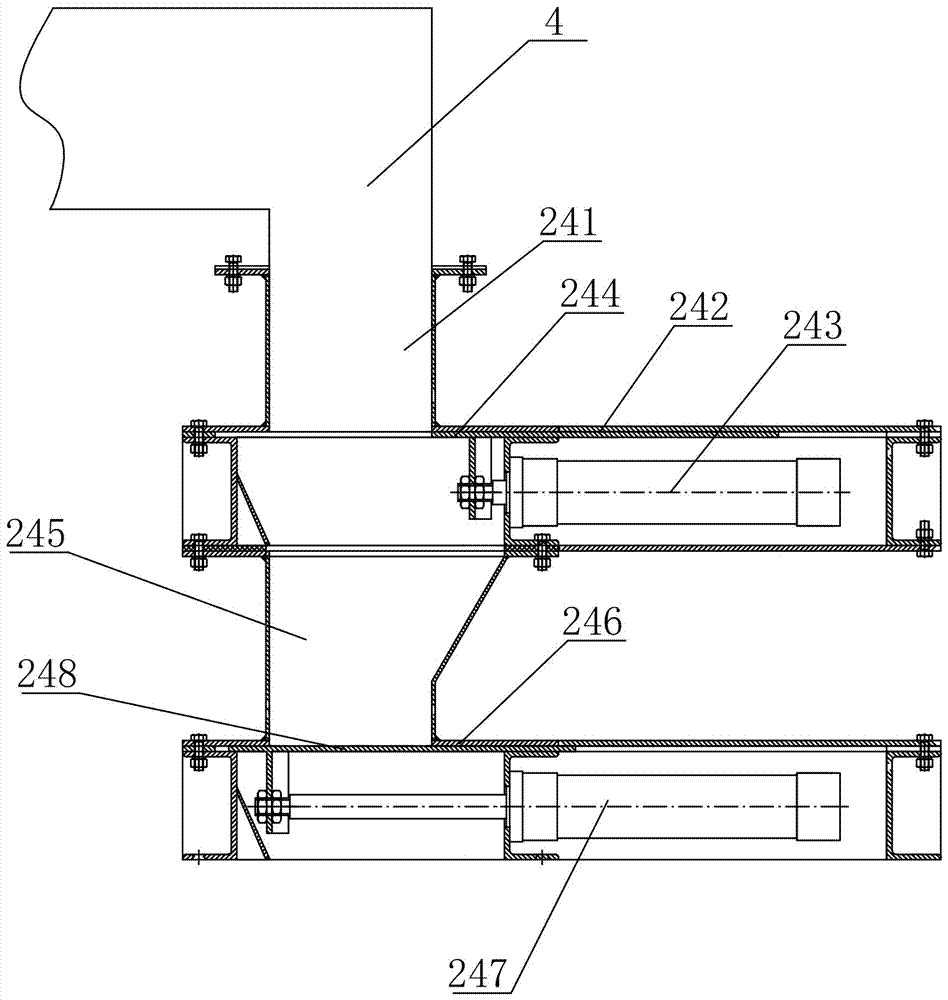

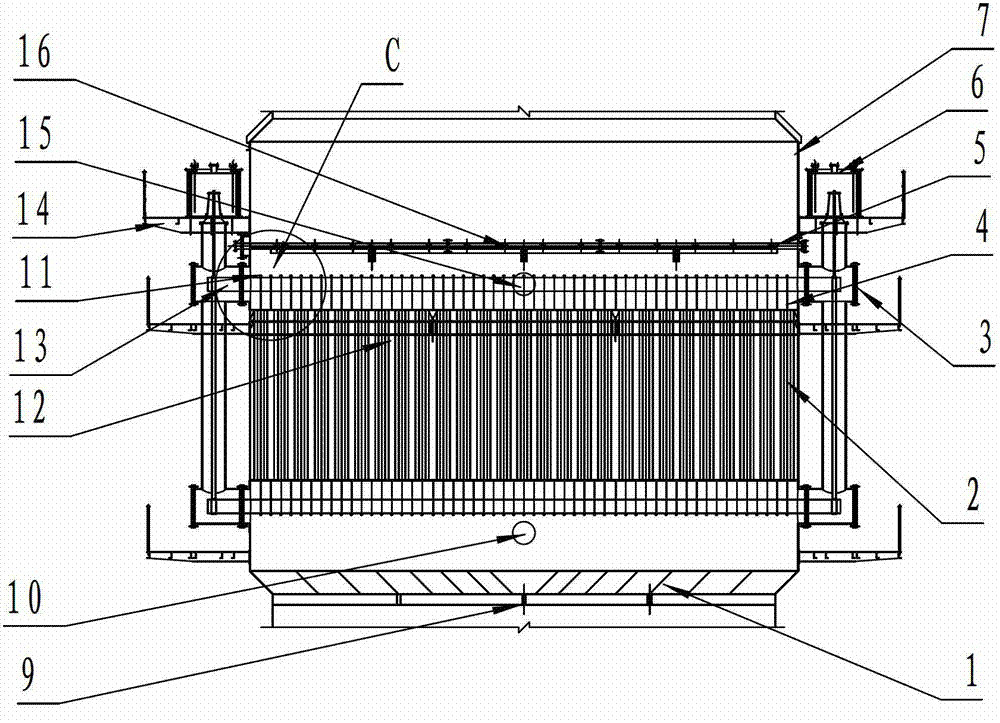

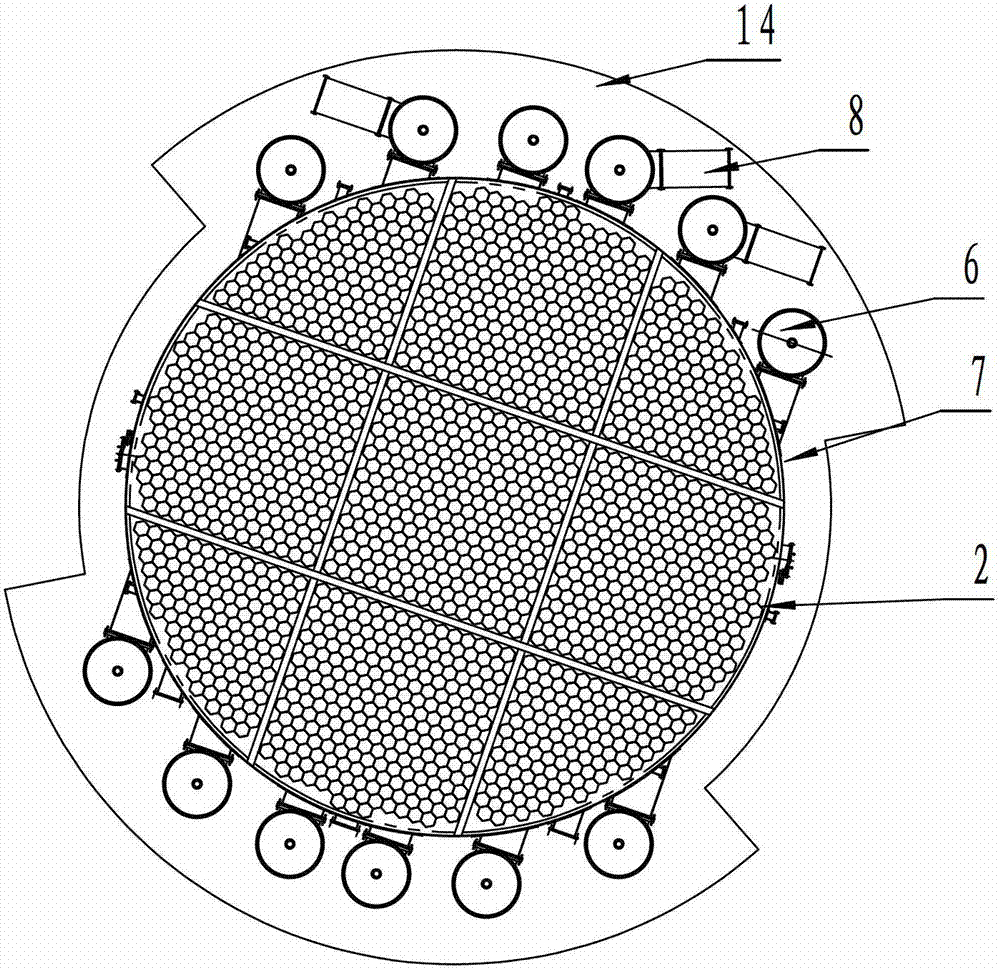

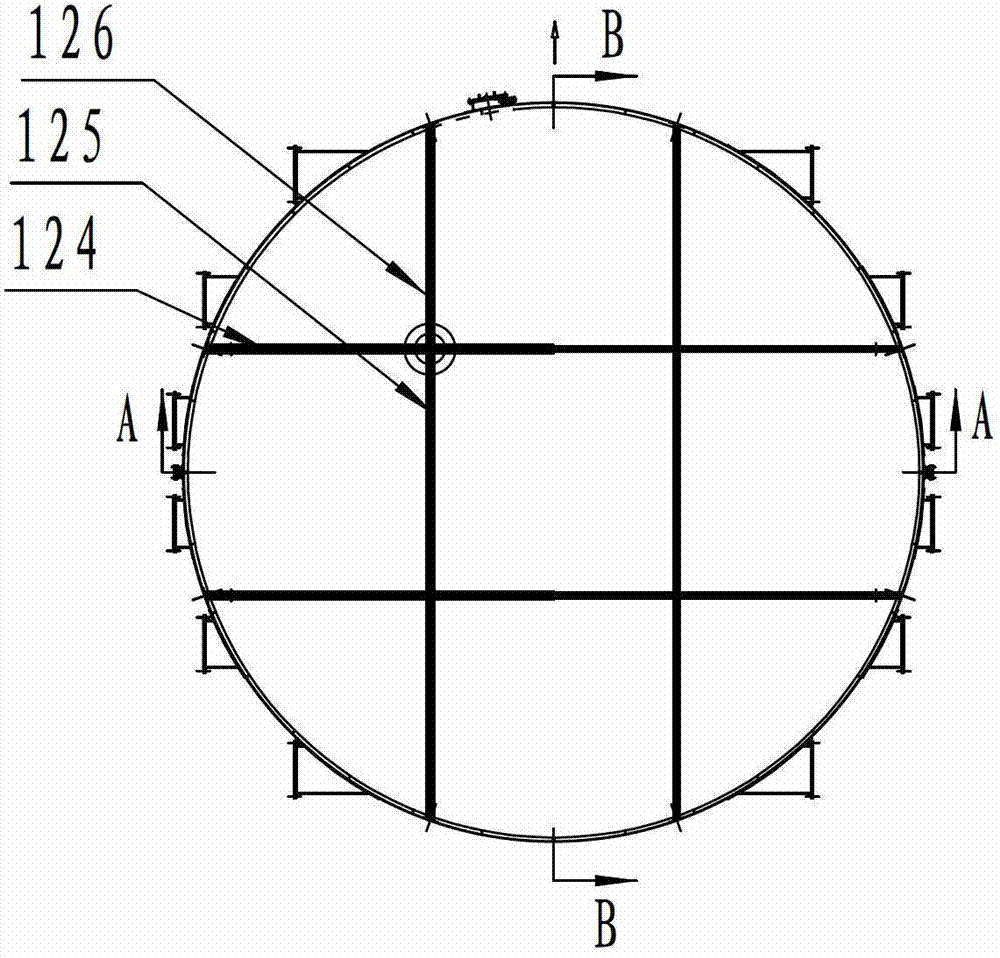

Industrial by-product gypsum reduction equipment

The invention relates to industrial by-product gypsum reduction equipment. The industrial by-product gypsum reduction equipment comprises a kiln head, a kiln tail, a roller, a feeding device, a discharging opening, a tail air-intake pipe, a power transmission device and a supporting device. Anhydrite gypsum and hemi-hydrate gypsum are conveyed into the sealed roller, meanwhile vapor is conveyed into the sealed roller, under certain pressure condition, the anhydrite gypsum, the hemi-hydrate gypsum and the vapor are mixed and uniformly stirred in the sealed roller, and the anhydrite gypsum is reduced into hemi-hydrate gypsum by using water of the hemi-hydrate gypsum and the vapor. Therefore, the problem of a plurality of anhydrite gypsum products of the current gypsum drying machine is effectively solved, the rate of transferring industrial by-product gypsum into hemi-hydrate gypsum is effectively improved, and the production efficiency of hemi-hydrate gypsum by the gypsum drying machine is improved.

