Patents

Literature

78results about How to "Increase grip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

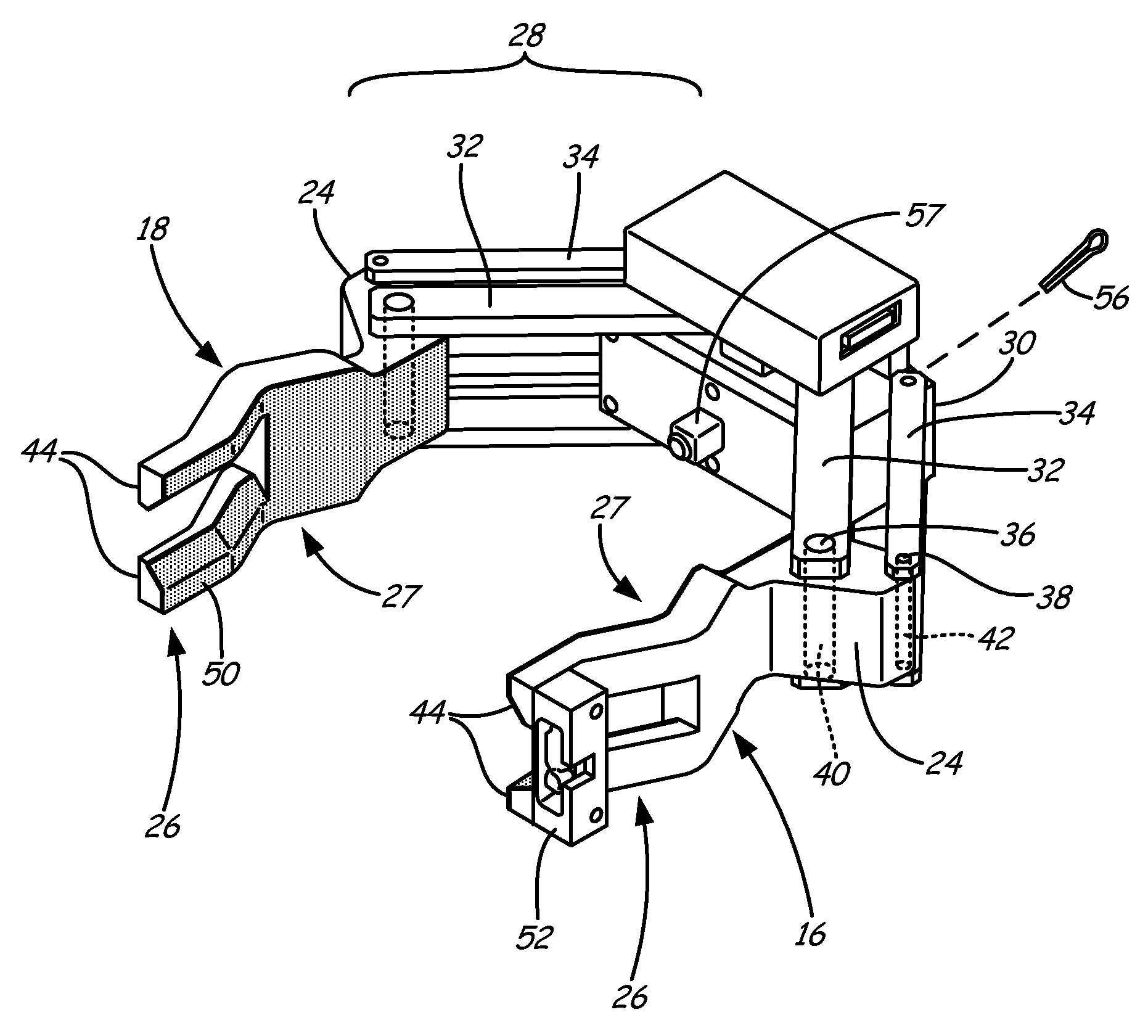

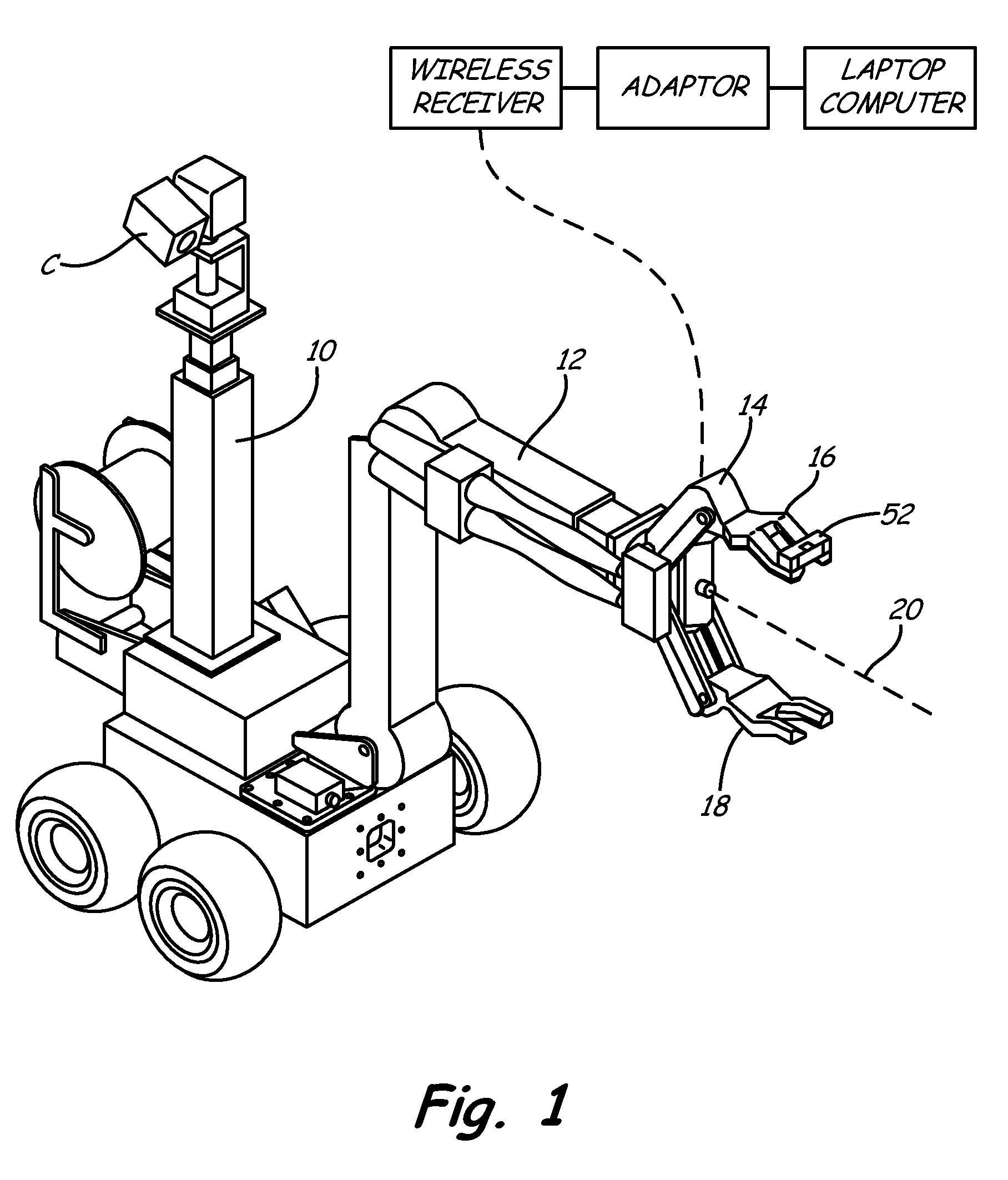

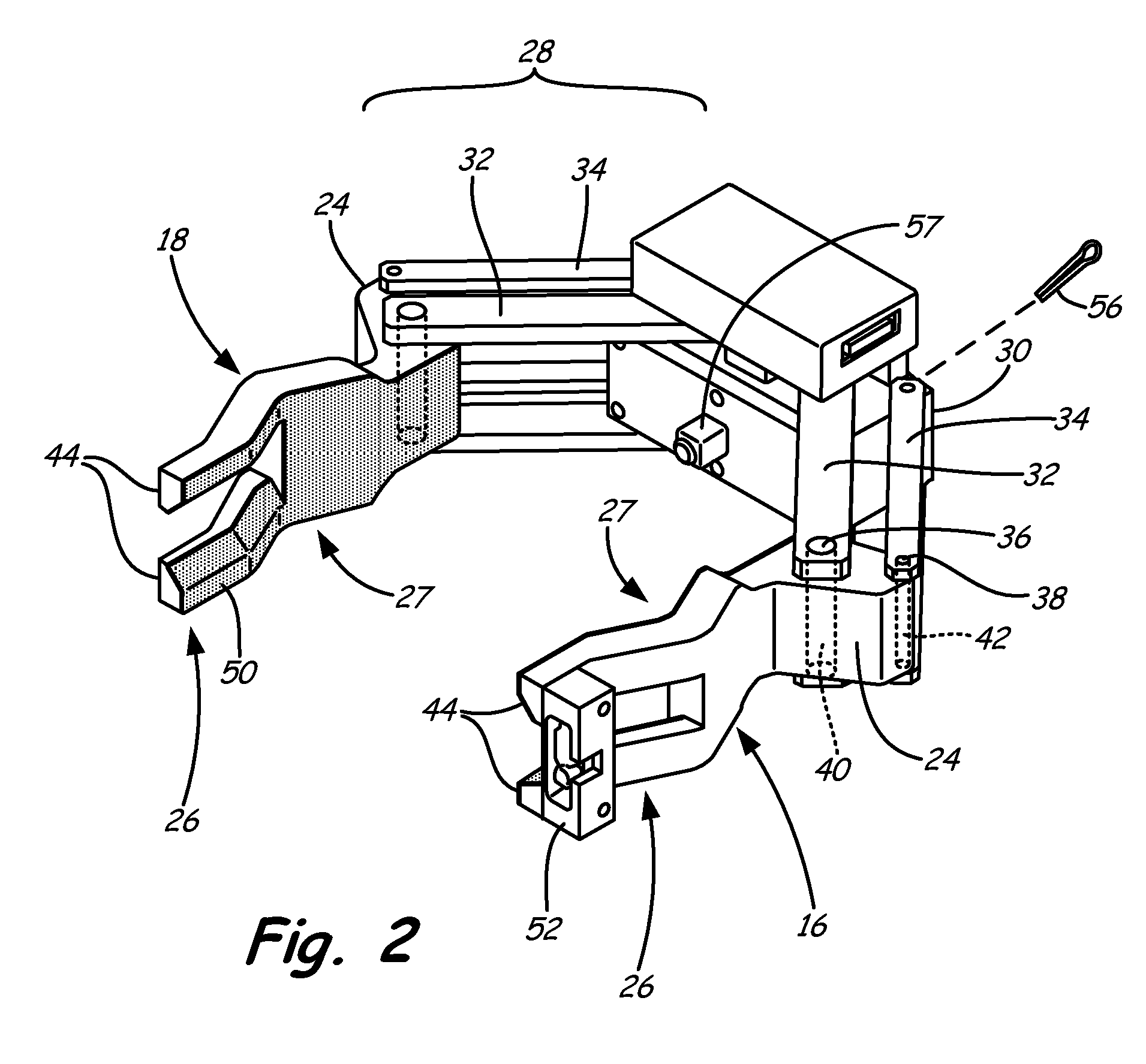

Gripper attachment for robot

InactiveUS20120286533A1Increase gripWell understandingGripping headsLifting devicesGrippersEngineering

A robot gripper attachment for use with conventional robotic platforms, the gripper having opposed claw members, each claw member in turn having a plurality of elongate projections. An inward facing surface of each projection is chamfered, defining an interior gripping surface. This gripping surface may be further provided with a friction material for increased grip. One or more cameras and sensors may be utilized to aid operation by providing the operator with information about depth, distance, and positioning.

Owner:UNIVERSITY OF NORTH DAKOTA

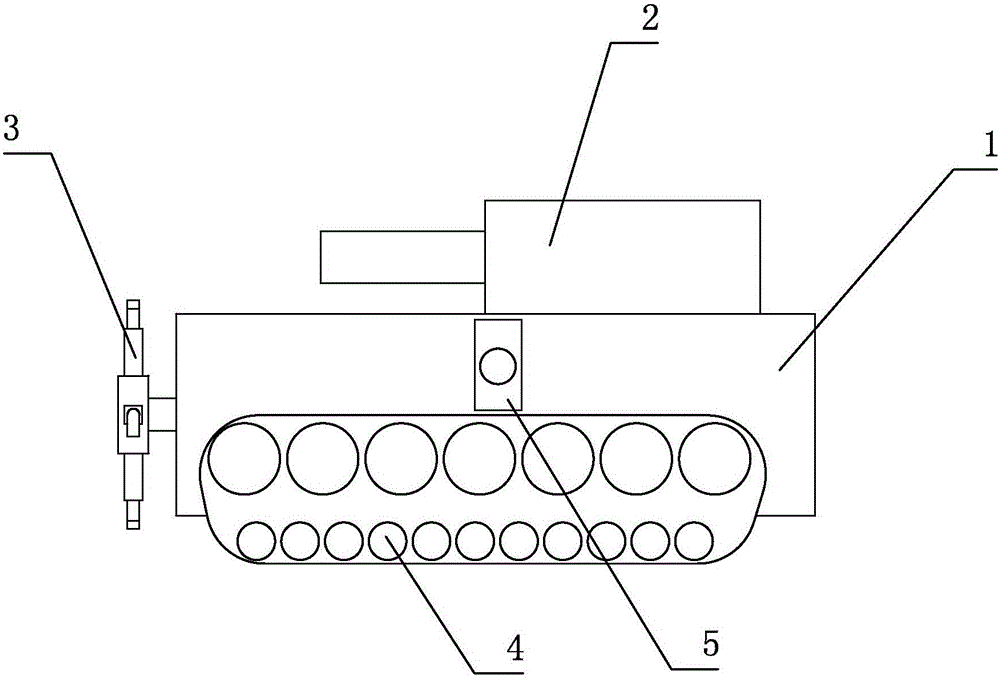

Fire-fighting robot

ActiveCN105056439AImprove fire extinguishing efficiencyAvoid Interfering with OperationFire rescueDrive shaftEngineering

The invention relates to a robot, in particular to a fire-fighting robot. The fire-fighting robot comprises a vehicle body. Traveling chain wheels are arranged on the two sides of the vehicle body. A water spraying device is arranged on the upper portion of the vehicle body. A turnover mechanism is arranged at the front end of the vehicle body. The turnover mechanism comprises a rotary disc and a driving shaft used for driving the rotary disc. A plurality of rotary arms are arranged on the rotary disc in the circumferential direction. A telescopic rod is arranged in each rotary arm. Each telescopic rod is composed of a front telescopic rod body and a rear telescopic rod body. A spring is arranged between each rear telescopic rod body and the front end of the corresponding rotary arm. The front telescopic rod bodies are sleeved with the springs. The rear end of each rear telescopic rod body is connected with a permanent magnet. The polarities of the opposite sides of each permanent magnet and an electromagnet are the same. According to the fire-fighting robot, the vehicle body can restore automatically to continue to complete the fire-fighting work, and fire extinguishing efficiency is improved.

Owner:新沂市时集建设发展有限公司

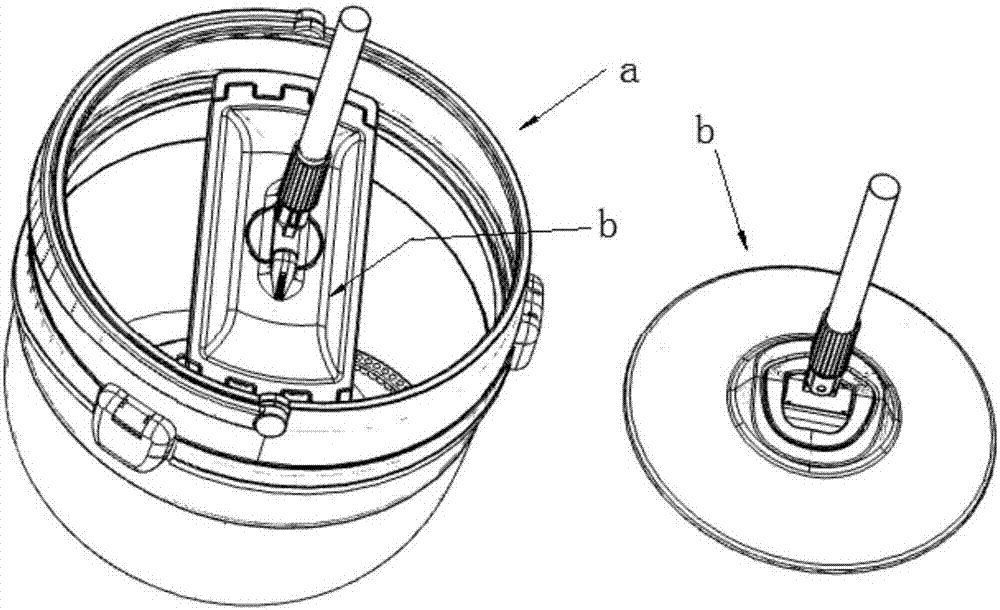

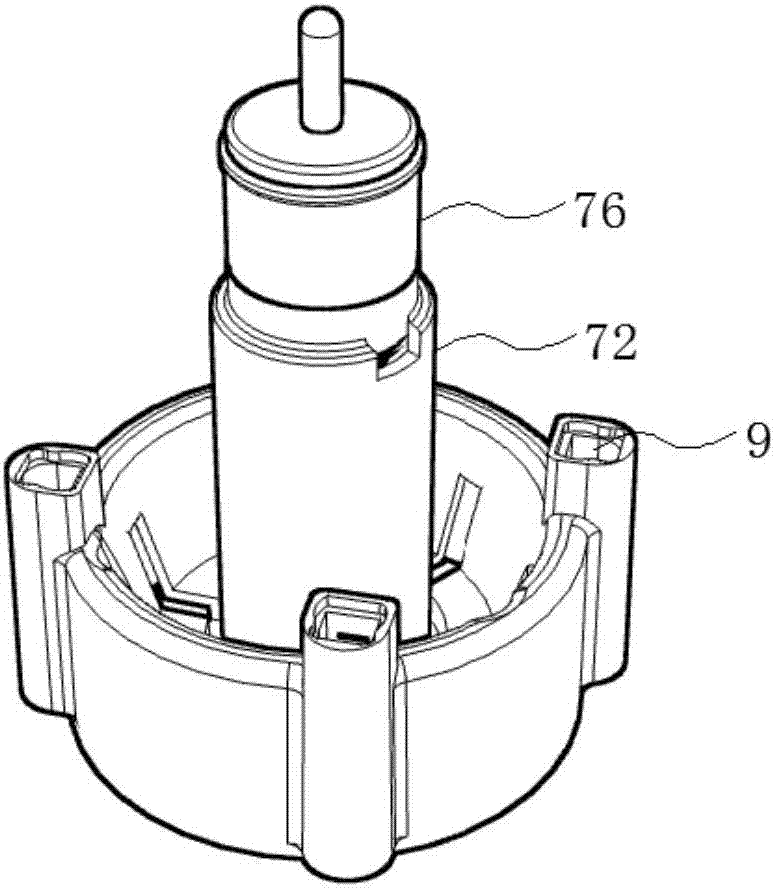

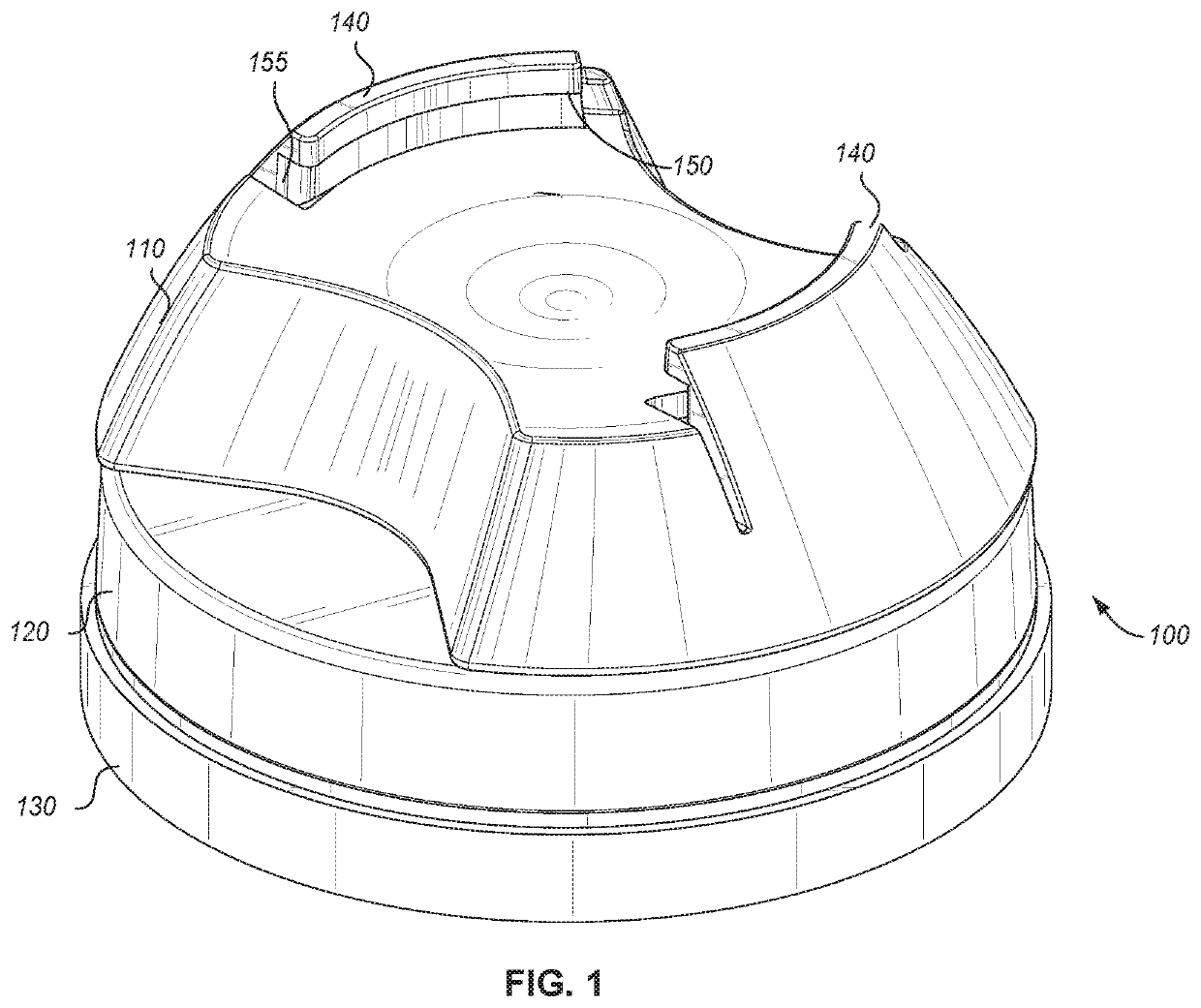

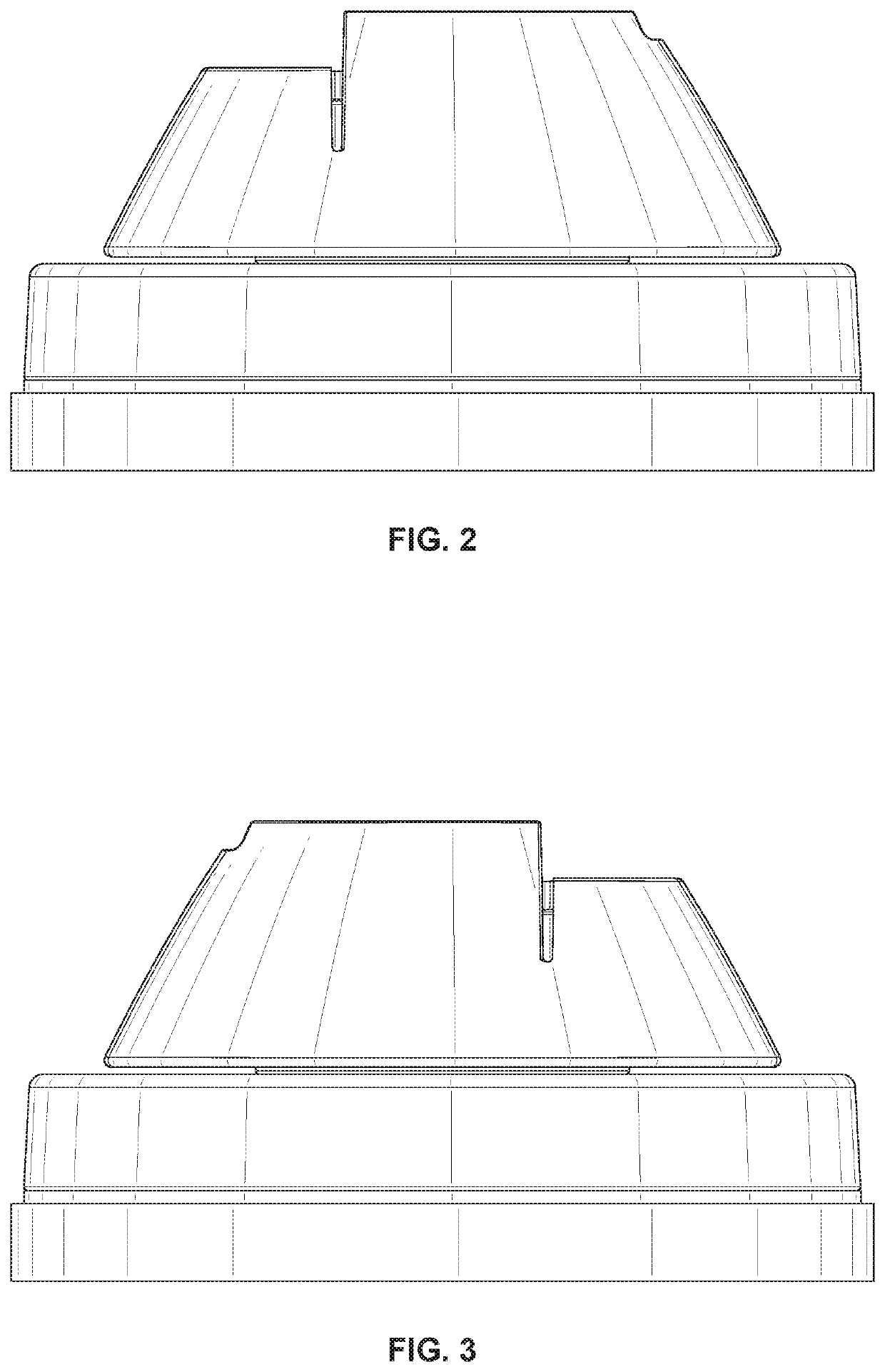

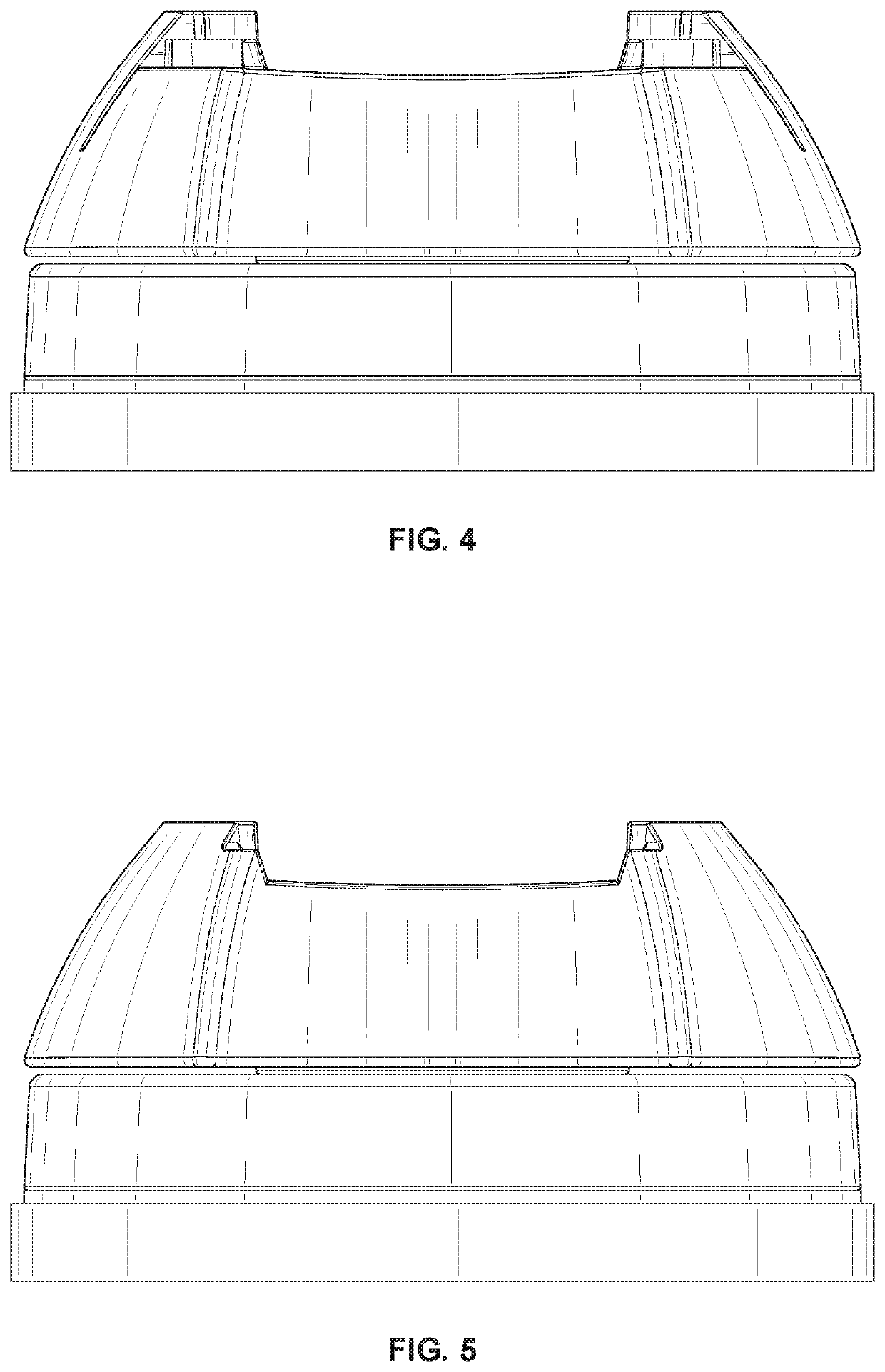

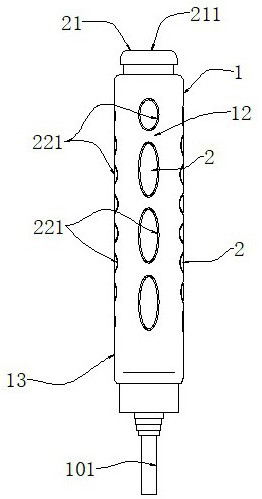

Cleaning tool

ActiveCN107997708ASimple structureEasy to manufactureCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a cleaning tool. The cleaning tool comprises a mop bucket and a mop. The mop comprises a mop rod, a bottom board and a rotation joint. The mop rod comprises an outer rod body and an inner rod body. The rotation joint comprises a first rotation part and a second rotation part. The bottom of the mop bucket is provided with a lifting mechanism. The lifting mechanism comprisesa fixing column fixed at the bottom of the mop bucket, a moving tube and a positioning rod. The moving tube is sheathed outside the fixing column. The positioning rod passes through the moving tube and is inserted in an inserting hole at the center of the fixing column, and the positioning rod is rotated relative to the fixing column. The lifting structure of the cleaning tool is simplified, and the operation is convenient, so the washing and dewatering functions of the mop are combined and coaxially performed, and the volume of the mop bucket can be reduced. The locking structure of the mop rod is simplified, and the angle between the mop rod and a faceplate can be conveniently adjusted and positioned. The locking structure is suitable for the mop or other cleaning tools with the similardemand. In addition, wiping cloth is effectively fixed on a bottom plate of the mop through a fixing claw by the lower faceplate, so the service life of the mop is prolonged.

