Ultrasonic tandem probe device and method

An ultrasonic and transmitting probe technology, which is used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. It reflects the actual depth of defects and other problems, and achieves the effect of solving difficult positioning and quantification, high measurement accuracy and small measurement error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The patent will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

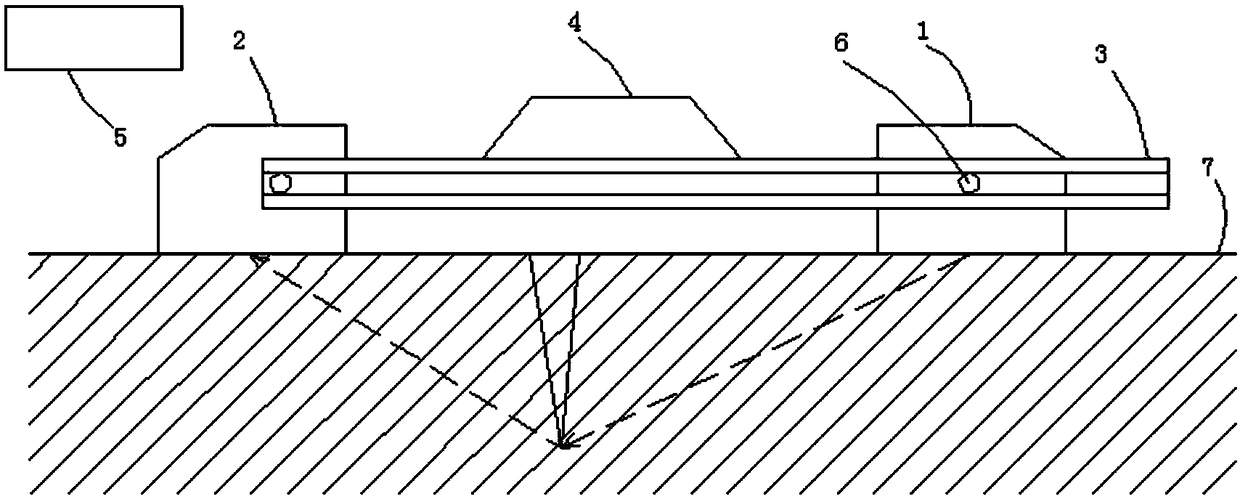

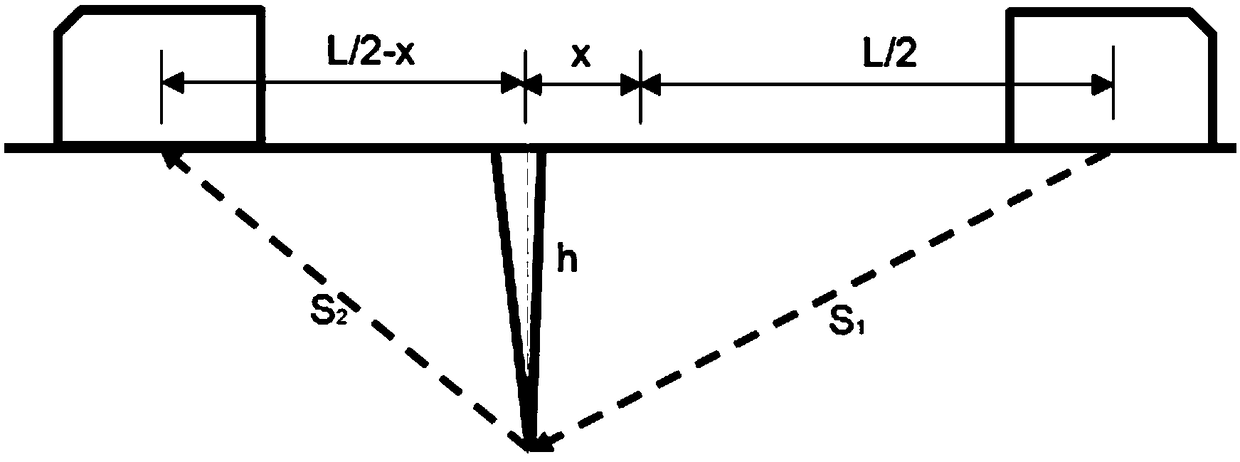

[0021] An ultrasonic tandem probe device and method, such as figure 1 As shown, it includes transmitting probe 1, receiving probe 2, connecting rod 3, push handle 4, and oscilloscope screen 5; transmitting probe 1 and receiving probe 2 select shear wave probes with the same angle, wherein transmitting probe 1 transmits ultrasonic waves; transmitting probe 1 transmits The ultrasonic waves form endpoint diffraction waves at the crack endpoints; the receiving probe 2 receives the endpoint diffraction waves; the connecting rod 3 is provided with a slot; The receiving probe 2 can slide freely in the card slot, and the limit screw 6 is used to fix the transmitting probe 1 and the receiving probe 2 during detection; the push handle 4 is fixedly installed on the connecting rod 3, and the operator pushes the push handle 4 during the detection process to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com