Patents

Literature

68results about "Radioactive element fibre treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

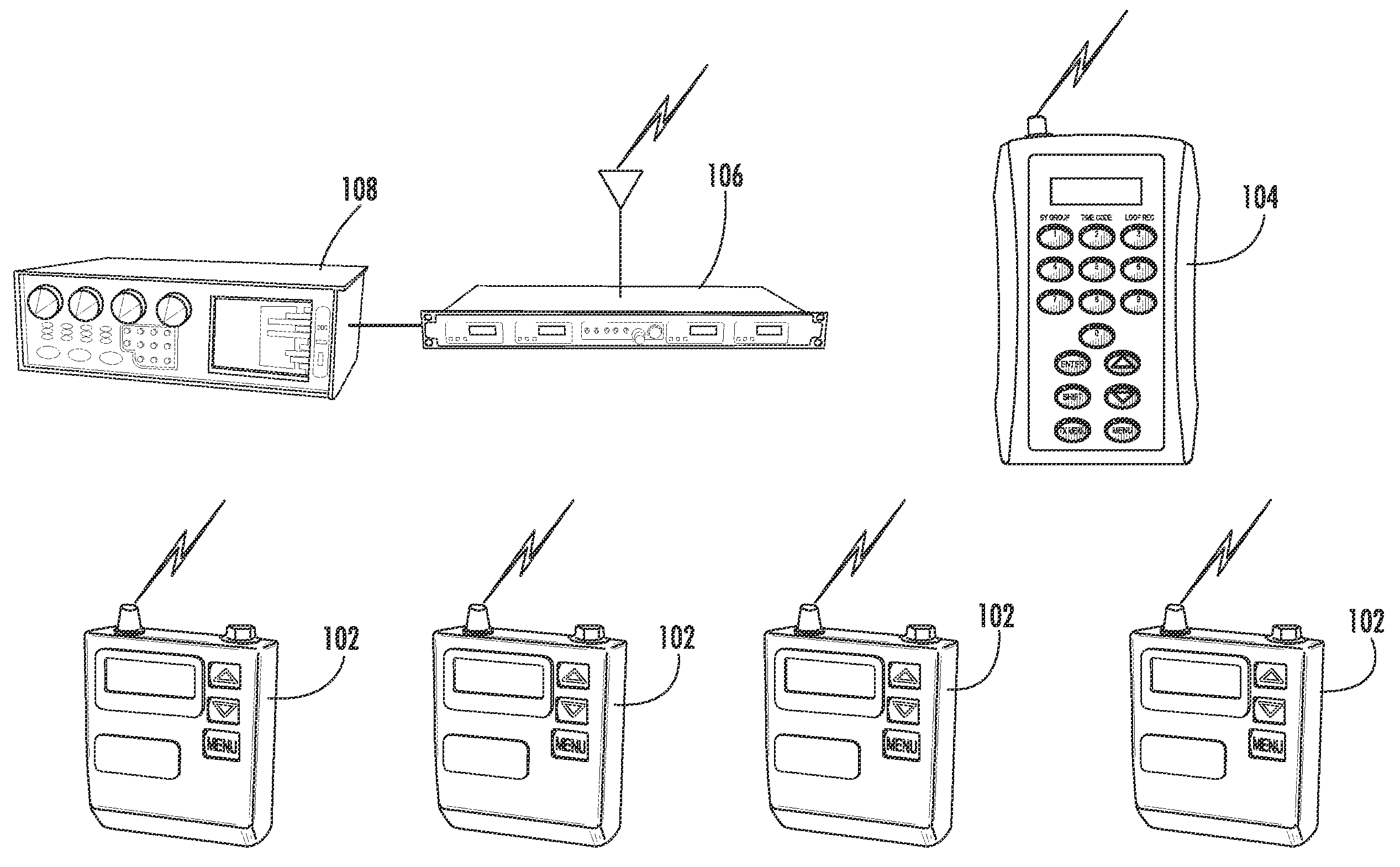

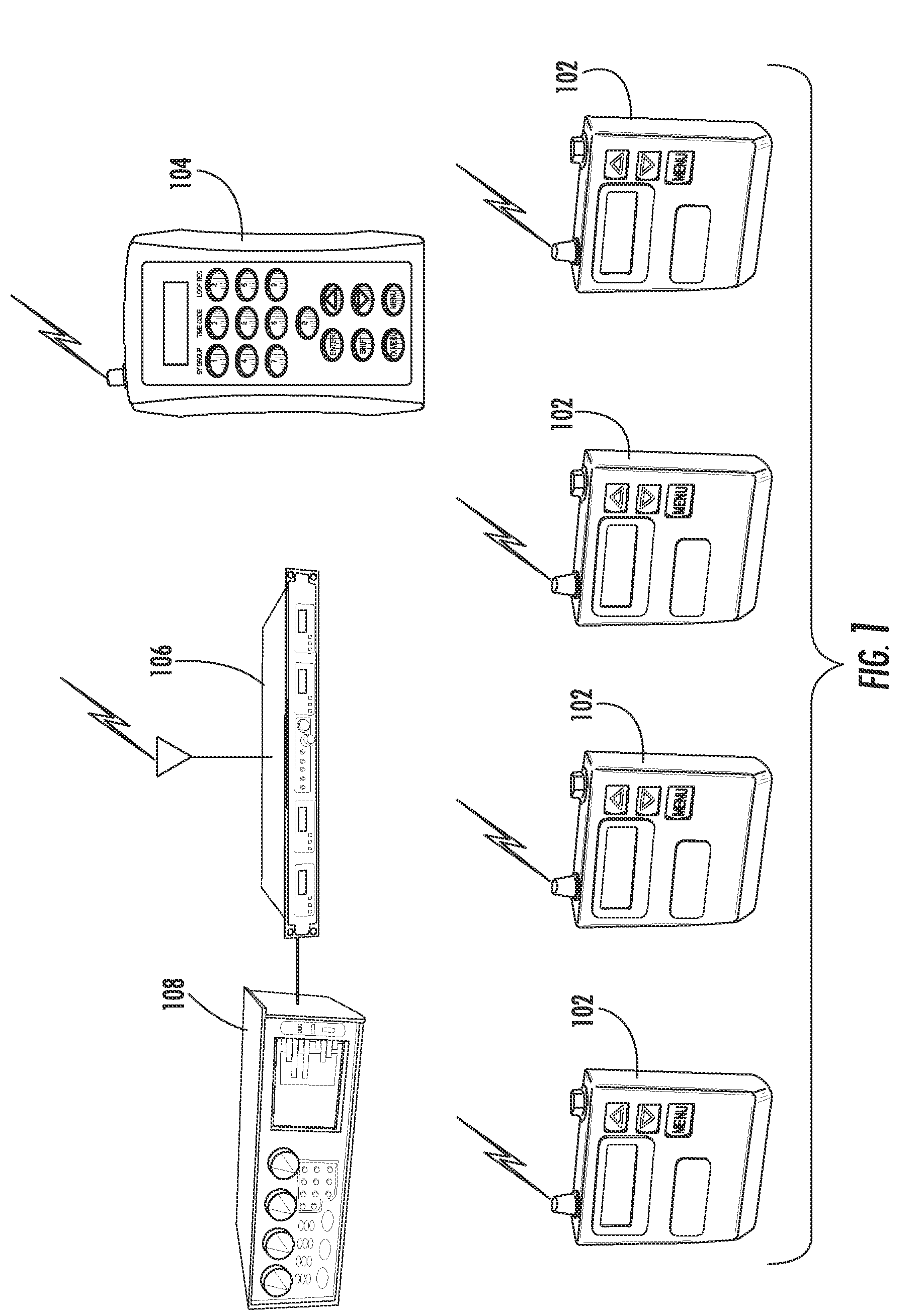

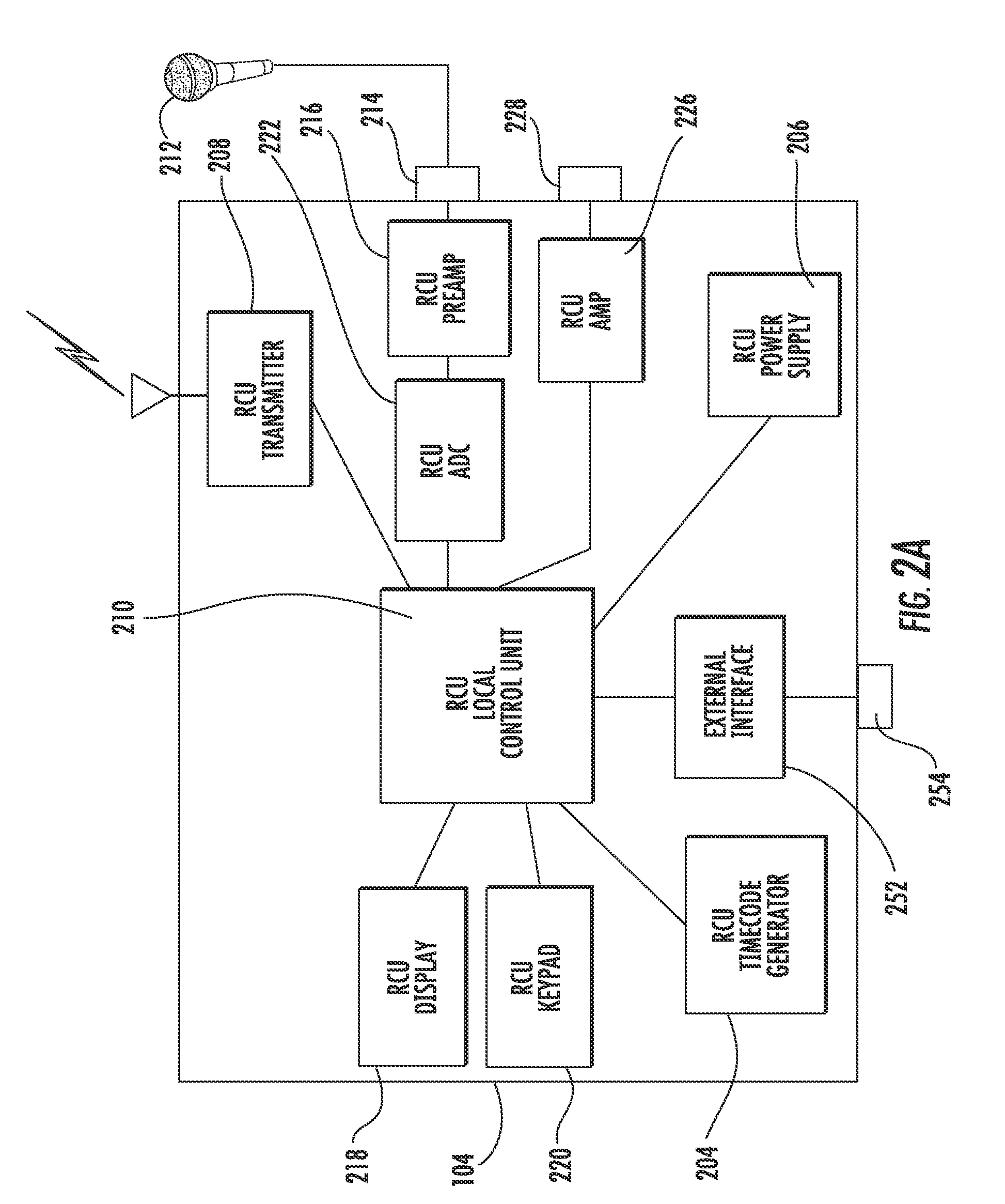

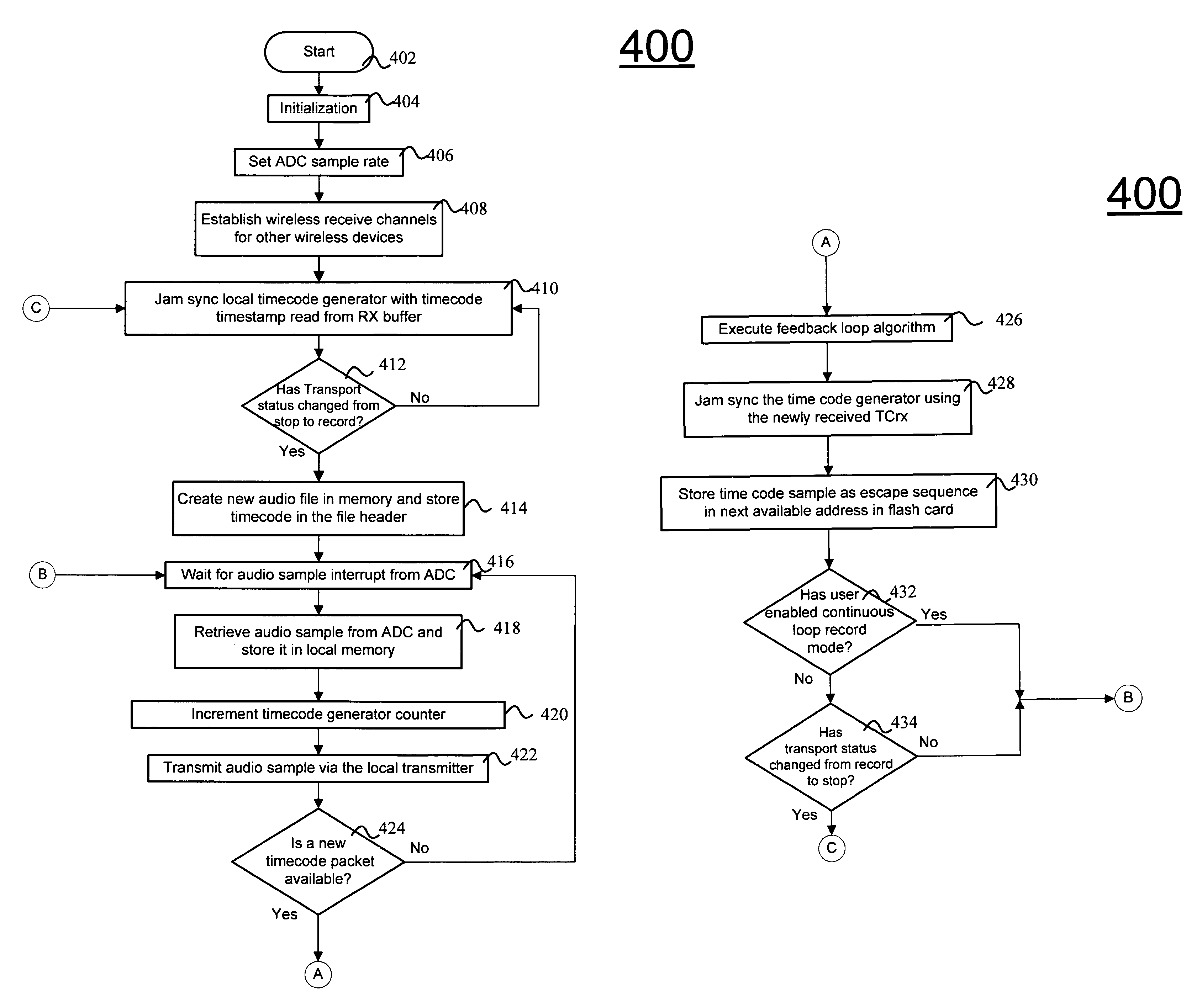

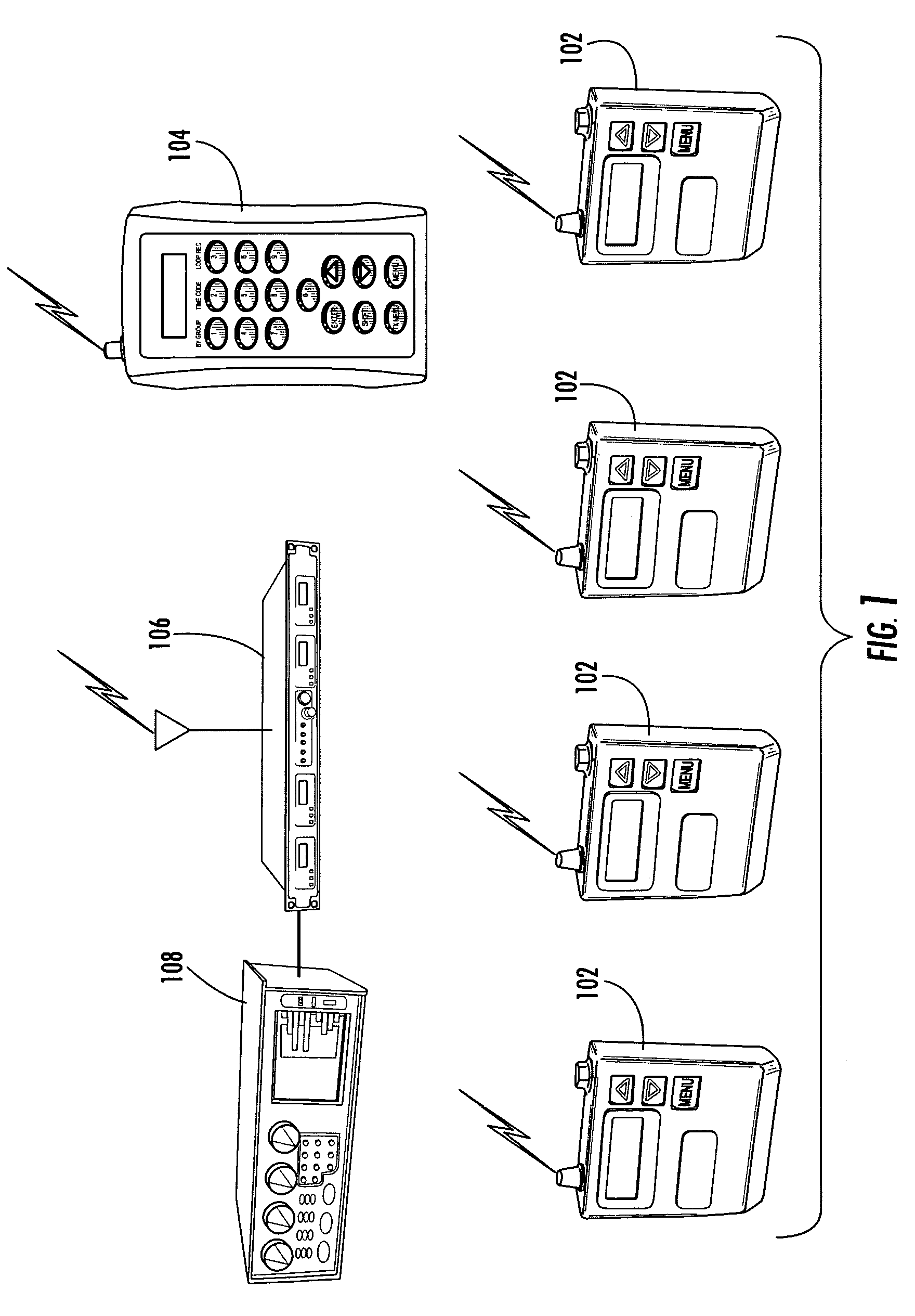

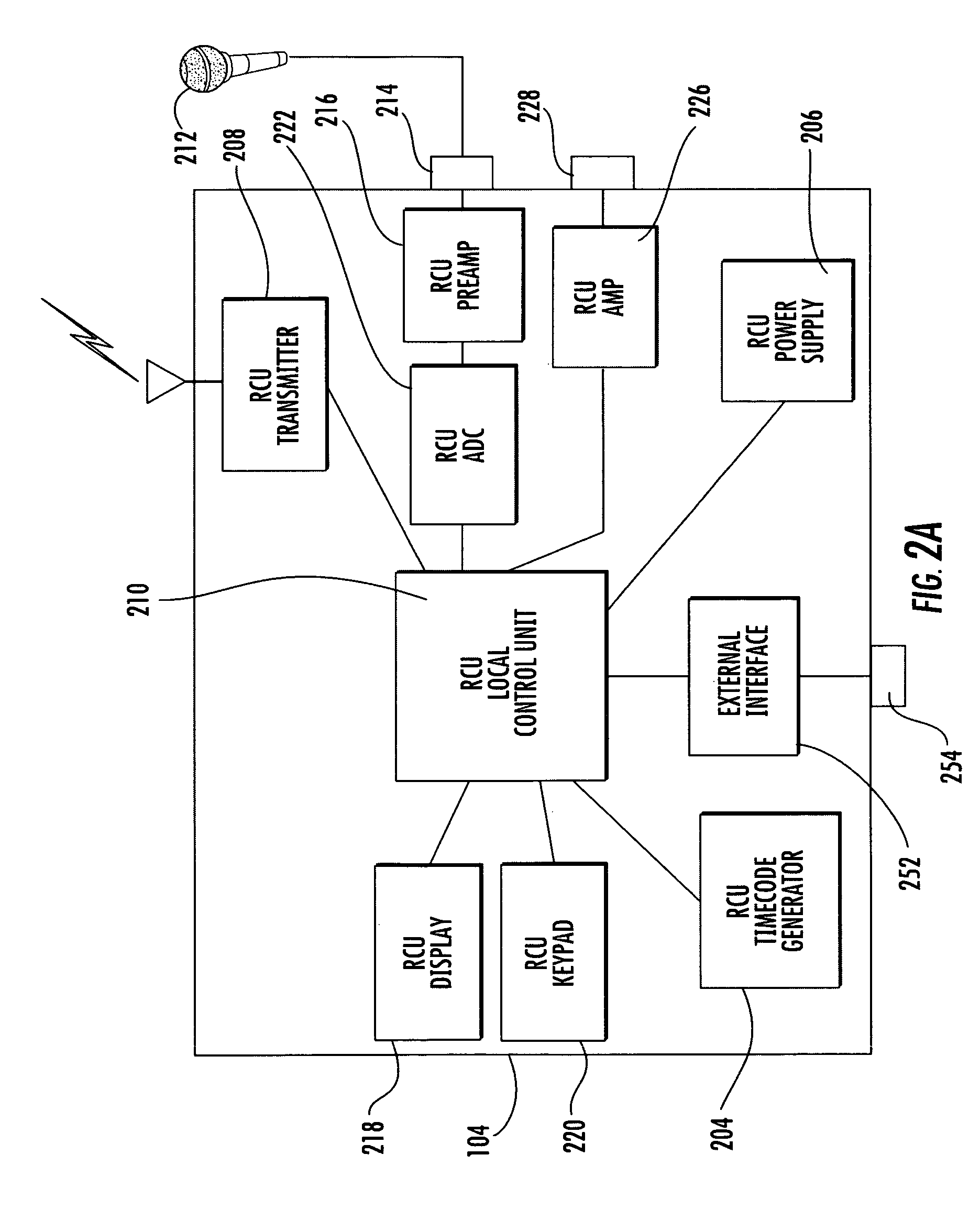

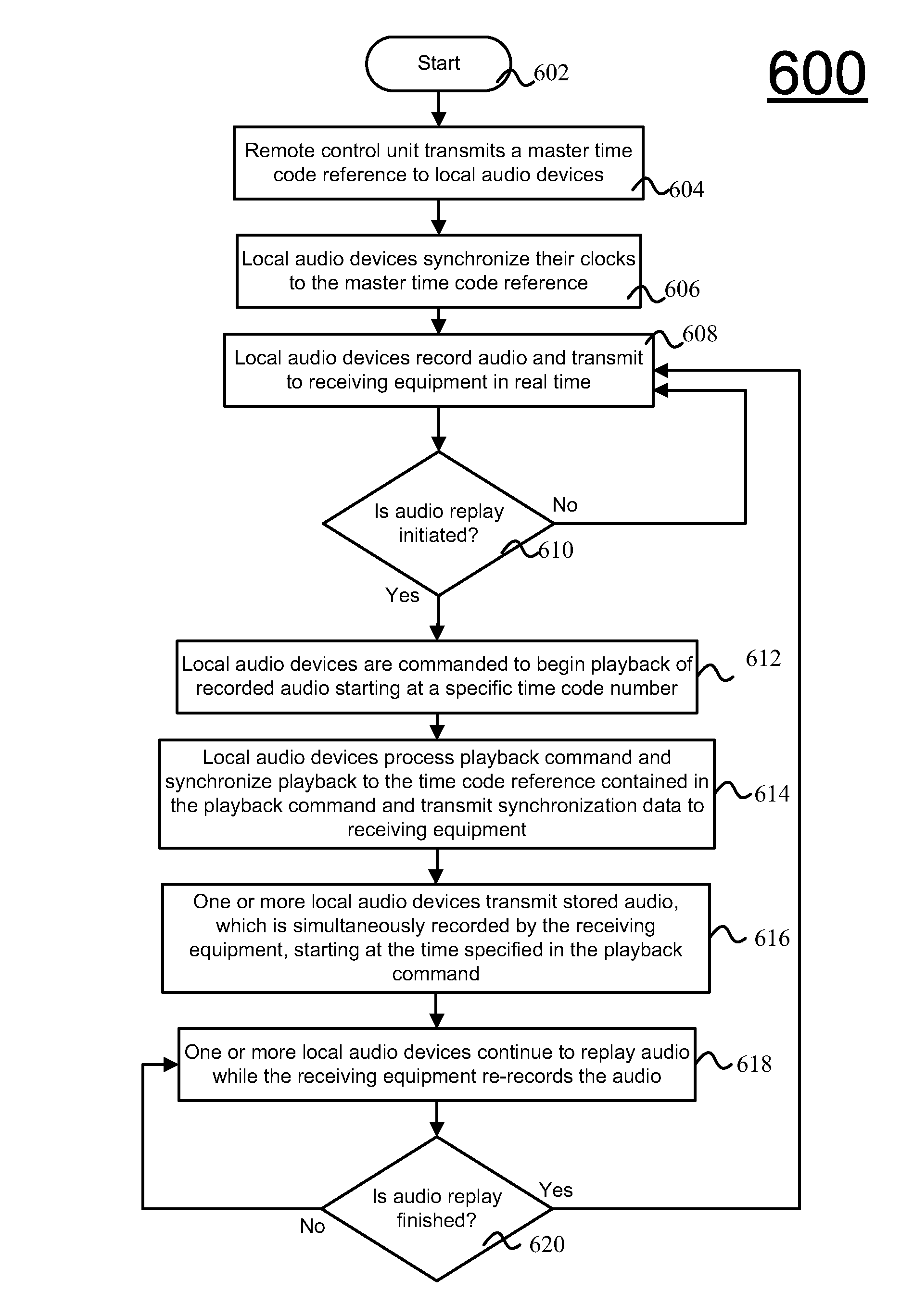

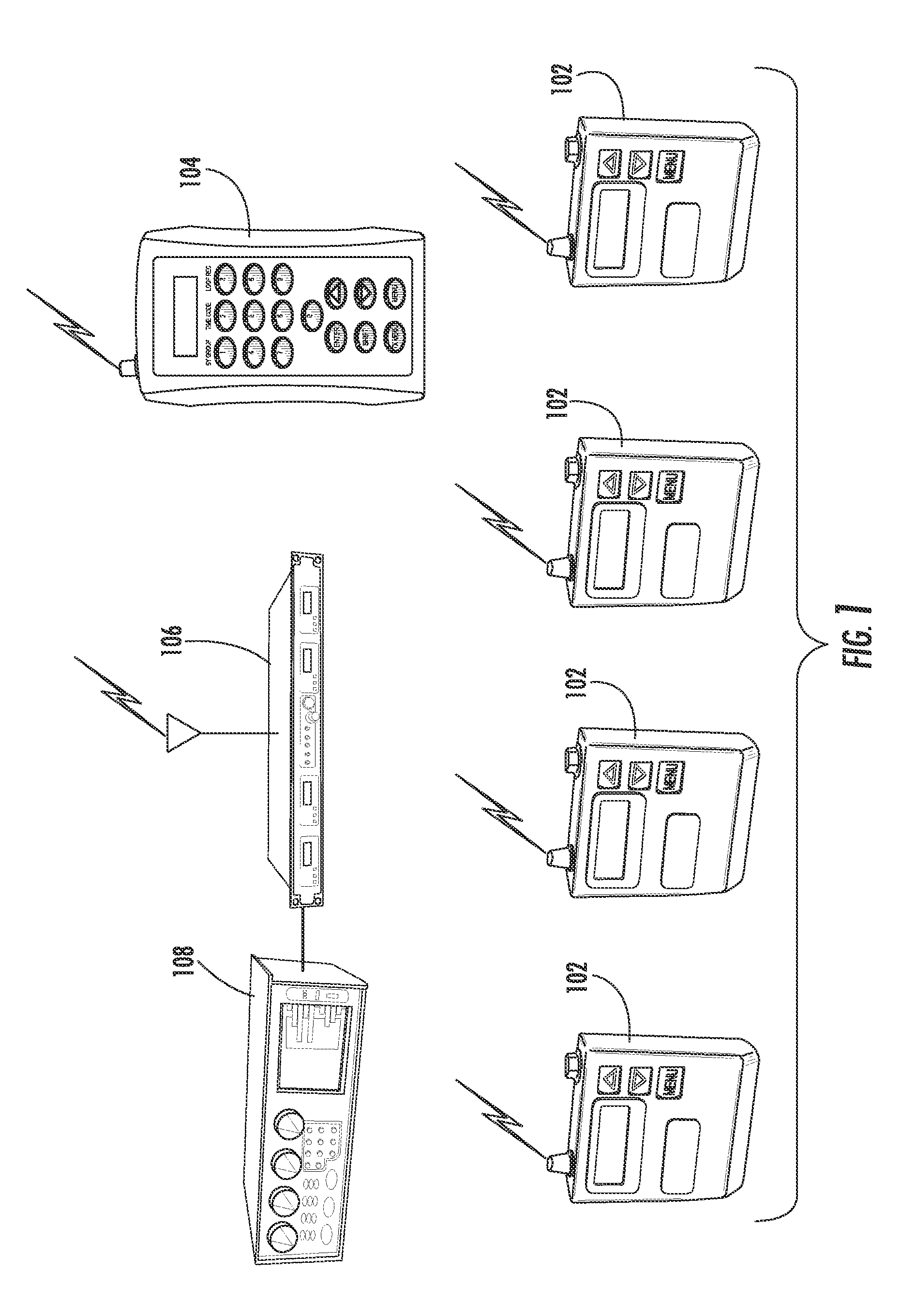

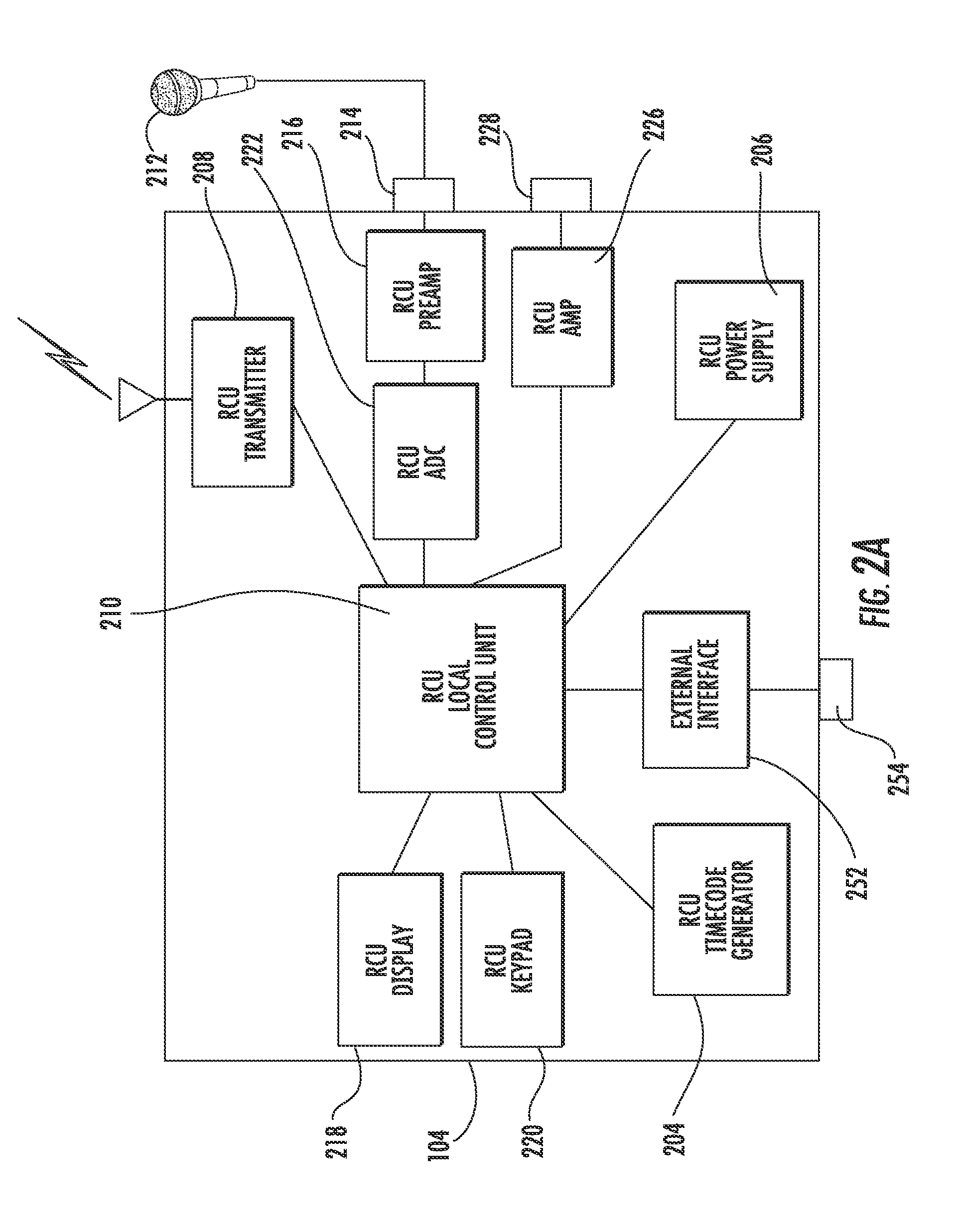

Virtual Wireless Multitrack Recording System

ActiveUS20100217414A1Radioactive element fibre treatmentTransmission systemsComputer hardwareData Corruption

Disclosed are systems and methods for wirelessly recording multi-track audio files without the data corruption or loss of data that typically occurs with wireless data transmission. In some aspects of the present invention, each performer is equipped with a local audio device capable of locally recording the respective performer's audio while also transmitting it to a master recorder. The locally recorded audio may then be used to repair or replace any audio lost or corrupted during transmission to the master recorder. Such repair or replacement may be performed electronically or via playback of the locally recorded audio. In other aspects of the present invention, a master recorder is not required since all locally recorded audio may be combined or otherwise processed post-recording. Locally recorded audio may include identifiers to aid in post-recording identification of such audio. A multi-memory unit is also provided to facilitate manipulation and processing of audio files.

