Patents

Literature

149results about How to "Good antibacterial and deodorant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing bamboo fiber

InactiveCN101538744AEfficient productionThe production process is stable and reliableCane mechanical workingWood working apparatusChemistryEmulsion

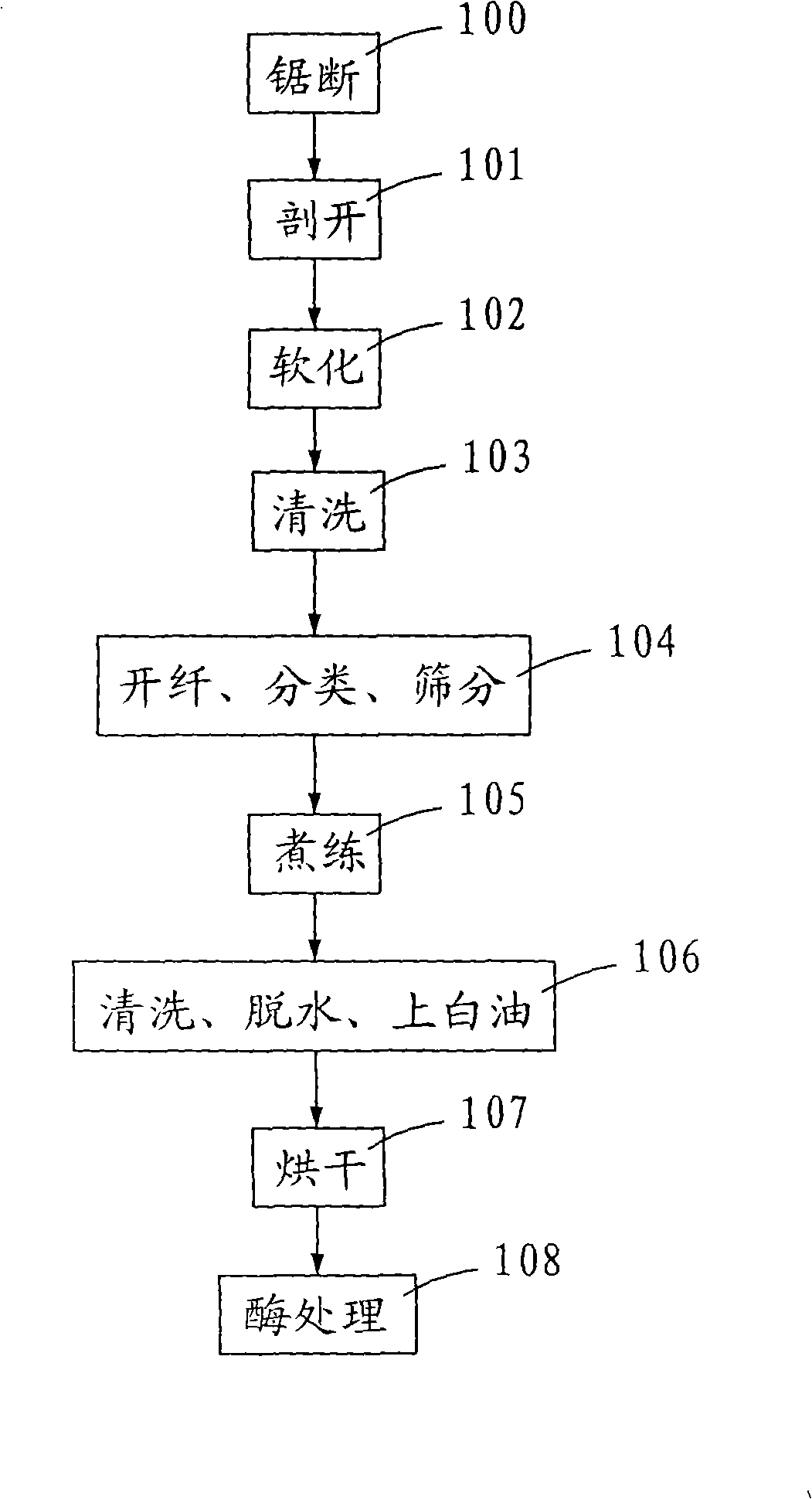

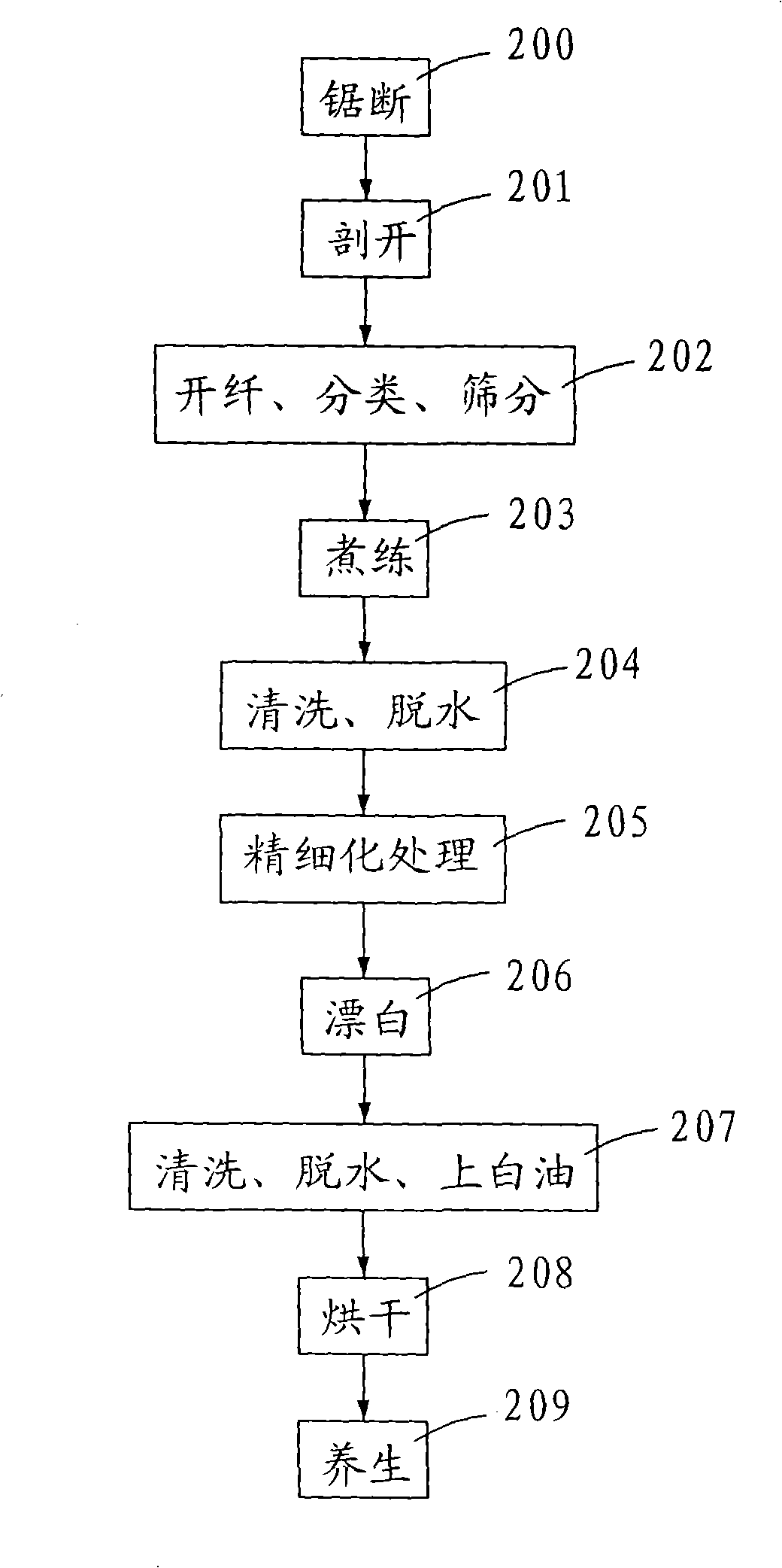

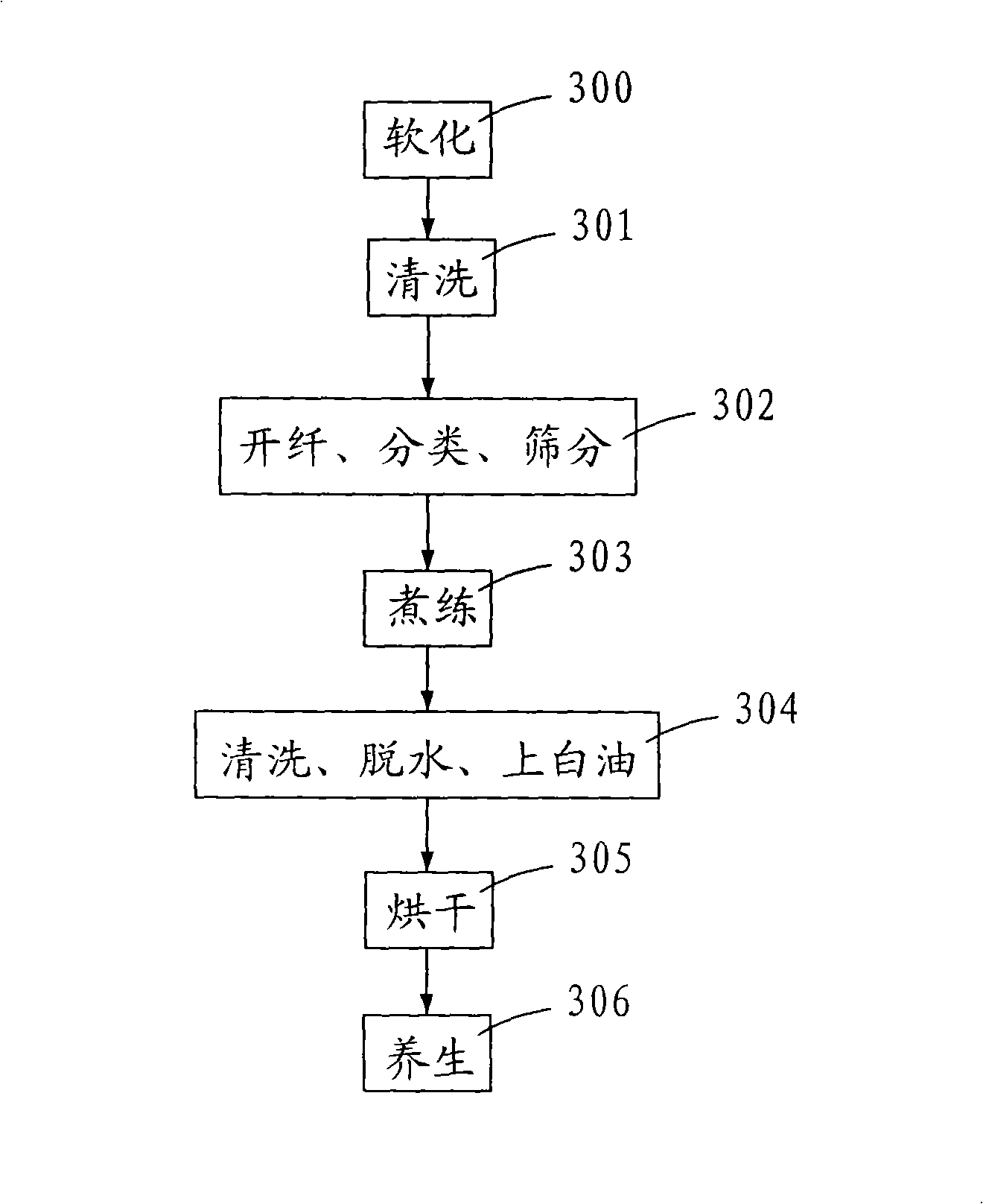

The invention provides a method for producing a bamboo fiber, comprising the following steps of sawing off, splitting and softening the bamboo, sending the bamboo material to a bamboo splitting separator to realize combing, splitting separation and airflow classification, thus obtaining the bamboo filament fiber; cooking and drying the bamboo filament fiber, cleaning, dehydrating, oiling and drying the bamboo filament fiber subsequently; and carrying out the enzyme treatment, thus obtaining the coarse bamboo fiber; subsequently carrying out fine treatment, cleaning and dehydrating, bleaching, cleaning, dehydrating, oiling, drying and curing by emulsion, thus obtaining the fine bamboo fiber. The method has high production efficiency, low processing cost and can prepare the bamboo fiber with the diameter within 0.03-0.15mm and the length within 30-300mm.

