Leakage-proof hydraulic pipe ferrule

A technology of hydraulic pipes and hydraulic oil pipes, which is applied in the field of leak-proof hydraulic pipe ferrules, which can solve the problems of hydraulic pipe joint ferrules rupture, failure to reach, and easy deformation, so as to avoid excessive movement damage, increase cushioning effect, and enhance holding The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

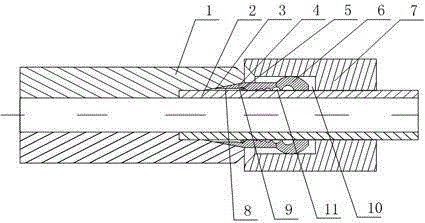

[0021] Such as figure 1 As shown, this embodiment includes a joint body 1, a hydraulic oil pipe 2 and a nut 7 threadedly fitted with the hydraulic oil pipe 2. The joint body 1 is sleeved on the hydraulic oil pipe 2, and at the connecting end of the joint body 1 and the hydraulic oil pipe 2 An inner tapered interface 3 is provided, and an active groove 10 is opened at the end of the nut 7 facing the joint body 1, and the ferrule is installed in the active groove 10 and its inner wall is bonded to the outer peripheral wall of the hydraulic oil pipe 2. The ferrule is composed of a buffer part 6 and a sealing part 4. The buffer part 6 is an elastic metal ring. The outer peripheral wall of the buffer part 6 is provided with an expansion part protruding outward along its radial direction and having an arc-shaped cross-section. The expansion part The arc top of the arc is in contact with the upper wall of the movable groove 10, the sealing part 4 is connected with the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com