Microwave high-frequency metal matrix circuit board

A high-frequency metal, circuit substrate technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of overheating of components on the circuit board, decreased reliability of the whole machine, easy falling off or breaking of the circuit layer of the circuit board, etc. Achieve excellent heat dissipation performance, reduce processing costs, and achieve good heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

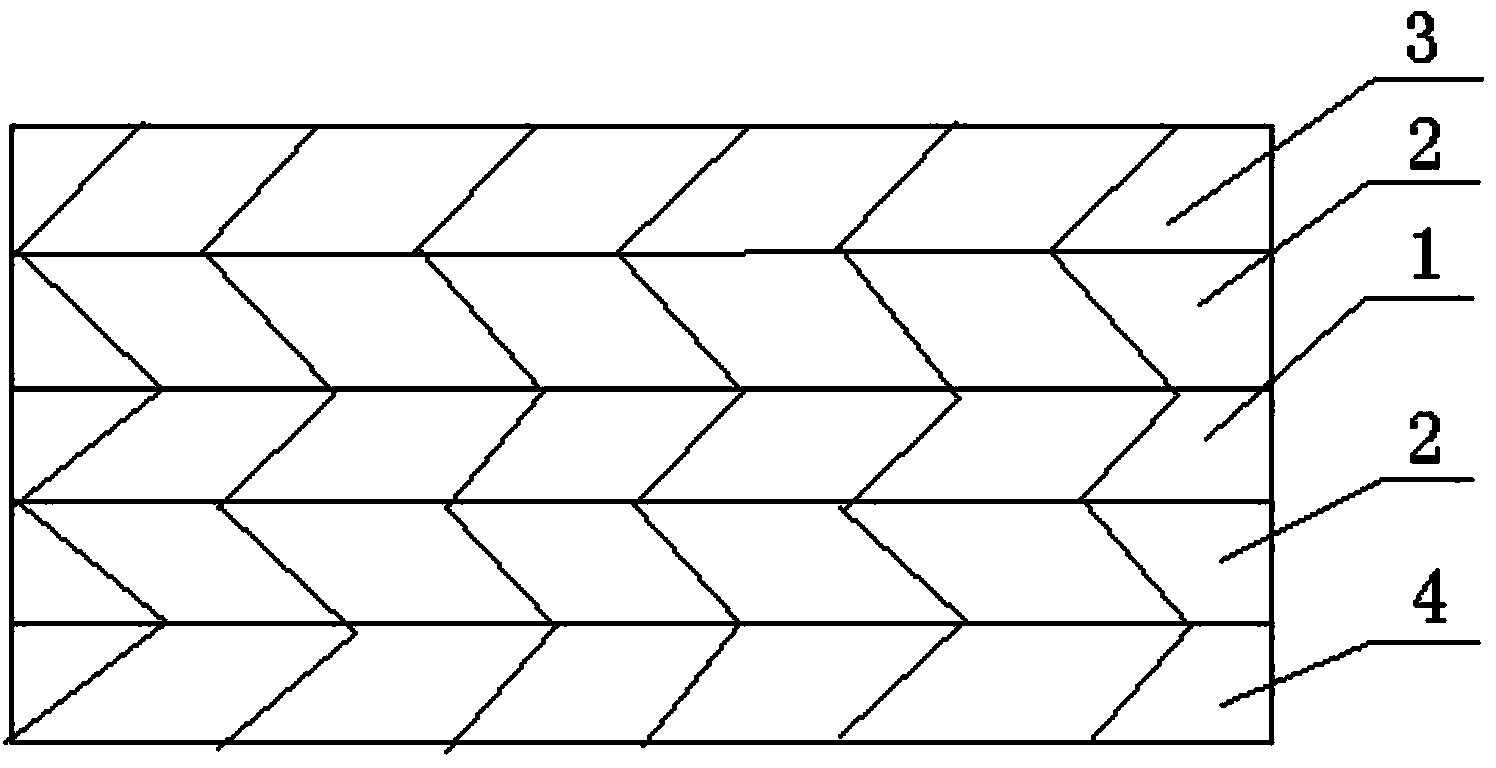

[0008] Such as figure 1 As shown, the present invention provides a microwave high-frequency metal-based circuit substrate, including a metal-based substrate 3, and the metal-based substrate 3 is any one of aluminum, aluminum alloy, copper, copper alloy, and stainless steel. One side of the substrate 3 is sequentially provided with an insulating dielectric material layer 1 and a copper foil layer 4, the thickness of the copper foil layer 4 is 35um-280um, and the metal-based substrate 3 and the insulating dielectric material layer 1 are bonded by the bonding sheet 2, so The insulating dielectric material layer 1 and the copper foil layer 4 are bonded by an adhesive sheet 2. The insulating dielectric material layer 1 is formed by ball milling polytetrafluoroethylene powder and polyphenylene ether powder and then pressed together. The adhesive sheet 2 It is a bonding sheet formed by PTFE dispersion liquid and glass cloth impregnated with glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com