High-pressure abrasive water-jet rock coring drilling machine

An abrasive water jet and coring drill technology is used in fractured rock, sandstone coring and small-diameter non-destructive coring drilling machines, and conglomerate fields. , affecting the accurate evaluation of shale oil and gas reservoirs, etc., to achieve the effects of low noise, convenient operation, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

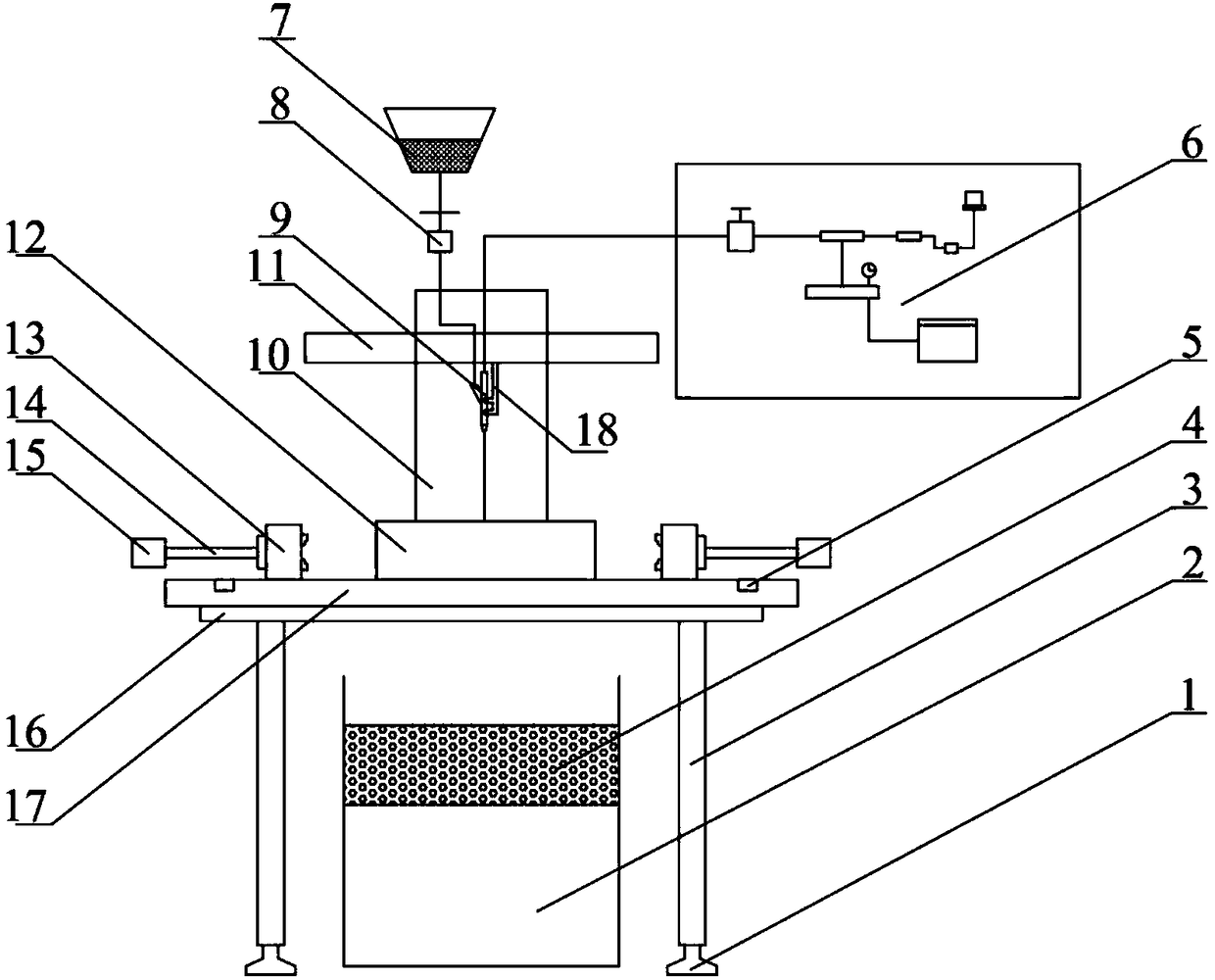

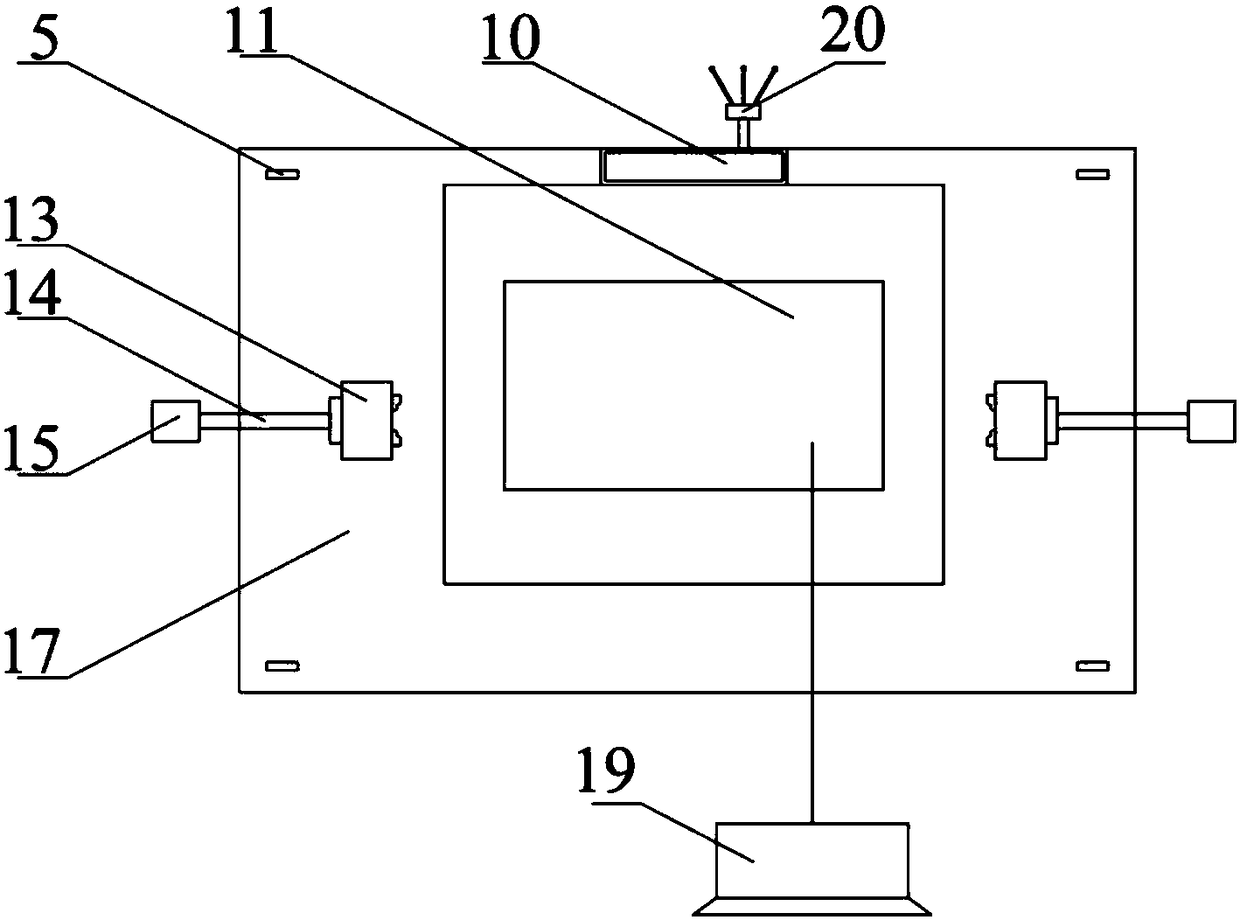

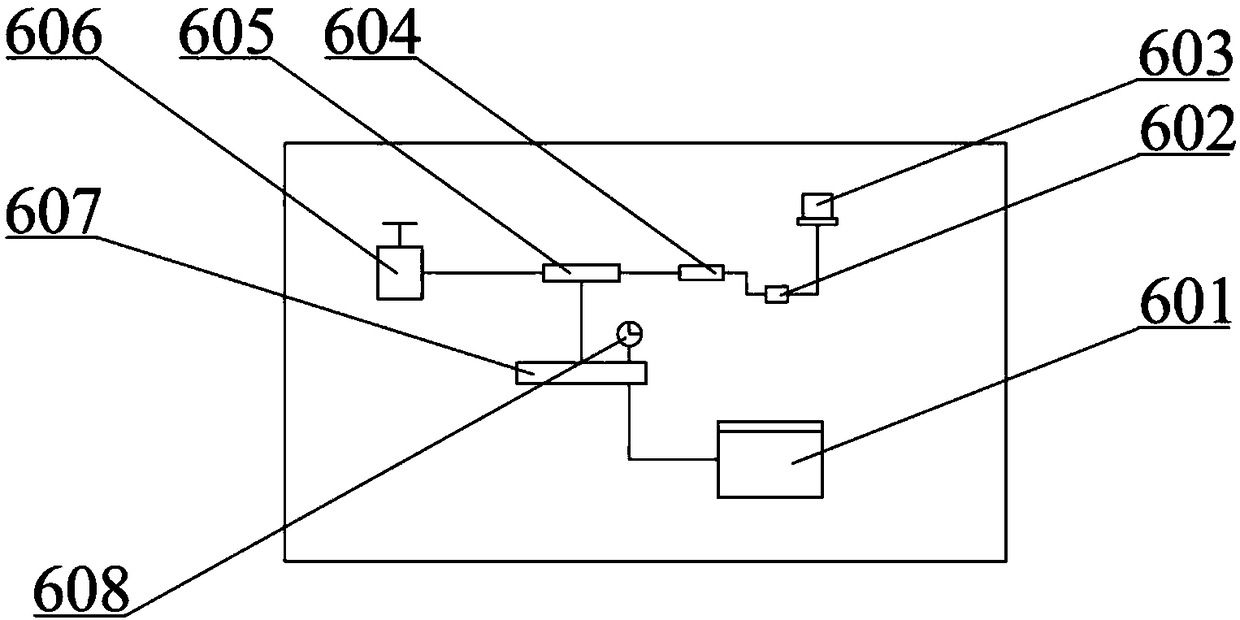

[0026] Such as Figure 1-3 As shown, a high-pressure abrasive water jet rock coring drilling machine provided by the present invention includes a drilling machine table 17, and a support frame 10 is arranged in the middle above the drilling machine table 17, and the support frame 10 is used to support the mechanical arm control system 11 , the mechanical arm control system 11 is provided with an up and down transmission rack, and the transmission shaft end of the rotating handle 20 is provided with a transmission gear, and the transmission gear and the transmission rack are engaged and driven by rotating the rotating handle 20 to drive The manipulator control system 11 moves up and down. The manipulator control system 11 is connected to the computer 19. The manipulator 18 is connected to the bottom of the manipulator control system 11. The end of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com