Spring and 3D net fabric combined mattress

A 3D, mesh technology, applied in the field of spring 3D mesh composite mattress, can solve problems such as unhealthy, uncomfortable, visceral compression, etc., and achieve the effect of avoiding performance degradation and excellent antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A spring 3D mesh composite mattress comprises a bottom layer and a surface layer, the bottom layer is a spring layer, the surface layer is a 3D mesh layer, and the spring layer and the 3D mesh layer are fixedly connected by screws.

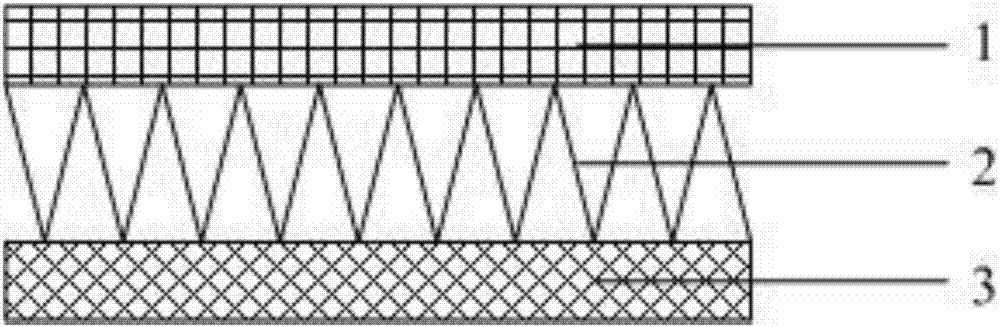

[0051] The 3D mesh layer is composed of a plurality of 3D meshes, and each 3D mesh is formed by hot-melt adhesive through a hot-pressing process. The hot-pressing temperature is 150° C., and the hot-pressing time is 20 minutes. Wherein, the structure of the 3D mesh is: the middle layer 2 of the 3D mesh is woven and connected with the upper surface layer 1 of the V-shaped 3D mesh and the lower bottom layer 3 of the 3D mesh. Please see attached figure 1 .

[0052] The warp-knitted spacer mesh cover layer is divided into an upper layer and a lower layer, wherein the lower layer matches the bottom layer and is fixed on the lower surface of the bottom layer by hot melt adhesive. Zippers open and close the upper and lower layers. When cleaning...

Embodiment 2

[0080] A spring 3D mesh composite mattress comprises a bottom layer and a surface layer, the bottom layer is a spring layer, the surface layer is a 3D mesh layer, and the spring layer and the 3D mesh layer are fixedly connected by screws.

[0081] The 3D mesh layer is composed of a plurality of 3D meshes, and each 3D mesh is formed by hot-melt adhesive through a hot-pressing process. The hot-pressing temperature is 150° C., and the hot-pressing time is 20 minutes.

[0082] The warp-knitted spacer mesh cover layer is divided into an upper layer and a lower layer, wherein the lower layer matches the bottom layer and is fixed on the lower surface of the bottom layer by hot melt adhesive. Zippers open and close the upper and lower layers. When cleaning is required, only the upper layer of the warp-knitted spacer mesh cover layer is cleaned.

[0083] The composite mattress is equipped with a warp-knitted spacer mesh cover layer, which is used as a protective cover of the composite...

Embodiment 3

[0107] A spring 3D mesh composite mattress comprises a bottom layer and a surface layer, the bottom layer is a spring layer, the surface layer is a 3D mesh layer, and the spring layer and the 3D mesh layer are fixedly connected by screws.

[0108] The 3D mesh layer is composed of a plurality of 3D meshes, and each 3D mesh is formed by hot-melt adhesive through a hot-pressing process. The hot-pressing temperature is 150° C., and the hot-pressing time is 20 minutes.

[0109] The warp-knitted spacer mesh cover layer is divided into an upper layer and a lower layer, wherein the lower layer matches the bottom layer and is fixed on the lower surface of the bottom layer by hot melt adhesive. Zippers open and close the upper and lower layers. When cleaning is required, only the upper layer of the warp-knitted spacer mesh cover layer is cleaned.

[0110] The composite mattress is equipped with a warp-knitted spacer mesh cover layer, which is used as a protective cover of the composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com