Water-based naon-sized pre-coated coil top coating and preparation method thereof

A coil coating, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor protection and decoration effect, poor film compactness, large particle size of polymer emulsion, etc. Healthy, harmless, good penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

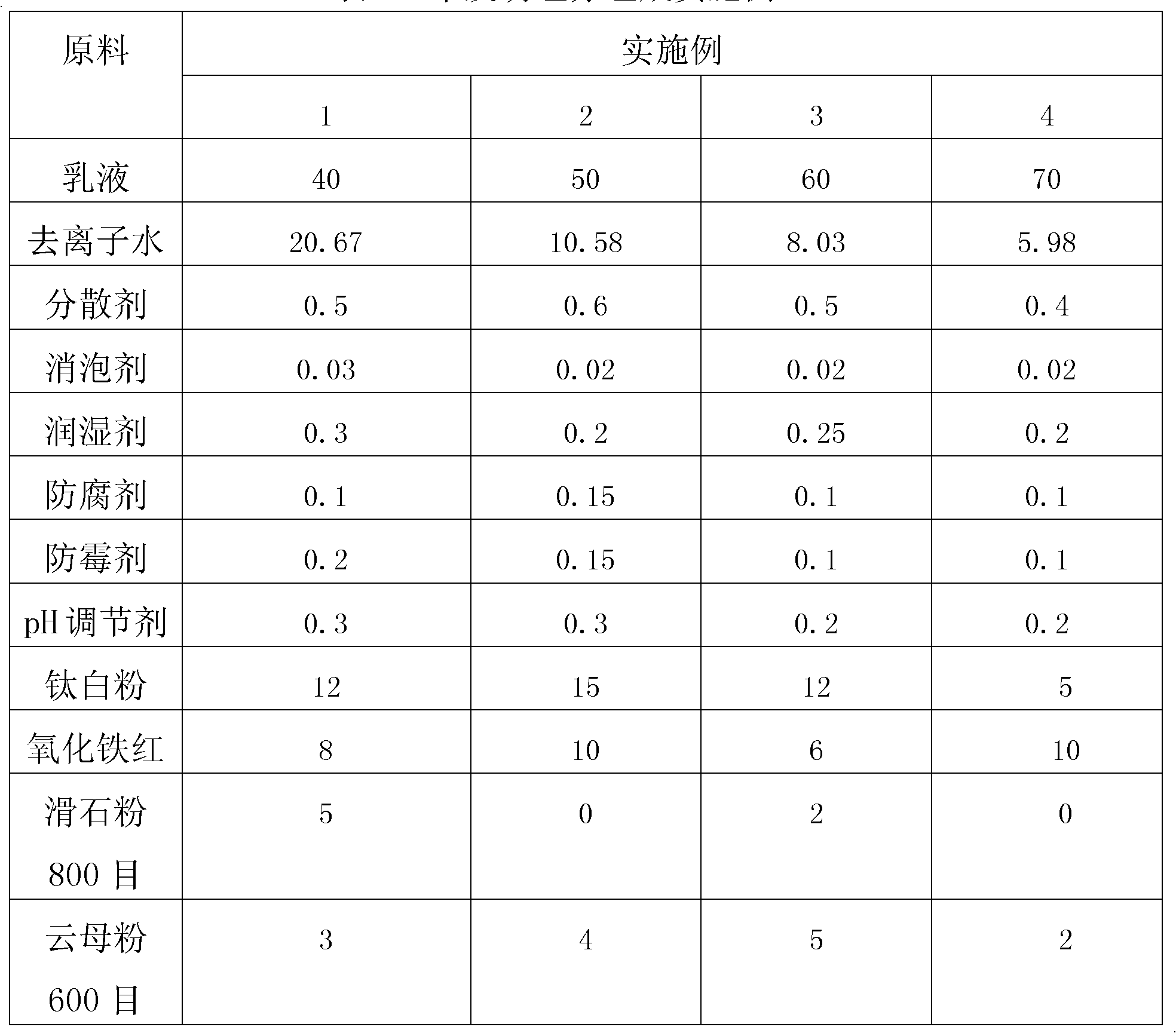

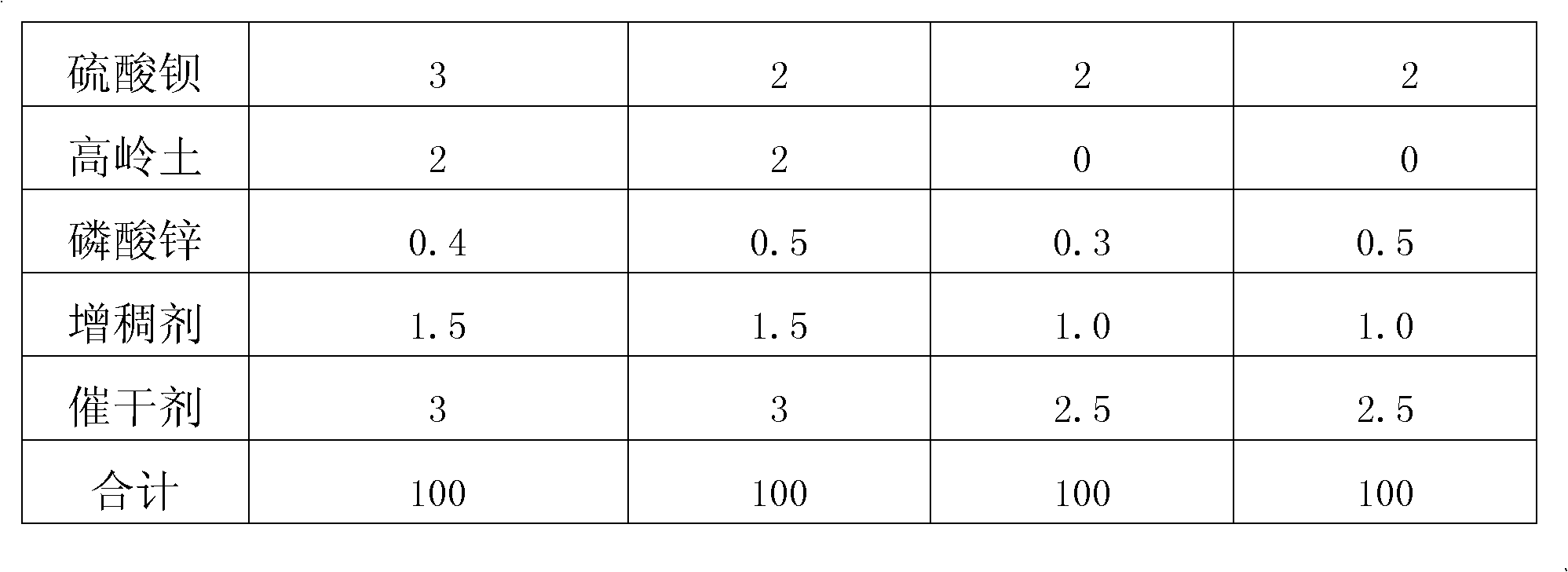

[0032] The present invention passes through numerous tests, and the four specific examples screened out are listed in Table 1, but the present invention is not limited to the following examples. In Table 1: the emulsion is an aqueous acrylic polyurethane nanopolymer emulsion with a particle size of less than 100 nm.

[0033] Table 1: Component composition embodiment 1-4 of the present invention

[0034]

[0035]

