A kind of antibacterial stainless steel and preparation method thereof

An antibacterial stainless steel and stainless steel technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of high technical requirements for preparation equipment and process, high processing cost, and achieve strong catalytic sterilization ability and high preparation cost. Low, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of antibacterial stainless steel, comprising the following steps:

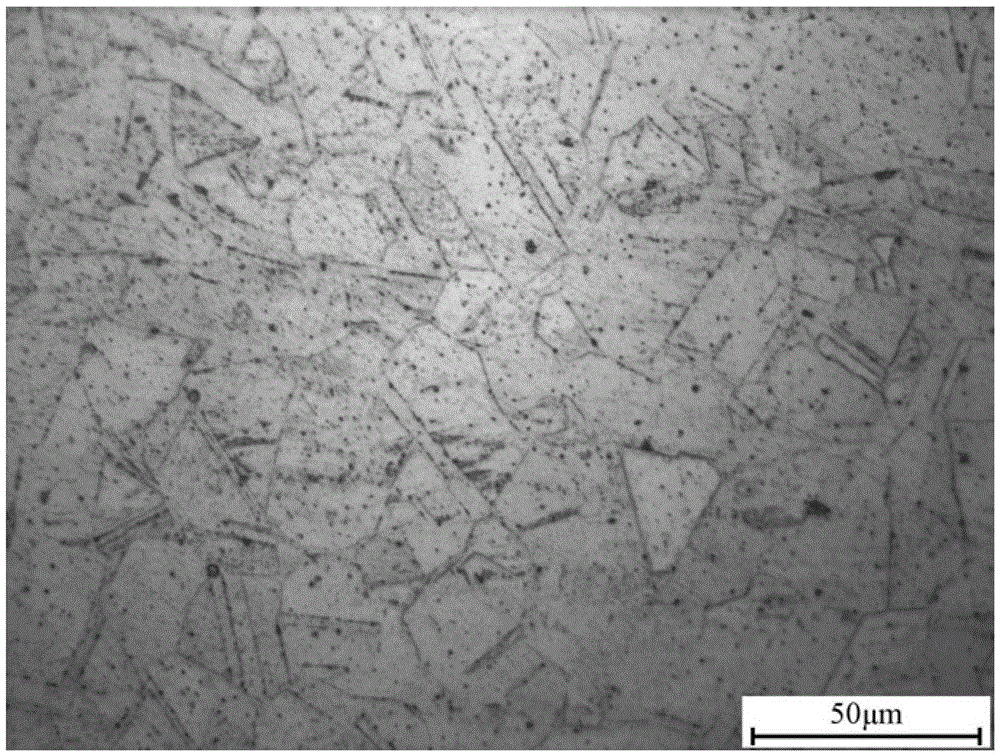

[0038] (1) Take stainless steel, see the microstructure of stainless steel figure 1 , using acetone to remove oil stains on the stainless steel surface in an ultrasonic environment, and the ultrasonic time is 8 minutes;

[0039] (2) pickling, the stainless steel after ultrasonic degreasing is pickled in hydrochloric acid for 2 minutes;

[0040] (3) Plating, add ammonium titanate, boric acid and deionized water into the container to prepare a plating solution, then keep the solution temperature at 40°C, place the pickled stainless steel in the plating solution for 48 hours ;

[0041] (4) Rinse and dry, rinse the surface after the permeation and plating is completed, and then dry, that is.

