Rolling method tobacco sheet production process

A tobacco sheet and production process technology, which is applied in the field of rolling tobacco sheet production technology, can solve the problems of sheet quantification not reaching the target, low tensile strength, easy volatility, etc., and achieve high engineering significance and market value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Such as figure 1 As shown, a rolling process for producing tobacco sheets includes the following steps:

[0034] Step 1. In the raw material pretreatment stage, coarse crushing and drying of large tobacco leaves and stems are prepared for the later fine crushing;

[0035] Step 2. Raw material crushing stage;

[0036] Step 3. Proportioning homogeneous mixing stage;

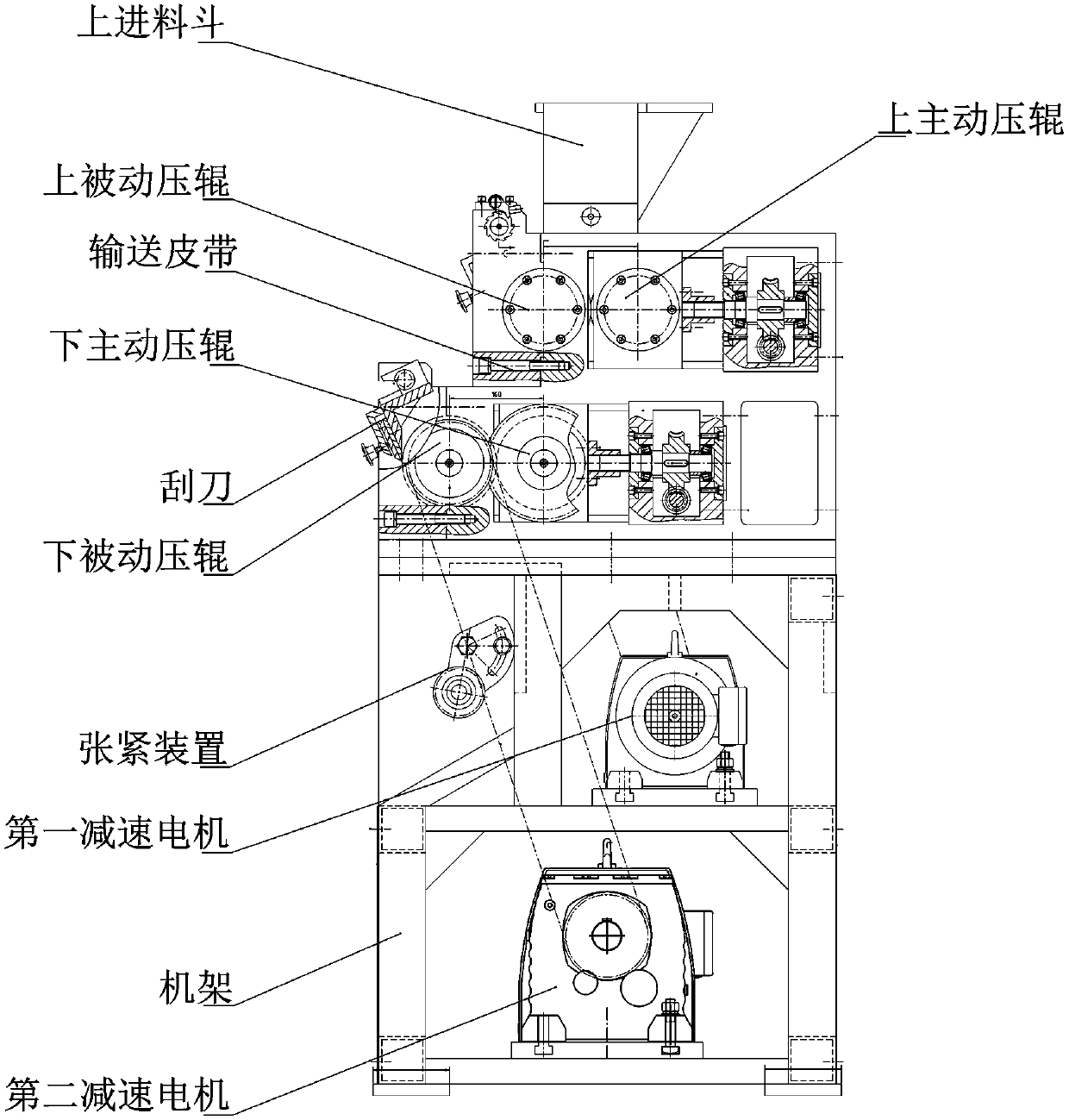

[0037] Step 4. Multi-stage rolling section, through multi-stage rolling, thin the sheet step by step, so that the quantitative and tensile strength meet the index requirements;

[0038] Step 5. In the low-temperature drying section of the slices, the slices are dried at low temperature by steam heating;

[0039] Step 6. Forming processing, rewinding or slicing the formed sheet.