Owner:ZHENGZHOU SUNDY BUILDING TECH

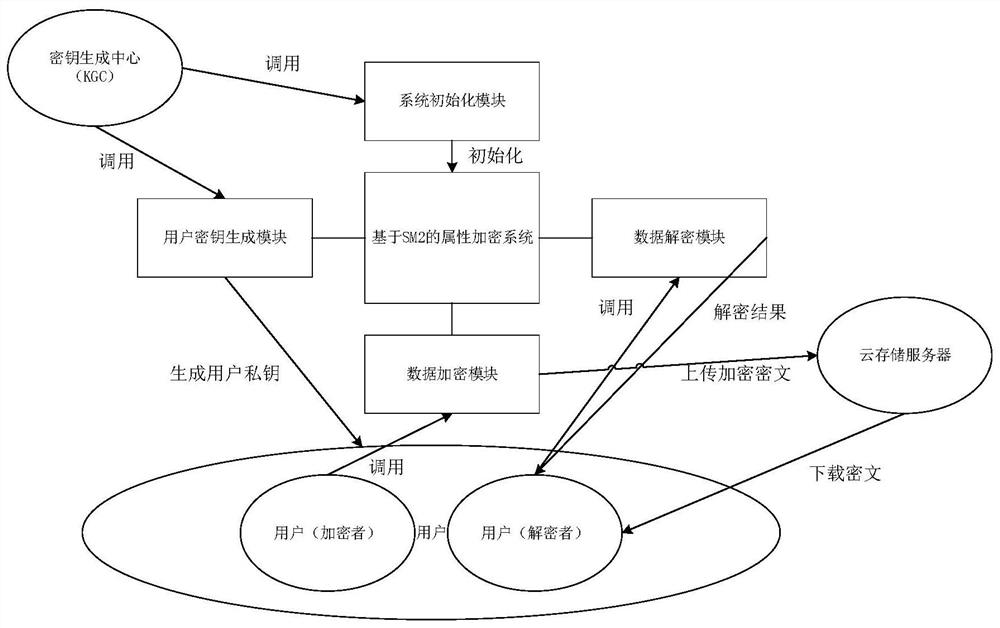

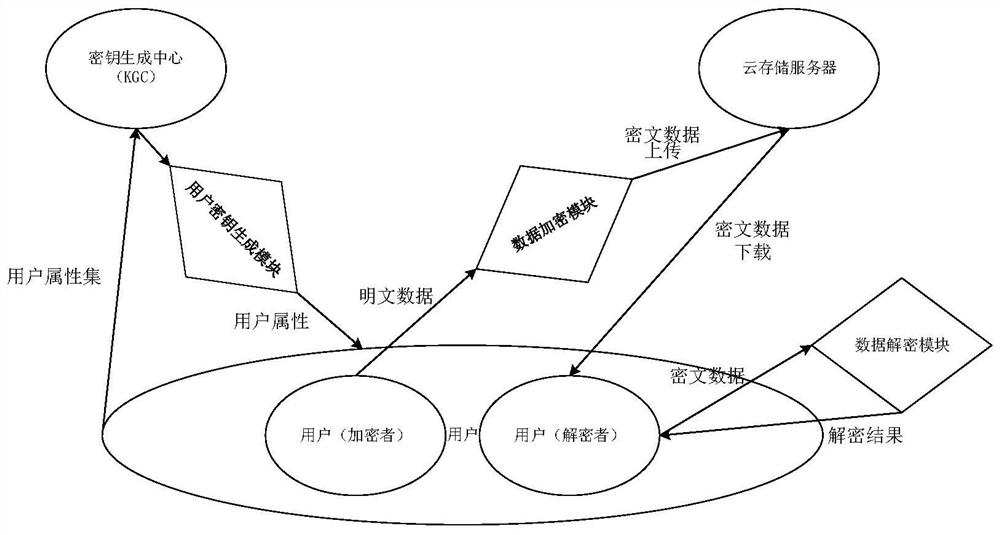

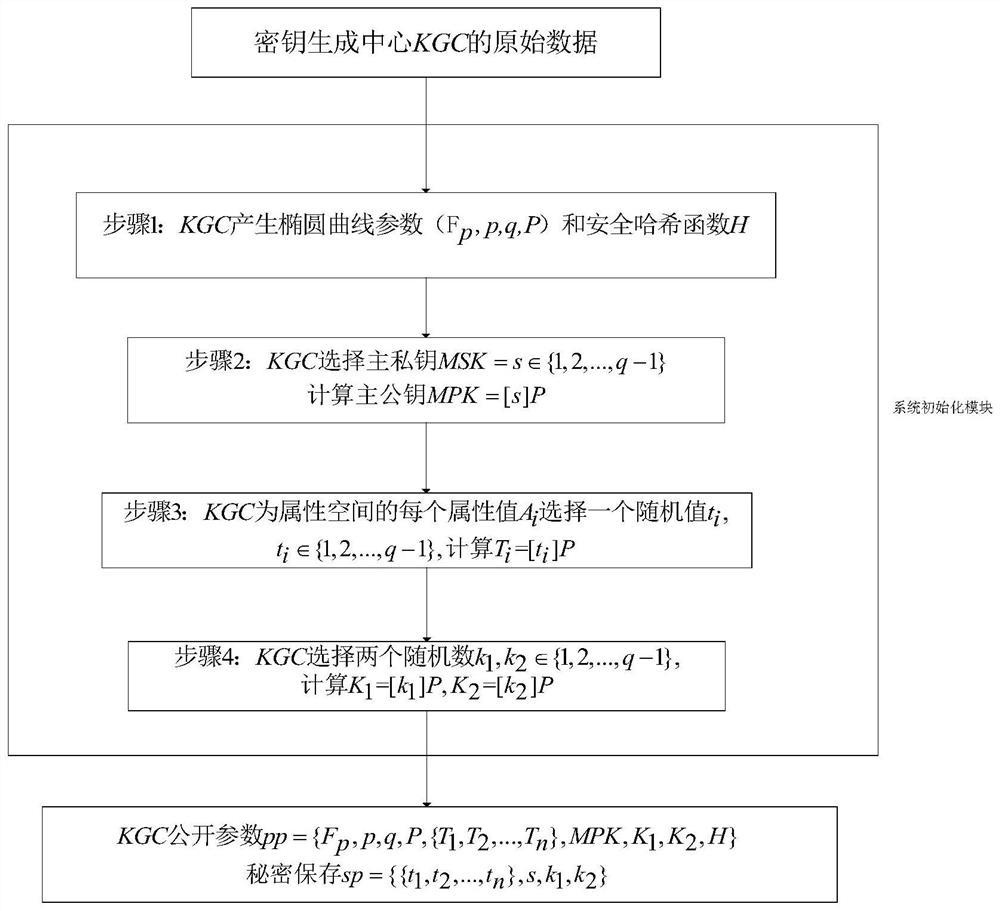

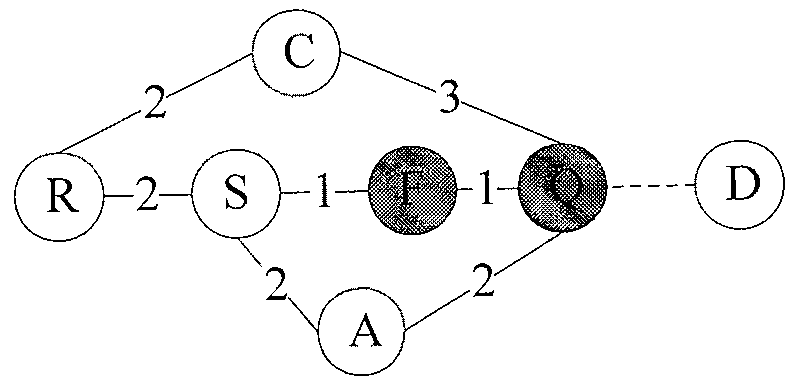

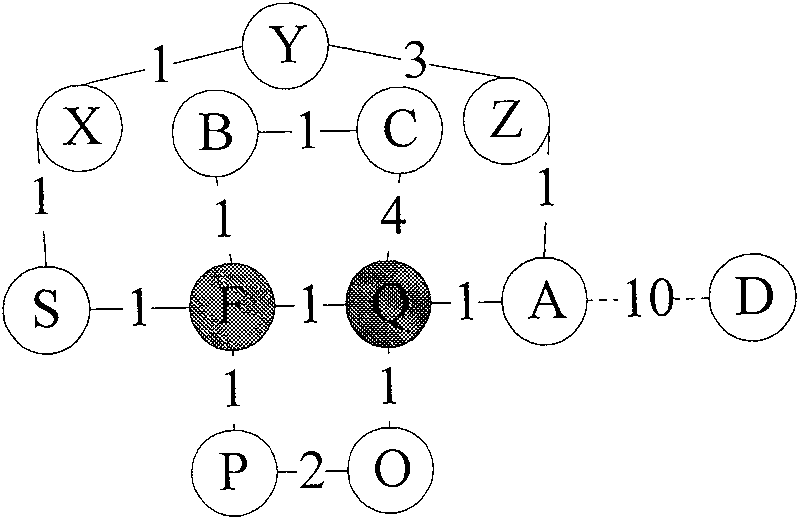

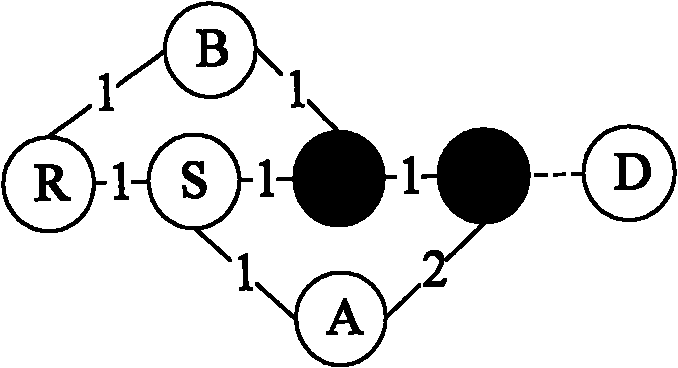

Cloud storage data encryption method and system and storage medium

ActiveCN111740988ASolve many problemsHigh efficiency requirementsKey distribution for secure communicationCiphertextEngineering

The invention discloses a cloud storage data encryption method and system and a storage medium. An encryption user initializes a generated public parameter according to a user access control tree constructed based on a preset user access control strategy and a trusted key generation center, and encrypts the data to be encrypted by using an attribute encryption mode to obtain an encrypted ciphertext, so that a decryption user conforming to the user access control tree decrypts the encrypted ciphertext according to a user private key generated by the trusted key generation center for the decryption user. According to the method, the use of a bilinear pair in an attribute-based encryption system (ABE) is canceled, the efficiency of an attribute-based encryption algorithm can be improved to agreater extent, and the high-efficiency requirement in a cloud storage environment is met.

Owner:WUHAN UNIV +7

IP fast rerouting method for improving inter-domain routing OSPF algorithm

ActiveCN101695053AEnsure correct forwardingReduce the number of addressingData switching networksRouting tableNetwork packet

An IP fast rerouting method for improving inter-domain routing OSPF algorithm includes following steps: (a) utilizing an OSPF algorithm to calculate normal routing and guide a normal routing table, (b) utilizing an ED-NotVia algorithm to find an NotVia address and generating an NotVia transfer table according to the NotVia address, (c) packing a raw packet via the NotVia address by a failure upstream node when fault is caused and does not complete convergence, and redirecting to a next hop of a fault point, (d), matching with a protection source to realize transfer of an NotVia packet when another router receives the NotVia packet, and (e), unpacking the NotVia packet when the NotVia packet achieves the next hop of the fault point, recovering the NotVia packet into a raw packet, and then transferring the raw packet into an original destination address through normal routing. ED-NotVia proposes to combine 'removing useless NotVia addresses' with 'unpacking in advance' for the first time. The method has the advantages of simple implementation, low cost, optimum protection path without unpacking bottle-neck and the like, and is adaptable to improving properties of inter-domain routing of a large-scale autonomous system in failure.

Owner:TSINGHUA UNIV

Process for smelting common silicomanganese alloy by smelting electric furnace to quickly convert high-silicon silicon-manganese alloy

InactiveCN112430755AImprovement of quality delivery rateSolve many problemsSmelting processManganese