Owner:ZAXCOM

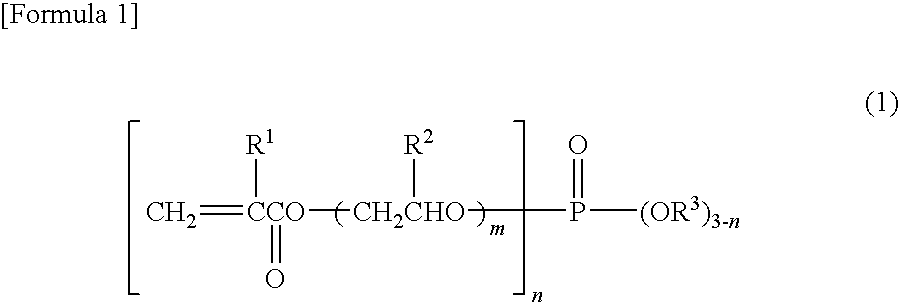

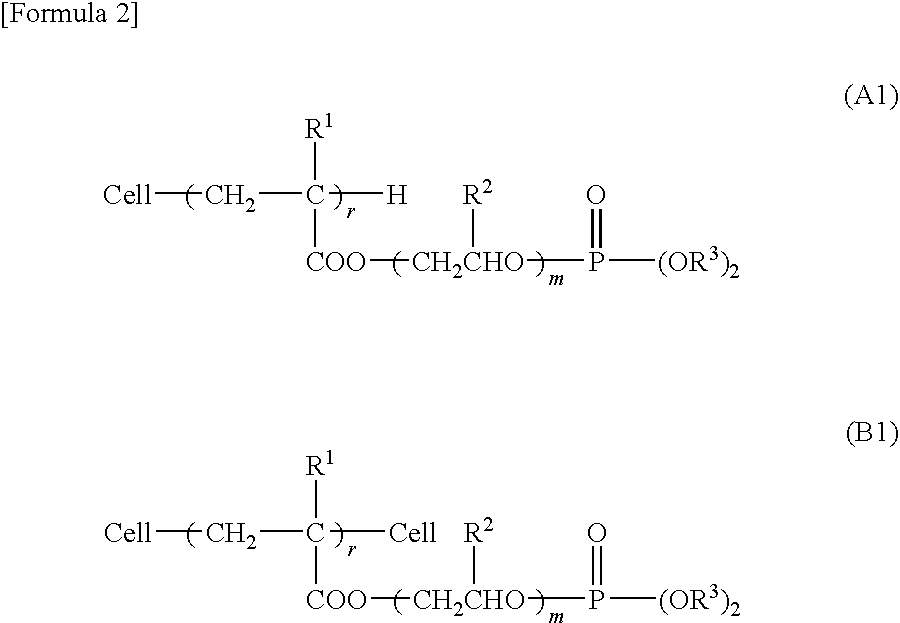

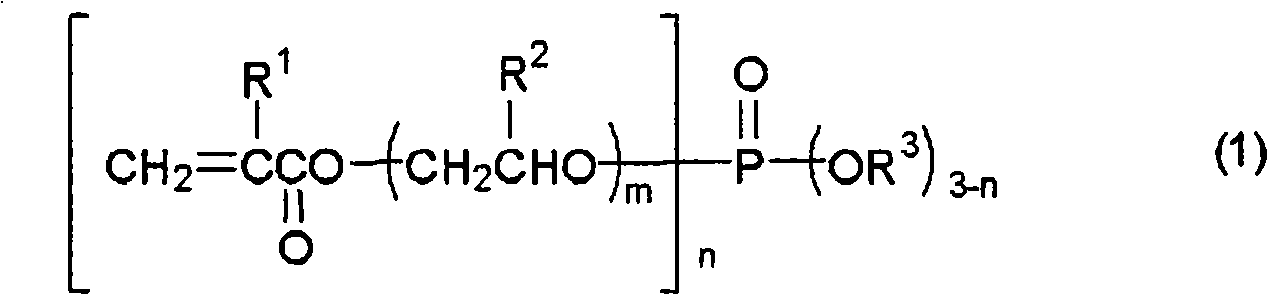

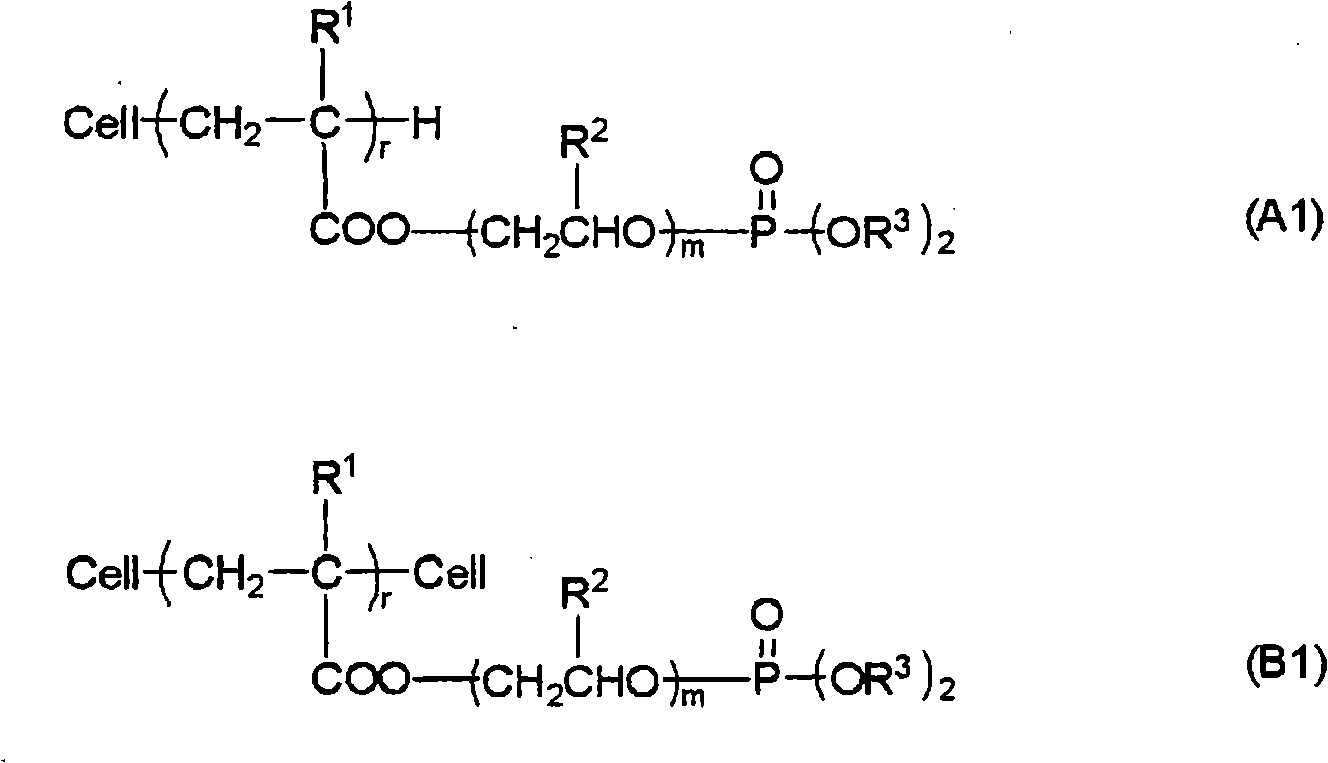

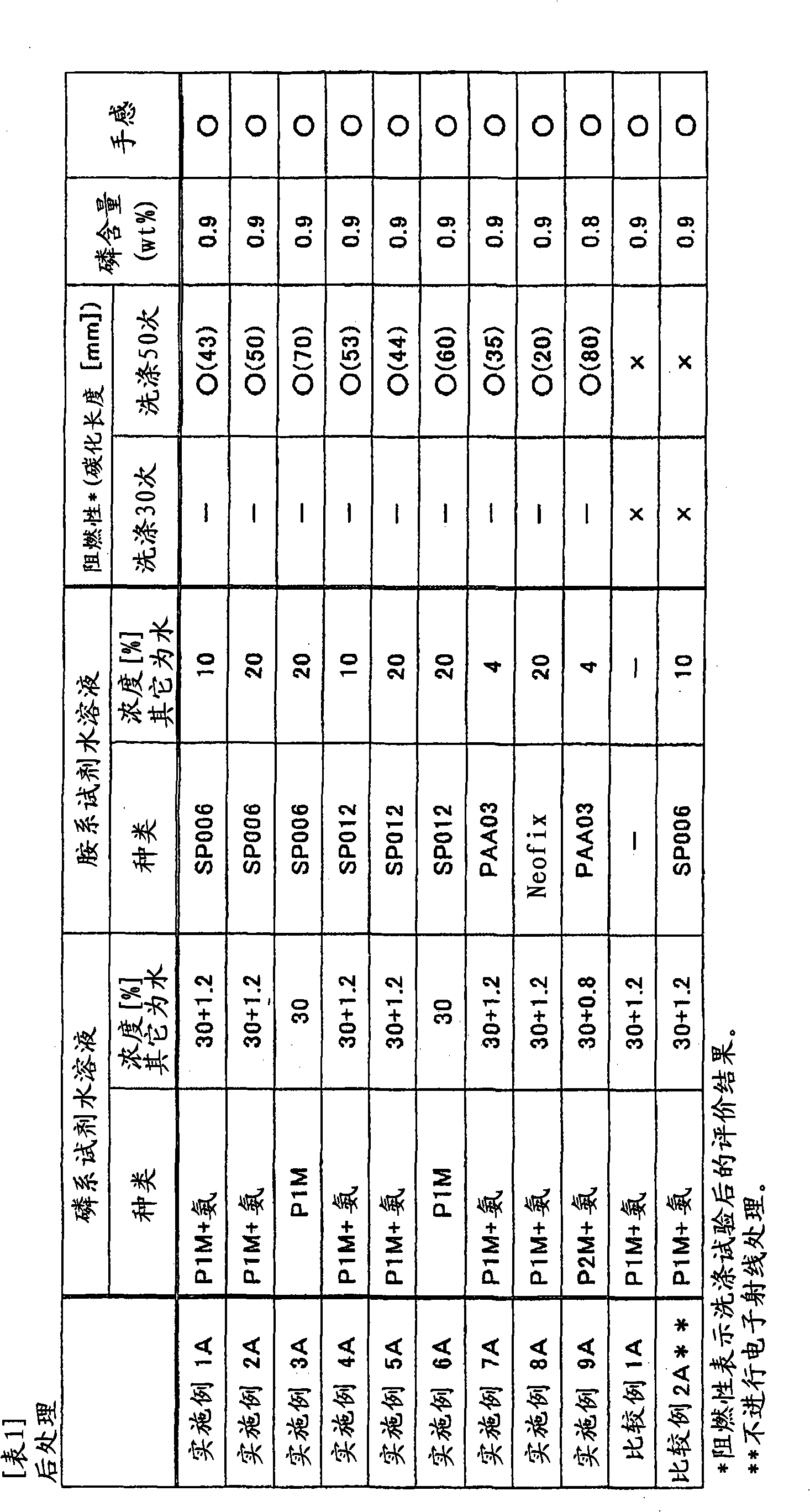

Flame-retardant processing method and flame-retarded cellulosic fiber material

InactiveUS20100261862A1Increased durabilityImproved flame retardance sufficientlyRadioactive element fibre treatmentHeat resistant fibresCellulose fiberPhotochemistry

A flame-retardant processing method, containing:a radiation processing step of irradiating a cellulosic fiber material with radiation;a phosphorus processing step of adding a radically polymerizable phosphorus-containing compound to the cellulosic fiber material; andan amine processing step of adding an amine compound to the cellulosic fiber material, and a flame-retarded cellulosic fiber material prepared by the method above.

