Fire-fighting robot

A technology of a fire-fighting robot and a turning mechanism, which is applied in the field of robots, and can solve the problems that the fire-fighting machine cannot be turned over automatically, affects the fire-fighting work, and the fire-fighting robot is overturned, and achieves the effects of easy reset, enhanced grasping force, and improved fire-fighting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

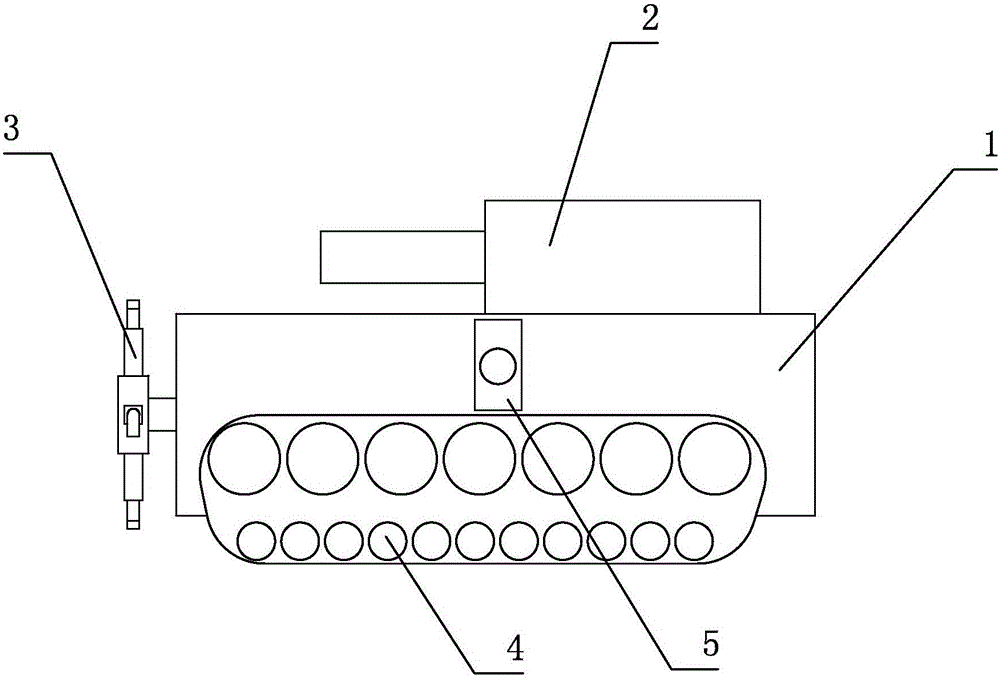

[0023] Such as figure 1 As shown, the fire-fighting robot includes a car body 1, the two sides of the car body 1 are provided with a traveling sprocket 4, the upper part of the car body 1 is provided with a water spray device 2, the front end of the car body 1 is provided with a turning mechanism 3, and the two sides of the car body 1 are provided with Auxiliary support mechanism 5, the auxiliary support mechanism 5 is located above the traveling sprocket 4.

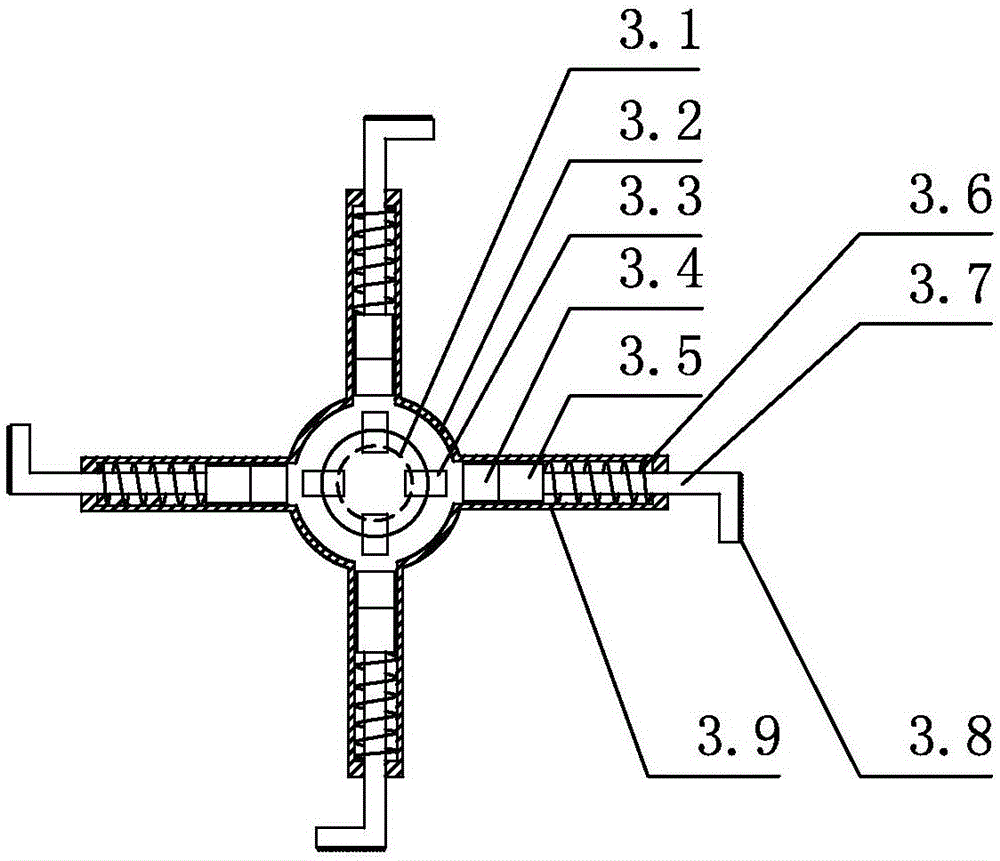

[0024] Such as figure 2 As shown, the turning mechanism 3 includes a turntable 3.2 and a drive shaft 3.1 for driving the turntable 3.2, and the drive shaft 3.1 is connected to a driving device. A plurality of rotating arms 3.9 are arranged along the circumference of the turntable 3.2, and 3 to 10 groups of rotating arms 3.9 can be arranged according to needs, and a telescopic rod is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com