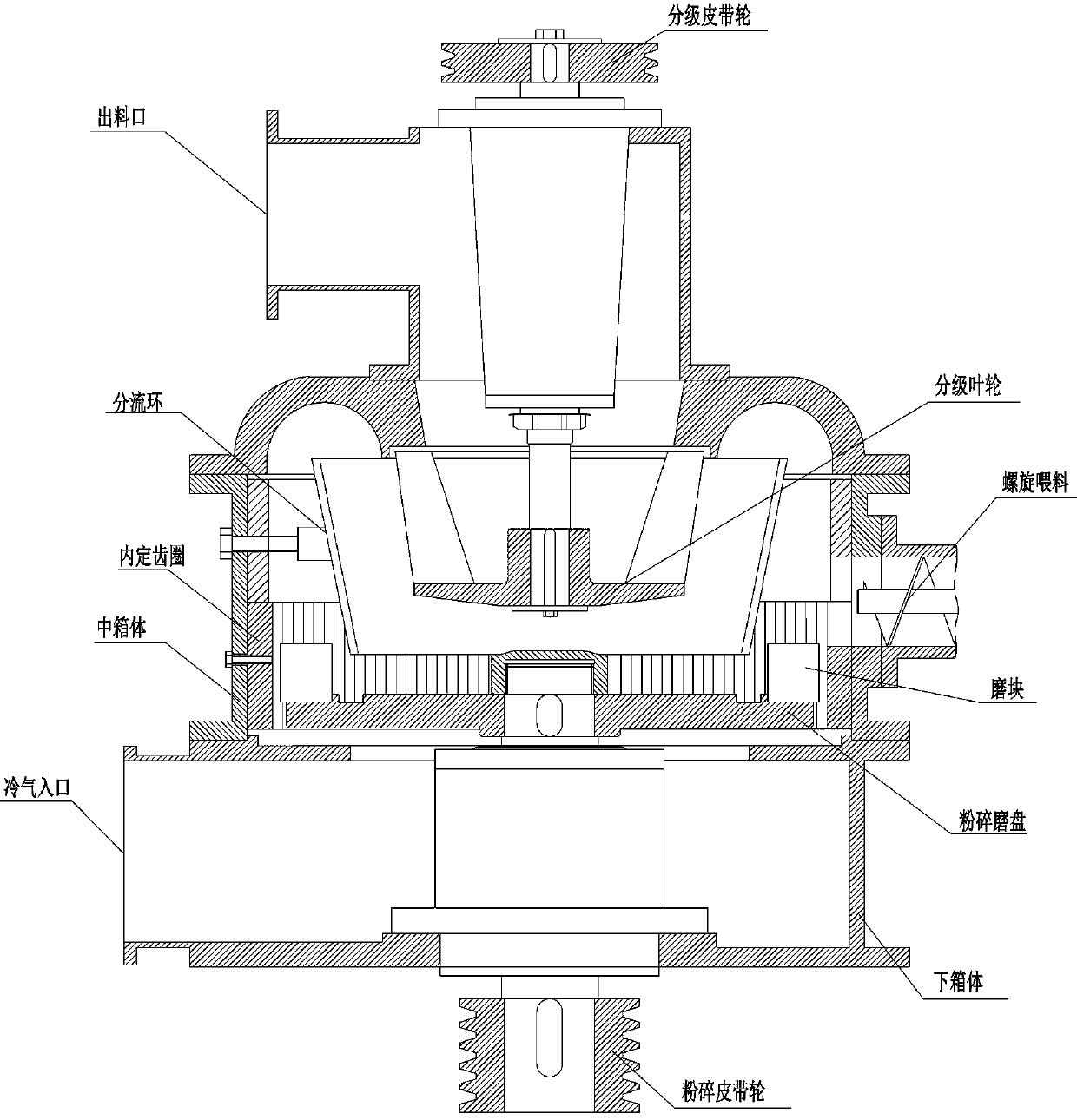

[0040] In step 2, use refrigerant type and air-cooled pulverizers to pulverize raw materials, which include spiral feeding, cold air inlet, lower box, crushing belt wheel, middle box, crushing grinding disc, internal fixed gear ring, grinding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com