Owner:FUJIAN DANHAI MATTRESS

Method for preparing silver metallized organic fiber and textile

This is a argent metallization producing method of organic fibre and fabric, which belongs to vacuum membrane plating and electroplating technologic field and mainly solves the problems of quality and producing batches of silver-gilt organic and fabric. Through physical vapour phase deposition technology, it firstly arranges smoothly and rolls up tidily the organic fibre bundle and fabric; lay them in the vacuum room, plate silver by magnetic controlling and sputtering, and monolayer or multilayer continuously plate membrane; then plate mulriple argent membrane according to different using demands. The binding force of the metallic argentic ion and organ fibre of the present invention is strong, it has no pollution, low costs and can be continuously produced. The products are applied in such industry as electronics, war industry communication, medical treatment, special type of spinning and so on. For instance, electric shielded products, military used shielded tent, special type of spinning antibacterial materials and civil health care spinning products.

Owner:夏芝林

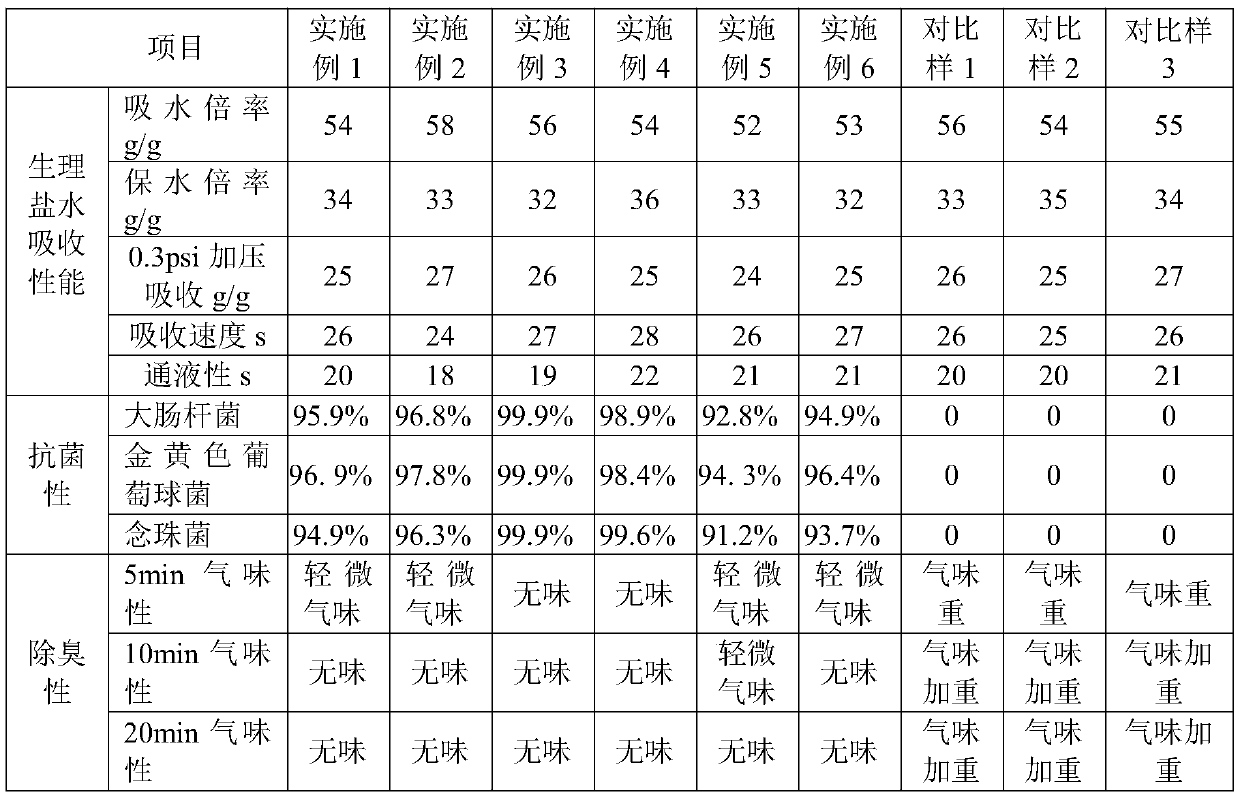

Preparation method and application of bacteriostatic and deodorant SAP (super absorbent polymer)

The invention provides a bacteriostatic and deodorant SAP (super absorbent polymer). The bacteriostatic and deodorant SAP is prepared through steps as follows: a primary crosslinking agent and a primary dispersing agent are added to an acrylic acid / acrylate mixed solution which is prepared from a basic compound by neutralizing an acrylic monomer solution, the mixed solution is uniformly stirred, an antibacterial agent is added, uniform stirring is continued, the temperature is increased to 35-70 DEG C, an initiating agent is added, polymerization is performed, and a colloidal SAP is obtained;the colloidal SAP is granulated and dried in sequence and is subjected to surface treatment with a composite antibacterial crosslinking agent at the temperature of 110-180 DEG C, and accordingly, theshell-core type SAP with a three-dimensional crosslinked network structure is obtained. The antibacterial agent is one or two of amino acid metal salt ion chelate and chitosan metal salt ion chelate.The bacteriostatic and deodorant SAP is applied to hygroscopic hygienic products, has remarkable bacteriostatic and deodorant properties, is low in cost and has great benefit, and the raw materials are available.

Owner:浙江卫星新材料科技有限公司

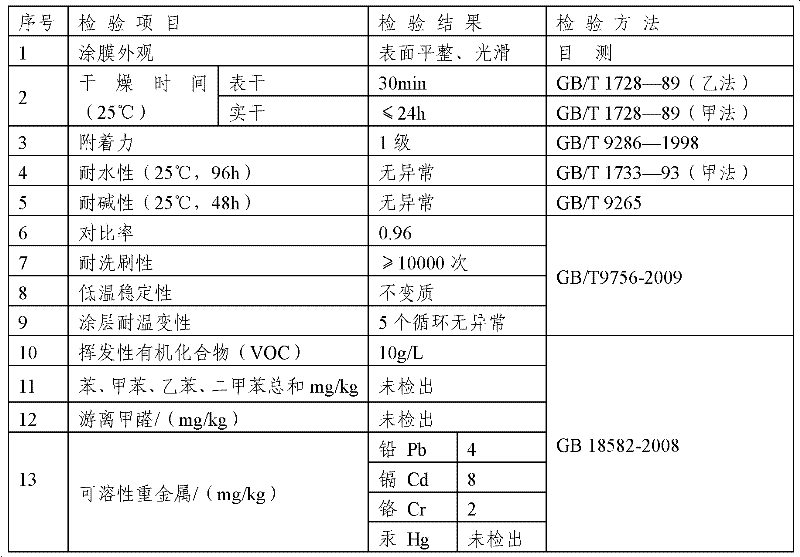

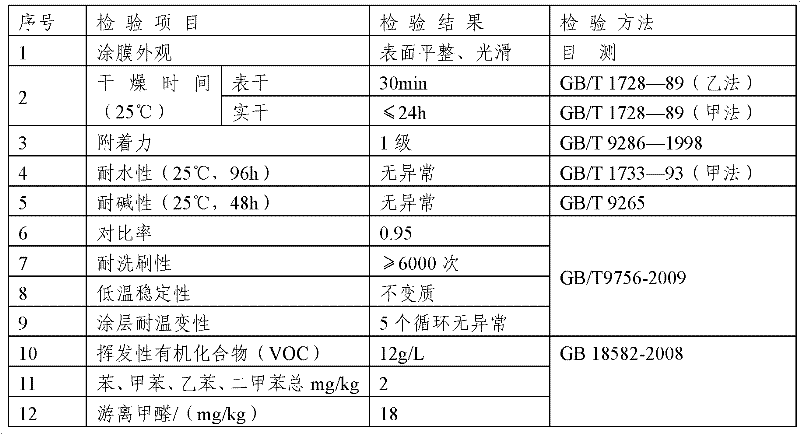

Antibacterial latex paint containing natural jade powder and preparation method for same

ActiveCN102643562AGood freeze-thaw resistanceLess free monomerAntifouling/underwater paintsPaints with biocidesVolatile organic compoundNanometre

The invention relates to an antibacterial latex paint containing natural jade powder and a preparation method for the same. The antibacterial latex paint contains the following ingredients in parts by weight: 50-150 parts of natural jade powder, and 5-15 parts of nanometre inorganic anionic auxiliary, wherein the grain diameter of the natural jade powder is 3000-6000 meshes. The latex paint provided by the invention can be coated on a wall surface or wood, and the paint film has the advantages of being weak in smell, low in VOC (volatile organic compound), good in covering power, good in adhesion power, resistant to scrub and the like, and can effectively kill the harmful bacteria contacted with the painted wall surface in a room simultaneously; and moreover, the latex paint is low in cost, good in construction performance and great in environmental protection performance, and is mainly applied to decoration and protection for the surfaces of wall body, wood, etc.

Owner:濮阳展辰新材料有限公司

Manufacturing method of antibacterial and deodorant duvet

ActiveCN103190789AGood antibacterial and deodorant effectLong-lasting antibacterial and deodorant functionBlanketFibre treatmentCompound aFiber

The invention aims to disclose a manufacturing method of an antibacterial and deodorant duvet. The manufacturing method comprises the following steps: (1) pretreating down; (2) manufacturing antibacterial and deodorant down fiber; (3) drying and sterilizing by ultraviolet; and (4) manufacturing the antibacterial and deodorant duvet. Compared with the prior art, by compounding a silver-based inorganic antibacterial agent RHA-T1 of NAFUR and a chitin antibacterial finishing agent SA-50DS of Japanese TK, the down fiber has a lasting antibacterial and deodorant function under the condition that a bonding agent is not added; and by a method of filling antibacterial fiber and the antibacterial and deodorant down fiber in a mixed way, the duvet has a more lasting antibacterial and deodorant effect, therefore, the aim of the invention is achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Production of modified chitin and viscose fiber dope mixture and its product

InactiveCN1424441AImprove dyeing effectGood biocompatibilityArtificial filaments from viscoseBiocompatibility TestingViscose fiber

A mixture used for preparing fibres, film, or foam material is prepared through controlling the deacetylated level of chitin-chitosan to 10-85% of -20-40 deg.c in alkalizing procedure, baretting reacting to prepare chitin-chitosan xanthogenate, and mixing it with the dope of viscose fibre. Its advantages are low cost, high colourability, biocompatibility and degradability and good antibacterial deodouring action.

