Built-up form for heatretaining compoiste concrete wall body

A heat-insulating concrete and combined formwork technology, which is applied in the direction of heat preservation, formwork/formwork components, formwork/formwork/work frame, etc., can solve the problems of enhancing the grip strength of built-in steel sheets and polystyrene materials, and achieve enhanced Grip strength, enhanced integrity and strength, and convenient adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

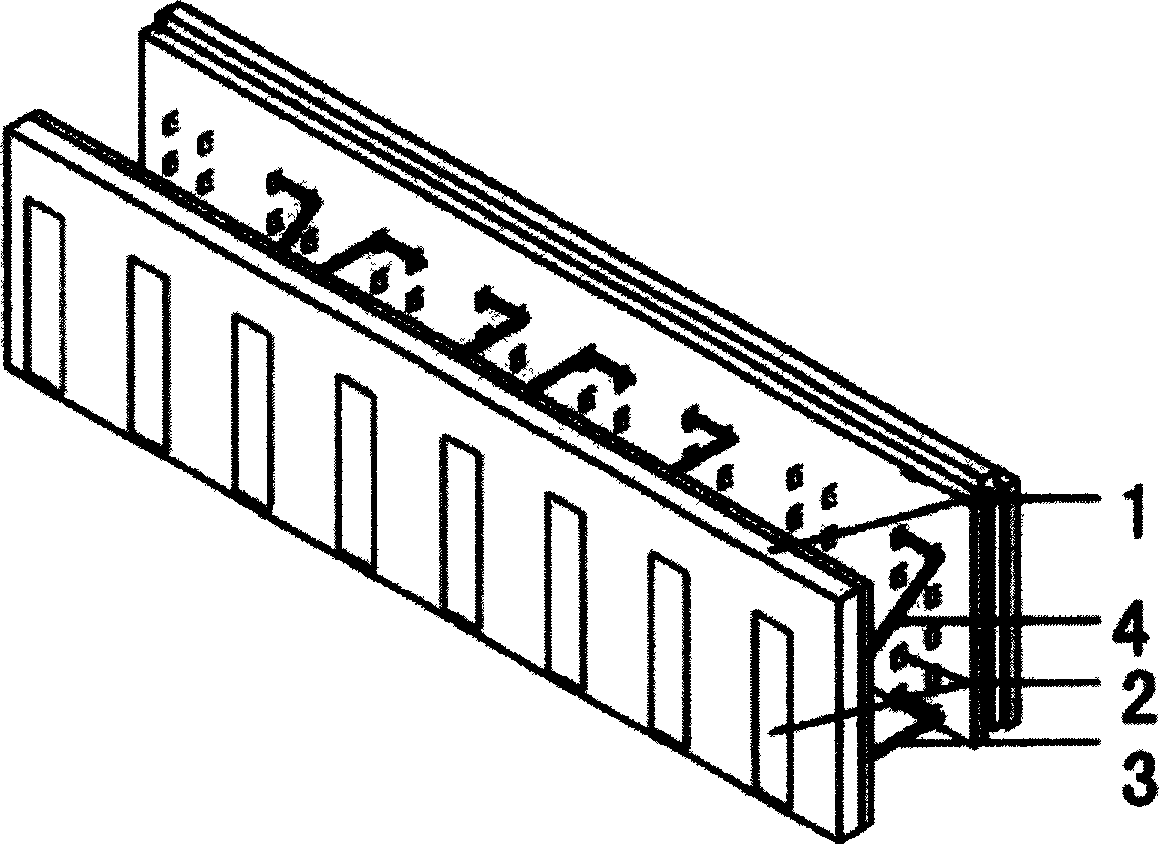

