Substrate material capable of adjusting moisture and manufacturing method of substrate material

A technology of base material and manufacturing method, applied in the field of base material for painting interior walls of buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

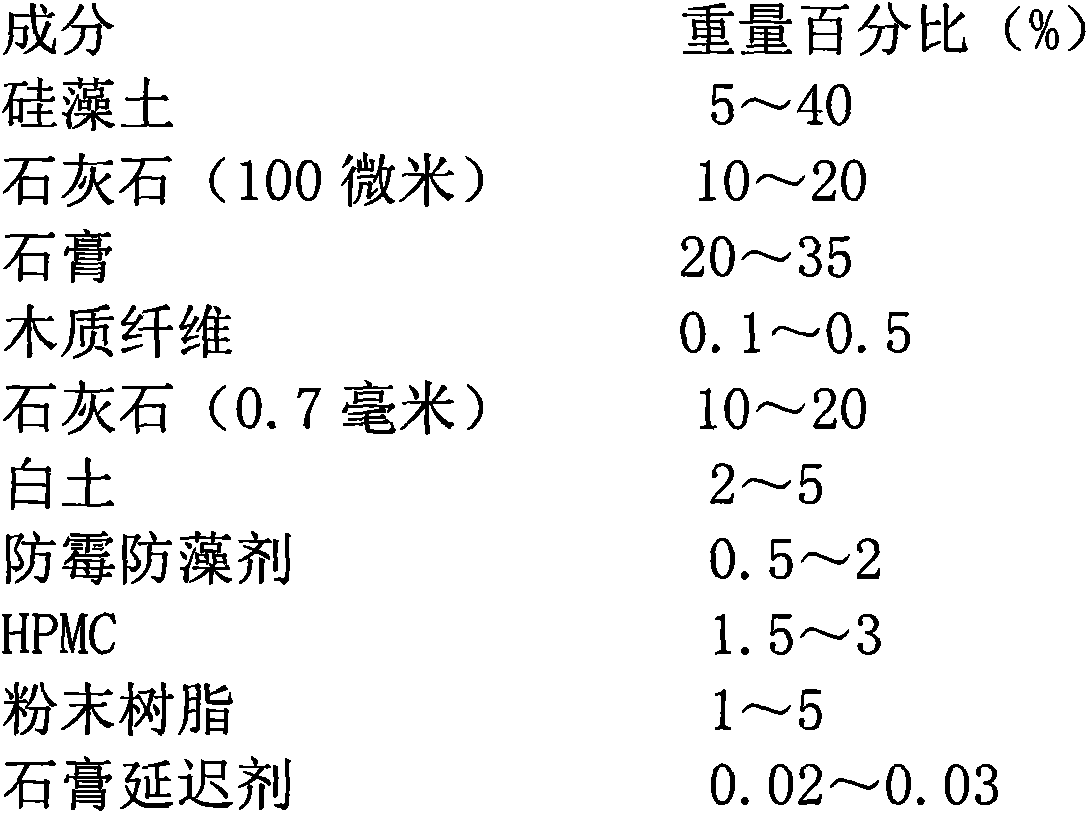

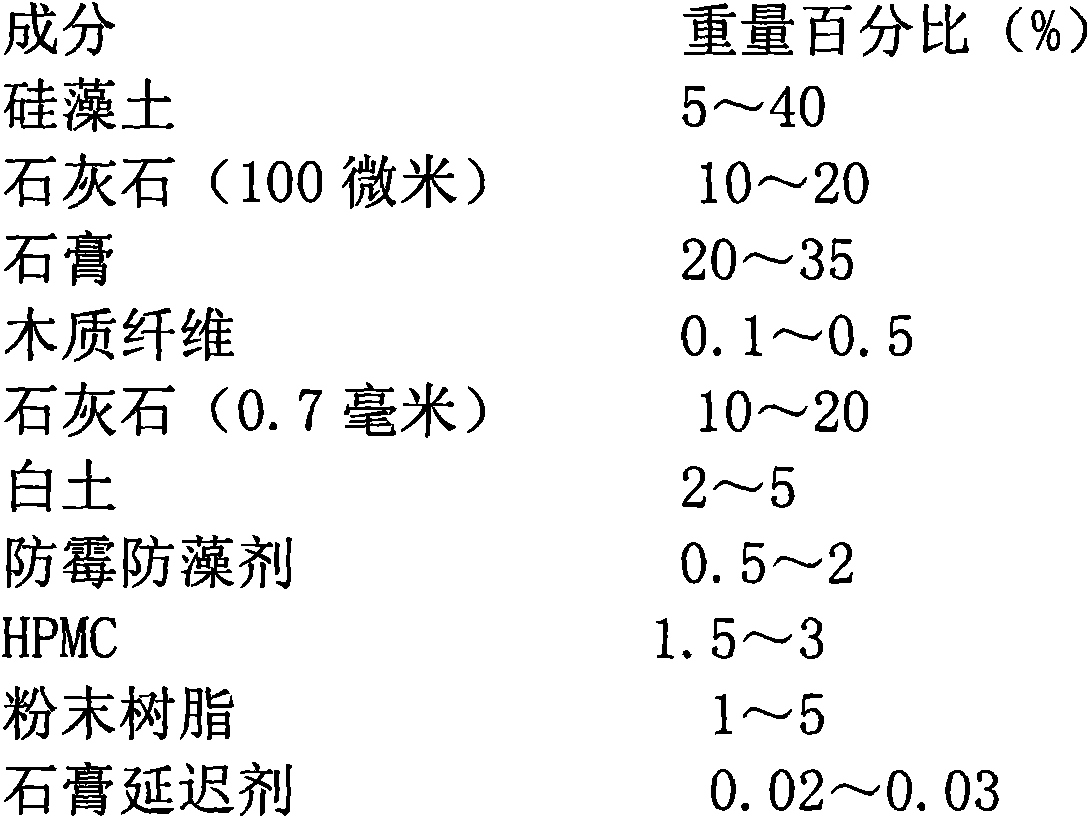

Embodiment 1

[0016] Take 40kg of unfired diatomite, 20kg of limestone (100 microns), 2kg of wood fiber, 30kg of gypsum, 10kg of limestone (0.7 mm), 2kg of white clay, 1kg of calcium persulfate, 2kg of HPMC, vinyl acetate-ethylene copolymerized redispersible glue Powder, 2kg, polyamide derivative calcium salt 0.02kg.

