Cleaning tool

A technology for cleaning tools and panels, which is applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., and can solve problems such as throwing out, wiping cloth falling off, and low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

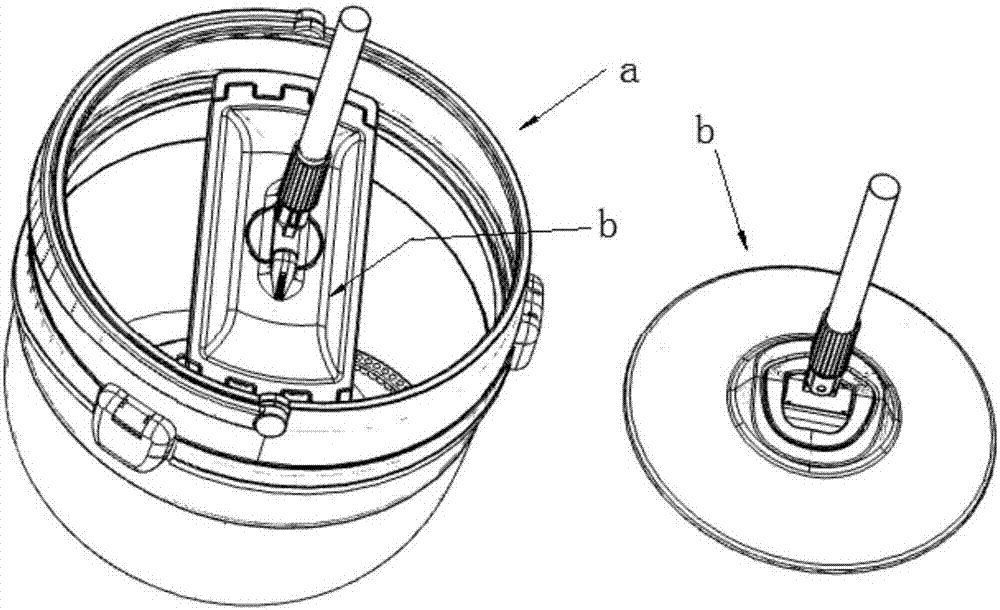

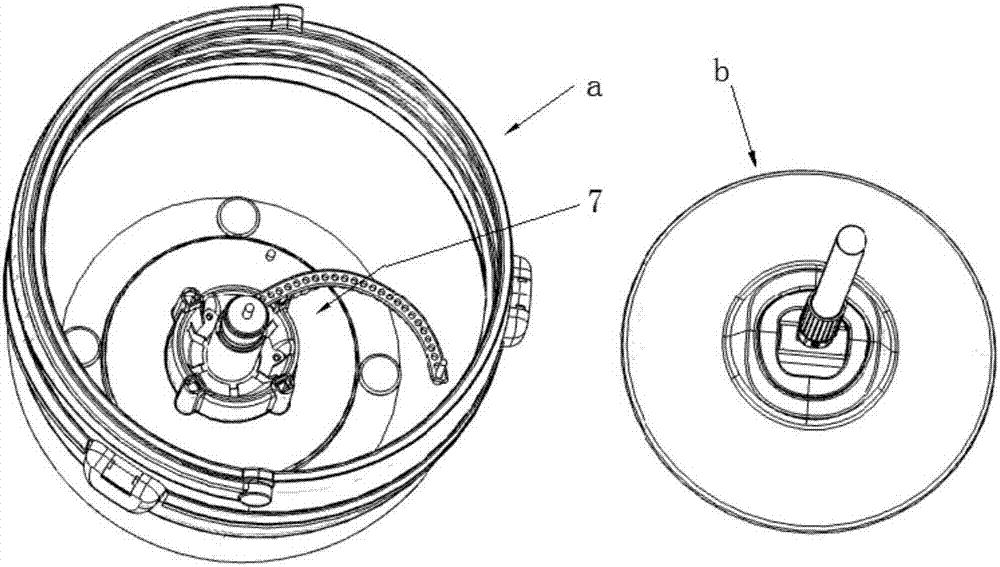

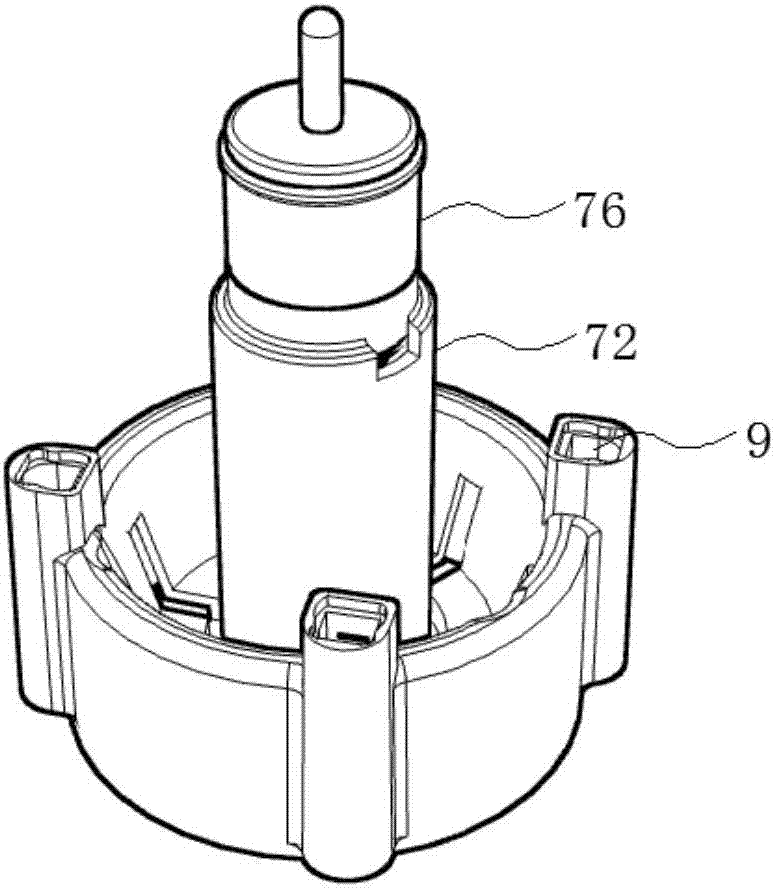

[0124] Embodiment: a kind of cleaning tool, as Figure 1-Figure 39 As shown, including mop bucket a and mop b;

[0125] The mop b includes a handle 5, a bottom plate and a rotating joint 4, the handle 5 includes an outer rod body 51 and an inner rod body 52, the outer rod body 51 and the inner rod body 52 are socketed, and the rotating joint includes a second A rotating member 41 and a second rotating member 42, the first rotating member 41 is rotatably connected to the second rotating member 42, the second rotating member 42 is rotatably connected to the connecting seat 3, and the first rotating member 42 is rotatably connected to the connecting seat 3. The rotating shaft of a rotating member 41 and the rotating shaft of the second rotating member 42 are perpendicular to each other, the first rotating member is connected to the handle, and the wiping cloth is located on the side of the bottom plate;

[0126] The bottom of the mop bucket a is provided with a lifting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com