Owner:KURASHIKI BOSEKI KK

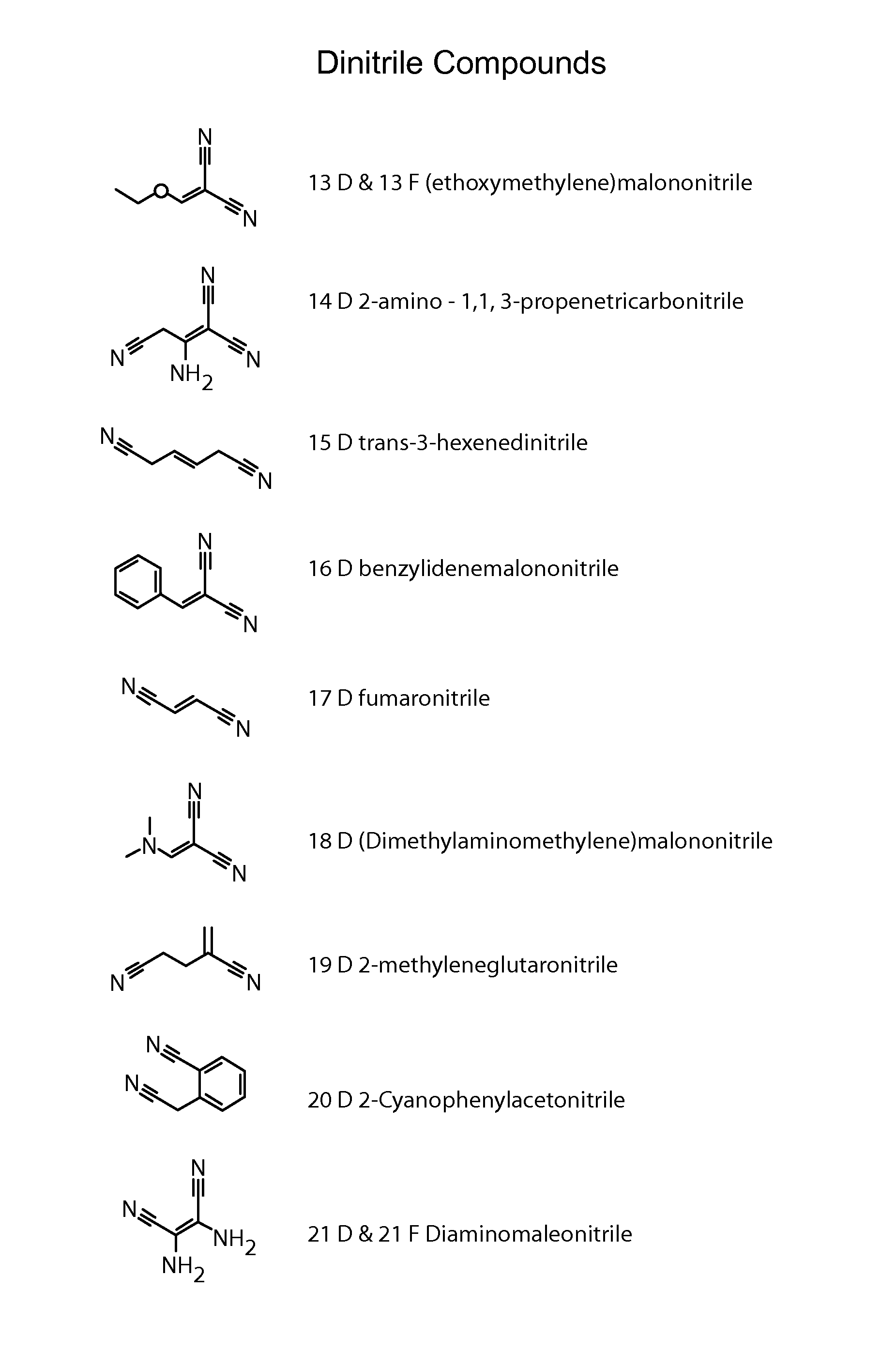

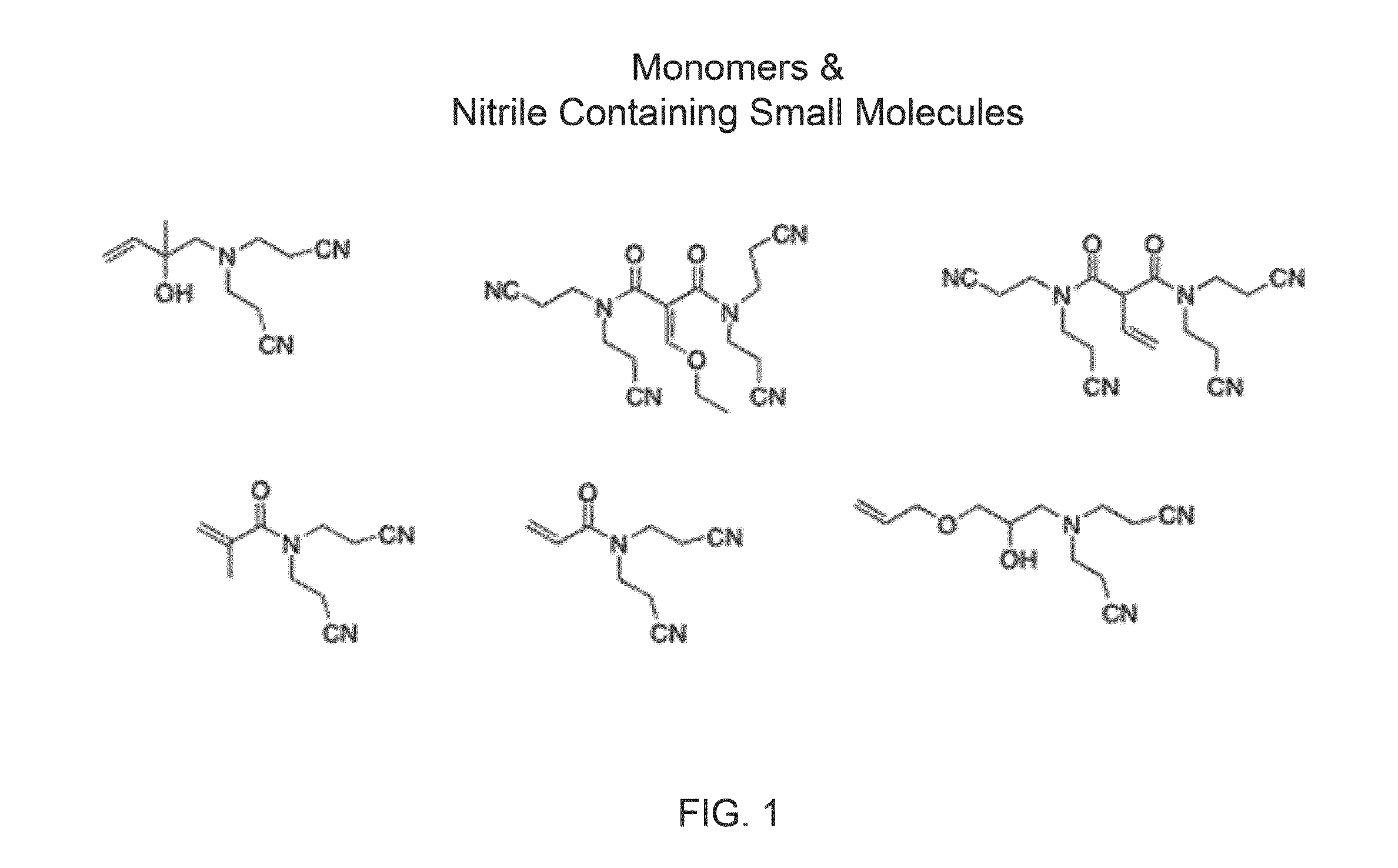

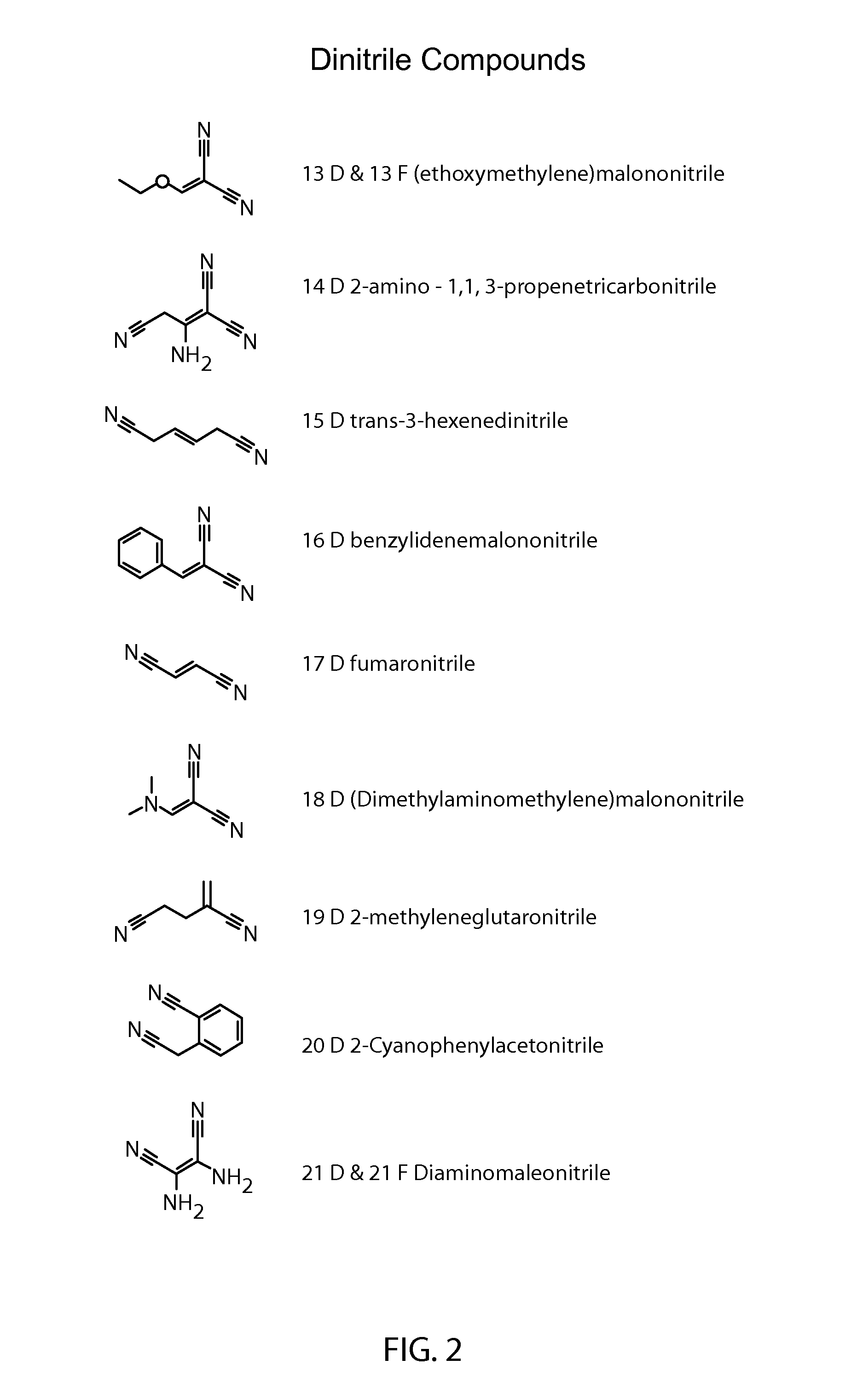

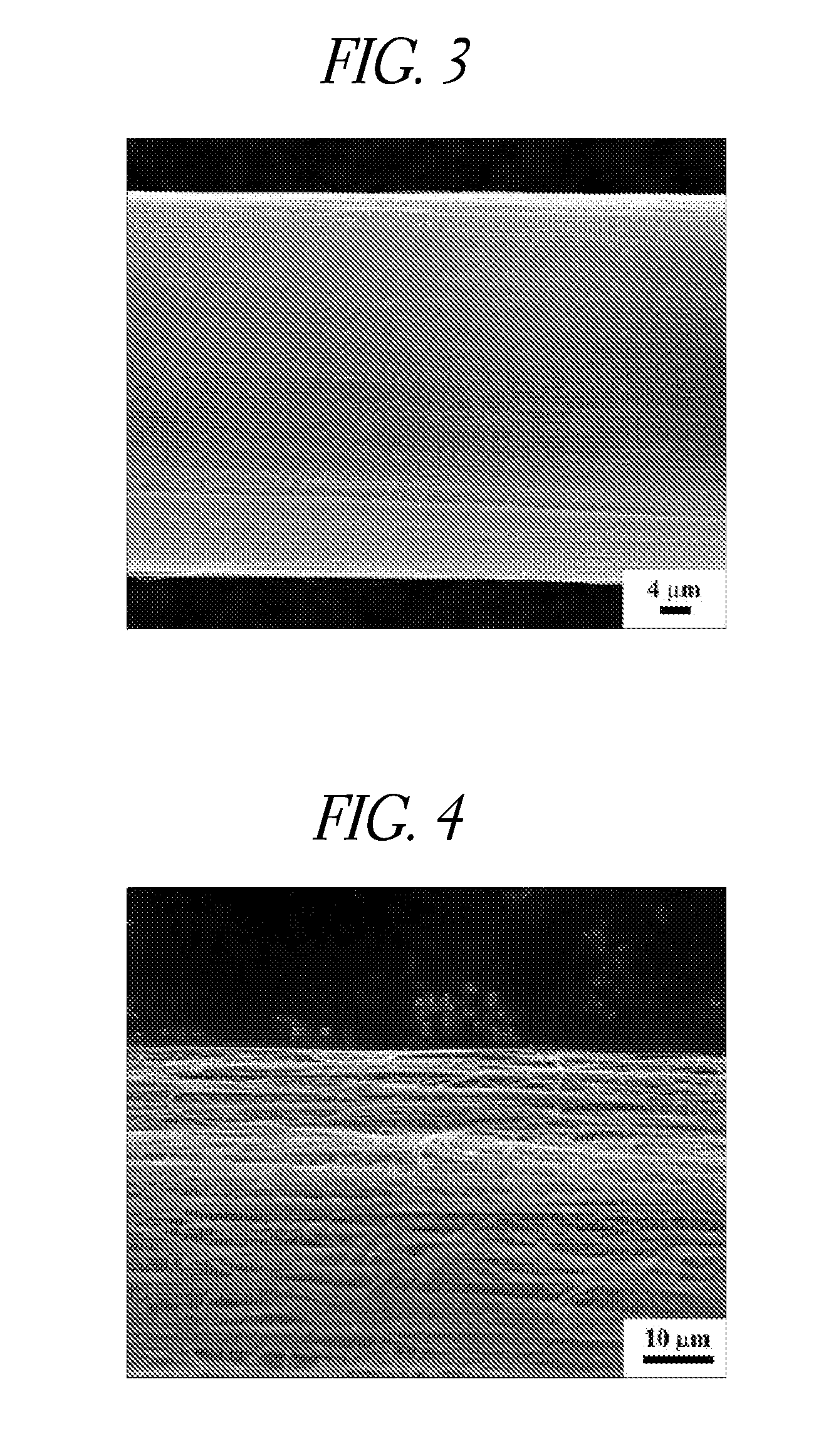

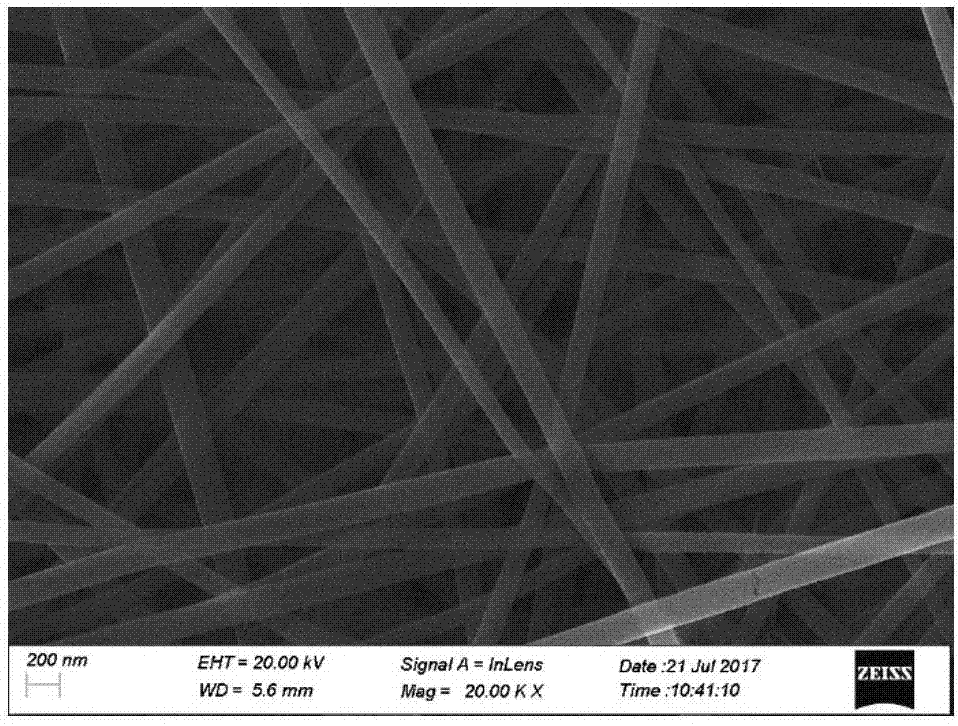

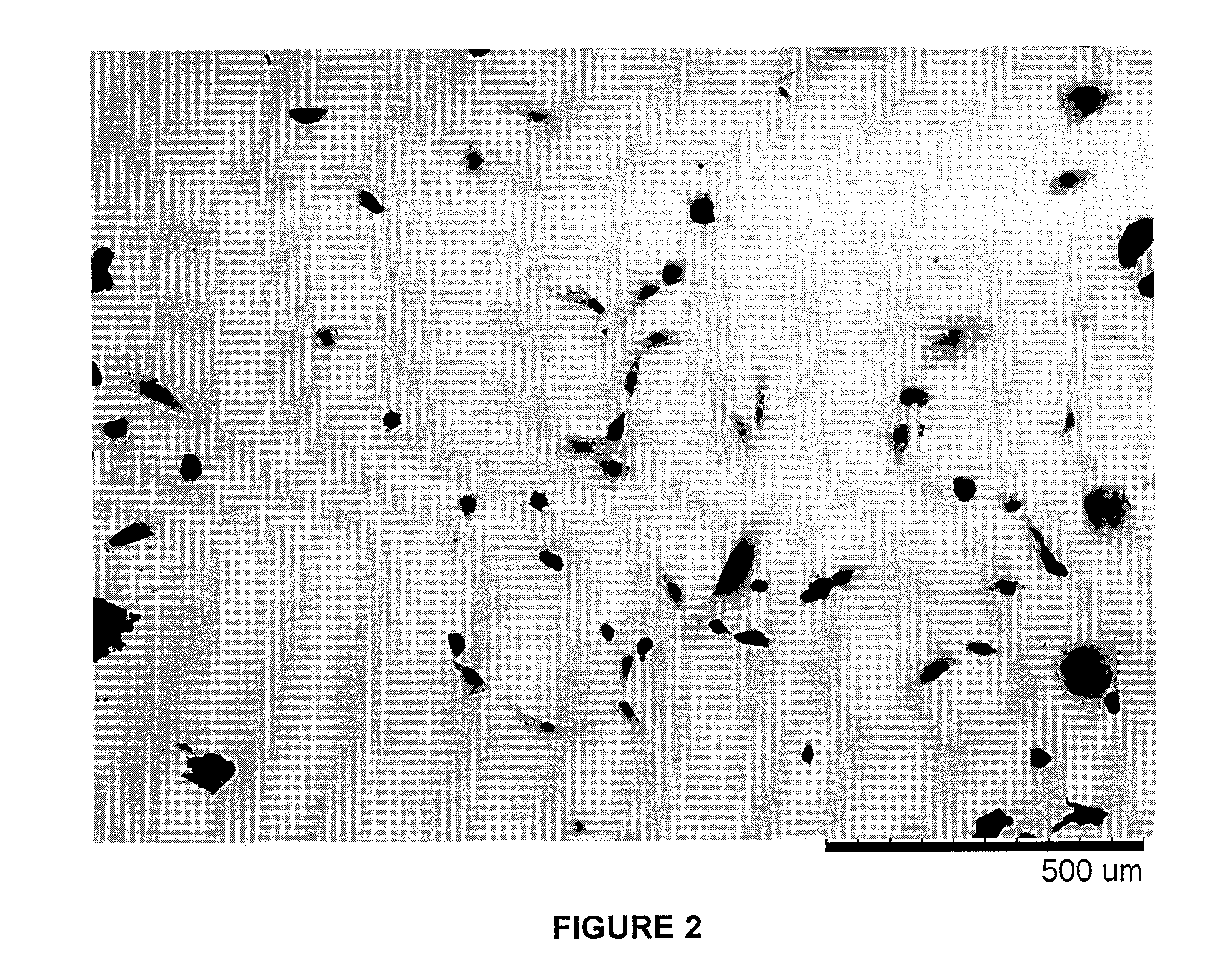

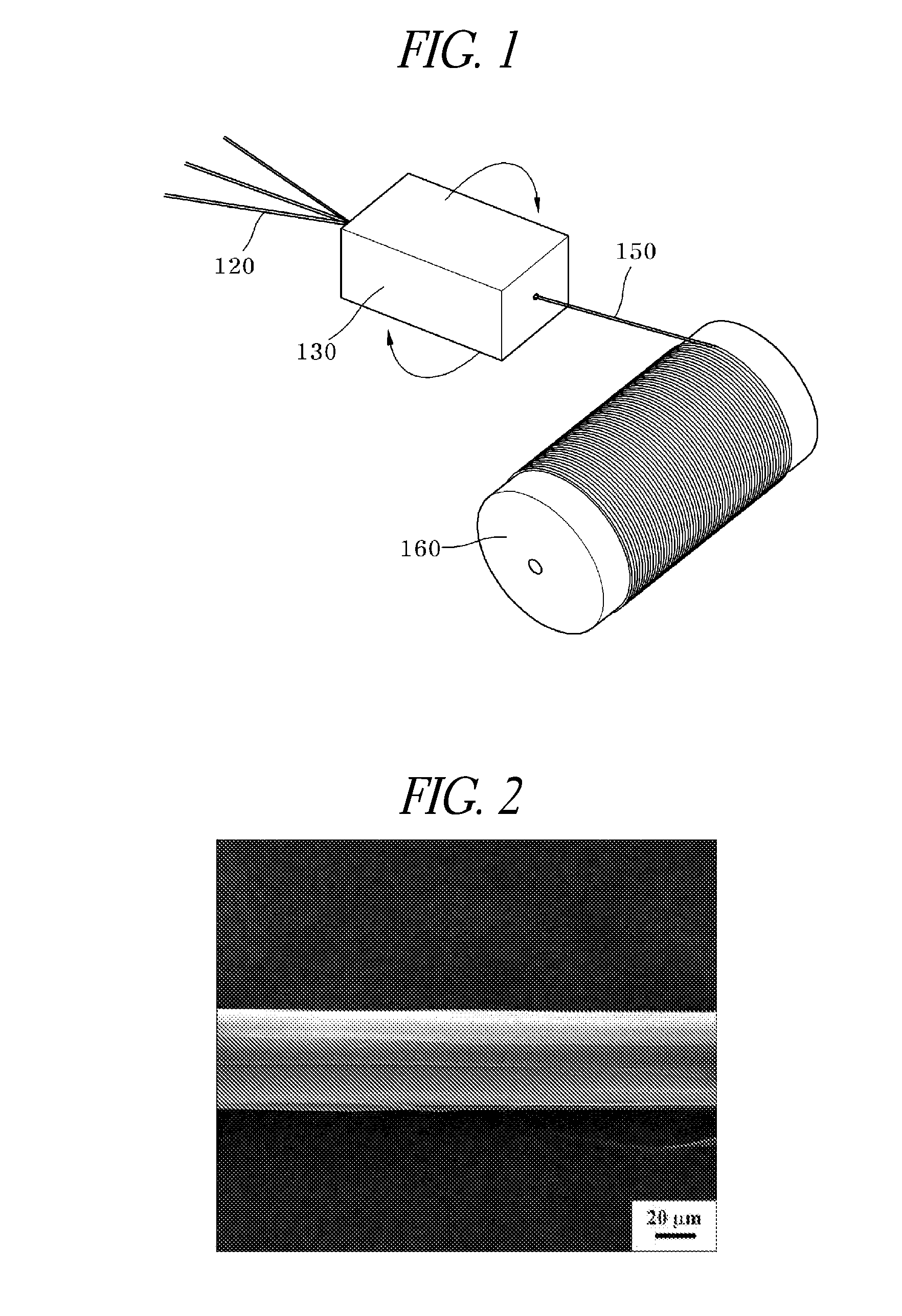

Fiber-based adsorbents having high adsorption capacities for recovering dissolved metals and methods thereof