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

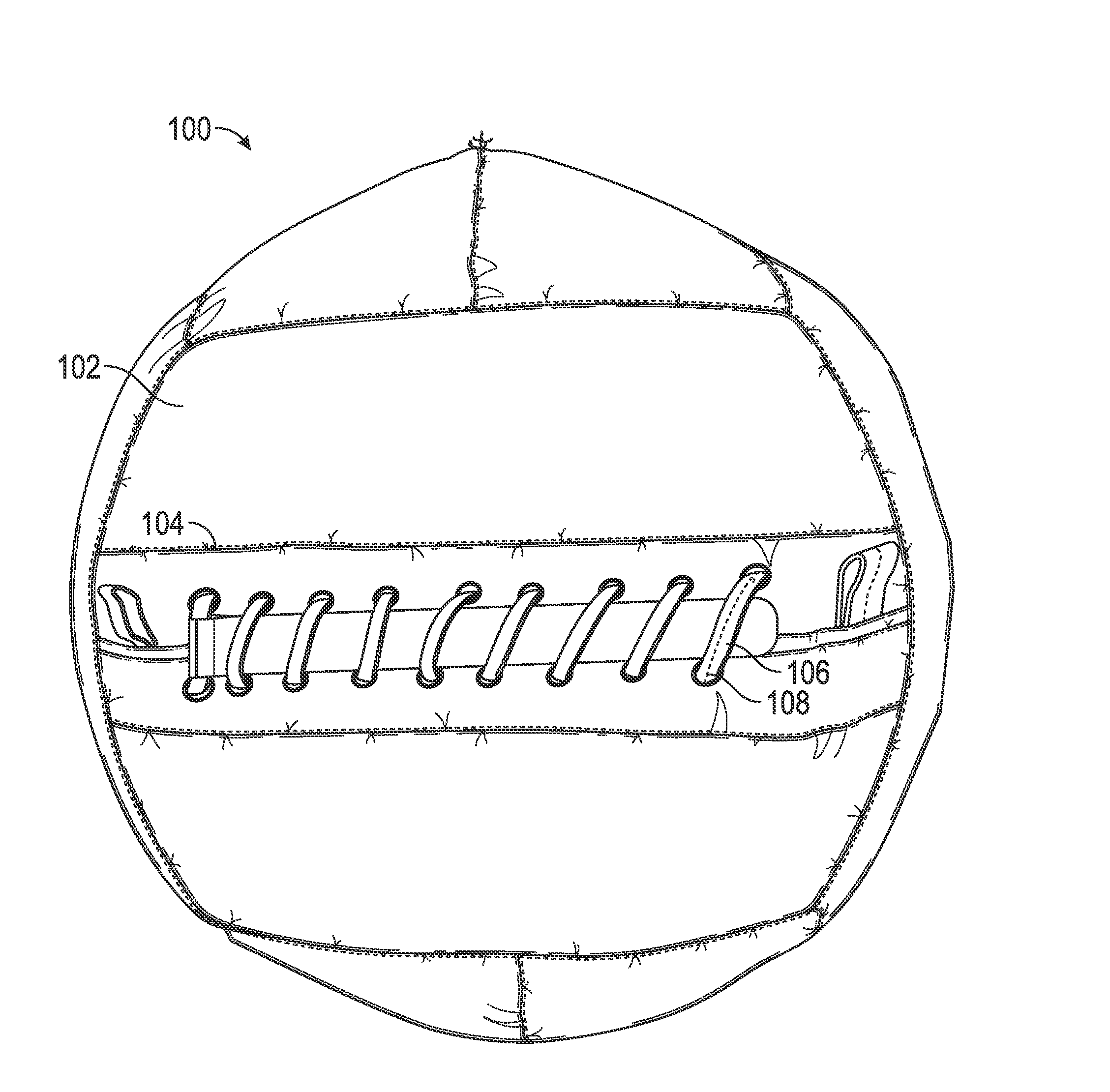

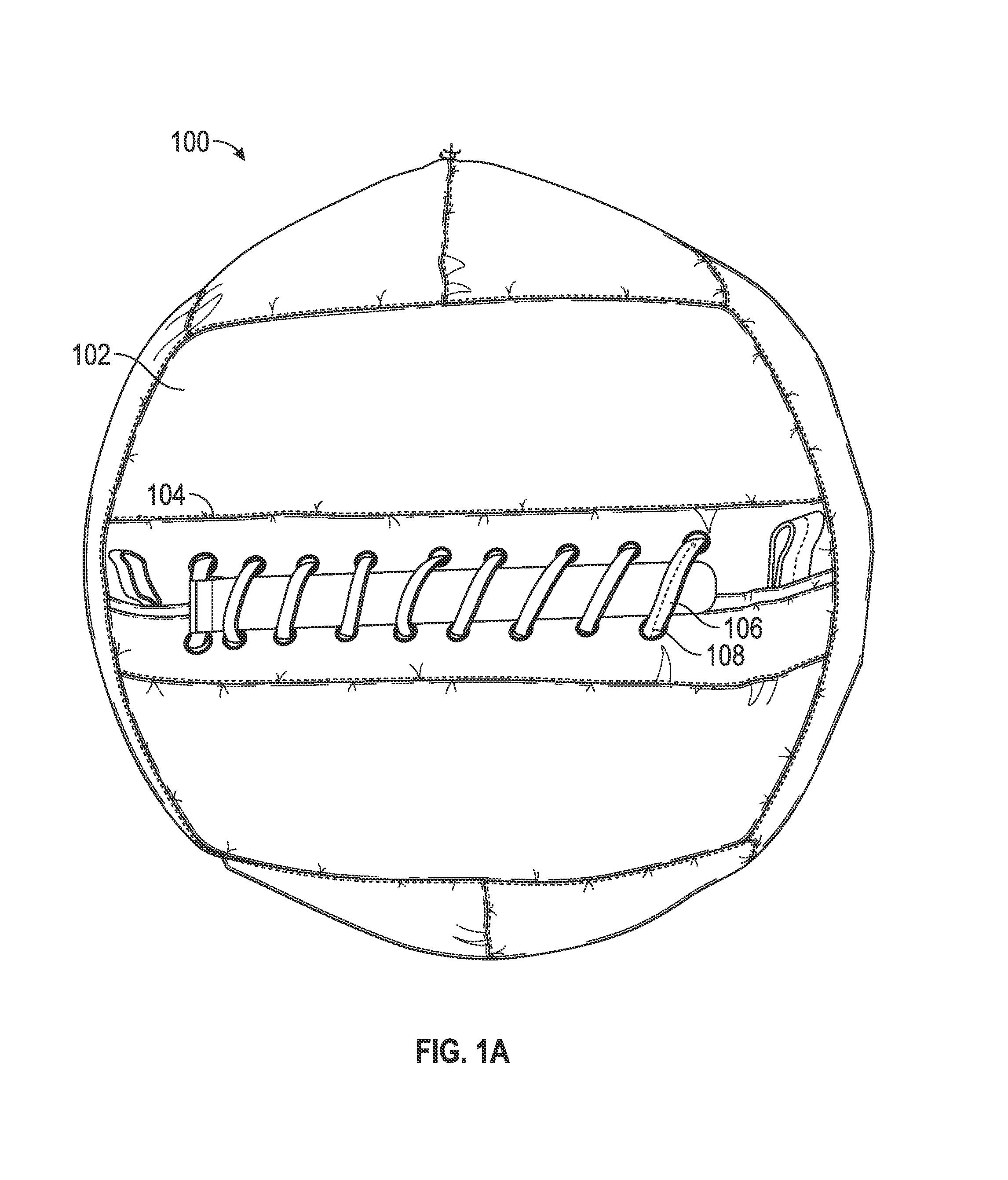

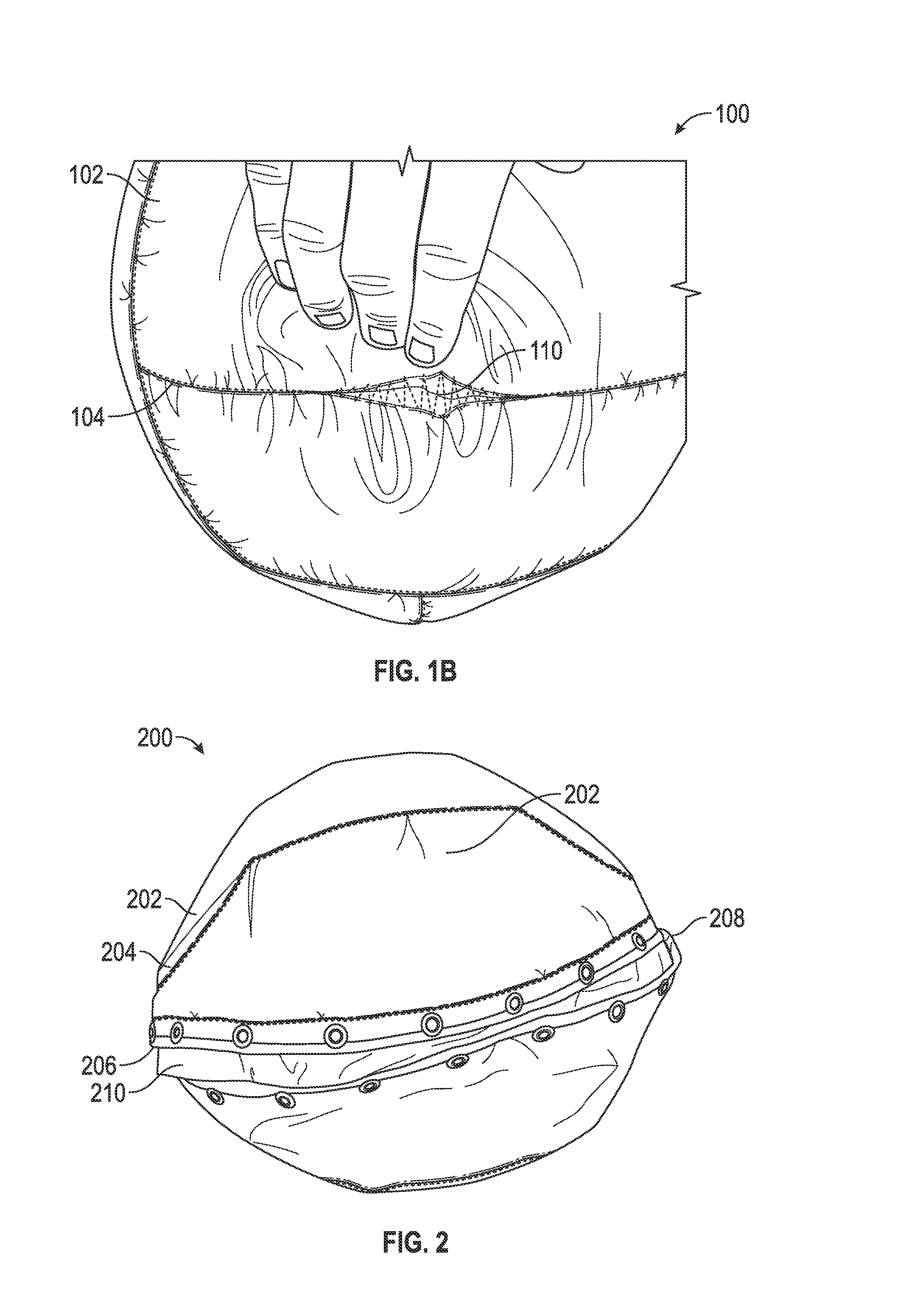

Protective cover for medicine ball and methods of making thereof

ActiveUS20140342859A1Increase gripMaintain it shape and integrityHollow inflatable ballsHollow non-inflatable ballsEngineeringHigh surface

A removable protective ball cover for a medicine ball is provided to protect an outer surface of the ball from wear and tear, increase the grip of the surface of the ball and maintain the balls' shape and structure. The ball cover may be formed from a durable material with high surface tension formed into a spherical shape with an opening that is used to encapsulate the medicine ball within the ball cover. The opening may be cinched closed by lacing the opening together to substantially, if not completely, cover the medicine ball and create a tight fit around the ball that will not move in relation to the ball. The ball cover may be formed from a series of specially-shaped panels which are triple stitched together with a backing material to prevent breaking of the cover.

Owner:NEWMAN DAVID RAY

Preparation method for diamond wire saw utilizing composite binder

ActiveCN106273007AImprove adhesion strengthImprove heat resistanceFine working devicesHeat resistanceDiamond wire saw

The invention discloses a preparation method for a diamond wire saw utilizing a composite binder. The method comprises following steps: step 1, surface pre-preparation of a wire saw matrix; step 2, surface processing of a diamond abrasive; step 3, preparation of the diamond abrasive and the composite binder into a combined coating; step 4, coating; step 5, primary curing; step 6, secondary curing. The preparation method for the diamond wire saw utilizing the composite binder has following advantages: the composite binder contains thermosetting resin and light-cured resin and is added with high-performance liquid rubber, a coupling agent, nano-ceramic powder and nano-copper powder so that adhesion intensity of the composite binder is improved, hear resistance of the composite binder is enhanced and holding force of the composite binder and the diamond abrasive is improved; the diamond abrasive is prevented from falling down during saw cutting so that the service lifetime of the diamond wire saw is prolonged; and meanwhile, two curing processes help strengthen the combination and adhesion among light-cured resin, thermosetting resin and the diamond abrasive and helps holding force of the composite binder and the diamond abrasive.

Owner:江苏益林金刚石工具有限公司

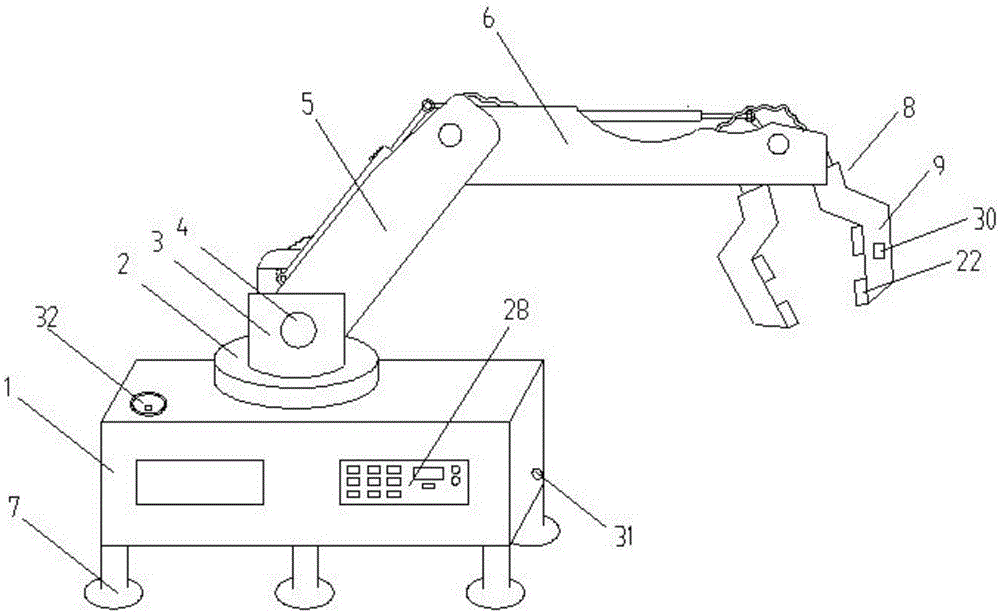

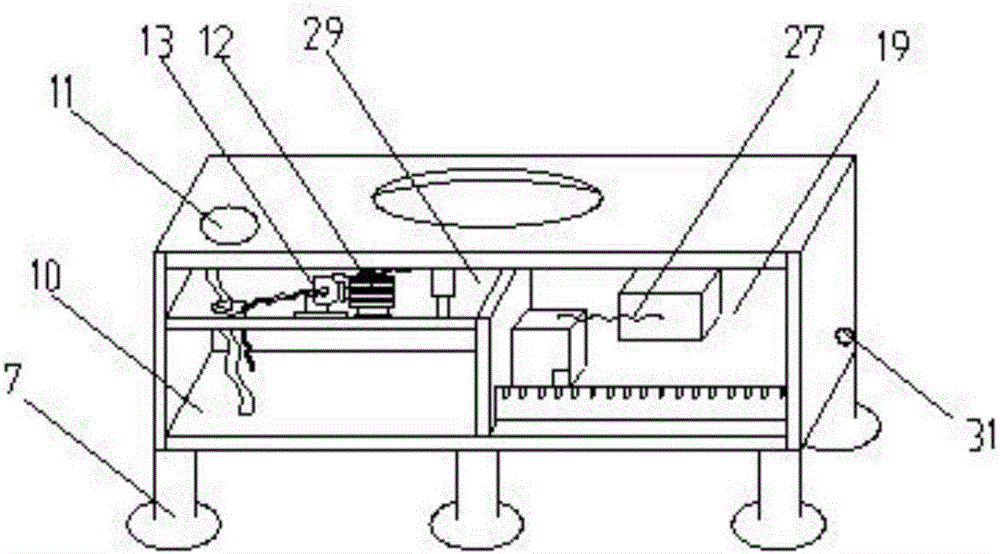

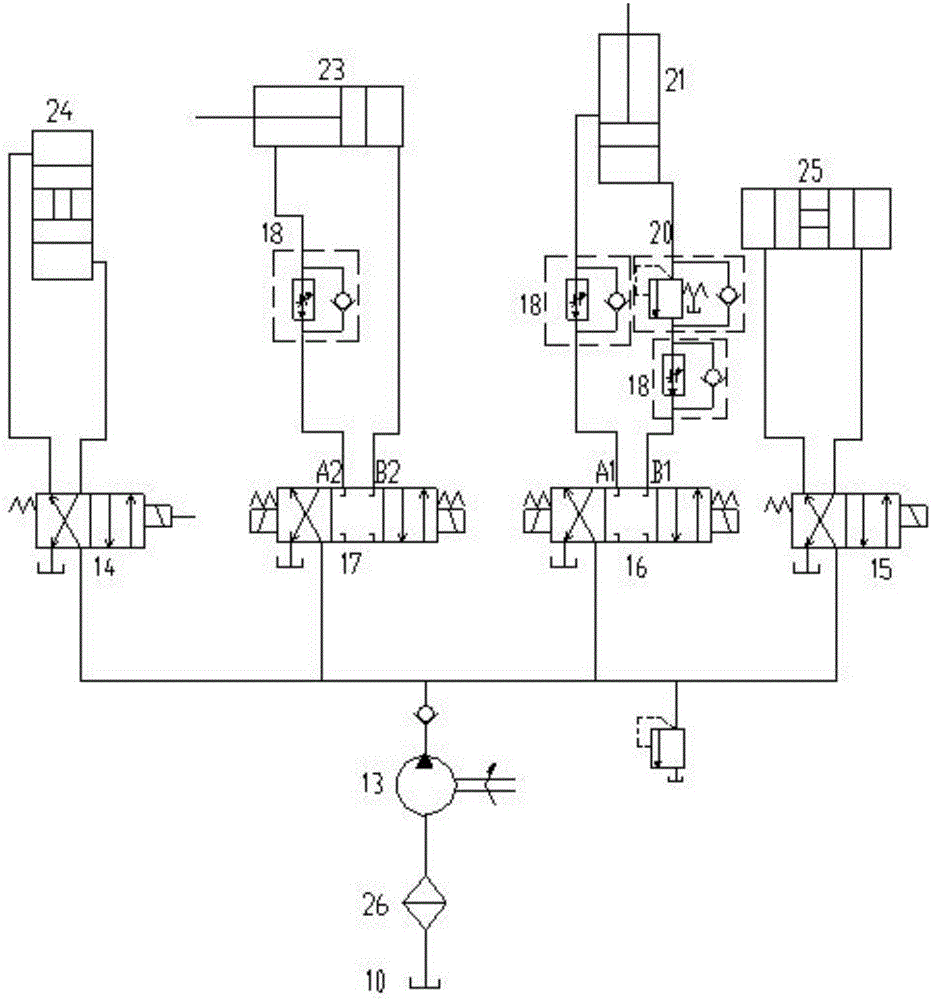

Hydraulic manipulator

The invention discloses a hydraulic manipulator comprising a tank body; a rotating boss and an oil filling port are formed in the tank body; the rotating boss is provided with a mounting part connected with a big arm through a mounting shaft; the big arm is hinged with one end of a forearm and is fixedly provided with a big arm cylinder; and the other end of the forearm is hinged with a gripper. When being used, the hydraulic manipulator can be mounted in a required place, and a required action is set through an operation panel as required and is stored. When the hydraulic manipulator is used, only a power supply is needed to be started every time, and a set action command is selected to operate; the inner side of each of two claws is provided with two cushion blocks, so that the grasping force of the gripper can be effectively increased; and an oil tank, a motor, a gear pump and an electric control mounting region are arranged inside the tank body, so that the structure of the hydraulic manipulator is simplified, and meanwhile, the hydraulic manipulator has the characteristic of simple appearance.

