Environment-friendly composite material with comprehensive properties

A composite material and comprehensive performance technology, applied in the field of comprehensive performance and environmentally friendly composite materials, can solve the problems of limited material use range, high material cost, etc., and achieve the effect of improving comprehensive mechanical properties, reducing toxic gases, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

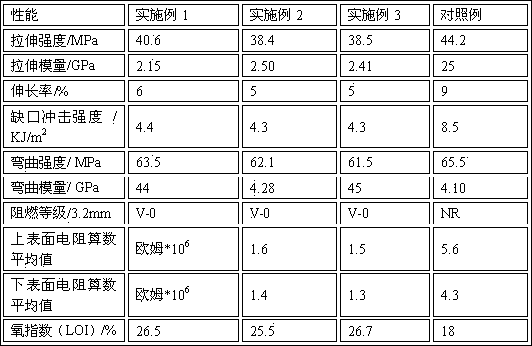

Examples

Embodiment 1

[0026] Add 73wt% of ABS resin and 5wt% of ABS-g-MAH to a high-speed mixer for mixing. After mixing evenly, add them to a twin-screw extruder for melt blending and extrusion, and control the temperature range of the extruder to 170°C. After extrusion, it is cooled to normal temperature in a water tank, pelletized by a pelletizer, and then the obtained pellets are put into an oven at a temperature range of 80°C and dried for 3 hours to obtain modified ABS particles; the modified ABS particles are mixed with carbon black and nickel-plated carbon fiber 10wt%; simultaneously added to a single-screw extruder for extrusion (barrel temperature: 215°C, screw speed 25r / min), weighed about 12 grams of the mixed material at 200°C. Samples of 70×3mm were molded. Then cut out 40×8×3mrD splines from the prepared samples for the test of electrical properties. The test results show that the resistivity of the material is 3.6×10 4 Ohm, apply a DC voltage of 1000V to the composite material, an...

Embodiment 2

[0028]Add 80wt% of ABS resin and 5wt% of ABS-g-MAH to the high-speed mixer for mixing. After mixing evenly, add them to the twin-screw extruder for melt blending and extrusion, and control the temperature range of the extruder to 200°C. After extrusion, it is cooled to normal temperature in a water tank, pelletized by a pelletizer, and then the obtained pellets are put into an oven at a temperature range of 90°C and dried for 4 hours to obtain modified ABS particles; the modified ABS particles are mixed with polypropylene Nitrile-based carbon fiber 10wt%; simultaneously added to a single-screw extruder for extrusion (barrel temperature: 215°C, screw speed 25r / min), weighed about 12 grams of the mixed material at 200°C. Samples of 70×3mm were molded. Then cut out 40×8×3mrD splines from the prepared samples for the test of electrical properties. The test results show that the resistivity of the material is 3.7×10 4 Ohm, apply a DC voltage of 2000V to the composite material, an...

Embodiment 3

[0030] Add 73wt% of ABS resin and 5wt% of ABS-g-MAH to the high-speed mixer for mixing. After mixing evenly, add them to the twin-screw extruder for melt blending and extrusion, and control the temperature range of the extruder to 210°C. After extrusion, it is cooled to normal temperature in a water tank, pelletized by a pelletizer, and then put the obtained pellets into an oven at a temperature range of 90°C and dried for 4 hours to obtain modified ABS particles; the modified ABS particles and carbon fiber 10wt % at the same time added to a single-screw extruder for extrusion (barrel temperature: 215°C, screw speed 25r / min), weighed about 12 grams of the mixed material at 200°C. Samples of 70×3mm were molded. Then cut out 40×8×3mrD splines from the prepared samples for the test of electrical properties. The test results show that the resistivity of the material is 3.1×10 4 Ohm, apply a DC voltage of 3000V to the composite material, and apply the voltage for 200s. The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com