Fire-fighting aerosol equipment for cooling and breaking flame

An aerosol and flame technology, applied in the direction of fire prevention equipment, etc., can solve the problems of increasing the volume and weight of fire extinguishing aerosol, changing the physical and chemical properties of aerosol, reducing the efficiency of aerosol production, etc., achieving light weight, low cost, and small device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

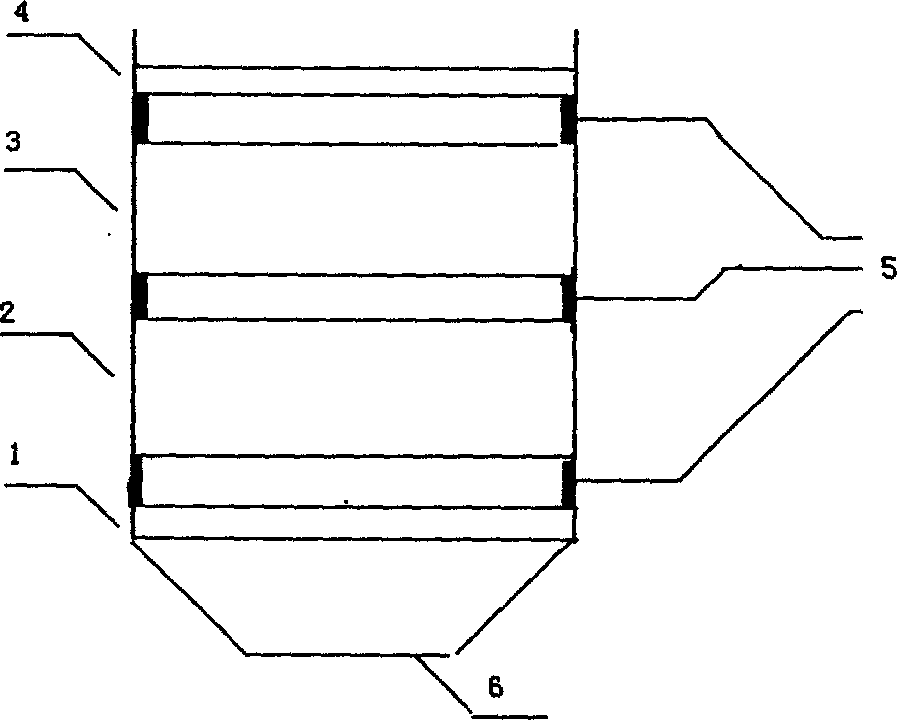

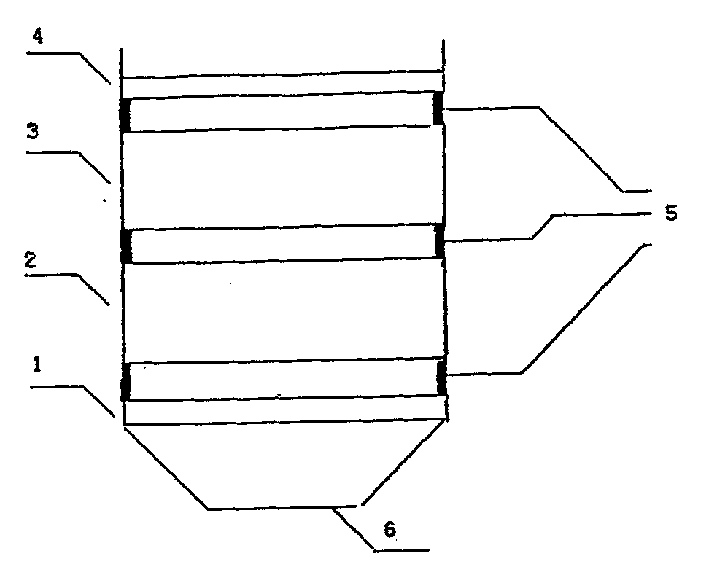

[0013] Dissolve one part of polyvinyl alcohol and one part of phenolic resin in 10 parts of water, stir to make glue, the mass ratio of calcium sulfate, zeolite, alumina and calcium carbonate = 0.20:0.20:0.25:0.35, use glue and post-production Form a cylinder with a column height of 0.5 cm. Vertically drill a number of small holes with a diameter of 4 mm on the upper and lower surfaces of the cylinder. The number of small holes per square centimeter is 5. After drying at 100 ° C, put it into the attached drawing The first layer of 1.

[0014] The mass ratio of sodium carbonate and sodium bicarbonate = 1: 1, glued with solid glue and made into a cylinder, the height of the column is 6 cm, and a number of small holes with a diameter of 4 mm are vertically drilled on the upper surface and the lower surface of the cylinder , the number of small holes per square centimeter is 5, and after being dried at 100°C, it is loaded into the second layer 2 in the accompanying drawing.

[00...

Embodiment 2

[0018] The mass ratio=0.30: 0.25: 0.25: 0.30 of calcium sulfate, zeolite, aluminum oxide and calcium carbonate, with the gluing of embodiment 1 and make cylinder after, column height is 0.5 centimetre, on cylinder upper surface and lower surface Vertically drill some small holes with a diameter of 4 mm, the number of small holes per square centimeter is 5, and pack into the first layer 1 in the accompanying drawing after drying at 100°C.

[0019] The mass ratio of sodium carbonate and sodium bicarbonate=1: 1, with the gluing of embodiment 1 and back make cylinder, column height is 6 centimetres, vertically drill out diameter on cylinder upper surface and lower surface and be 4 millimeters Some small holes, the number of small holes per square centimeter is 5, after drying at 100 ℃, pack into the second layer 2 in the accompanying drawing.

[0020] The mass ratio of calcium carbonate and zinc hydroxide=1: 1, with the gluing of embodiment 1 and back make cylinder, column height ...

Embodiment 3

[0023] The mass ratio of calcium sulfate, zeolite, aluminum oxide and calcium carbonate=0.40: 0.15: 0.20: 0.25, with the gluing of embodiment 1 and back make cylinder, column height is 0.5 centimetre, on cylinder upper surface and lower surface Vertically drill some small holes with a diameter of 4 mm, the number of small holes per square centimeter is 5, and pack into the first layer 1 in the accompanying drawing after drying at 100°C.

[0024] The mass ratio of sodium carbonate and sodium bicarbonate=1: 1, with the gluing of embodiment 1 and back make cylinder, column height is 6 centimetres, vertically drill out diameter on cylinder upper surface and lower surface and be 4 millimeters Some small holes, the number of small holes per square centimeter is 5, after drying at 100 ℃, pack into the second layer 2 in the accompanying drawing.

[0025] The mass ratio of calcium carbonate and zinc hydroxide=1: 1, with the gluing of embodiment 1 and back make cylinder, column height i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com