Owner:ZHUHAI HENGQIN QI XIANG TECH CO LTD

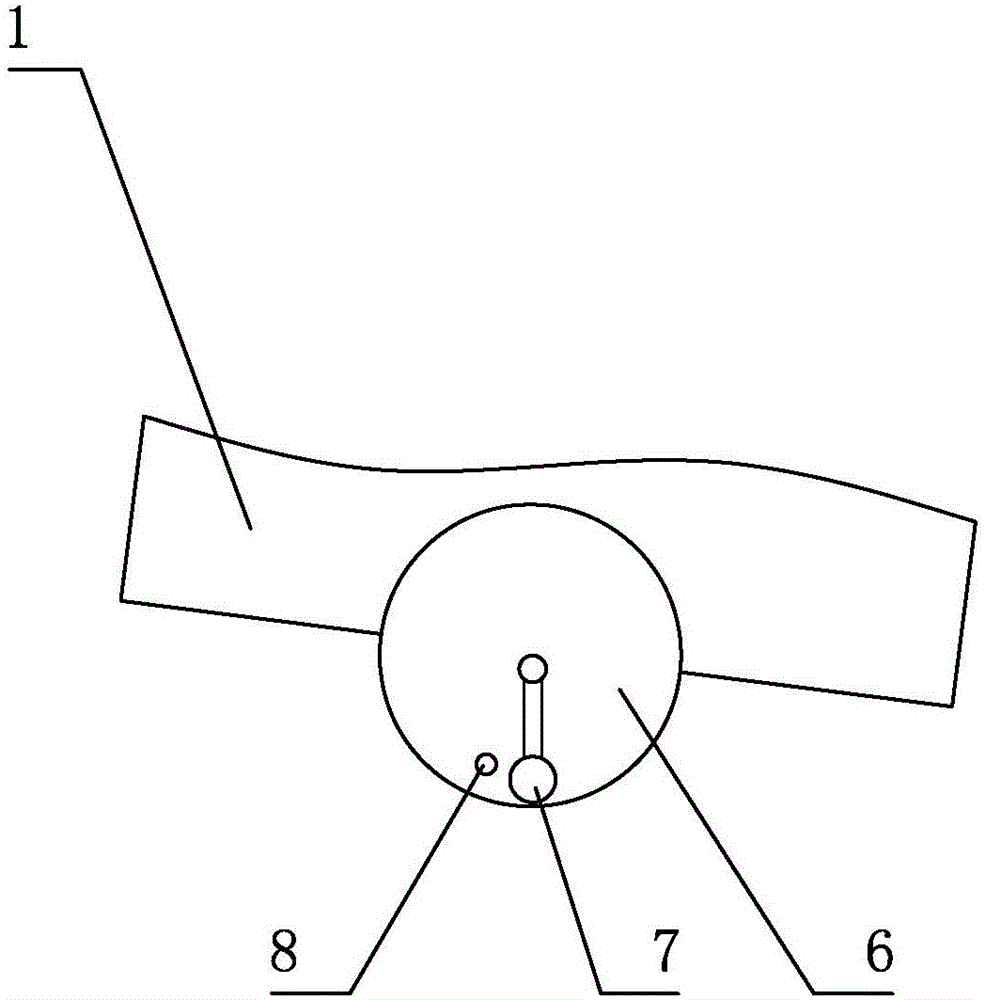

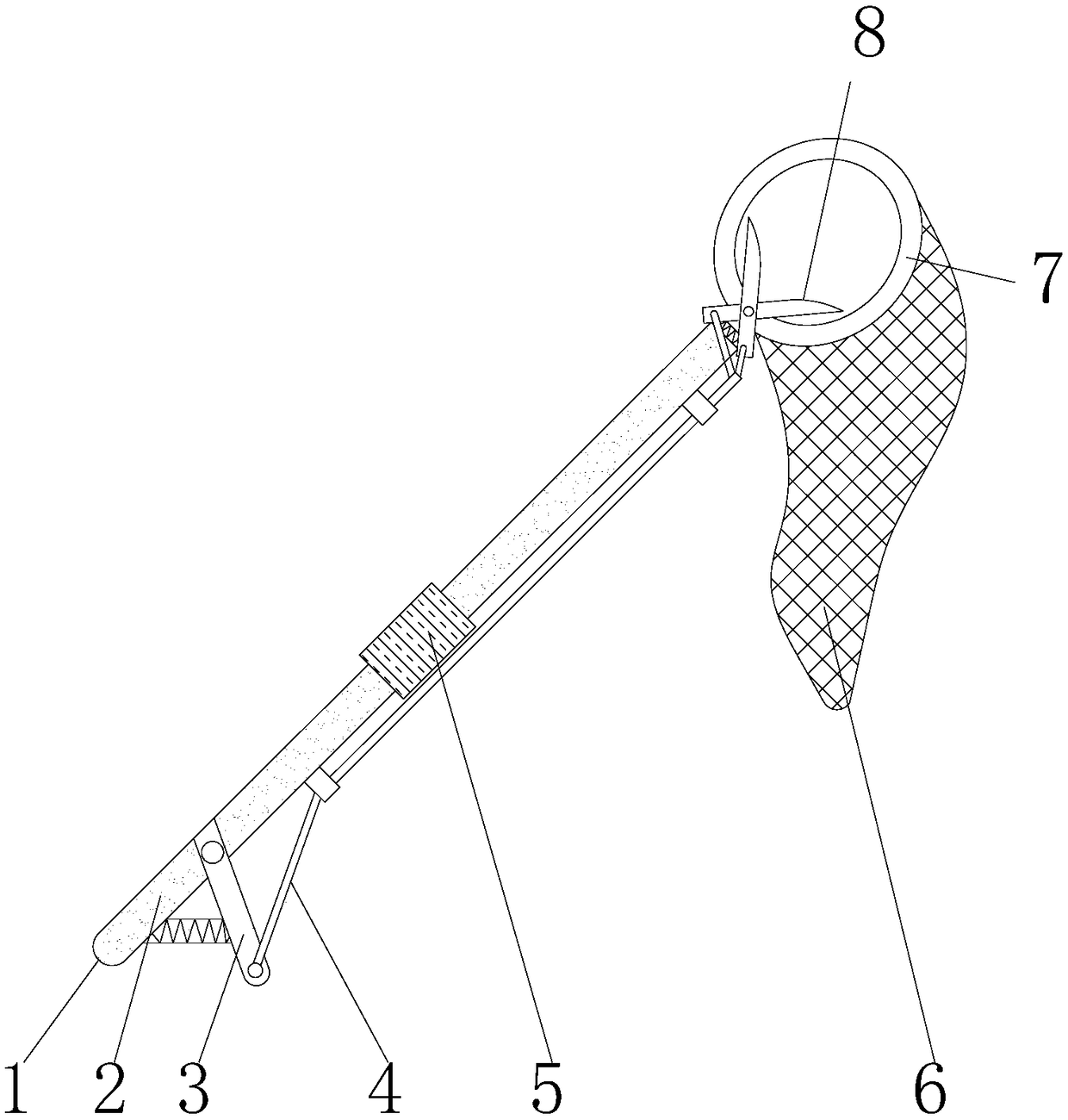

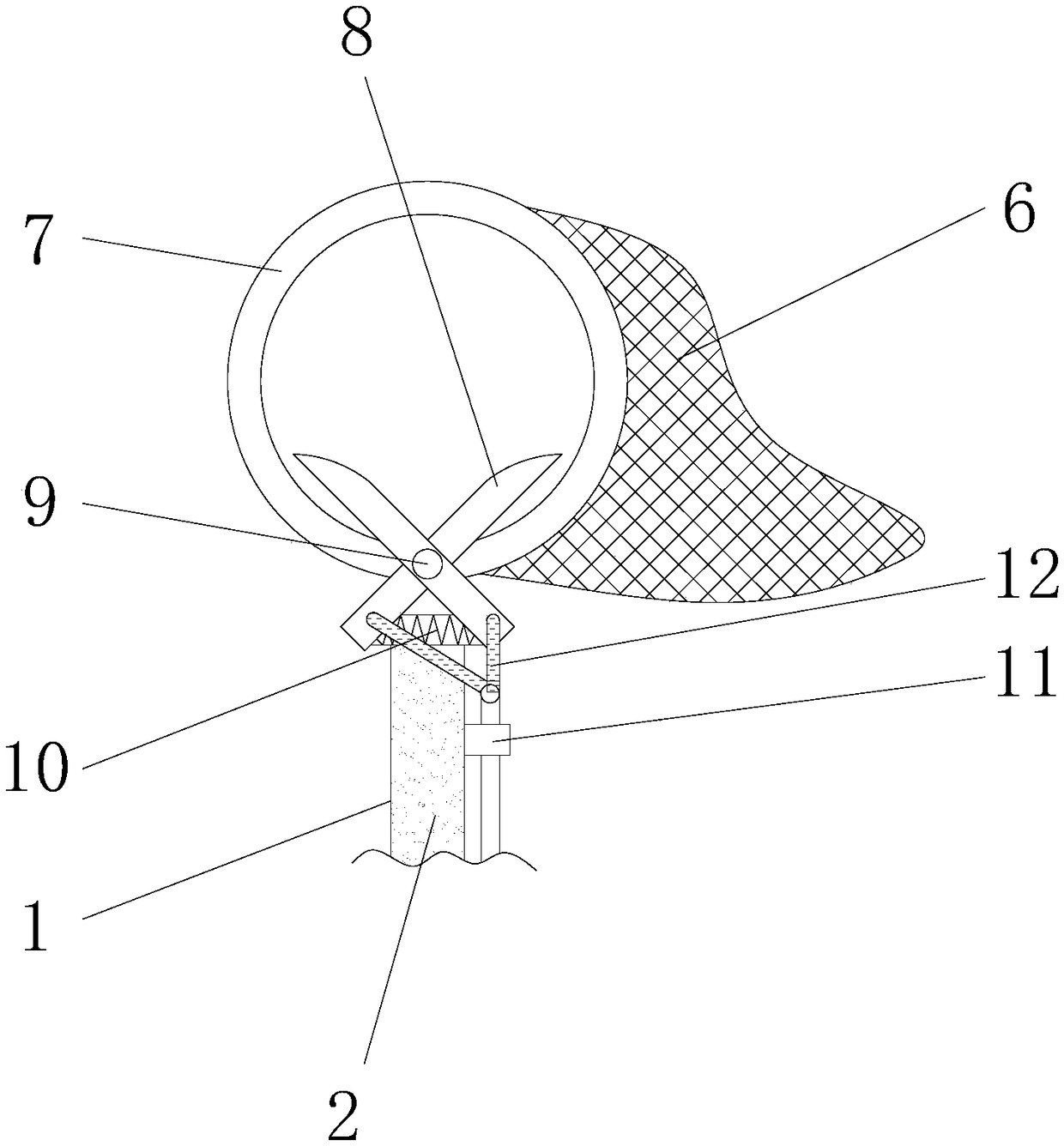

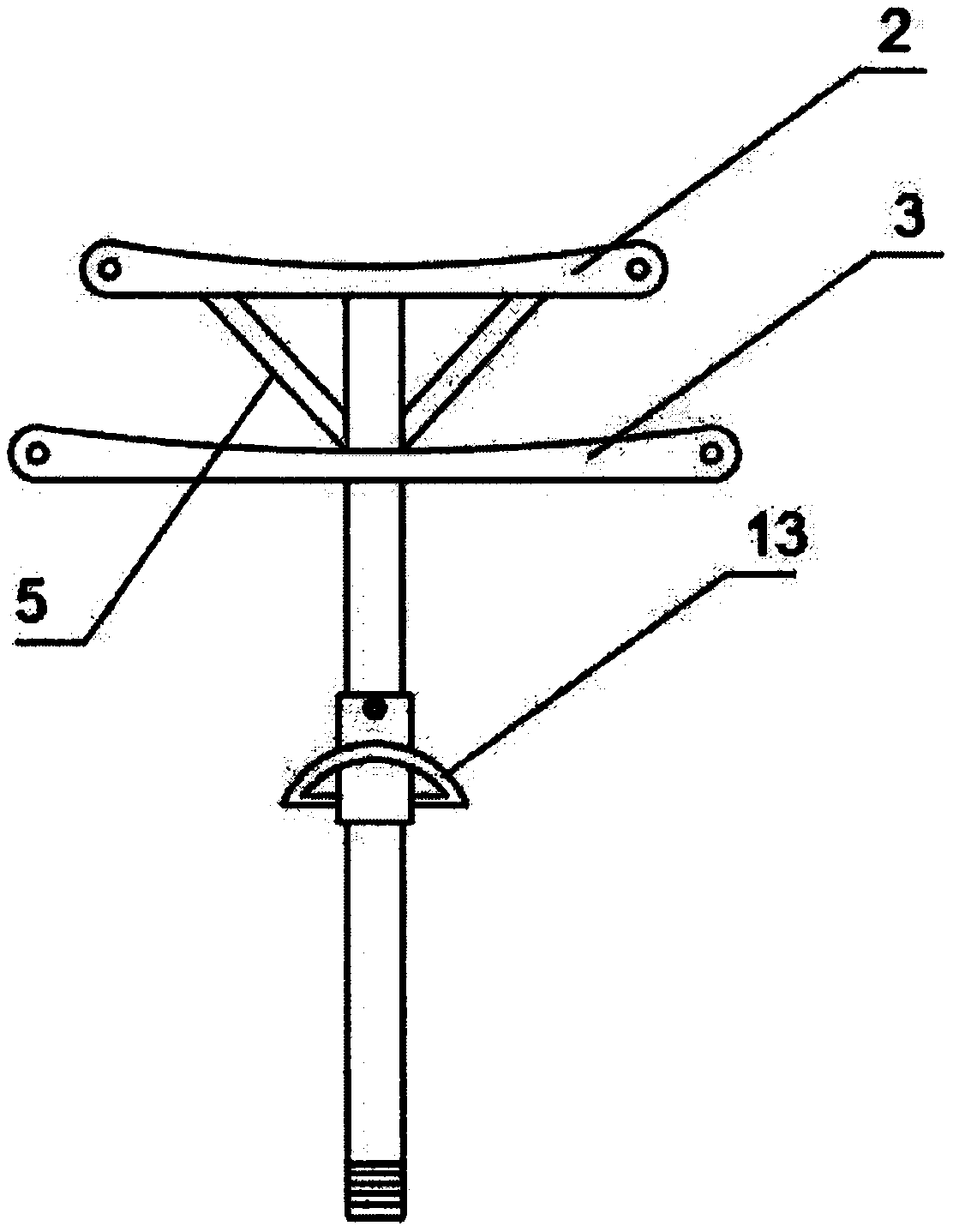

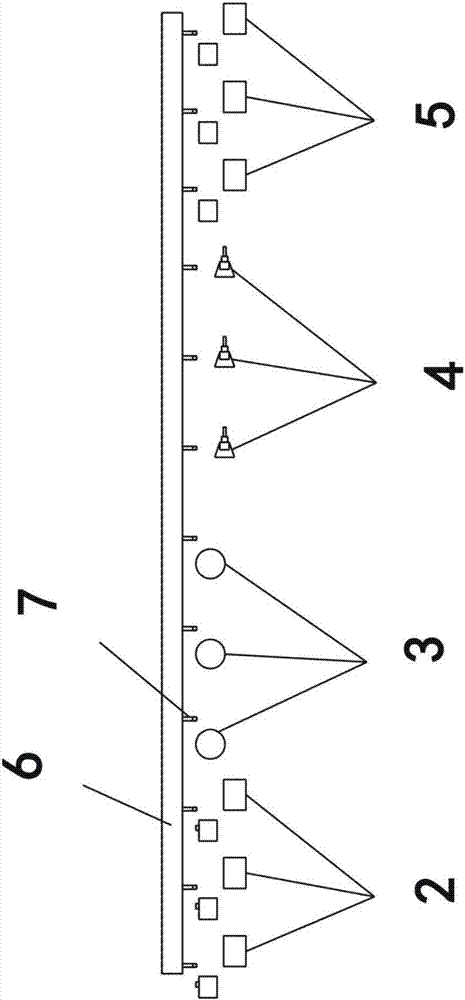

Multifunctional fruit picking device

The invention discloses a multifunctional fruit picking device. The multifunctional fruit picking device comprises a stretchable rod, a collecting holding rod is arranged at the bottom end of the stretchable rod, a first reset spring is arranged between the bottom end of the collecting holding rod and the stretchable rod, a plastic collecting net frame is installed at the bottom end of the stretchable rod, a collecting woven net bag is installed at the bottom end of the plastic collecting net frame, two collecting scissors are installed on the plastic collecting net frame, a fixing hole is formed in the stretchable rod, and a collecting pulling rope is arranged in the fixing hole. By means of the multifunctional fruit picking device, the problems that through an existing fruit picking device, picking efficiency is low, operation is complex, the picking height cannot be adjusted according to the actual fruit picking height, and the using effect is poor are solved.

Owner:魏佳怡

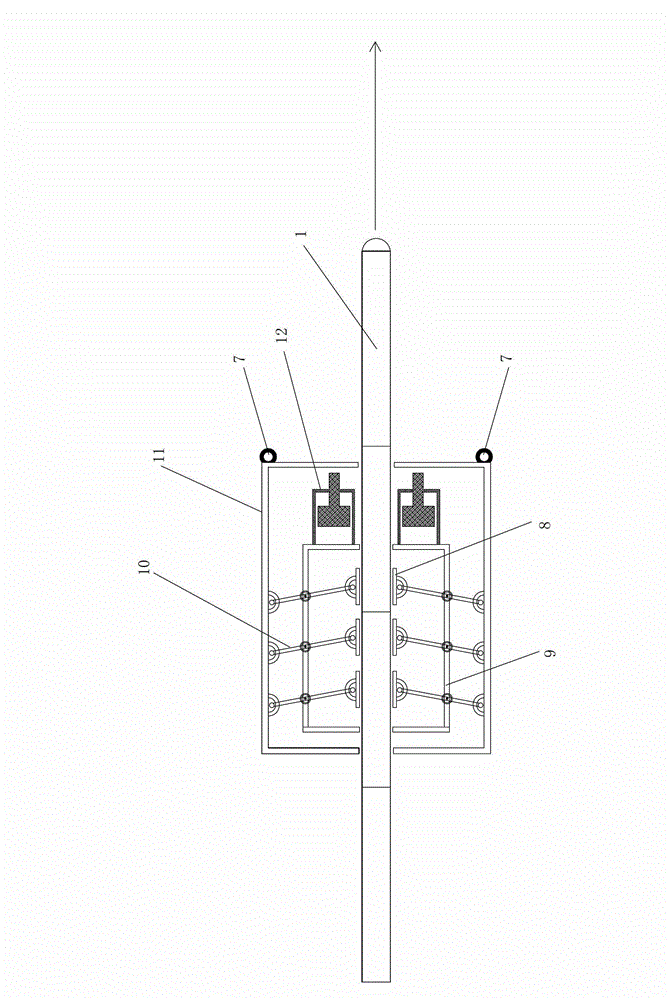

Robot gripper

The invention provides a robot gripper which comprises a mounting bracket, at least one electromagnetic suction disc, and at least one group of rotary clamping air cylinder group. The electromagneticsuction discs are arranged at the bottom of the mounting bracket; the rotary clamping air cylinder group comprises two symmetrically arranged clamping air cylinders, cylinders of the two clamping aircylinders are separately connected to two opposite side walls of the mounting bracket, piston rods of the two clamping air cylinders stretch out of the bottom of the mounting bracket downward; the piston rods of the clamping air cylinders can rotate between a clamping position for clamping a workpiece and a releasing position for releasing the workpiece. The robot gripper provided with the electromagnetic suction discs and the rotary clamping air cylinders has the electromagnetic adsorption gripping and mechanical gripping function. Compared with the prior art, the gripping force of the robotgripper is enhanced to a relatively great extent, so that the workpiece is gripped stably.

Owner:无锡威卓智能机器人有限公司

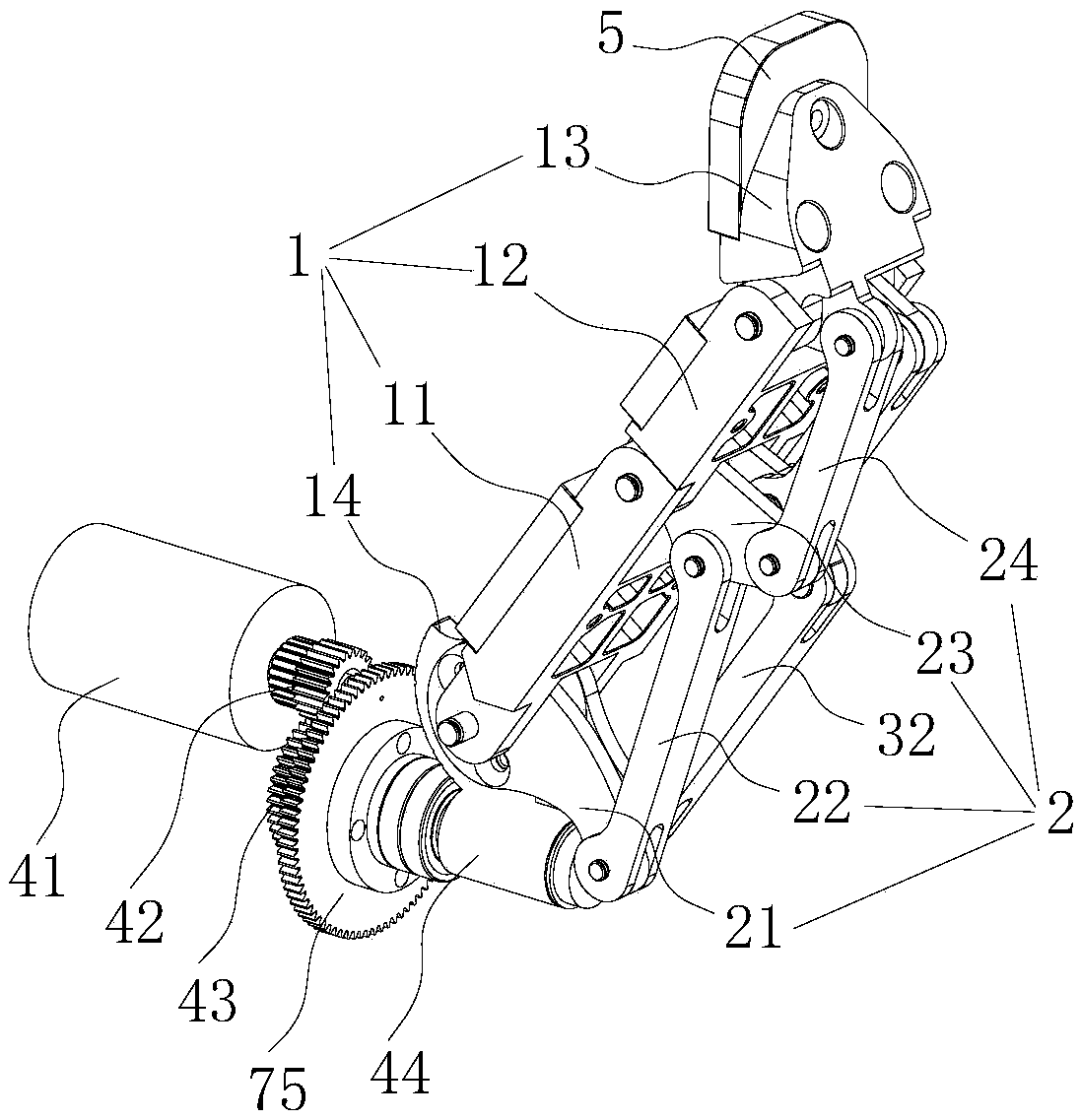

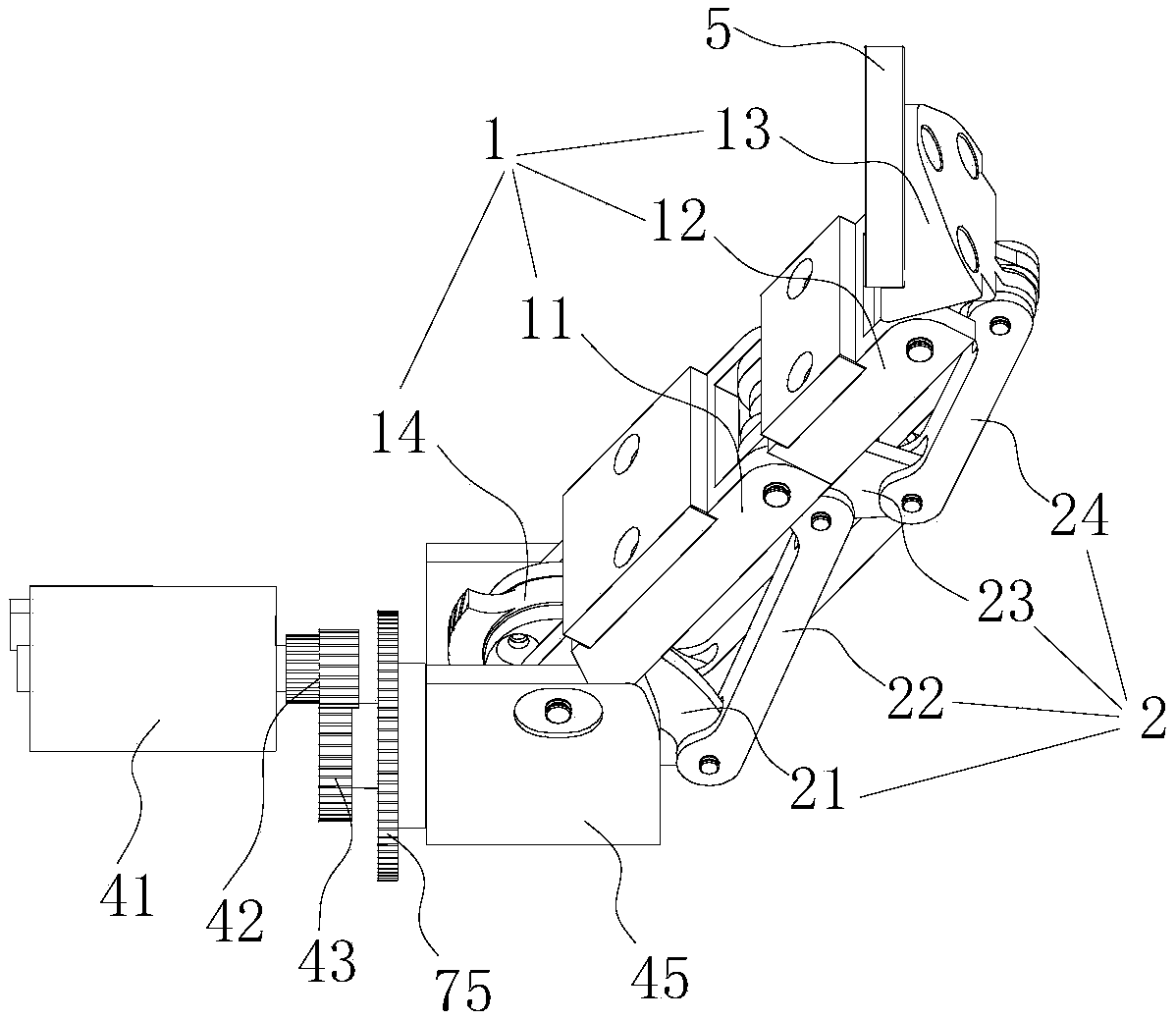

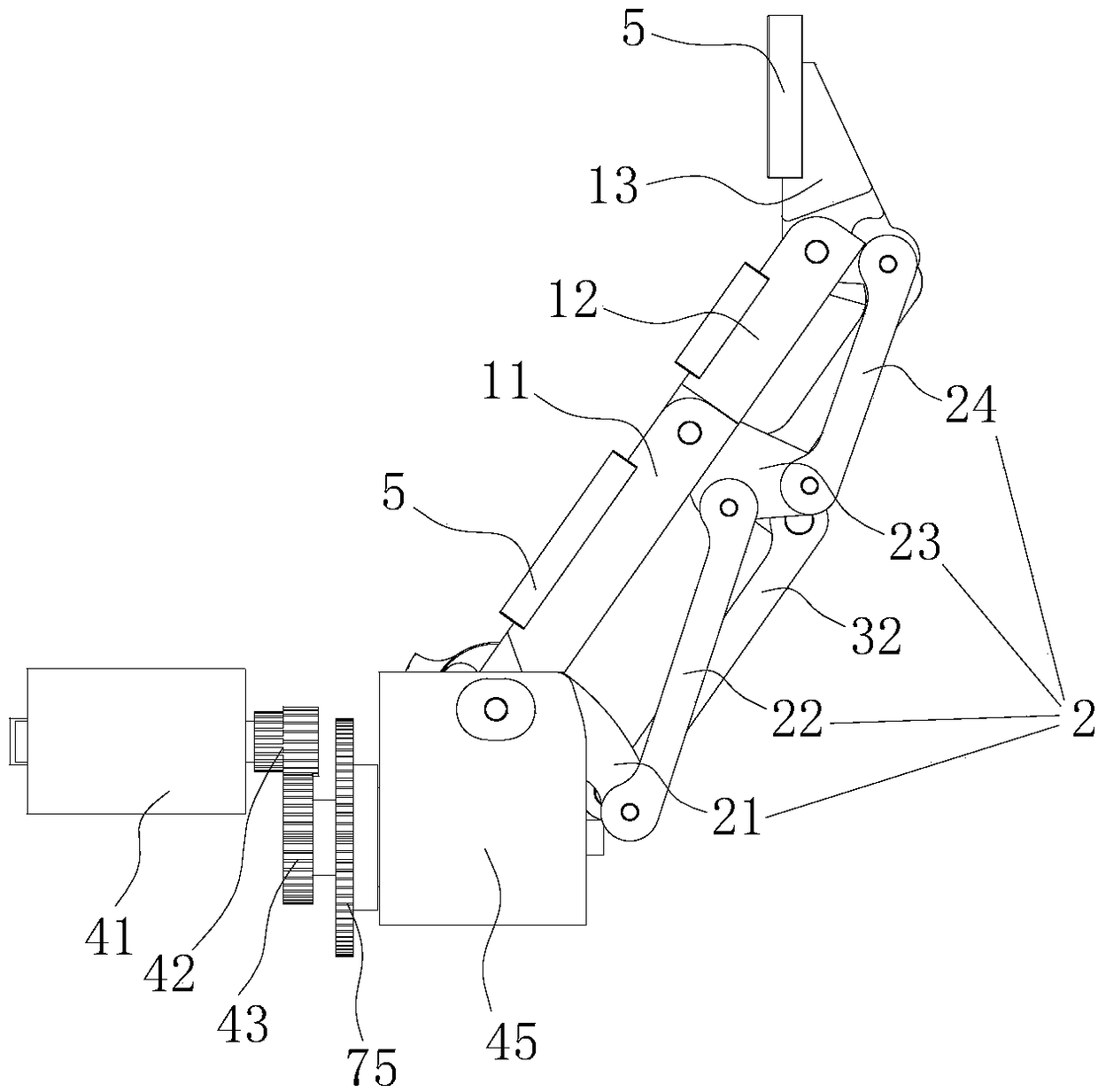

Mechanical finger and manipulator including same

PendingCN109202945AImprove gripPlay the role of power transmissionGripping headsFinger jointLeft fingers

The invention relates to the technical field of automation equipment, and aims at providing a mechanical finger and a manipulator including the same. The mechanical finger in the technical scheme comprises a finger joint group, a force guiding traction chain driving the finger joint group to bend, a self-locking traction chain driving the finger joint group to bend and self lock, and a grasping driving mechanism driving the force guiding traction chain and the self-locking traction chain to bend. The manipulator comprises three mechanical fingers and a fixing seat, wherein the three mechanicalfingers are two left fingers located at one side of the fixing seat and a right finger located at the other side of the fixing seat; three grasping driving mechanisms in the three mechanical fingersare two first grasping driving mechanisms located at one side of the fixing seat and a second grasping driving mechanism located at the other side of the fixing seat; and the fixing seat is fixedly connected with first driving devices in the first grasping driving mechanisms and the second grasping driving mechanism. Thus, a workpiece can be stably grasped.

