Patents

Literature

84results about How to "Does not change chemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for effectively reducing metal content in polyetheretherketone

ActiveCN101486784ASimple purification processNo need for heat and pressureCentrifugationDistilled water

The invention relates to a method for effectively reducing the metal content in a polyetheretherketone at normal temperature and pressure. The method mainly comprises purification, centrifugation, washing, and drying. The invention uses hydrochloric acid as purification agent and adds the polyetheretherketone particles into hydrochloric acid solution with certain concentration; after the purification treatment is finished and the centrifugation hydrochloric acid removal is carried out, and then the distilled water is washed to neutral and dried; and polyetheretherketone particles of high quality can be obtained. The method not only can effectively reduce the metal content in the polyetheretherketone and does not change the physical and chemical properties of the polyetheretherketone, but also has the advantages of simple process, easily-fetched raw material, no need of temperature and pressure increase, and low cost.

Owner:JILIN ZHONGYAN HIGH PERFORMANCE PLASTIC

Production technology of low-temperature instant-dissolving agar

The invention discloses production technology of low-temperature instant-dissolving agar. The technology includes the steps: adding cosolvent into seaweed glue liquid or adding water into agar and cosolvent, boiling, dissolving completely, processing through a high-pressure or superpressure device, dehydrating through a plate-and-frame filter press, microwave drying to sterilize till an appropriate amount of water is left, smashing and sieving to obtain low-temperature instant-dissolving products (physical modified agar); or processing through the high-pressure or superpressure device and spray-drying to obtain the products (physical modified agar); or processing through the high-pressure or superpressure device, superfreezing, thawing, filter-pressing, extruding through a screw compressor, airing and smashing to obtain the products (physical modified agar). The low-temperature instant-dissolving agar produced by using the technology method has the advantages of being fast in dissolving at the low temperature.

Owner:青岛德慧海洋生物科技有限公司

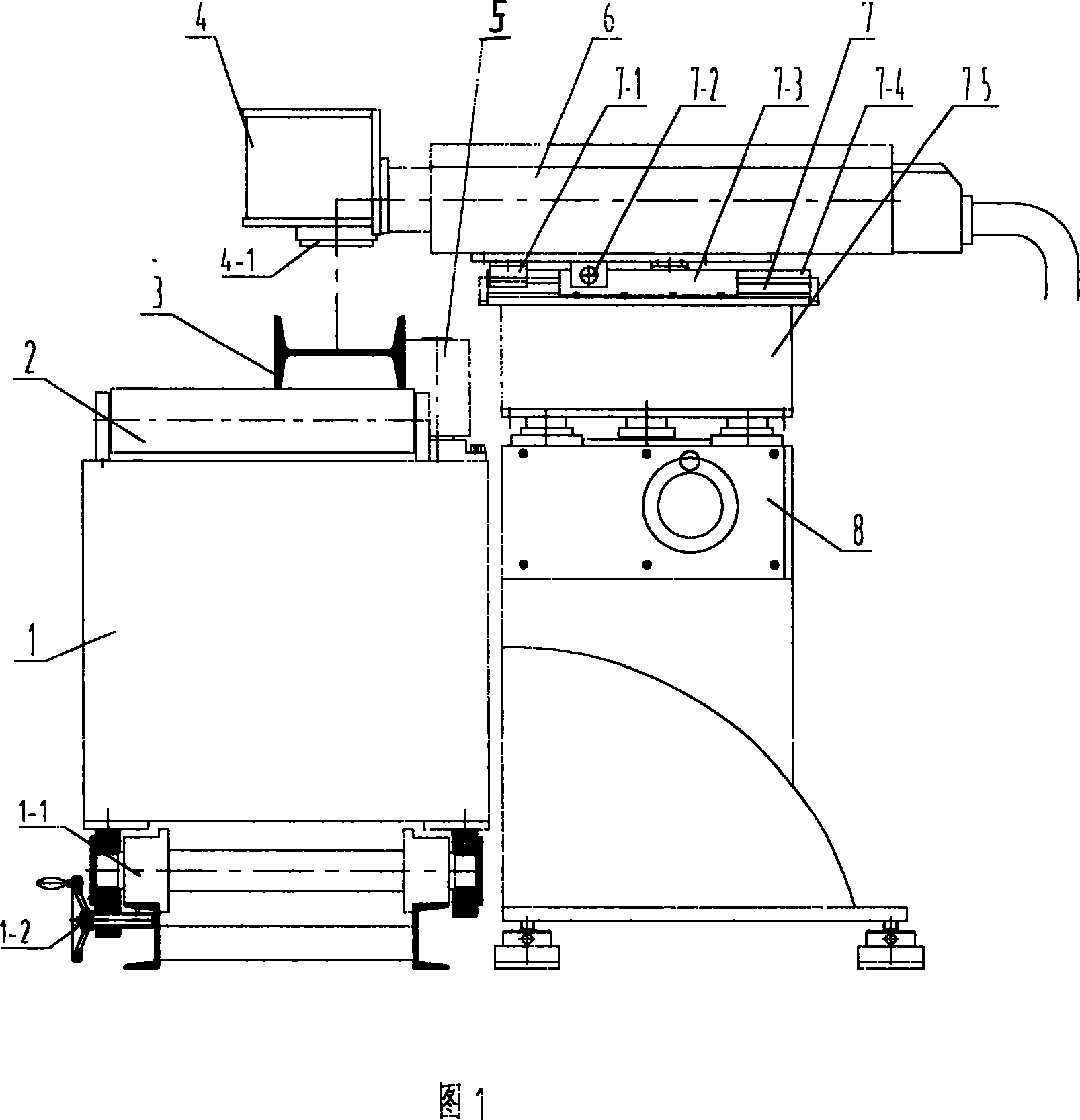

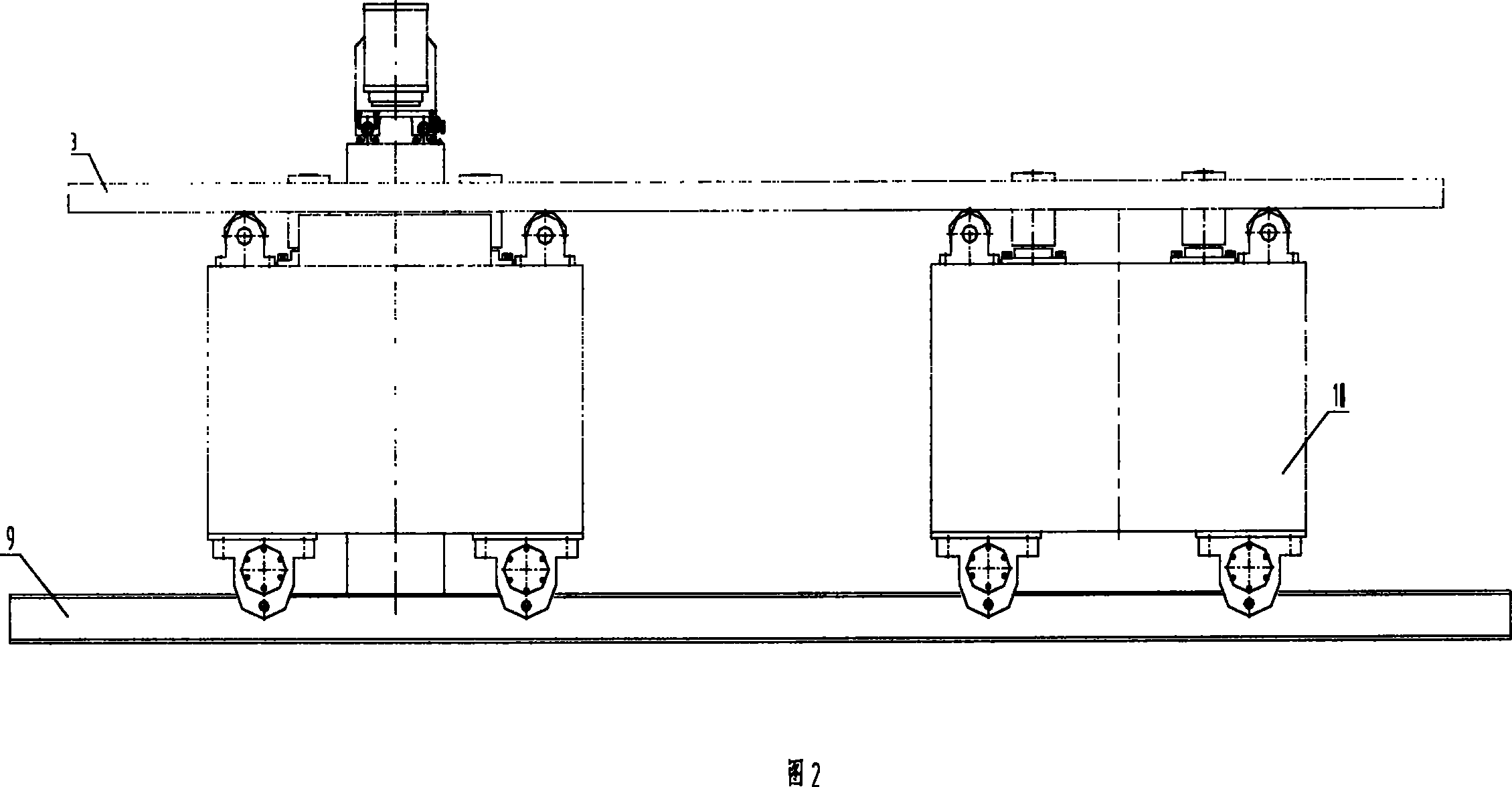

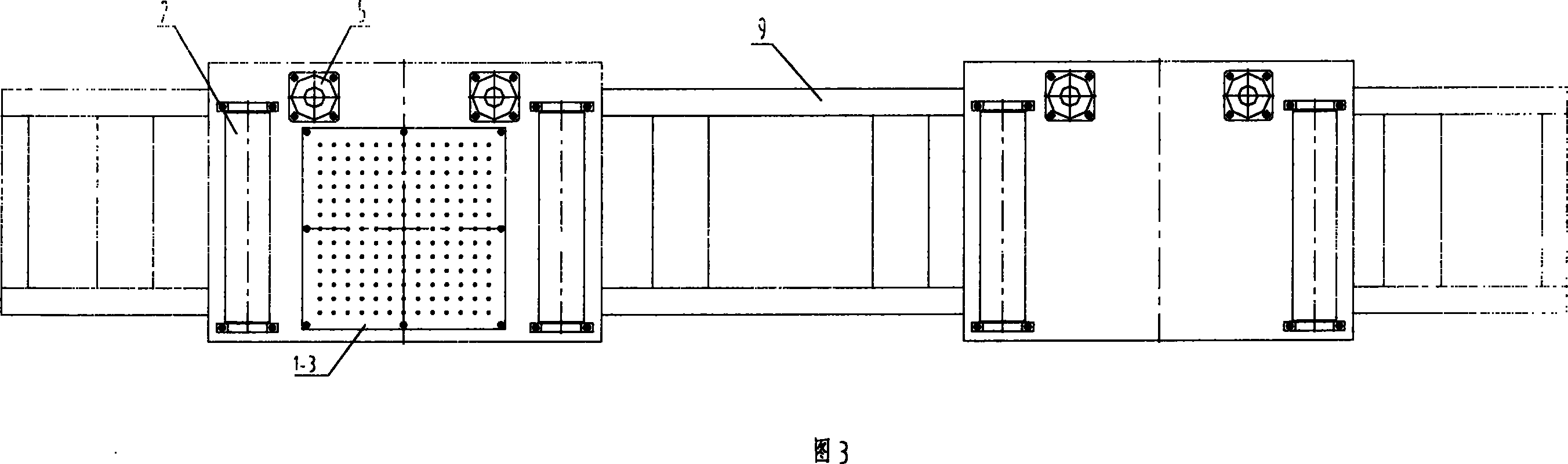

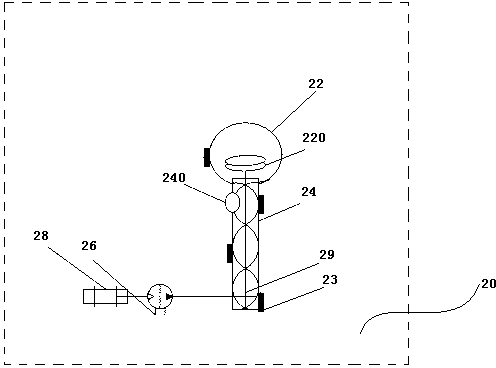

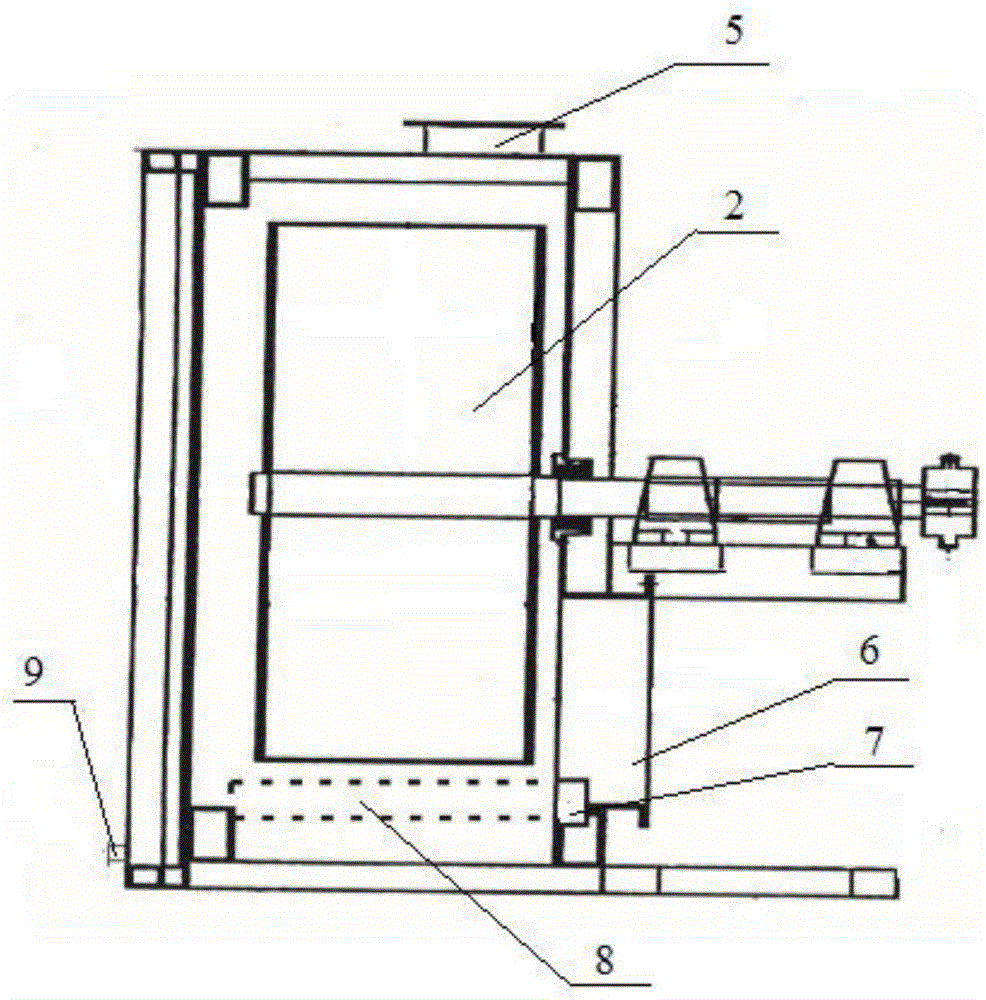

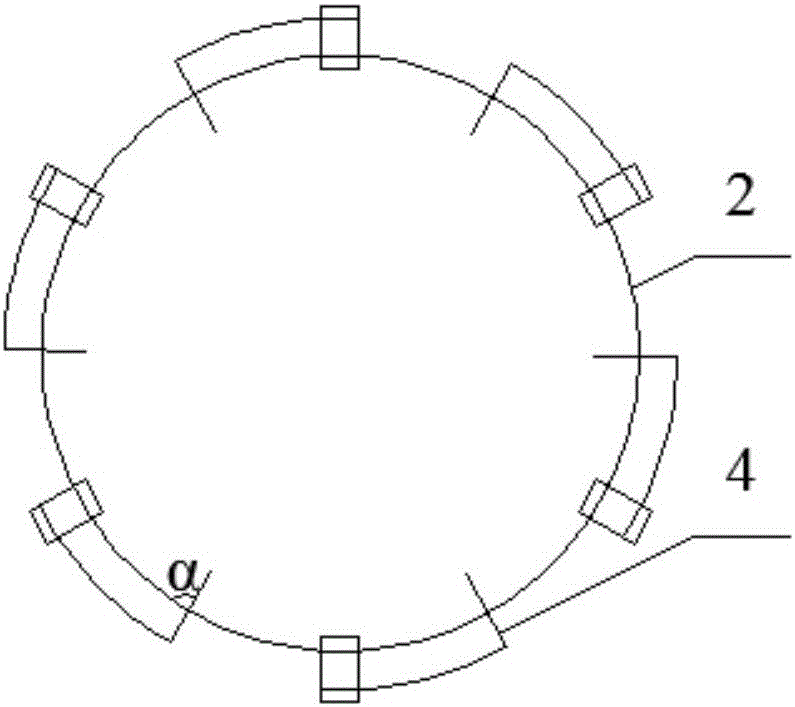

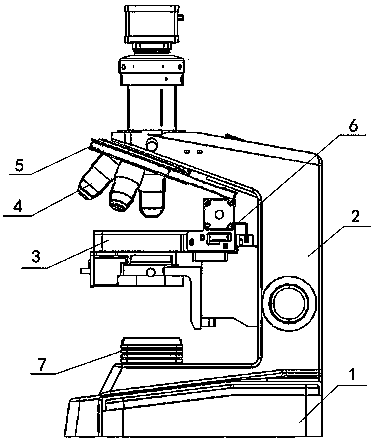

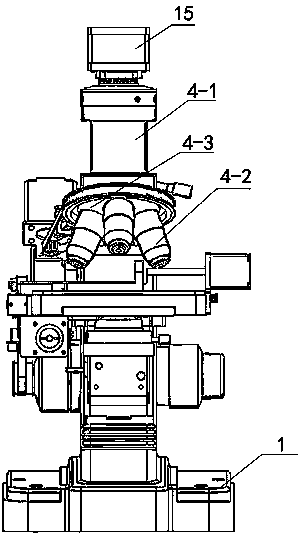

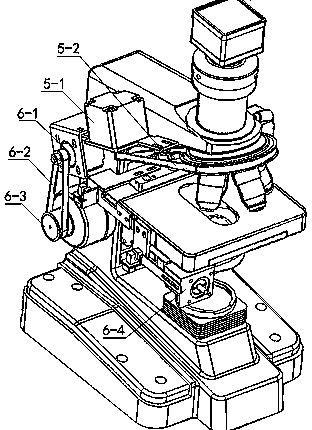

Laser mark printing device for section steel

InactiveCN101121349ADoes not change mechanical propertiesCausing mechanical deformationAblative recordingLaser beam welding apparatusGraphicsOptical flat

The invention relates to the field of laser marking. The invention discloses a laser marking device for section steel, which includes a computer system, a laser, and an optical flat-field mirror located below the light-emitting part of the laser. It is characterized in that it also includes a main workbench trolley , workpiece, laser X-direction precision sliding table, laser Y-direction precision lifting mechanism, guide rail, driven work trolley, among which, the main workbench trolley and the slave work trolley are on the guide rail, and the workpiece is placed on the main workbench trolley and the slave work trolley The upper surface of the trolley is located below the optical flat field mirror. The invention has high efficiency, does not affect the performance of workpieces, can realize laser marking on large workpieces, changes the operation mode of manual painting on section steel for model marking, and can mark permanent pictures and texts on section steel.