Owner:上海士林纤维材料有限公司

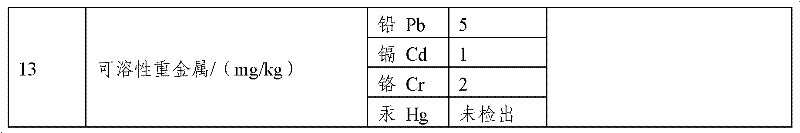

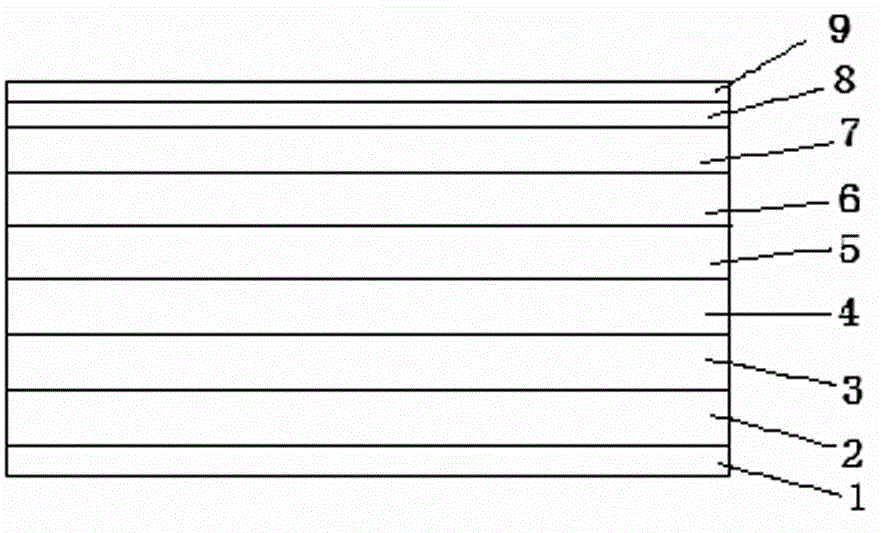

Environment-friendly antibacterial moistureproof wallpaper

ActiveCN104060500AAntifungal agent hasWith antifungal agentCovering/liningsSpecial paperMoisture resistanceMoisture barrier

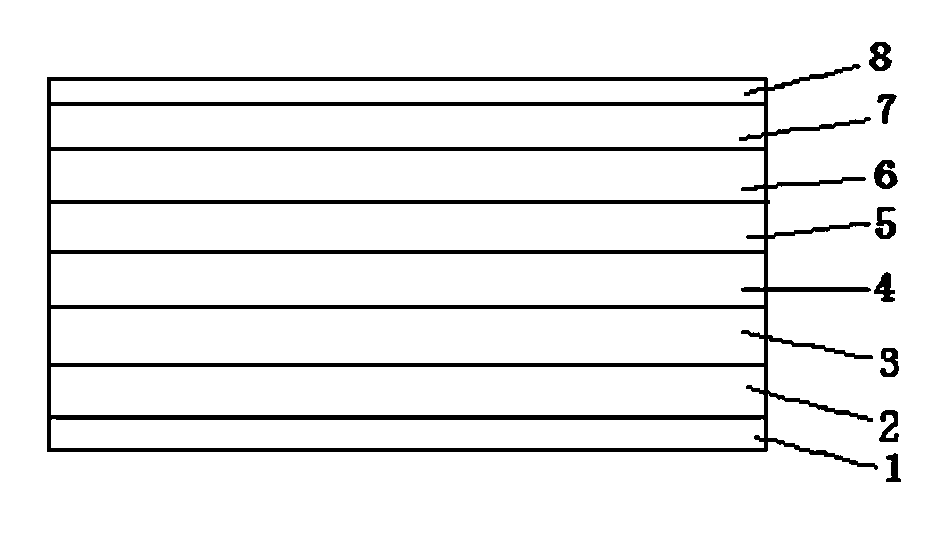

The invention provides an environment-friendly antibacterial moistureproof wallpaper, comprising a base layer, wherein a waterproof coating is arranged on the back side of the base layer; a coating layer is arranged on the base layer; a bamboo charcoal fiber layer is arranged on the coating layer; a bamboo charcoal fiber reinforcing layer is arranged on the bamboo charcoal fiber; an antibacterial layer is arranged on the bamboo charcoal fiber reinforcing layer; a printing embossing layer is arranged on the antibacterial layer; a moistureproof layer is coated on the printing embossing layer; a polytetrafluoroethylene layer is arranged on the moistureproof layer; a laminating layer is arranged on the polytetrafluoroethylene layer. The four layers, namely the bamboo charcoal fiber layer, the polytetrafluoroethylene layer, the moistureproof layer and the laminating layer, have certain moisture resistance, and have quadruple protection roles, so that the wallpaper disclosed by the invention has excellent moisture resistance. The antibacterial layer, the bamboo charcoal fiber layer and the coating layer have antibacterial properties and triple protection roles, so that the wallpaper disclosed by the invention has excellent antibacterial property.

