Method for controlling non-metallic inclusions in steel

A technology for non-metallic inclusions and quantity control, which is applied in the fields of gear steel, high-quality spring steel, pipeline steel, and non-metallic inclusions in control steel, which can solve the problem of many calcium-aluminate non-metallic inclusions, etc. The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

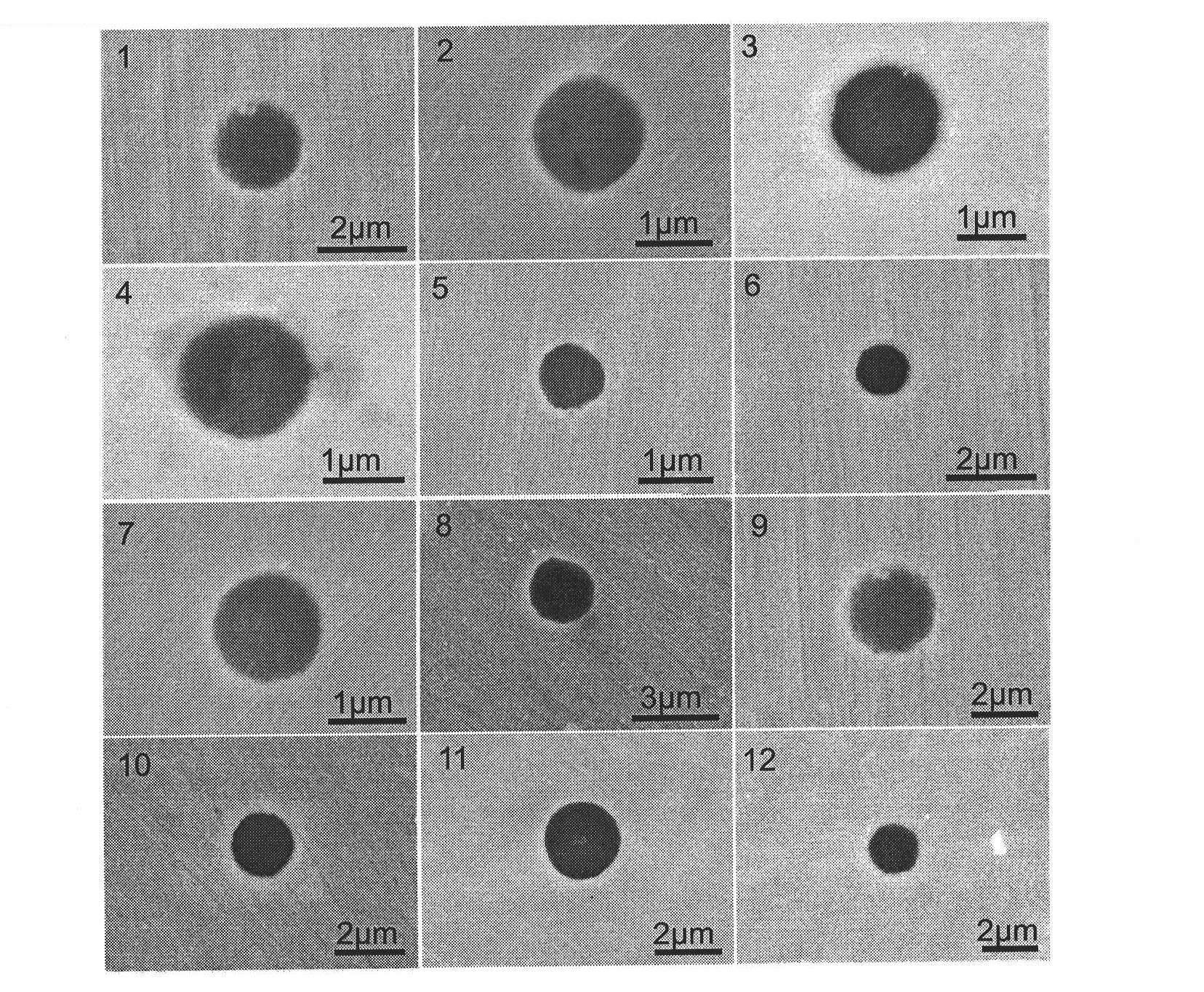

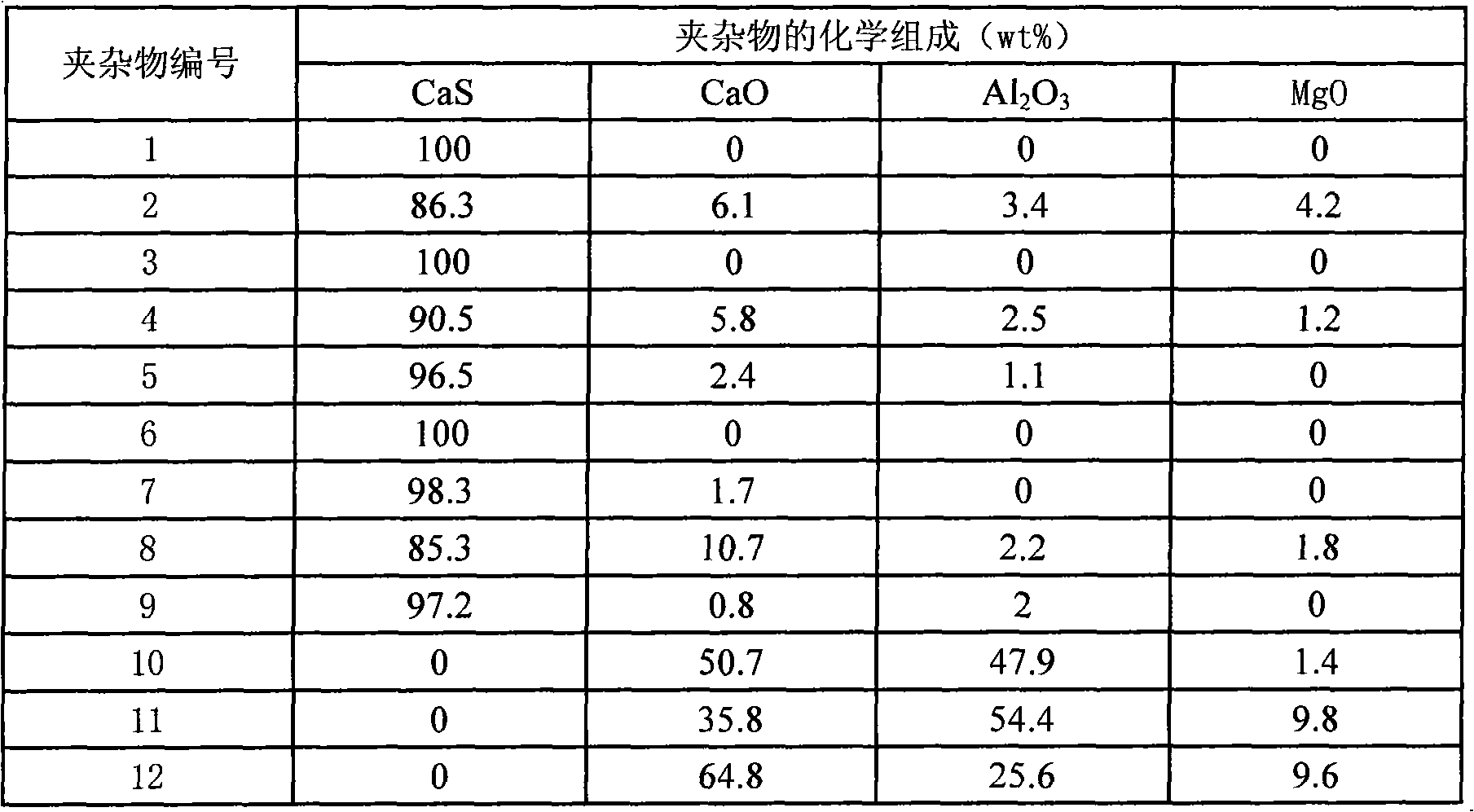

[0018] Embodiment (4 heats test results)

[0019] 210 tons of oxygen double-blown converter, adding 1100kg of aluminum and iron (aluminum content: 40wt%), 1800kg of lime, 400kg of fluorite, slagging material (CaO: 90wt%, Al 2 o 3 : 10wt%) 500kg. After tapping, the molten steel [Al] contents in the four heats were 0.035wt%, 0.047wt%, 0.052wt%, and 0.042wt%, respectively. The intensity is 1150Nl / min.