Owner:顺诠达(重庆)电子有限公司

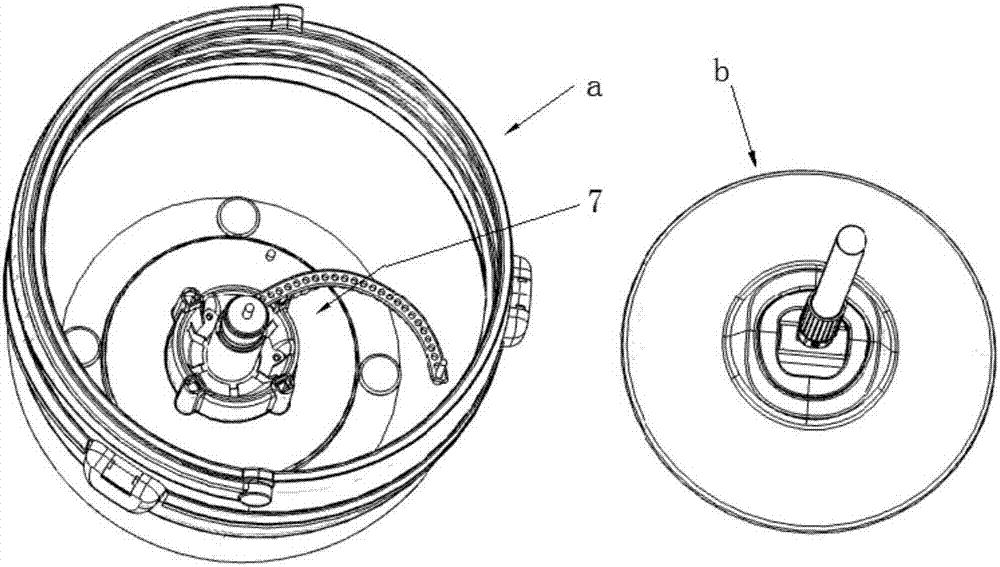

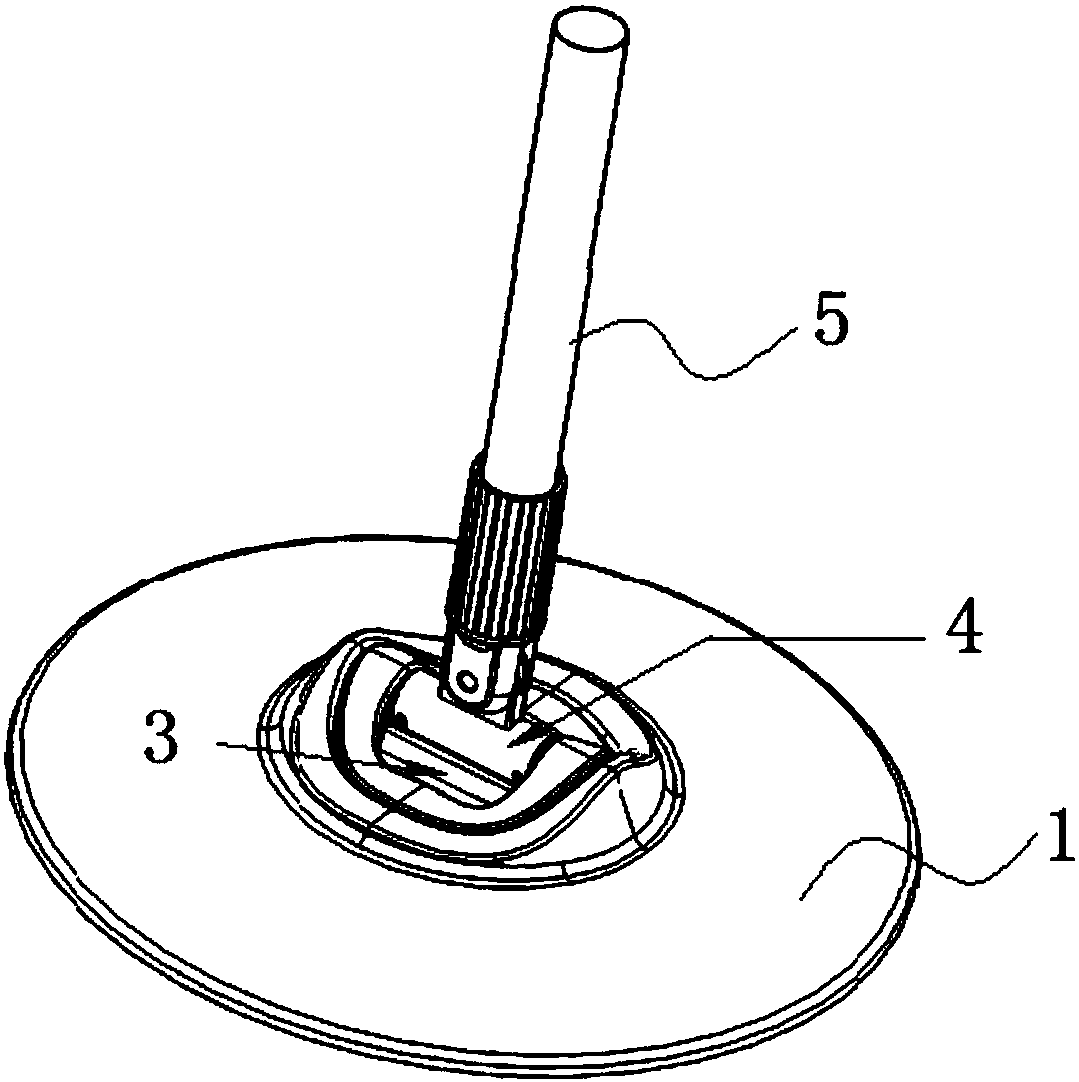

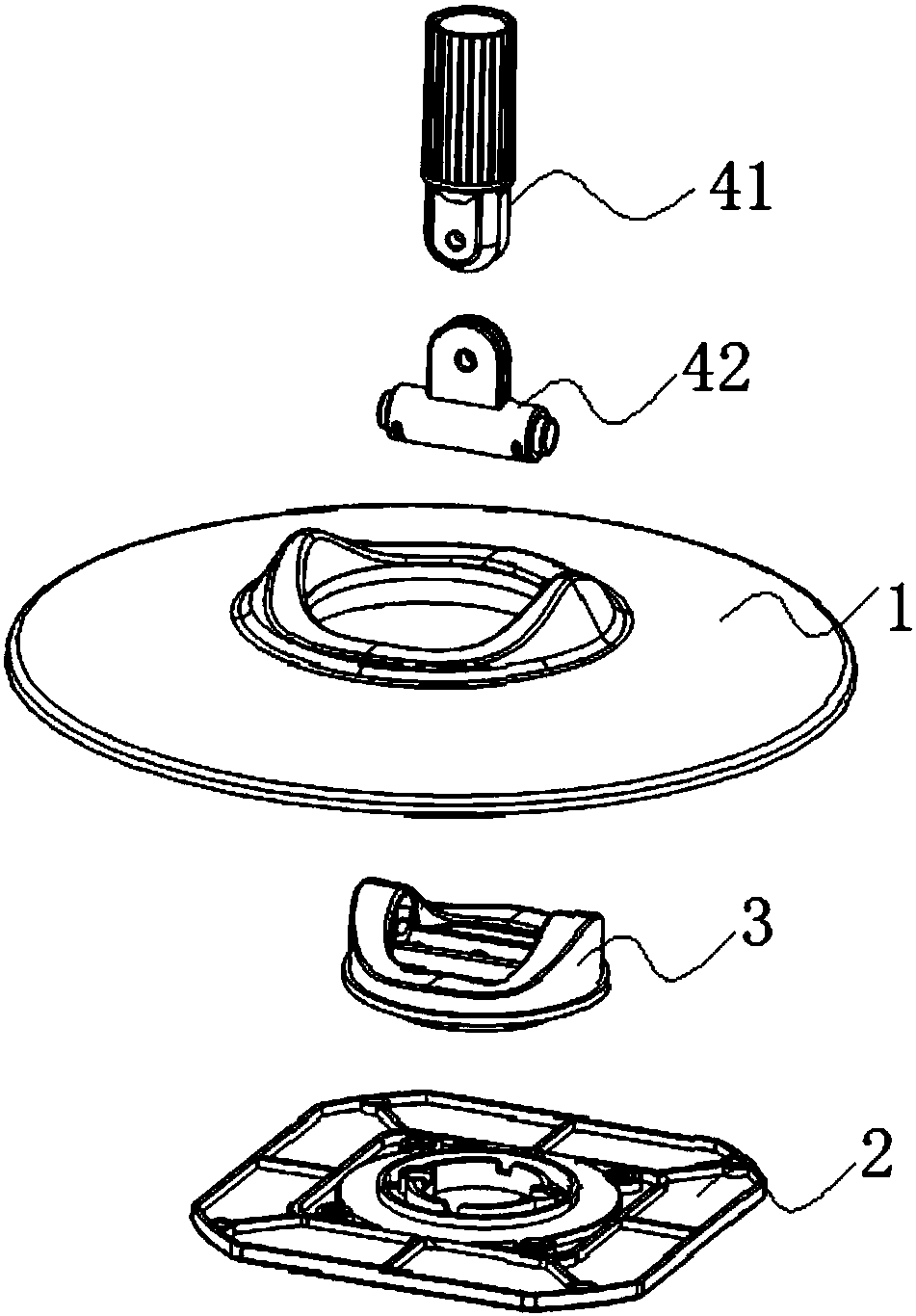

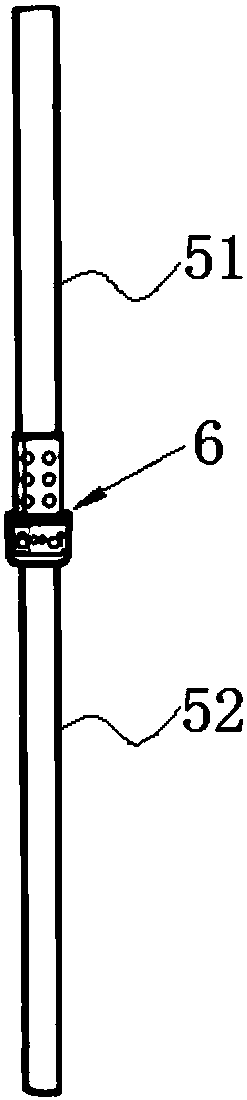

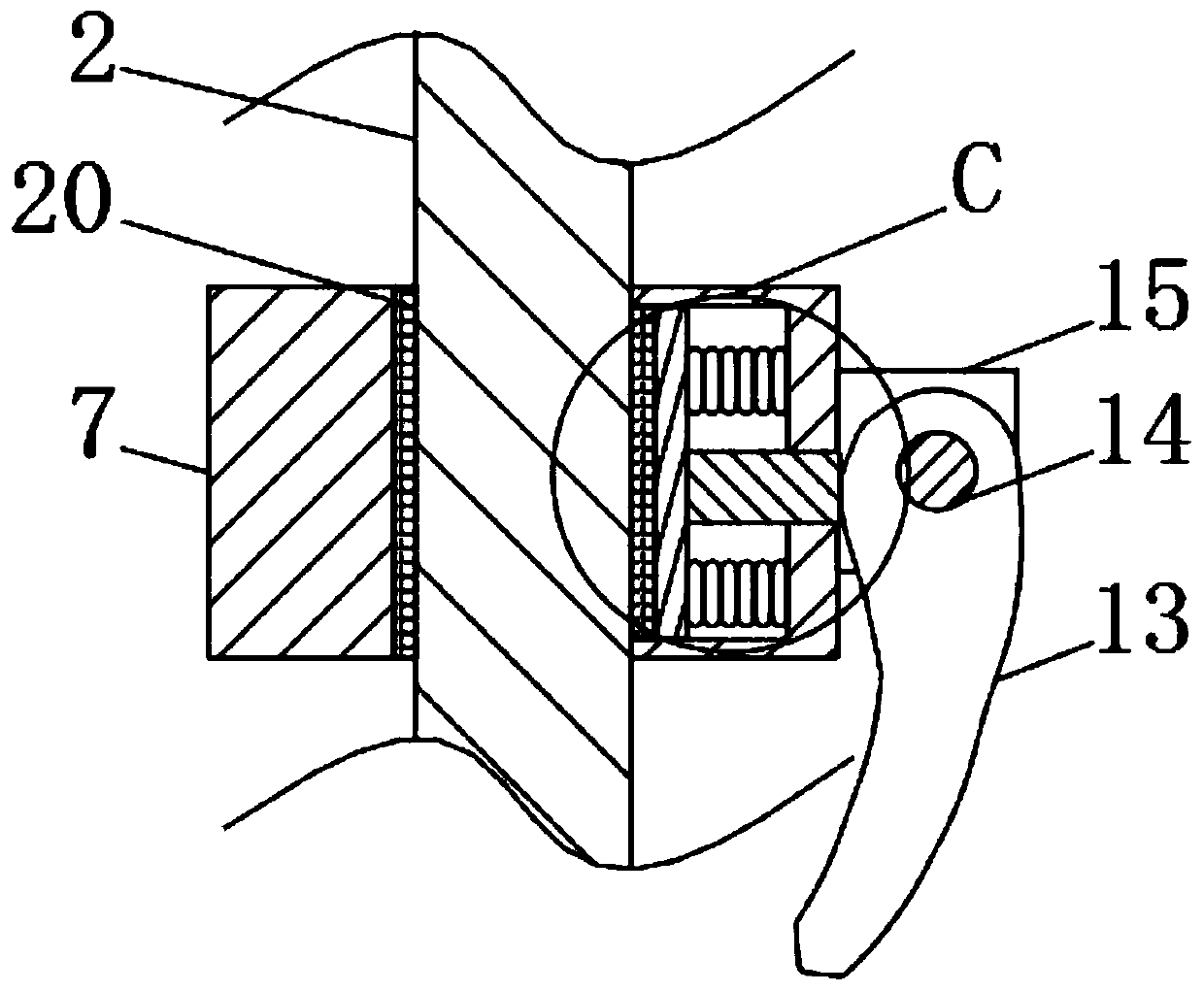

Long-handle cleaning tool

PendingCN108209775AEasy to adjust the angleQuick snap assemblyCarpet cleanersFloor cleanersRotational jointSurface plate

The invention discloses a long-handle cleaning tool, which comprises a panel, a connecting seat and a telescopic rod, and further comprises a rotational joint, wherein the rotational joint comprises afirst rotary piece and a second rotary piece; the first rotary piece is rotatably connected to the second rotary piece; the second rotary piece is rotatably connected to the connecting seat; a rotating shaft of the first rotary piece is perpendicular to a rotating shaft of the second rotary piece; the first rotary piece is connected to the telescopic rod; a wiping rag is arranged at the lower side of the panel; the telescopic rod comprises an outer rod body and an inner rod body; and the outer rod body and the inner rod body mutually sleeve. According to the long-handle cleaning tool providedby the invention, a locking structure of the telescopic rod is simple; moreover, convenient angle adjusting and locating can be achieved between the telescopic rod and the panel, so as to adapt to various cleaning angles during cleaning; therefore, the long-handle cleaning tool is applicable to a mop and other cleaning tools having similar requirements; and in addition, the wiping rag is effectively fixed to a base plate of the mop by a lower panel via a fixing claw, so that the service life of the mop is prolonged.

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

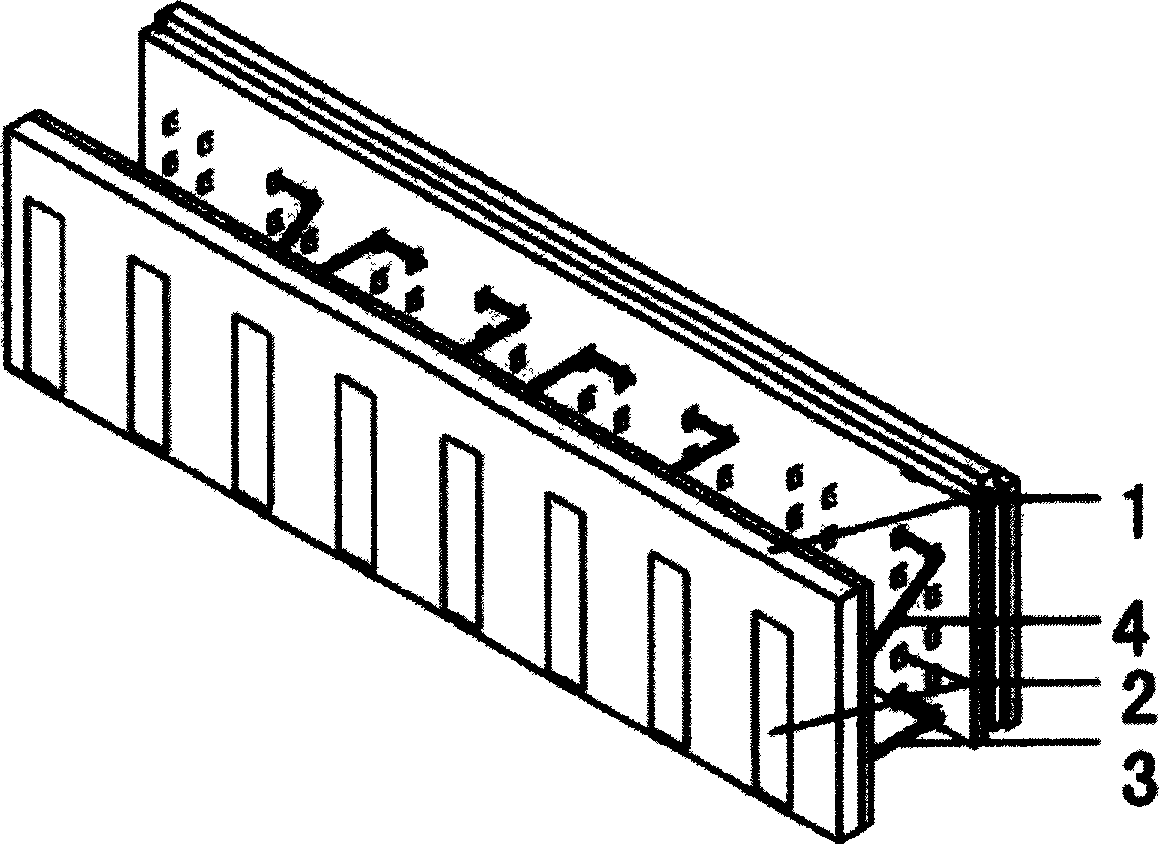

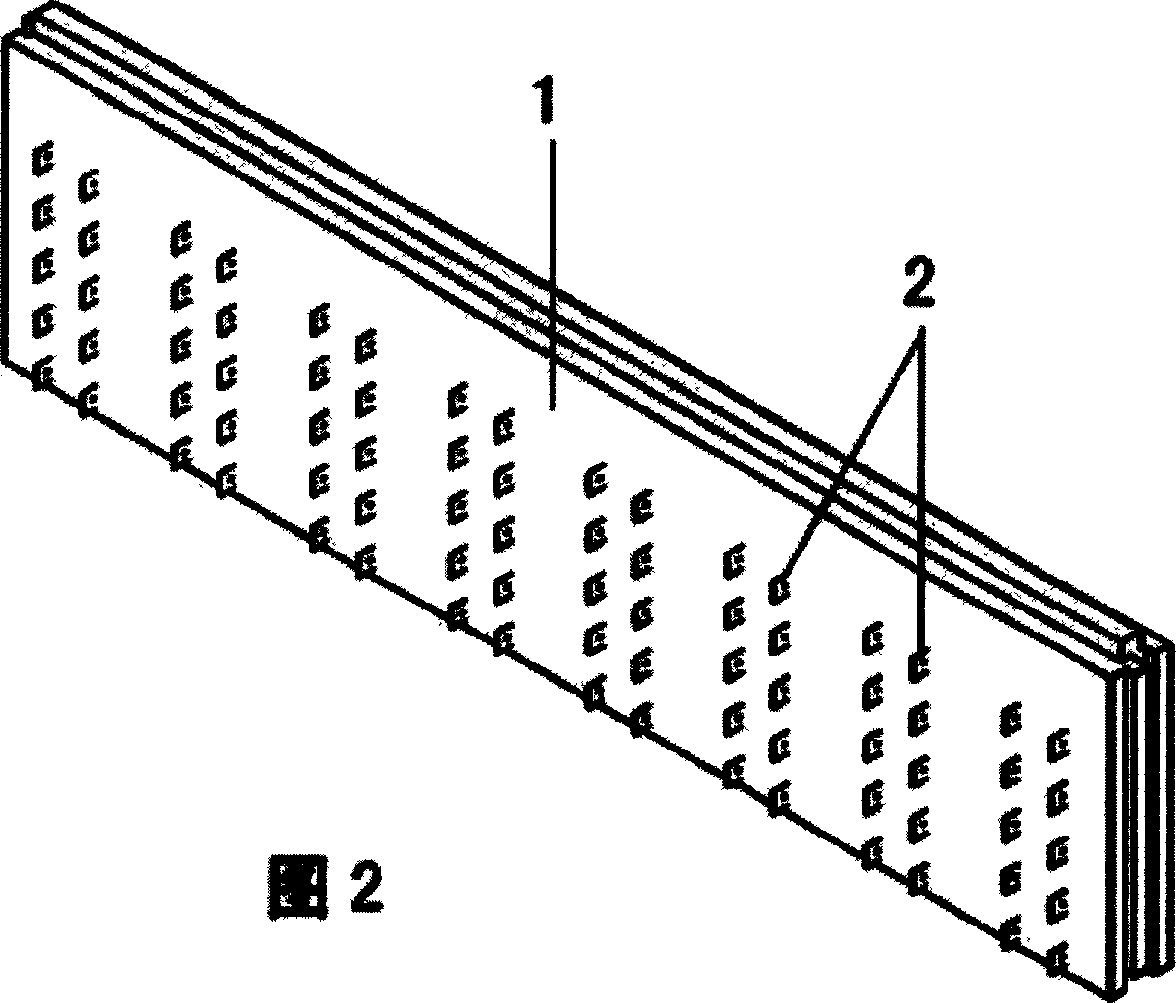

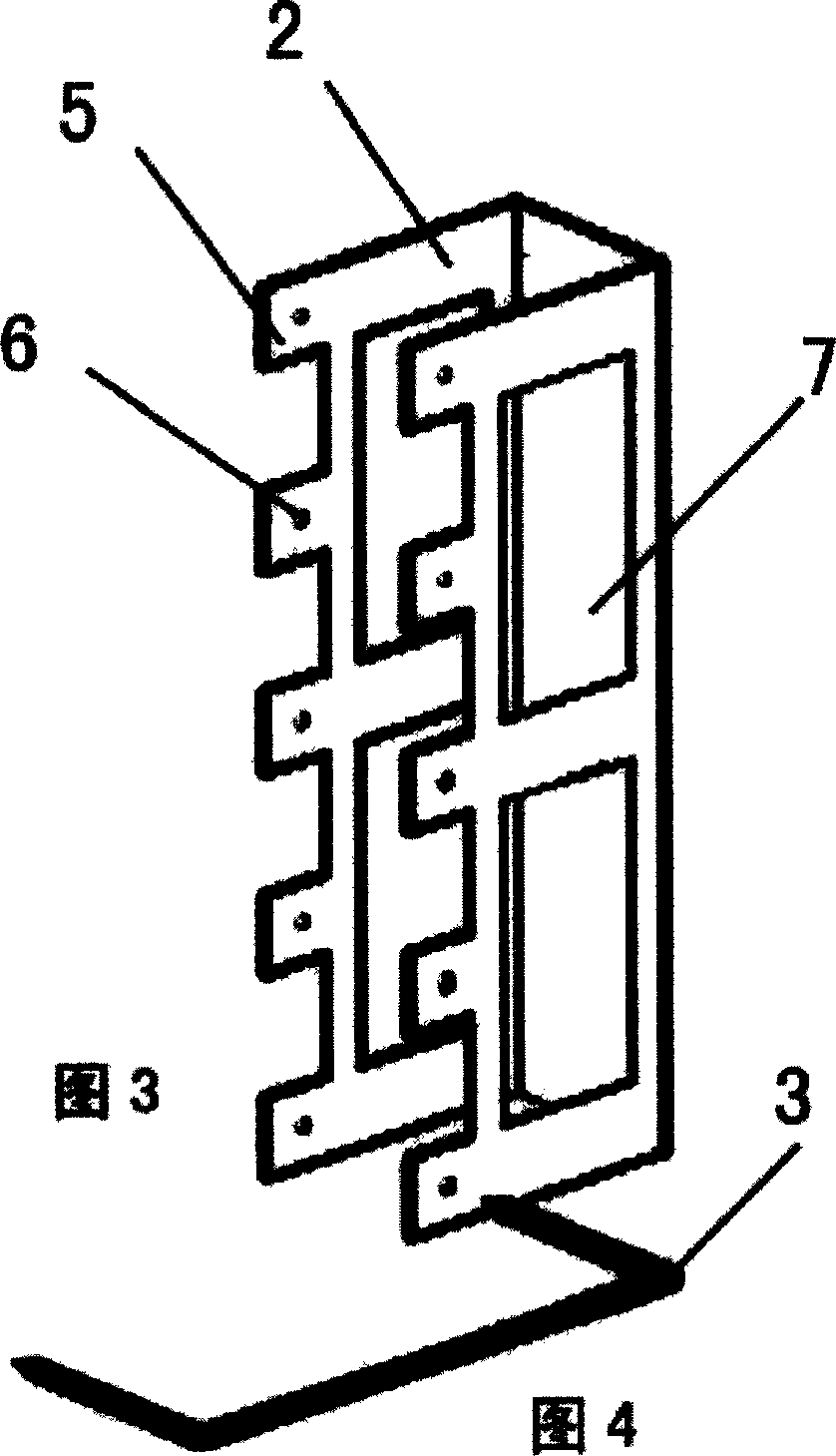

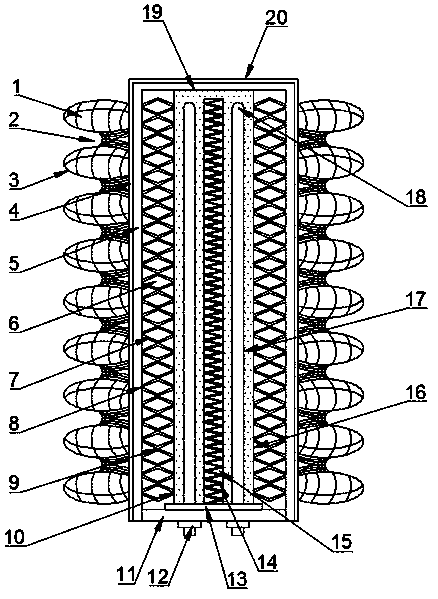

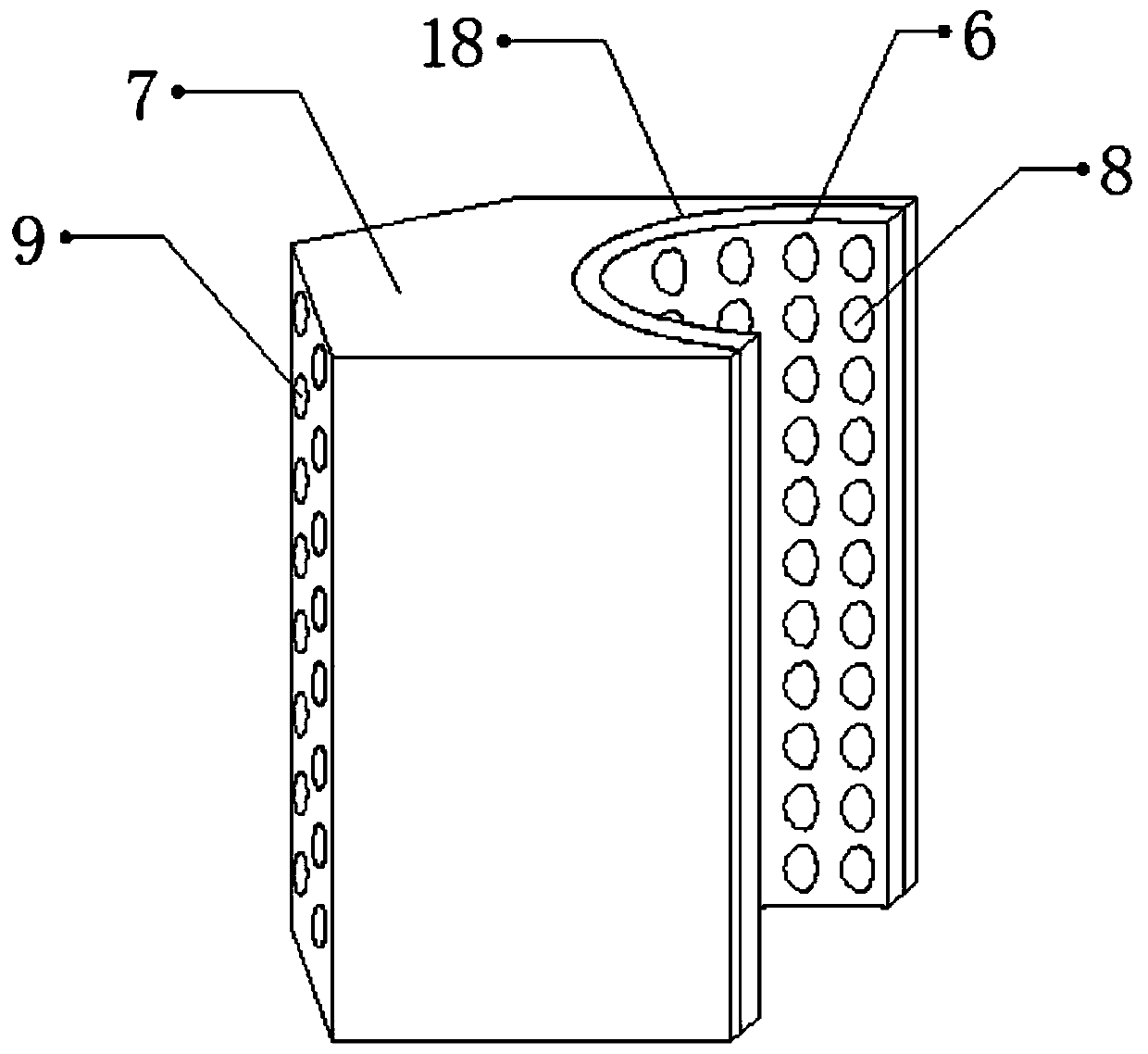

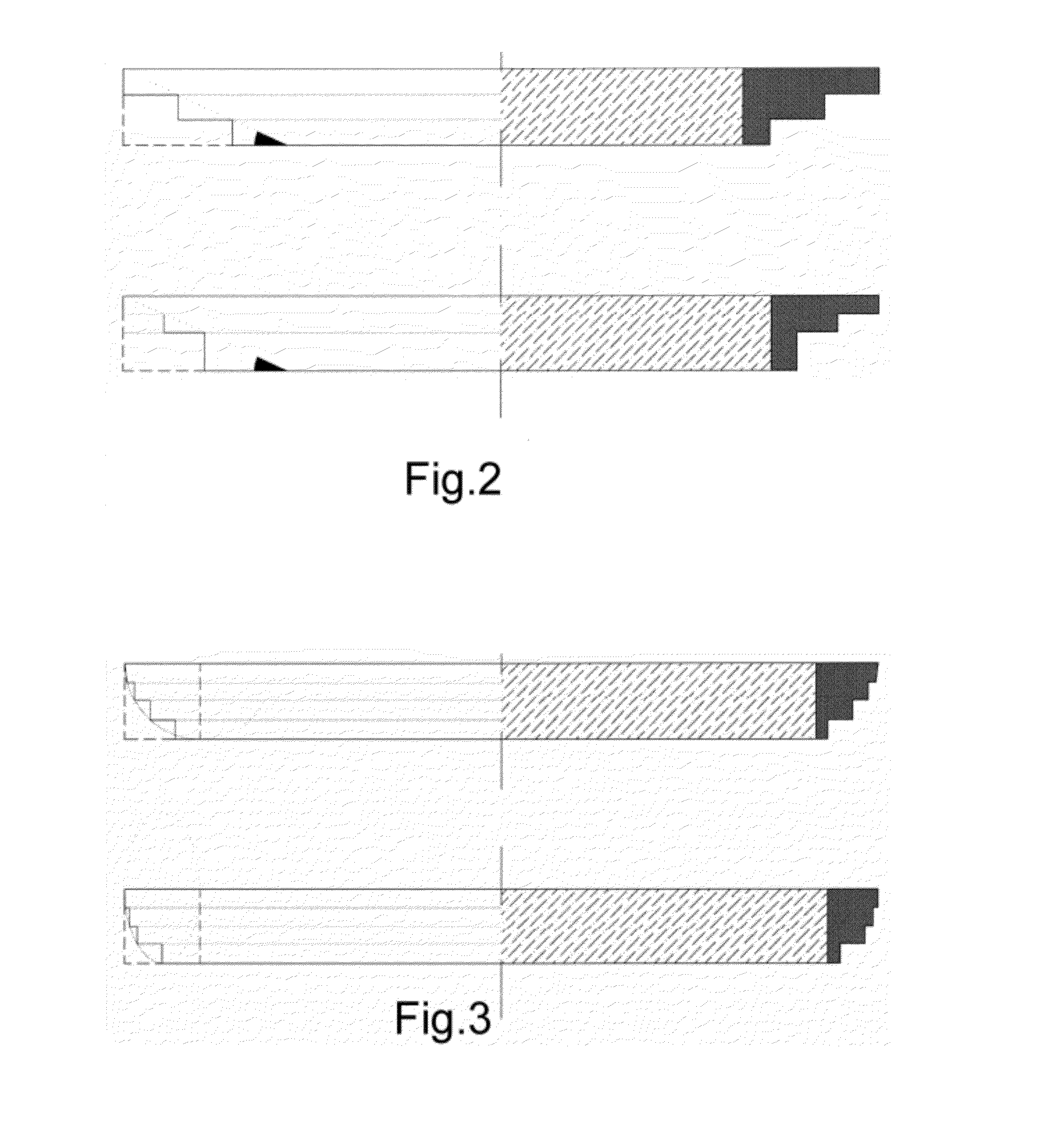

Built-up form for heatretaining compoiste concrete wall body

InactiveCN1687547AIncrease gripImproves integrity and strengthWallsForms/shuttering/falseworksMultiple functionPolystyrene

This is a kind of composite heat insulation concrete wall body combinatorial template. It makes two pieces of polystyrene foam boards equipped parallel as side template, inside which places steel pieces. Between the two boards joints linking ribs. Its two rows of inside set steel pieces are opposition, distribute in even interval and vertically covered in the side template of the polystyrene foam boards. Its cross section is 'íÃ' shape, and the edges of the two bending surface have accidented sockets, on which leaves through holes. The accidented sockets and through holes bare their heads at the inner of the template of the polystyrene foam boards. The connecting rib curved hooks at both ends are respectively get through the through holes of the inside set steel pieces at both sides. It ulteriorly enhances the grasping and wrapping force of the inside set steel pieces and polystyrene materials. It is convenient to provide fixing points for inner and outer wall decoration, and ulteriorly enhances the integrity and intensity. It also has the following advantages: it's permanent heat preservation template having several functions as heat preservation, sound insulation and water-proof.