Owner:苏州圣典企业管理咨询有限公司

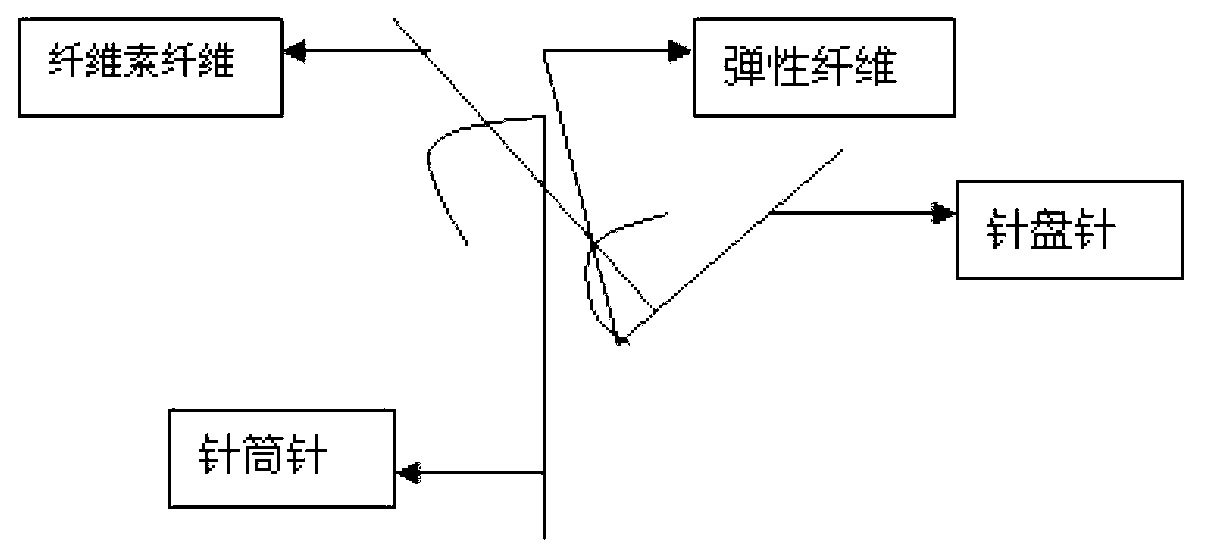

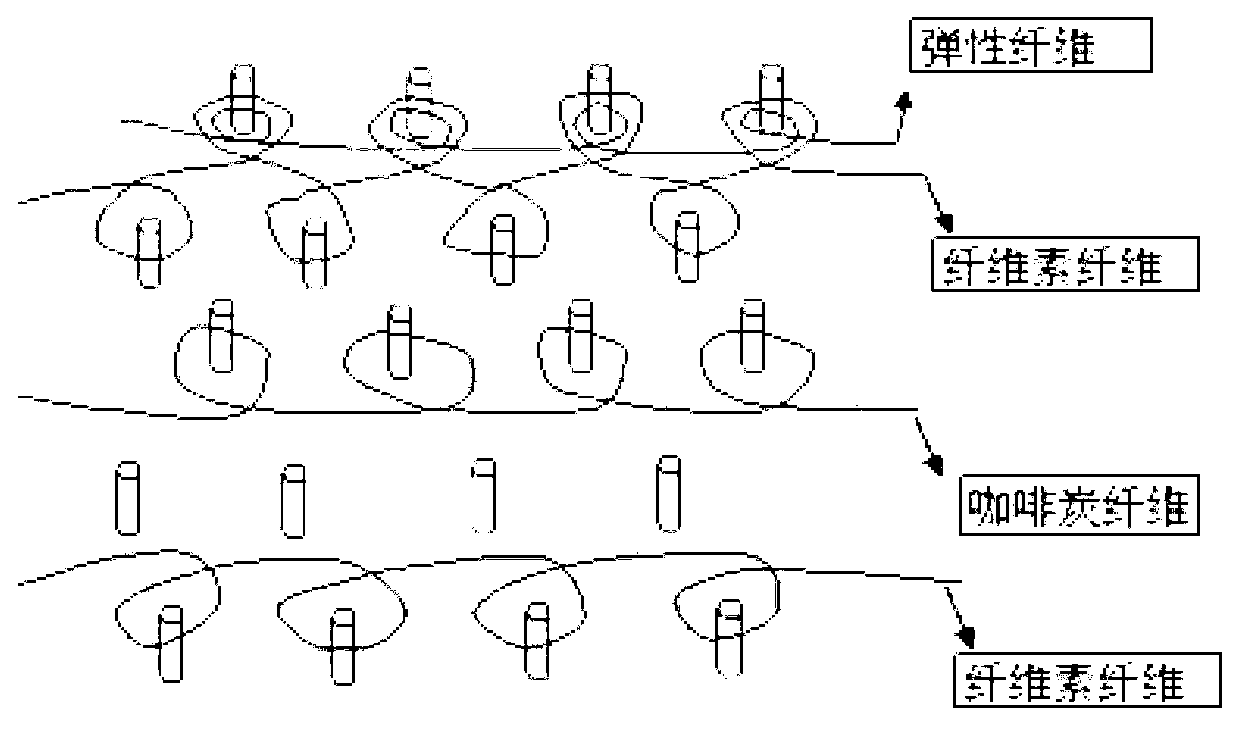

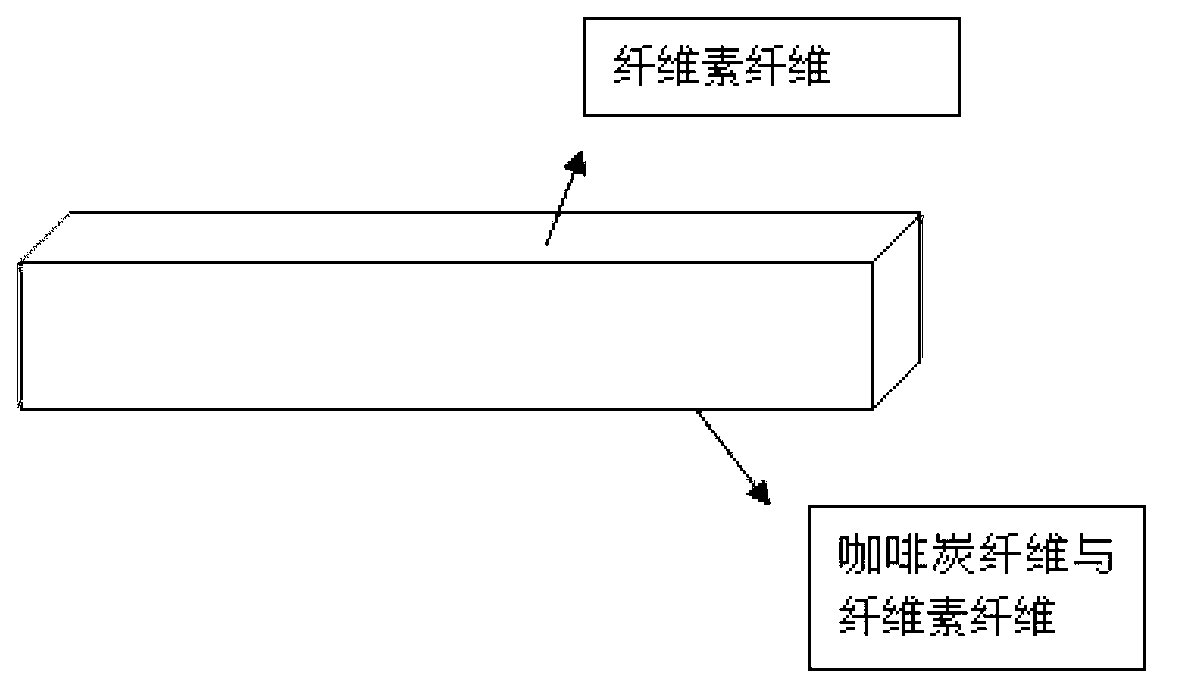

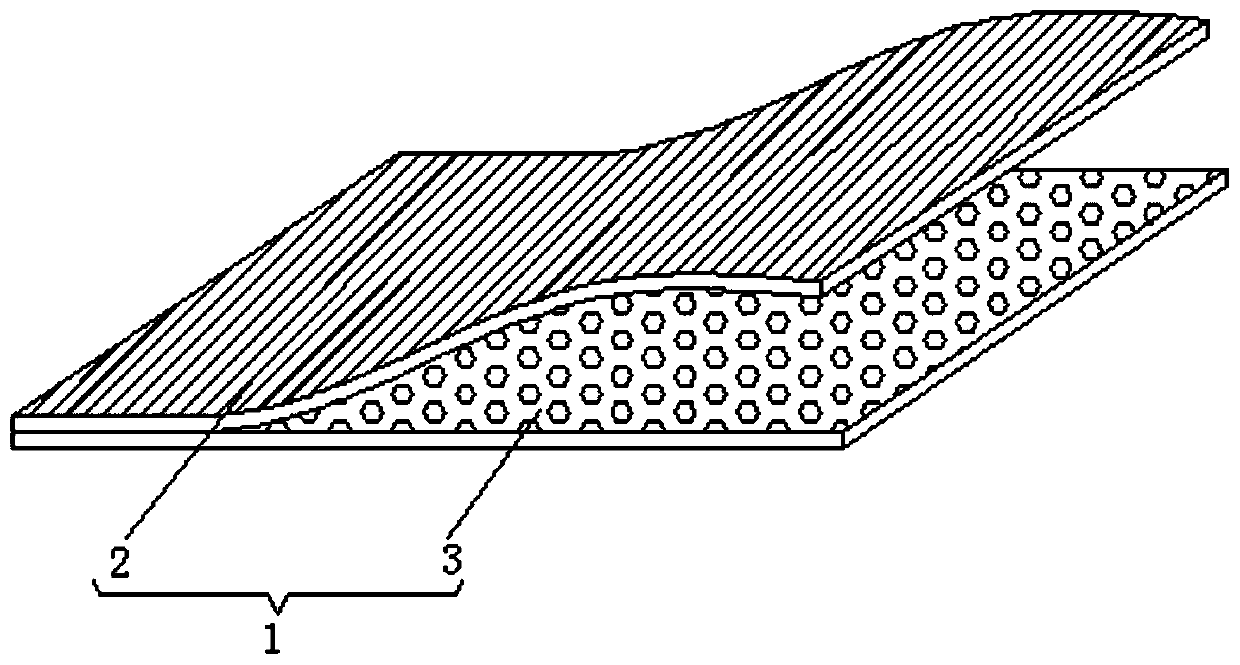

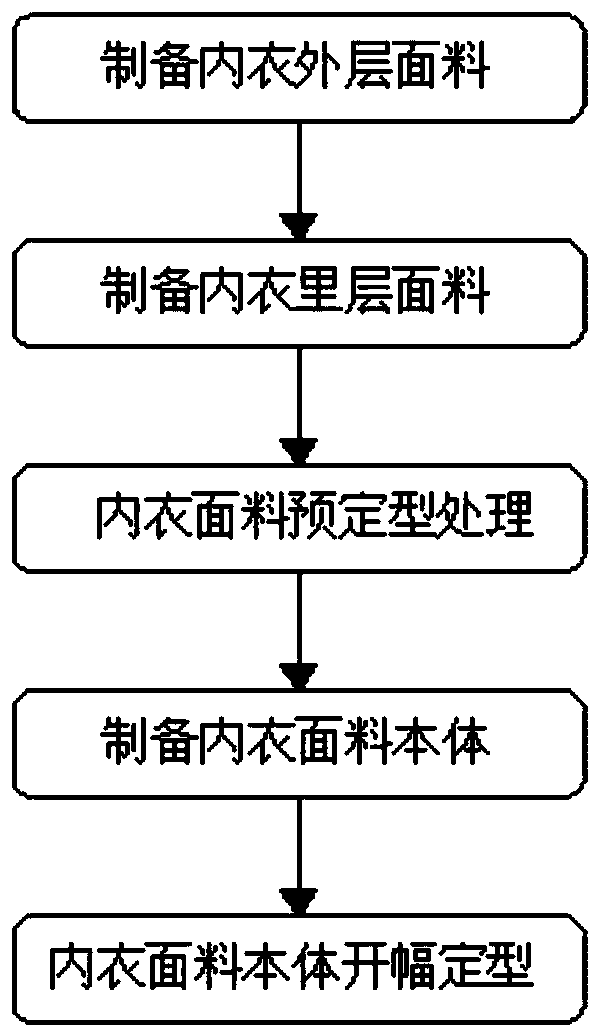

Multifunctional knitted underwear shell fabric and preparation method thereof

ActiveCN103251138AFunction increaseThe preparation process is scientific and environmentally friendlyWeft knittingBiochemical fibre treatmentCarbon fibersCellulose fiber

The invention relates to multifunctional knitted underwear shell fabric and a preparation method thereof. The shell fabric comprises an inner layer structure and an outer layer structure. An outer layer comprises cellulosic fibers and elastic fibers, an inner layer comprises coffee carbon fibers and cellulosic fiber blended yarns, and the weight ratio of the coffee carbon fibers to the cellulosic fiber blended yarns is 35-40: 60-65. The preparation method comprises the following steps of structure designing, weaving by adopting a weft knitting double-face multi-needle channel rib needle machine, fabric presetting, pre-processing, dyeing, post-processing, fixation, washing and drying. The multifunctional knitted underwear shell fabric is obtained through the method. The multifunctional knitted underwear shell fabric has the advantages that preparing processes are scientific and environment-friendly, cost is saved and effects are durable. The multifunctional knitted underwear shell fabric has good water sucking performance and a function of infrared, is anti-bacteria, deodorizing, environment-friendly, moisture-absorbing, anti-pilling and good in elastic recovering property, and can be dried fast and can heat. In addition, the multifunctional knitted underwear shell fabric solves the technical problem that the color systems of coffee carbon fiber products are few, the coffee carbon fiber products are made to be colorful, and the multifunctional knitted underwear shell fabric has good application prospect.

Owner:NINGBO DAQIAN TEXTILE

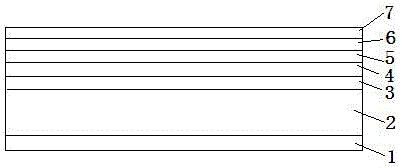

Environment-friendly antibacterial and deodorization wallpaper

ActiveCN104074101AAntibacterial and deodorantGood antibacterial and deodorant effectCovering/liningsSpecial paperAnti bacteriaAntibacterial agent

The invention provides environment-friendly antibacterial and deodorization wallpaper. The environment-friendly antibacterial and deodorization wallpaper comprises a base layer, wherein the back face of the base layer is provided with a waterproof coating; a coating layer is arranged on the base layer; an antibacterial layer is arranged on the coating layer; an adsorption deodorization layer is arranged on the antibacterial layer; a printing embossing layer is arranged on the adsorption deodorization layer and is coated with an antibacterial and deodorization compound layer; the antibacterial and deodorization compound layer is provided with a film coating layer. According to the wallpaper, the coating layer is provided with an antibacterial agent and a deodorization agent so that the wallpaper has antibacterial and deodorization properties; meanwhile, the adsorption deodorization layer, the antibacterial layer and the antibacterial and deodorization compound layer are further arranged so as to realize multiple protection, the antibacterial and deodorization properties of the wallpaper can be greatly improved and the performance of the wallpaper is excellent; overall, the wallpaper is environmental-friendly and multifunctional wallpaper.

Owner:TAICANG SANYI HEATING & CHILLING PROJECT CO LTD

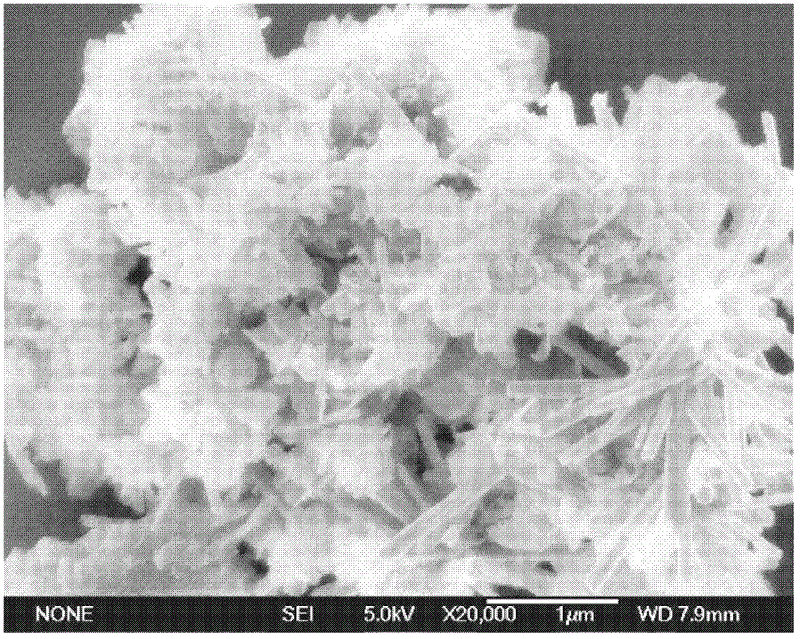

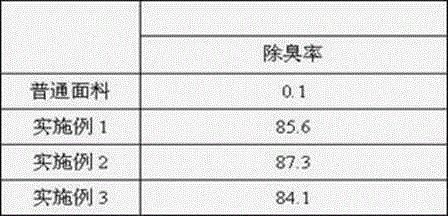

Antibacterial, deodorant and efficient deodorizing cellulose fibers and preparation method thereof

InactiveCN106637456AIncrease contentLong-lasting and stable antibacterial and deodorizing functionsArtificial filaments from viscoseWet spinning methodsAlpha-CelluloseChemistry

The present invention provides antibacterial, deodorant and efficient deodorizing cellulose fibers and a preparation method thereof, wherein the cellulose fibers have good antibacterial and deodorizing effects through high adsorption opal powder and a pteris multifida poir extract contained in the cellulose fibers, and the finished product fibers can be widely used in the fields of bedding, clothing, and medical supplies. The preparation method comprises: 1) preparing high adsorption opal powder having a particle size of less than 3 [mu]m and meeting viscose fiber production by using a wet grinding method, and mixing with a microcapsule slurry using a pteris multifida poir extract as a core material and using a melamine formaldehyde resin as a wall material to prepare a composite antibacterial and deodorizing agent; 2) preparing a viscose raw liquid by adopting a cellulose slurry meal as a raw material, and adding the composite antibacterial and deodorizing agent accounting for 4-20 wt% of the alpha-cellulose in the viscose to prepare a blended spinning liquid; and 3) spinning the blended spinning liquid, and carrying out subsequent treatment to obtain the antibacterial, deodorant and efficient deodorizing cellulose fibers. The method of the present invention has the simple process, and is suitable for industrial production.

Owner:ZHONGDI HOME TEXTILES

Nano silver antibacterial deodorant socks

The invention relates to nano-silver antibacterial deodorant socks and a process thereof. In the invention, a nano silver composite antibacterial material is added in socks for daily life for treatment, the preparation method thereof is as follows: utilizing a liquid-phase chemical reduction method to prepare nano silver to obtain spherical particles the particle size of which is 10-80nm, dispersing the particles to obtain nano silver solution with efficient antibiosis and deodorization activity, utilizing nano silver, 0.1-1% of adhesive PDA, 0.02-0.1% of softening agent amino-silicone and the like to form modified nano silver composite dispersion liquid, and utilizing the processes of impregnating, drying and finishing to adhere nana silver on the surface of socks, thus obtaining antibacterial deodorant socks meeting requirements.