Owner:武汉楚天激光(集团)股份有限公司

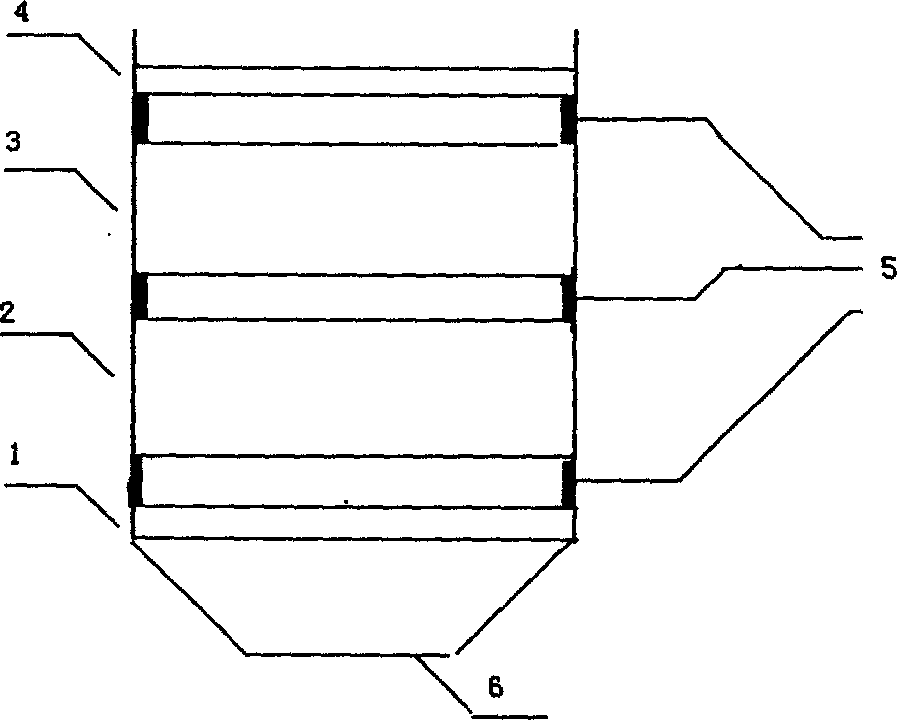

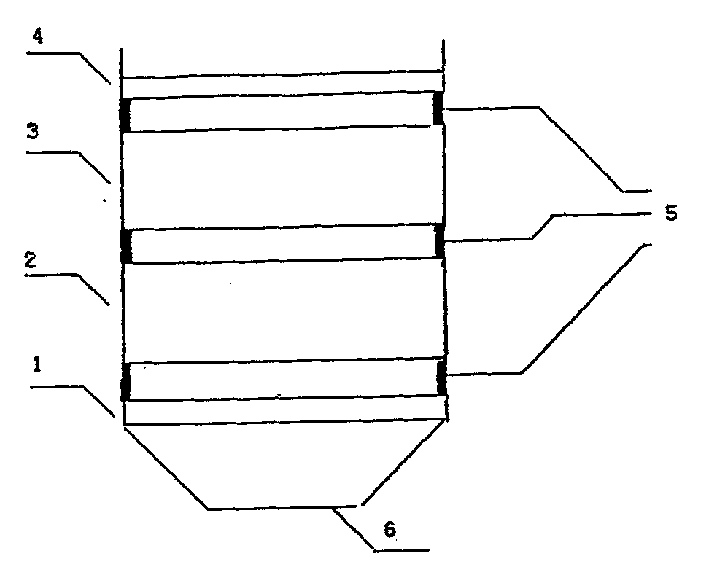

Fire-fighting aerosol equipment for cooling and breaking flame

InactiveCN1600391ADoes not change physicsDoes not change chemical propertiesFire extinguisherEngineeringSecondary layer

A cooling and flame-isolating appts. for extinguishing fire by aerosol features that the chemicals are used for cooling because the chemicals are decomposed at different temps to absorb heat. It is a 4-layer structure in which the first and the fourth layers are used for isolating flame, and the second and the third layers for cooling purpose.

Owner:ZHEJIANG UNIV OF TECH

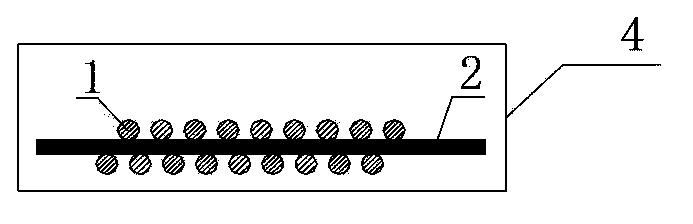

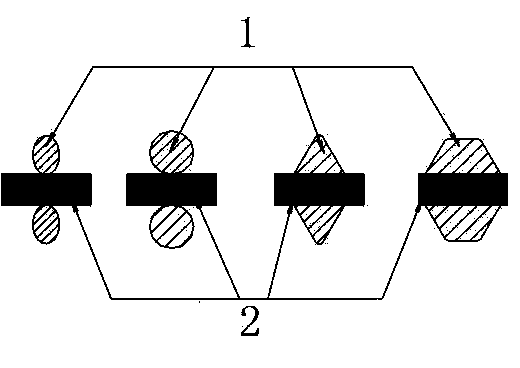

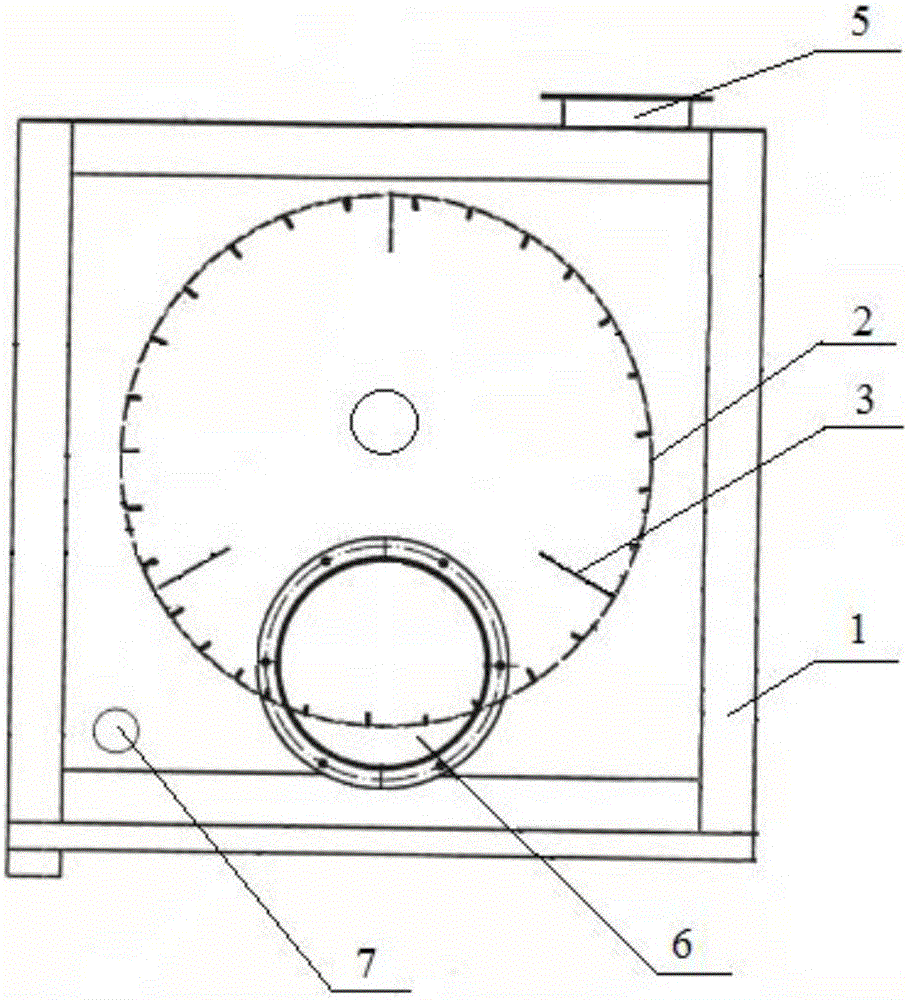

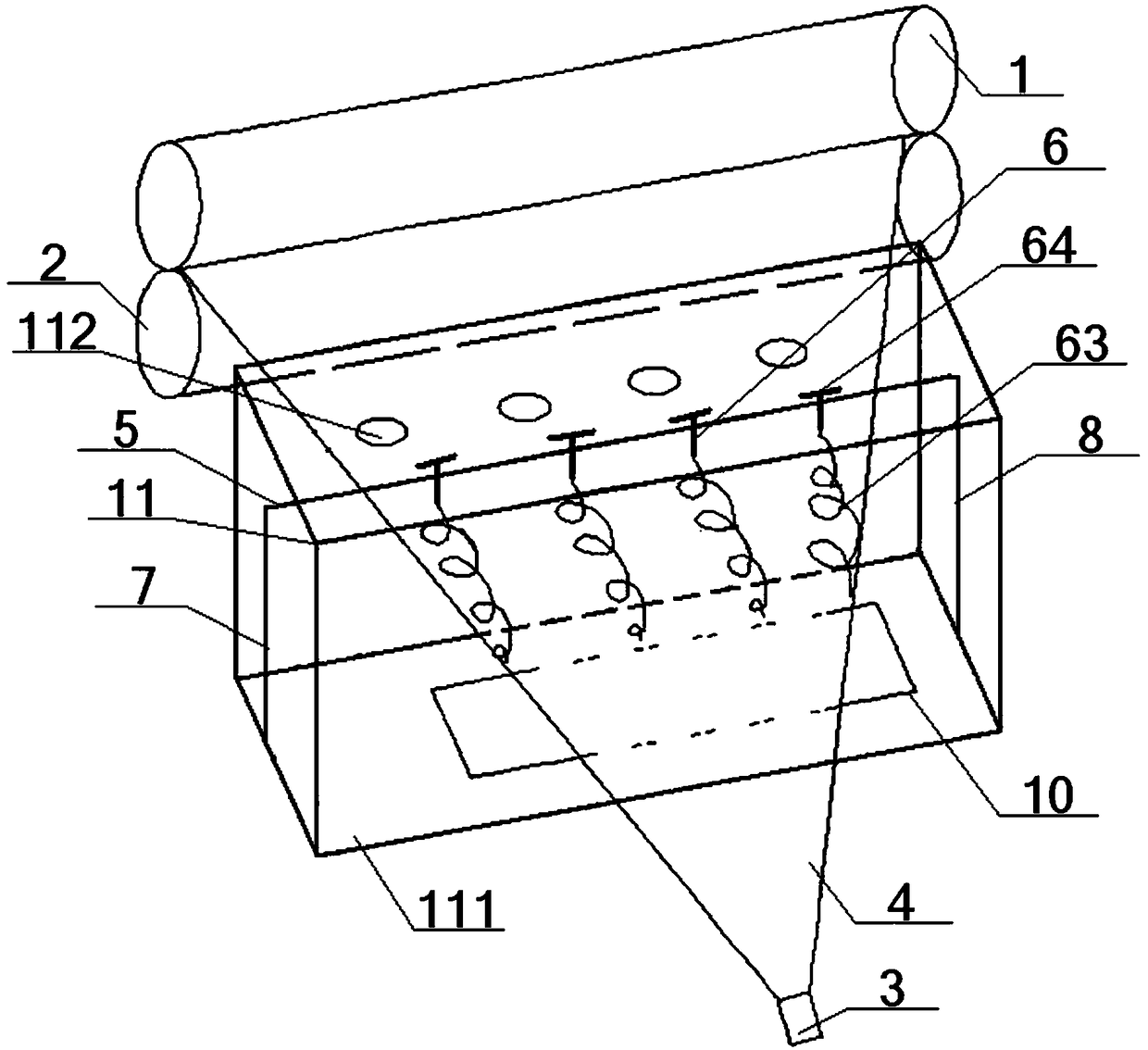

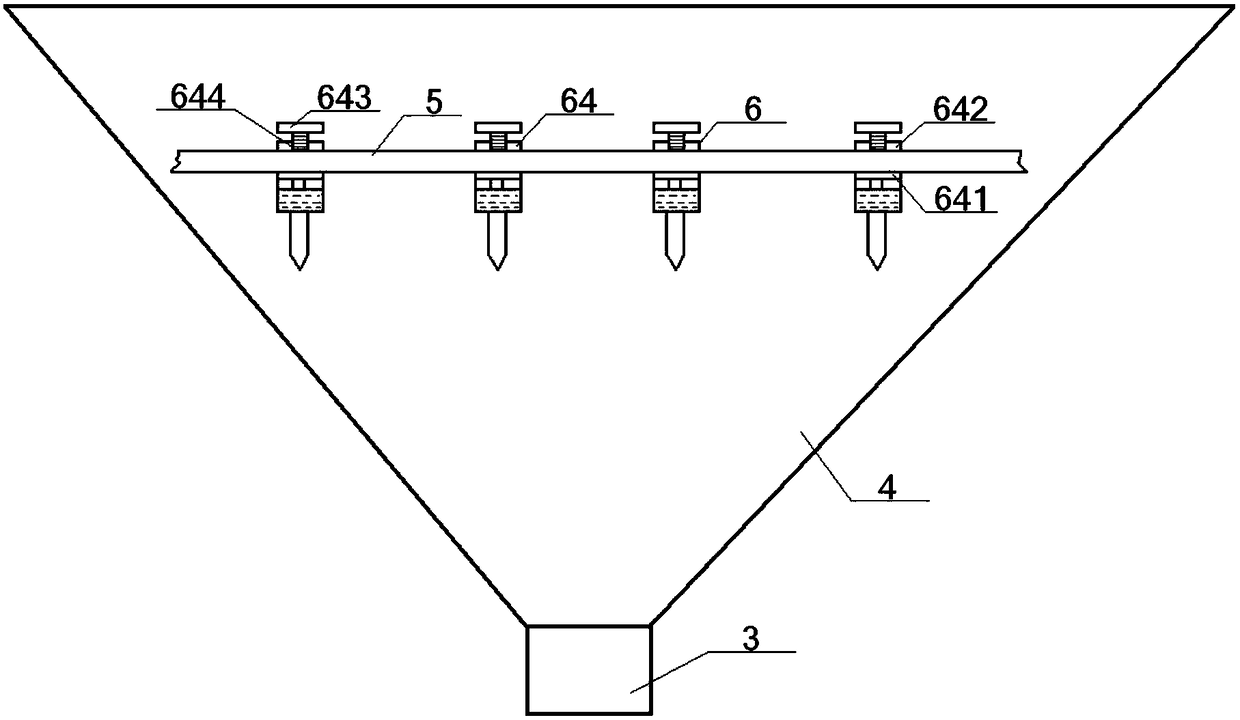

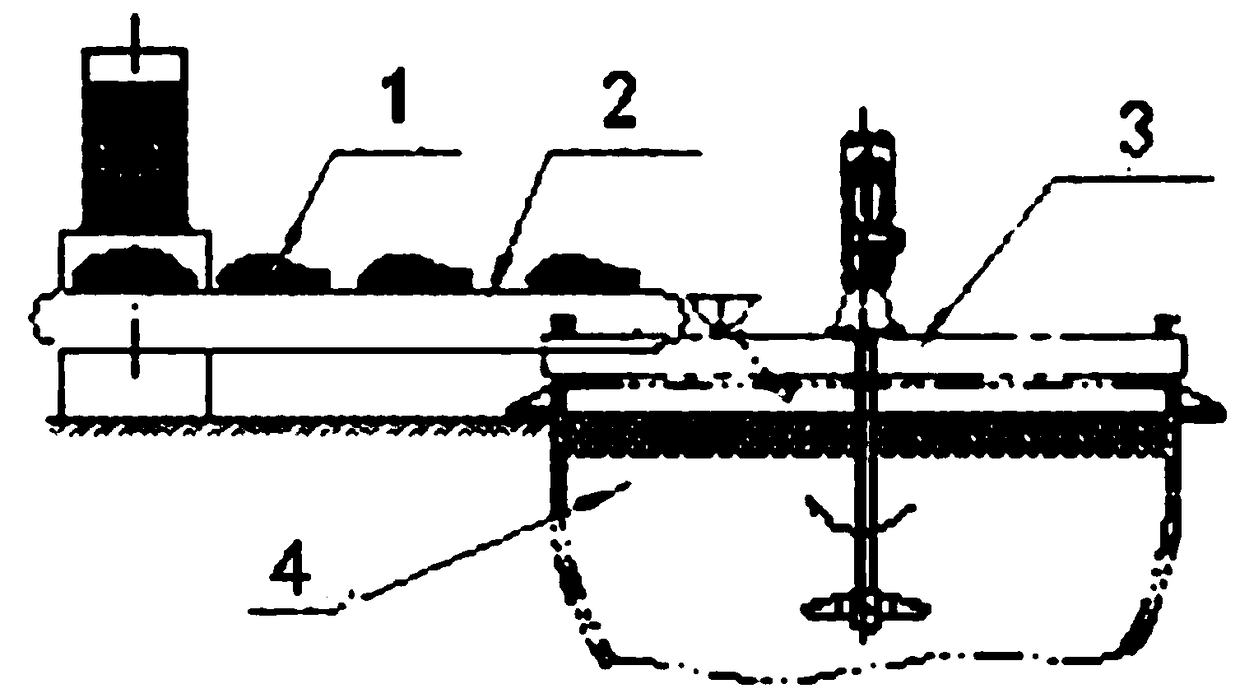

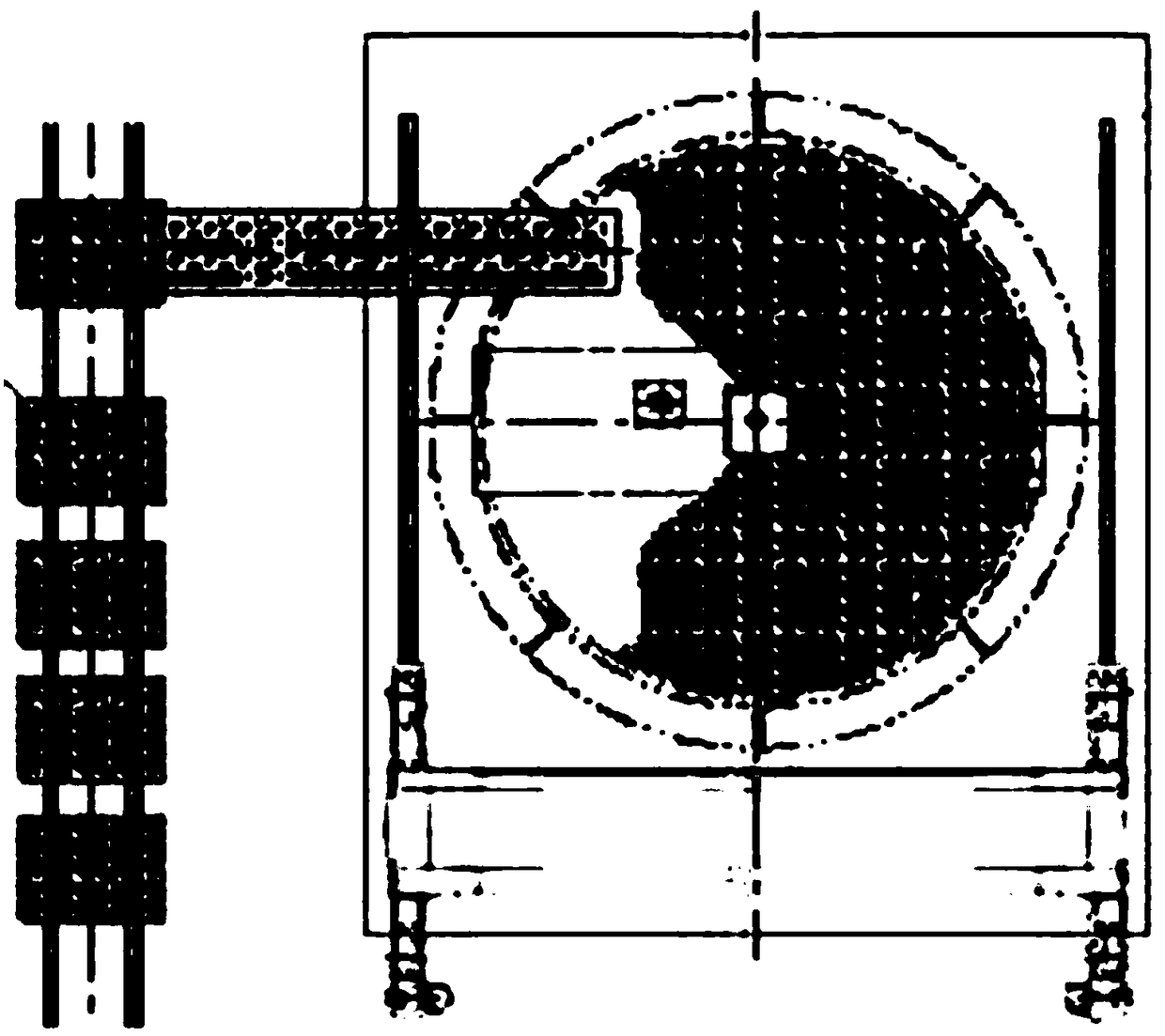

Device for promoting reaction by direct contact between blast furnace slag particles and biomass particles

InactiveCN103265964APromote pyrolysis gas productionSimple structureDirect heating destructive distillationBiofuelsSlagPhysical chemistry

The invention relates to a device for promoting reaction by direct contact between blast furnace slag particles and biomass particles. The device comprises a feeding device, a reaction device, a separation device and a gas purification and collection device, wherein the feeding device is provided with a discharge pipe of the feeding device; the bottom of the reaction device is provided with a discharge hole of the reaction device, and the top of the reaction device is provided with an air outlet and a feeding hole of the reaction device; the separation device is provided with a slag outlet, and the top of the separation device is also provided with a feeding hole of the separation device; the discharge pipe of the feeding device is communicated with the feeding hole on the top of the reaction device; the discharge hole at the bottom of the reaction device is communicated with the feeding hole on the top of the separation device; and the air outlet on the top of the reaction device is communicated with the gas purification and collection device. The device can be used for promoting gas production of biomass pyrolysis by the high temperature provided by the collision between the blast furnace slag particles and the biomass particles in the reaction device; and finally, the mixed particles are separated, the separated blast furnace slag particles can be taken as building materials, and the separated biomass particles can be taken as carbon fuel, so that the device is energy-saving and environment-friendly.

