Method for formation of spiral layer inside catheter

A helix and catheter technology, applied in the field of forming the helical layer inside the catheter, can solve the problems of high cost, difficulty in pushing, high friction, etc., and achieve the effect of low cost and increased biological risk and structural risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

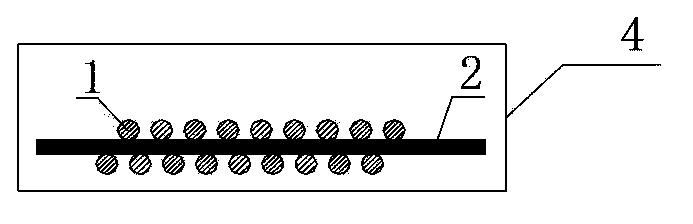

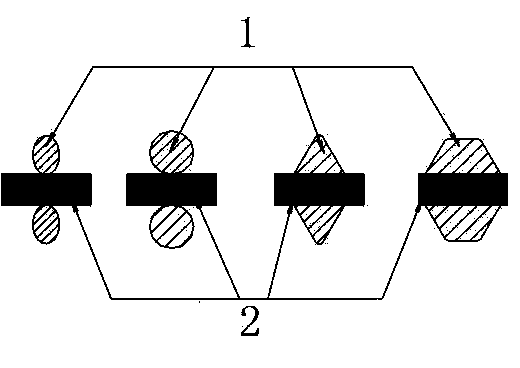

[0056] The helical layer wire 1 is made of 304V stainless steel wire with a circular cross section. The pitch of the helical layer wire 1 is 0.2mm, the length of the helical layer wire 1 in the axial direction is 300mm, and the inner diameter of the helical layer is 0.016inch. The outer diameter is 0.020inch. A 0.016 inch mandrel (used as the lining wire 2 ) was threaded into the helically layered wire 1 to obtain a mandrel 4 with helical layers.

[0057] Make a single-chamber, three-layer polymer tubing (as the body of catheter 3) again, length is 250mm, outer diameter is 0.028inch, and inner diameter is 0.021inch, and its inner layer is LDPE (low density polyethylene), and outer layer is Polyamide PA12 with an adhesive layer in the middle;

[0058] The mandrel 4 with the helical layer is penetrated into the above-mentioned single-cavity, three-layer polymer pipe, and the polymer pipe is coated on the mandrel 4 with the helical layer by hot extrusion;

[0059] The mandrel 4...

example 2

[0061] Use Nitinol material, trapezoidal cross-section (the length of the upper bottom is 0.05mm, the length of the lower bottom is 0.15mm, and the height is 0.05mm) to make the helical layer wire 1, the pitch of the helical layer wire 1 is 0.2mm, and the helical layer wire 1 is on the shaft The upward length is 300mm, the inner diameter of the helical layer is 0.016inch, and the outer diameter of the helical layer is 0.020inch. A 0.016 inch mandrel (used as the lining wire 2 ) was threaded into the helically layered wire 1 to obtain a mandrel 4 with helical layers.

[0062] First make a single-chamber, three-layer polymer tubing (used as the main body of the catheter 3), the length is 250mm, the outer diameter is 0.028inch, the inner diameter is 0.021inch, its inner layer is PTFE (polytetrafluoroethylene), and the outer layer is Polyamide PA12 with an adhesive layer in the middle;

[0063] The mandrel 4 with the helical layer is penetrated into the above-mentioned single-cav...

example 3

[0066] Adopt 304V stainless steel, make the mandrel 4 that length is 300mm with helical layer by micro-engraving, the section of the helical layer of mandrel 4 is equilateral triangle (side length is 0.05mm), the pitch of the helical layer of mandrel 4 is 0.05mm, The inner diameter d of the helical layer is 0.016inch, and the outer diameter D of the helical layer is 0.020inch. A PTFE coating is coated on the surface of the mandrel 4 with the helical layer, and the thickness of the coating is 2 μm.

[0067] First make a single-lumen, three-layer polymer pipe (used as the body of the catheter 3), the length is 250mm, the outer diameter is 0.028inch, and the inner diameter is 0.021inch. The inner layer is PTFE, the outer layer is polyamide PA12, and the middle is adhesive layer;

[0068] The mandrel 4 with the helical layer is penetrated into the above-mentioned single-cavity, three-layer polymer pipe, and the polymer pipe is coated on the mandrel 4 with the helical layer by hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com