Owner:WUYI UNIV +1

Environment-friendly wallpaper capable of adjusting humidity

ActiveCN104060501AExcellent overall performanceExtended service lifeCovering/liningsSpecial paperPolymer chemistryPolytetrafluoroethylene

The invention provides environment-friendly wallpaper capable of adjusting humidity. The environment-friendly wallpaper comprises a base layer, wherein a waterproof coating is arranged on the back side of the base layer; a coating layer is arranged on the base layer; a bamboo charcoal fiber layer is arranged on the coating layer; a bamboo charcoal fiber reinforcing layer is arranged on the bamboo charcoal fiber layer; a printing embossing layer is arranged on the bamboo charcoal fiber reinforcing layer; a humidity adjusting layer is coated on the printing embossing layer; a polytetrafluoroethylene layer is arranged on the humidity adjusting layer; a laminating layer is arranged on the polytetrafluoroethylene layer. The bamboo charcoal fiber layer and the humidity adjusting layer are arranged on the wallpaper disclosed by the invention. The wallpaper disclosed by the invention also has good humidity adjustability while having good antibacterial deodorizing properties, and thus being green environment-friendly multifunctional wallpaper as a whole.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Method for preparing health care fibre and health care fibre produced by the same method

InactiveCN101210354AAntimicrobial durabilityImprove dyeing effectConjugated cellulose/protein artificial filamentsCelluloseAdhesive

The invention discloses a production method of health fiber and a health fiber produced by the method. The method comprises the following steps of preparing a chitin adhesive and a cellulose adhesive respectively from chitin and cellulose, mixing to obtain a spinning solution, and producing the health fiber by the mixed spinning solution. The health fiber production method of the invention has low requirement for temperature and vacuum degree for alkalization, sulfonation, etc., and is convenient and suitable for industrial production. The health viscose fiber containing chitin as a portion thereof has a plurality of characteristics such as long bacterial resistance, good chromaticity, biocompatibility, bacterial resistance as well as deodorization, and easy degradation.

Owner:CHTC HELON

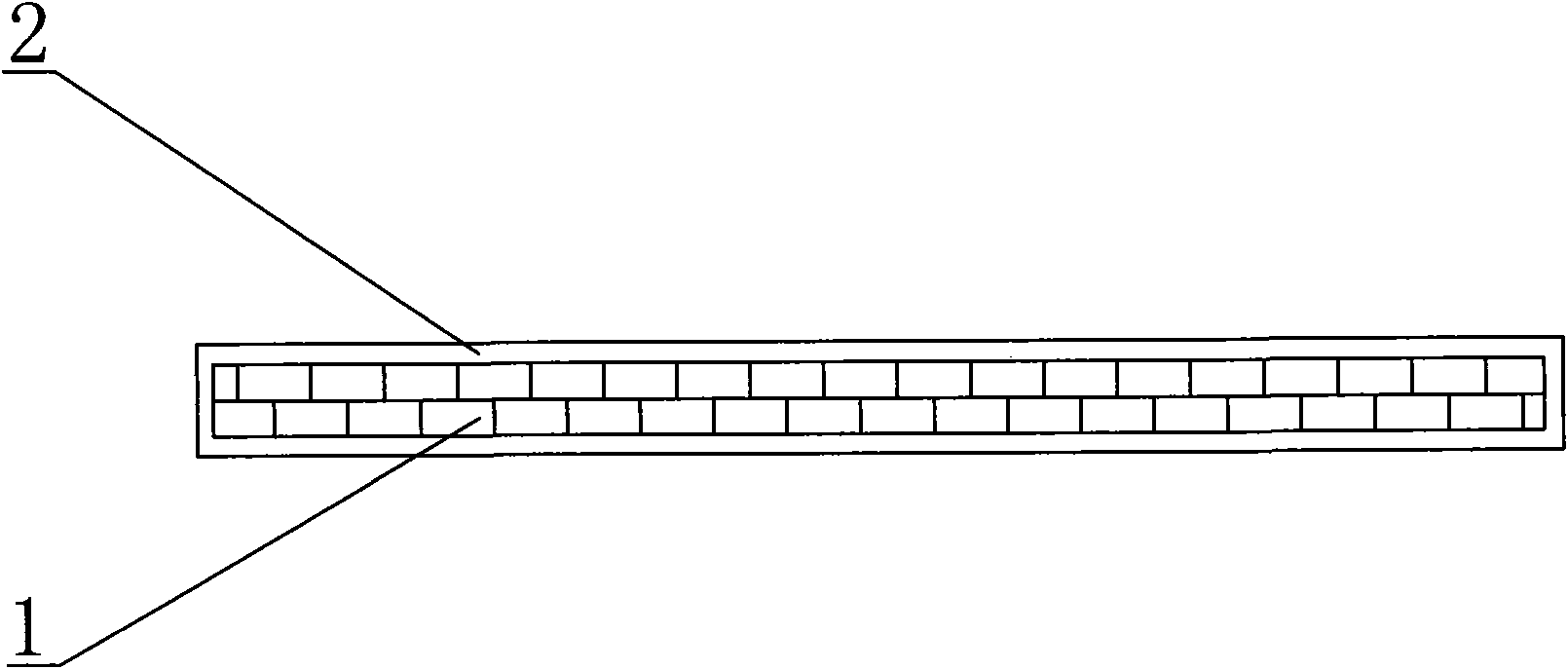

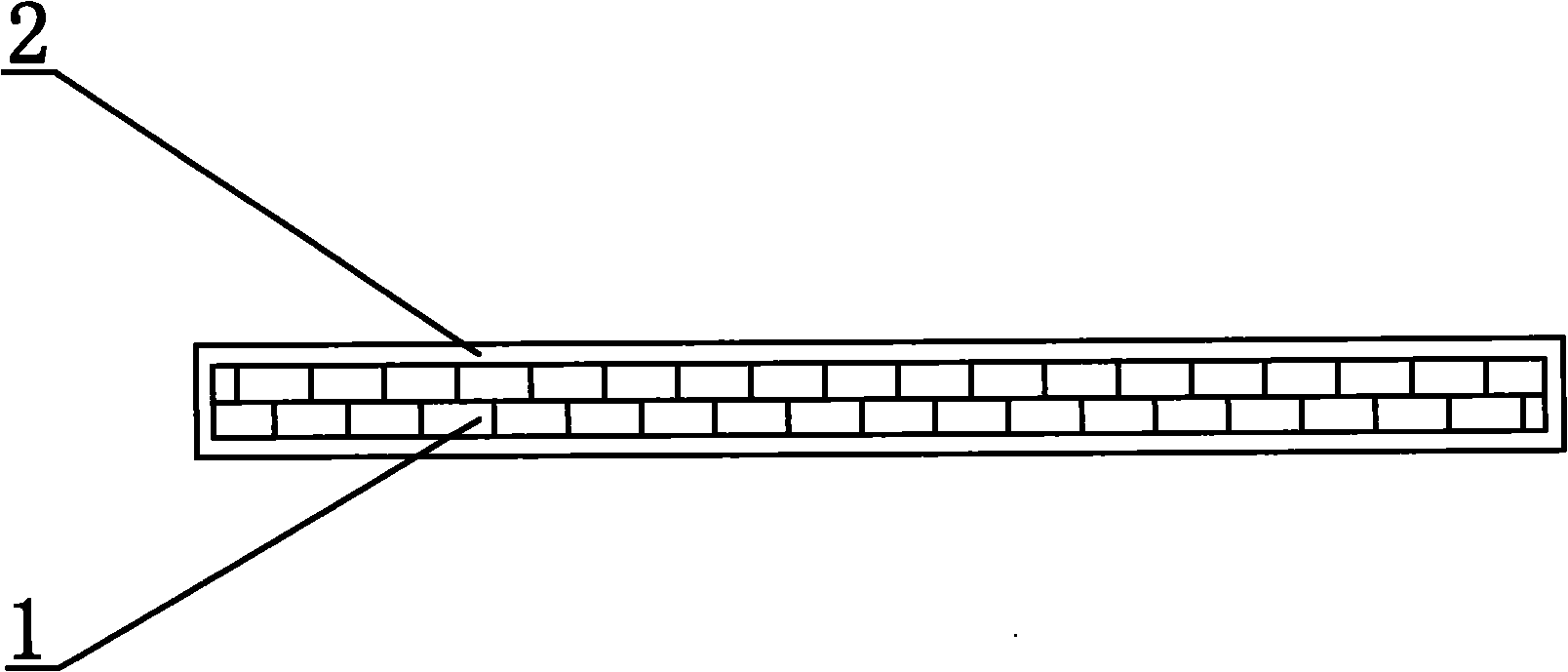

Molecular resonance plate

ActiveCN101898904AIncrease metabolic energyReduce the burden onWater/sewage treatmentResonanceHuman health

The invention discloses a molecular resonance plate which can achieve resonance with the surrounding environment. The molecular resonance plate comprises tile type ceramic materials at a middle layer and negative charged ion generating materials coated around the tile type ceramic materials. The molecular resonance plate provided by the invention can activate the purified water, can release a large amount of negative ions, has the advantages of high temperature resistance, no toxicity, no harm and no radioactivity, and is beneficial to the human health.

Owner:NEW SUN BIO SCI

Method for preparing bamboo charcoal and polyamide composite fibers by in situ polymerization

InactiveCN102409424AImprove continuous stabilityGood antibacterial and deodorant effectArtifical filament manufactureMonocomponent polyamides artificial filamentSolventChemistry

The invention relates to a method for preparing bamboo charcoal and polyamide composite fibers by in situ polymerization. The method comprises the following steps of: adding two polymerization monomers, a solvent, and bamboo charcoal modified nano micropowder to a stainless steel polymerization reaction kettle, carrying out an intermediate reaction, after the reaction is finished, cooling, crystallizing, centrifugally separating, washing and filtering to obtain a composite 66 salt for preparing a bamboo charcoal and polyamide composite melt; preparing the composite 66 salt into an aqueous solution, then adding to an autoclave, carrying out an intermittent or continuous melt polycondensation reaction to obtain the bamboo charcoal and polyamide composite melt, and carrying out melt spinningwith a melt spinning machine to obtain nascent filament fibers; and drying the nascent filament fibers, oiling, stretching, shaping, and winding to obtain bamboo charcoal and polyamide composite fiber filaments or cutting the fibers to obtain chopped fibers. By in situ polymerization, the bamboo charcoal nano modified micropowder is highly dispersed in a polymer matrix, thus the continuous stability of fiber preparation is improved, the fiber processing performance is excellent, and the physical and mechanical properties of the bamboo charcoal fibers are improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

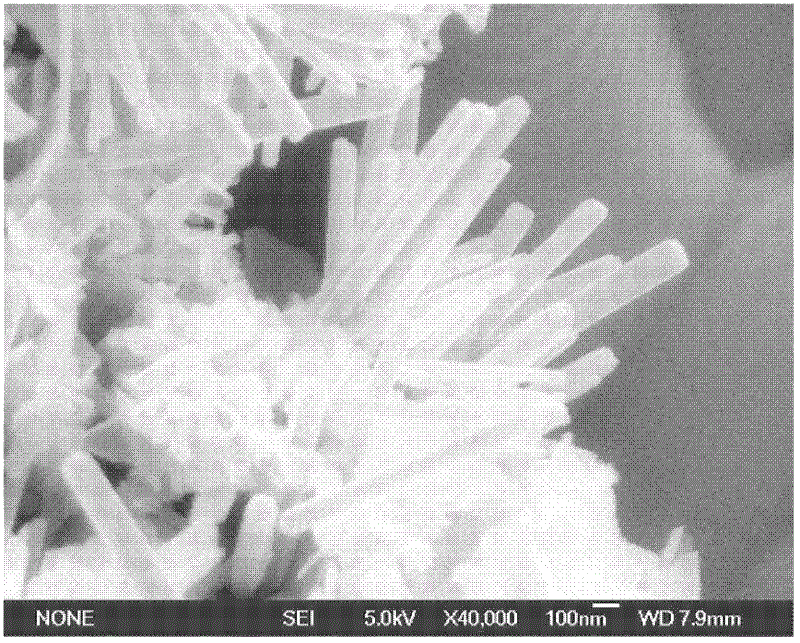

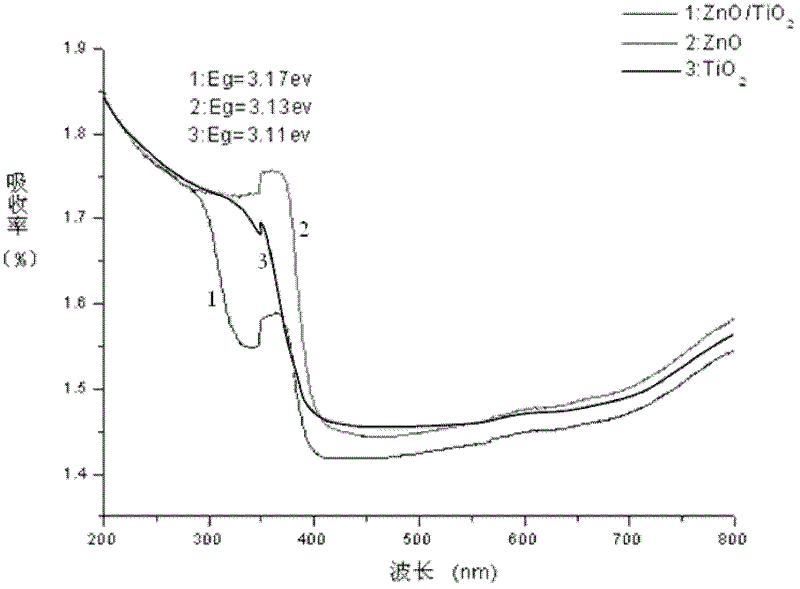

Preparation method and application of ZnO/TiO2 composite powder

ActiveCN102618109ALower temperature conditionsGood controllabilityAntifouling/underwater paintsPaints with biocidesChemistryLacquer

