Inorganic nano antibacterial thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, inorganic nano technology, applied in the field of inorganic nano antibacterial thermoplastic elastomer and its preparation, can solve the problems of easily decomposable antibacterial persistence, poor chemical thermal stability, toxicity, etc., and achieves no change in mechanical properties and processing properties. , stable performance, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

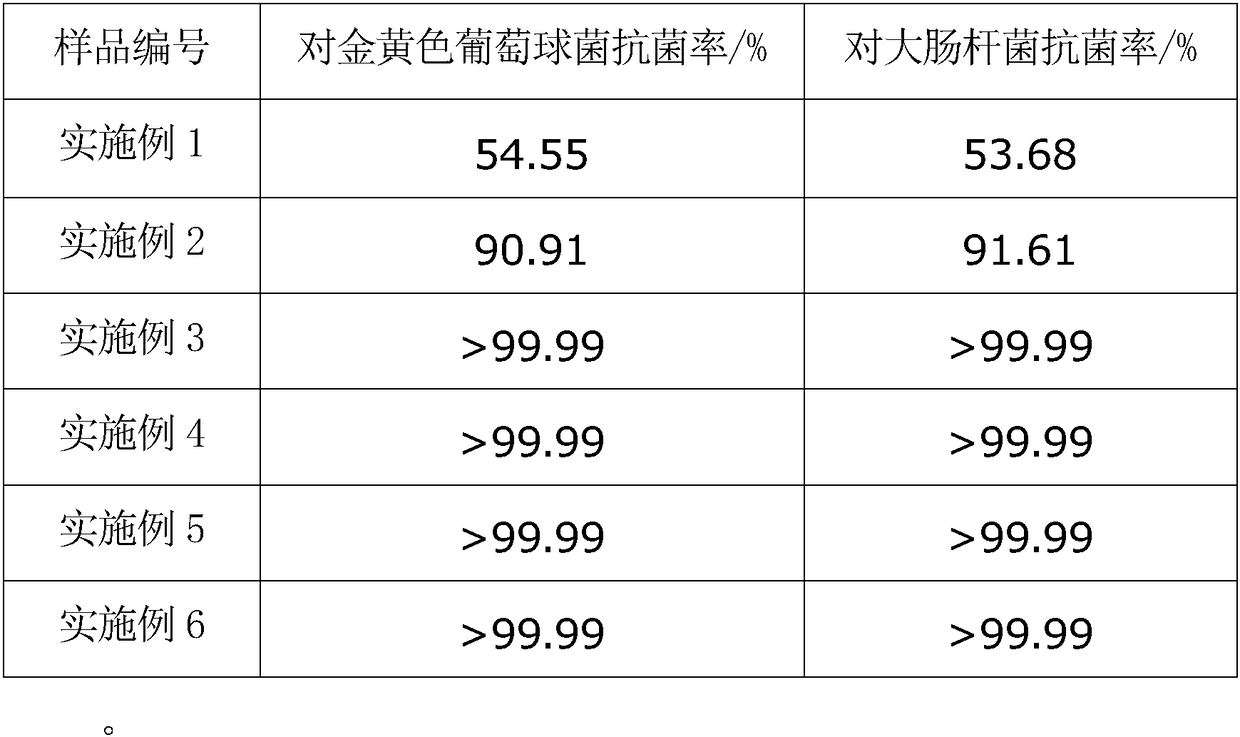

Examples

preparation example Construction

[0028] The invention discloses an inorganic nano antibacterial thermoplastic elastomer and a preparation method thereof. A kind of inorganic nano antibacterial thermoplastic elastomer, by mass percentage, comprises following material:

[0029] SEBS 15~30%

[0030] Rubber filling oil 10~30%

[0031] Polypropylene 10-25%

[0032] Inorganic nano antibacterial powder 1~2%

[0033] Coupling agent 0.1~0.5%

[0034] Surfactant 0.1~0.5%

[0035] Other additives 0-2%.

[0036] In this technical solution, the SEBS is selected from one or more of American Kraton G1651, 1654, Taiwan TSRC's 3152, 6151, and Yueyang Petrochemical's YH503. The rubber extender oil is one or a mixture of naphthenic oil and paraffin oil. The polypropylene is selected from one or more of homopolymerization and copolymerization polypropylene. The inorganic nano-antibacterial powder is one or a mixture of nano-silver powder or nano-zinc oxide powder. The coupling agent is one or more of silane coupling age...

Embodiment 1

[0045] (1) Put the nano-zinc oxide powder in an electrothermal constant temperature blast drying oven, control the temperature at 110°C, dry for 2 hours, weigh 200g of nano-zinc oxide powder and put it in a 5L high-speed mixer, and drop 10g of silane coupling agent at the same time Put it into a high-speed mixer, the stirring speed is 1000r / min, after continuous stirring for 10min, discharge the material for later use.

[0046] (2) Weigh 24g of the material in step (1), add 973.6g of naphthenic oil, add Aerosol OT-75 2.4g, stir at high speed for 30min, stirring speed 800r / min, obtain the naphthenic oil dispersion of nano-zinc oxide liquid.

[0047](3) Take by weighing 875g Kraton SEBSG1651 and put it into a high-speed mixer, take by weighing 1000g of the dispersion liquid of step (2) and add in Kraton SEBSG1651 while stirring, fully stir and mix, the stirring speed is 600r / min, and the stirring time is 5min, then Stand still for 12 hours, fully absorb oil, and prepare SEBS wi...

Embodiment 2

[0051] (1) Put the nano-zinc oxide powder in an electrothermal constant temperature blast drying oven, control the temperature at 110°C, and dry it for 2 hours, weigh 200g of nano-zinc oxide powder and place it in a 5L high-speed mixer, and drop 10g of silane coupling agent at the same time Put it into a high-speed mixer, the stirring speed is 1000r / min, after continuous stirring for 10min, discharge the material for later use.

[0052] (2) Take by weighing 36g of the material in step (1), add in 960.4g of naphthenic oil, add Aerosol OT-753.6g, stir at high speed for 30min, stirring speed 800r / min, obtain the naphthenic oil dispersion of nano-zinc oxide .

[0053] (3) Take by weighing 875g Kraton SEBSG1651 and put it into a high-speed mixer, take by weighing 1000g of the dispersion liquid of step (2) and add in Kraton SEBSG1651 while stirring, fully stir and mix, the stirring speed is 600r / min, and the stirring time is 5min, then Stand still for 12 hours, fully absorb oil, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com