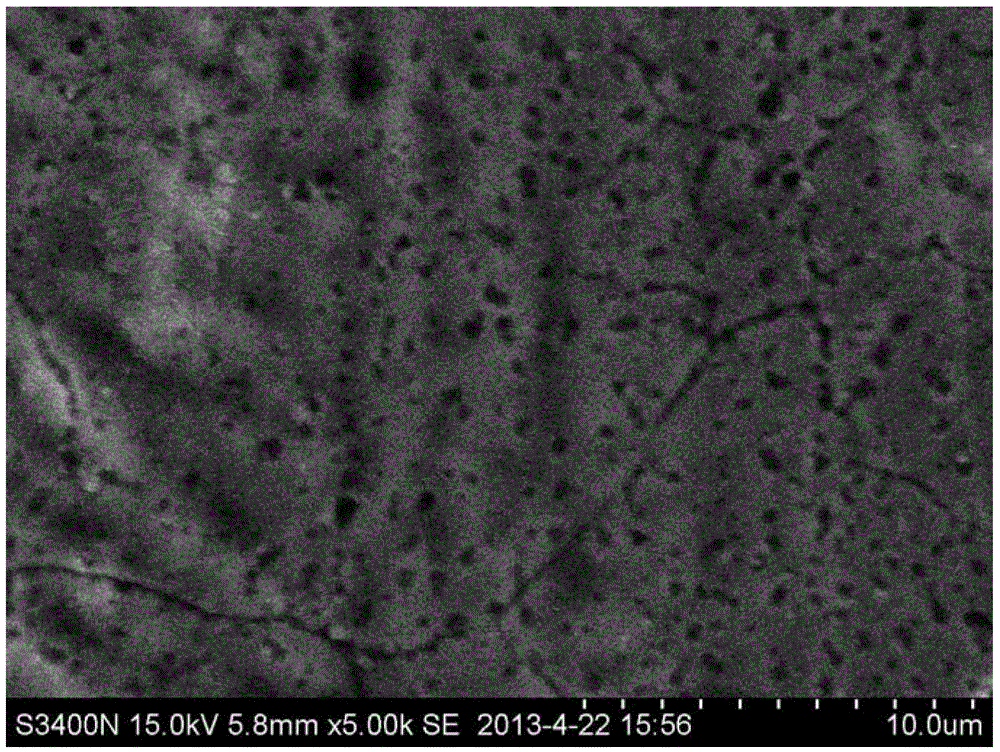

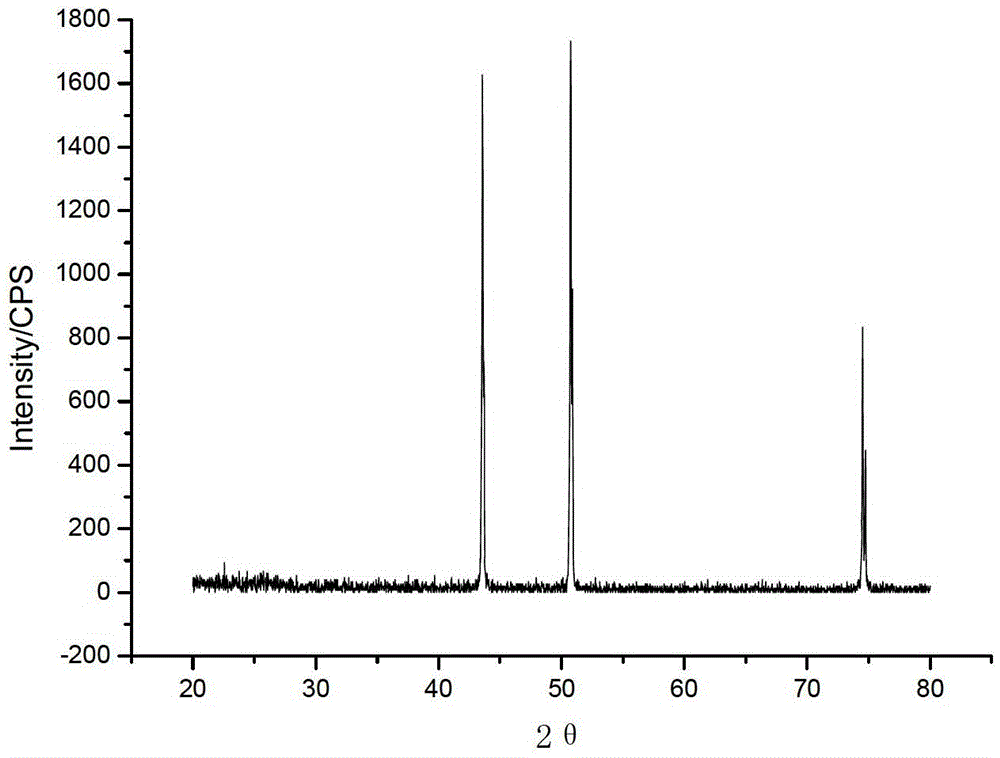

[0042] figure 2 is the SEM picture (ie scanning electron microscope picture) of the prepared antibacterial stainless steel, from figure 2 It can be seen that the coating on the surface of s...

Embodiment 2

[0046] A preparation method of antibacterial stainless steel, comprising the following steps:

[0047] (1) Take stainless steel and polish the surface of the stainless steel with 1000-mesh sandpaper to make the surface roughness Ra0.045;

[0048] (2) Use ethyl acetate and remove oil stains on the stainless steel surface in an ultrasonic environment. The amount of ethyl acetate is just enough to cover the stainless steel sample, and the ultrasonic time is 15 minutes;

[0049] (3) Use NaOH, NaCO 3 、Na 3 PO 4 and NaSiO 4 Prepare chemical degreasing fluid, in which NaOH concentration is 50g / L, NaCO 3 The concentration is 35g / L, Na 3 PO 4 The concentration is 30g / L, NaSiO 4 The concentration is 6g / L, the temperature of the chemical degreasing solution is maintained at 50°C, and the sample treated in step (2) is placed in the chemical degreasing solution for 20 minutes;

[0050] (4) Pickling, pickling the sample treated in step (3) in hydrochloric acid solution for 1 minute, a...

Embodiment 3

[0055] A preparation method of antibacterial stainless steel, comprising the following steps:

[0056] (1) Take stainless steel, first use 800-mesh sandpaper, and then use 1000-mesh sandpaper to polish the stainless steel surface, so that the surface roughness is Ra0.042;

[0057] (2) Use acetone to remove oil stains on the stainless steel surface in an ultrasonic environment. The amount of acetone is just enough to cover the stainless steel sample, and the ultrasonic time is 12 minutes; after ultrasonic degreasing, wash with absolute ethanol for 6 minutes, and then use deionized water Blow dry after washing;

[0058] (3) Use NaOH, NaCO 3 、Na 3 PO 4 and NaSiO 4 Prepare chemical degreasing fluid, in which NaOH concentration is 60g / L, NaCO 3 The concentration is 30g / L, Na 3 PO 4 The concentration is 20g / L, NaSiO 4 The concentration is 8g / L, the temperature of the chemical degreasing solution is maintained at 60°C, and the sample treated in step (2) is placed in the chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com