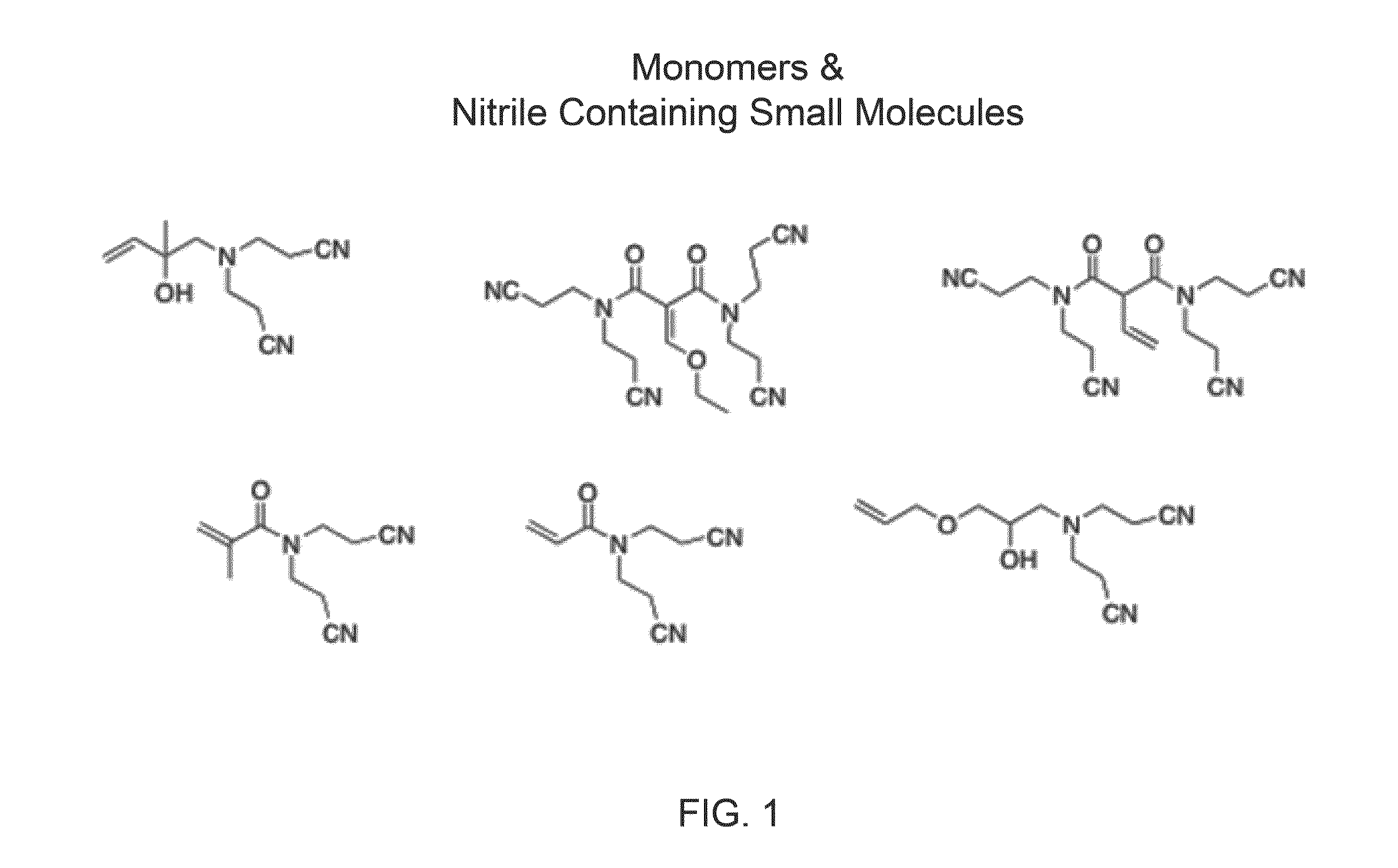

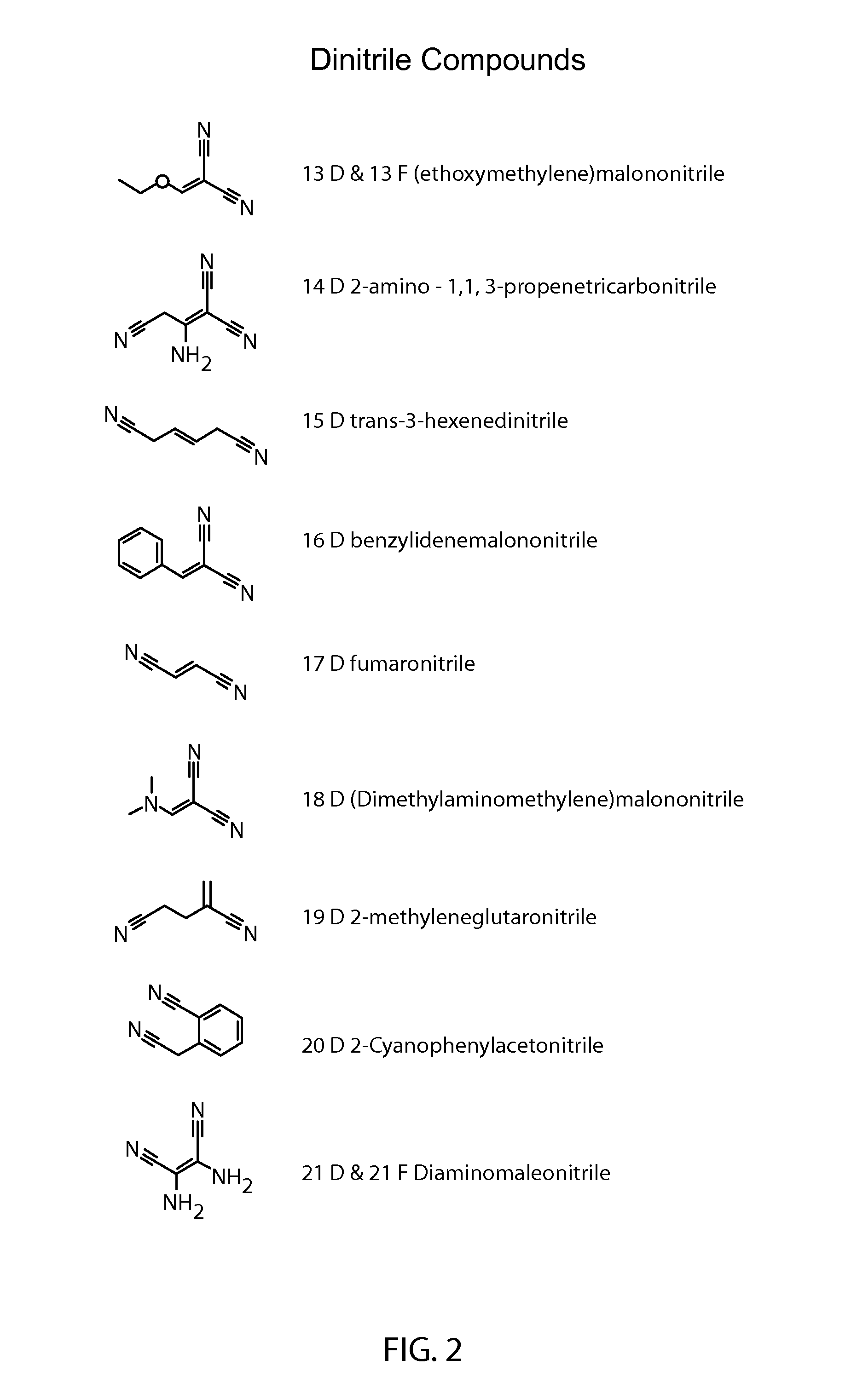

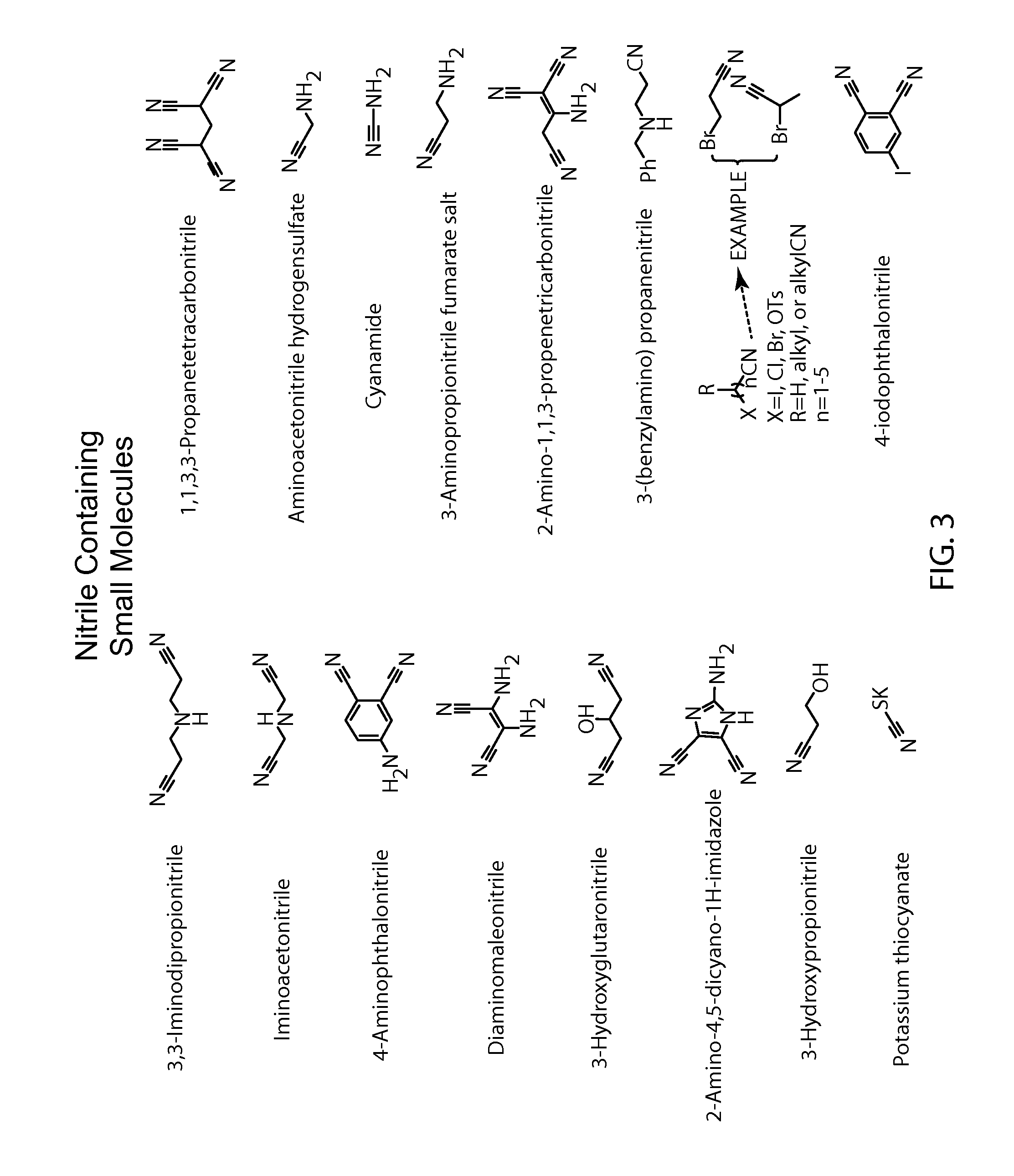

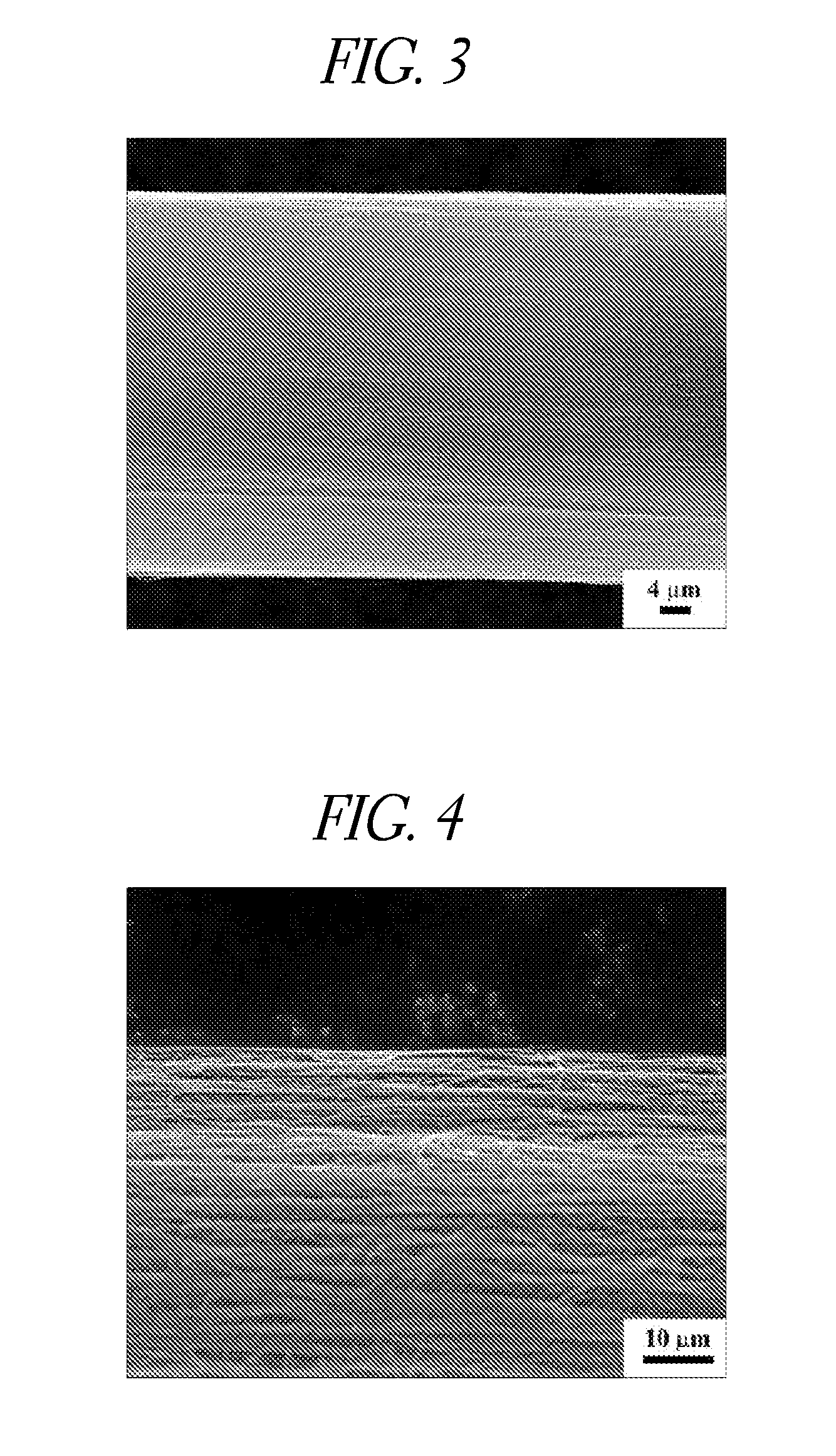

ActiveUS20130071659A1Improve adsorption capacityIncrease surface areaRadioactive element fibre treatmentFibre typesFiberHydroxylamine

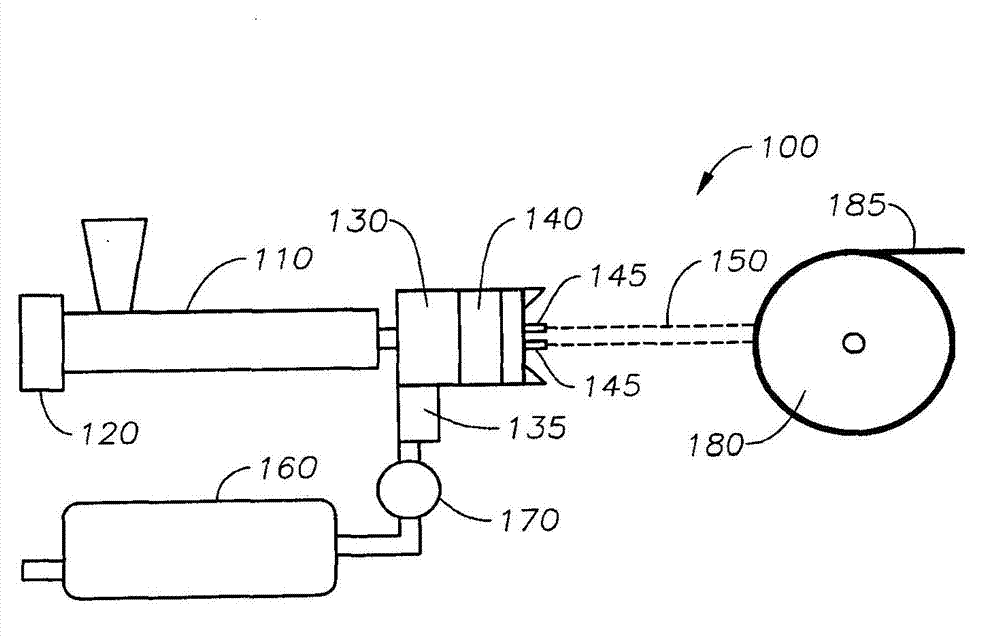

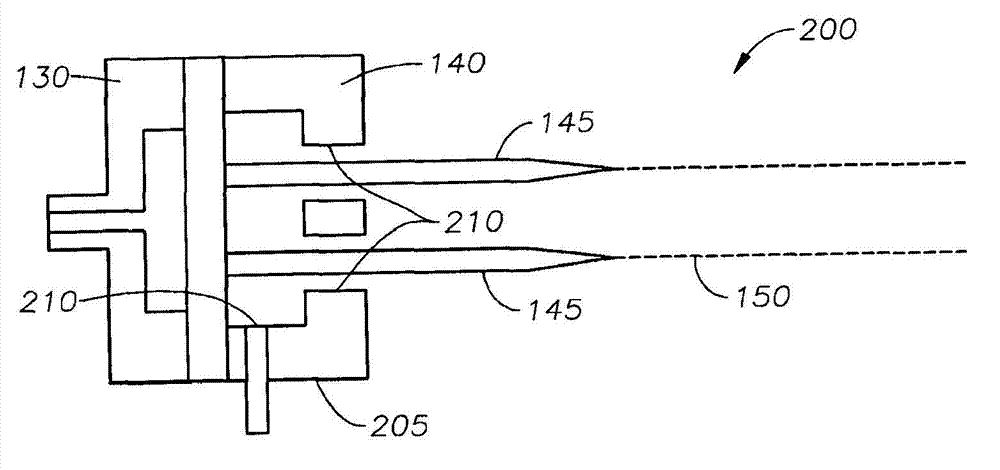

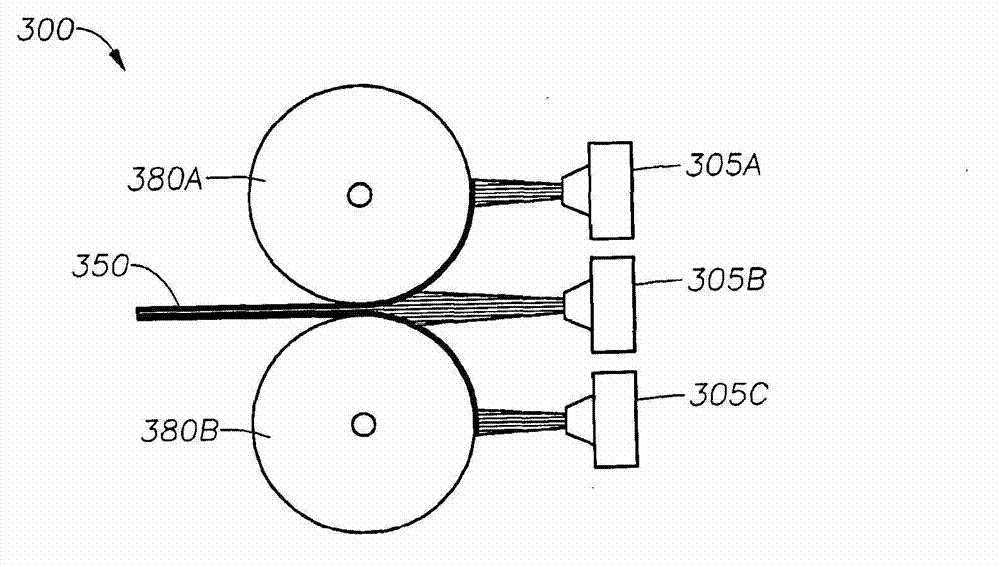

A fiber-based adsorbent and a related method of manufacture are provided. The fiber-based adsorbent includes polymer fibers with grafted side chains and an increased surface area per unit weight over known fibers to increase the adsorption of dissolved metals, for example uranium, from aqueous solutions. The polymer fibers include a circular morphology in some embodiments, having a mean diameter of less than 15 microns, optionally less than about 1 micron. In other embodiments, the polymer fibers include a non-circular morphology, optionally defining multiple gear-shaped, winged-shaped or lobe-shaped projections along the length of the polymer fibers. A method for forming the fiber-based adsorbents includes irradiating high surface area polymer fibers, grafting with polymerizable reactive monomers, reacting the grafted fibers with hydroxylamine, and conditioning with an alkaline solution. High surface area fiber-based adsorbents formed according to the present method demonstrated a significantly improved uranium adsorption capacity per unit weight over existing adsorbents.