Owner:CHONGQING UNIV

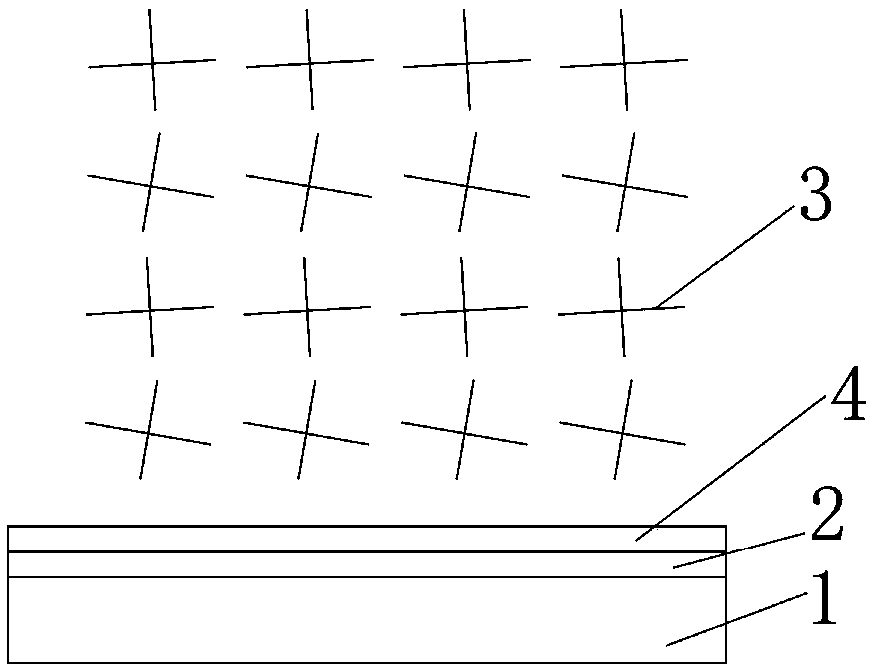

High frequency metal core circuit substrate production method

InactiveCN103547074AHigh peel strengthImprove adhesionPrinted circuit manufactureCircuit susbtrate materialsGlass fiberTetrafluoroethylene

The invention discloses a high frequency metal core circuit substrate production method. The method includes adopting tetrafluoroethylene powder and polyphenylene ether powder, performing ball-milling through a ball milling machine, then placing substrate dielectric material in a mole, forming a substrate dielectric material layer at high temperature in a pressed manner, selecting glass fiber cloth, placing in PTFE resin, preimpregnating through an impregnator, producing glass cloth impregnated bonding sheet by high-temperature sintering, finally selecting a copper foil layer, an insulation dielectric material layer, a glass cloth impregnated bonding sheet and a metal core, arranging the insulation dielectric material layer above the copper foil layer, inserting the glass cloth impregnated bonding sheet between the insulation dielectric material layer and the copper foil layer and bonding, arranging the metal core above the insulation dielectric material layer, inserting the glass cloth impregnated bonding sheet between the insulation dielectric material layer and the metal core and bonding, and finally forming in a pressed manner with pressure in the high-temperature environment. The high frequency metal core circuit substrate has the advantage of simple structure, reasonable design, good insulation, low thermal resistance, high thermal conductivity, good radiating performance, stable and reliable performance, and low producing cost.

Owner:朱云霞

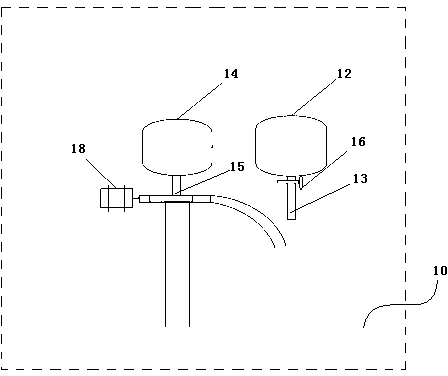

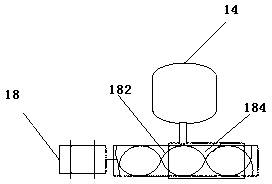

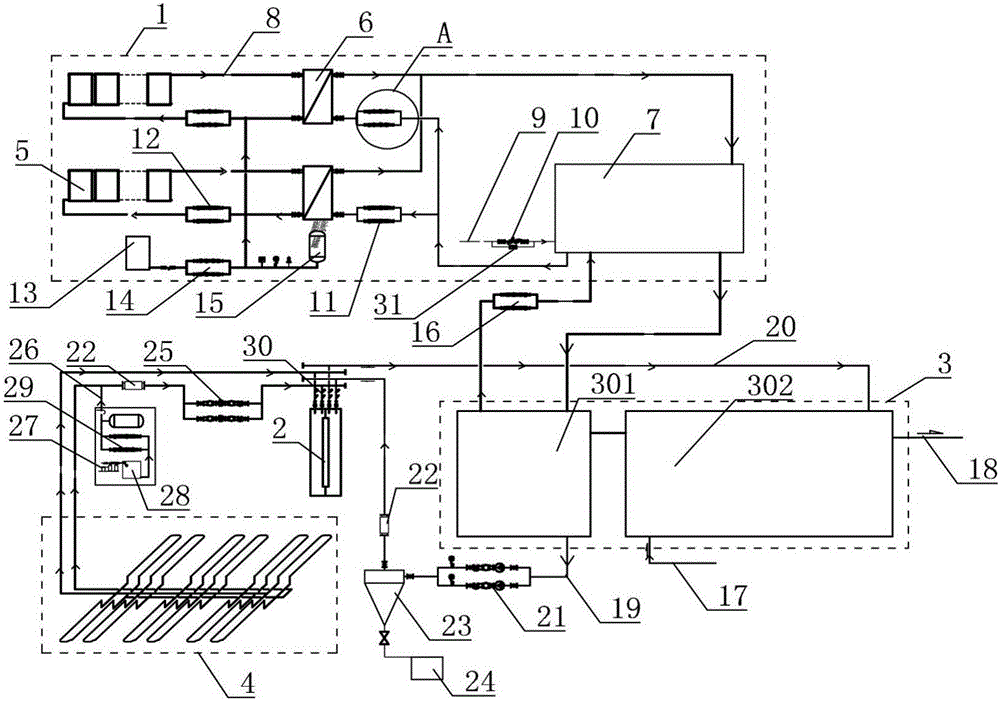

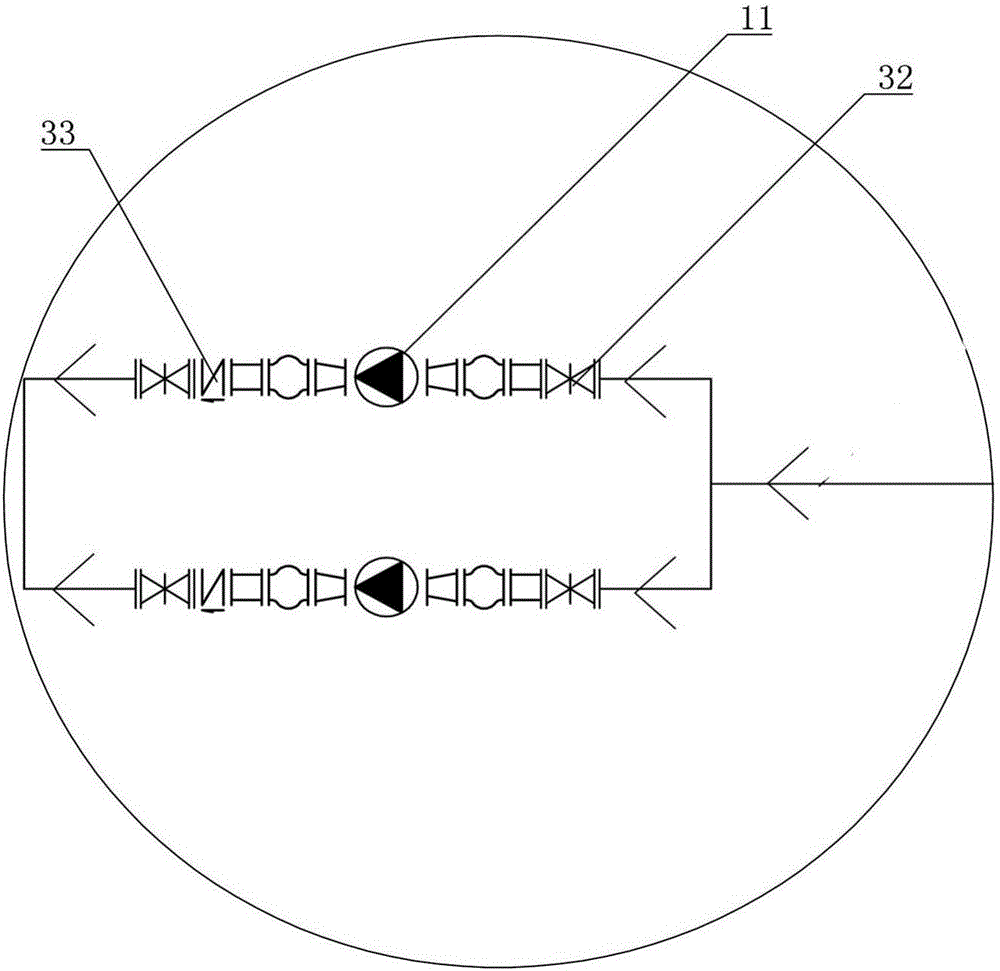

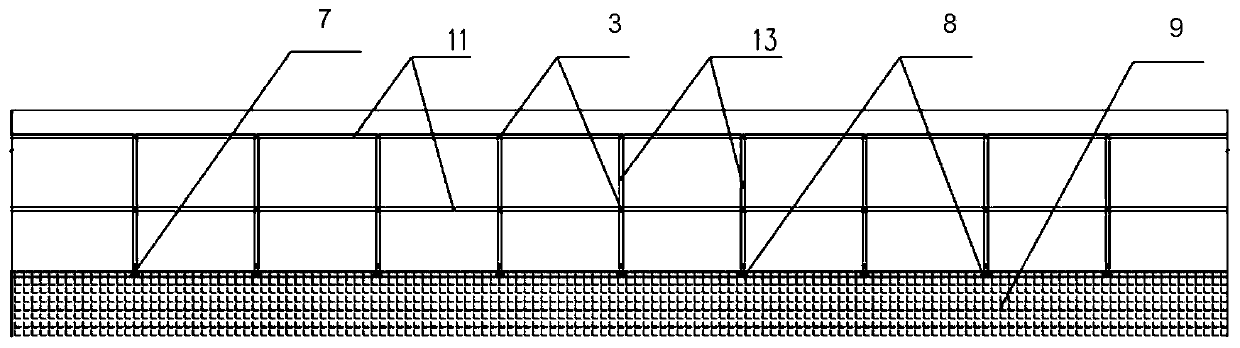

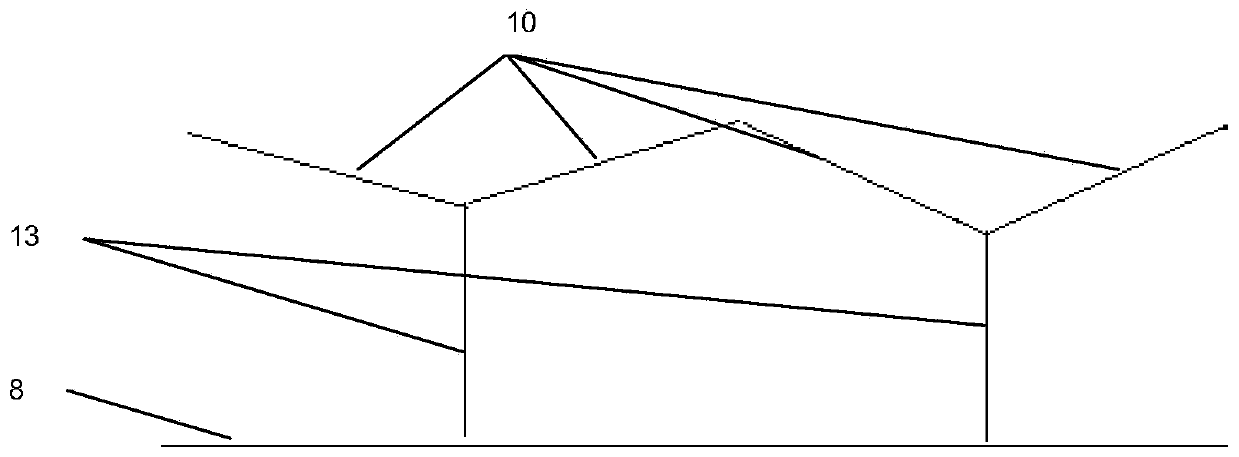

Solar heating warming system for vegetable fruit greenhouse

ActiveCN105993722ASmall pressure fluctuationsEasy to controlSolar heating energySolar heat devicesWater source heat pumpAutomatic control

The invention discloses a solar heating warming system for a vegetable fruit greenhouse, belongs to the field of heating ventilation and aims at solving the problem that an existing vegetable greenhouse heating manner pollutes the environment. The solar heating warming system comprises a solar device, a water-source heat pump unit, a hot water storage tank and an underground hot water heating device, wherein the solar device and the hot water storage tank are connected by virtue of a pipeline to form a circulation loop, the water-source heat pump unit and the hot water storage tank are connected by virtue of a pipeline to form a circulation loop, and the water-source heat pump unit and the underground hot water heating device are connected by virtue of a pipeline to form a circulation loop. The technical scheme of the invention provides a heating warming system combining solar energy, a water-source heat pump and underground water heating, so that a heating manner of a vegetable greenhouse is more environment-friendly; and PLC automatic control can be realized, and management cost is saved.

Owner:青海鑫瑞新能源技术开发有限公司

Method for formation of spiral layer inside catheter

ActiveCN103991210ANo increased riskLow costDomestic articlesTubular articlesEngineeringMechanical engineering

A method of forming a spiral layer on the inside of a catheter comprises: preparing a hollow tube-shaped base material to be used as a catheter body; preparing a core shaft, the outer surface of said core shaft being provided with a spiral layer, the material of the outer surface being offset from the material of the hollow tube-shaped base material, and the size of said spiral layer being designed such that the outer diameter of the spiral of said spiral layer is less than or equal to the inner diameter of the hollow tube-shaped base material; inserting the core shaft into the inside of the hollow tube-shaped based material; by means of heating, sleeving the hollow tube-shaped base material onto the spiral layer of the core shaft such that the depth to which said spiral layer is embedded into said base material is less than or equal to the height of said spiral layer; and extracting the core shaft from the hollow tube-shaped base material, thereby forming a spiral layer on the inside of the hollow tube-shaped base material. Because the core shaft having the spiral layer can be reused, the cost of said invention is low. Moreover, the formation of the spiral layer on the inside of the catheter does not involve other substances and thus does not introduce additional biological or structural risks.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

Method for preparing low temperature instant agar

InactiveCN106107924AGuaranteed high gel strengthChange chemical propertiesFood scienceFluidized bed dryingDrum drying

The invention discloses a method for preparing a low temperature instant agar, and belongs to the field of food engineering. The method is as below: fully dispersing an agar powder and a cosolvent in water under stirring, boiling to dissolve completely, modifying the dissolved agar and cosolvent mixed solution by a high pressure homogenizer, drying by drum drying equipment, crushing, then dissolving in cold water, centrifuging to remove the cosolvent in the supernatant; and finally drying and grinding a precipitate by a fluidized bed to obtain the low temperature instant agar.

Owner:HEBEI BROS ILONG FOOD TECH LLC

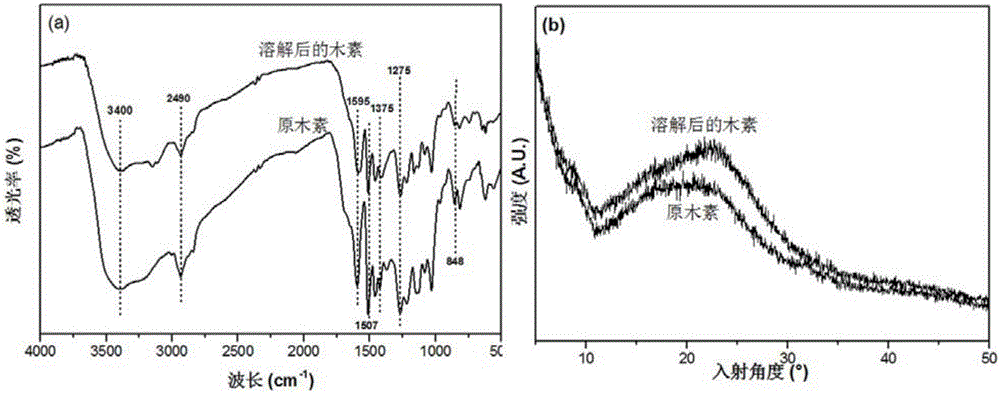

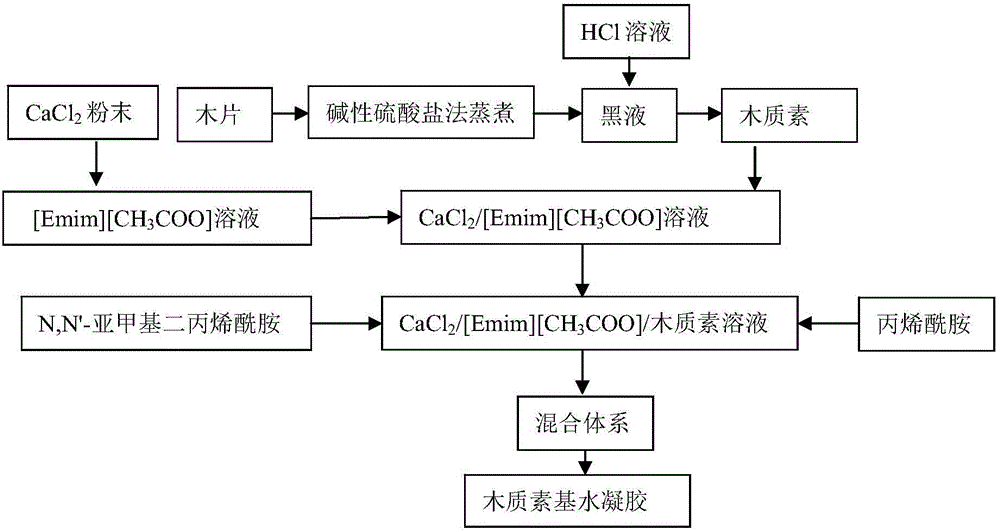

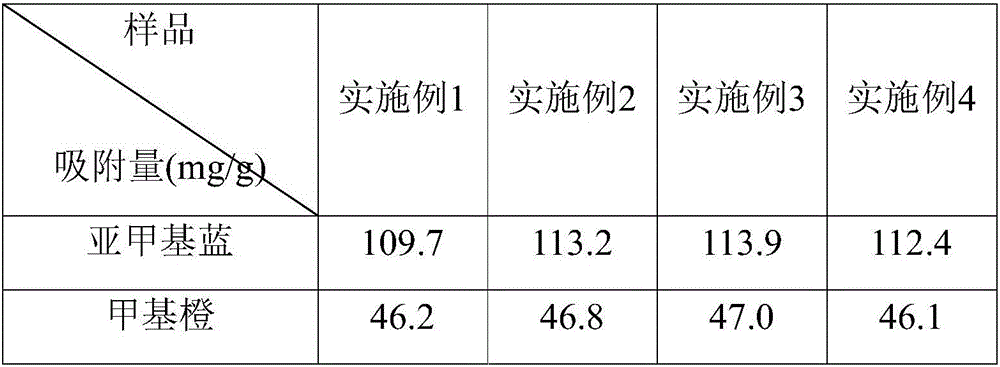

Green preparation method and application of lignin-based hydrogel

InactiveCN106336489ASimple preparation processThe preparation process is green and pollution-freeOther chemical processesWater contaminantsOrganic dyeDyeing wastewater