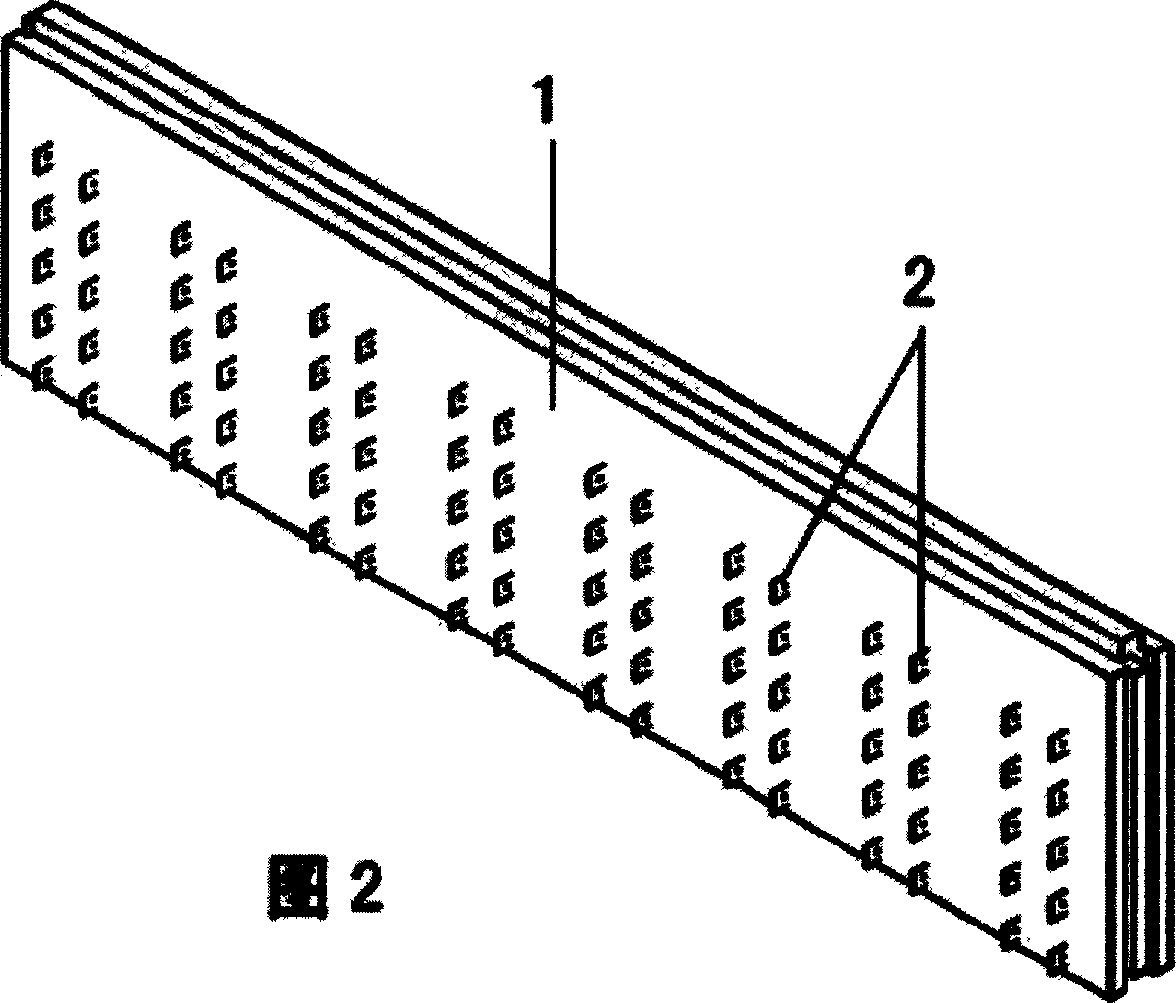

[0024] Examples see figure 1 -4. This compound formwork for thermal insulation concrete walls consists of two polystyrene foam boards arranged in parallel as the side formwork 1, with built-in steel sheets 2 built into the boards, and horizontal connecting ribs 3 connected between the two boards. And / or oblique connecting ribs 4, two rows of built-in steel sheets are opposite, evenly spaced, and vertically buried in the polystyrene foam board side formwork.

