Aromatic polyamide fabric soft-bodied robot

A polyaramid and robot technology, applied in the field of flexible robots, can solve the problems of affecting the grasping force, limited passing ability, low output volume ratio, etc., and achieve the effect of increasing wear resistance and enhancing grasping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

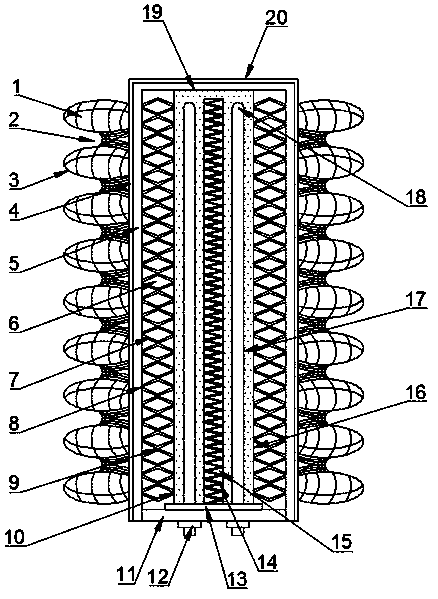

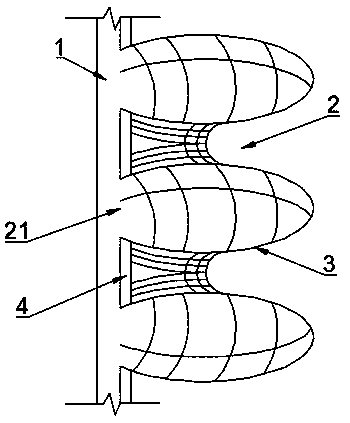

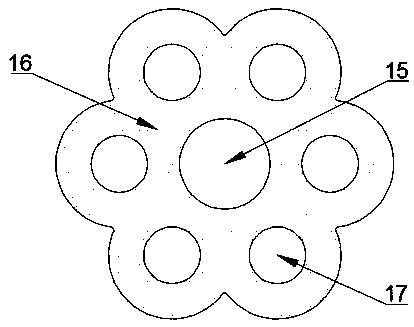

[0022] see Figure 1-Figure 3 , a soft robot made of polyaramid fabric, comprising a soft finger 1, a fabric cover 3, an elastic cover 5, an elastic support frame 7, a spring column 14 and an elastic base 16, the elastic base 16 is arranged in the elastic cover 5, elastic A deformation cavity 6 is set between the base body 16 and the elastic sleeve 5, and an elastic support frame 7 is arranged in the deformation cavity 6. The elastic support frame 7 is in an annular structure as a whole and is sleeved outside the elastic base body 16. The elastic support frames 7 are interlaced with each other. Composed of elastic rods, the connection between the elastic support frame 7 and the inner wall of the elastic sleeve 5 is an external support point 8, and the interlaced elastic rods on it are set as cross support points 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com