The invention belongs to the technical field of functional materials, and in particular discloses a green preparation method and application of a lignin-based hydrogel. The preparation method comprises the following steps: adding CaCl2 powder to 1-ethyl-3-methylimidazolium acetate, stirring for dissolving, adding lignin, stirring, then adding acrylamide and N,N'-Methylenebisacrylamide, adding hydrogen peroxide, stirring evenly, and putting reaction system in nitrogen or carbon dioxide gas protection for reaction to obtain the lignin-based hydrogel. The preparation method has the advantages of simple preparation process, easy operation, and pollution-free and green preparation process, and is suitable for industrialized production; the obtained product can adsorb organic dyes in printing and dyeing wastewater, effectively reduces the content of the dyes in the wastewater, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

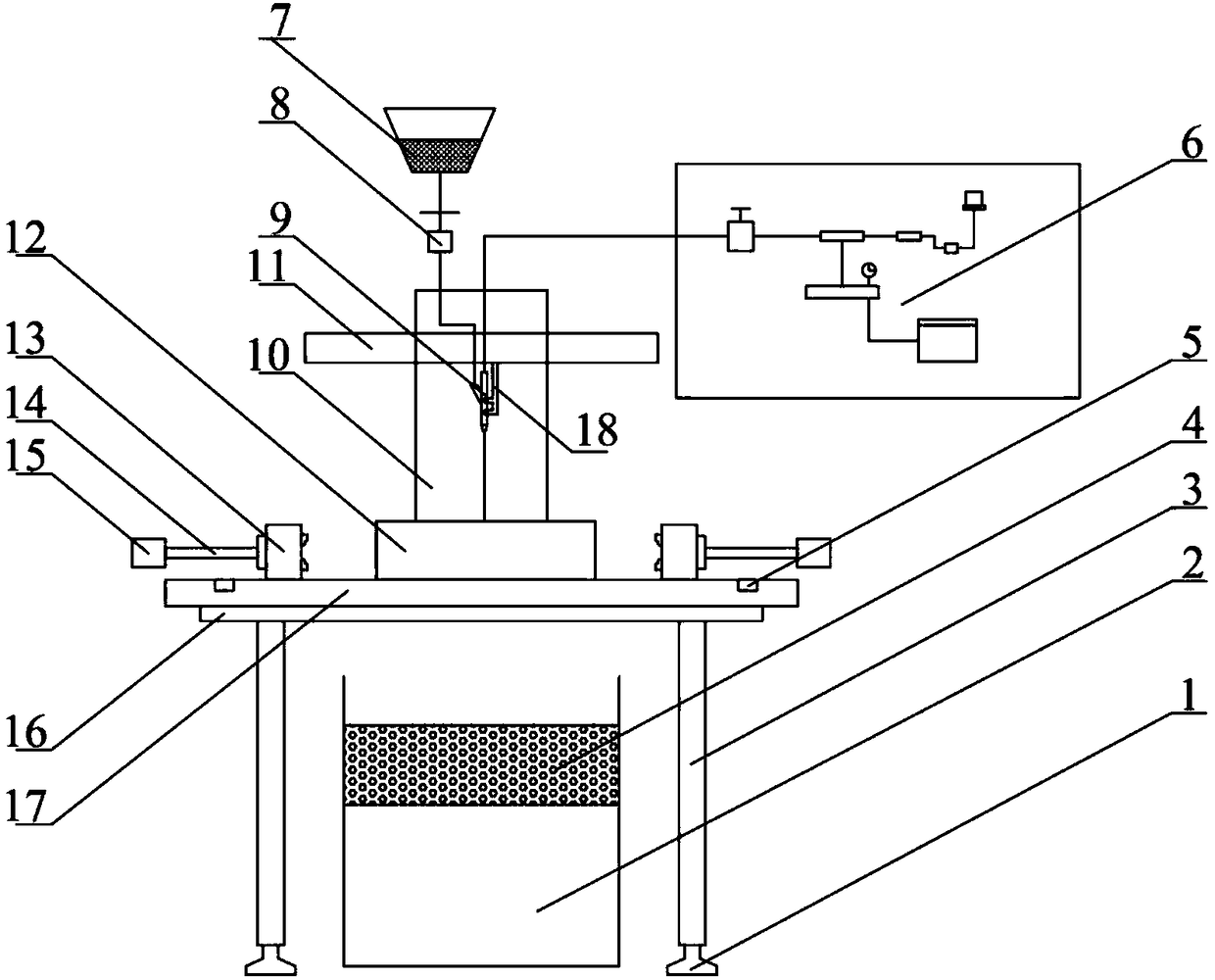

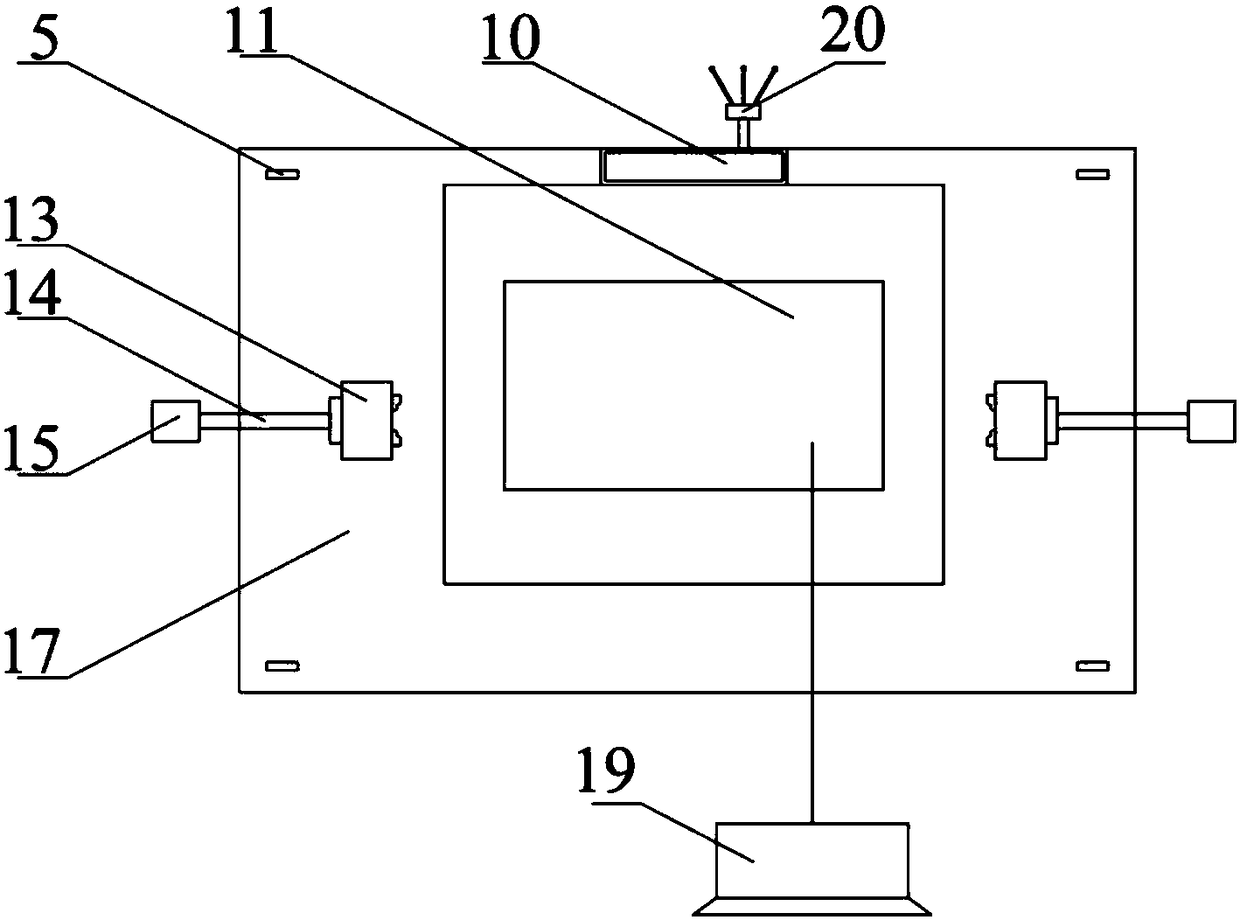

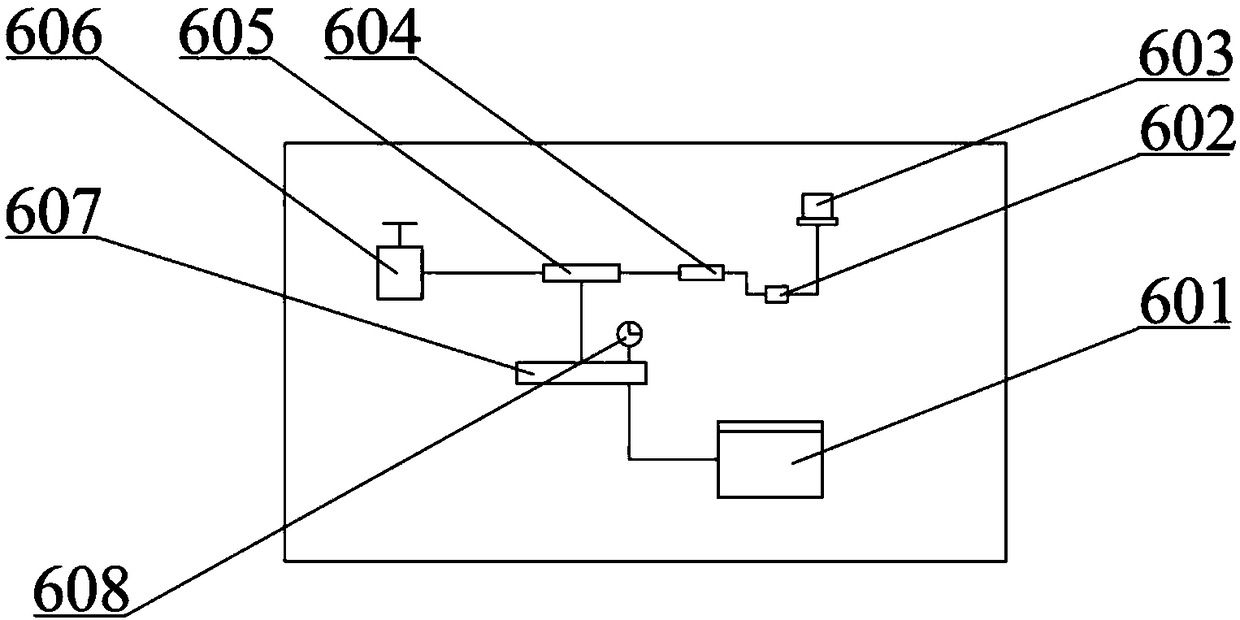

High-pressure abrasive water-jet rock coring drilling machine

InactiveCN108453627ANo change in mechanicsDoes not change physicsWithdrawing sample devicesAbrasive feedersLithologyRock core

The invention discloses a high-pressure abrasive water-jet rock coring drilling machine which comprises a drilling machine table-board, wherein a support frame is arranged at a middle position above the drilling machine table-board; the support frame is used for supporting a manipulator control system; a transmission rack in a vertical direction is arranged on the manipulator control system; a transmission gear is arranged at a transmission shaft end of a rotating handle; the transmission gear and the transmission rack are meshed by rotating the rotating handle to further drive the manipulatorcontrol system to move up and down; the manipulator control system is connected with a computer; a manipulator is connected below the manipulator control system; a downward nozzle is fixed at the endof the manipulator; the nozzle is respectively connected with a high-pressure water supply device and an abrasive tank by virtue of pipelines; a group of three-jaw chucks is symmetrically arranged atpositions on two sides of the support frame above the drilling machine table-board. The high-pressure abrasive water-jet rock coring drilling machine disclosed by the invention is safe and reasonablein overall structural design, is applicable to coring of rock of various lithology and any size, and is particularly applicable to nondestructive coring of high-strength fissured rock, conglomerate rock and sandstone and small-diameter rock.

Owner:SINOPEC SHENGLI OILFIELD +1

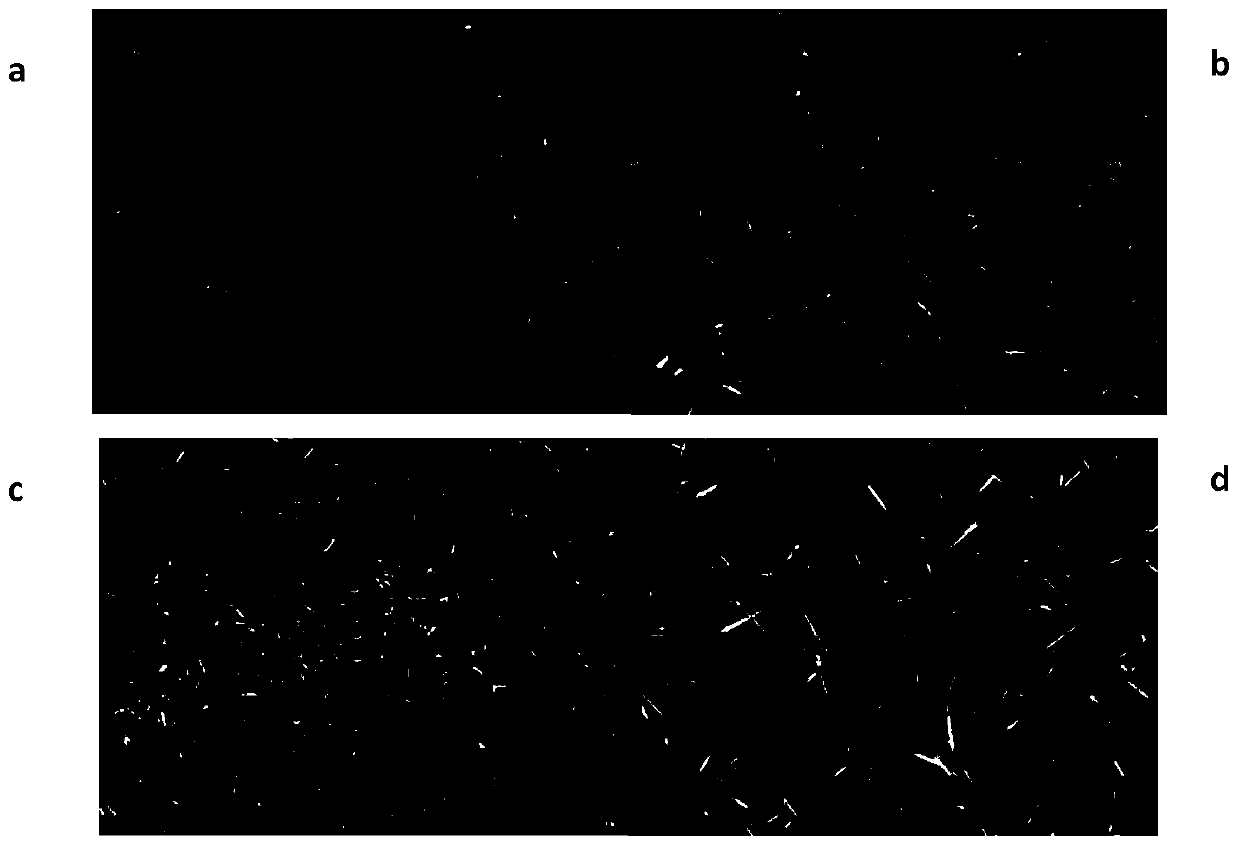

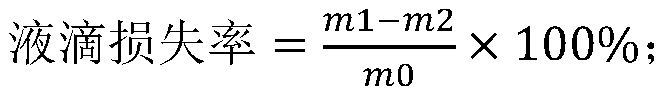

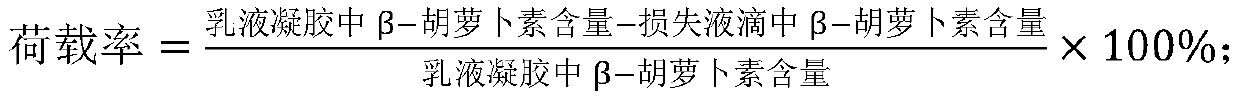

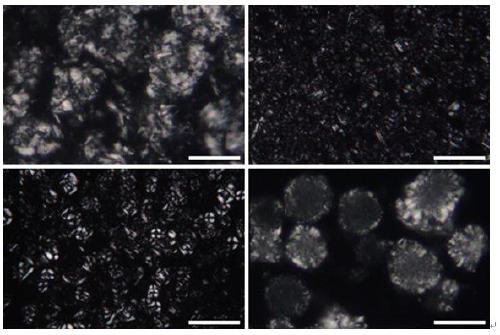

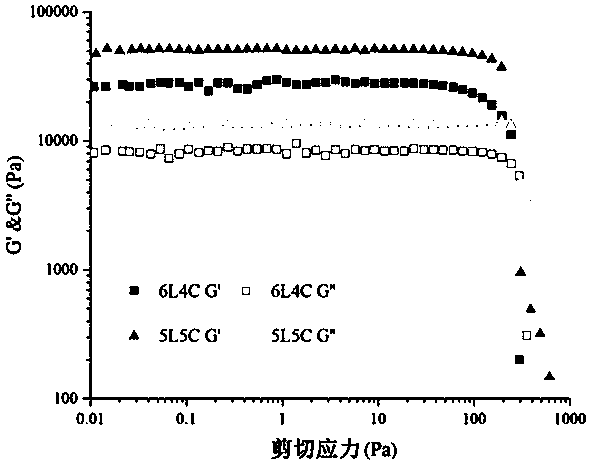

Egg yolk-phytosterol-polysaccharide composite emulsion gel and preparation method thereof

ActiveCN110089694AIncrease productivityDoes not change chemical propertiesLipidic food ingredientsFood ingredient as gelling agentYolkOil phase

The invention discloses an egg yolk-phytosterol-polysaccharide composite emulsion gel and a preparation method thereof, which belong to the technical field of processing of saturated fat substitutes.The method utilizes the emulsification and crystallization regulation of egg yolk, regulates the crystal form of phytosterol in the emulsion gel while emulsifying the liquid oil, a high oil-phase oil-in-water emulsion is prepared firstly, and then a semi-solid plastic fat product with low liquid droplet loss is obtained by heating and cooling gelation of the edible gum. The egg yolk-phytosterol-polysaccharide composite emulsion gel prepared by the invention can be used as a substitute fat for high saturated animal fat, also can be used as a delivery carrier of fat-soluble nutrients, and has wide application prospect in low-saturated fat foods and fat-soluble nutrient enhanced foods.

Owner:JIANGNAN UNIV

Physical method and equipment producing skinned walnut kernel

InactiveCN106213527AChemical damage noNo pollution in the processHuskingHullingRolling resistancePulp and paper industry

A physical method producing skinned walnut kernels belongs to the walnut skinning technical field, and comprises the following steps: A, adding walnut kernels with skins into a first level roller oven, starting the machine and flowing hot air so as to enable the walnut kernel skin to be crispy, using rolling friction to separate crispy skin from the surface of the walnut kernel, thus obtaining walnut kernel with primary treatment; B, placing walnut kernels with primary treatment into a secondary roller oven, starting the machine and flowing into saturation wet vapour under controlled speed, wetting the endothelial of the walnut kernel, stopping the machine, and standing; C, starting the machine and controlling roller speed, flowing into hot air until the skin of the walnut kernel dries, contracts and becomes crispy, and using the friction force between the walnut kernel and the roller inner wall in a roller rotary process, thus removing skin of the walnut kernel, and obtaining finely processed walnut kernel. The invention also provides equipment using same method; the method and equipment can easily remove skins without affecting the walnut.