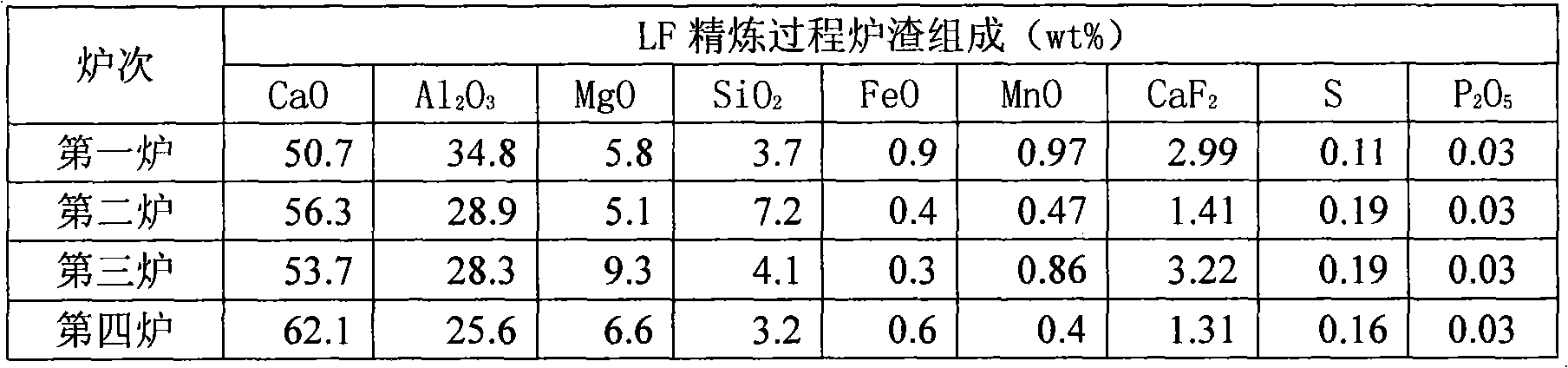

[0020] During the LF smelting process, 200kg of aluminum particles are added to the surface of the slag to reduce the FeO content in the slag. The composition of the slag in the ladle of the 4 heats is shown in Attached Table 2.

[0021] After slagging, carry out bottom blowing Ar strong stirring desulfurization, the bottom blowing intensity is 1000Nl / min, and the time is 15 minutes. After bottom blowing and strong stirring desulfurization, the sulfur content of molten steel in the four heats is controlled to be 0.0006wt%, 0.0006wt%, 0.0008wt%, 0.0007wt%, and the total oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com