The invention discloses a process for smelting common silicomanganese alloy by a smelting electric furnace to quickly convert high-silicon silicomanganese alloy, which belongs to the technical field of ferroalloy production, and particularly relates to a process for smelting different varieties of silicomanganese alloys to solve the problems of a long transition period and more transition productsof the common silicomanganese smelting high-silicon silicomanganese alloy. The process comprises the following steps of: (1) proportioning; (2) preparing before transition smelting; (3) adjusting thecoke type; (4) ensuring that the high-silicon silicon-manganese material can enter the smelting electric furnace at the same time one day before transition smelting; (5) making the basicity of the slag in the transition period of transition smelting to be 1.1 times of the basicity in the conventional transition smelting process; (6) enabling tapping time to be not shorter than 40 min; and (7) dephosphorizing outside the smelting electric furnace, adding lime powder or fluorite powder when the liquid level of slag iron in the ladle reaches 1 / 3, and stopping adding until the P component in thehigh-silicon silicomanganese alloy reaches the standard. The transition period of transition smelting is shortened to be within one day, the alloy quality cashing rate is increased by 20% or above, the recovery rate is increased by about 2%, transition products are few, and various consumptions are greatly reduced.

Owner:嘉峪关宏电铁合金有限责任公司

Wet-type sintering desulfurization flue gas deep purification device

ActiveCN102962135AAvoid Equipment CorrosionReduce corrosion rateElectrode carrying meansExternal electric electrostatic seperatorHeavy metalsFlue gas

Belonging to flue gas purification devices, the invention especially discloses a wet-type sintering desulfurization flue gas deep purification device, i.e. a device using the wet-type sintering desulfurization flue gas purification technology. The purification device includes a shell that is installed at the upper part of a desulfurization tower and is a part of the desulfurization tower body. The device is characterized in that: the inside of the shell is equipped with vertically mounted precipitation anode tube bundles and corona electrodes. The precipitating electrode tube bundles are supported by tube bundles inside the tower and fixed in the shell. The upper and lower ends of the corona electrodes are respectively connected to corona electrode small beams at the upper side and lower side of a corona electrode large beam, two ends of which are hung on a hanging rod in a side tube. A flushing instrument and an upper gas chamber are disposed over the precipitation electrode, the lower part of the shell is equipped with a gas distribution instrument, and a lower gas chamber is disposed between the precipitation electrode and the gas distribution instrument. A tower body platform outside the shell is provided with insulation boxes and transformers. The device can effectively remove micro-fine dust, acidic fog drops, nitrogen oxides, heavy metals, sulfates and other harmful substances from flue gas, and the removal rate can reach over 90%.