Owner:河北乾罡生物科技有限公司

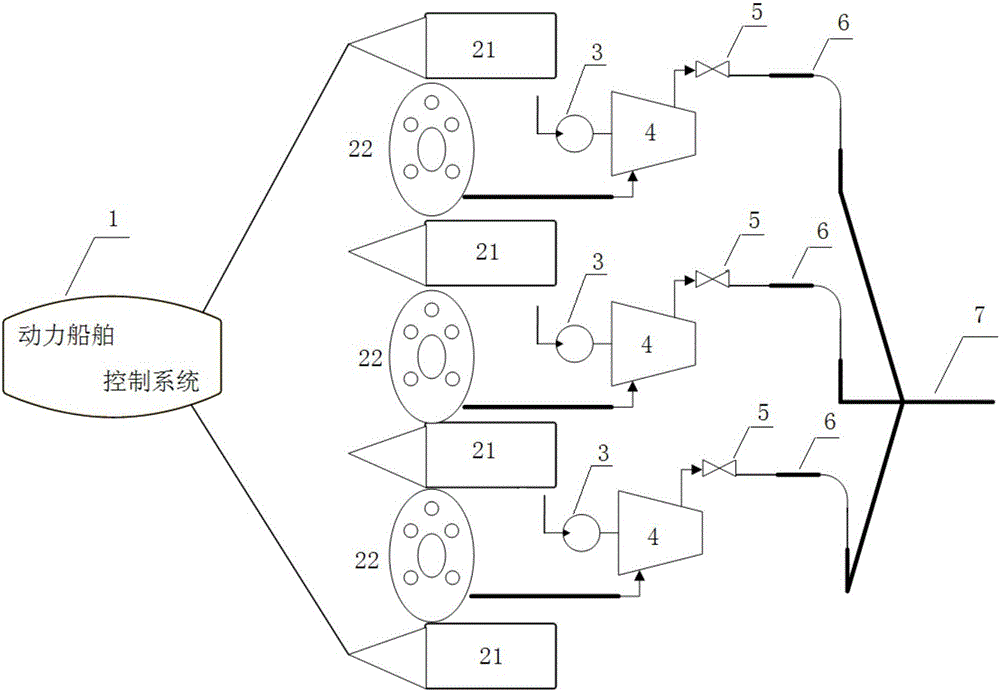

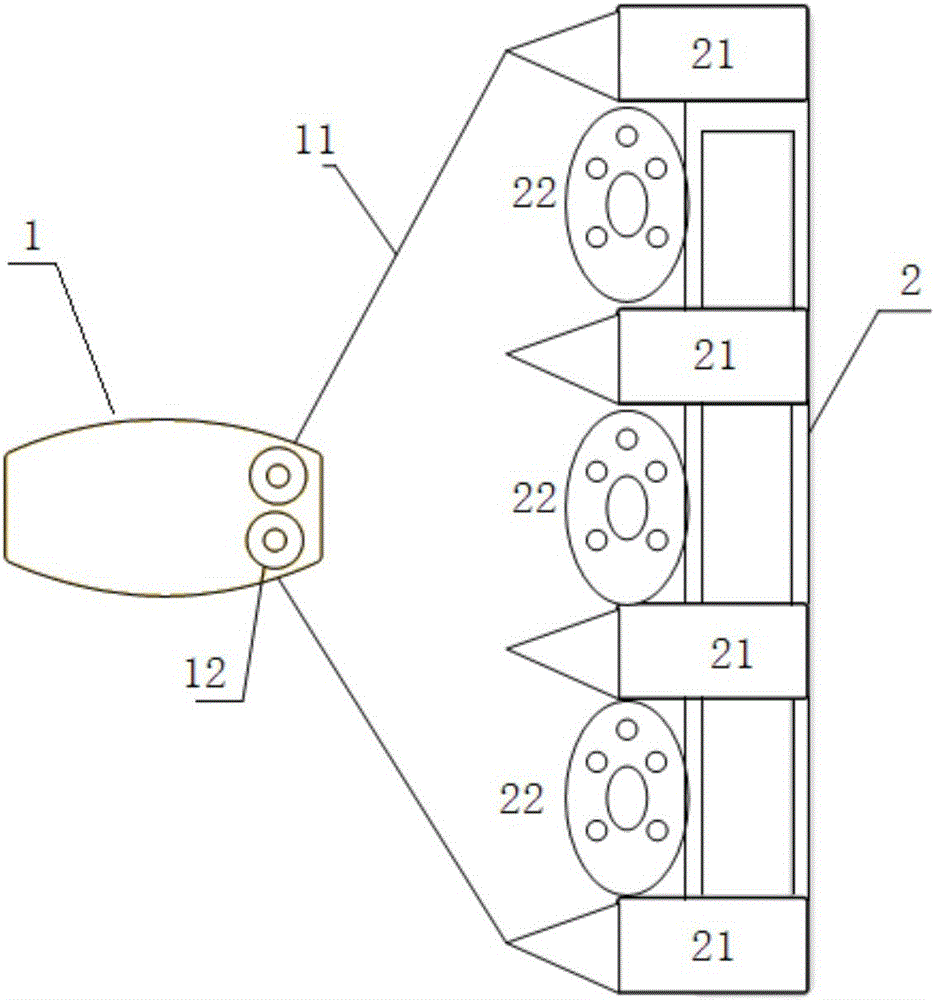

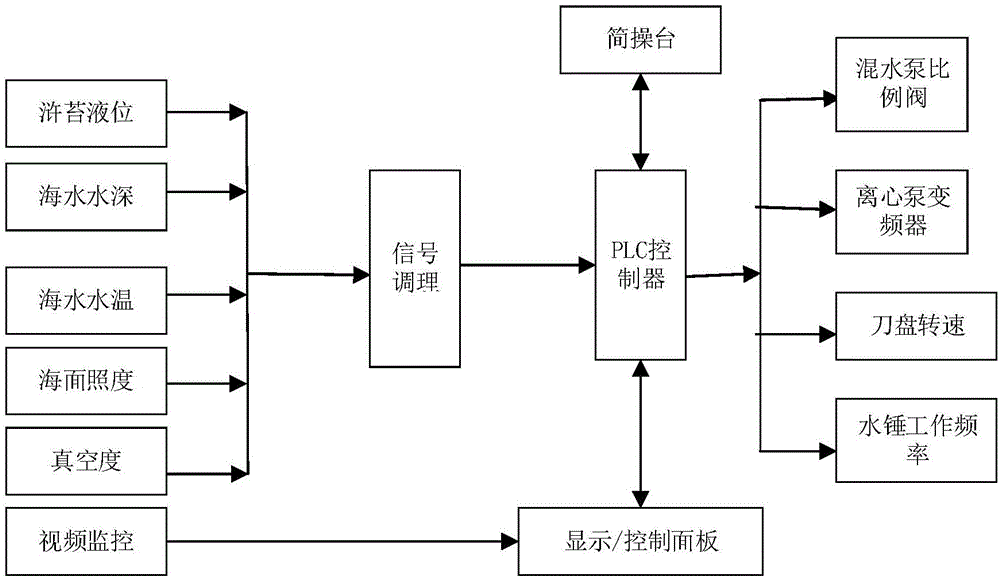

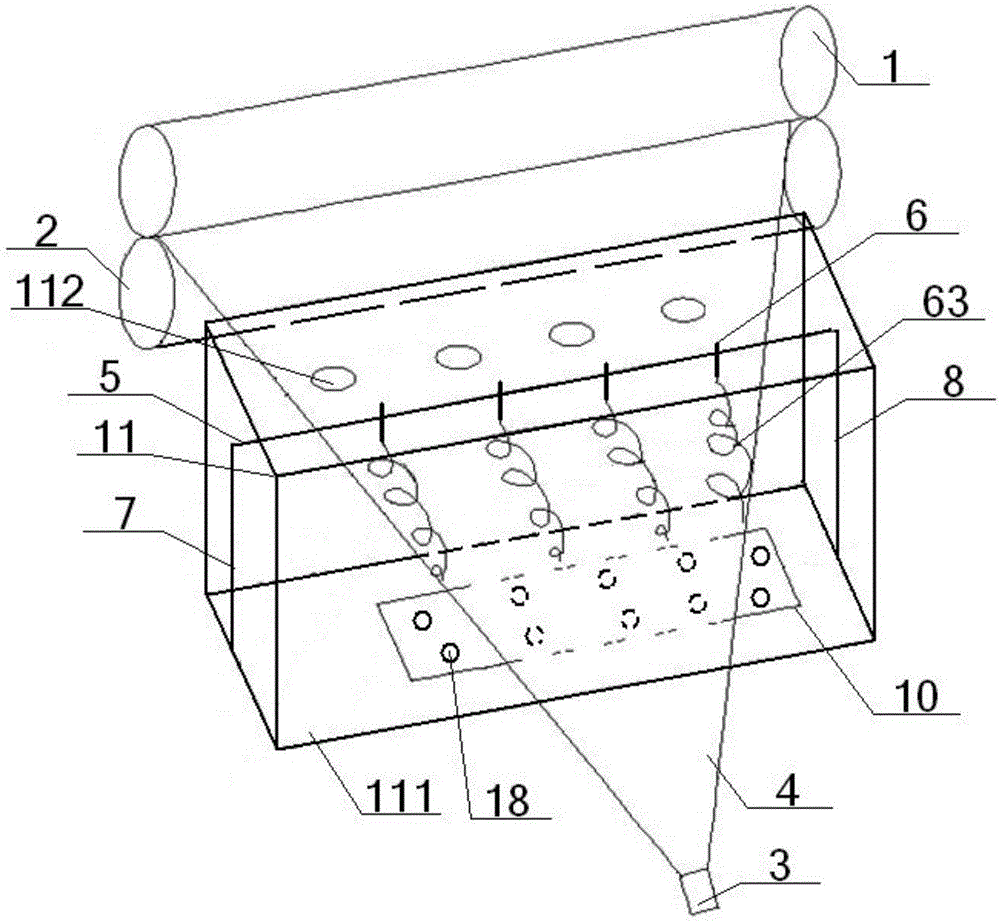

System and method for treating enteromorpha on sea

InactiveCN106368192ANo impact on the traffic environmentDoes not affect the hygienic environmentWater cleaningMetal working apparatusBuoyEngineering

The invention provides a system for treating enteromorpha on the sea. A power boat carries a control system, environmental information is sampled, and various parts of the system are controlled; the power boat drives a rear-stage buoy platform in a dragging mode; and the buoy platform carries water mixing systems, pressure increasing systems, water hammer systems, tube reducing and pressure adjusting systems and a deep drainage system. By the system and method for treating the enteromorpha on the sea, the enteromorpha can be directly treated on the sea, land transfer and land disposition are not required, and urban transport, environmental hygiene and air quality are not affected; and a physical mode is adopted in the whole process, any chemical preparations are not used, chemical properties of the enteromorpha are not changed, and therefore, the system and method for treating the enteromorpha on the sea are economical and environmentally friendly, are pollution-free, and do not have any harm on a marine environment or a marine ecosystem.

Owner:高晓涵

Preparation technique of low-temperature instant carrageenan

The invention discloses a preparation technique of low-temperature instant carrageenan, comprising the following steps: adding co-solvent in seaweed gel liquid or boiling carrageenan and co-solvent in water until the carrageenan and the co-solvent are dissolved completely; processing by a high-pressure apparatus or an ultra-high-pressure apparatus, dehydrating by a plate-and-frame filter press, drying and sterilizing to a proper water content by microwave, crushing and filtering so as to obtain the low-temperature instant product (physically modified carrageenan); or processing by a high-pressure apparatus or an ultra-high-pressure apparatus, and then spray-drying so as to obtain the low-temperature instant product (physically modified carrageenan); or processing by a high-pressure apparatus or an ultra-high-pressure apparatus, freezing at ultra-low temperature by an individual quick freezing machine, unfreezing, filter-pressing, extruding by a screw compressor, drying, and crushing so as to obtain the low-temperature instant product (physically modified carrageenan). The low-temperature instant carrageenan produced by the preparation technique disclosed by the invention has the following characteristics of being quickly dissolved at low temperature.

Owner:青岛德慧海洋生物科技有限公司

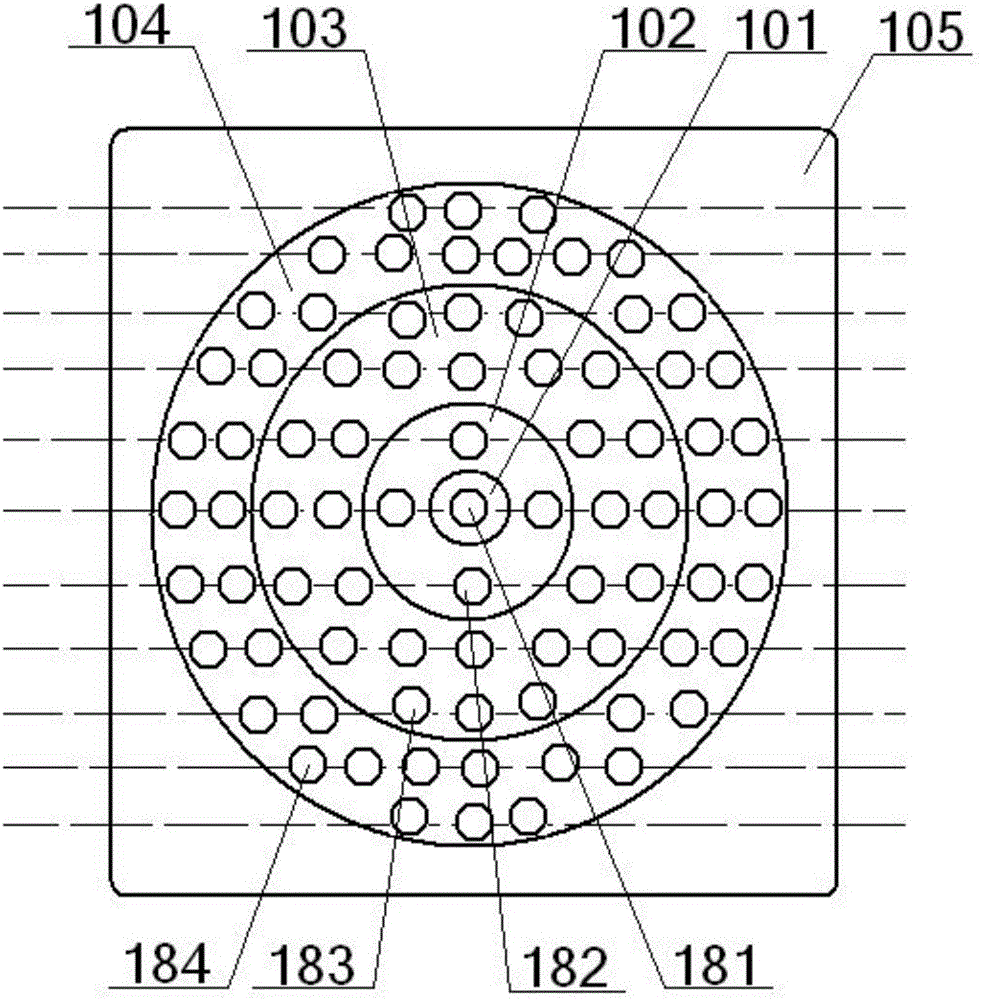

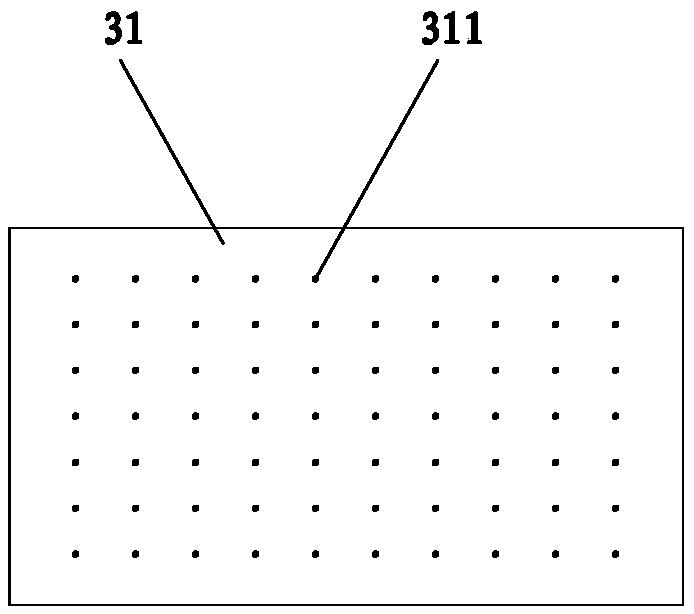

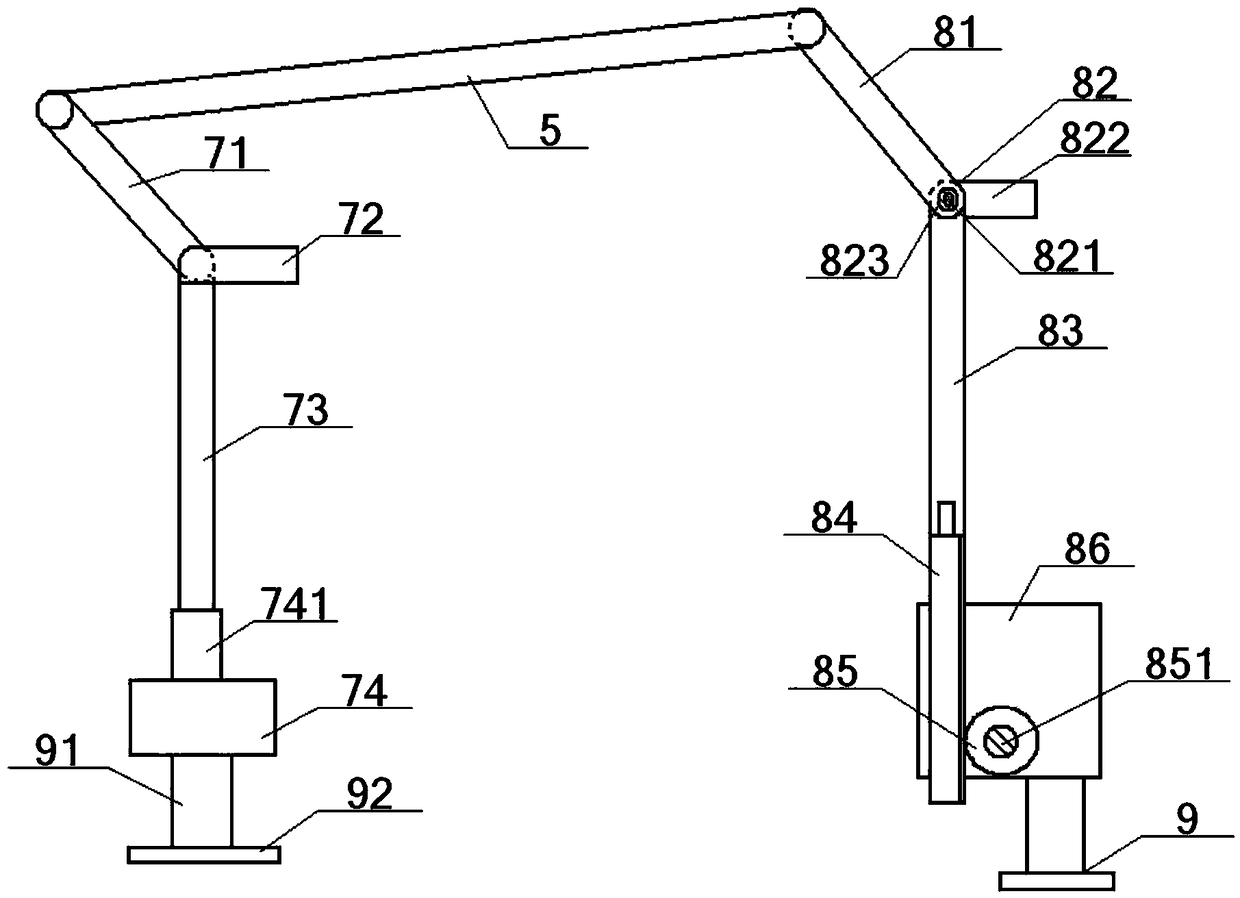

Equipment of improving card silver quality through net supporting plate to guide electrostatic spinning and using method

ActiveCN105926054AGood antistatic effectAccelerateElectro-spinningNon-woven fabricsElectrospinningCarbon nanotube

Equipment of improving card silver quality through a net supporting plate to guide electrostatic spinning comprises an upper roller, a lower roller, a horn mouth and a cotton net. One side of the cotton net penetrates in from a gap in front of the upper or lower roller while the other side of the same penetrates out from the horn mouth, a net supporting plate with a guide air hole is arranged below the cotton net, a transverse fixing rod mounted with multiple electrostatic spinning nozzles is suspended above the cotton net, and two ends of the transverse fixing rod are connected with a vertical adjusting device with a longitudinal moving device arranged at the bottom. When the equipment is in use, the electrostatic spinning nozzles spray electrostatic spinning to realize stacking on the cotton net, the electrostatic spinning is electroconductive nanofiber containing polyaniline, multi-wall carbon nanotube or graphene, height of the nozzles and gaps between the nozzles and the lower roller are adjusted through the vertical adjusting device and the longitudinal moving device, and the guide air hole finishes electrostatic spinning through wind powder to improve uniformity. Due to the design, the phenomenon of static electricity can be solved, card silver quality and subsequent processing are unaffected, and the equipment is high in adjustability, environment-friendliness and static electricity removing efficiency and quite low in cost.