The invention discloses a preparation method and application of ZnO / TiO2 composite powder. The preparation method comprises the following steps: dissolving soluble a zinc salt, a surfactant and butyl titanate in alcohol, and mixing to obtain a raw material liquid; adding a strong base aqueous solution to the raw material liquid under the stirring condition to obtain a mixed liquid; and reacting the mixed liquid at 120-180 DEG C for 8-16h, washing and drying to obtain the ZnO / TiO2 composite powder. The preparation method is relatively low in temperature conditions, good in controllability, simple in preparation and strong in operability, is favorable to industrialized popularization and production, and has wide application prospects. The obtained ZnO / TiO2 composite powder is complete in crystallization, small in original granularity, uniform in distribution and low in agglomeration, and is particularly suitable to be used as an additive for an automobile paint to be applied to the automobile paint, so that the automobile finish coat has the advantages of being plump in lacquer film, level and bright, strong in adhesion force, high in hardness, good in light retention rate, excellent in natural solarization performance and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

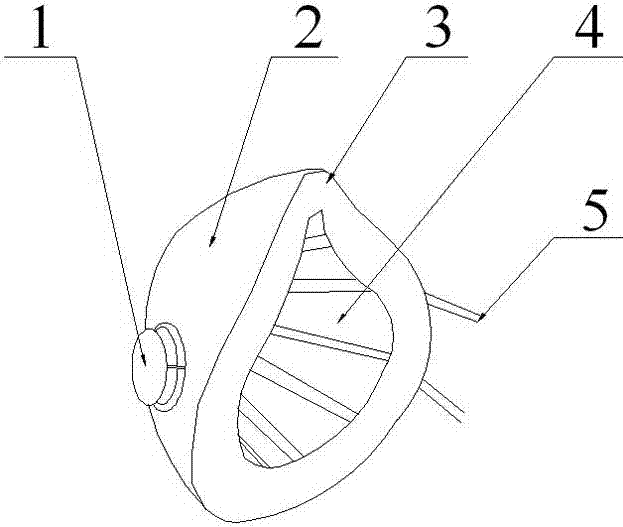

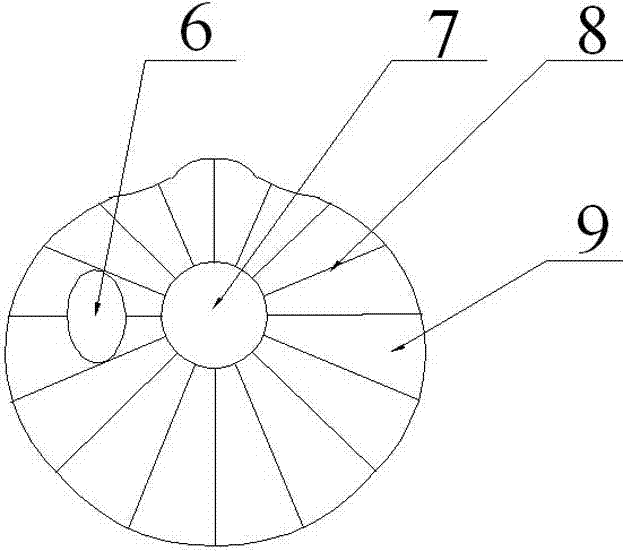

Gauze mask

PendingCN107343677AComfort functionRelieve nervous fatigueProtective garmentSpecial outerwear garmentsPolyesterEngineering

The invention discloses a gauze mask applied to the field of daily life. The gauze mask comprises a gauze mask body, an annular face connecting part and ear hangers, wherein the annular face connecting part is combined with the periphery of the gauze mask body, and the ear hangers are connected to two sides of the gauze mask body; a mask body bracket is further arranged on the inner surface of the gauze mask body and is of an annular structure; the face connecting part is synthesized from nylon fibers or polyester fibers; a radial protruded flow guide component is arranged on the mask body bracket and forms a channel between the gauze mask body on the outer side and the mask body bracket on the inner side; and an air suction hole and an air exhaust hole are further formed in the mask body bracket, and the channel is connected with the air suction hole. The gauze mask is simple in structure, novel in design and high in practical value, simultaneously has the effects of oxygen supplementation, antibiosis and deodorization as well as dust removal, purification and haze prevention and is convenient to mount, dismount and clean, and harmful substances of bacteria are unlikely to propagate.

Owner:张争

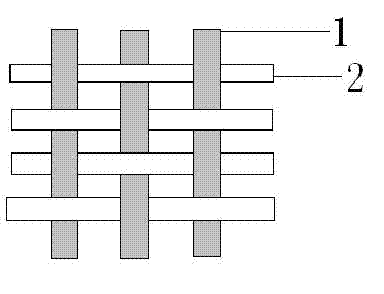

Blended fibriia composite fabric

The invention discloses a blended fibriia composite fabric. The blended fibriia composite fabric comprises a hygroscopic and breathable layer which is a surface layer and an antibiotic and radiation-proof layer which is an internal layer, the hygroscopic and breathable layer is obtained through blending braiding of 15-22wt% of sisal fibers and 78-85wt% of pina fibers, and the antibiotic and radiation-proof layer is obtained through blending braiding of 45-51wt% of hemp fibers and 49-55wt% of kendir fibers. The blended fibriia composite fabric has a double-layer structure design, the hygroscopic and breathable layer which is the surface layer has the characteristics of tough texture, wear resistance, acid and alkali resistance, and good hygroscopic and breathable properties, and the hygroscopic and breathable layer which is the internal layer has the characteristics of antibiosis, deodorization, ultraviolet resistance and healthcare, so the fabric has the characteristics of cooling, comfortableness, unlikely damage, and maintenance of the cleanness and health of human bodies.

Owner:SUZHOU TANXI TEXTILE TECH CO LTD

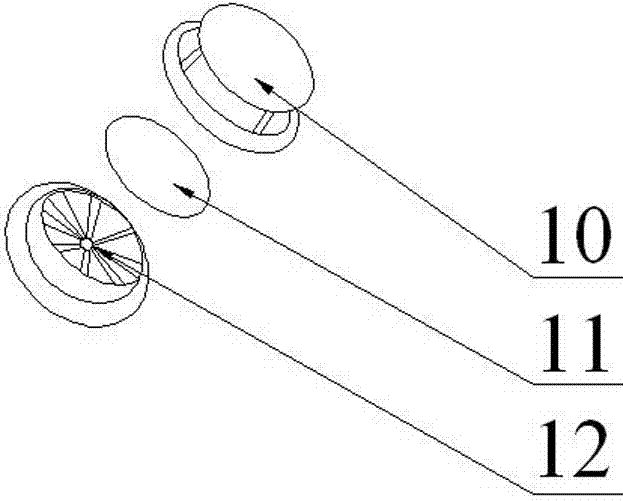

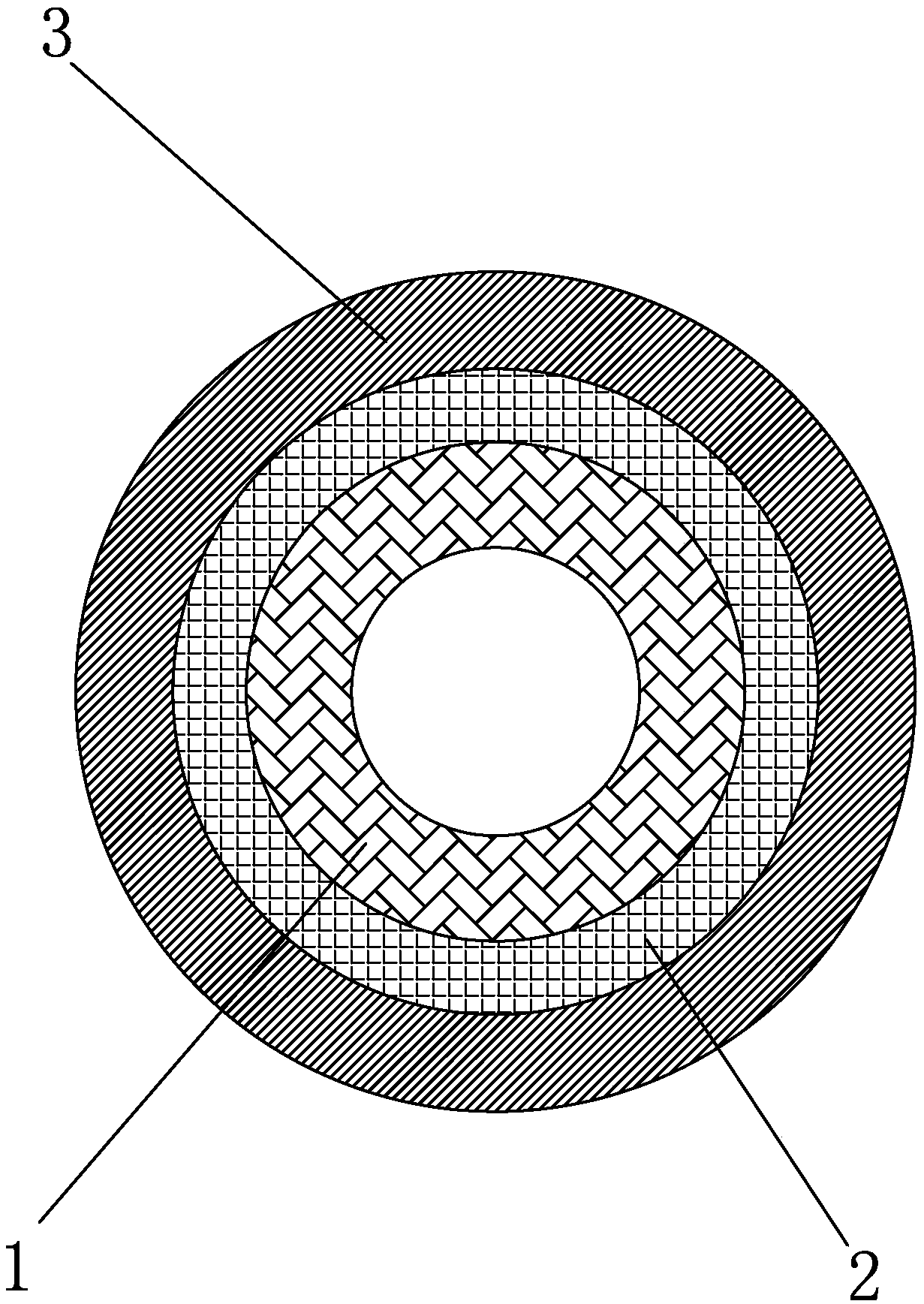

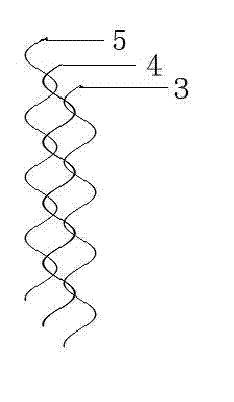

Hollow soft antibacterial yarn

PendingCN109183225AImprove breathabilityGood air permeability, good antibacterial and deodorizing propertiesYarnYarnCarbon fibers

The invention discloses a hollow soft antibacterial yarn. The yarn includes a yarn body, wherein the yarn body is of a sheath core structure, the yarn body is a hollow yarn, an inner portion is a hollow core, the yarn body sequentially includes a bamboo charcoal fiber layer, a coffee carbon fiber layer and a colored cotton fiber layer from the inside to the outside in the radial direction of the yarn body, the hollow core of the yarn body is formed through hydrolysis of a core yarn made of the water-soluble vinylon fiber, the bamboo charcoal fiber layer is formed by spirally winding raw bamboofibers, the bamboo charcoal fiber layer is internally filled with silver nano particles, the coffee carbon fiber layer is formed through spirally covering the coffee carbon fiber outside the bamboo charcoal fiber layer, and the colored cotton fiber layer is formed by spirally covering the colored cotton fiber outside the coffee carbon fiber layer. The yarn is advantaged in that the hollow yarn structure is utilized, the bamboo charcoal fiber layer and the coffee carbon fiber layer are arranged internally, and the yarn is super soft and super fluffy, has good warmth keeping effect, breathability, good antibacterial and deodorizing performance, the bright color and no dye need and can realize environmental protection and energy saving.