Owner:SHANDONG GUOSHUN CONSTR GRP

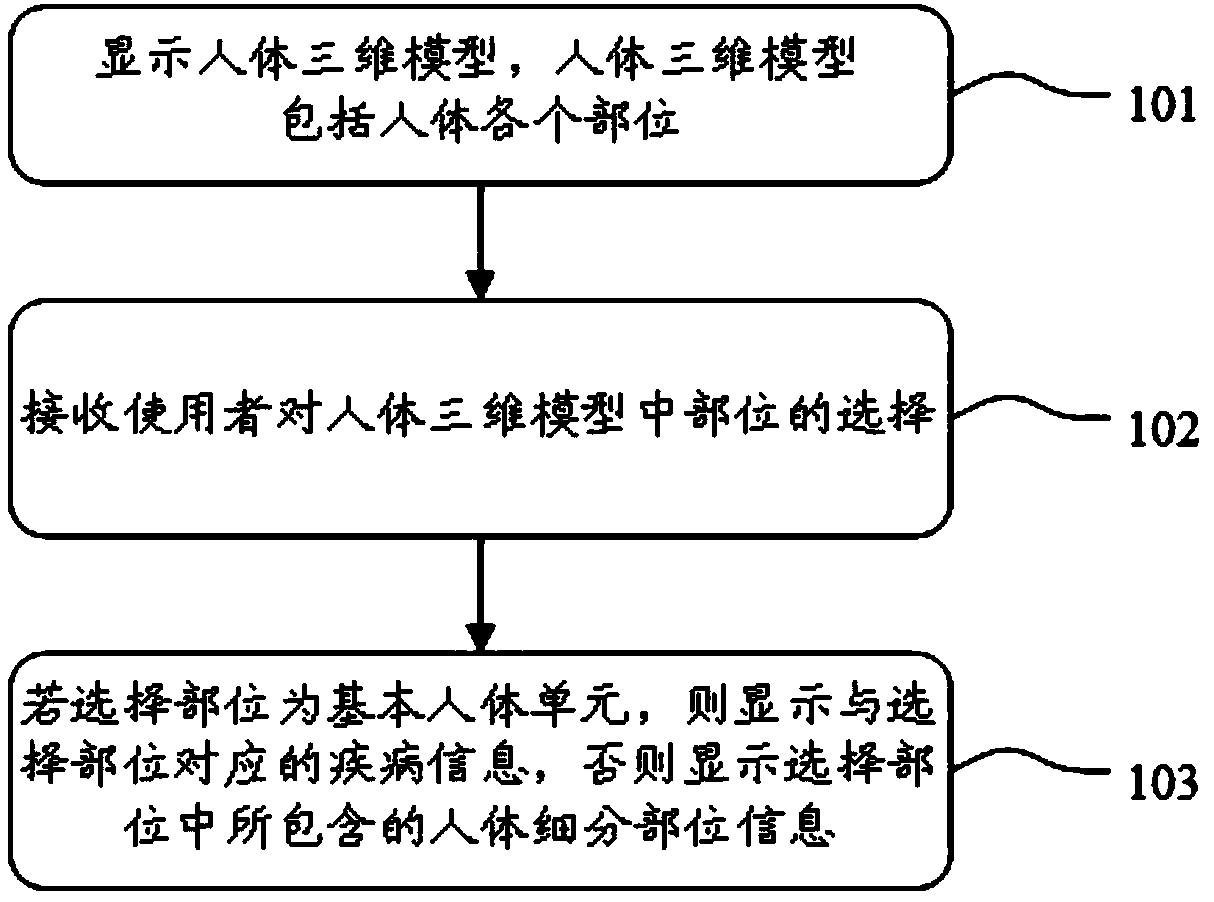

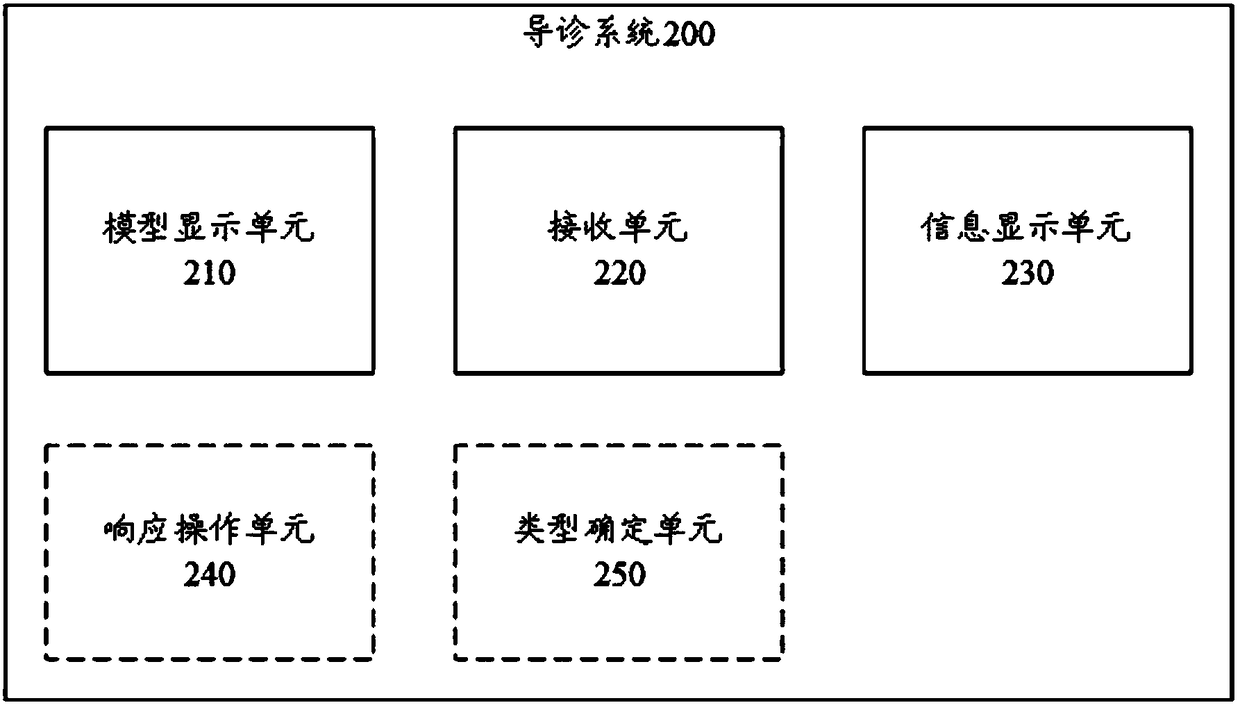

Hospital guidance method and hospital guidance system

InactiveCN108074637ASolve non-intuitive problemsSolve many problemsMedical imagesHealthcare resources and facilitiesDiseaseGuidance system

The application discloses a hospital guidance method and a hospital guidance system. The hospital guidance method includes the following steps: displaying a human body three-dimensional model, the human body three-dimensional model including all parts of a human body; receiving selection of the parts in the human body three-dimensional model by a user; and if the selected parts are basic human body units, then displaying disease information corresponding to the selected parts, otherwise, displaying human body subdivided part information included in the selected parts. According to the technical solution of the embodiment, the human body parts are selected through the human body three-dimensional model, thereby solving the problem that human body parts displayed in a human body planar graphare not visual and direct enough.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Low-foam screen washing liquid for silk screen printing

InactiveCN103215155AEasy to cleanSolve many problemsSurface-active non-soap compounds and soap mixture detergentsActive agentDefoaming Agents

The invention relates to a low-foam screen washing liquid for silk screen printing, and belongs to the technical field of the silk screen printing. The low-foam screen washing liquid comprises the following raw materials in parts by weight: 20-40 parts of ethylene glycol monobutyl ether, 3-10 parts of potassium hydroxide, 5-15 parts of dimethyl siloxane, 2-6 parts of glycerin monostearate, 3-12 parts of light calcium carbonate, 5-10 parts of emulsifying agent, 2-9 parts of dispersing agent, and 2-5 parts of surface active agent. The low-foam screen washing liquid for the silk screen printing solves the problem that foams of screen washing liquid in the prior art are more. The low-foam screen washing liquid is prepared by reasonably adopting a defoaming agent for matching and combined action, so that a cleaning effect of the screen washing liquid is better, and pollution is reduced.