Owner:WUHAN TEXTILE UNIV

Antibiotic-free pig feed formula and processing process thereof

PendingCN109258948AHealthy meatGreat tasteFood processingAnimal feeding stuffAntibiotic freeWater soluble

The invention provides an antibiotic-free pig feed formula, which breaks through the formula and process form of conventional pig feed. On the basis of ensuring nutritions required by pigs, the feed formula completely avoids antibiotic type additives; all raw materials are natural plant raw materials subjected to mechanical processing; the chemical property of the raw materials is not changed; thefed pigs are pure natural; the meat quality is healthier; the mouthfeel is better. The invention also provides a processing process of the antibiotic-free pig feed formula. The raw materials are subjected to quantitative packaging by using water-soluble edible packaging paper. In a practical use process, a corresponding quantity of quantitative package is put into water according to the requiredfood quantity of the pigs; the water-soluble edible packaging paper is directly dissolved in the water; then, the raw materials and the water are uniformly stirred; the feed can be fed to the pigs; the operation is convenient and clean; the feeding environment is sanitary and safe; the practicability is high.

Owner:FUJIAN JINNONGWEI FEED CO LTD

Method for preparing phthalocyanine monocrystal thin film on copper film modified graphene substrate

InactiveCN107747130ADoes not change the physicsDoes not change chemical propertiesPolycrystalline material growthFrom condensed vaporsCharge carrierThin layer

The invention provides a method for preparing a phthalocyanine monocrystal thin film on a copper film modified graphene substrate, belonging to the technical field of graphene. The method provided bythe invention can be used for preparation of an organic field effect device with high performance. In the organic field effect device, the graphene is frequently used as an electrode coating, and thehigh conductivity and the crystallization induction effect of the graphene to an organic molecular thin film are utilized to improve the injection and transmission efficiency of a current carrier in the device, so performances of the device are improved. According to the invention, a graphene substrate usually induces phthalocyanine molecules to form a pi-pi stacked structure which is perpendicular to the graphene substrate, and the pi-pi stacked structure is unfavourable for transmission of the current carrier in the horizontal direction parallel to the surface of the substrate. Thus, throughmodification of a copper nanoparticle thin layer with a thickness of 1 nanometer on the graphene substrate, controllable growth of the phthalocyanine monocrystal thin film with a monocrystal structure and with a molecular pi-pi stacked direction parallel to the graphene substrate can be realized.

Owner:SHAOXING UNIVERSITY

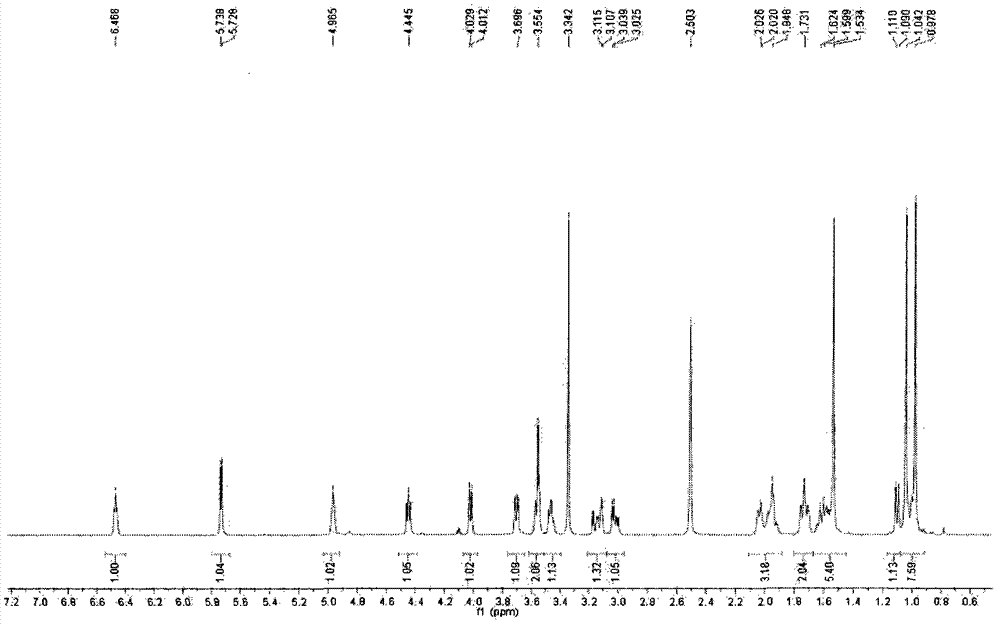

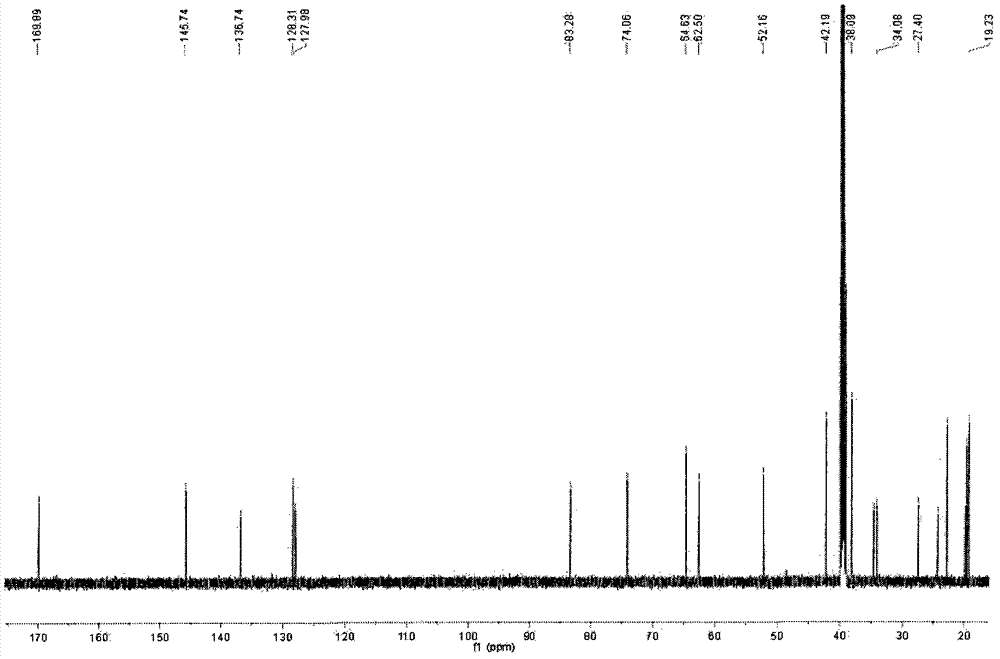

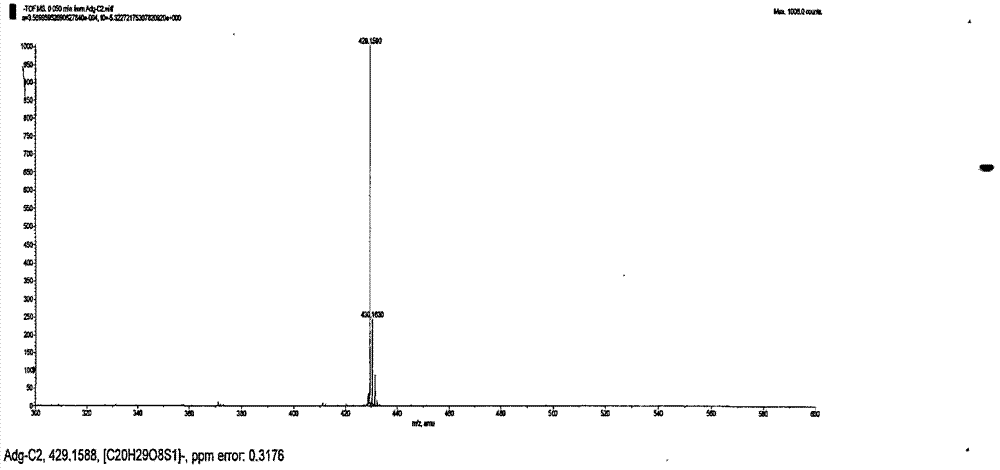

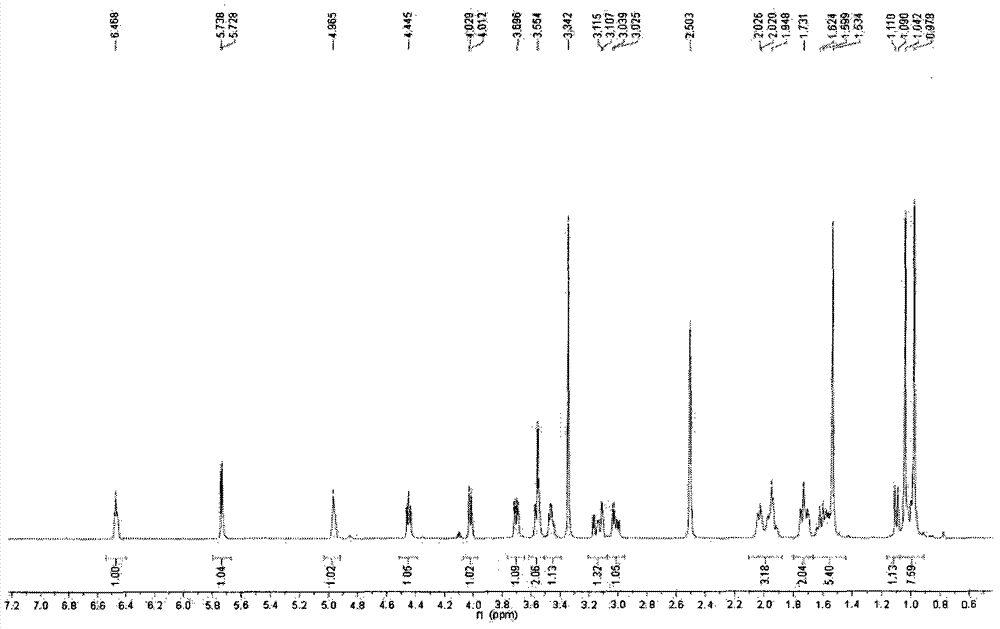

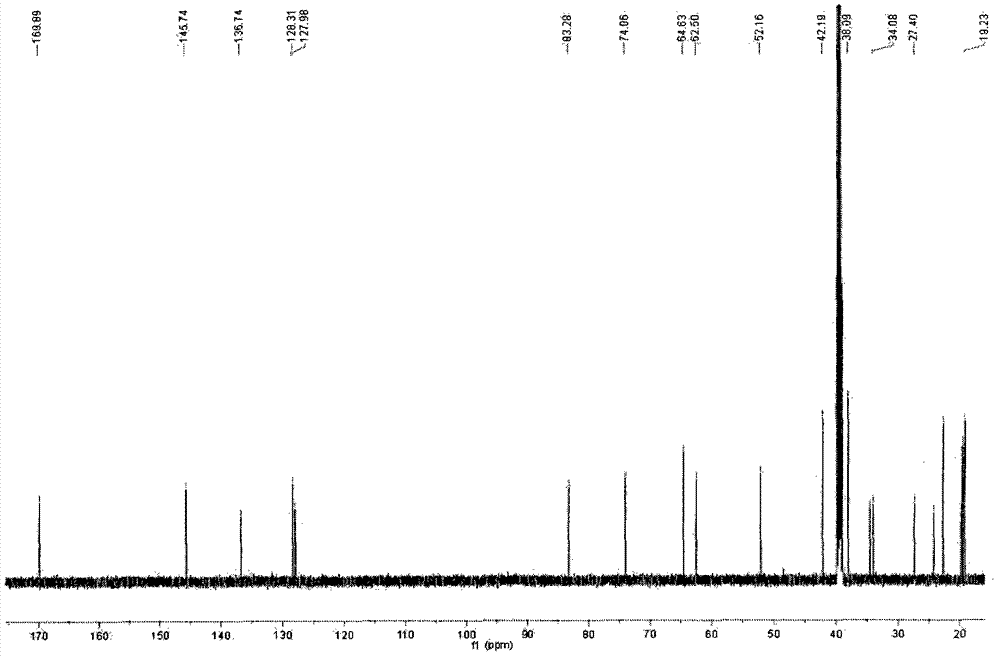

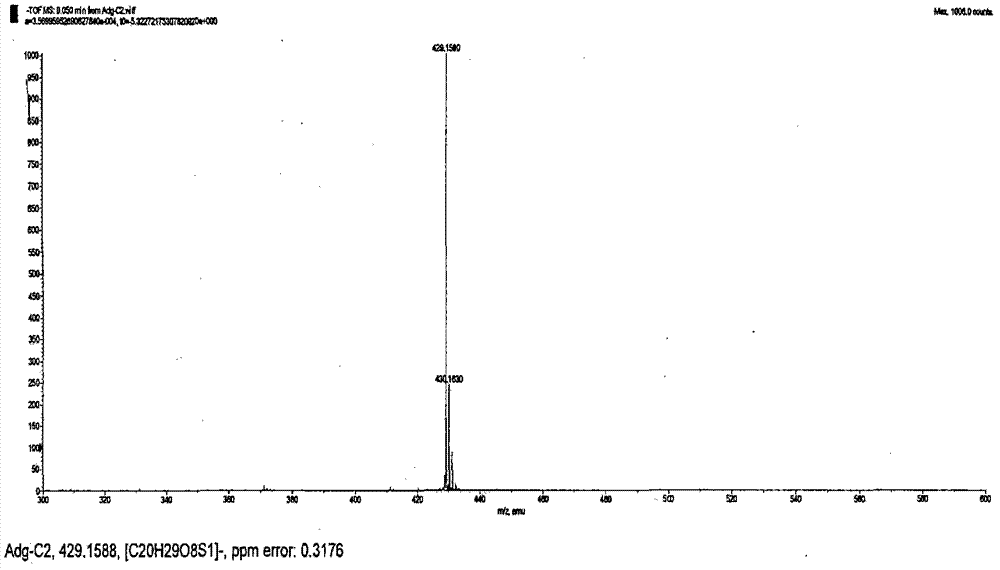

Once preparation method of composite of 17-hydrogen-9-dehydro-andrographolidume-3-sodium (or potassium) disulfate and 17-hydrogen-9-dehydro-andrographolidume-3, 19-sodium (or potassium) disulfate, and purposes of prepared medicine

ActiveCN103156840AEasy to prepareMild conditionsOrganic active ingredientsOrganic chemistryAnti-inflammatoryDrug

The invention relates to a composite of 17-hydrogen-9-dehydro-andrographolidume-3-sodium (or potassium) disulfate and 17-hydrogen-9-dehydro-andrographolidume-3, 19-sodium (or potassium) disulfate, and discloses components of the composite, and a once preparation method of the components. The composite can be used for preparing medicine having antipyretic, anti-inflammatory and antiviral purposes. The composite is made into dosage forms which can be accepted pharmaceutically.