Owner:苏州璟珮新材料科技有限公司

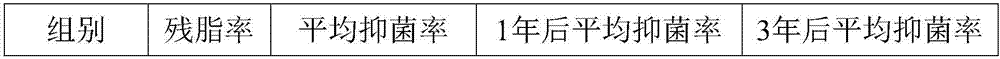

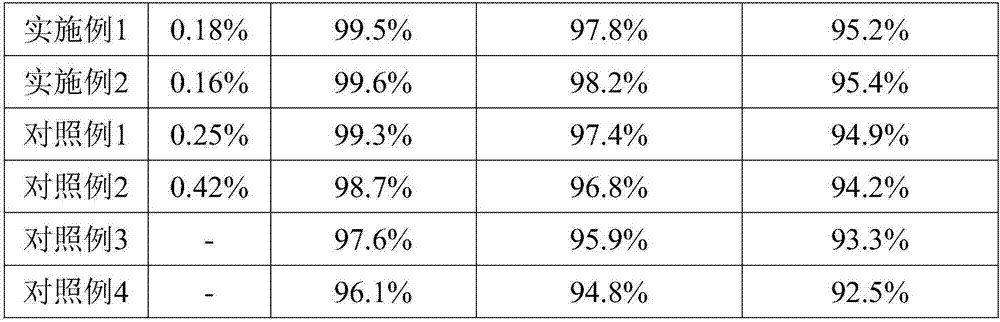

Preparation method of down fiber for processing antibacterial and deodorant duvet

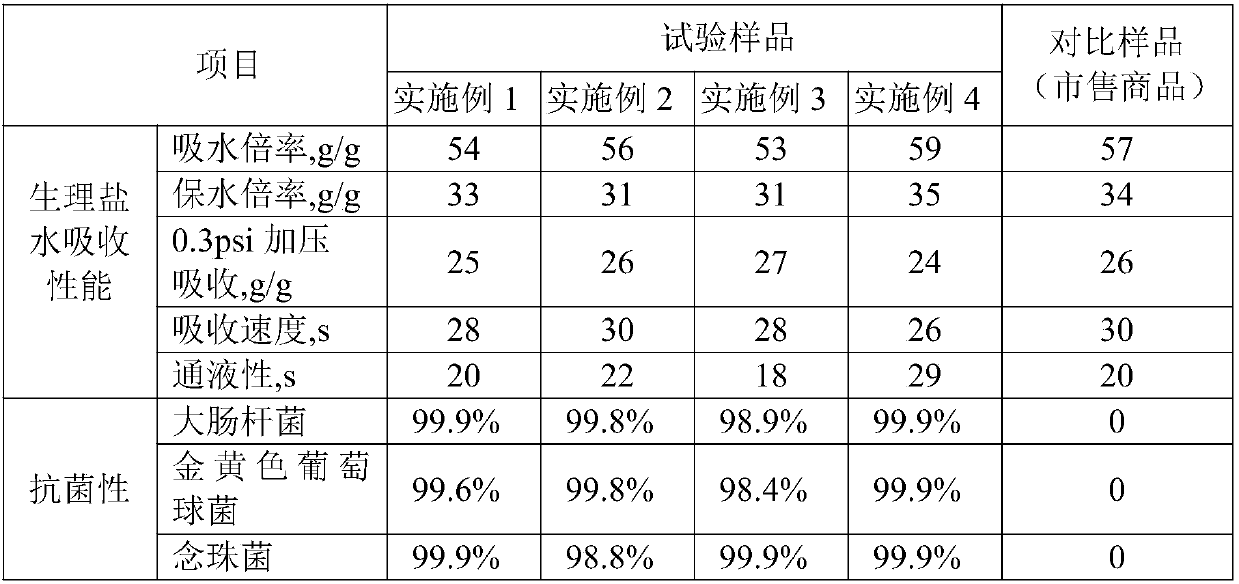

InactiveCN107164967AGood antibacterial and deodorant effectResidual fat rate reducedBiochemical fibre treatmentAnimal fibresFiberEscherichia coli

The invention discloses a preparation method of down fiber for processing an antibacterial and deodorant duvet, and relates to the technical field of duvet processing. The preparation method comprises: (1) down degreasing treatment; (2) antibacterial and deodorant treatment solution preparation; (3) antibacterial and deodorant treatment of down; and (4) antibacterial and deodorant down fiber molding. According to the present invention, the prepared antibacterial and deodorant down fiber has excellent antibacterial and deodorant effects, the average antibacterial rate of the antibacterial and deodorant down fiber on Staphylococcus aureus, Candida albicans and Escherichia coli can achieve more than 99%, the average antibacterial rate of the duvet prepared from the prepared antibacterial and deodorant down fiber on Staphylococcus aureus, Candida albicans and Escherichia coli can achieve more than 97% after the duvet is normally used for 1 year, and the average antibacterial rate of the duvet prepared from the prepared antibacterial and deodorant down fiber on Staphylococcus aureus, Candida albicans and Escherichia coli can achieve more than 95% after the duvet is normally used for 3 year.

Owner:ANHUI SANXIANG DOWN

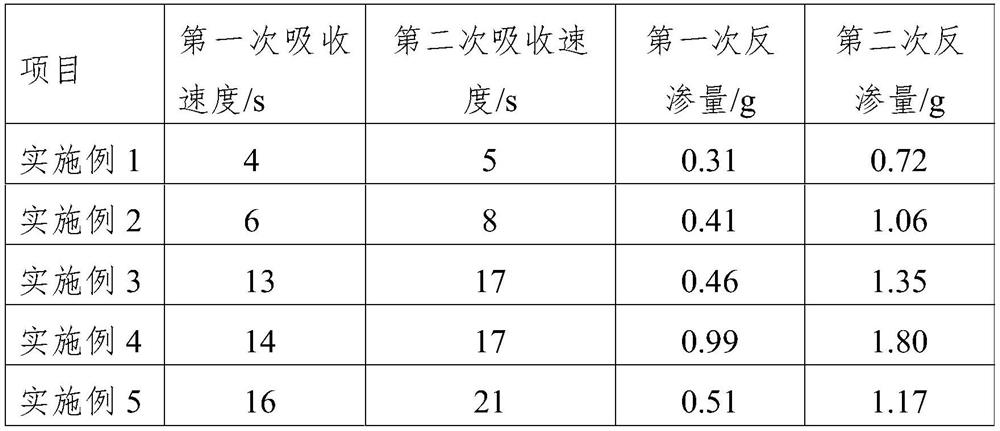

Quick-absorption dry and comfortable type absorption article and manufacturing method thereof

InactiveCN113693831AImprove drynessHelp infiltrationAbsorbent padsBandagesEngineeringNonwoven fabric

The invention provides a quick-absorption dry and comfortable type absorption article and a manufacturing method thereof and belongs to the technical field of hygienic products. The quick-absorption dry and comfortable type absorption article comprises an absorption main body, wherein the absorption main body sequentially comprises a liquid-permeable surface layer, a flow guide layer, a covering layer, an absorption layer, a breathable bottom layer and a bottom film non-woven fabric from top to bottom, wherein the flow guide layer is made of a China-hemp antibacterial material; the covering layer is made of at least one of non-woven fabric or super-absorbent resin absorbent paper; and the absorption layer comprises a first absorption layer and a second absorption layer, the first absorption layer is a convex absorption small core body, and the size of the convex absorption small core body is smaller than that of the second absorption layer. The absorption article provided by the invention has the properties of bacteriostasis, odor removal, high liquid infiltration speed, high absorptivity, good dryness and the like.

Owner:诺宸股份有限公司

Anti-microbial deodorizing super absorbent resin compound

InactiveCN110075342AImprove washdown resistanceStrong antibacterial and deodorizing effectAbsorbent padsBandagesCross-linkPolymer science

The invention provides an anti-microbial deodorizing super absorbent resin compound which comprises a pre-crosslinked acrylic polymer. In parts by weight, 0.5-20 parts of plant antibacterial agent isjointed in 100 parts of pre-crosslinked acrylic polymer; a cross-linking agent is used for treating the surface of the pre-crosslinked acrylic polymer; the plant antibacterial agent is prepared from the following materials by weight percent: 20%-35% of tea leaves, 30%-45% of folium artemisiae argyi and 25%-45% of leonurus. A method of combining the pre-crosslinked acrylic polymer with the plant antibacterial agent includes the following steps: jointing the plant antibacterial agent in the pre-crosslinked acrylic polymer; or bonding the plant antibacterial agent on the surface of the pre-crosslinked acrylic polymer by adopting a cross-linking solution for performing surface thermo-crosslinking treatment; adopting the cross-linking solution for performing surface thermo-crosslinking treatment on the pre-crosslinked acrylic polymer at 70-180 DEG C, thereby acquiring the super absorbent resin compound.

Owner:邦丽达(福建)新材料股份有限公司

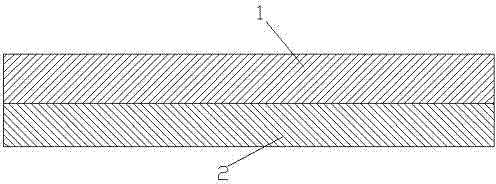

Anti-bacterium deodorization fabric and preparation method thereof

ActiveCN104824892ASimple structureLow costSynthetic resin layered productsWoven fabricsBiotechnologyFiber

The invention provides anti-bacterium deodorization fabric which comprises a basic cloth layer, a fabric layer and an anti-bacterium deodorization layer arranged between the basic cloth layer and the fabric layer. The anti-bacterium deodorization layer is woven from warp and weft. The warp is antibacterial fibers containing nano-silver particles. The mass of the nano-silver particles accounts for 0.0015% to 0.0020% of the total mass of the antibacterial fibers. The weft is antibacterial fibers treated through a deodorization finishing liquid. The anti-bacterium deodorization fabric has the advantages that the structure is simple, cost is low, raw materials are acquired conveniently, the antibacterial effect is quite excellent, anti-bacterial time is long, and the broad-spectrum antibacterial effect is achieved.

Owner:天派针织股份有限公司

Mould-proof antibacterial composite wallpaper

InactiveCN106088495AImprove antibacterial propertiesReduce manufacturing costCovering/liningsCoatingsEngineeringAntibacterial property

The invention discloses mould-proof antibacterial composite wallpaper which comprises a jute fiber layer. A waterproof and mould-proof layer is arranged on the back face of the jute fiber layer, and a coating layer is arranged on the upper face of the jute fiber layer. A diatomite layer is arranged on the upper face of the coating layer, and a printed and embossed layer is arranged on the diatomite layer. The upper face of the printed and embossed layer is coated with an antibacterial mould-proof layer which is provided with a covering film layer. The mould-proof antibacterial composite wallpaper is safe, environmentally friendly, low in cost, economical and applicable, has the good mould resistance and antibacterial property and has using and popularization value.