Owner:朱秦江

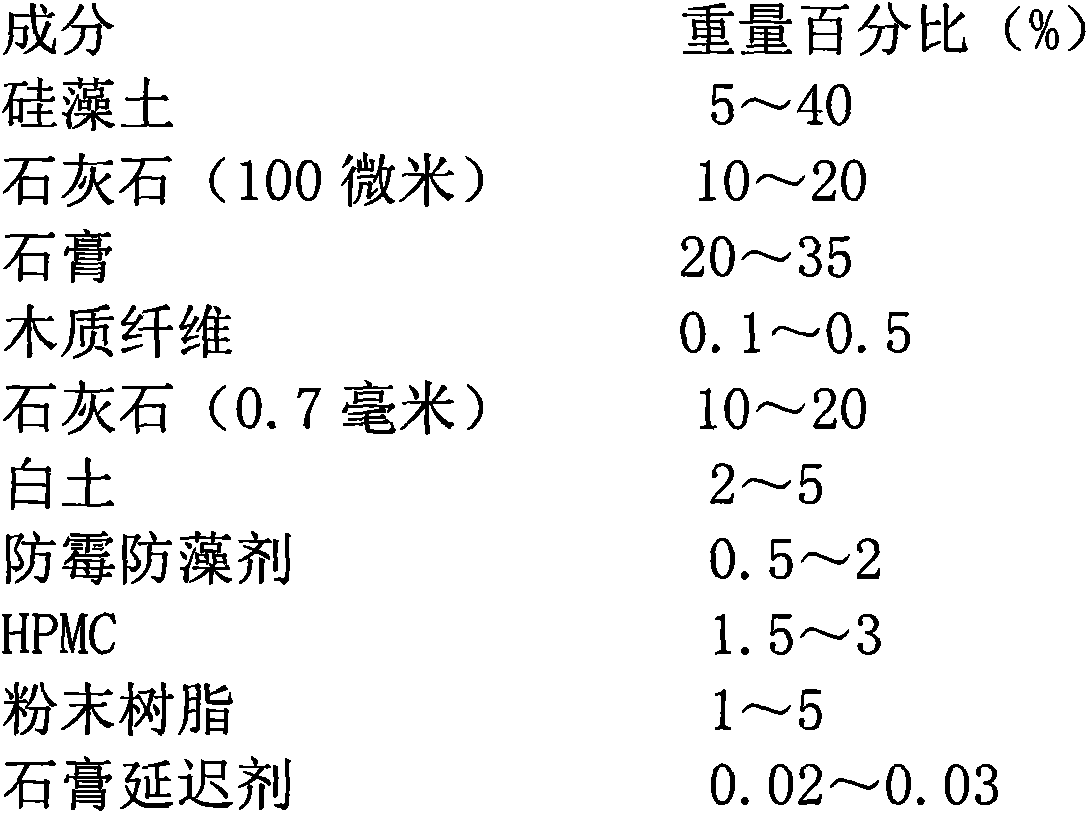

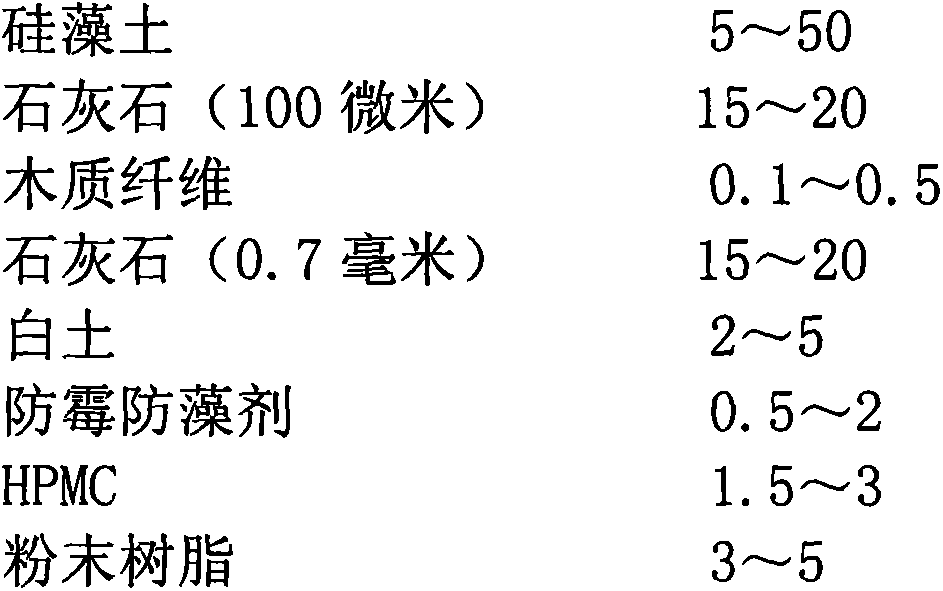

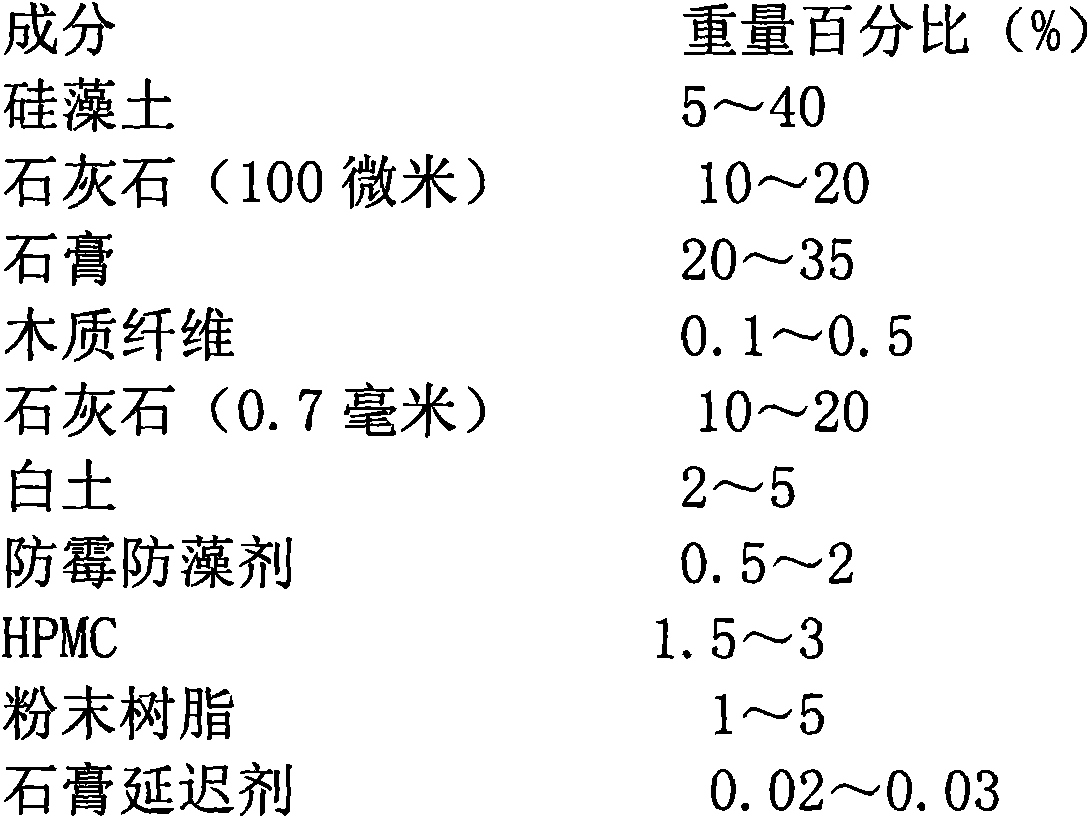

Substrate material capable of adjusting moisture and manufacturing method of substrate material

The invention discloses a substrate material capable of adjusting moisture and a manufacturing method thereof, and discloses a substrate material for painting indoor walls of buildings. The substrate material contains sintered and non-sintered diatomite ingredients and auxiliary materials, such as gypsum, limestone, wood fiber, carclazyte, anti-mildew algicide, hydroxypropyl methylcellulose and powdered resin, and the like. The method is simple and easy to implement. Since having reasonable material proportion, the substrate material has strong crack resistance, adhesion, abrasion resistance, moisture absorption and moisture releasability; the root cause is as follows: the diatomite is used as the main raw material; since the diatomite is porous and has big specific surface area, the diatomite can store moisture and has excellent moisture retention; the moisture can be released in dry condition. Since having wood fiber and powdered resin, and the like, the crack resistance and abrasion resistance are strengthened; the fastness of the substrate material to a wall surface is improved. Moist and mildew can be effectively avoided by adding the anti-mildew algicide, and thus indoor environment is more environment friendly. The substrate material capable of adjusting moisture is ideal, and solves the problems of the existing substrate material.

Owner:营口盼盼硅藻材料集团有限公司

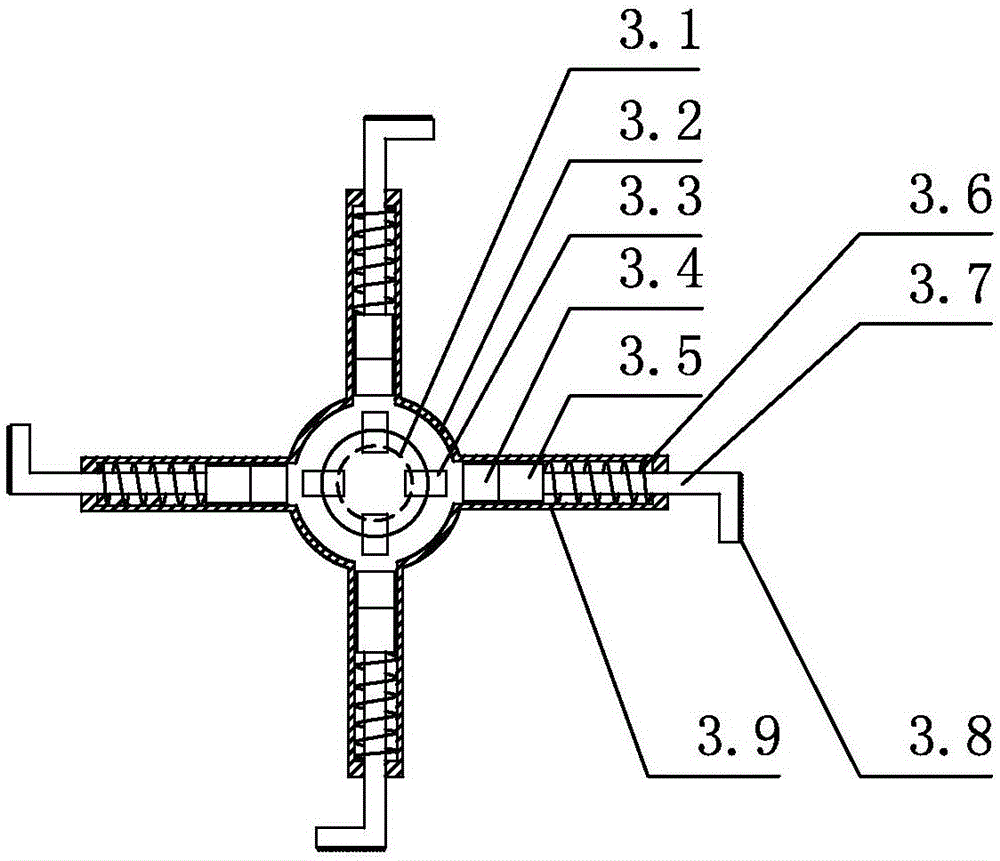

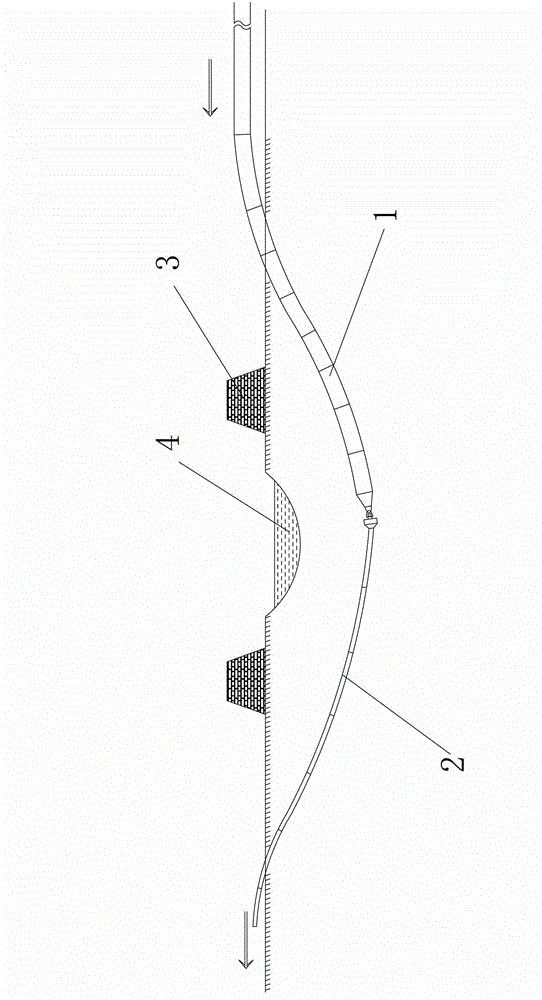

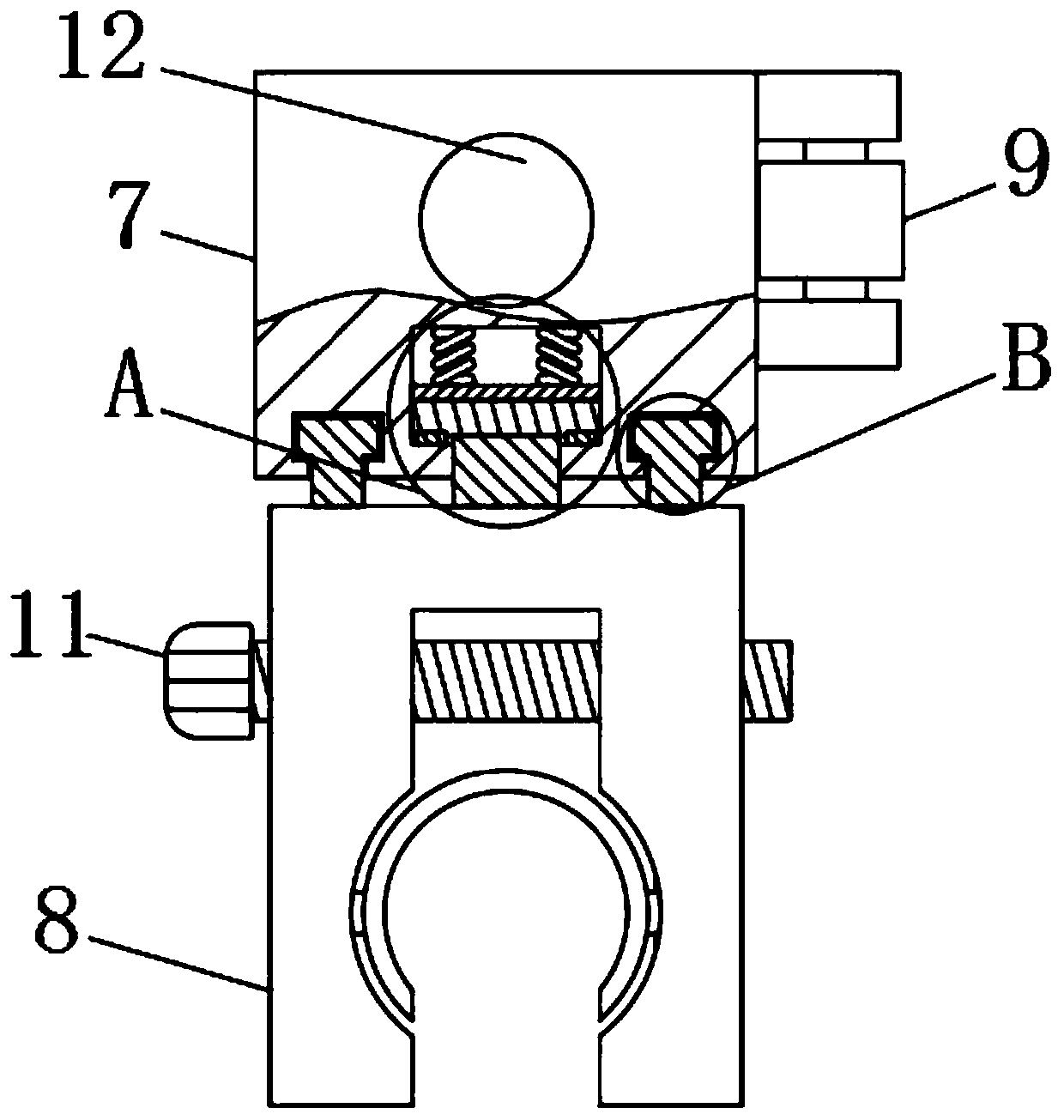

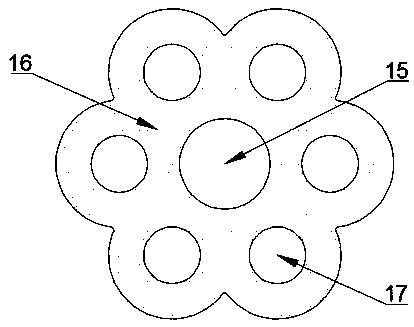

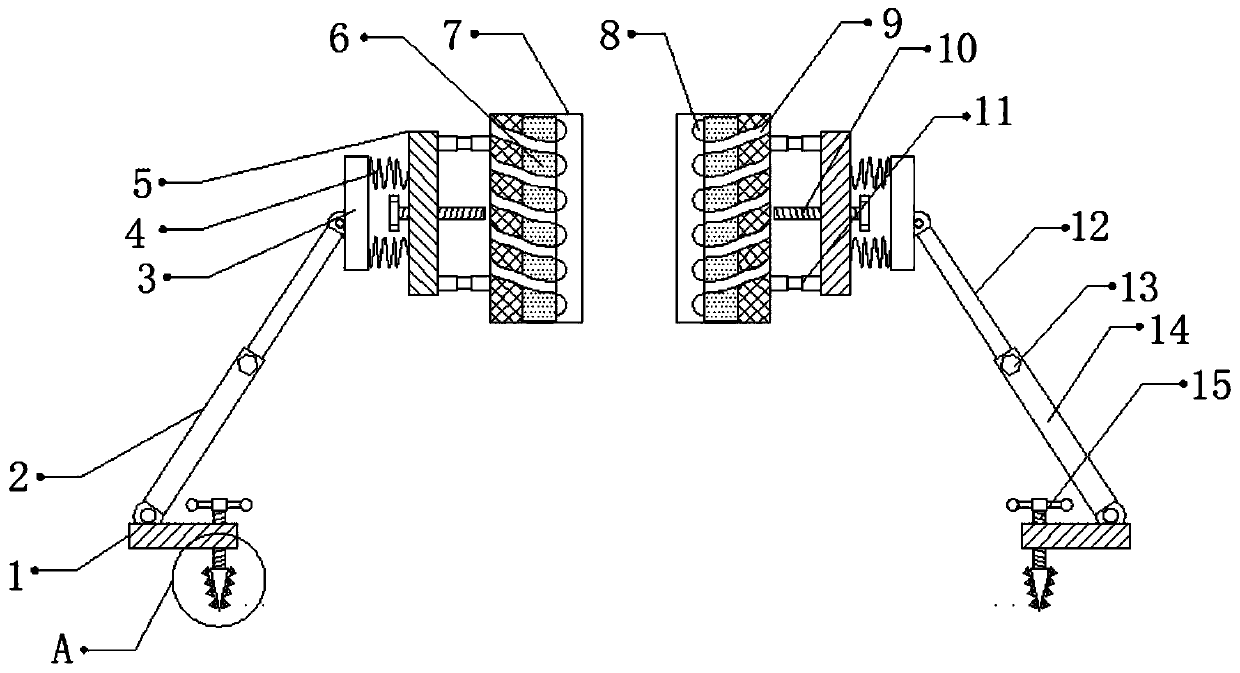

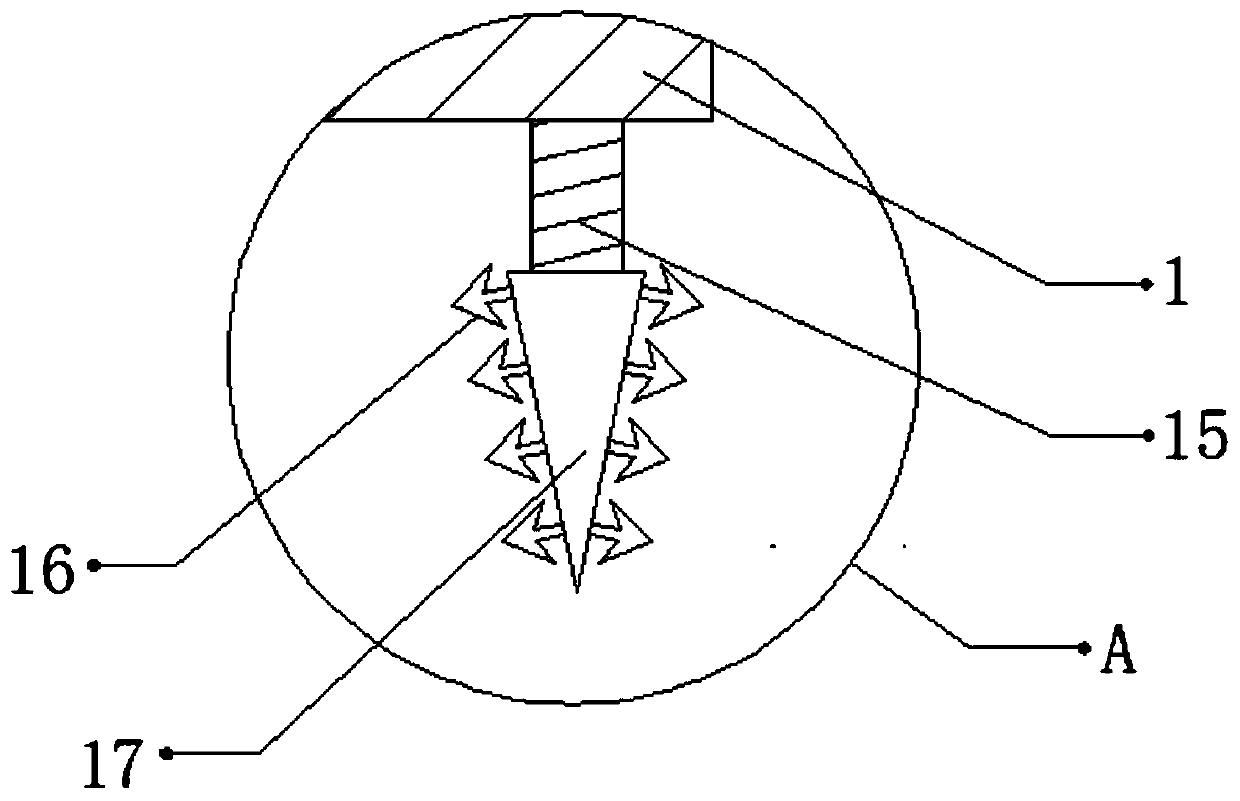

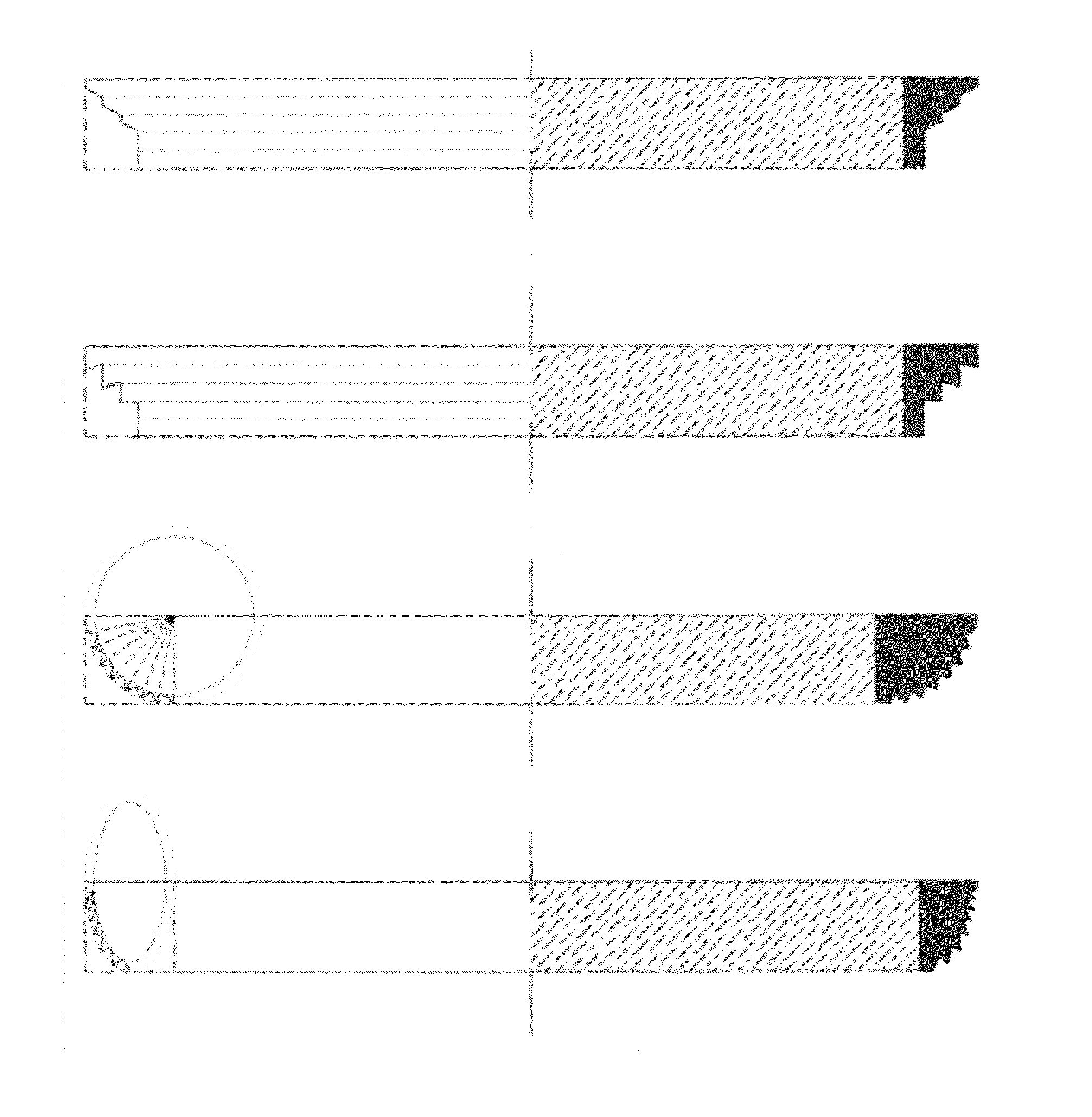

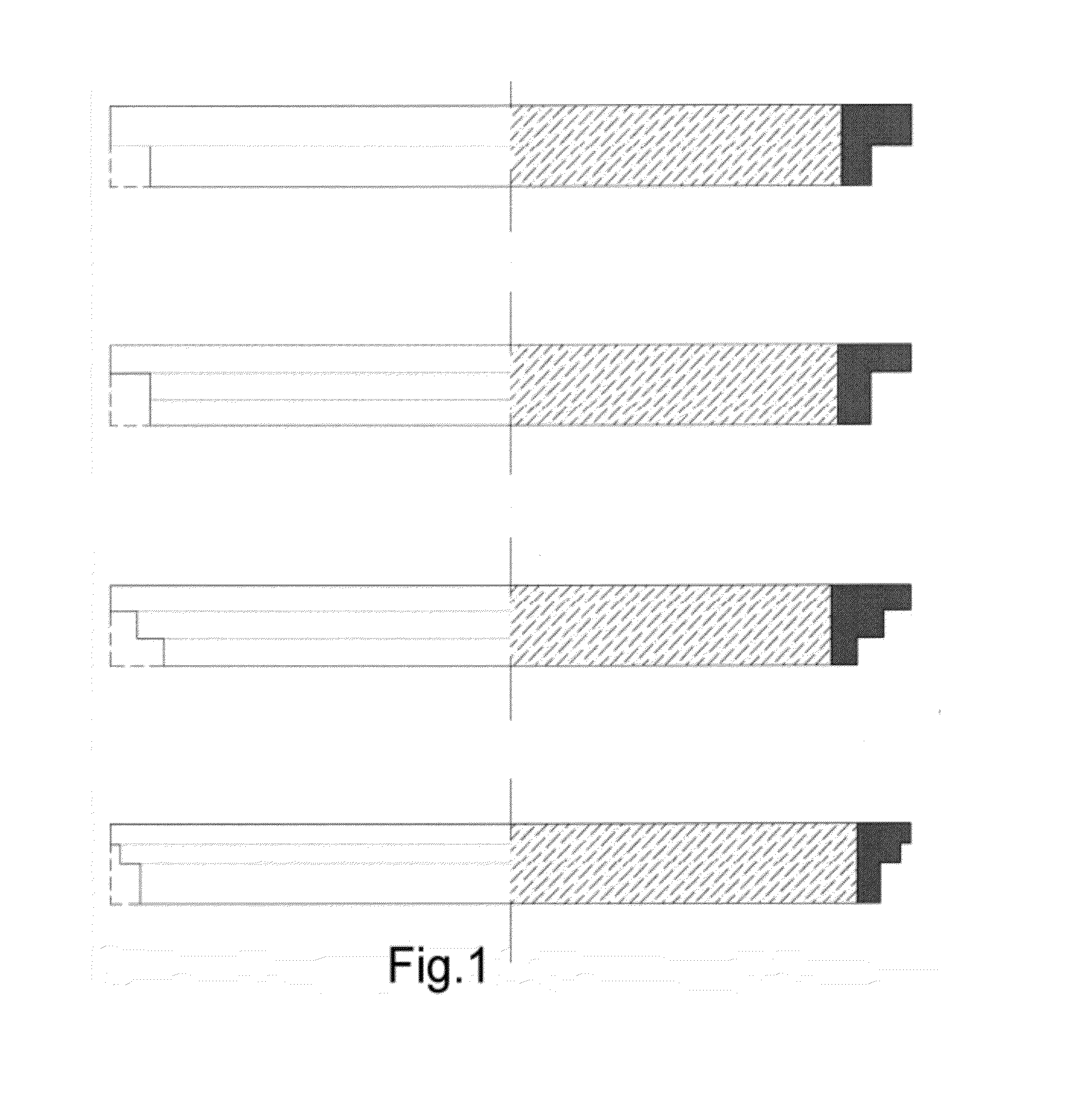

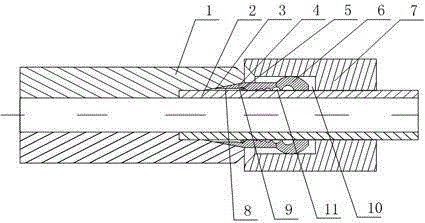

Pipeline self-locking, clasping and pushing device and usage method thereof

InactiveCN103148285AIncrease gripPrevent slippingPipe laying and repairRelative displacementSelf locking

The invention relates to the machine field, in particular to a pipeline self-locking, clasping and pushing device and a usage method thereof. The device comprises more than one pushing ejector rod, wherein an anti-slip clasping and pushing piece is arranged at one end of each pushing ejector rod; the anti-slip clasping and pushing pieces are arc-shaped; the anti-slip clasping and pushing pieces define and surround a cylindrical pipeline channel used for accommodating a pipeline; the other end of each anti-slip clasping and pushing piece is connected with an outer frame in a hinge manner; the middle of each anti-slip clasping and pushing piece is connected with an inner frame in a hinge manner; a hydraulic self-locking and clasping mechanism is arranged between the outer frame and the inner frame on the same side; the hydraulic self-locking and clasping mechanism exerts force on the outer frame and the inner frame in opposite directions, so that relative displacement happens to the outer frame and the inner frame, the pushing ejector rods rotate with connection points of the pushing ejector rods and the outer frame and the inner frame serving as rotation pivots, and further the anti-slip pushing piece clasps the pipeline; and more than one traction force connector is arranged at one end, connected with the hydraulic self-locking and clasping mechanism, of the outer frame. The pipeline self-locking, clasping and pushing device can clasp the pipeline and push the pipeline to move forward.