Owner:李莉

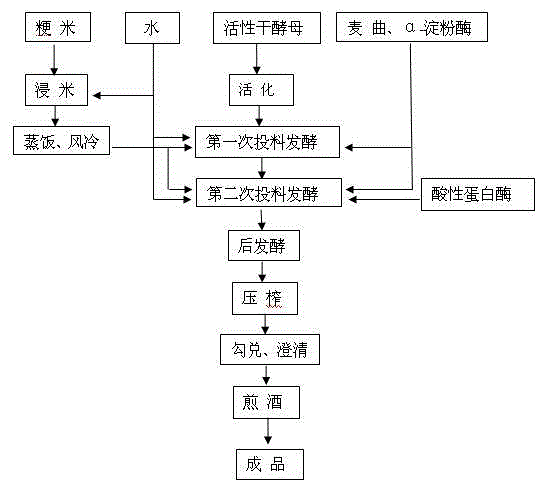

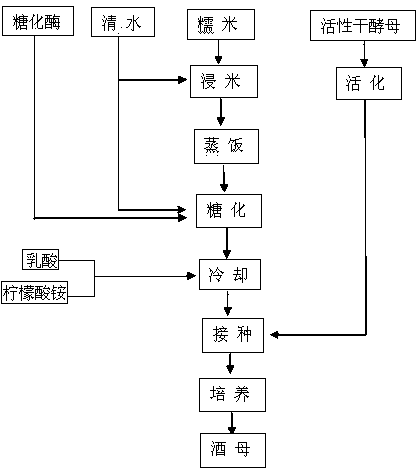

Manufacturing technology of japonica rice wine

InactiveCN104694329APrevent agingVigorous fermentation capacityAlcoholic beverage preparationBiotechnologyManufacturing technology

The invention relates to a manufacturing technology of a japonica rice wine. The manufacturing technology of the japonica rice wine comprises the following steps: (1) soaking rice; (2) cooking rice, and cooling the rice; (3) dosing materials for the first time for fermentation; (4) dosing materials for the second time for fermentation; (5) implementing post-fermentation; (6) squeezing, boiling wine, and filling the wine in jars. In the manufacturing technology of the japonica rice wine, the rancidity of the fermented mash is prevented effectively by utilizing an active dry yeast and a twice-dosing method. A quick brewing yeast is replaced by the active dry yeast for the fermentation, thereby avoiding bacteria contaminations caused by the brewing yeast. The twice-dosing method is employed; all the yeasts are added during the first dosing, thus the inoculum size is increased by comparing to a once-dosing method. The inoculum size is up to 1.4-1.6%o. Accordingly, the yeasts are superior in numbers. The yeasts are provided with new nutrition during the second dosing, thereby expanding the cultivation effect, generating more new yeast cells, preventing the yeasts from aging, and keeping a strong fermenting ability of the yeasts. Accordingly, the growth of infectious microbes can be inhibited effectively.

Owner:绍兴国家黄酒工程技术研究中心有限公司

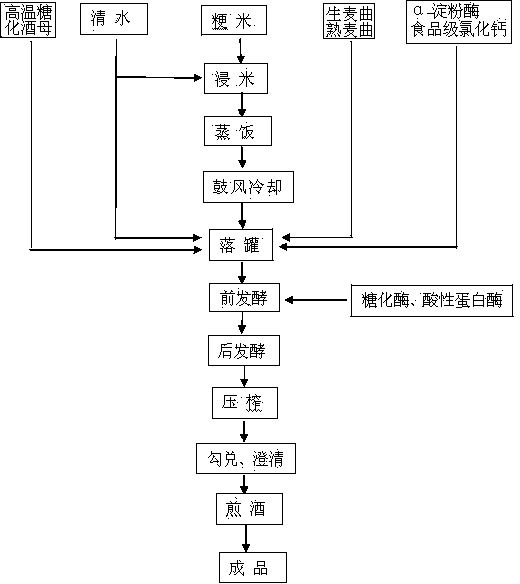

Production process of polished round-grained rice red wine fermented in great tank

ActiveCN104293590ASolve the mushy problemHigh activityMicroorganism based processesAlcoholic beverage preparationBiotechnologyChaptalization

The invention relates to a production process of polished round-grained rice red wine fermented in a great tank, belonging to the technical field of yellow rice wine brewing. The production process comprises the following steps: soaking rice; steaming rice and cooling; dropping the rice into a tank; pre-fermenting, namely starting harrowing for the first time 8-10 hours after dropping the rice into the tank, adding 100000 U saccharifying enzyme and 50000U acid protease in a certain proportion while harrowing for the first time, then starting harrowing once every two hours, controlling the highest product temperature to be no more than 33 DEG C, introducing chilled water to cool fermenting mash; after the primary fermentation is ended, gradually lowering the product temperature to 15-17 DEG C, feeding the product into a post-fermenting tank to ferment after fermenting for 4 days in the pre-fermenting tank; performing post-fermenting; squeezing, carrying out sterilization and filling the wine into jars. According to the production process disclosed by the invention, the rice is soaked for a short time, various enzyme preparations and activators are added, and high-temperature saccharifying yeast wine is used for fermenting, so that the problems that the fermented mash is pasted and has many bubbles.

Owner:绍兴国家黄酒工程技术研究中心有限公司

Carbonizing technology for waste crop straw resources

InactiveCN105602590AIncrease the calorific value of combustionHigh strengthBiofuelsSpecial form destructive distillationCombustionAdditive ingredient

The invention relates to the field of straw carbonizing, in particular to a carbonizing technology for waste crop straw resources. The carbonizing technology includes the following steps that 1, the waste straw resources are collected and smashed; 2, a binding agent is added into smashed straw powder and stirred; 3, after stirring is completed, the powder material is heated and dehydrated; 4, water content analysis is conducted on the dehydrated material in the step 3; 5, after the water content meets the requirement, the temperature continues to be raised, and the material is carbonized; 6, the carbonized material and ingredients are mixed, and the mixture is fed into a rod manufacturing and forming extruder to be extruded and formed; 7, the carbon rods are naturally cooled to normal temperature. The charcoal obtained by adopting the carbonizing technology has the advantages of being large in combustion heat value, high in strength, resistant to ablation and the like.