Owner:UT BATTELLE LLC

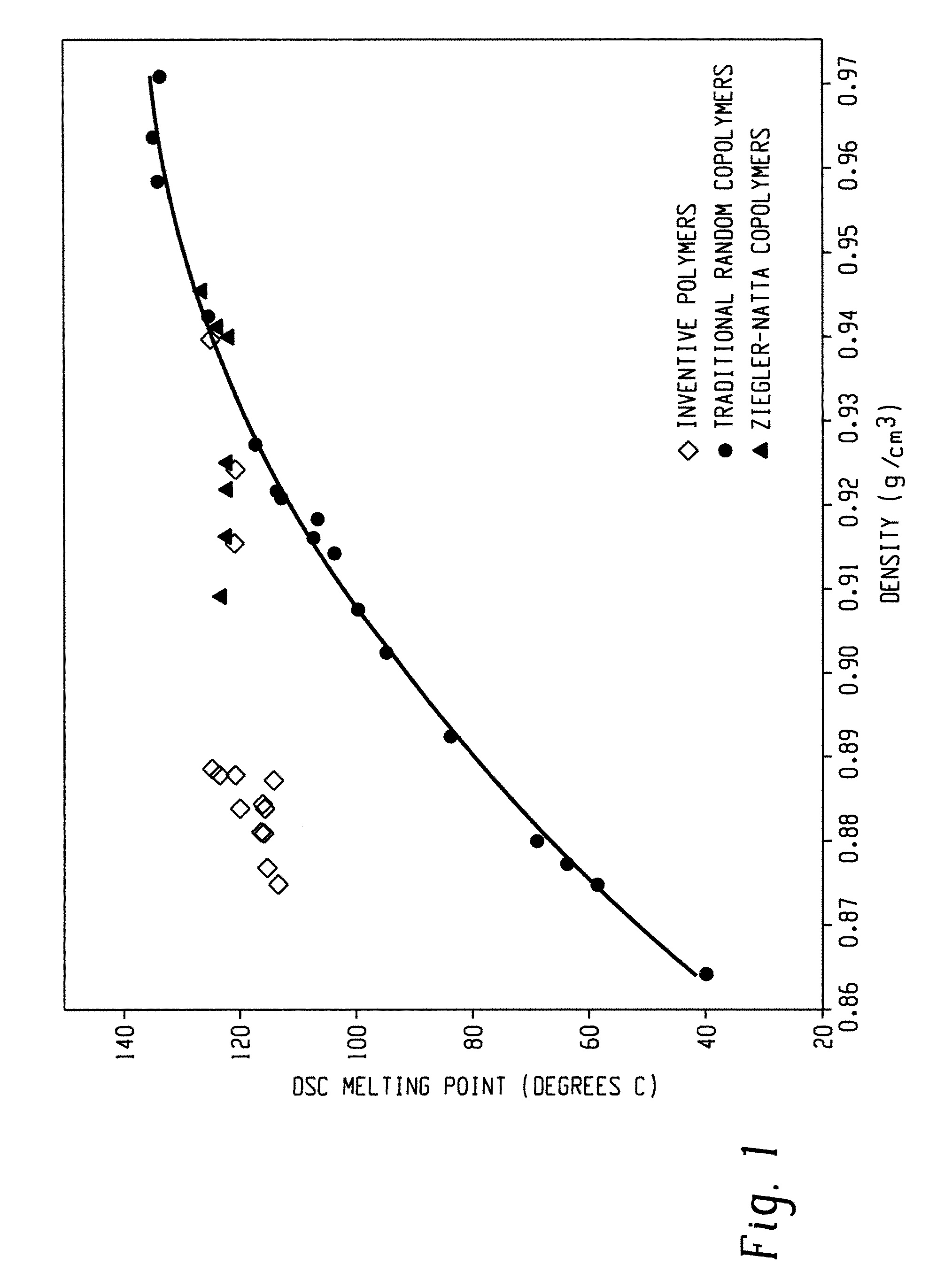

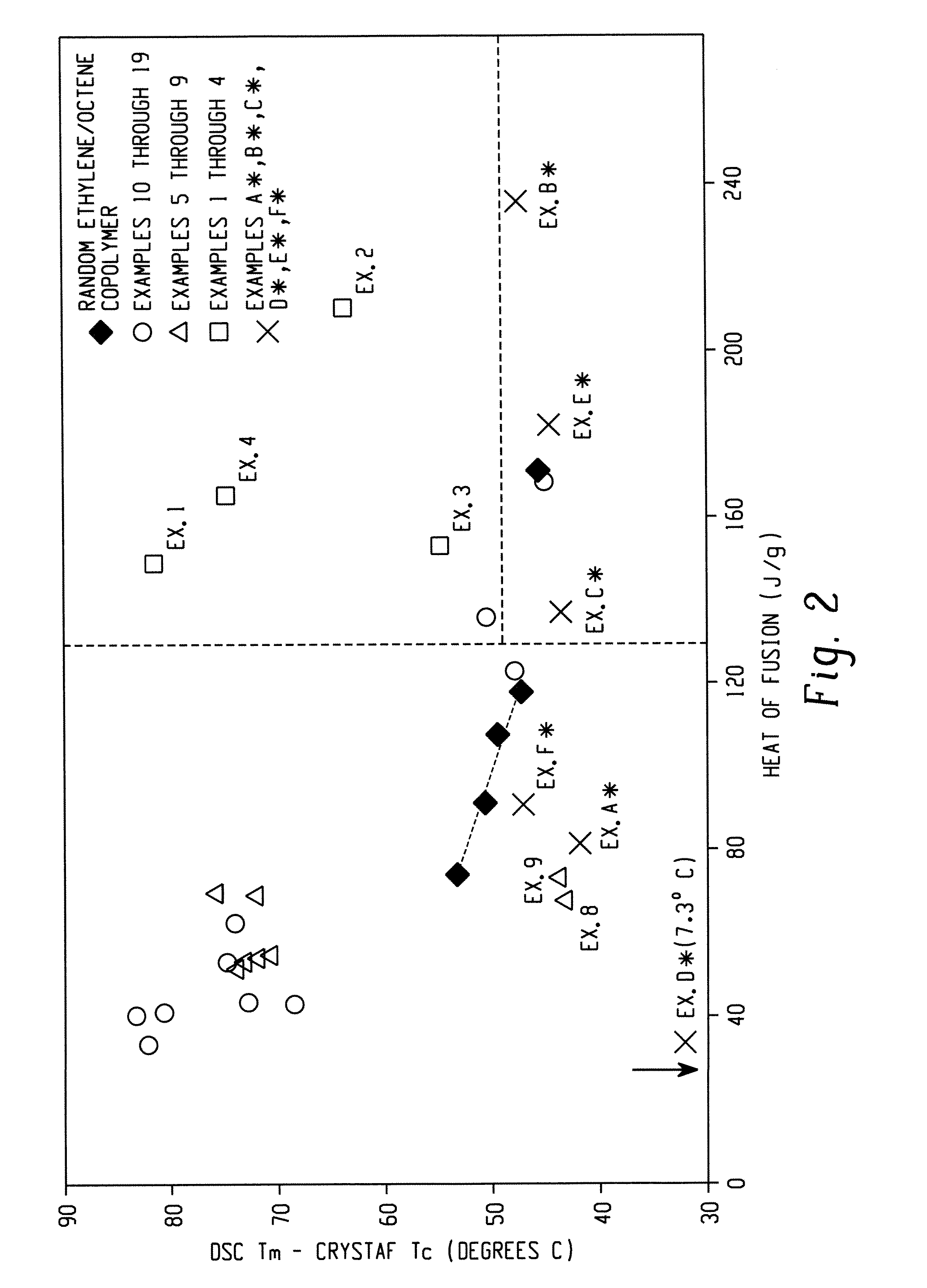

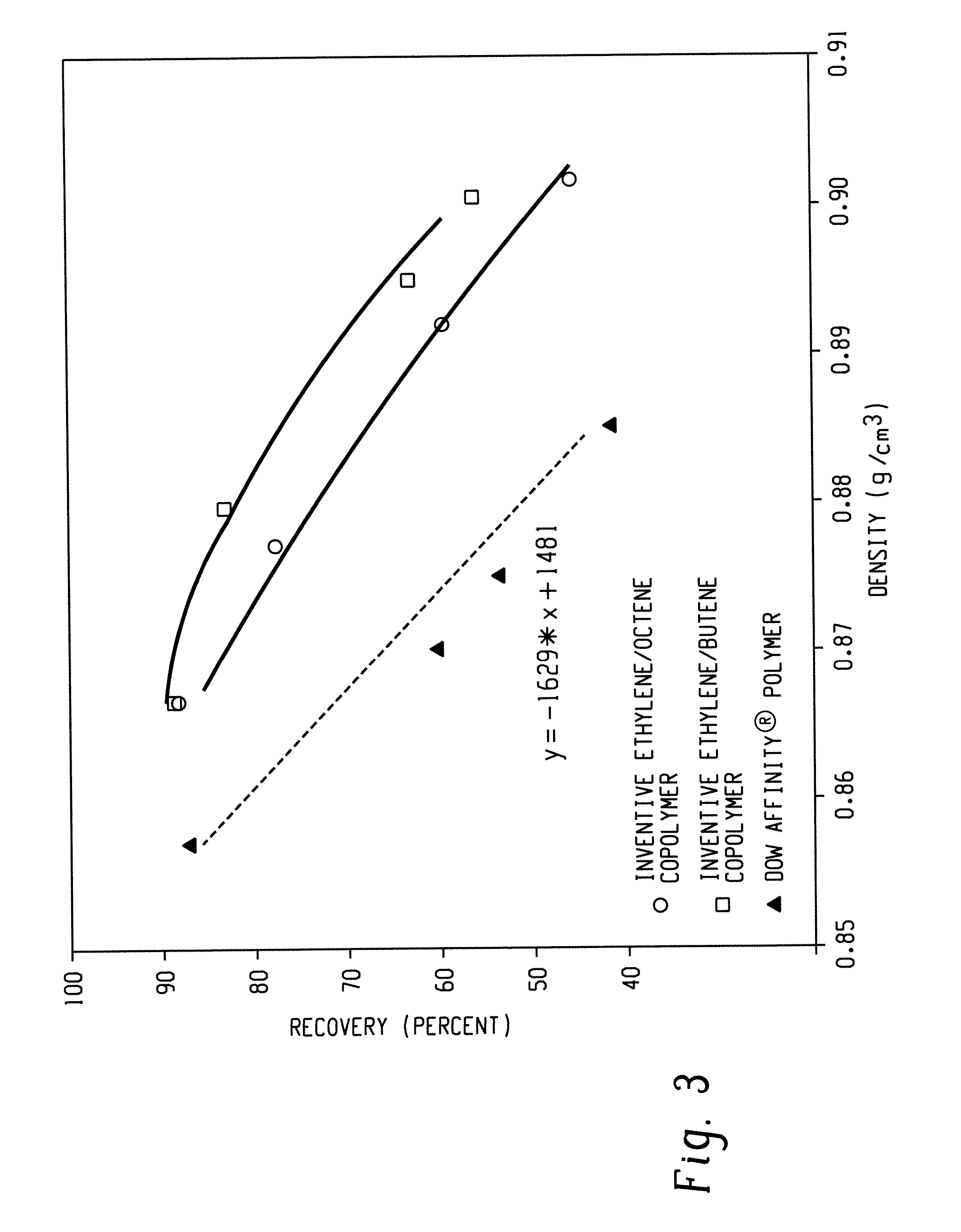

Fibers and Knit Fabrics Comprising Olefin Block Interpolymers

InactiveUS20080081854A1Reduce defectsReduce buildWeft knittingRadioactive element fibre treatmentFiberChemistry