[0017] Production method

[0018] Put the above-mentioned materials in a dry state into the mixing mixer, and stir well and evenly.

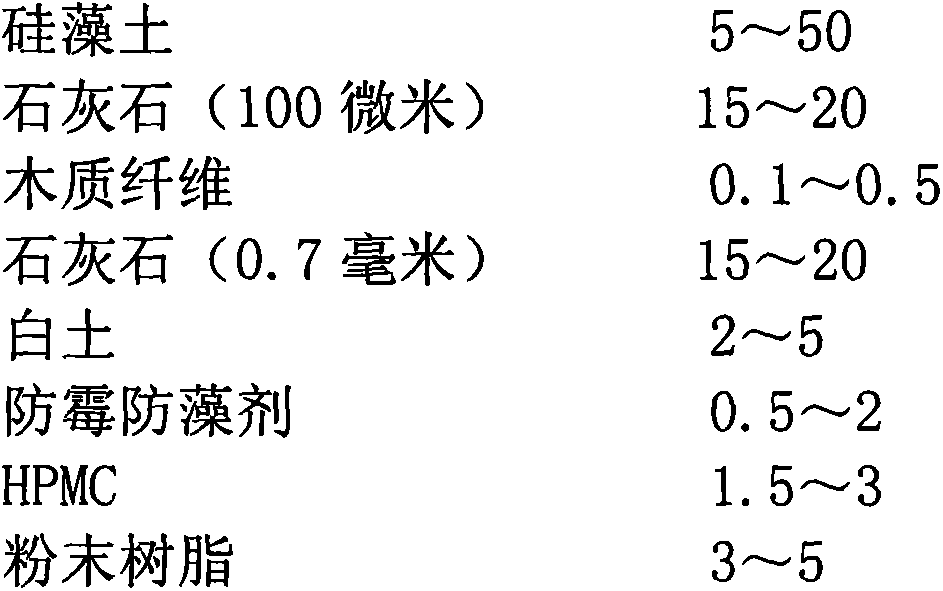

Embodiment 2

[0020] Get 40kg of calcined diatomite, 20kg of limestone (100 microns), 2kg of wood fiber, 20kg of limestone (0.7mm), 2kg of clay, 1kg of calcium persulfate, 2kg of HPMC, and 2kg of vinyl acetate-ethylene copolymerized redispersible rubber powder.

[0021] Production method

[0022] Put the above-mentioned materials in a dry state into the mixing mixer, and stir well and evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com