Owner:ANHUI DADI ENERGY SAVING SCI & TECH

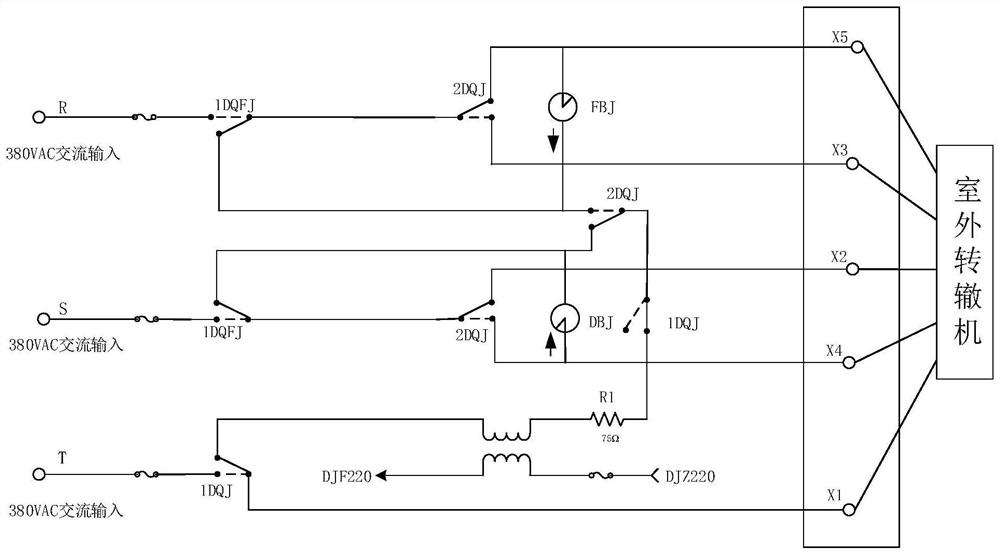

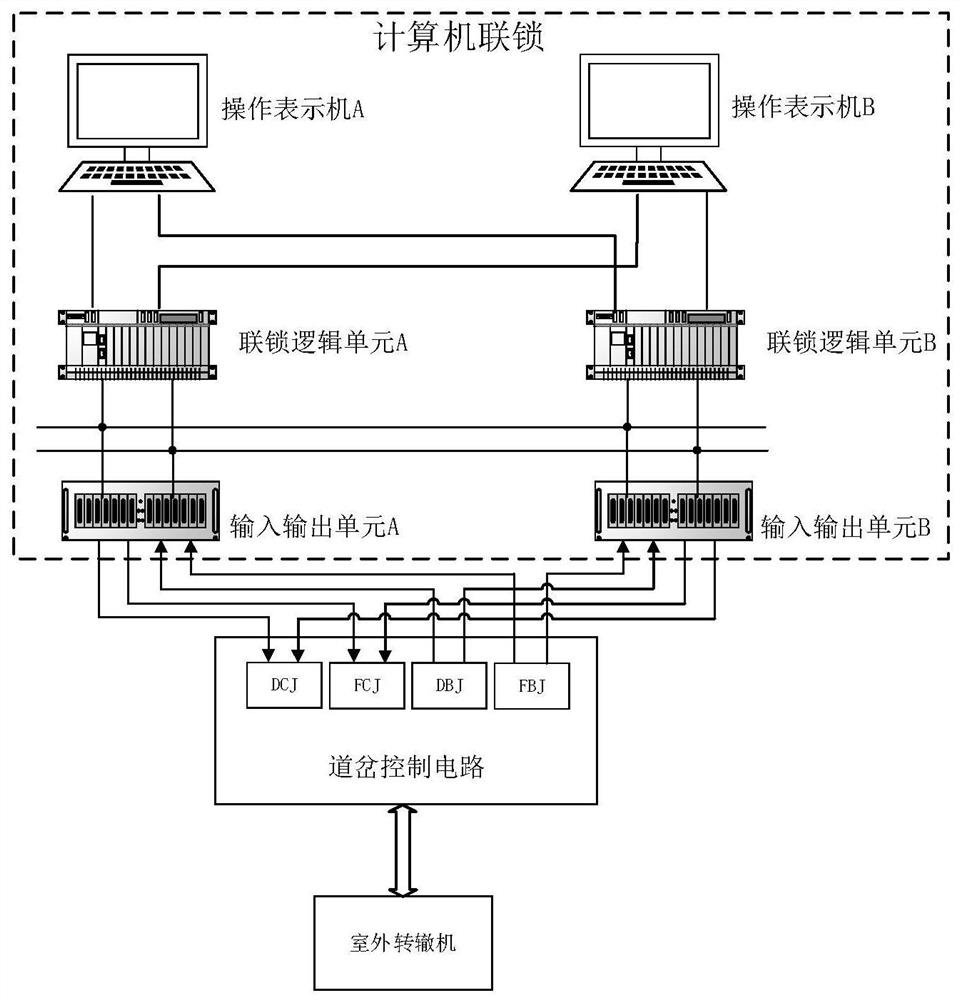

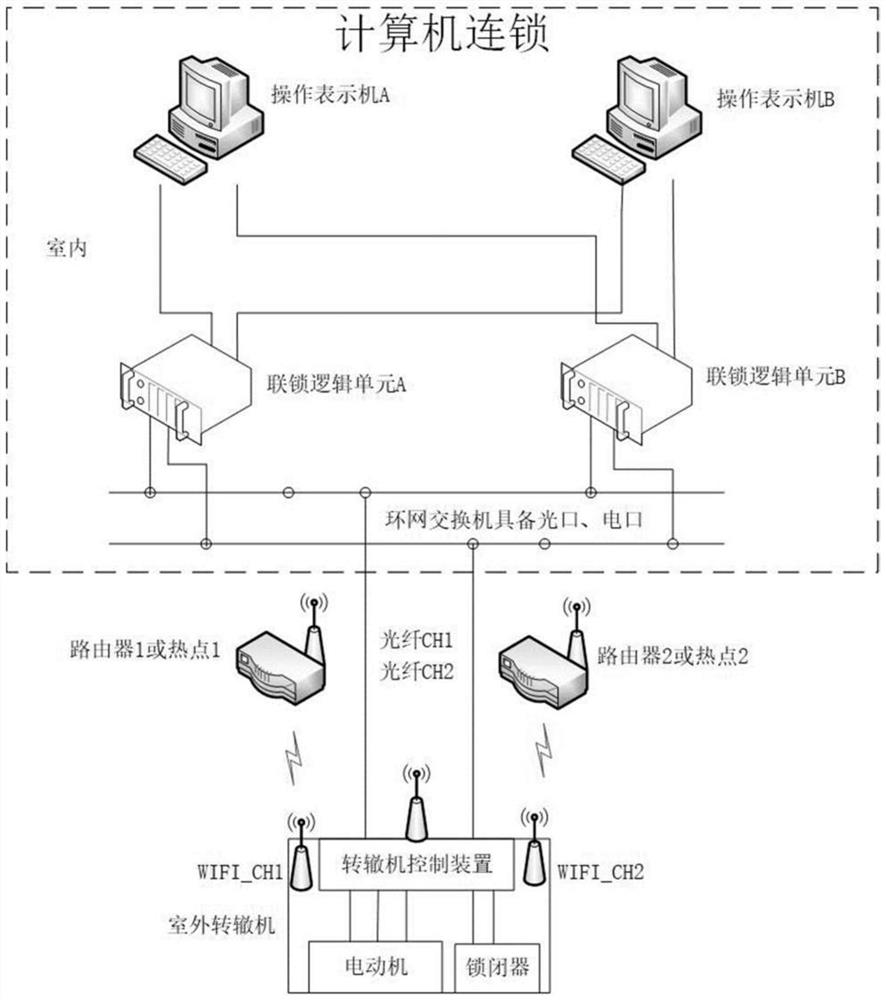

Point switch control device

ActiveCN112606869ASolve many problemsSimple controlPoint-signal interlocking arrangmentsElectric devices for scotch-blocksPower switchingControl engineering

The embodiment of the invention discloses a point switch control device which is arranged in a point switch and comprises a power module; a strong current control module which comprises a turnout control loop, a power switch control circuit, a first switch control circuit and a second switch control circuit, and the turnout control loop is connected with a motor of the point switch through three control circuits U, V and W and comprises three power switches, three first switches and four second switches; a power supply control circuit which is used for controlling the three power supply switches to be switched on or off; a first switch control circuit which is used for controlling the three first switches to be switched on or off; a second switch control circuit which is used for controlling one of the four second switches to be closed; and a trackside control module which is used for receiving the operation instruction sent by the computer interlocking system, controlling the load switch machine through the turnout control loop, and reporting the state of the switch machine and the state information of the turnout control loop to the computer interlocking system.

Owner:BEIJING HOLLYSYS

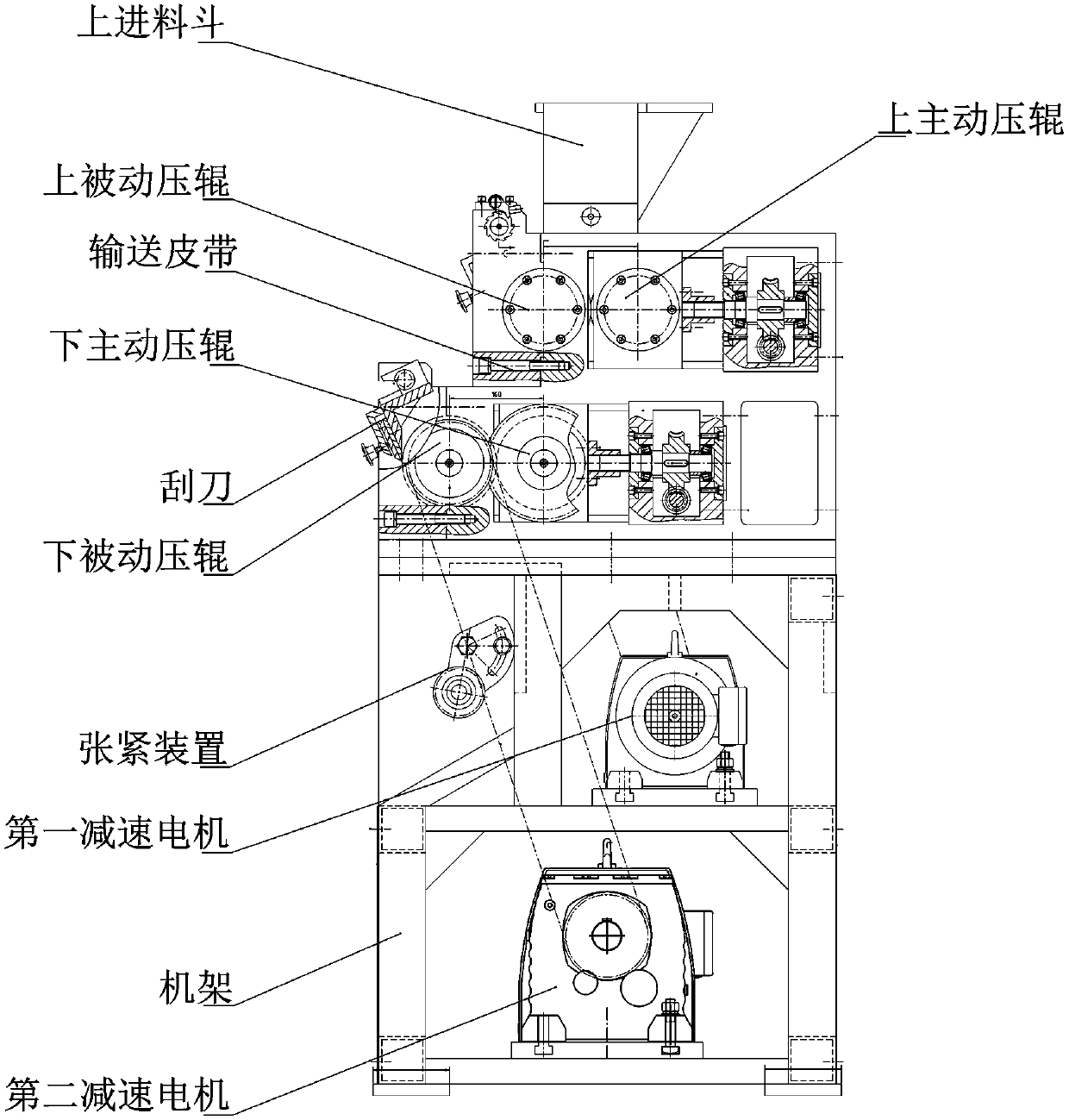

Rolling method tobacco sheet production process

ActiveCN110897190ASolving Quantitative ProblemsResolve Tensile StrengthTobacco preparationNicotiana tabacumMechanical engineering