Owner:DOW GLOBAL TECH LLC

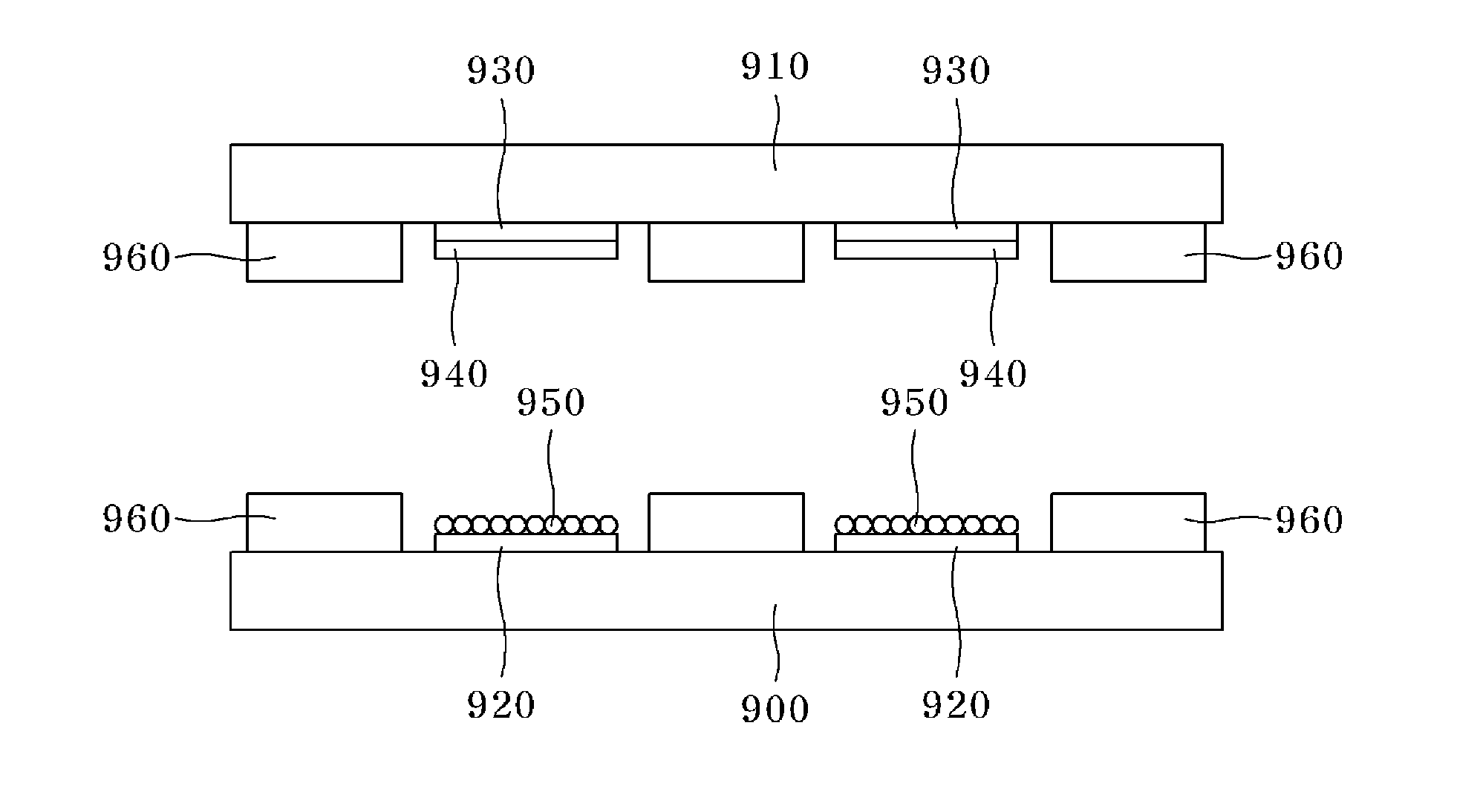

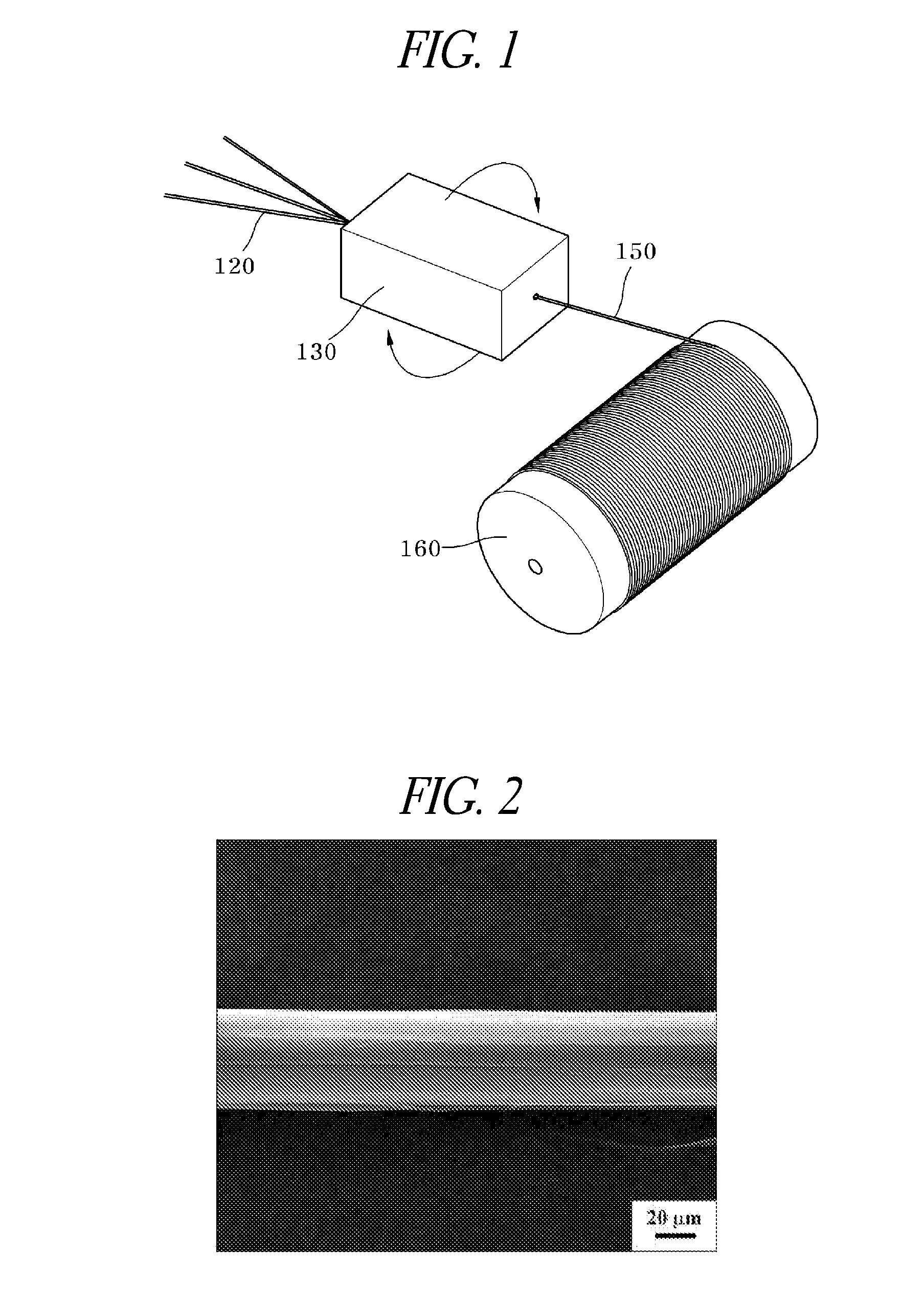

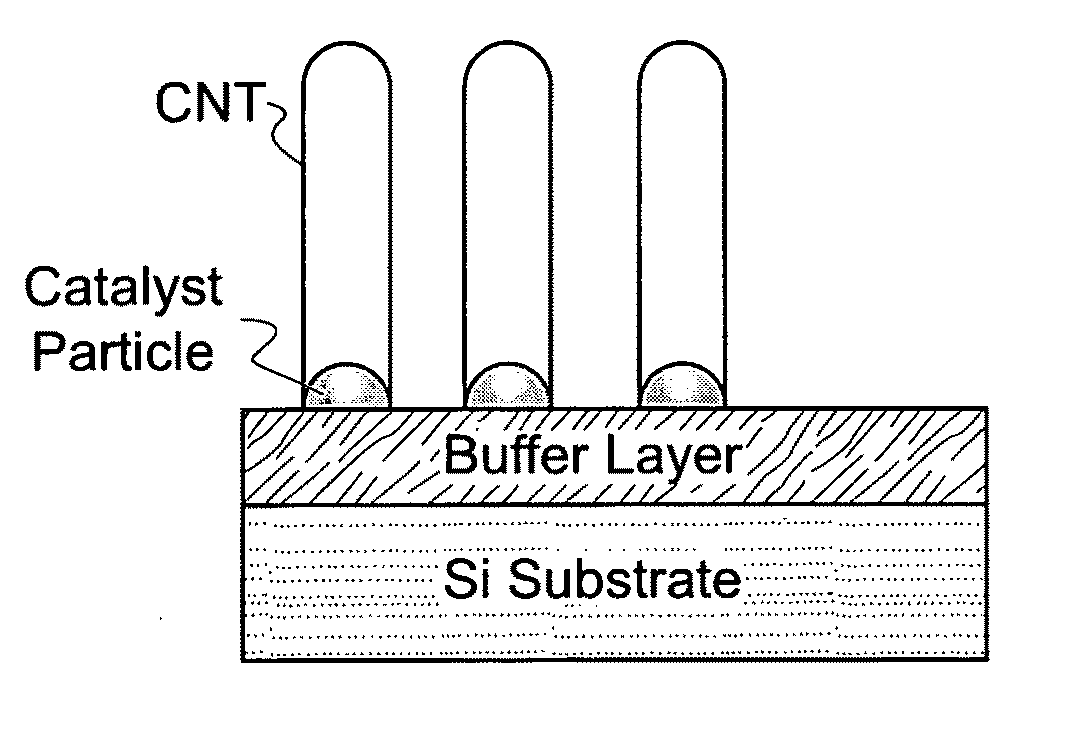

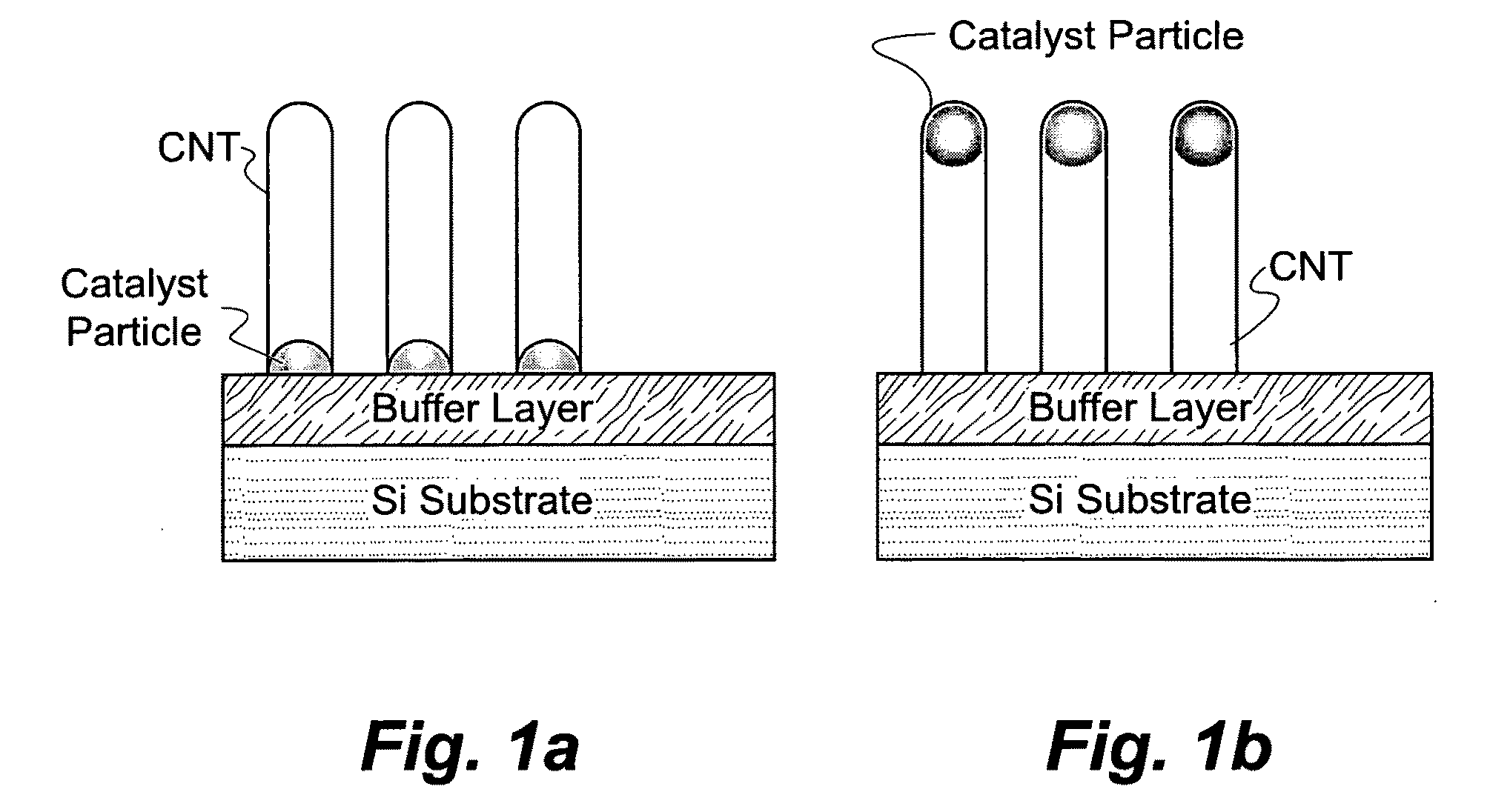

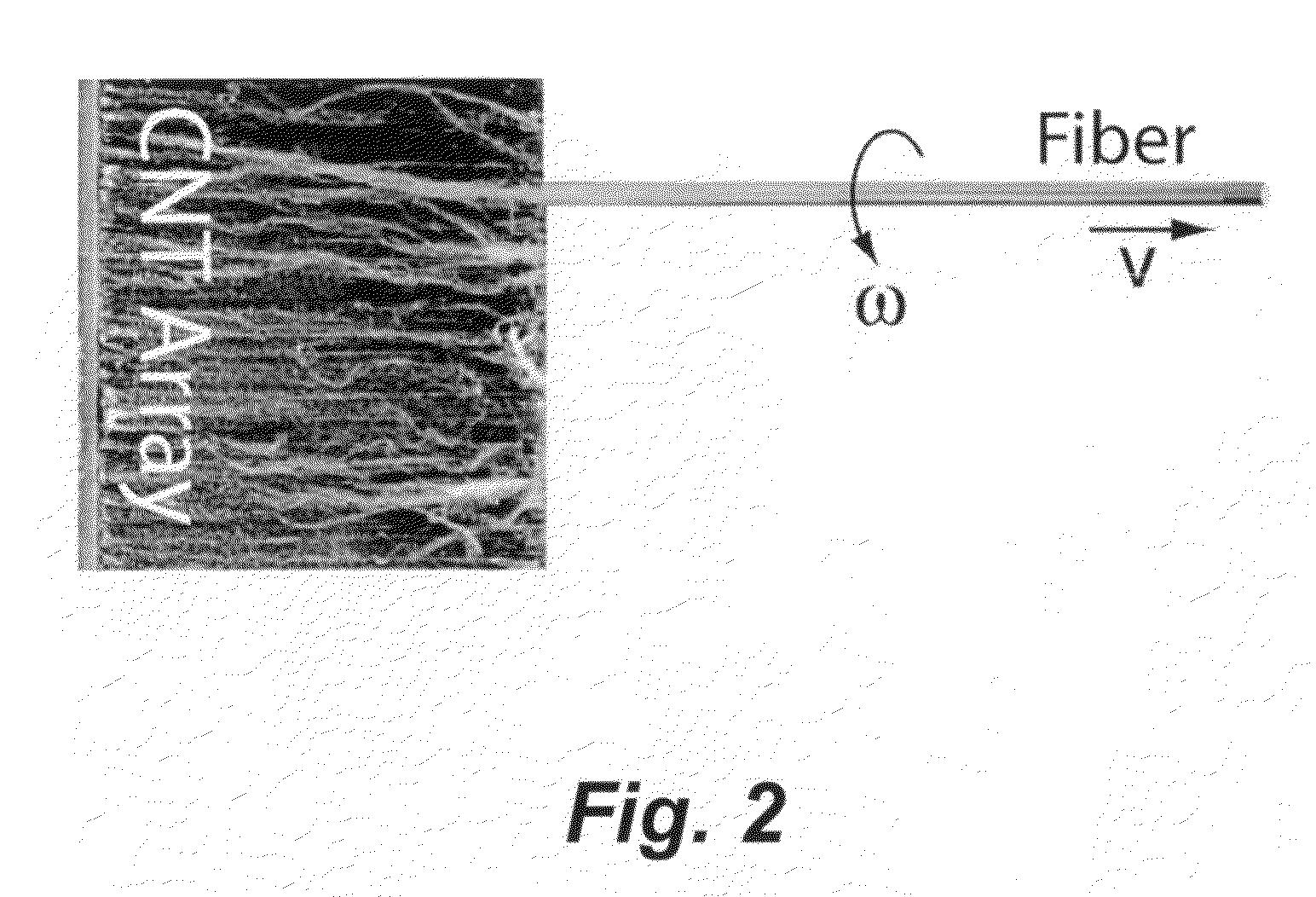

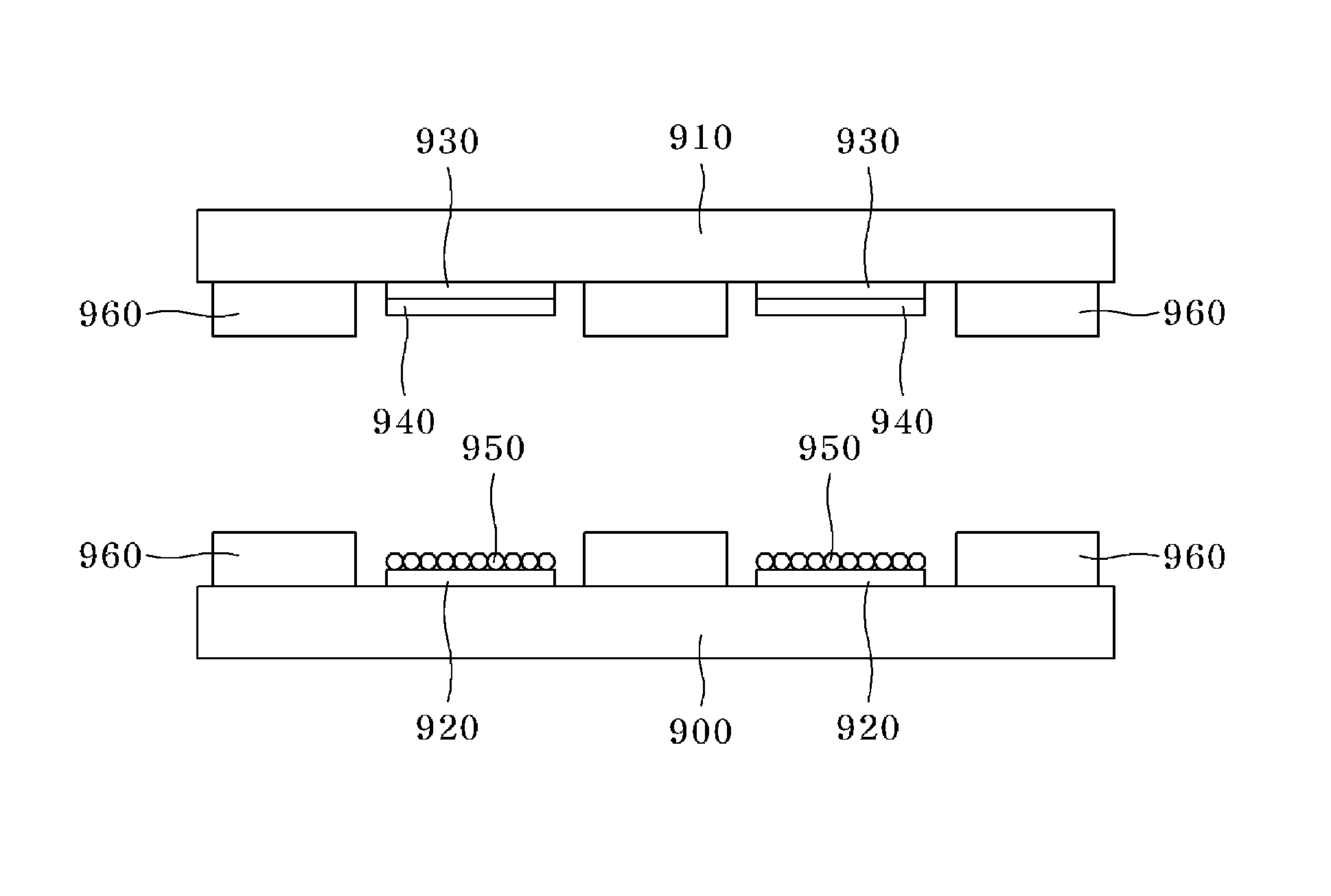

Surface field electron emitters using carbon nanotube yarn and method of fabricating carbon nanotube yarn thereof

ActiveUS20100181896A1Improve homogeneityGood reproducibilityCarbon fibresThermionic cathodesCarbon nanotube yarnLight emitting device

Surface field electron emitters using a carbon nanotube yarn and a method of fabricating the same are disclosed. To fabricate the carbon nanotube yarn for use in fabrication of simple and efficient carbon nanotube field electron emitters, the method performs densification of the carbon nanotube yarn during rotation of a plying unit and heat treatment of the carbon nanotube yarn that has passed through the plying unit without using organic or inorganic binders or polymer pastes. The method fabricates the carbon nanotube yarn with excellent homogeneity and reproducibility through a simple process. The carbon nanotube yarn-based surface field electron emitters can be applied to various light emitting devices.