Owner:辽河油田建设有限公司

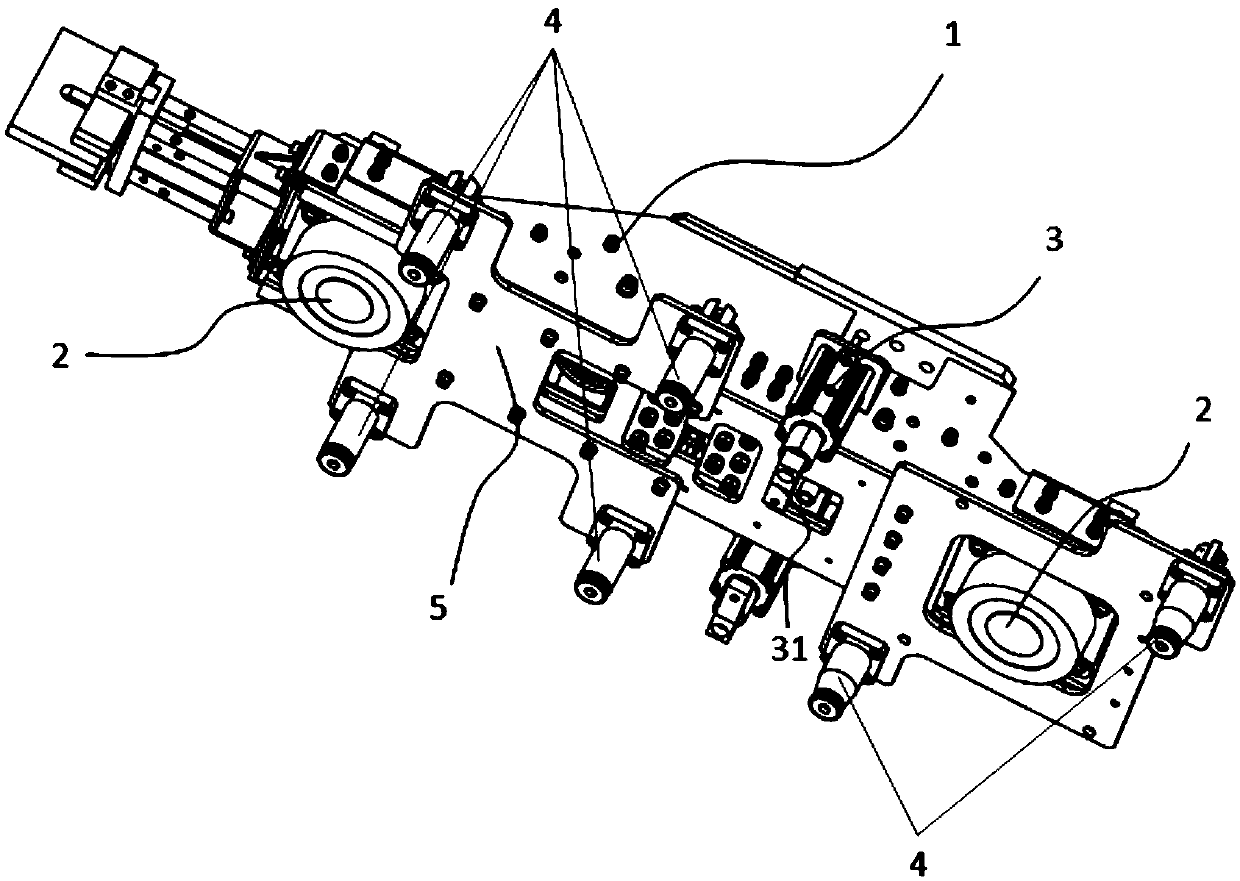

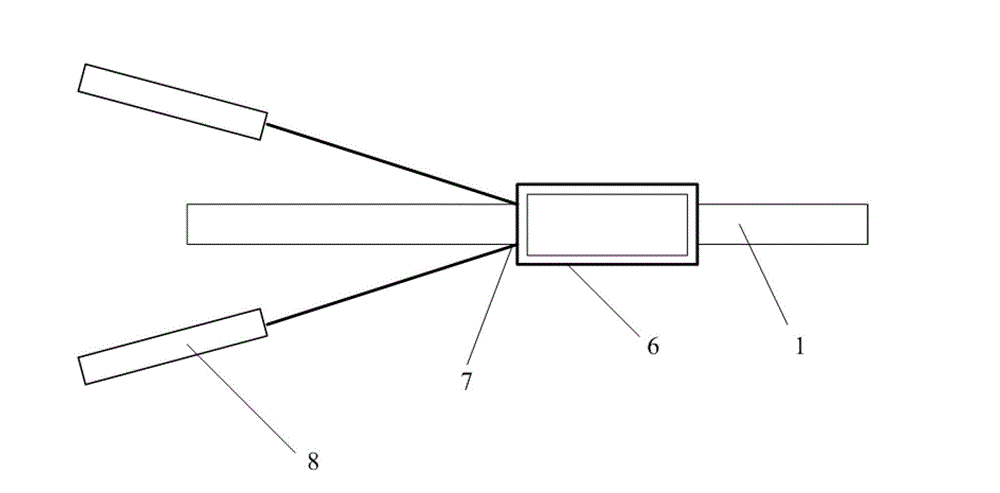

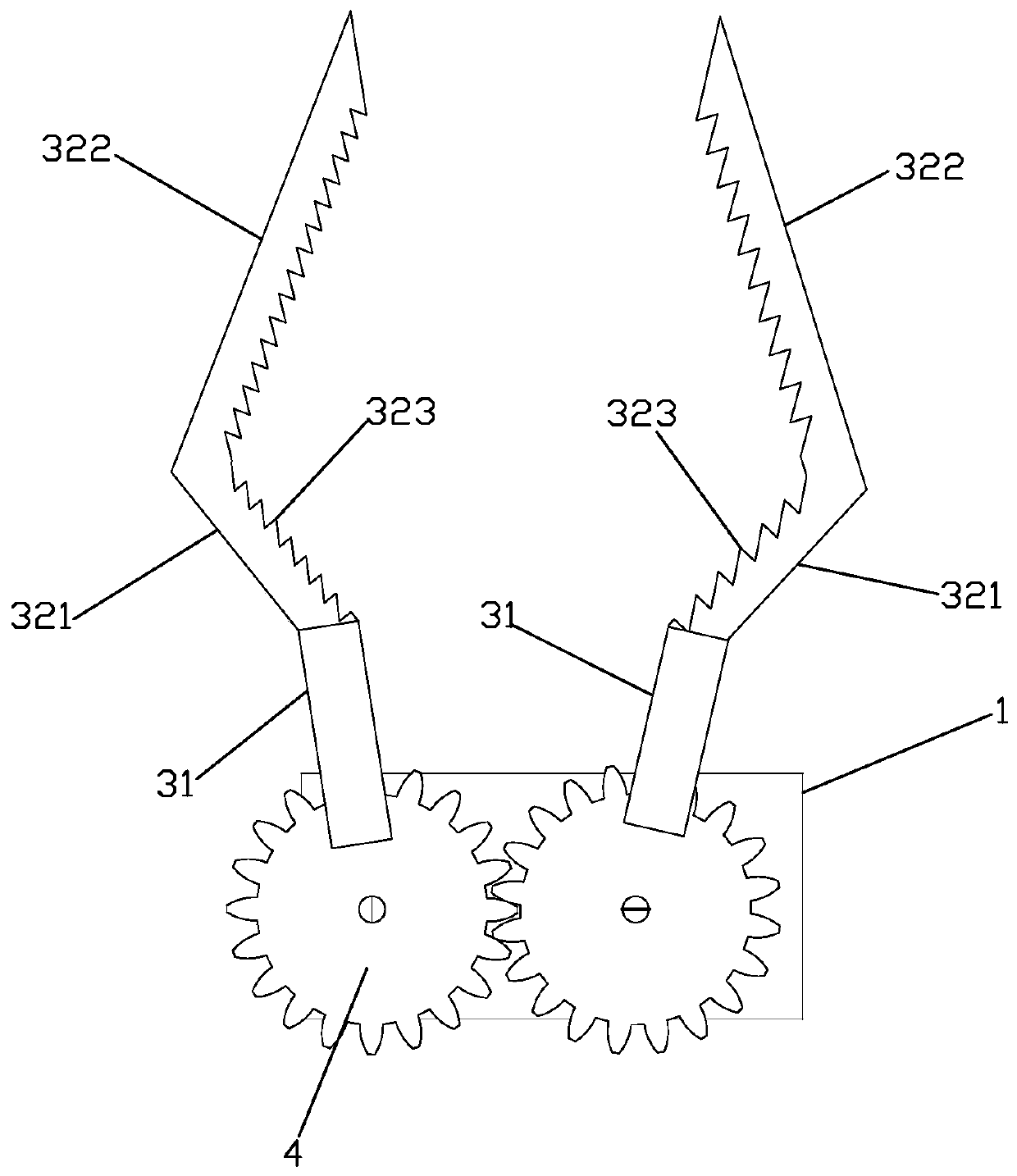

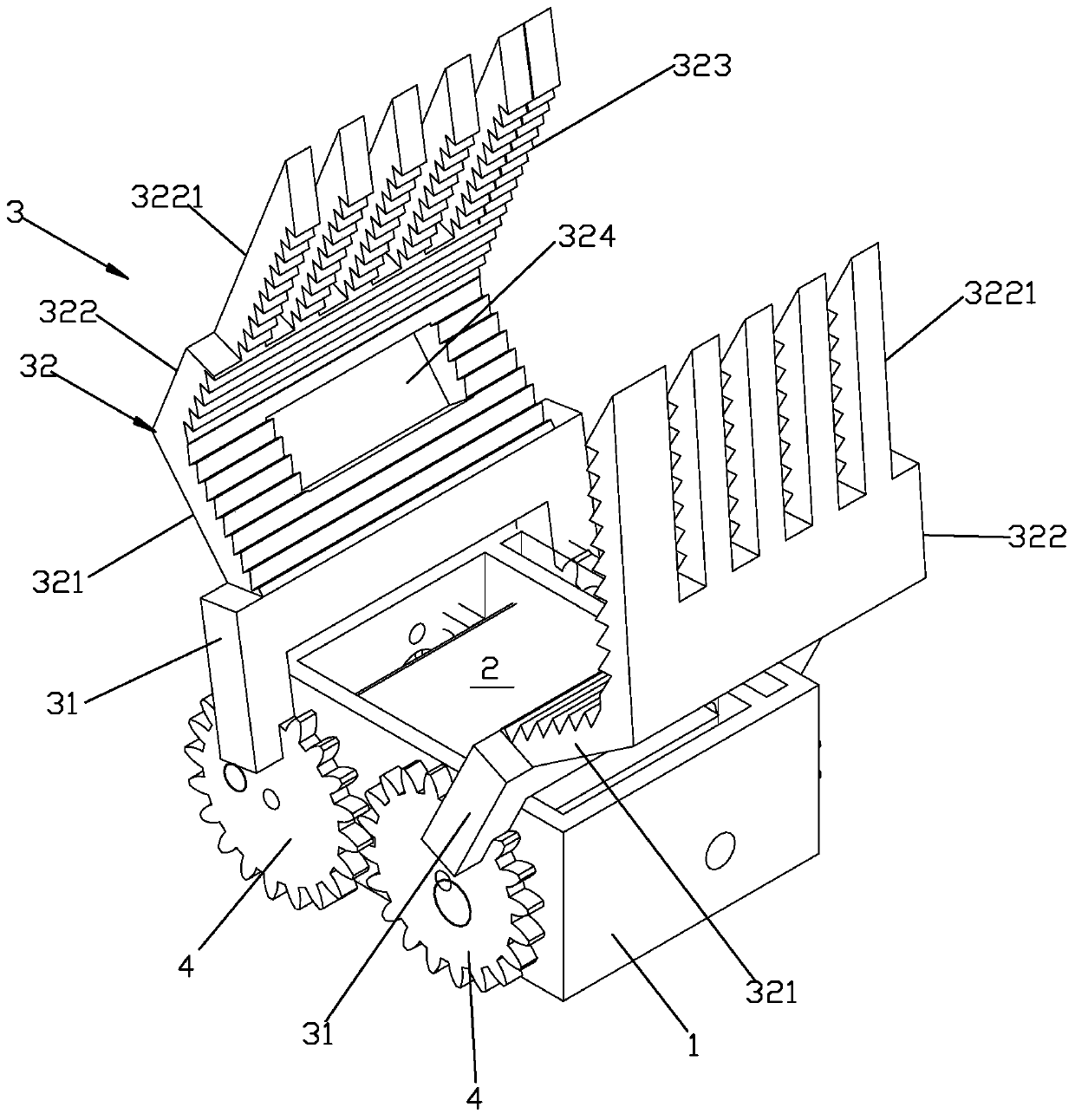

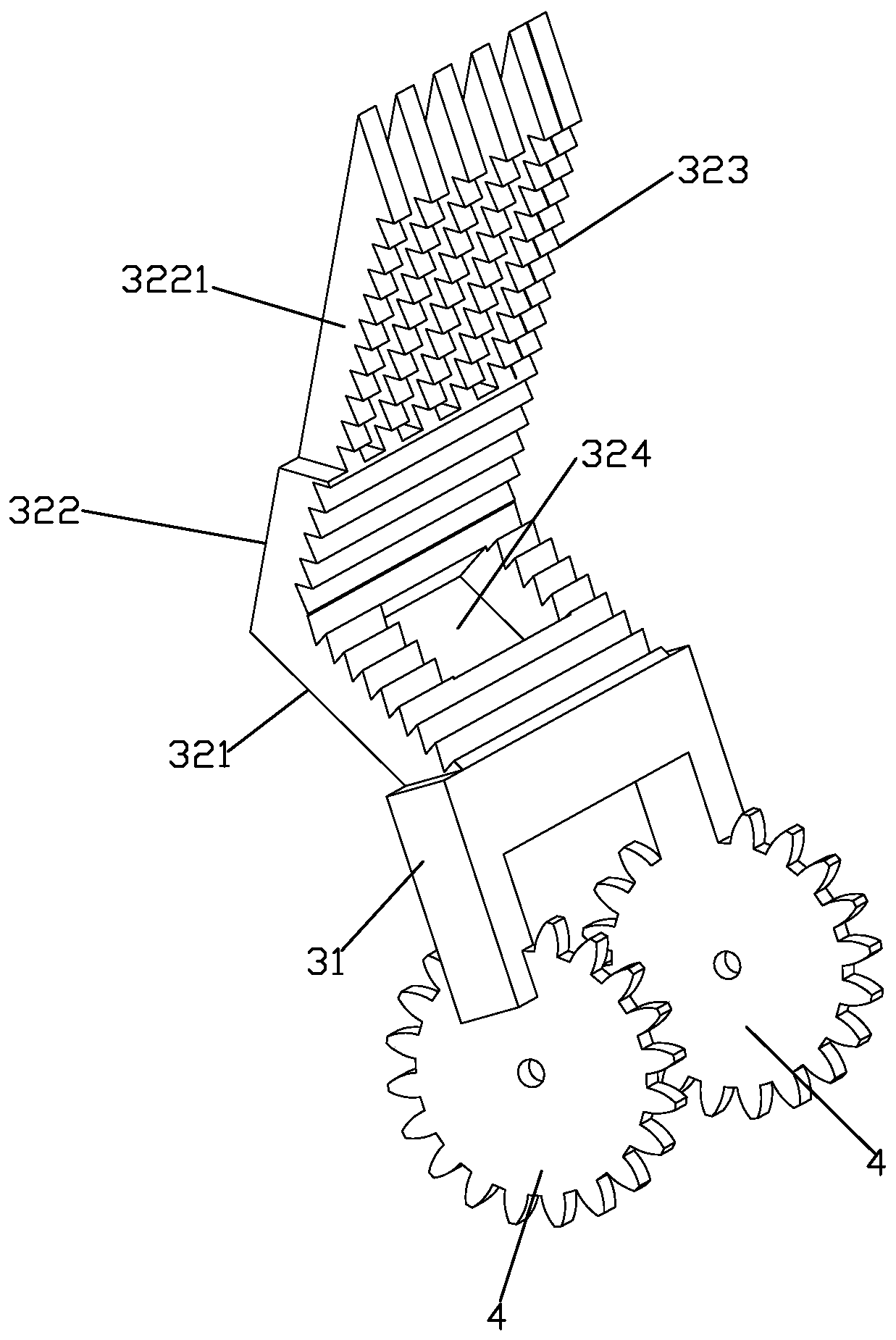

Mechanical gripper mechanism for transfer robot

The invention discloses a mechanical gripper mechanism for a transfer robot. The mechanical gripper mechanism for the transfer robot comprises a steering engine and a mechanical gripper unit; the mechanical gripper unit comprises two gear parts which are engaged with each other; a gripper is eccentrically and fixedly arranged on each gear part; a gripper part is of a V-shaped structure; the V-shaped openings of the gripper parts of the two grippers are opposite to each other; the steering engine drives the two gear parts to rotate reversely and synchronously to drive the two grippers to swingeccentrically face to face to clamp a cargo, or swing eccentrically back to back to loosen the cargo; the mechanical gripper mechanism for the transfer robot is compact in structure; the required avoiding space is smaller; the cargo can be gripped and loosened in a narrow space; the gripping strength is great; and the gripping is stable and reliable.

Owner:HUAQIAO UNIVERSITY

Multi-level seal hydraulic pipe ferrule

InactiveCN105351643AEnough gripImprove air tightnessJoints with sealing surfacesEngineeringHigh pressure

The invention discloses a multi-level seal hydraulic pipe ferrule. The multi-level seal hydraulic pipe ferrule comprises a connector body, a hydraulic oil pipe and a nut, wherein the hydraulic oil pipe is sleeved with the connector body; an inner conical face connector is arranged at the connection end of the connector body and the hydraulic oil pipe; a movable groove is formed in the end, right facing the connector body, of the nut; a ferrule body is installed in the movable groove, the inner wall of the ferrule body is attached to the peripheral wall of the hydraulic oil pipe, the ferrule body is composed of a buffer portion and a sealing portion, the sealing portion extends into the inner conical face connector in the axis direction of the ferrule, and a first sealing face and a second sealing face form an annular space along with the hydraulic oil pipe. The first sealing face is tightly attached to the peripheral wall of the hydraulic oil pipe, the second sealing face and the peripheral wall of the hydraulic oil pipe keep an annular space, the inner wall of the body of the sealing portion is tightly attached to the peripheral wall of the hydraulic oil pipe, and the lateral wall of the buffer portion and the arc expansion portion on the outer wall of the buffer portion are tightly attached to the lateral wall of the movable groove respectively, so that air tightness of a ferrule assembly under high temperature and high pressure is ensured.

Owner:四川海搏液压机械有限公司

Systems and methods for a suction cup device holder

A holder for a mobile device, the mobile device including a raised disc on a face of the device, includes a rotating portion, the rotating portion including a raised portion, the raised portion including a groove shaped to receive the raised disc in a sliding fashion. The holder further includes a base portion interconnected with the rotating portion. The holder further includes a suction cup interconnected with the rotating portion, such that when the rotating portion is rotated, the suction cup is pulled into the base portion.

Owner:AYLO LLC

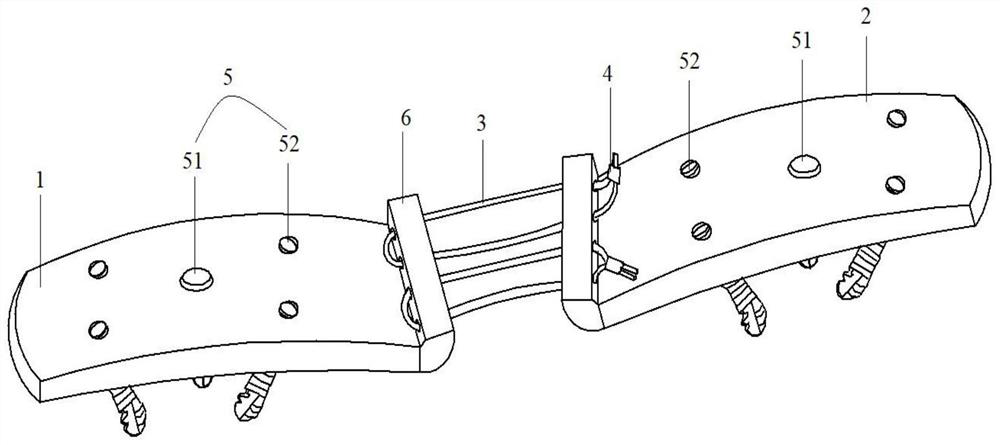

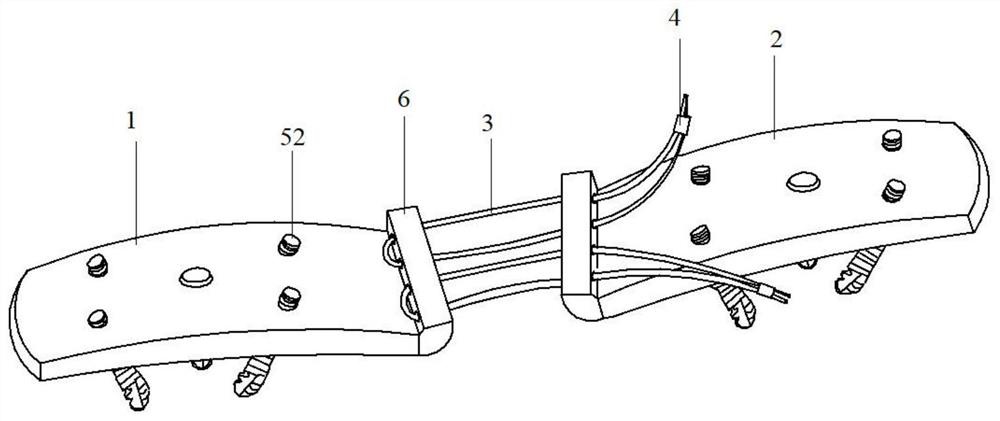

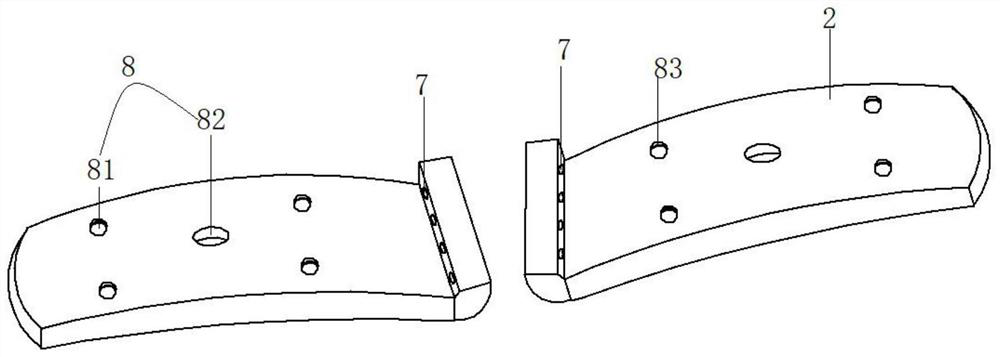

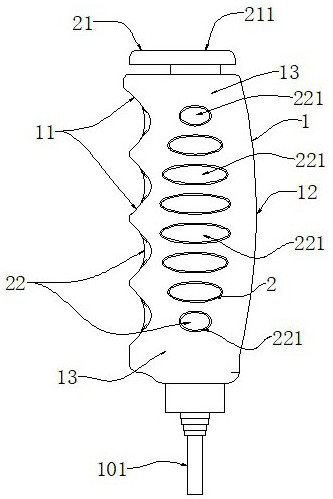

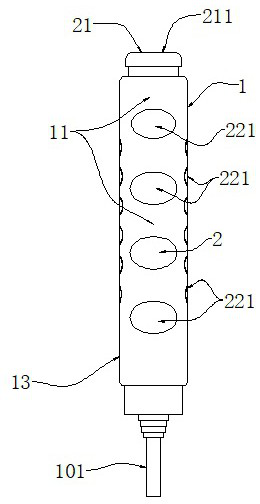

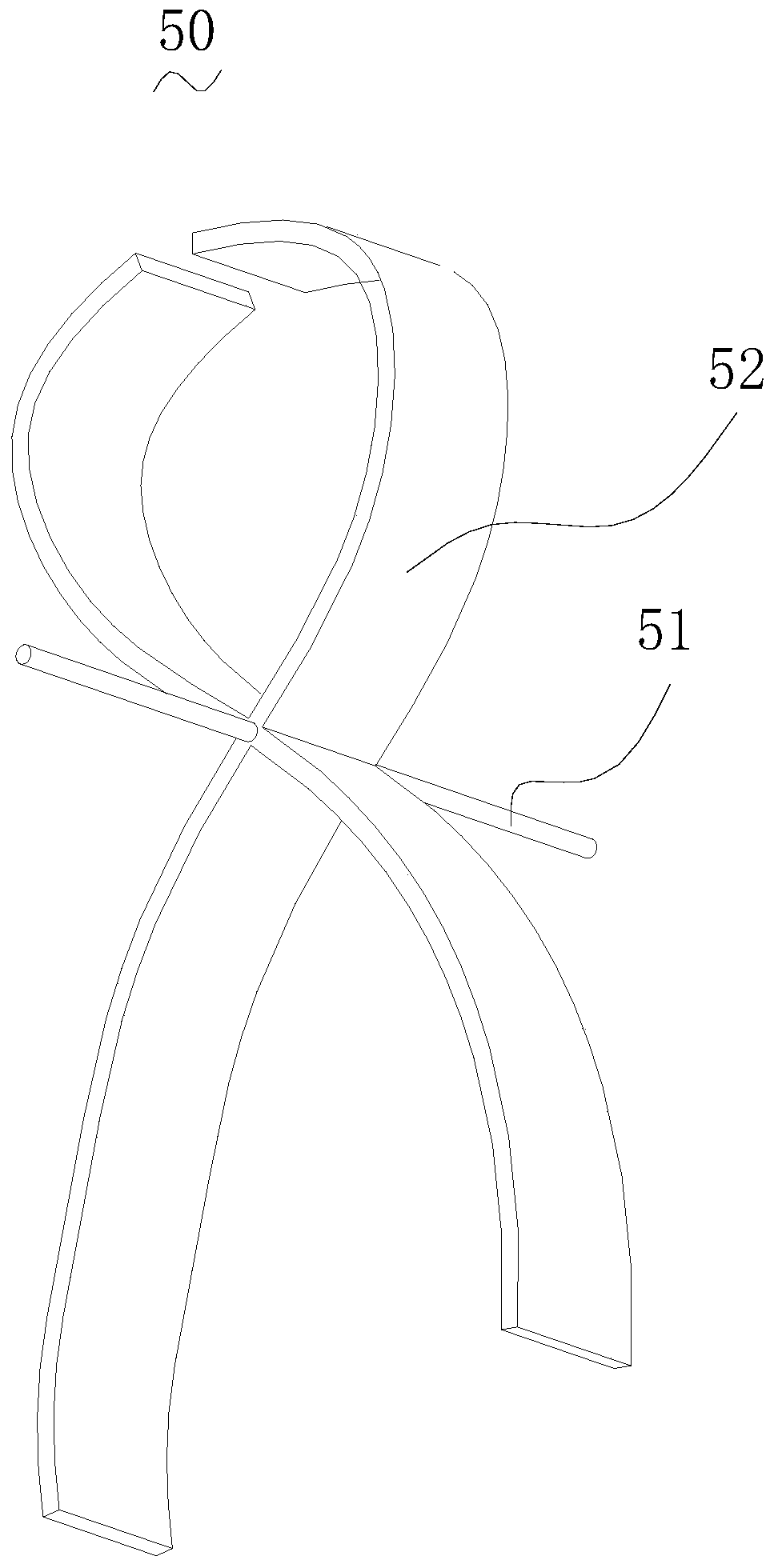

Elastic fixation device for acromioclavicular joint

The invention relates to an elastic fixation device for an acromioclavicular joint. The elastic fixation device comprises a clavicle end locking plate, an extremitas acromialis locking plate, polyester fiber loops, polyester fiber loop locks and screws, wherein a steel plate bulge is arranged on each of the clavicle end locking plate and the extremitas acromialis locking plate and is of a cuboid structure; a plurality of polyester fiber loop holes are formed in one side surface of each steel plate bulge; the polyester fiber loops pass through the corresponding polyester fiber loop holes in thesteel plate bulges to connect the clavicle end locking plate and the extremitas acromialis locking plate; a plurality of screw holes are formed in the clavicle end locking plate and the extremitas acromialis locking plate; and the screws are matched with the screw holes. The elastic fixation device has the advantages that the acromioclavicular joint can be elastically fixed, and the elastic fixation device conforms to the biomechanical principle of the joint, and can avoid related complications caused by use of a clavicular hook plate in the past.

Owner:JINSHAN HOSPITAL FUDAN UNIV

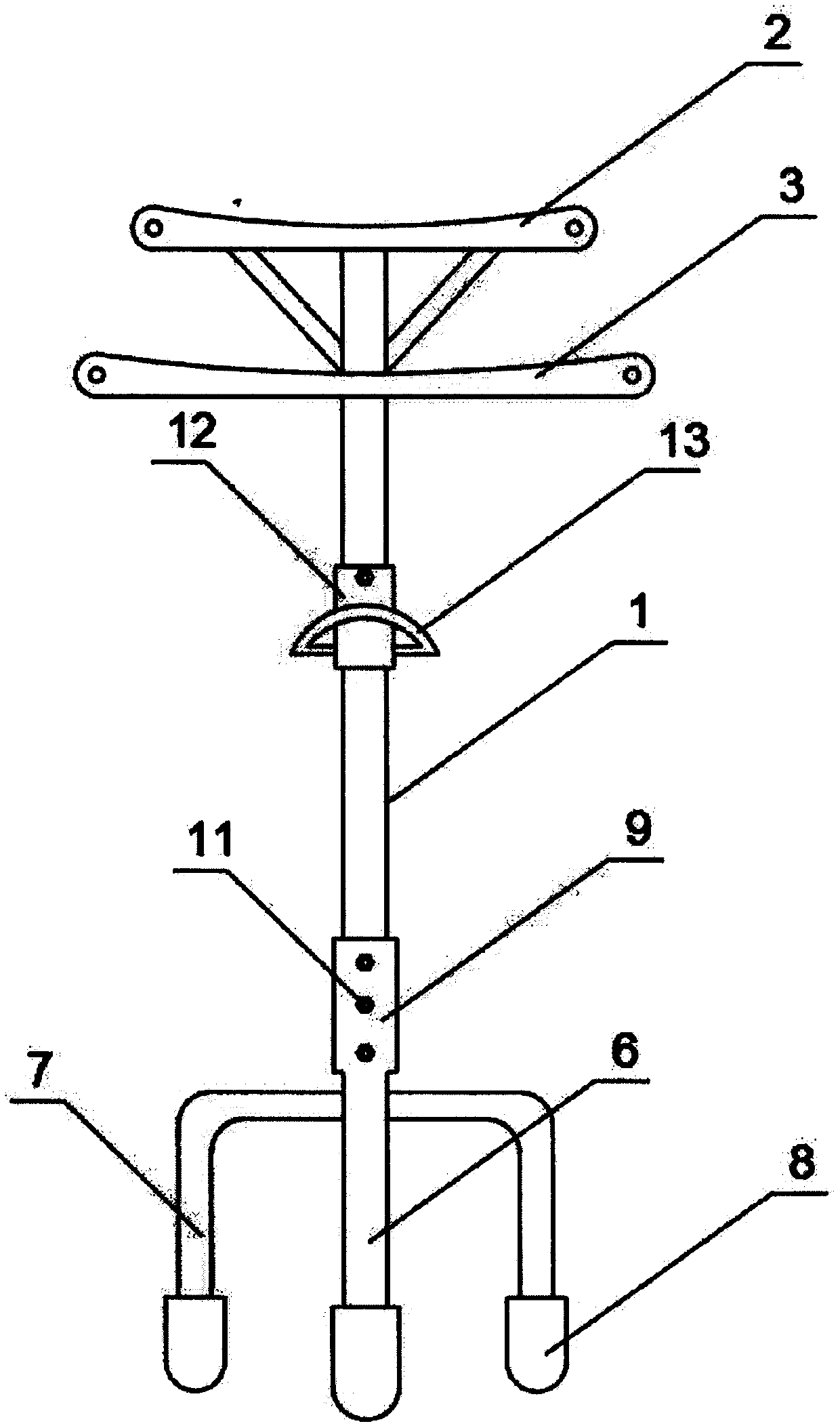

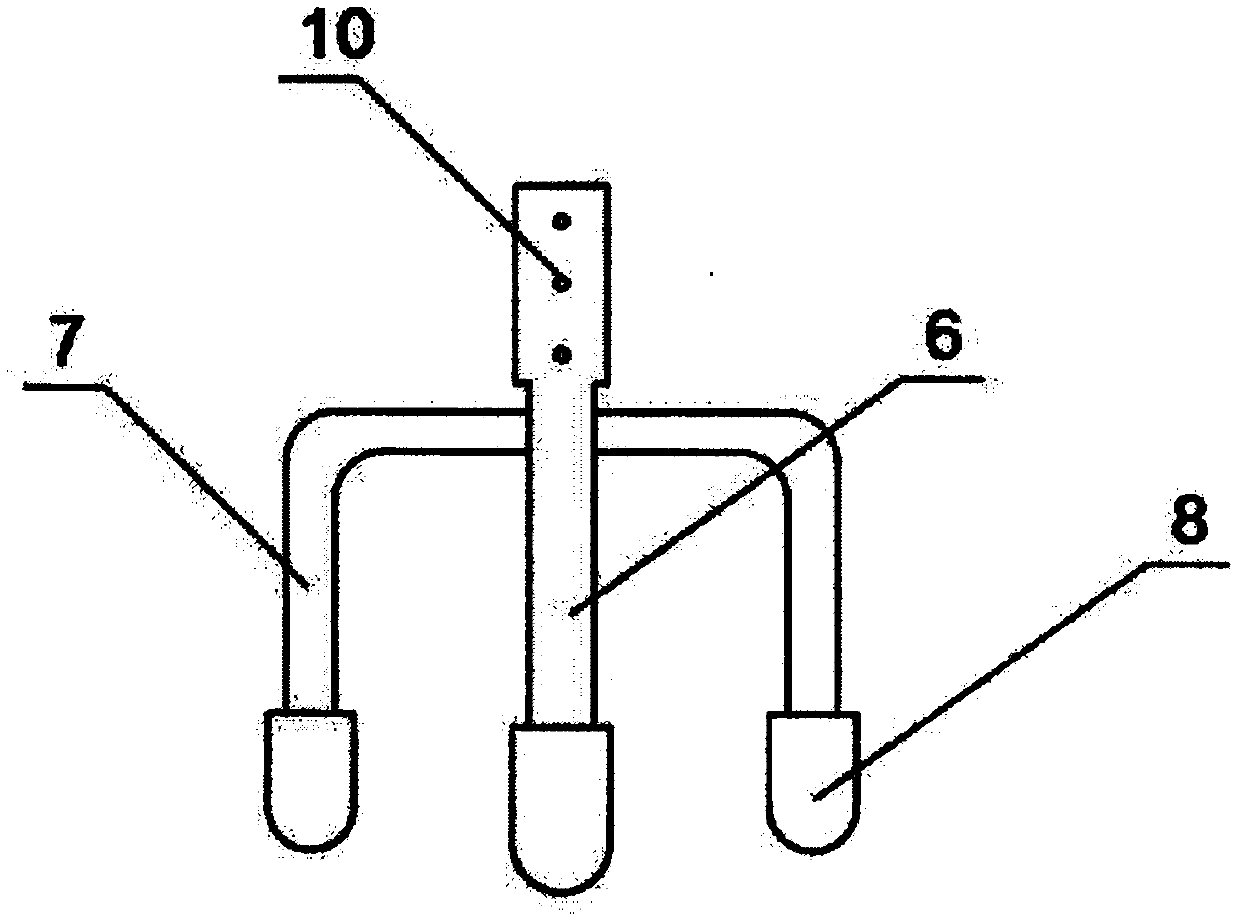

Orthopedic nursing walking stick

InactiveCN110693680APrevent fallingEasy to holdCrutchesPhysical medicine and rehabilitationOrthopedic department

The invention relates to the technical field of medical instruments, in particular to an orthopedic nursing walking stick which comprises a main supporting rod. A horizontal armpit walking stick is arranged at the top of the main supporting rod and detachably connected with the top of the main supporting rod, a leg support is arranged at the bottom of the main supporting rod and includes a main supporting leg and two auxiliary supporting legs, the two auxiliary supporting legs are arranged on two sides of the main supporting leg, a sliding sleeve is arranged on the main supporting rod in a sleeving manner, a holding ring is arranged on the sliding sleeve, a positioning screw is arranged on the sliding sleeve, and the sliding sleeve is fixed onto the main supporting rod through the positioning screw. According to the orthopedic nursing walking stick, one main supporting leg and two auxiliary supporting legs are arranged on the leg support of the bottom of the main supporting rod, a certain protection action can be achieved when a patient walks, the patient conveniently holds the walking stick through the holding ring on the sliding sleeve, the holding degree of the patient for the walking stick is further improved, the walking stick is more flexibly controlled by the patient, the sliding sleeve can be slidably positioned on the main supporting rod, and the position of the holding ring can be adjusted.