A rolling method tobacco sheet production process comprises the following steps that 1, in the raw material pretreatment stage, coarse smashing and drying treatment is conducted on large tobacco leaves and tobacco stems, and preparation is made for later-period fine smashing; 2, a raw material crushing stage; 3, proportioning, homogenizing and mixing; 4, a multi-stage rolling section: the sheets are thinned step by step through multi-stage rolling, so that the quantification and the tensile strength of the sheets meet the index requirements; 5, a slice low-temperature drying section, wherein the slices are heated through steam and dried at a low temperature; and 6, molding treatment: rolling or slicing and shredding treatment is performed on the molded sheet. The rolling method tobacco sheet production process aims to solve the technical problems that in the traditional rolling process, the sheet quantification cannot reach the index, and the tensile strength is low, and the sheet is easy to volatilize when not combusted at low temperature.

Owner:中国船舶工业总公司七一五研究所宜昌分部

Comprehensive environment-friendly carbonizing technology by using waste crop straw resources

InactiveCN103952203AThe process steps are simpleEasy to operateBiofuelsSolid fuelsMixed materialsHeating temperature

The invention relates to a comprehensive environment-friendly carbonizing technology by using waste crop straw resources. The technology comprises the steps of (1) collecting waste straw resources in agriculture production to be taken as a main material, and smashing the straw into 80-100 mesh; (2) adding a binder into the powder of the smashed straw, or adding some saw dust, bamboo powder and the like simultaneously, then putting into a stirrer to stir; (3) heating the stirrer while stirring, so as to better mix the powders, wherein the heating temperature is controlled at 50-60DEG C, and the heating time is 30-60minutes; (4) analyzing the water content of the mixed materials, and controlling the water content of the material at 15-20%; (5) sending the straw powder with qualified water content into a rod molding extruder for extrusion forming, wherein the heating temperature in the rod molding extruder is guaranteed to be not less than 200DEG C so as to obtain carbon rods of the specific size; and (6) naturally cooling down the obtained carbon rods to room temperature.

Owner:JIESHOU LIYU ENERGY

Sisal hemp fiber and polypropylene fiber mixture interior ornament material of vehicle

The invention provides a sisal hemp fiber and polypropylene fiber mixture interior ornament material of a vehicle. First, Sisal hemp is cut into sisal hemp fiber with 5 to 7 cm; second, the sisal hemp fiber is put into a stainless steel container and is mixed with sodium hydroxide solution to soak and stir for 1 hour; third, the sisal hemp fiber is cleaned with clear water for removing sodium hydroxide and then the sisal hemp fiber is put into hot water with 30 to 60 temperature so as to removing residual sodium hydroxide with constant temperature bath; fourth, the sisal hemp fiber is dried by a dryer; fifth, mixed liquid of methyl methacrylate of 0.5 to 1 percent blended with clear water every 100kg and nitric acid ene ammonium of 0.5 to 0.1 percent is used to soak for reaction; sixth, the sisal hemp fiber is dried after being cleaned with clear water; seventh, the sisal hemp fiber and polypropylene fiber are put on a wool comber for opening mixture; the sisal hemp fiber is within the range of 60 to 70 percent and the polypropylene fiber is within the range of 30 to 40 percent; eighth, the sisal hemp fiber and the polypropylene fiber mixture is carded to be a net by a carding machine; ninth, the sisal hemp fiber and the polypropylene fiber mixture is spread to be mixture material with 1500 g per square meter by a parallel net-spread machine; and tenth, the mixture material is molded into an interior ornament type part by a mould-pressing molding machine.

