Novel steel strand

A new type of steel strand technology, applied in textiles and papermaking, textile cables, building components, etc., can solve the problems of small contact area of steel wire, low friction force, sliding and retraction of the edge of the core wire, etc., to improve safety and strength, good mechanical properties, the effect of increasing the grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

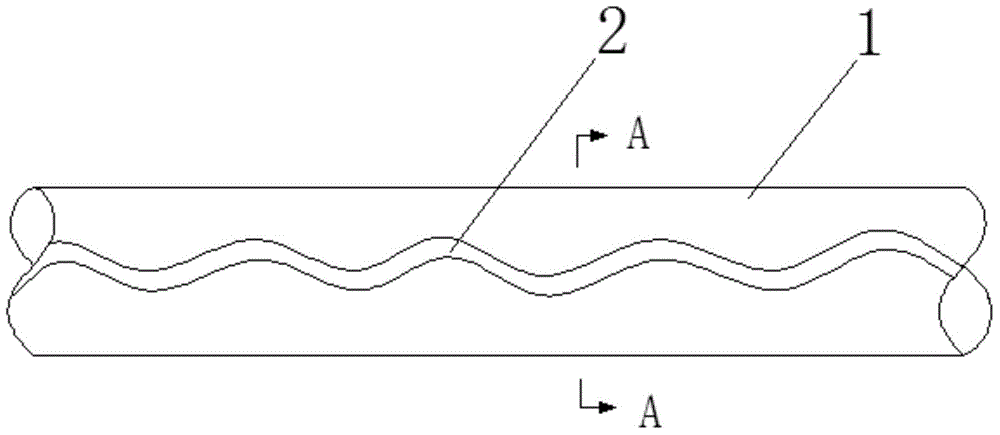

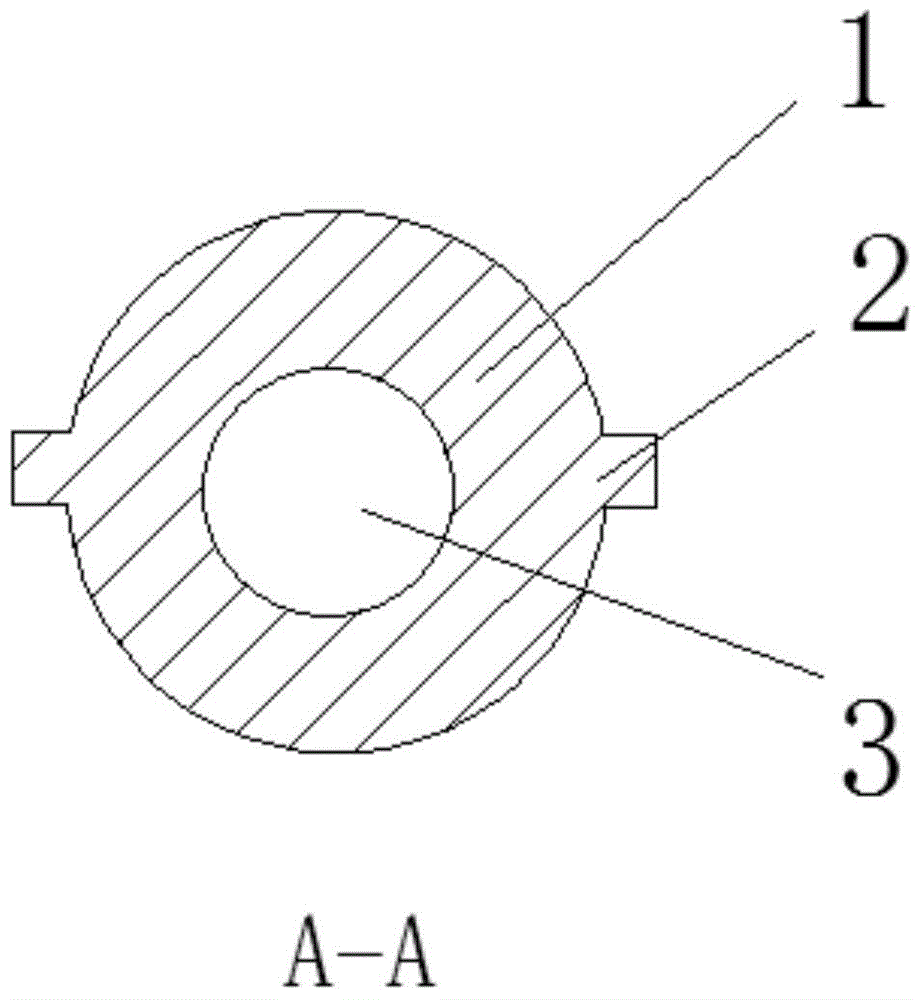

[0014] Such as figure 1 and figure 2 As shown, the present invention includes a body composed of a center wire 3 and a side wire 1, wherein the center wire 3 is a solid smooth round steel wire, and the side wire 1 is a hollow ring-shaped steel wire inside, and the center wire 3 just can The center of the edge wire 1 is inserted, and there are 2 to 4 continuous raised ribs 2 on the surface of the prestressed steel wire body.

[0015] When in use, due to the adoption of the above-mentioned technical scheme, on the basis of the smooth steel wire, the grip force to the cement is increased, and the safety and strength of the use are improved. At the same time, the structure of the center wire and side wire of this kind of steel strand makes The friction between the two increases, which solves the problem of slipping and retracting between the center wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com