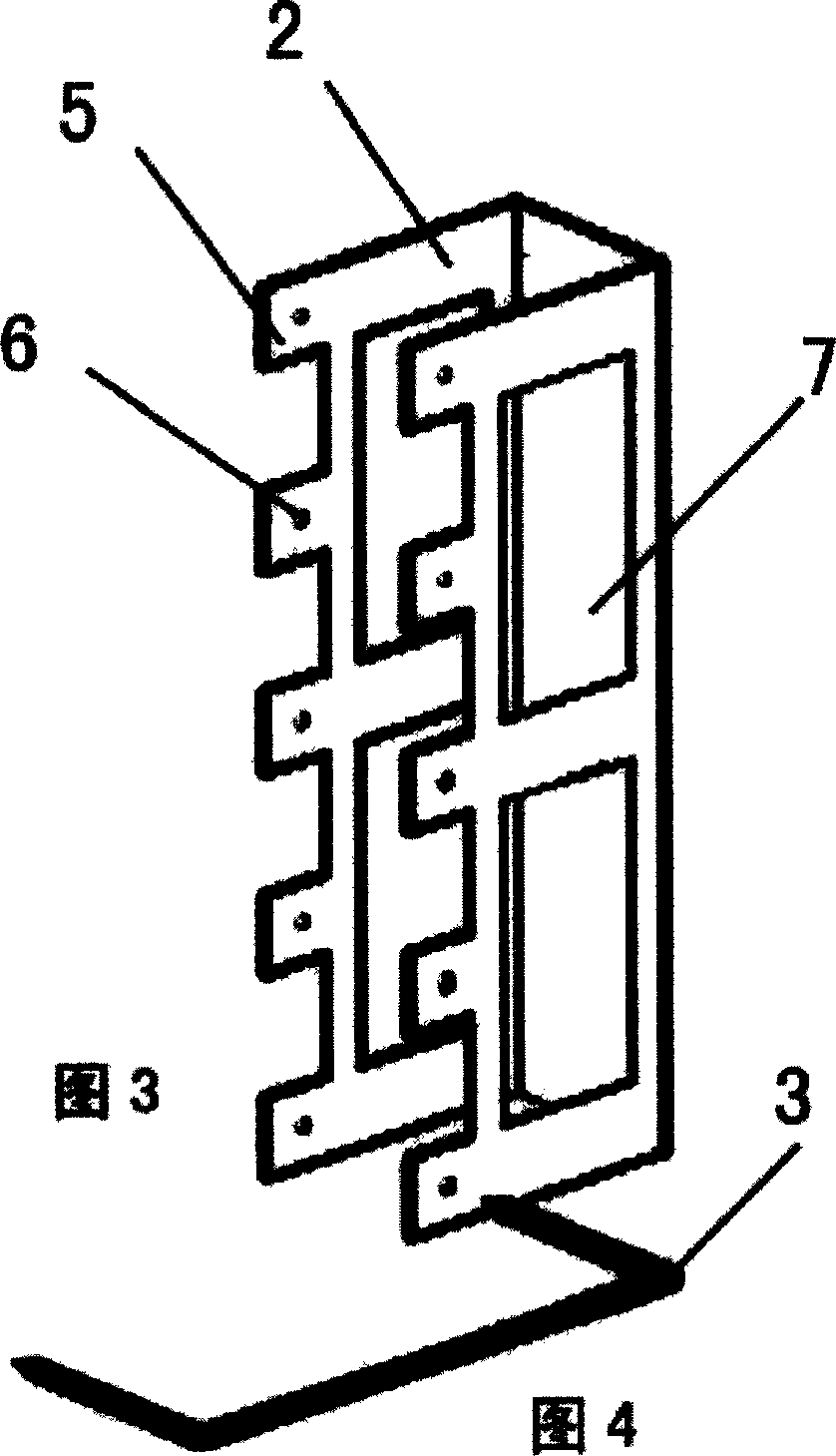

[0025] see figure 1 , 2, 3, in order to further enhance the integrity and strength of the template, and enhance the gripping force of the built-in steel sheet and polystyrene material, the cross-section of the built-in steel sheet is Kai-shaped, and the edges of the two bending surfaces have concave-convex teeth 5 , have a through hole 6 on the concave-convex teeth, the concave-convex teeth and the through holes are exposed on the inner surface of the polystyrene foam board side formwork, and the tooth profile of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com