Owner:刘海霞

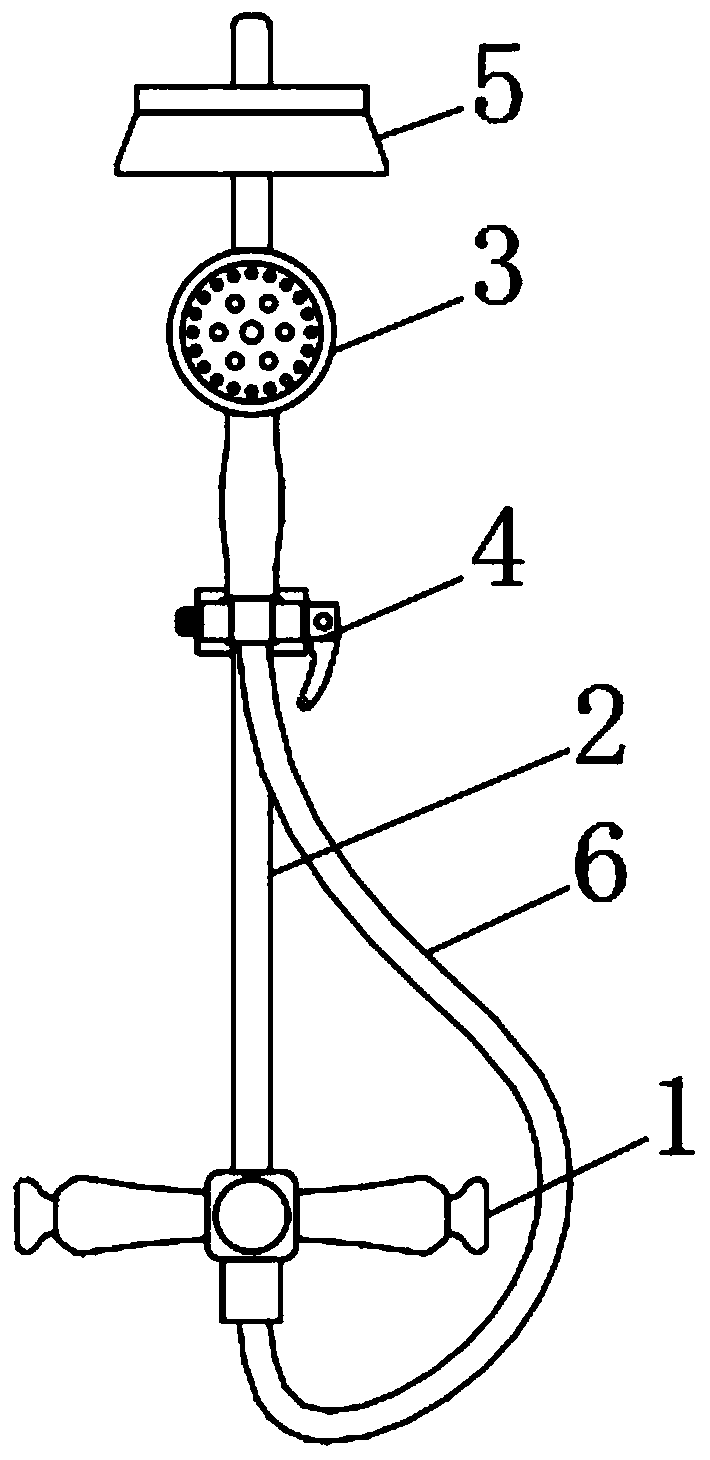

Shower head with multi-angle adjustment

The invention discloses a shower head with multi-angle adjustment. The shower head includes a water control valve, a fixed bracket, a movable shower head, a movable bracket, a fixed shower head and aconnecting pipe. The fixed bracket is fixedly mounted on the top of the water control valve. The water control valve and the fixed bracket are fixed to a wall. The movable bracket is movably connectedto the outer side of the fixed bracket. The movable shower head matches the movable bracket. The movable shower head is connected to a water outlet of the water control valve through the connecting pipe. The shower head with the multi-angle adjustment greatly facilitates the user's adjustment of the height of the shower head through a movable lifting assembly, and can maintain a good positioningcapability after being used for a period of time through a first rotating assembly and a second rotating assembly to avoid the problem that the shower head cannot be maintained after an angle is adjusted, which greatly improves the use experience of a user.

Owner:杭州西屋个人护理用品有限公司

Aromatic polyamide fabric soft-bodied robot

InactiveCN108621132AGood flexibilityRigidProgramme-controlled manipulatorGripping headsPliabilityPolyamide

The invention discloses an aromatic polyamide fabric soft-bodied robot. The aromatic polyamide fabric soft-bodied robot comprises soft-bodied fingers, a fabric sleeve, an elastic sleeve, an elastic supporting frame, a spring column and an elastic base body. The elastic base body is arranged in the elastic sleeve. A deformation cavity is formed between the elastic base body and the elastic sleeve.The elastic supporting frame is arranged in the deformation cavity. An elastic supporting cavity is formed in the middle of the elastic base body. A plurality of inflation channels are formed in the outer side of the elastic supporting cavity at equal intervals in the same circumferential direction. The elastic base body is arranged in the elastic sleeve, the elastic supporting frame is mounted between the elastic base body and the elastic sleeve, the spring column and the inflation channels are formed in the elastic base body, one side of the elastic base is expanded and bent to the other side of the elastic base body by inflating the inflation channels, thus, operations of contracting, stretching and bending are conducted, when the elastic base body is bent, the spring column has certainflexibility and certain stiffness, the multiple soft-bodied fingers are arranged outside the elastic sleeve, the grabbing strength of the robot is improved, and the abrasion resistance is good by additionally arranging an aromatic polyamide fabric layer.

Owner:FOSHAN YIBEIER TECH

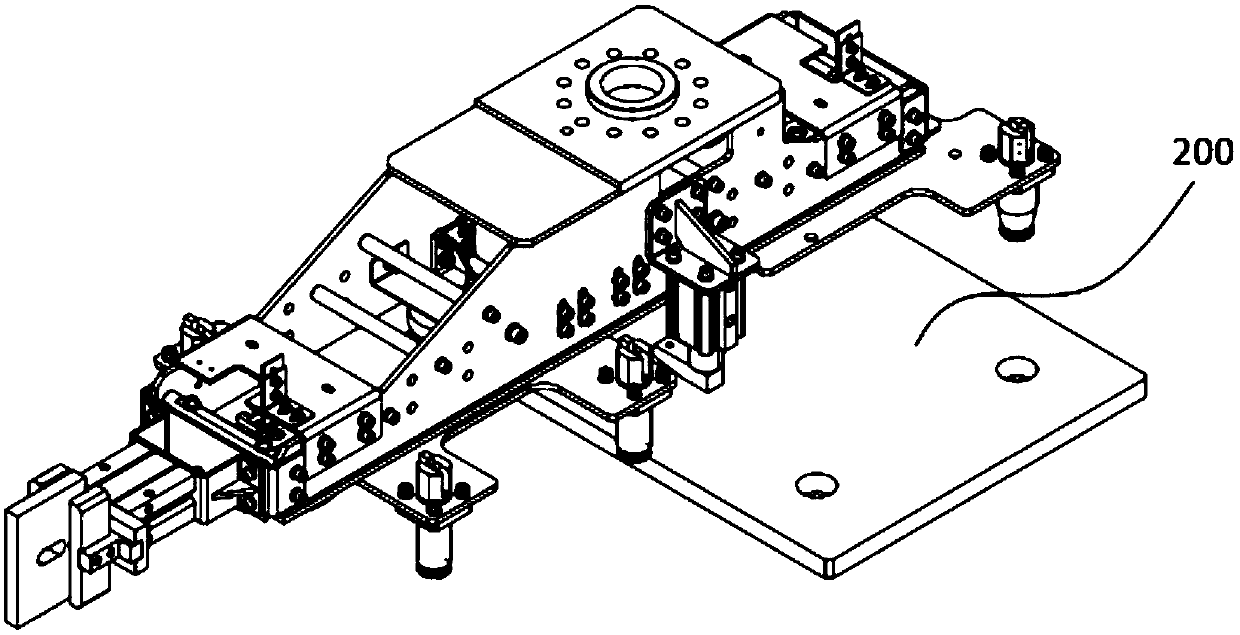

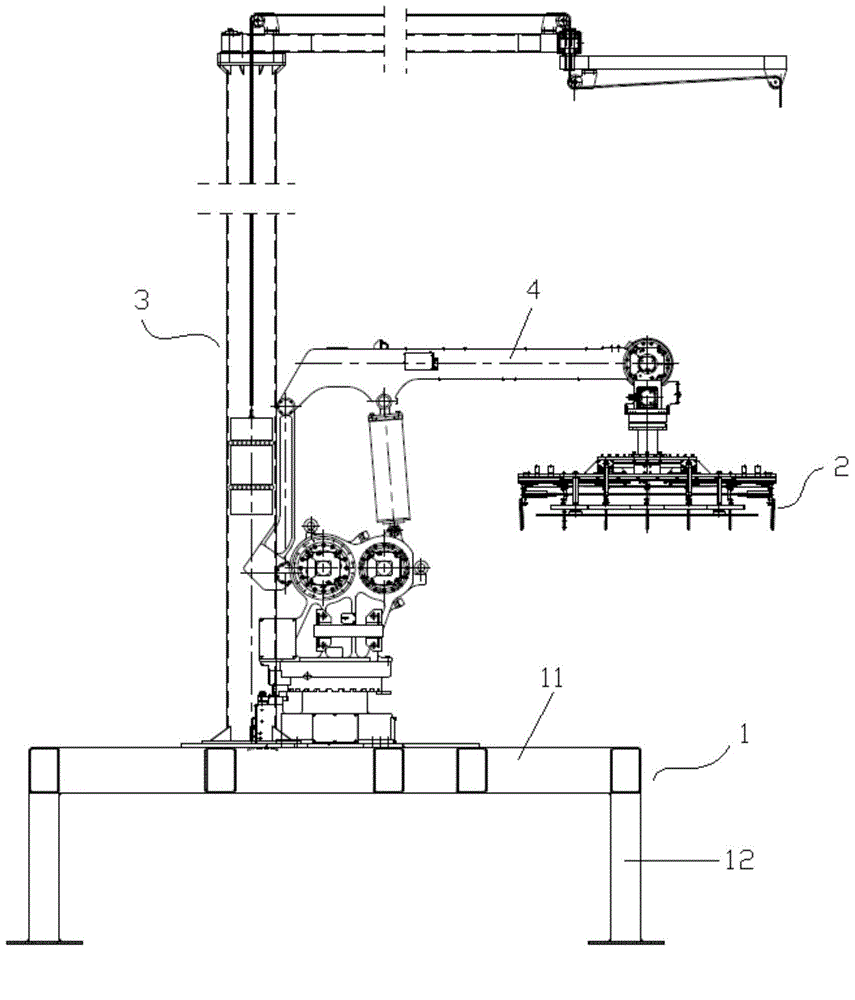

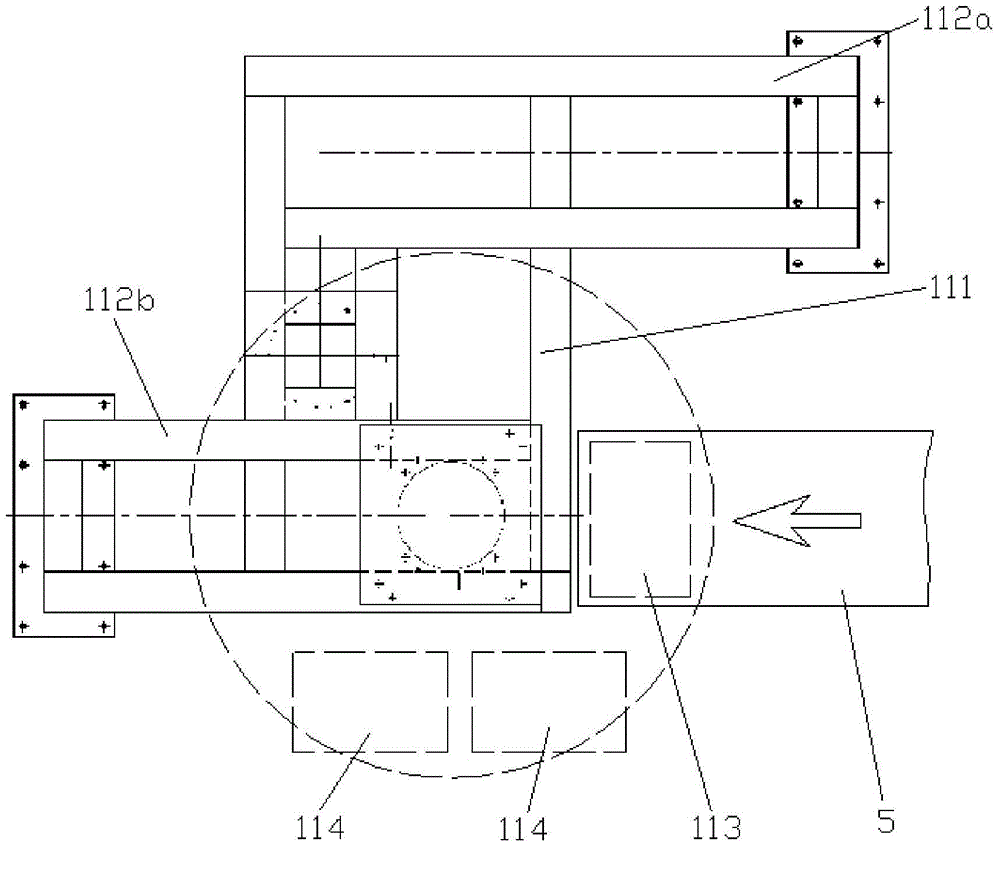

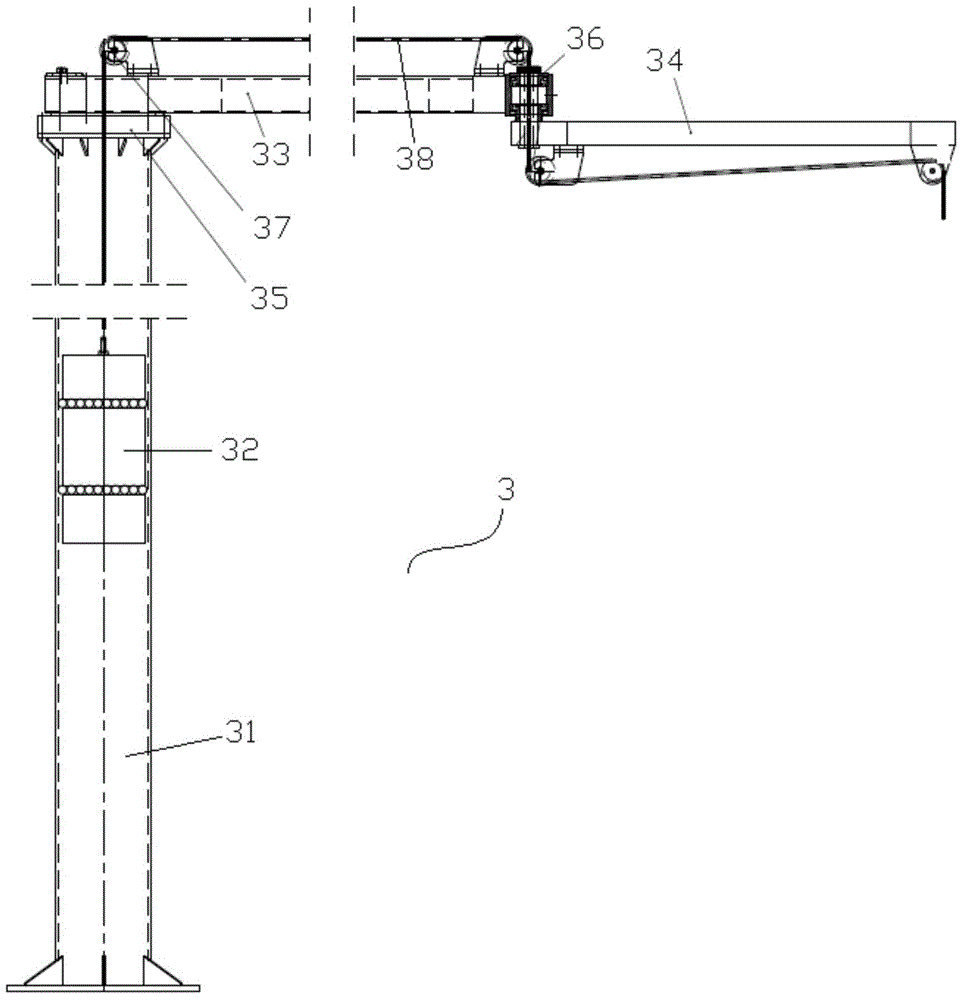

Blank stacking robot system

InactiveCN104310073AStable jobSimple structureStacking articlesDe-stacking articlesRobotic systemsBrick

The invention discloses a blank stacking robot system which comprises a blank stacking robot, a balance weight device and a machine seat. The blank stacking robot comprises a blank grabbing device used for grabbing brick blanks and stacking the same, the balance weight device is connected with the blank grabbing device and used for increasing grabbing weight of the blank grabbing device, the machine seat comprises a horizontal frame body used for supporting the balance weight device and the blank stacking robot, the horizontal frame body comprises a middle load-bearing frame body and two balance weight frame bodies perpendicularly extending from two ends of the middle load-bearing frame body to opposite directions respectively and used for improving balance performance of the horizontal frame body, the blank stacking robot and the balance weight device are mounted on the middle load-bearing frame body, one of the balance weight frame bodies and the middle load-bearing frame body surround to form a blank grabbing area of the blank grabbing device, and a conveyor used for conveying the brick blanks is arranged in the blank grabbing area. The grabbing weight of the blank stacking robot is increased by arranging the balance weight device, so that the blank stacking robot is enabled to be applied on a large-yield production line, and cost is saved.

Owner:SHANDONG JUXIANG MACHINERY

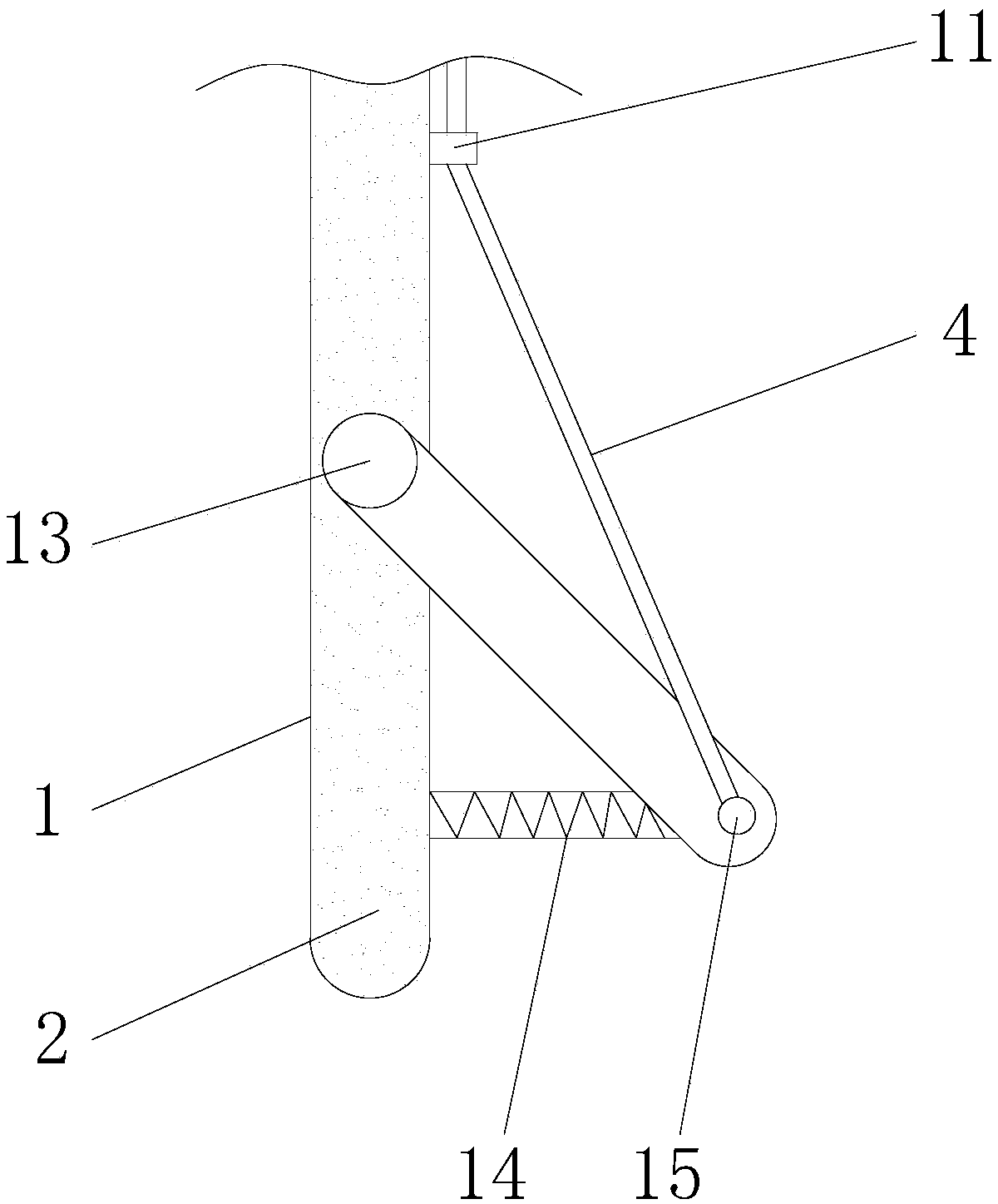

Tree supporting device for garden

InactiveCN111357562AReduce frictionStable supportWatering devicesAnimal repellantsStructural engineeringMechanical engineering

Owner:郭振

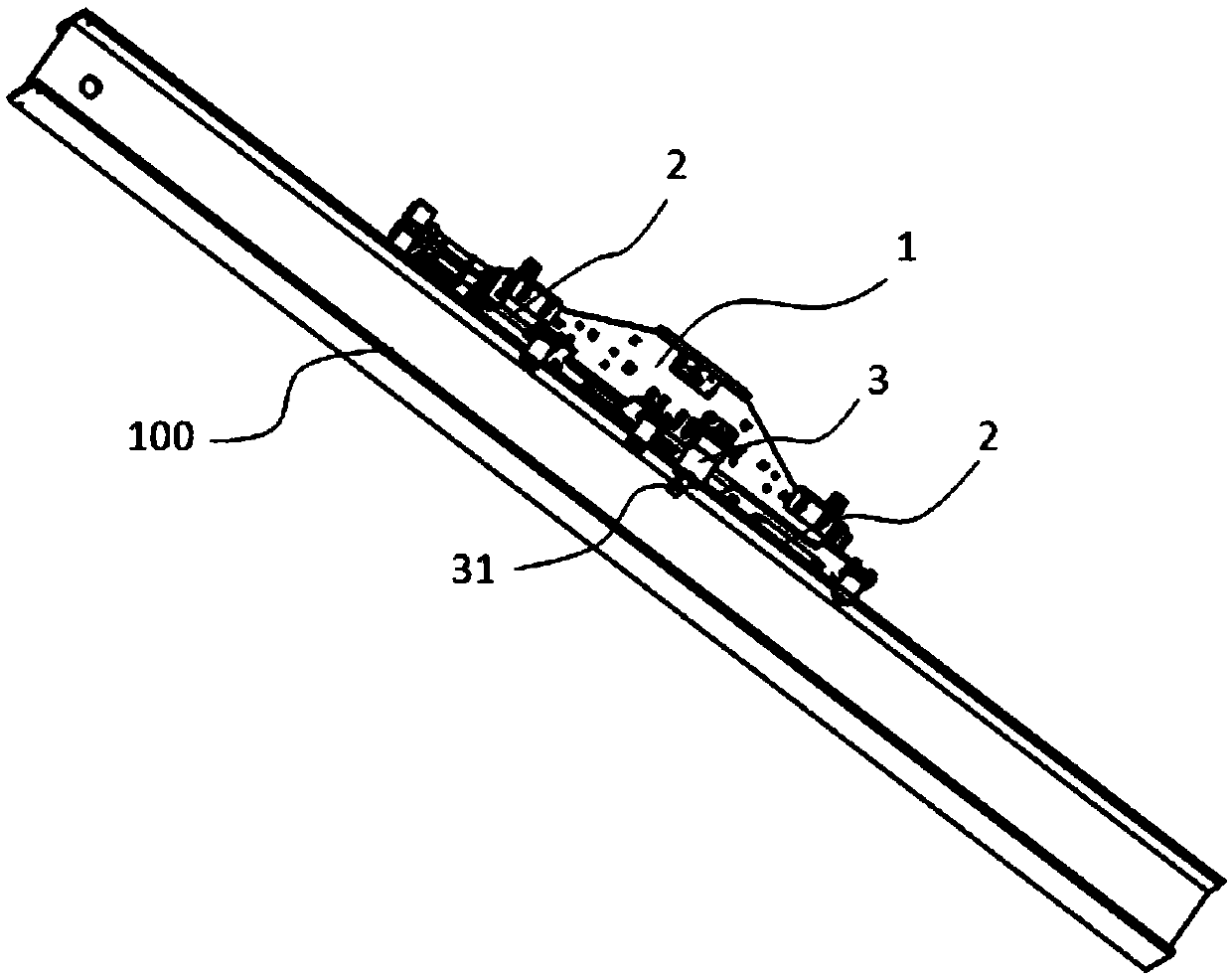

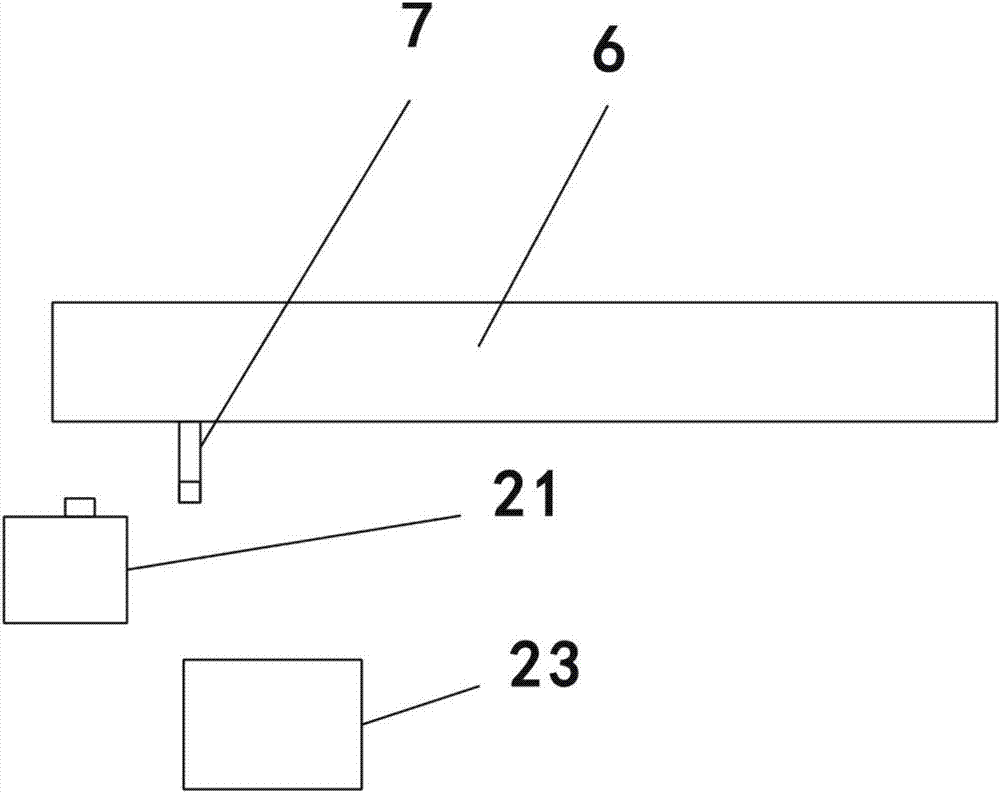

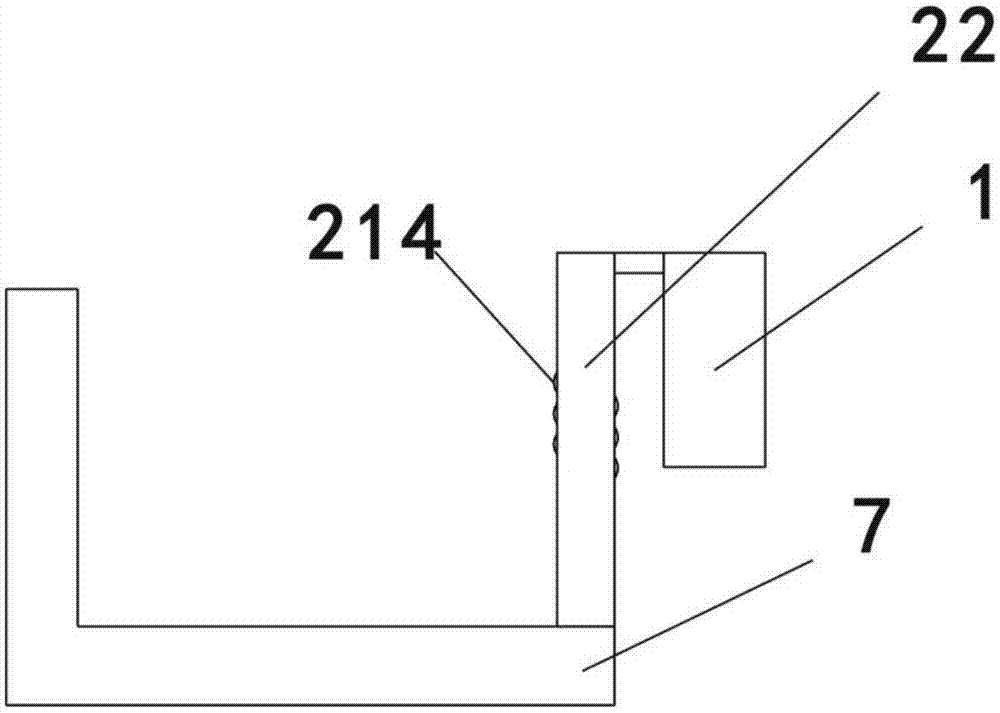

Vehicle mobile phone base painting production line

InactiveCN107321547AEffectively fixedIncrease success ratePretreated surfacesCoatingsProduction lineEngineering

The invention relates to the technical field of vehicle decoration use part production, in particular to a vehicle mobile phone base painting production line. The vehicle mobile phone base painting production line comprises three vehicle mobile phone base finisher devices, three vehicle mobile phone base painter devices, three vehicle mobile phone base drier devices, three vehicle mobile phone base inspector devices and a conveying belt; the three vehicle mobile phone base finisher devices, the three vehicle mobile phone base painter devices, the three vehicle mobile phone base drier devices and the three vehicle mobile phone base inspector devices are arranged on the outer side of the conveying belt in sequence; and multiple L-shaped fixed bases are arranged on the surface of the conveying belt.