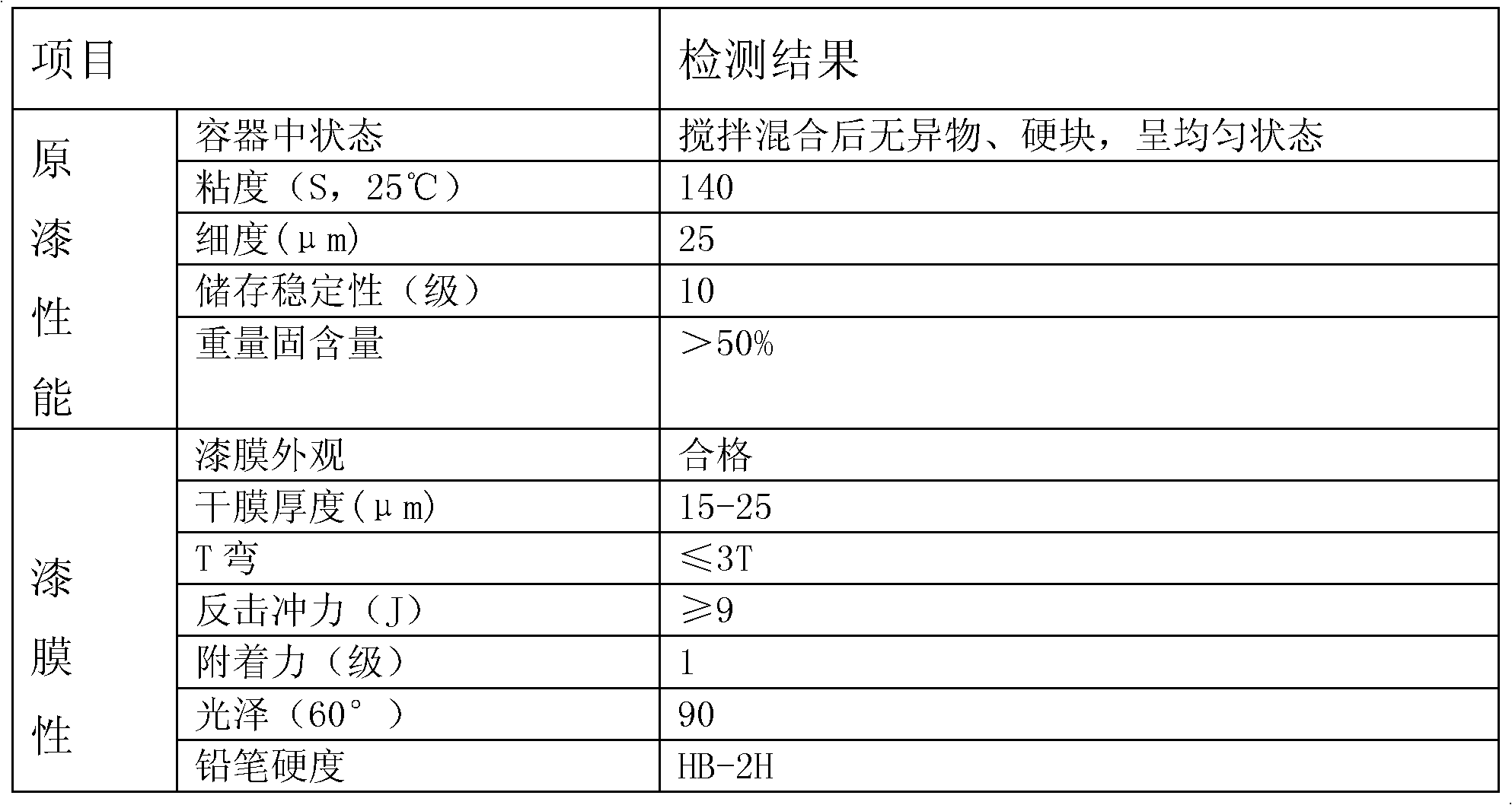

[0036] By systematic research and experiments on the proportions of each component and the order of addition in the water-based nanometer pre-coated coil paint topcoat formula in the present invention, the best performance examples are as follows:

[0037] Weigh 54% of nanopolymer emulsion, 0.25% of wetting agent, 0.4% of dispersant, 0.02% of defoamer, 0.25% of pH regulator, 0.15% of preservative, 0.15% of antifungal agent and Add 13.38% deionized water into the paint mixing tank, and disperse for 10 minutes at the speed of the disperser at 800 rpm. Then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com