Owner:JIANGZI QINGFENG PHARMACEUTICALS INC

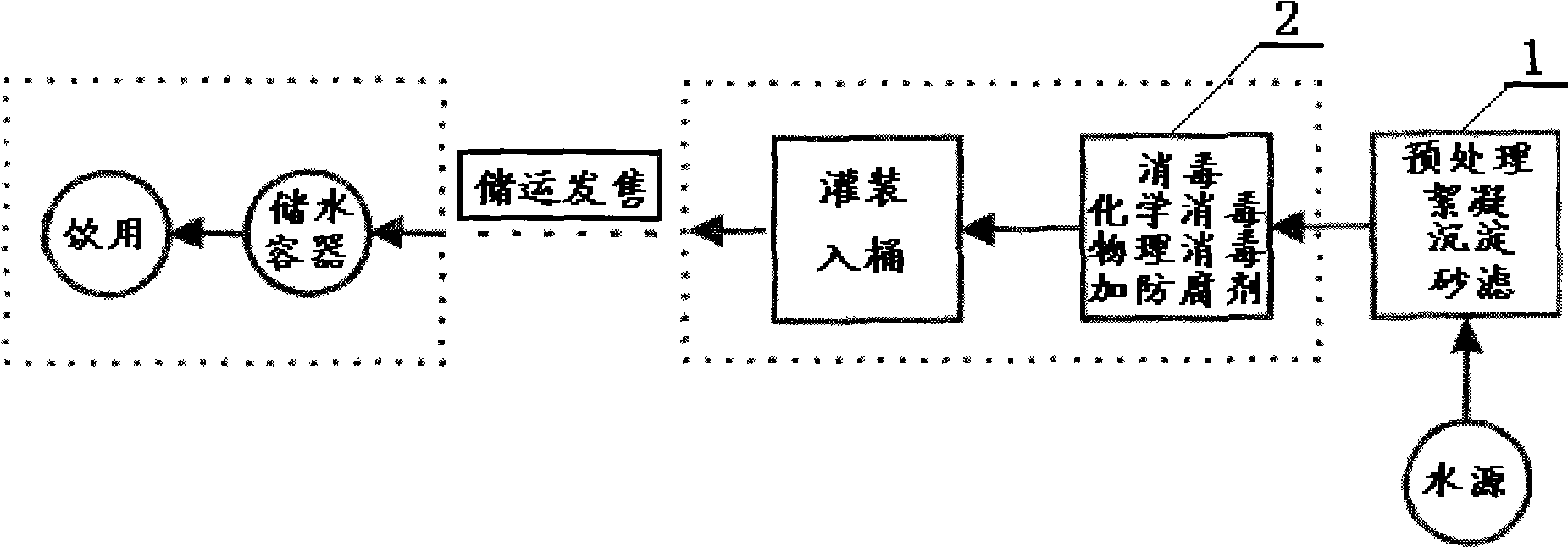

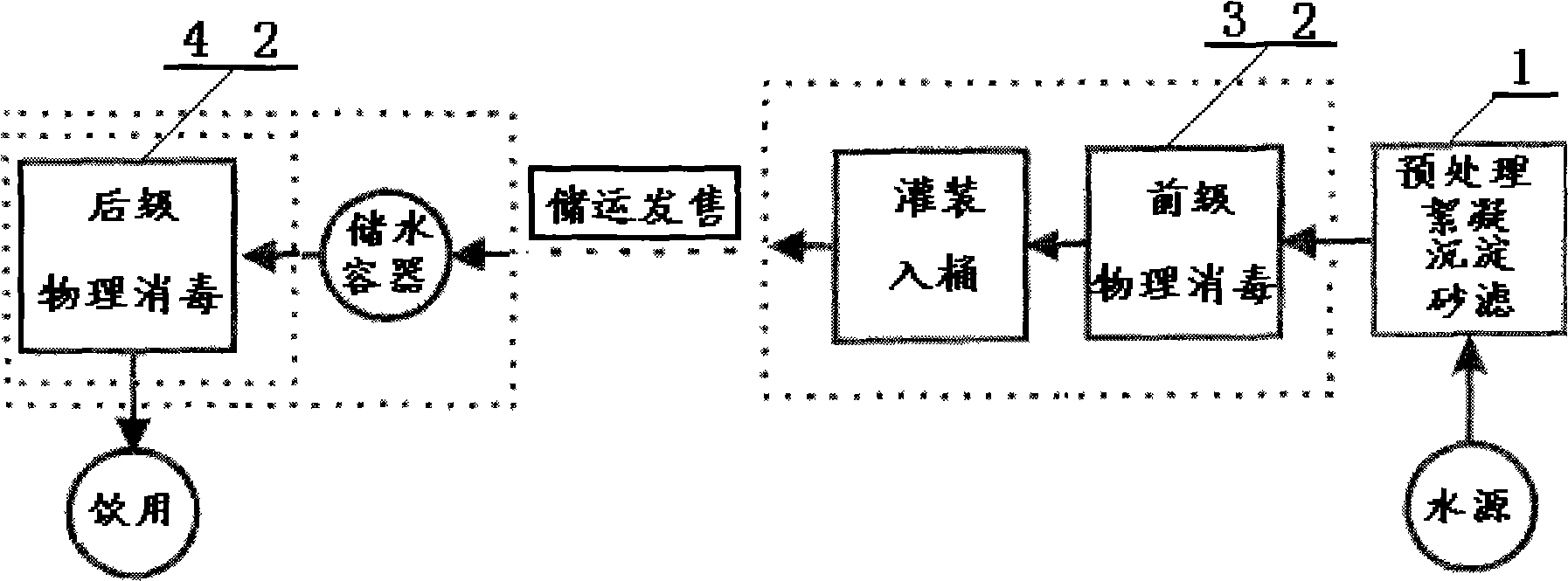

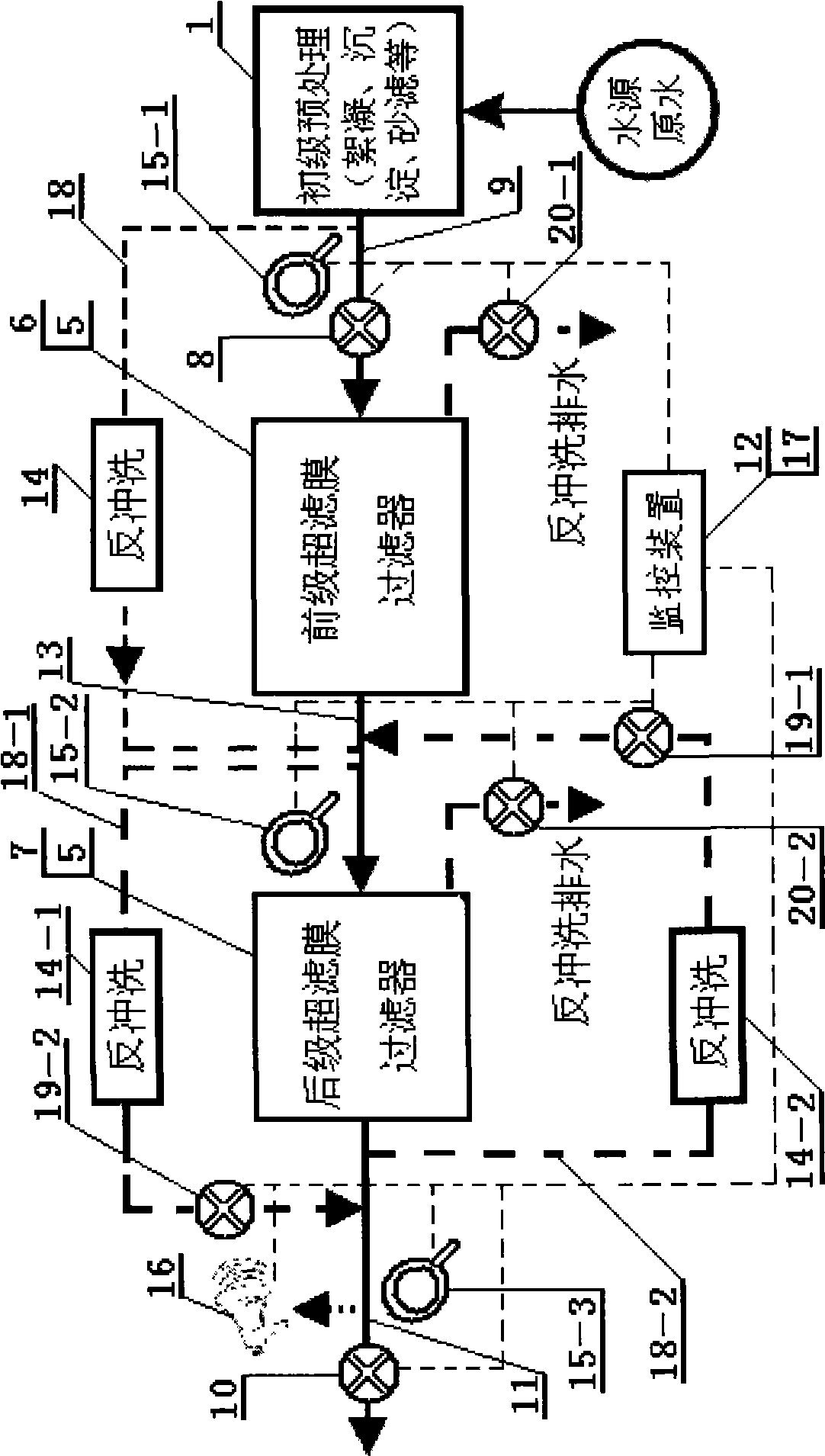

Composite and separable physical disinfection method and device of barreled drinking water

InactiveCN101531431AOvercoming the difficulty of no disinfection persistenceWill not reduce the contentWater/sewage treatment by irradiationMultistage water/sewage treatmentWater productionDisinfection methods

The invention relates to a composite and separable physical disinfection method and a device of barreled drinking water; full physical disinfection technology without any chemical sanitizing agent and any chemical preservative is utilized; a disinfection system consists of a forward series connection type ultrafiltration membrane filter system in a water production factory and backward series connection type ultraviolet radiation disinfection systems respectively set at all user ends; a disinfection safety automatic detection control device is also configured; more than 99.99 percent of viruses in the original water and more than 99.9 percent of other pathogenic microbes can be killed; more than 99.9 percent of generated reproduction bacteria caused by barrel wall stemming and water gas mixing during storage and transportation after the barreled drinking water is packed and during the operation can be killed; meanwhile, any disinfection by-product can not be generated; the drinking water of good quality and with remained quantity property can be obtained; the method can practically solve the problems that the disinfection by-product is generated in the current chemical technology and the current physical disinfection technology is short of disinfection durative and safety; the view having been generally recognized by the water production industry for a long time is changed that the physical disinfection technology cannot be used separately and can be combined with the chemical disinfection method; thus, the method of the invention has strong practicability.

Owner:李杰

Once preparation method of composite of 17-hydrogen-9-dehydro-andrographolidume-3-sodium (or potassium) disulfate and 17-hydrogen-9-dehydro-andrographolidume-19-sodium (or potassium) disulfate, and purposes of medicine prepared by the same

InactiveCN103159708AEasy to prepareImprove productivityAntibacterial agentsOrganic active ingredientsHydrogenPotassium

The invention relates to a composite of 17-hydrogen-9-dehydro-andrographolidume-3-sodium ( or potassium) disulfate and 17-hydrogen-9-dehydro-andrographolidume-19-sodium (or potassium) disulfate, and discloses components of the composite, and a once preparation method of the components. The composite can be used for preparing medicine having antipyretic, anti-inflammatory and antiviral purposes. The composite is made into dosage forms which can be accepted pharmaceutically.

Owner:JIANGZI QINGFENG PHARMACEUTICALS INC

Equipment and method for improving card sliver quality by single-row nozzle mobile electrospinning method

ActiveCN105926088BStatic electricity quickly dissipatesHigh speedFilament/thread formingLap forming devicesElectrospinningNanofiber

Equipment of improving card silver quality through a single-row-nozzle moving type electrostatic spinning method comprises an upper / lower roller, a horn mouth and a cotton net. One side of the cotton net penetrates in from a gap in front of the upper / lower roller while the other side of the same penetrates out from the horn mouth, a transverse fixing rod suspended above the cotton net is connected with multiple electrostatic spinning nozzles through a nozzle connecting device, and two ends of the transverse fixing rod are connected with a vertical adjusting device with a longitudinal moving device arranged at the bottom. When the equipment is in use, the electrostatic spinning nozzles spray electrostatic spinning to realize stacking on the cotton net, the electrostatic spinning is electroconductive nanofiber containing polyaniline, multi-wall carbon nanotube or graphene, and spraying angle, degree of freedom and height of the nozzles and gaps between the nozzles and the roller are adjusted through the nozzle connecting device, the vertical adjusting device and the longitudinal moving device. Due to the design, the phenomenon of static electricity can be solved, card silver quality and subsequent processing are unaffected, and the equipment is high in adjustability, environment-friendliness and static electricity removing efficiency and quite low in cost.

Owner:HUBEI FENGSHU THREAD MFG

A high-pressure water jet punching and/or cutting mechanism and its application method

InactiveCN108637915BDoes not change chemical propertiesWill not changeAbrasive feedersAbrasive machine appurtenancesPunchingMostly True

Owner:南京鼎久机械装备有限公司

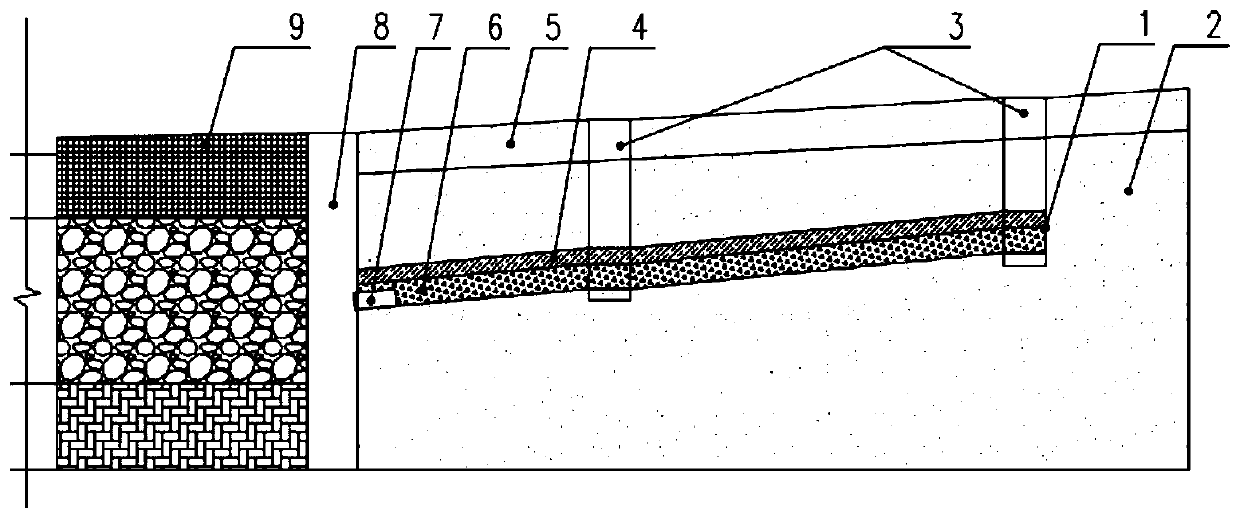

Construction method and system for drainage and salt leaching of soil in saline-alkali soil

PendingCN110495277AInhibition of anti-salt effectChange chemical propertiesSoil-working methodsAlkali soilPipeflow

The invention discloses a construction method for drainage and salt leaching in saline-alkali soil. The method comprises the following steps that 1, several longitudinal trenches are dug in the parallel direction of the road, intervals are arranged every 60-100 meters in the longitudinal trenches, and the two sides of the adjacent intervals incline to the middle, wherein the inclined slope is 0.35-0.5%; 2, in the vertical direction of the road, multiple transverse trenches are dug and led to municipal road drainage pipelines, wherein the gradient of the transverse trenches is 0.35-0.5%; 3, thebottoms of the trenches are tamped and then uniformly filled with stones and yellow sand, and the stones, the yellow sand and earthwork are separated through non-woven fabrics; 4, HDPE double-wall corrugated pipes are used for connection at the junctions of the stone blind trenches and the municipal road drainage pipelines, and the joints are blocked through non-woven fabrics; 5, inspection wellsare constructed at the junctions of the trenches; 6, before backfill planting soil modeling, fresh water is utilized for irrigation and leaching, and the salt content is reduced. Accordingly, the transformed region has the long-term suppression effect on salt return, by connecting with a municipal pipe network, the underground water level of the region can be lowered, and water level rise and reclaimed salinization caused by transpiration can be controlled.

Owner:SHANGHAI INST OF TECH

Preparation method of ABC dry powder extinguishing agent

ActiveCN107551443ADoes not change the physicsDoes not change chemical propertiesFire extinguisherCarbon fibersPhosphate

The invention provides a preparation method of an ABC dry powder extinguishing agent. The preparation method comprises the steps that raw materials including, by weight, 50-80 parts of monoammonium phosphate, 8-20 parts of ammonium sulfate, 5-15 parts of carbon nanofibres, 1-5 parts of mica, 1-5 parts of silicone oil, 1-5 parts of tetrafluoroboric acid pyrrolizidine spiro cyclic quaternary ammonium salt, 0.1-1 part of methylcyclopentadienyl manganese tricarbonyl, 0.01-0.1 part of chloride(indenyl)bi(triphenylphosphine)ruthenium(II), 0.01-0.1 part of cerium stabilized zirconia beads and 1-5 parts of a coupling agent are mixed, specifically, the total weight parts are 100; silicone oil is sprayed into the mixture, and a crude product is obtained; and the crude product is smashed and dried, and accordingly the ABC dry powder extinguishing agent is obtained.

Owner:JIANGSHAN HAIWEI TECH

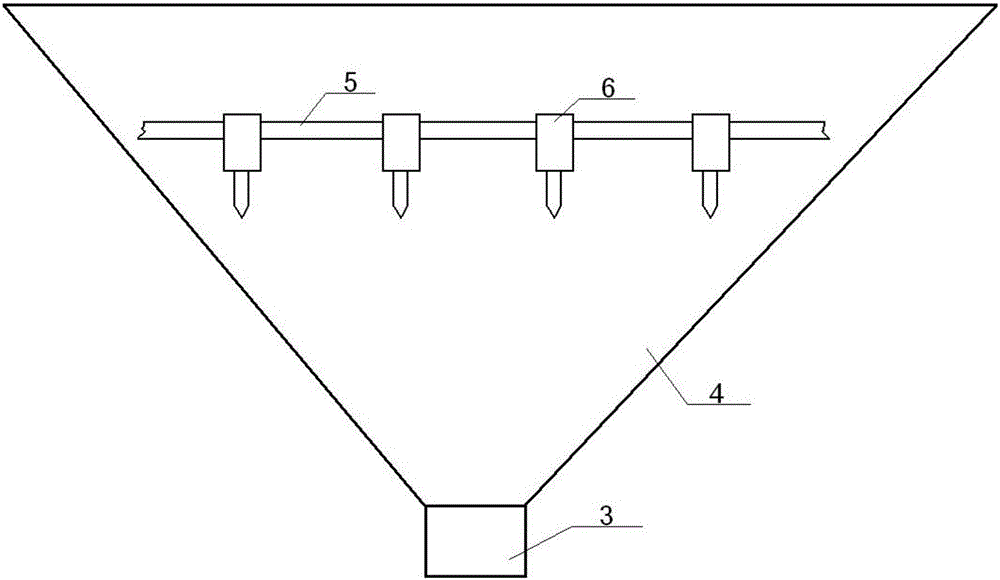

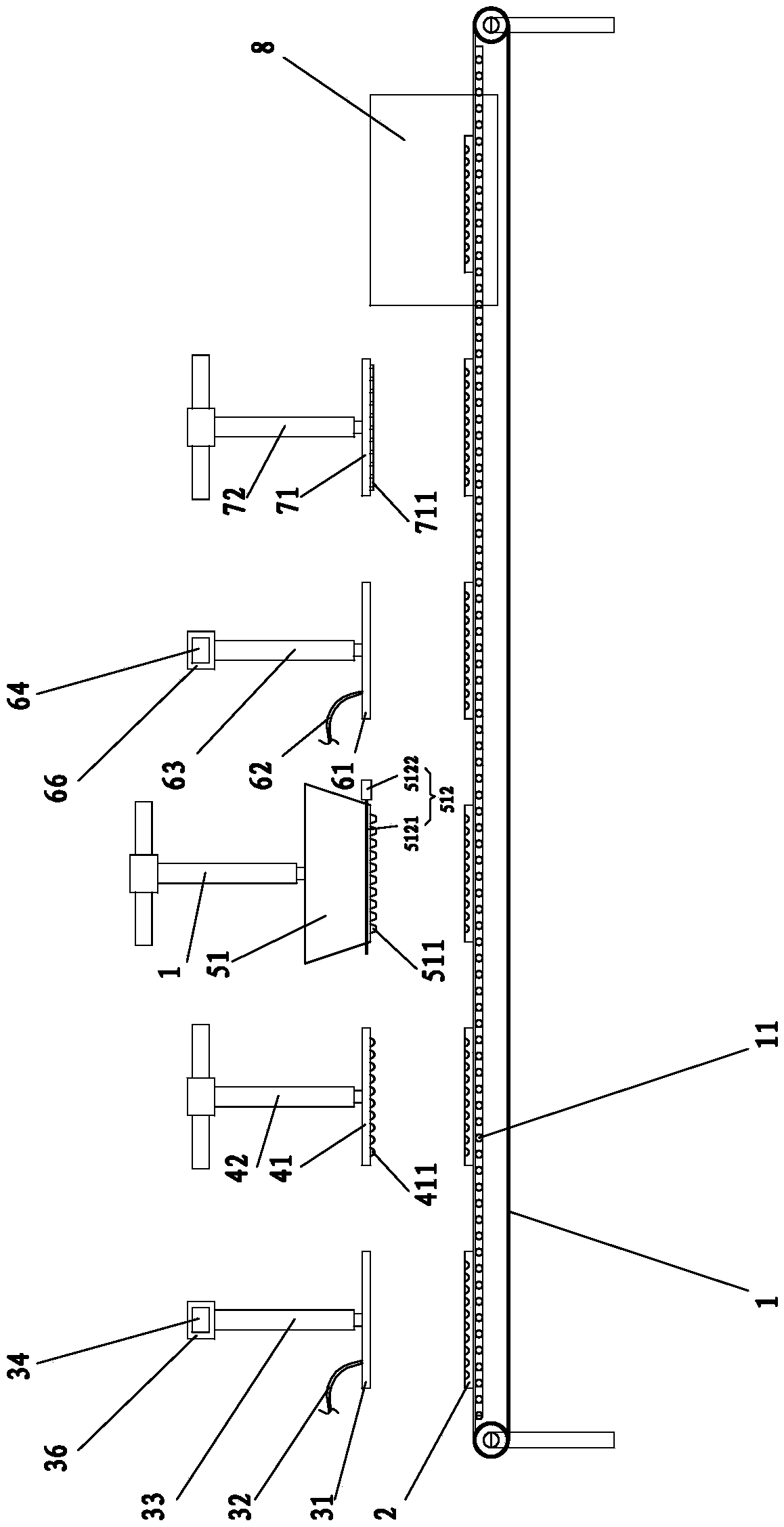

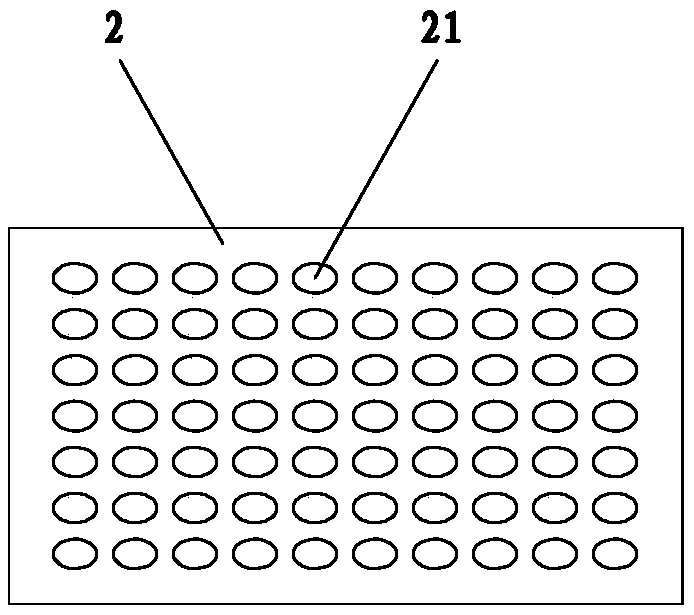

Anode residue treatment process suitable for non-ferrous metal pyrometallurgy

InactiveCN109055756AImprove collection effectRealize the collectionProcess efficiency improvementResidual BlocksMoisture

The invention discloses an anode residual treatment process suitable for non-ferrous metal pyrometallurgy. The process comprises the following steps of: 1, washing anode residual sheets by using cleanwater; 2, making the anode residual sheets into blocks; 3, drying flow: carrying out drying to remove moisture on the surfaces of the anode residual blocks (1); 4, putting: continuously putting the anode residual blocks (1) into a recovery device; and 5, smelting recovery: putting the put anode residual blocks (1) into a smelting device to make a new anode plate. Among above steps, material conveying is carried out by adoption of a conveying line (2). The process has the advantages of being short in residual smelting time, continuous in putting, high in working efficiency and good in smoke collection effect.