Owner:桐乡风腾专利运营有限公司

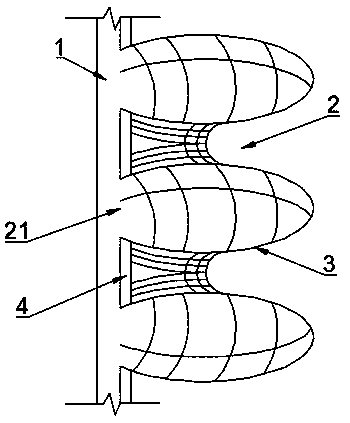

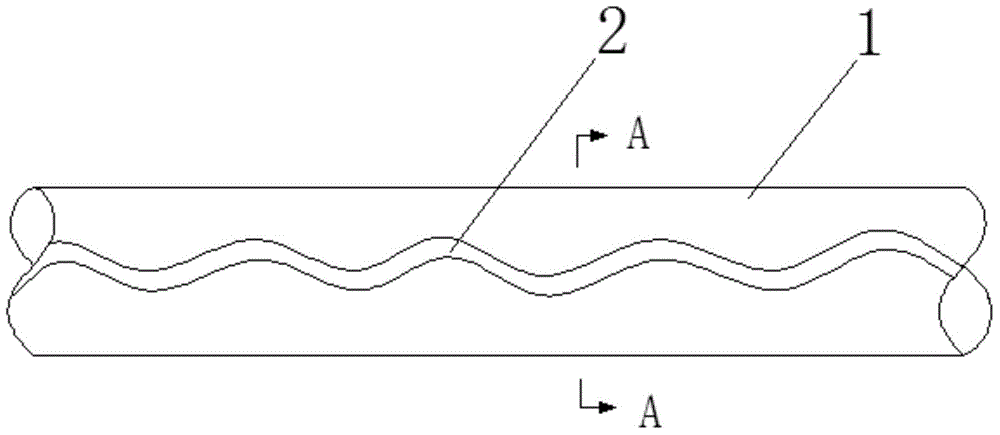

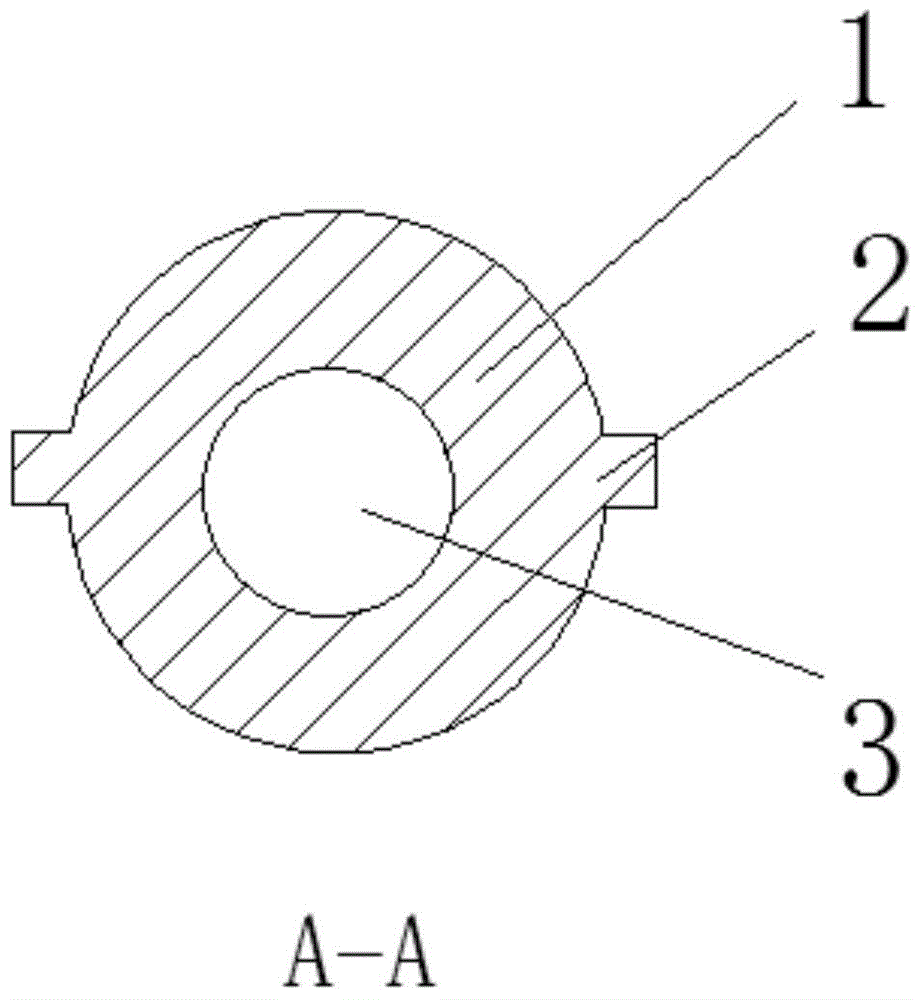

Novel steel strand

InactiveCN104631163AIncrease gripIncreased strength and safetyBuilding reinforcementsTextile cablesPre stressPrestressed concrete

The invention provides a novel steel strand which comprises a body composed of one center wire and one edge wire. The center wire is a solid polished steel wire, the edge wire is an internally hollow annular steel wire, and the center wire can be just inserted into the center of the edge wire. The novel steel strand is characterized in that the surface of the body is provided with a plurality of continuous protruding ribs, the protruding ribs are in a weave shape or a fold line shape in the moving orientation, and 2-4 protruding ribs are arranged. The novel steel strand has the advantages that by the adoption of the technical scheme, the problems of slippage ad retraction between the center wire and the edge wire of the steel strand are solved, good mechanical performance of the steel strand is maintained, the steel strand body is made to have higher cohesive force, sliding is not generated easily, and the quality of prepressed concrete components is improved; meanwhile, the protruding rids are additionally arranged on the basis of the polished steel wire, the bond stress on cement is enhanced, and safety and strength in the using process are improved.

Owner:SILVERY DRAGON PRESTRESSED MATERIALS CO LTD

Wool top production process capable of reducing short wool content of wool tops

ActiveCN113046871AAvoid being pulled offIncrease gripContinuous processingCarding machinesWoolCombing

The invention relates to a wool top production process capable of reducing the short wool content of wool tops. The wool top production process comprises the following steps: A, carding, specifically, feeding cleaned loose wool into an improved carding machine to prepare first slivers with the weight of 40 g / m and second slivers with the weight of 8 g / m; B, gilling 1, specifically, transforming a gilling machine 1 to prepare slivers with the weight of 8 g / m; C, gilling 2, specifically, transforming a gilling machine 2 to prepare slivers with the weight of 40 g / m; D, gilling 3, specifically, transforming a gilling machine 3 to prepare slivers with the weight of 8 g / m; E, combing, specifically, manufacturing the slivers with the weight of 20 g / m through a combing machine; F, re-gilling 1, specifically, manufacturing the slivers with the weight of 20 g / m through a re-gilling machine 1; G, re-gilling 2, specifically, manufacturing the slivers with the weight of 8 g / m through a re-gilling machine 2; H, recombing, specifically, manufacturing the slivers with the weight of 20 g / m through a recombing machine; I, gilling and combing the slivers; and J, balling. In this way, manpower is saved, the production cost is reduced, and the content of short wool in the wool tops is greatly reduced.

Owner:TIANYU WOOL IND ZHANGJIAGANG FREE TRADE ZONE CO LTD

Edges for skis, snowboards and ice skates

Edges for skis snowboard and skates that with the incorporation of more than one edge allow for an increased grip when turning and braking.It has a special application in the sports sector where you move over snow or ice, where edges of these characteristics are required.

Owner:FRIBERG ULF MORGAN

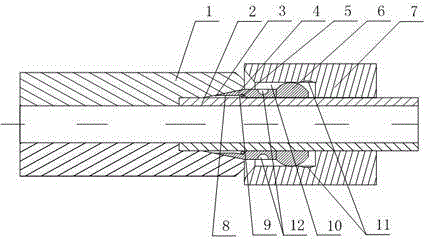

Leakage-proof hydraulic pipe ferrule

The invention discloses a leakage-proof hydraulic pipe ferrule. The leakage-proof hydraulic pipe ferrule comprises a connector body, a hydraulic oil pipe and a nut, wherein the hydraulic oil pipe is sleeved with the connector body; an inner conical face connector is arranged at the connection end of the connector body and the hydraulic oil pipe; a movable groove is formed in the end, right facing the connector body, of the nut; a ferrule body is installed in the movable groove, the inner wall of the ferrule body is attached to the peripheral wall of the hydraulic oil pipe, the ferrule body is composed of a buffer portion and a sealing portion, the sealing portion extends into the inner conical face connector in the axis direction of the ferrule, and a first sealing face and a second sealing face form an annular space along with the hydraulic oil pipe. The first sealing face is tightly attached to the peripheral wall of the hydraulic oil pipe, the second sealing face and the peripheral wall of the hydraulic oil pipe keep an annular space, the inner wall of the body of the sealing portion is tightly attached to the peripheral wall of the hydraulic oil pipe, and the lateral wall of the buffer portion and the arc expansion portion on the outer wall of the buffer portion are tightly attached to the lateral wall of the movable groove respectively, so that air tightness of a ferrule assembly under high temperature and high pressure is ensured.

Owner:四川海搏液压机械有限公司

Control method of handheld emergency stop device

ActiveCN113655845APrevent malfunctionIncrease grip strengthControlling membersMedical equipmentHand partsHand held

The invention discloses a control method of a handheld emergency stop device. An emergency stop function is achieved through the combined action of a control module and a manual switch, and the control device can directly send out a trigger signal according to collected pressure information to control equipment to conduct emergency stop. According to the autonomous triggering function, conditions can be set in a self-defined mode according to needs, and the set conditions are hand holding and pressing states of a user in the using process.

Owner:SUZHOU HAOBRO MEDICAL DEVICE

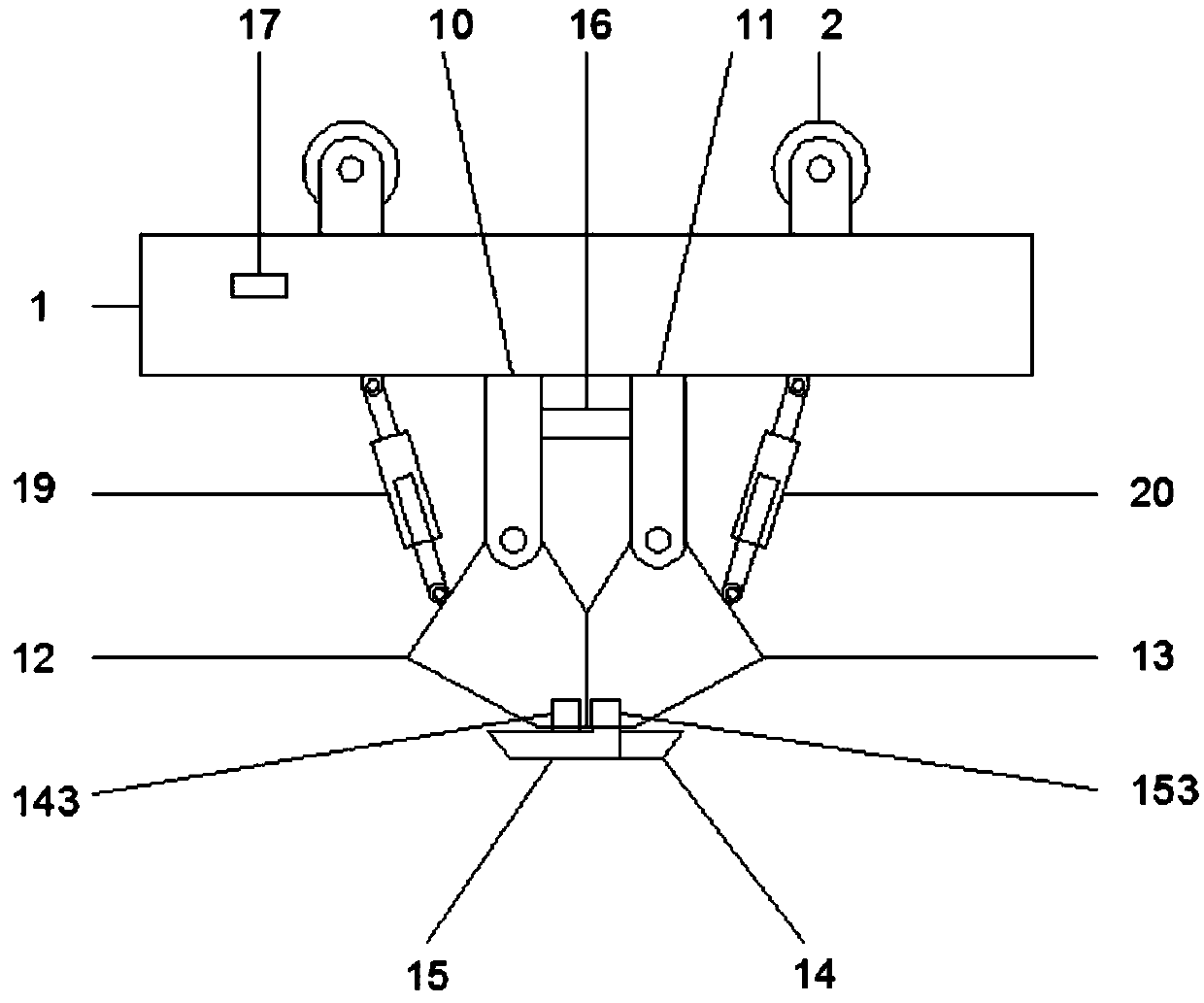

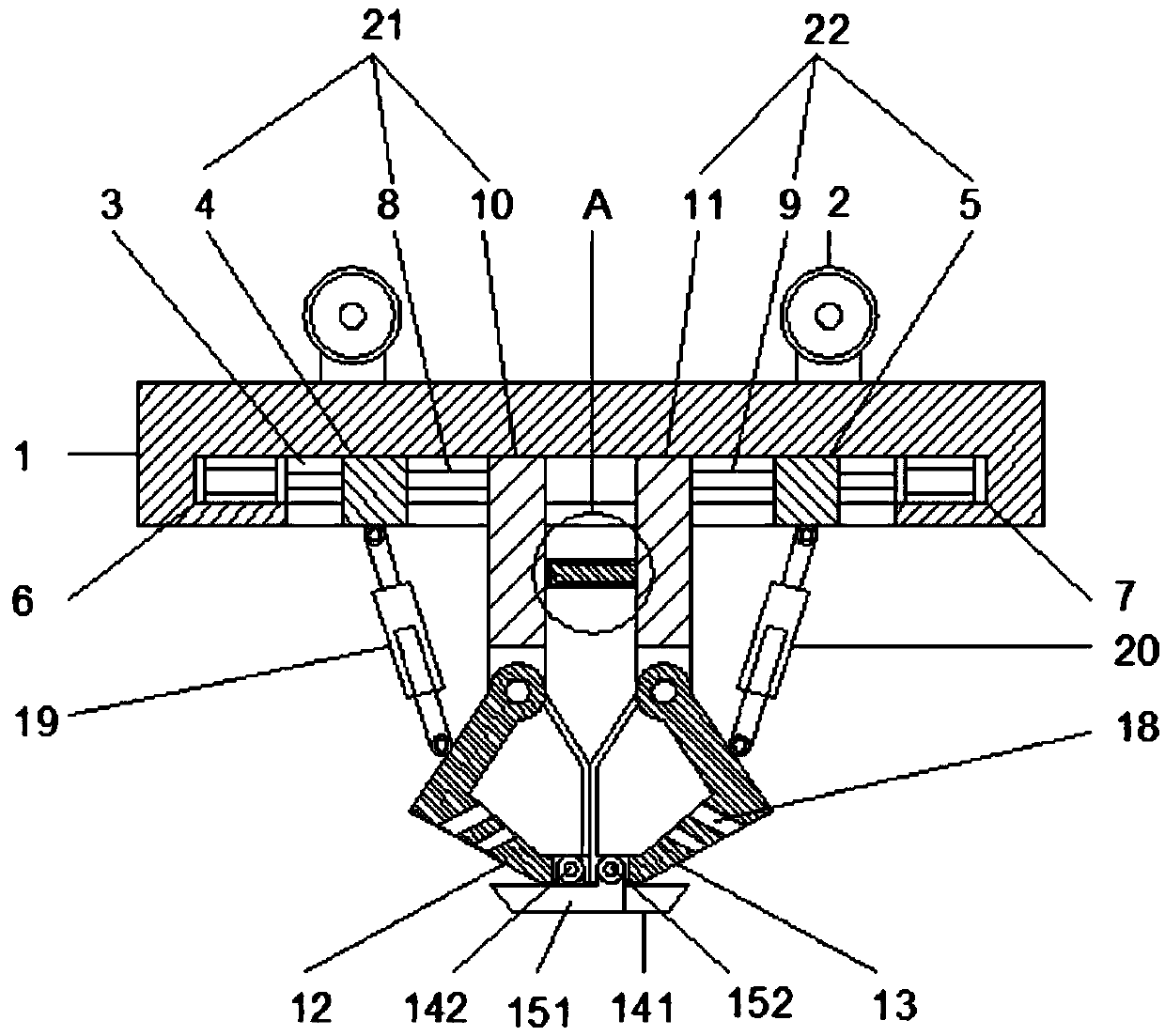

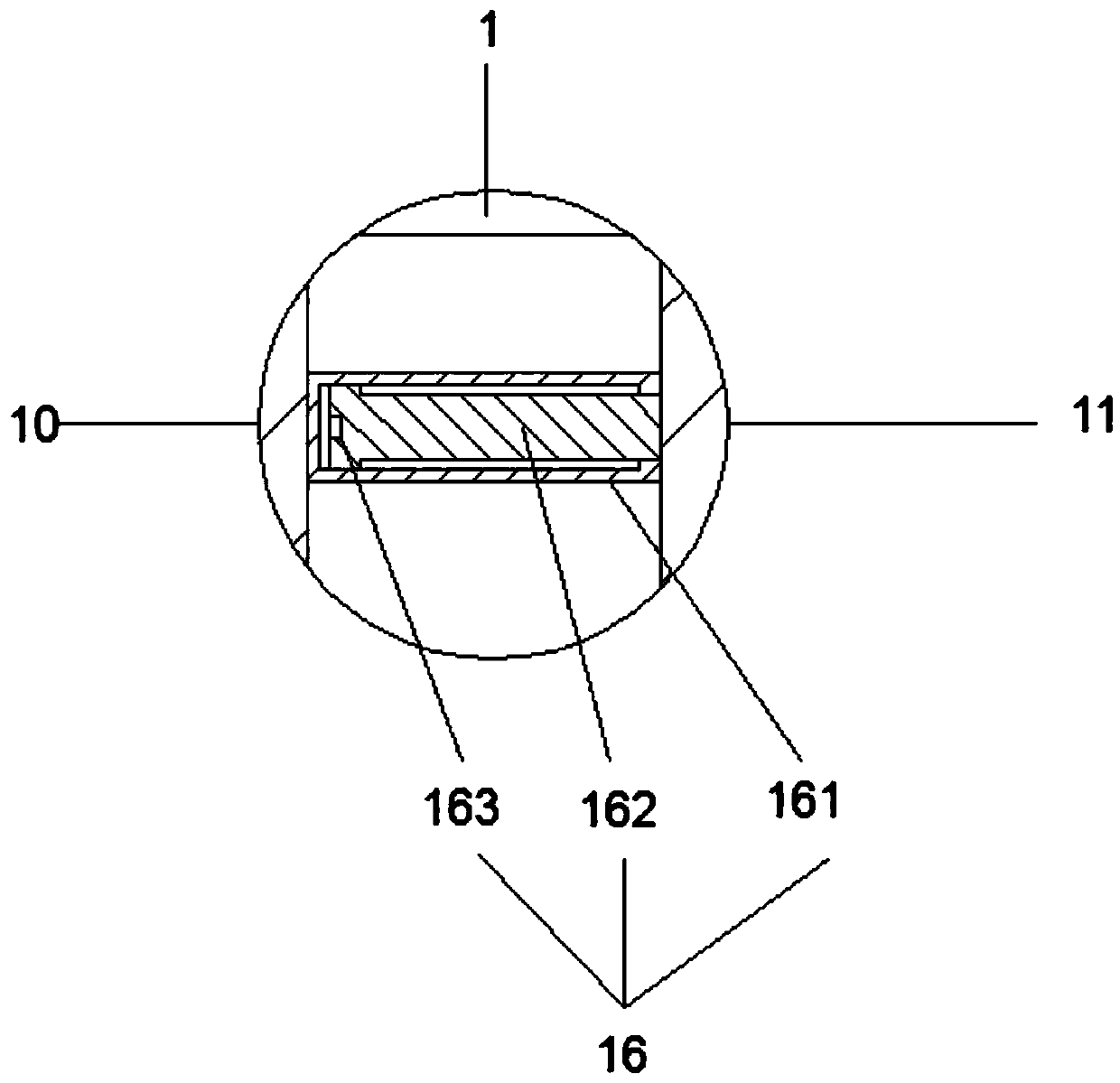

Hydraulic engineering decontamination grab bucket

ActiveCN109577300ARealize the measurement of gripping sizeIncrease gripWater cleaningPulleyControl engineering

The invention discloses a hydraulic engineering decontamination grab bucket, and relates to the technical field of hydraulic engineering equipment. The hydraulic engineering decontamination grab bucket comprises a support frame and pulleys. The pulleys are arranged on the top of the support frame, a slide groove is formed in the support frame, a first slide hydraulic cylinder and a second slide hydraulic cylinder are symmetrically arranged in the slide groove, a left slide mechanism and a right slide mechanism are slidably connected into the slide groove, a left grab bucket is hinged to the left slide mechanism, a right grab bucket is hinged to the right slide mechanism, a left grab jaw mechanism is arranged at the bottom of the left grab bucket, a right grab jaw mechanism is arranged at the bottom of the right grab bucket, a left hydraulic rod is hinged onto the left slide mechanism, one end of the left hydraulic rod is connected onto the left slide mechanism, the other end of the left hydraulic rod is connected onto the left grab bucket, and a right hydraulic rod is hinged onto the right slide mechanism. The hydraulic engineering decontamination grab bucket has the advantage thatthe hydraulic engineering decontamination grab bucket is provided with the slide hydraulic cylinders, the slide mechanisms, the hydraulic rods and the grab buckets and accordingly can be in diversified dirt grabbing modes.

Owner:芜湖市泽川水利工程有限公司

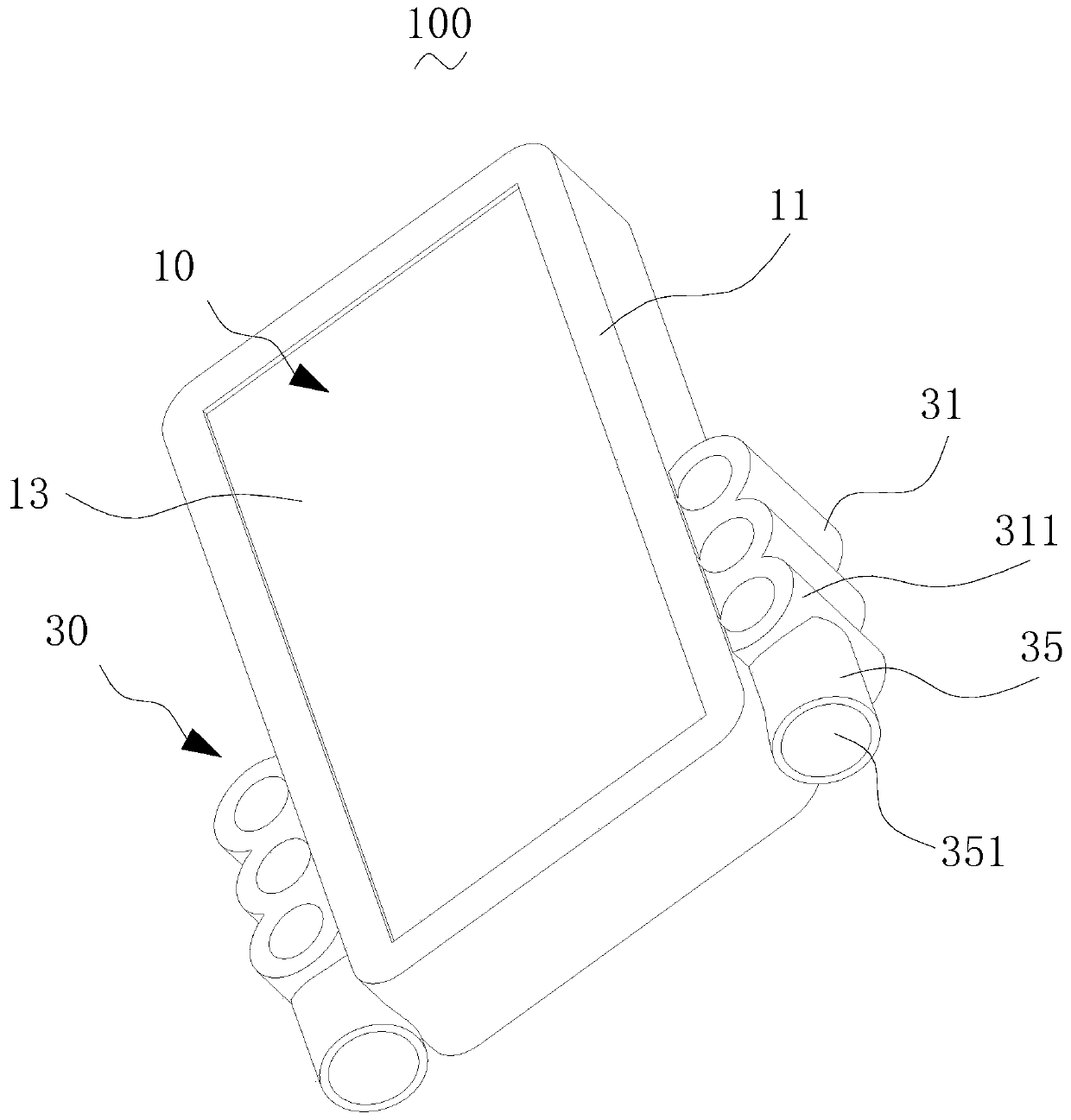

communication equipment

ActiveCN108810202BIncrease gripEasy to watchTransmissionTelephone set constructionsSoftware engineeringMechanical engineering

The invention relates to communication equipment. The communication equipment comprises a communication body and a holding component, wherein the communication body is a rectangular block, the holdingcomponent comprises a holding part and a penetration cylinder, the holding part is arranged on the side wall of the communication body and is close to one end of the communication body, the holding part comprises multiple insertion cylinders that are arranged in parallel, the multiple insertion cylinders all extend in parallel to the thickness direction of the communication body, the penetrationcylinder is arranged at one side of the holding part in protruding manner, the penetration cylinder extends toward the end of the communication body, the penetration cylinder extends in parallel to the length direction of the communication body, and a penetration groove is formed in the penetration cylinder. The communication equipment is convenient to hold stably.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com