Owner:湖北南泽汽车复合材料有限公司

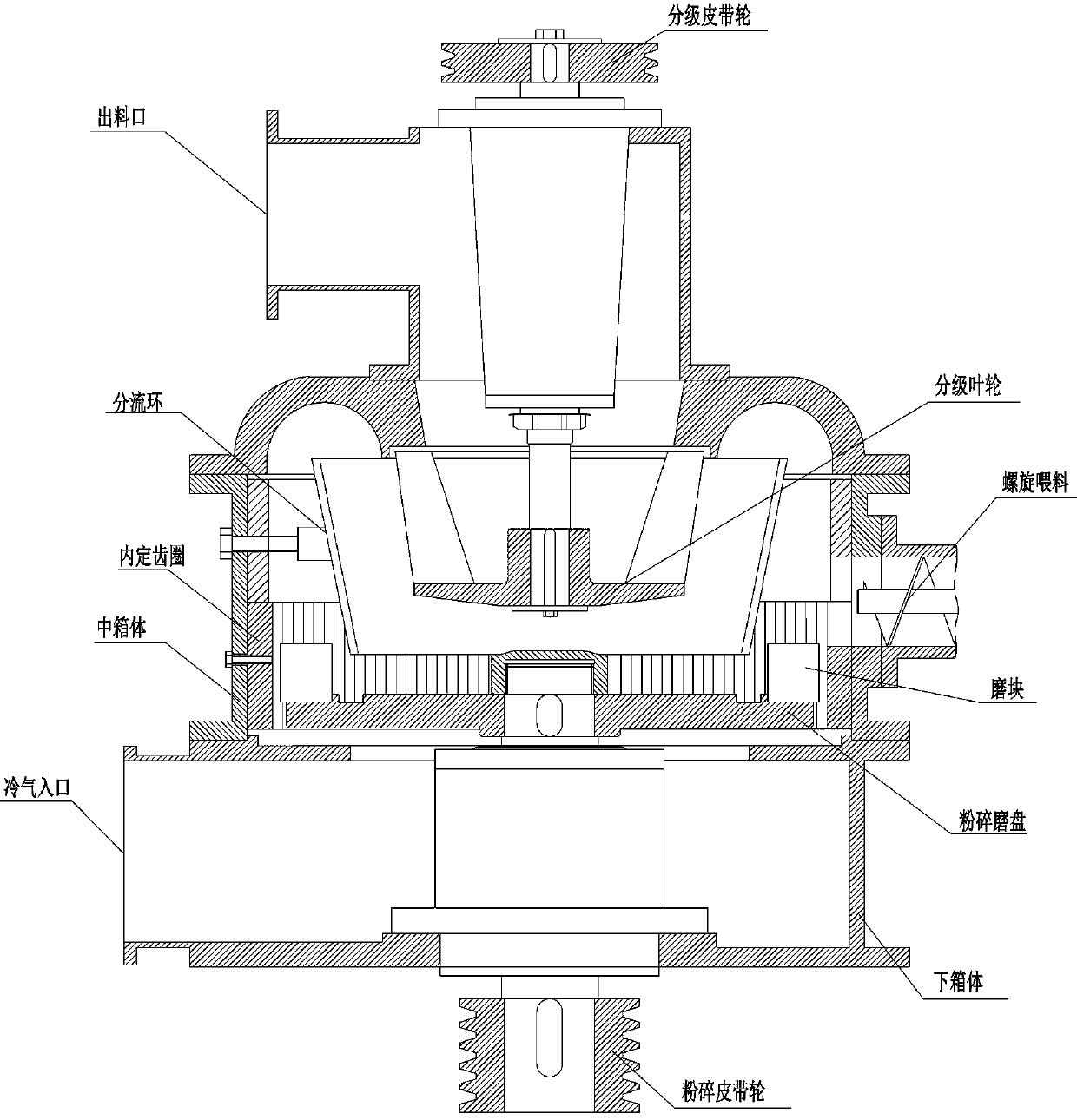

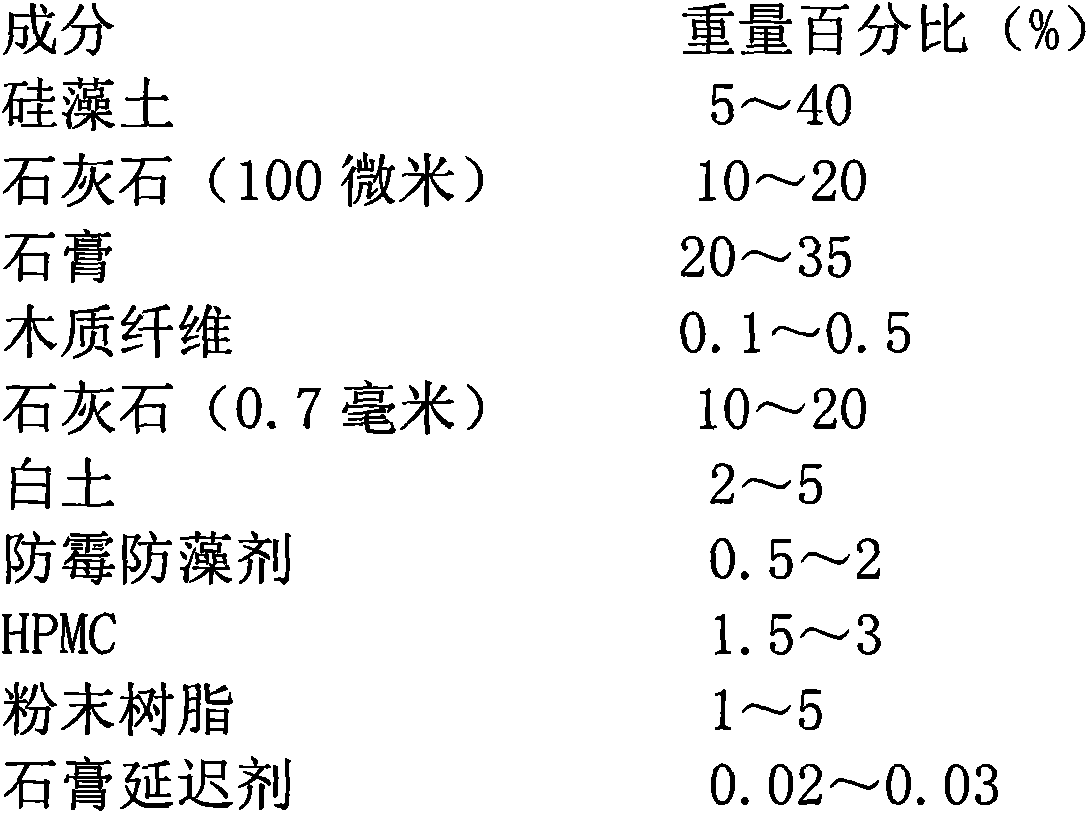

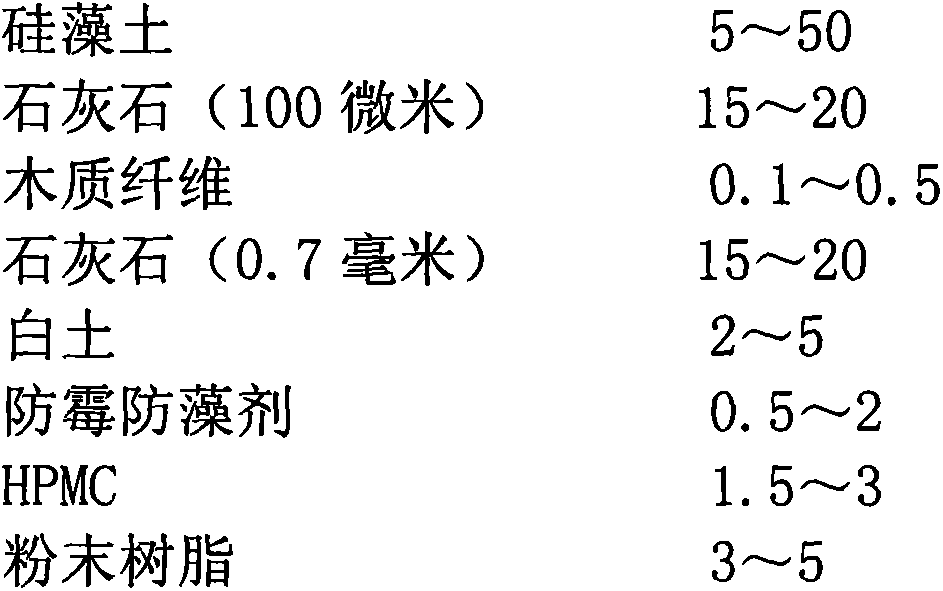

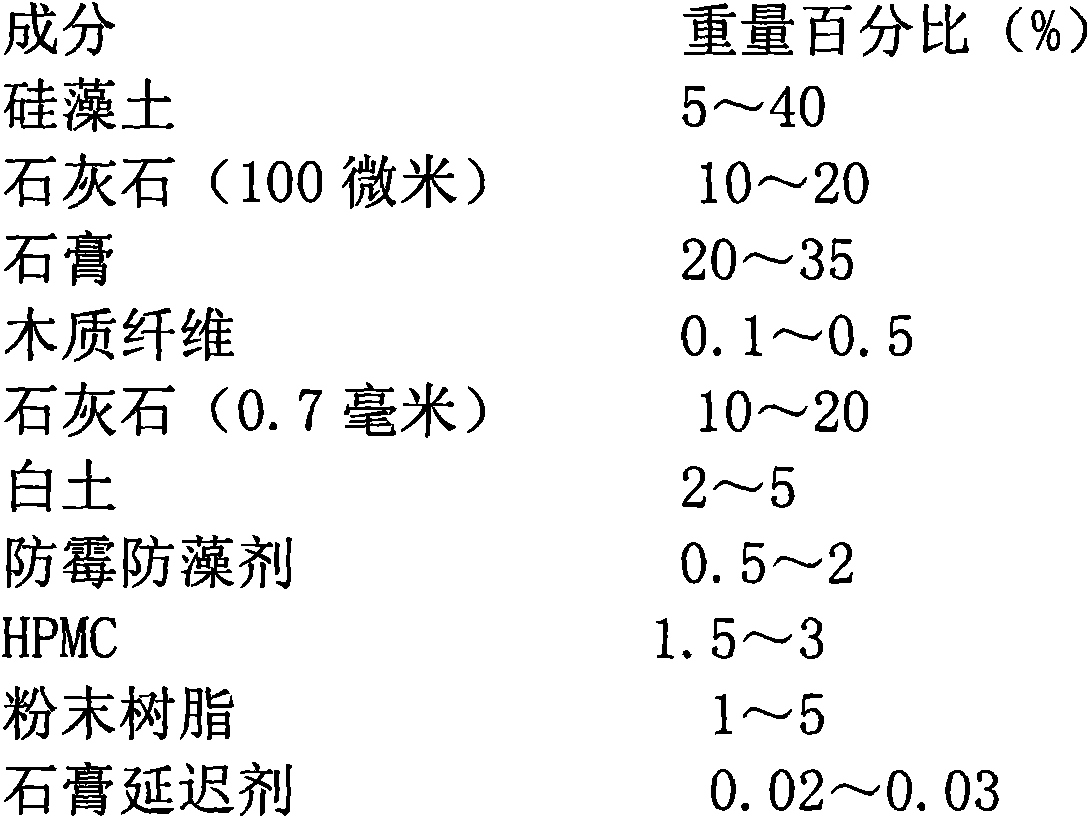

Substrate material capable of adjusting moisture and manufacturing method of substrate material

The invention discloses a substrate material capable of adjusting moisture and a manufacturing method thereof, and discloses a substrate material for painting indoor walls of buildings. The substrate material contains sintered and non-sintered diatomite ingredients and auxiliary materials, such as gypsum, limestone, wood fiber, carclazyte, anti-mildew algicide, hydroxypropyl methylcellulose and powdered resin, and the like. The method is simple and easy to implement. Since having reasonable material proportion, the substrate material has strong crack resistance, adhesion, abrasion resistance, moisture absorption and moisture releasability; the root cause is as follows: the diatomite is used as the main raw material; since the diatomite is porous and has big specific surface area, the diatomite can store moisture and has excellent moisture retention; the moisture can be released in dry condition. Since having wood fiber and powdered resin, and the like, the crack resistance and abrasion resistance are strengthened; the fastness of the substrate material to a wall surface is improved. Moist and mildew can be effectively avoided by adding the anti-mildew algicide, and thus indoor environment is more environment friendly. The substrate material capable of adjusting moisture is ideal, and solves the problems of the existing substrate material.

Owner:营口盼盼硅藻材料集团有限公司

Clean and environment-friendly production method for methionine hydroxyl analogue

InactiveCN109232336ASolve inseparableHigh purityOrganic compound preparationSulfide preparationOrganic solventMethionine hydroxy analog

The invention relates to a clean and environment-friendly production method for a methionine hydroxyl analogue, aiming at solving the problems in a traditional production technological method that themethionine hydroxyl analogue and ammonium salt are difficult to separate and more methionine hydroxyl analogues are carried in the byproduct ammonium salt; the purity of the obtained ammonium salt ishigh; in a whole process, less odor is generated; the whole production process is safe, clean and environmentally friendly, and nearly no wastewater is discharged; the problem of extracting by utilizing an organic solvent in a traditional production technology is solved or the problem that a mixture of the methionine hydroxyl analogue and the ammonium salt are concentrated at high temperature sothat the methionine hydroxyl analogue is decomposed to generate odorous gas is solved; the content of a monomer in an obtained product is greater than that of a traditional production technology and the quality of the product is relatively high.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com