Owner:钱学东

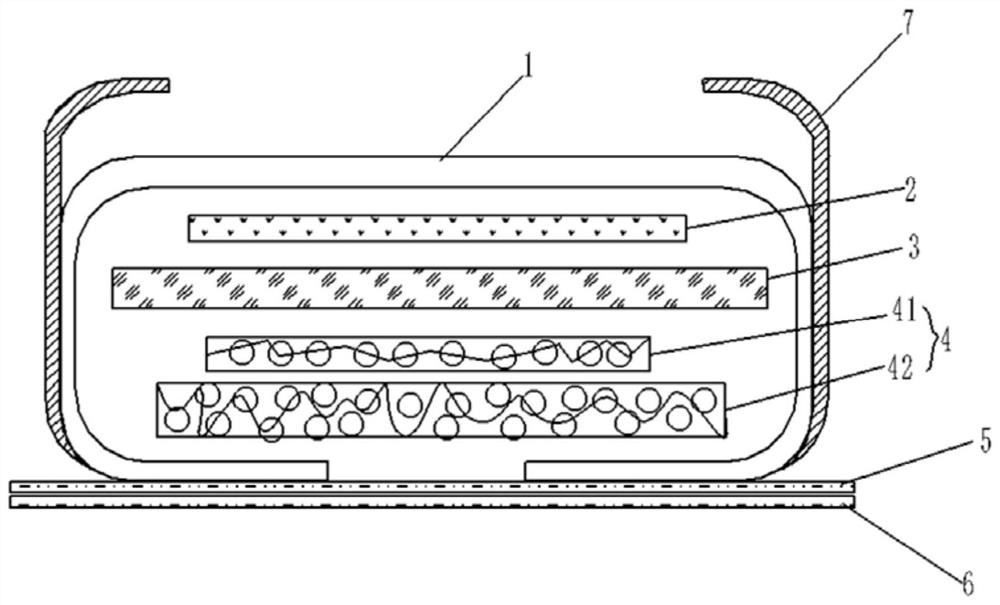

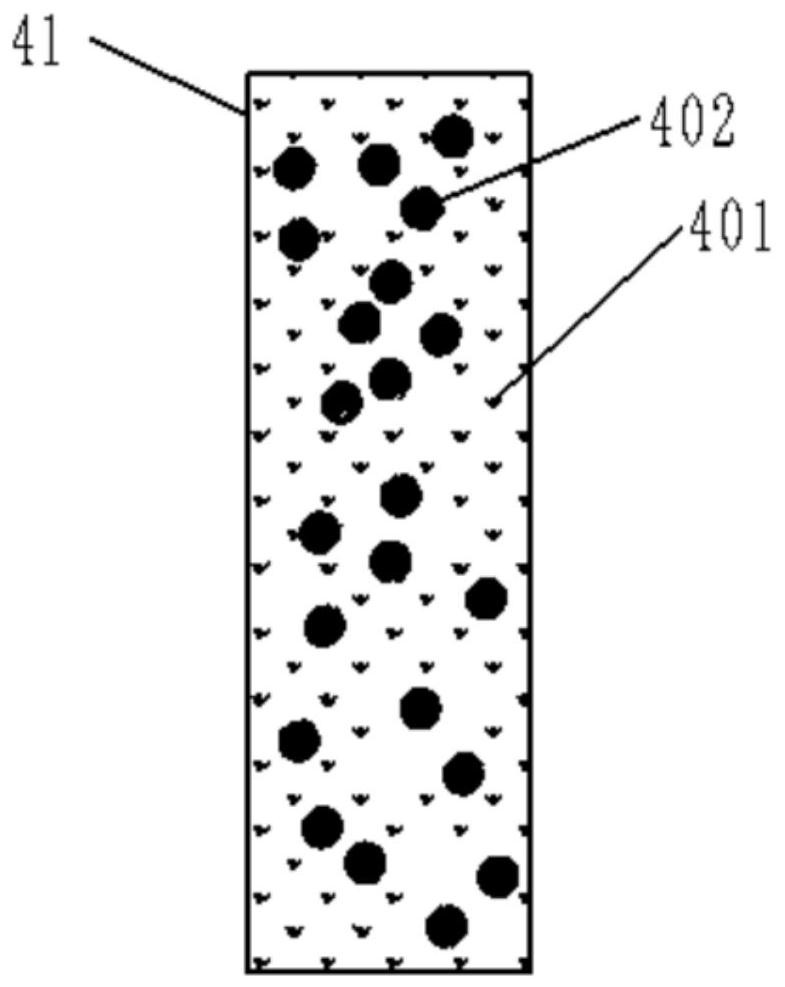

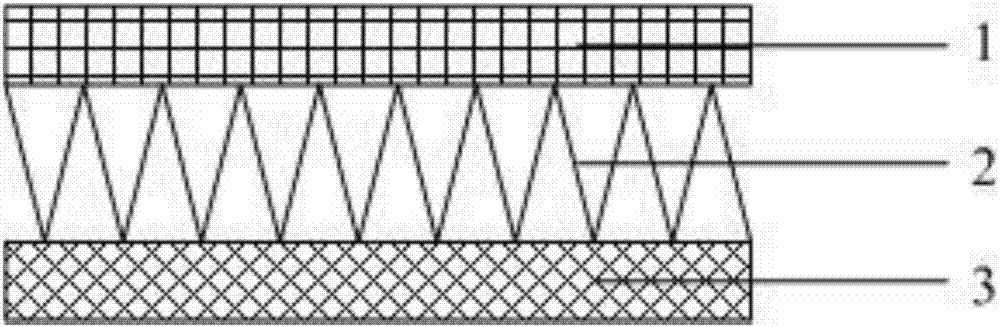

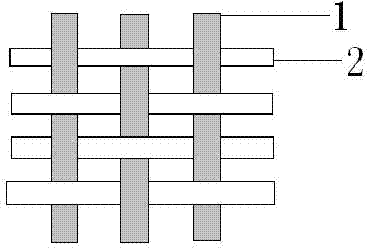

Spring and 3D net fabric combined mattress

ActiveCN107951268AGood antibacterial and deodorant effectImprove antibacterial propertiesStuffed mattressesSpring mattressesSurface layerEngineering

The invention relates to a spring and 3D net fabric combined mattress. The spring and 3D net fabric combined mattress comprises a bottom layer and a surface layer, wherein the bottom layer is a springlayer, the surface layer is a 3D net fabric layer, and the spring layer and the 3D net fabric layer are fixedly connected by adopting screws; the 3D net fabric layer is composed of a plurality of pieces of 3D net fabrics, and each 3D net fabric is prepared by adopting a hot melt adhesive through a hot-pressing technology; a warp-knitted spacing net fabric sleeve layer comprises an upper layer anda lower layer, the lower layer and a bottom layer are matched with each other, and the lower layer is fixed to the lower surface of the bottom layer through the hot melt adhesive; the upper layer andthe lower layer are pulled open and closed through a zipper. When the spring and 3D net fabric combined mattress needs to be washed, only the upper layer of the warp-knitted spacing net fabric sleevelayer is washed. For the combined mattress provided by the invention, the arranged warp-knitted spacing net fabric sleeve layer is taken as a protection cover of the combined mattress, and the combined mattress has the advantages of easy washing, dirt resistance and breathability.

Owner:FUJIAN JINJIANG HUAYU WEAVING

Anion containing bamboo carbon fiber quilt with antibacterial and deodorizing functions and preparation method of bamboo carbon fiber quilt

InactiveCN106702572AImproves UV protectionImprove breathabilityCarbon fibresBlanketChemistryAntibacterial effect

The invention relates to an anion containing bamboo carbon fiber quilt with antibacterial and deodorizing functions and a preparation method of the bamboo carbon fiber quilt. The bamboo carbon fiber quilt comprises a core filler which is prepared from, by weight, 10%-20% of bamboo charcoal fiber, 10%-20% of cotton fiber, 10%-15% of nano-silver fiber and 50%-55% of anion viscose fiber. Air permeability and heat dispersion of the product are increased, and antibacterial effect is achieved.

Owner:ZHENGZHOU DEHUI TEXTILE CO LTD

Antibacterial comfortable underwear knitted fabric

InactiveCN110281618AAntibacterial comfortGood antibacterial and deodorant effectSynthetic resin layered productsFiberYarn

The invention discloses antibacterial comfortable underwear knitted fabric. The knitted fabric comprises a underwear knitted fabric body, underwear outer layer fabric and underwear inner layer fabric, wherein the underwear knitted fabric body is formed by connecting the underwear outer layer fabric and the underwear inner layer fabric by spinning and weaving. The underwear inner layer fabric of the antibacterial comfortable underwear knitted fabric disclosed by the invention is composite fiber yarn made by mixing chitin fiber yarn and bamboo fiber yarn, and the chitin fiber yarn per se has excellent antibacterial and bacteriostatic effects; meanwhile, bamboo quinone in the bamboo fiber yarn has antibacterial, anti-mite and deodorant properties, and chlorophyll and copper chlorophyll in the bamboo fiber yarn have relatively good deodorant effect, so that the antibacterial comfortable underwear knitted fabric has the antibacterial and deodorant effects.

Owner:JIHUA 3542 TEXTILE CO LTD

Multi-ingredient blending knitting plus material

The invention discloses a knitting plus material, in particular to a multi-ingredient blending knitting plus material, which comprises warp yarns and weft yarns, wherein the warp yarns adopt coolmax fiber yarns, the weft yarns adopt blending fiber yarns, the blend fiber yarns are mixtures of bamboo fiber, pearl fiber and soyabean protein fiber. The multi-ingredient blending knitting plus material disclosed by the invention has the advantages of good moisture conduction and ventilation performance, skin-affinitive and wear-resistant performance, antimicrobial deodorization performance, ultraviolet protection, skin protection and health care performance and the like, and simultaneously, the plus material also has the characteristics that green effect and safety are realized, the hand feeling is exquisite, and the texture is soft and smooth.

Owner:JIANGSU XIDENGBO FASHION

Deodorizing oil smoke-containing air filtering material and preparation method thereof

InactiveCN105126446AImprove filtering effectGood antibacterial and deodorant effectFiltration separationCoconut oilBoric acid

The invention discloses a deodorizing oil smoke-containing air filtering material. The deodorizing oil smoke-containing air filtering material is prepared from 20-30 parts by weight of polypropylene fibers, 20-30 parts by weight of jute fibers, 5-10 parts by weight of apocynum venetum fibers, 5-10 parts by weight of tea fibers, 3-5 parts by weight of aloe fibers, 10-20 parts by weight of oil absorption resin, 0.1-0.2 parts by weight of dodecyl dimethyl benzyl ammonium chloride, 4-6 parts by weight of coconut oil, 0.3-0.5 parts by weight of boric acid and 10-15 parts by weight of a composite modifier. The deodorizing oil smoke-containing air filtering material can effectively filter solids and liquid particles in oil smoke exhaust gas, can reduce damage, has good purifying effects, and can effectively reduce oil smoke exhaust gas-caused environmental pollution. Through compounding with raw materials, the filtering material has good antibiosis and deodorizing performances, good wholesomeness and high practicality.

Owner:ANHUI PHOENIX INT CO LTD

Wear-resistant bacteriostatic bamboo-fiber rib fabric and processing method thereof

InactiveCN110714265AImprove comfortGood flexibilityRadioactive element fibre treatmentWeft knittingBiotechnologyCarbon fibers

The invention discloses a wear-resistant bacteriostatic bamboo-fiber rib fabric and a processing method thereof. The rib fabric is prepared from, by weight, 38-44 parts of cotton fiber, 45-50 parts ofbamboo fiber, 20-25 parts of flax fiber, 12-15 parts of bacteriostatic anti-odor fiber, 8-10 parts of polyimide fiber, 6-8 parts of algae carbon fibre, and 4-8 parts of modal fiber. The rib fabric isprepared from various fibers, the bamboo fiber has good breathability, water absorptivity, high wear resistance, good dying property and the like, and has functions such as natural antibacterial property, bacteriostat, mite controlling, deodorizing and ultraviolet resistance; particularly, the average bacteriostasis rate of the bacteriostatic anti-odor fiber to staphylococcus aureus, candida sporogenes and colibacillus is equal to or higher than 99%, and thus excellent antibacterial and deodorizing effect can be achieved.

Owner:苏州神马织针器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com