Owner:HUNAN HONGFEI MACHINERY

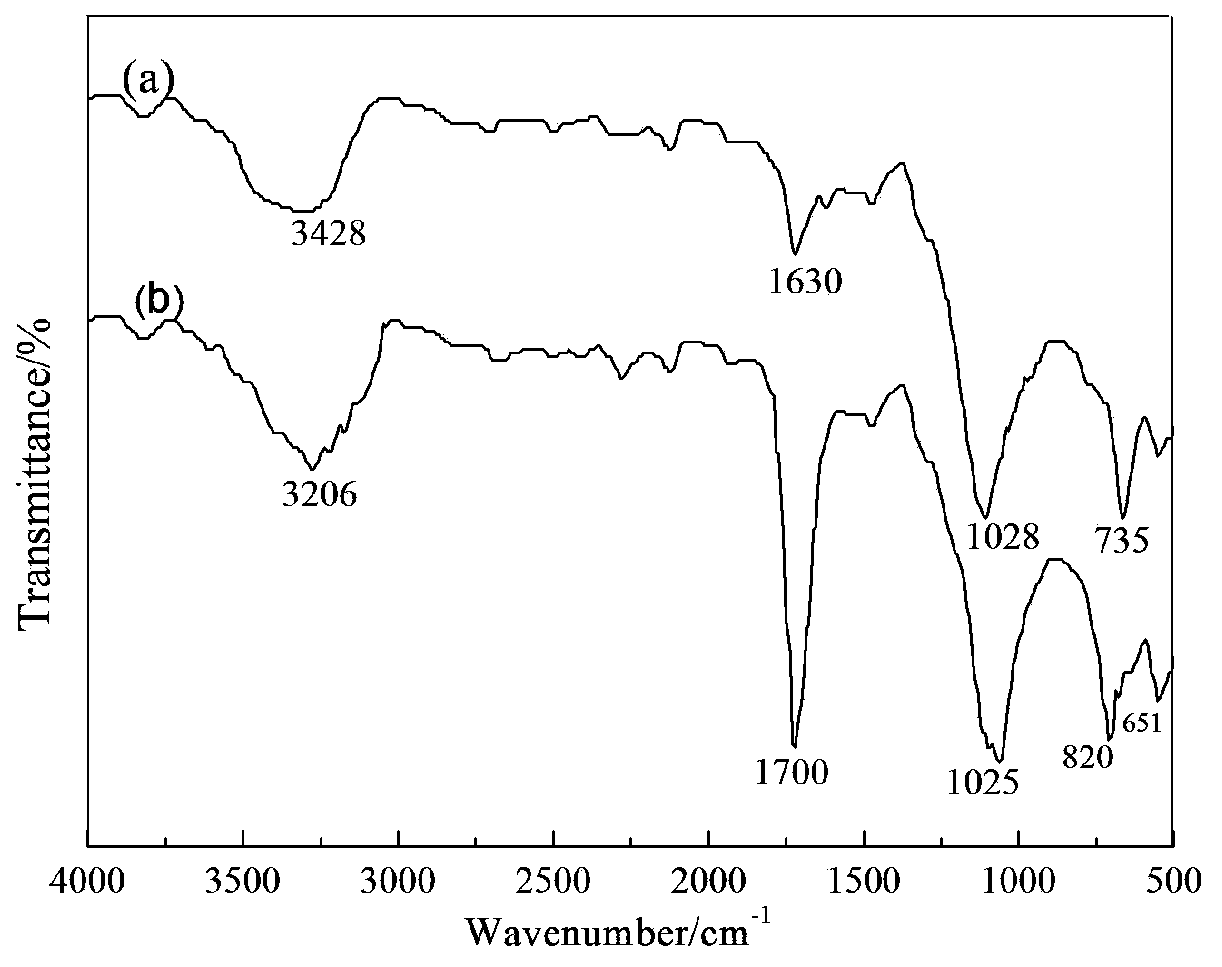

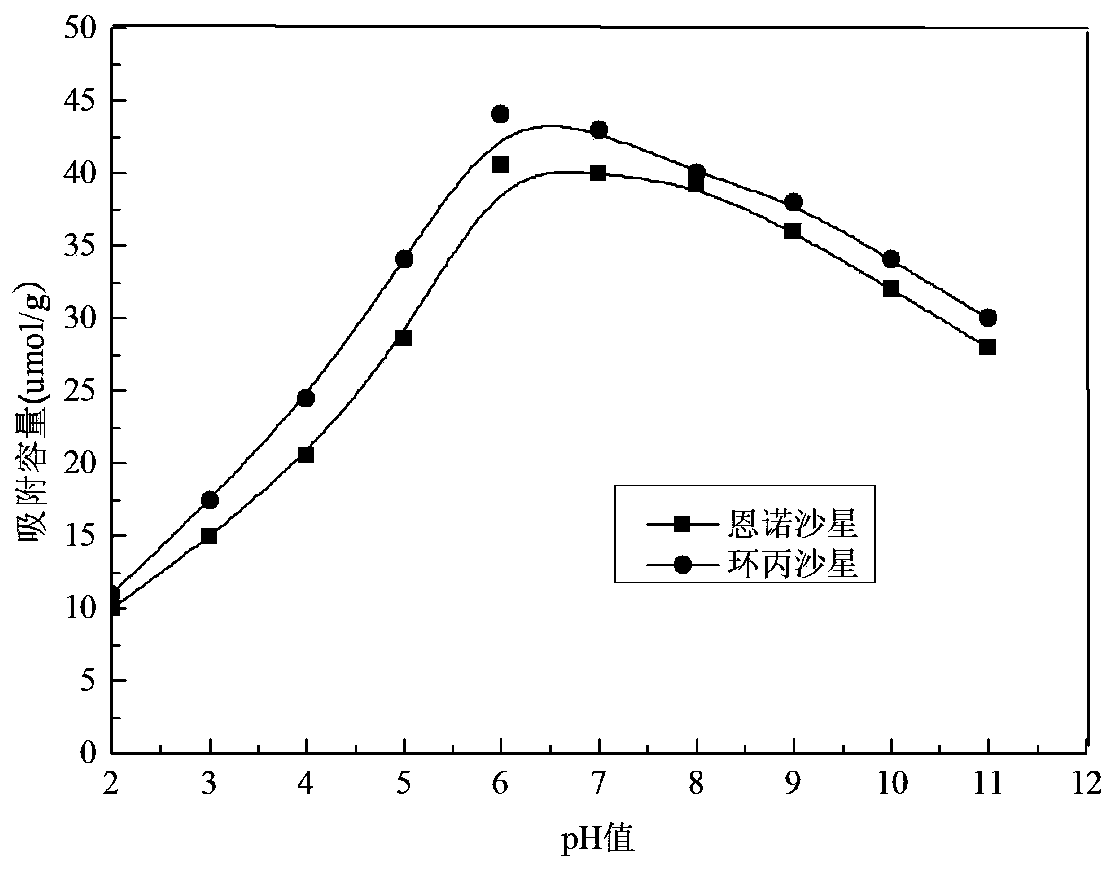

Potassium acetate based porous carbon adsorption material taking fly ash cenospheres as template and preparation method and applications thereof

InactiveCN110252246APromote activationHigh specific surface areaOther chemical processesWater contaminantsActivation methodPorous carbon

The invention discloses a preparation method of a potassium acetate based porous carbon adsorption material taking fly ash cenospheres as a template. The preparation method comprises following steps: at first, preparing a uniform solution from potassium acetate, wrapping the surface of fly ash cenospheres by the uniform solution, filling the uniform solution into cavities of the fly ash cenospheres , carrying out carbonization, then removing fly ash to obtain the hollow structure of fly ash, and generating micro pores by a high temperature alkali activation method to prepare a hierarchical porous carbon material with a large specific surface area. Solid industrial wastes namely fly ash hollow cenospheres (FACs) are taken as a hard template; a cheap biomass material namely potassium acetate is taken as a carbon source, the prepared hierarchical porous carbon material is used to process antibiotic (fluoroquinolone) sewage, and the processing effect is good.

Owner:HENAN UNIV OF URBAN CONSTR

Novel composite edible oil gel and preparation method thereof

ActiveCN111248300AEfficient bindingDoes not change chemical propertiesEdible oils/fatsFood gradeProcess engineering

The invention belongs to the technical field of edible oil, and particularly relates to a novel composite edible oil gel and a preparation method thereof. The novel composite edible oil gel comprisesedible oil and a composite gel, wherein the composite gel comprises lecithin and ceramide; and the novel composite edible oil gel is obtained by performing heating to dissolve the composite gel in theedible oil and then performing cooling and curing. The edible oil gel prepared by the method is green, simple, convenient and safe, has no toxic or side effect, is economical and environmentally friendly, has good oil holding capacity, and is convenient for long-term storage and transportation. The chemical property of an oil phase is not changed, and trans-fatty acid is not generated. In addition, lecithin and ceramide show different functional characteristics under different proportions, and edible oil gels meeting different requirements can be customized by adjusting the proportions of lecithin and ceramide, so that the novel composite edible oil gel has a wide application range.

Owner:SOUTH CHINA AGRI UNIV

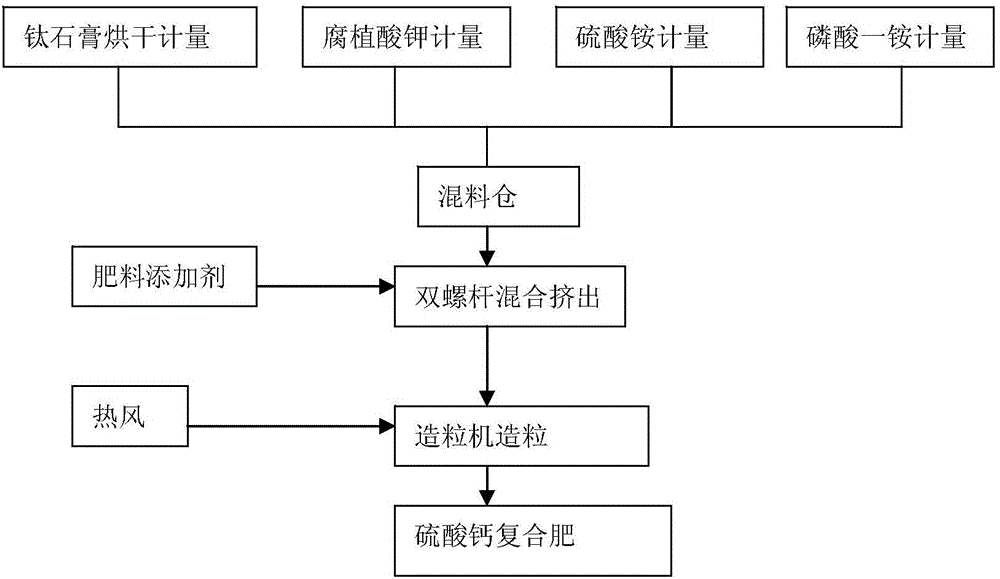

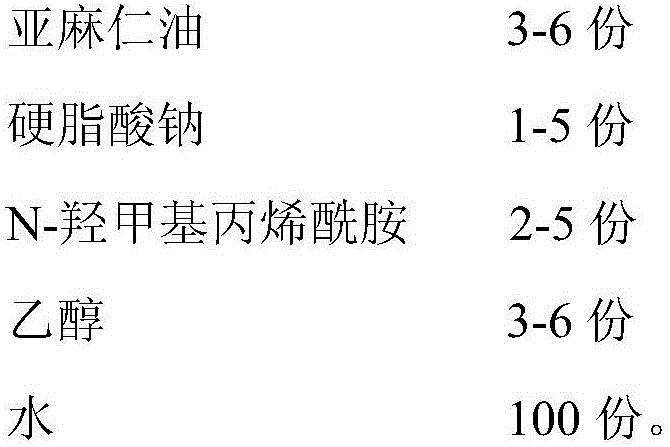

Method for preparing calcium sulfate composite fertilizer by using solid waste titanium gypsum

InactiveCN105948904AMeeting Calcium and Sulfur NeedsGuaranteed pHCalcareous fertilisersAlkali orthophosphate fertiliserChemical synthesisSodium stearate

The invention belongs to the technical field of preparation of fertilizers, and concretely relates to a method for preparing a calcium sulfate composite fertilizer by using solid waste titanium gypsum. The method comprises the following steps: 1, preparing a fertilizer additive: adding flaxseed oil, sodium stearate, N-hydroxymethyl acrylamide and ethanol to water, and stirring above added materials to obtain the fertilizer additive for later use; and 2, adding titanium gypsum, ammonium sulfate, potassium humate and monoammonium phosphate to a mixing bin, mixing added materials, carrying out triple helical stirring, carrying out double-screw mixing extrusion on the obtained mixture, adding the fertilizer additive to the front segment of a double-screw extruder, allowing a material extruded through the double-screw extruder to a granulator, granulating the material, and bagging the granulated material to obtain the calcium sulfate composite fertilizer. The calcium sulfate composite fertilizer prepared through using the titanium gypsum is different from other chemically synthesized composite fertilizers, and the production process of the composite fertilizer and the final product are safe, environmentally-friendly and nontoxic, and are harmless to human bodies and animals.

Owner:SHANDONG DONGJIA GRP CO LTD

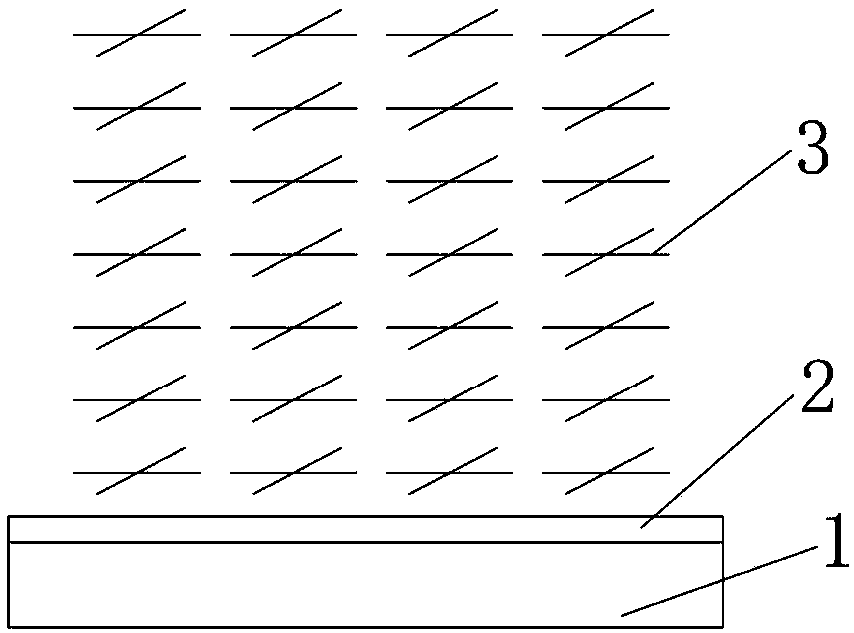

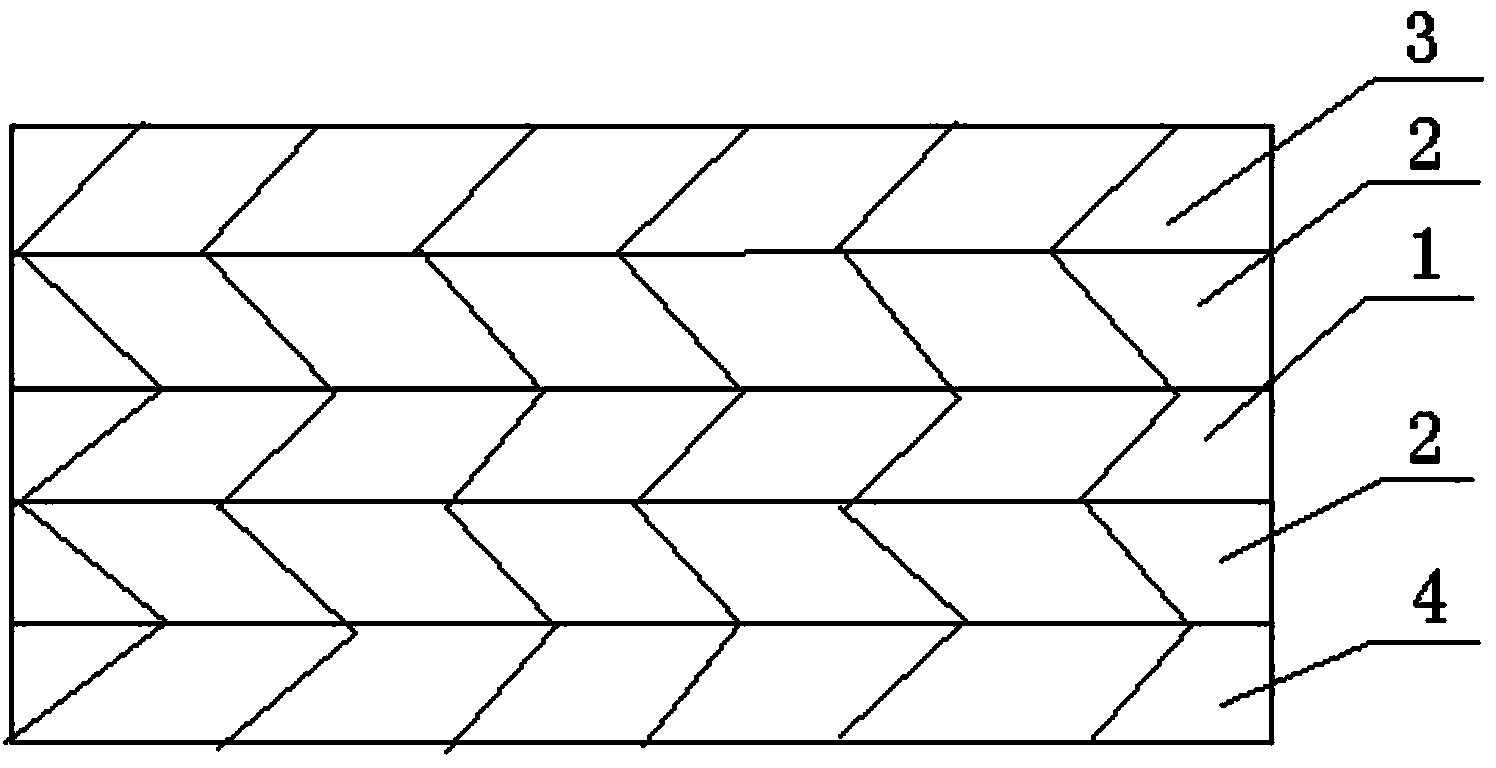

Microwave high-frequency metal matrix circuit board

InactiveCN103533750ASimple structureImprove insulation performanceCircuit susbtrate materialsHigh humidityMicrowave

The invention discloses a microwave high-frequency metal matrix circuit board, comprising a metal matrix circuit board (3); an insulation medium material layer (1) and a copper foil layer (4) are sequentially arranged at one surface of the metal matrix circuit board (3); the metal matrix circuit board (3) is bonded with the insulation medium material layer (1) by one bonding sheet (2); the insulation medium material layer (1) and the copper foil layer (4) are bonded by one bonding sheet (2); the insulation medium material layer (1) is formed by laminating and mixing teflon powder and polyphenyl ether in a ball-milling mode; the bonding sheets (2) are formed by gum dipping of teflon dispersion liquid and woven glass fabric. The microwave high-frequency metal matrix circuit board has the advantages such as simple structure, good insulation property, low heat resistance, high heat conduction, excellent radiating property, stable and reliable performances, low manufacturing cost and usability under a high-humidity high-temperature environment for a long time.

Owner:朱云霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com