Softening clothes washing condensate ball and preparation method thereof

A technology of laundry coagulation and suppleness, which is applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent compounding agents, etc., can solve the problems of poor washing ability and suppleness effect, and achieve good washing ability and suppleness effect , Safe and convenient to use, strong aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

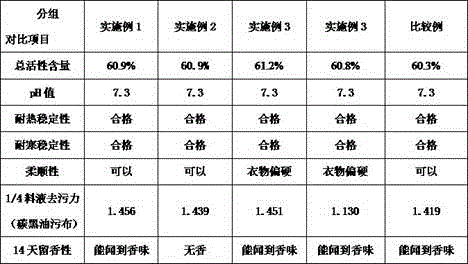

Examples

Embodiment 1

[0029] Weigh 1.5kg of fatty alcohol polyoxyethylene ether (9EO), 800g of fatty alcohol polyoxyethylene ether (7EO), and 150g of behenamidopropyl ethyl dimethylamine ethosulfate in a 3L beaker, and place in a 45 ℃ water bath, stir evenly with a glass rod, set aside;

[0030]Weigh 3kg of isomeric C13 fatty alcohol polyoxyethylene ether, 1.2kg of fatty alcohol polyoxyethylene ether sodium sulfate, 2.87kg of propylene glycol, 200g of detergent synergist WR, and 200g of isomeric alcohol polyoxyethylene ether into the mixing tank in turn, Stir for 30 minutes, slowly add the feed liquid into the above beaker under stirring and mix evenly, add 3g fungicide, 2g alkaline protease, 80g microcapsule essence in turn after 10 minutes of stirring, stop stirring after 30 minutes, pour the feed liquid Put it into a plastic bucket and seal it for later use;

[0031] Open the sealing cover of the plastic bucket, add the material liquid to the feeding port of the laundry bead automatic packaging...

Embodiment 2

[0033] Weigh 1.5kg of fatty alcohol polyoxyethylene ether (9EO), 800g of fatty alcohol polyoxyethylene ether (7EO), and 150g of behenamidopropyl ethyl dimethylamine ethosulfate in a 3L beaker, and place in a 45 ℃ water bath, stir evenly with a glass rod, set aside;

[0034] Weigh 3kg of isomeric C13 fatty alcohol polyoxyethylene ether, 1.2kg of fatty alcohol polyoxyethylene ether sodium sulfate, 2.87kg of propylene glycol, 200g of detergent synergist WR, and 200g of isomeric alcohol polyoxyethylene ether into the mixing tank in turn, Stir for 30 minutes, slowly add the material liquid into the above beaker under stirring and mix evenly, add 3g of fungicide, 2g alkaline protease, 100g of ordinary essence in turn after 10 minutes of stirring, stop stirring after 30 minutes, pour the material liquid into In a plastic bucket, sealed for later use;

[0035] Open the sealing cover of the plastic bucket, add the material liquid to the feeding port of the laundry bead automatic packa...

Embodiment 3

[0037] Weigh 1.5kg of fatty alcohol polyoxyethylene ether (9EO), 800g of fatty alcohol polyoxyethylene ether (7EO), and 150g of quaternary ammonium cationic softener into a 3L beaker, heat in a water bath at 45°C, and use a glass rod to Stir well and set aside;

[0038] Weigh 3kg of isomeric C13 fatty alcohol polyoxyethylene ether, 1.2kg of fatty alcohol polyoxyethylene ether sodium sulfate, 2.87kg of propylene glycol, 200g of detergent synergist WR, and 200g of isomeric alcohol polyoxyethylene ether into the mixing tank in turn, Stir for 30 minutes, slowly add the feed liquid into the above beaker under stirring and mix evenly, add 3g fungicide, 2g alkaline protease, 80g microcapsule essence in turn after 10 minutes of stirring, stop stirring after 30 minutes, pour the feed liquid Put it into a plastic bucket and seal it for later use;

[0039] Open the sealing cover of the plastic bucket, add the material liquid to the feeding port of the laundry bead automatic packaging ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com