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND

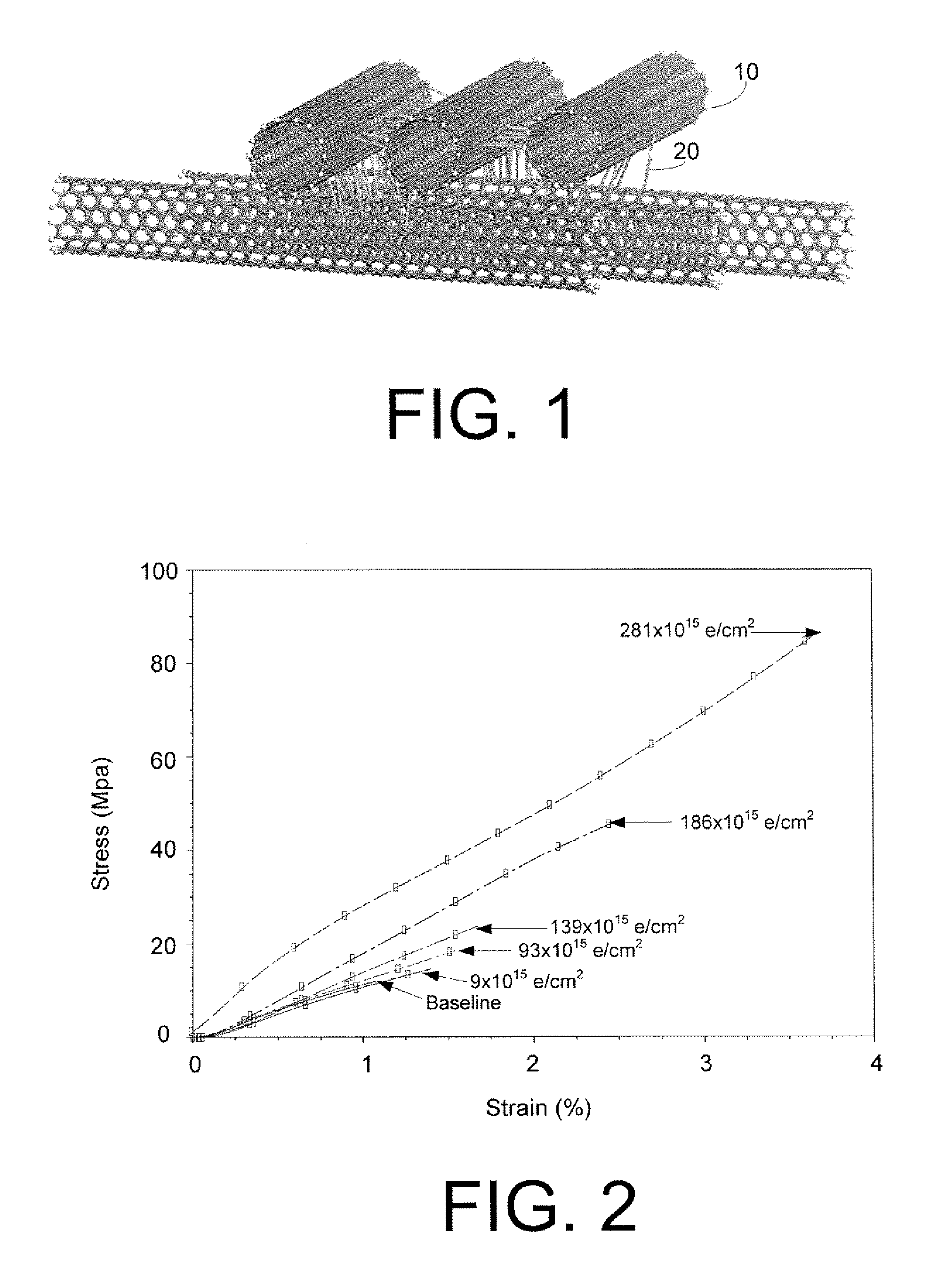

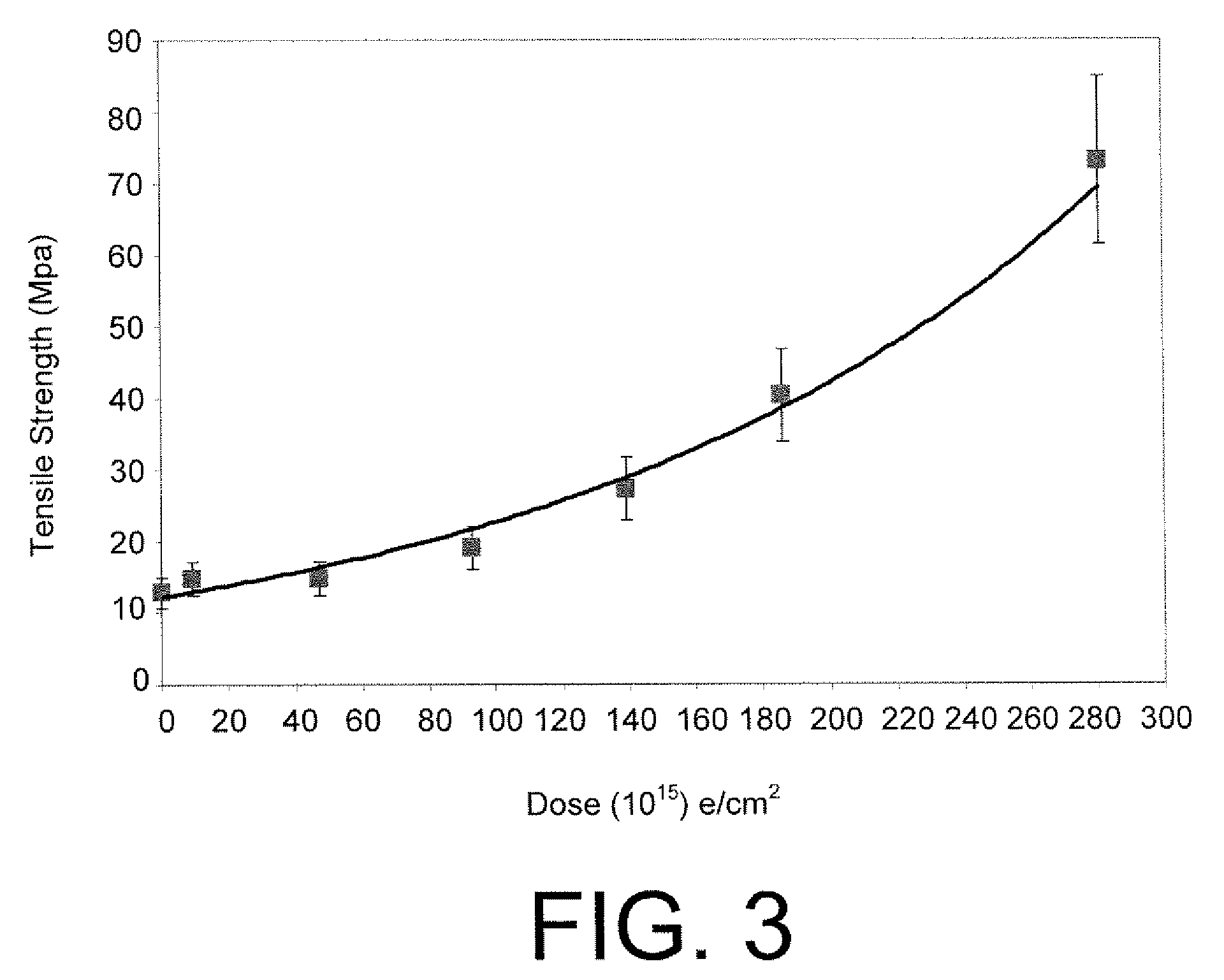

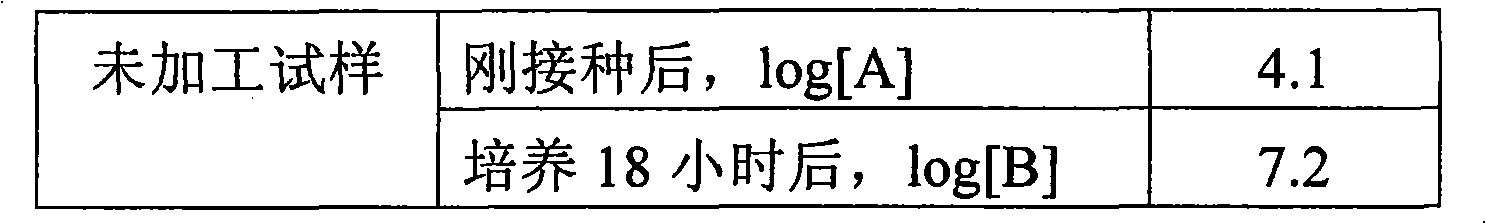

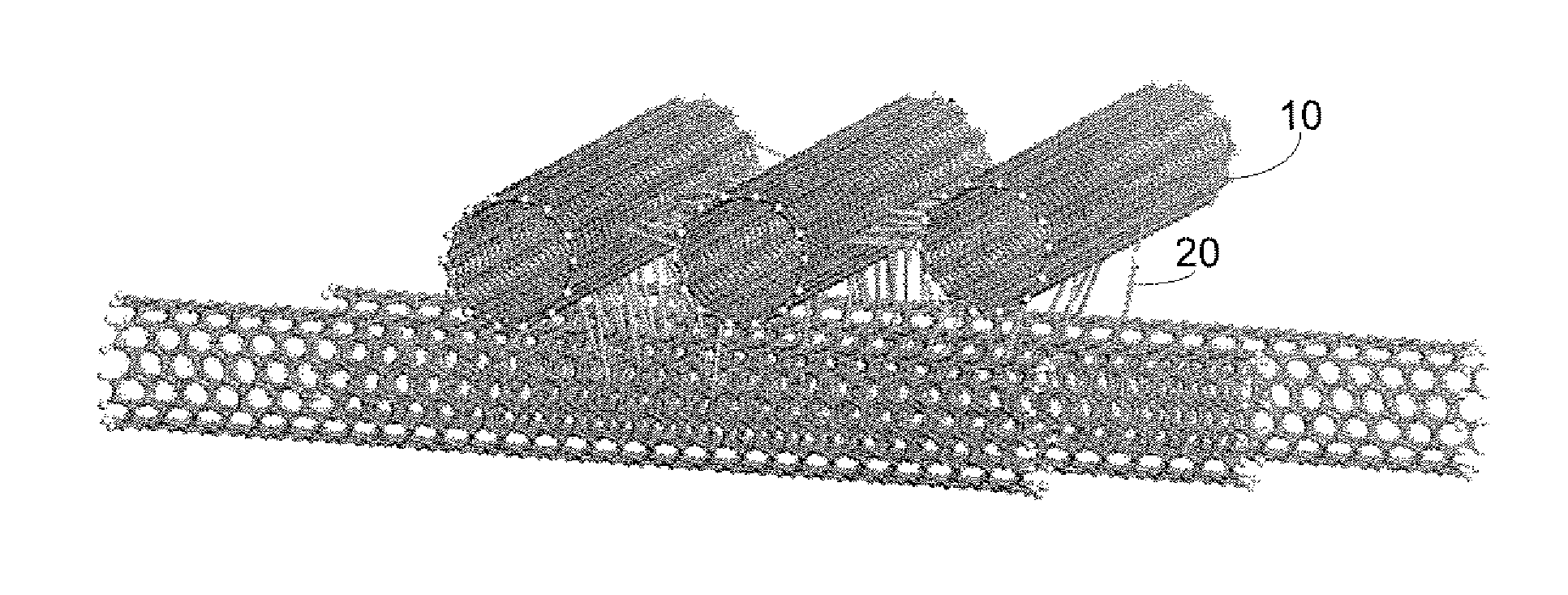

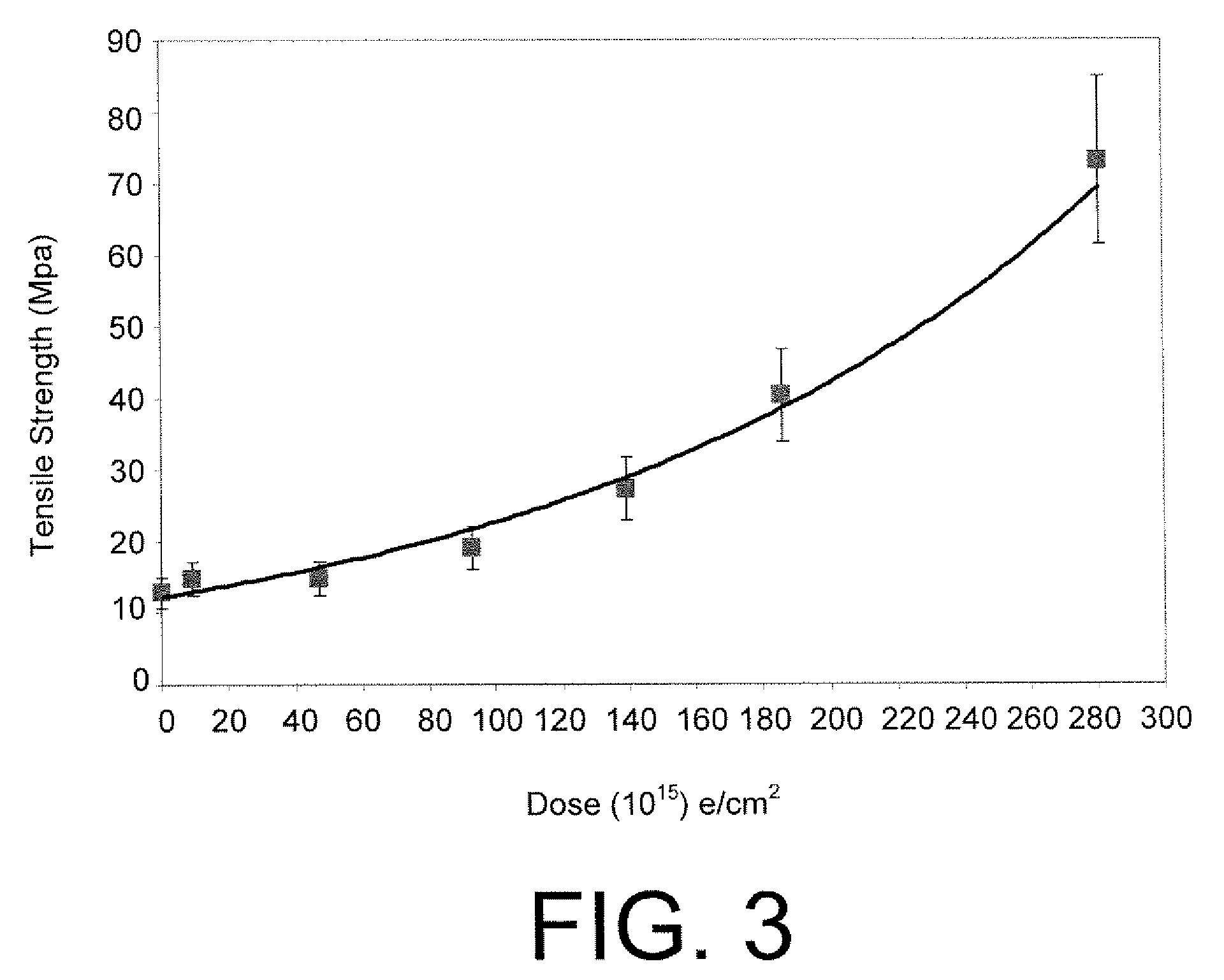

Method for functionalization of nanoscale fiber films

InactiveUS7862766B2Increase modulusHigh strengthMaterial nanotechnologyCarbon compoundsFiberNanofiber

Methods are provided for functionalizing a macroscopic film comprised of nanoscale fibers by controlled irradiation. The methods may include the steps of (a) providing a nanoscale fiber film material comprising a plurality of nanoscale fibers (which may include single wall nanotubes, multi-wall nanotubes, carbon nanofibers, or a combination thereof); and (b) irradiating the nanoscale fiber film material with a controlled amount of radiation in the open air or in a controlled atmosphere. The step of irradiating the nanoscale fiber film material is effective to functionalize the plurality of nanoscale fibers. Irradiated nanoscale fiber films are also provided having improved mechanical and electrical conducting properties.

Owner:FLORIDA STATE UNIV RES FOUND INC

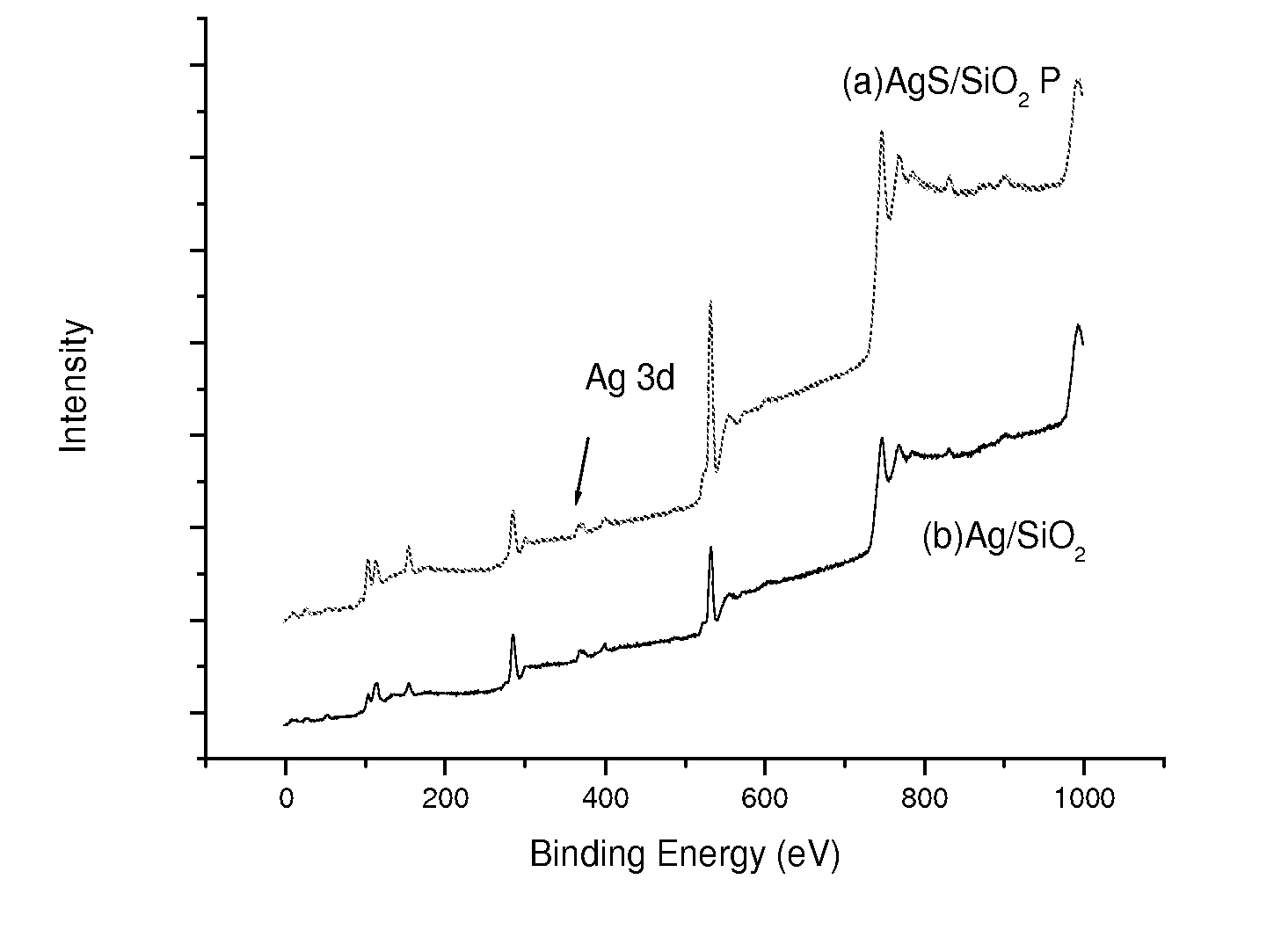

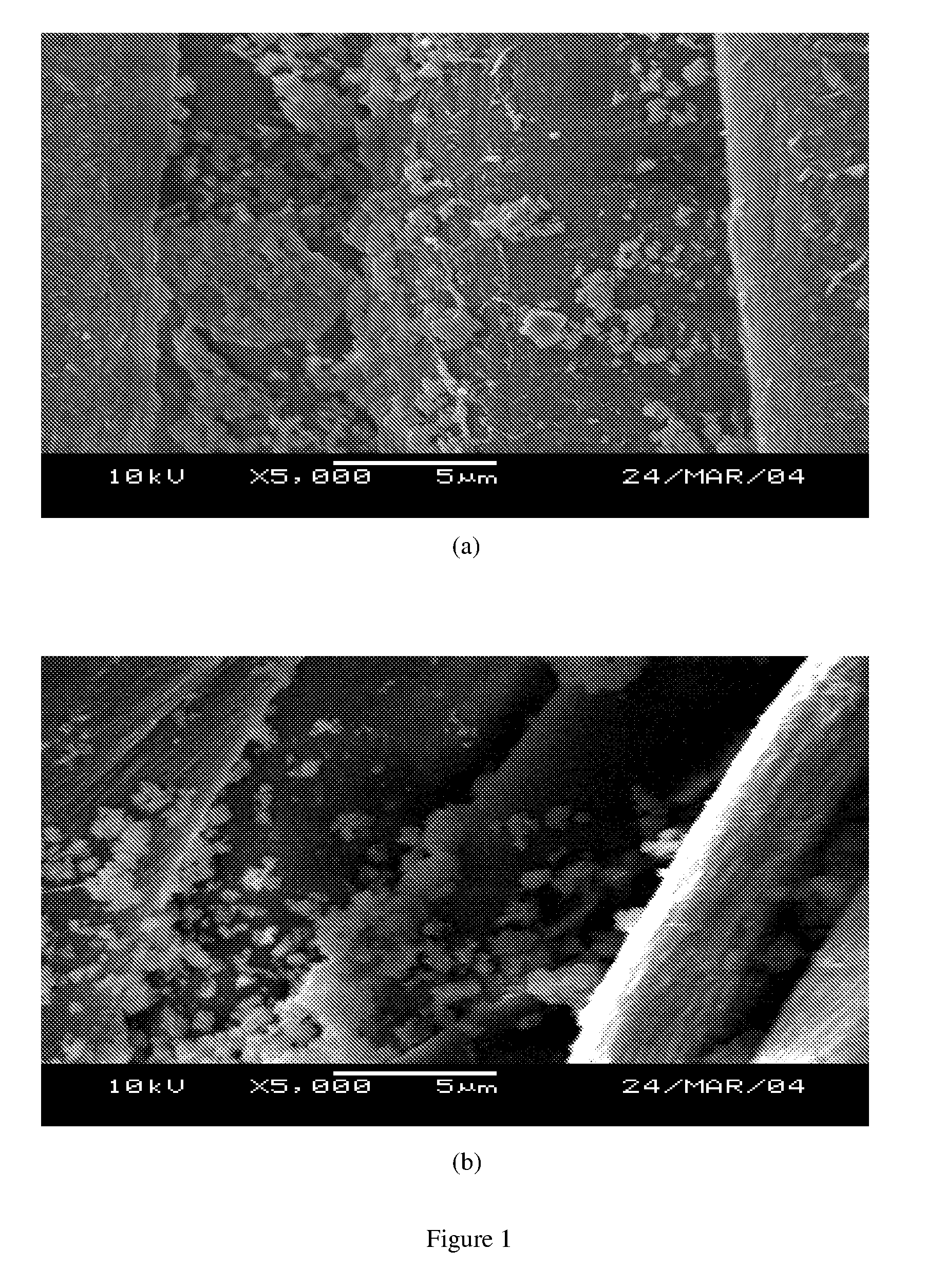

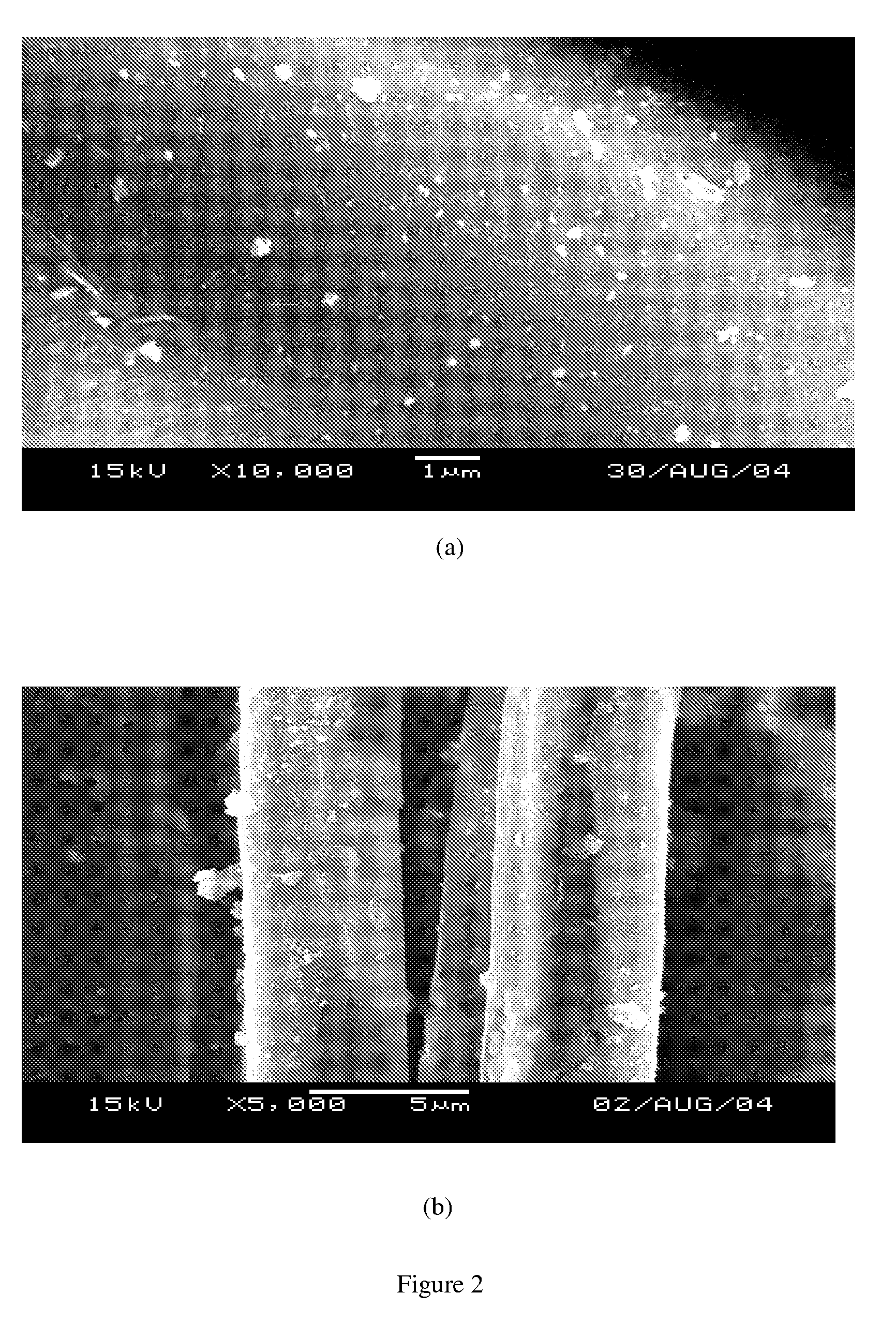

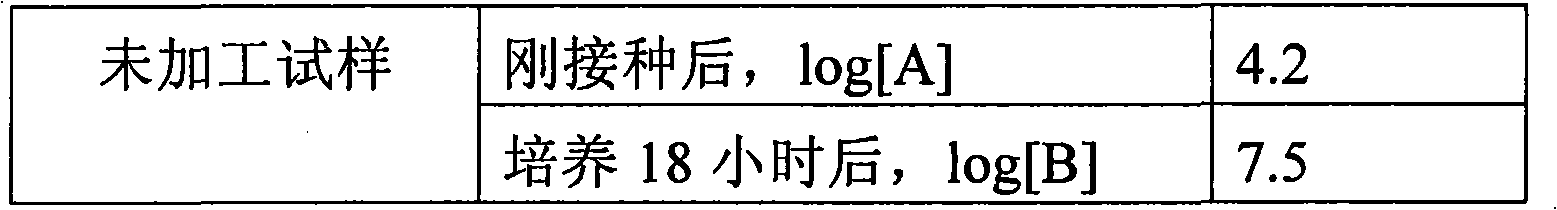

Radiation Method for Fabrication of Nano-sized Compound Antibacterial Fabric Textile

InactiveUS20090092645A1Improve antibacterial propertiesAntibacterial agentsBiocideFiberPolyethylene terephthalate glycol

The invention discloses an innovative process to produce highly antibacterial nano-composite fabric textile containing silver metal compound. The process mainly uses high-energy D-ray radiation to modify silver type of bactericides and graft or crosslink them onto Nylon or PET fiber surface to produce excellent antibacterial textile products. The mechanism uses silver nano-compound as performance additive and through Co-60 irradiation technique reduces and firmly fastens silver particles onto Nylon or PET (Polyethylene Terephthalate) fiber material. Because the inorganic silver type bactericides actively interact with enzymes in bacteria or destroy cell walls to achieve good bactericidal effect, the radiation process does not need initiators or other additives. So the process is simple and effective. The test results prove excellent bactericidal power and potential value in household or medical textile products.

Owner:WU TE HSING +5

Virtual wireless multitrack recording system

ActiveUS7929902B1Radioactive element fibre treatmentTransmission systemsComputer hardwareData Corruption

Disclosed are systems and methods for wirelessly recording multi-track audio files without the data corruption or loss of data that typically occurs with wireless data transmission. In some aspects of the present invention, each performer is equipped with a local audio device capable of locally recording the respective performer's audio while also transmitting it to a master recorder. The locally recorded audio may then be used to repair or replace any audio lost or corrupted during transmission to the master recorder. Such repair or replacement may be performed electronically or via playback of the locally recorded audio. In other aspects of the present invention, a master recorder is not required since all locally recorded audio may be combined or otherwise processed post-recording. Locally recorded audio may include identifiers to aid in post-recording identification of such audio. A multi-memory unit is also provided to facilitate manipulation and processing of audio files.

Owner:ZAXCOM

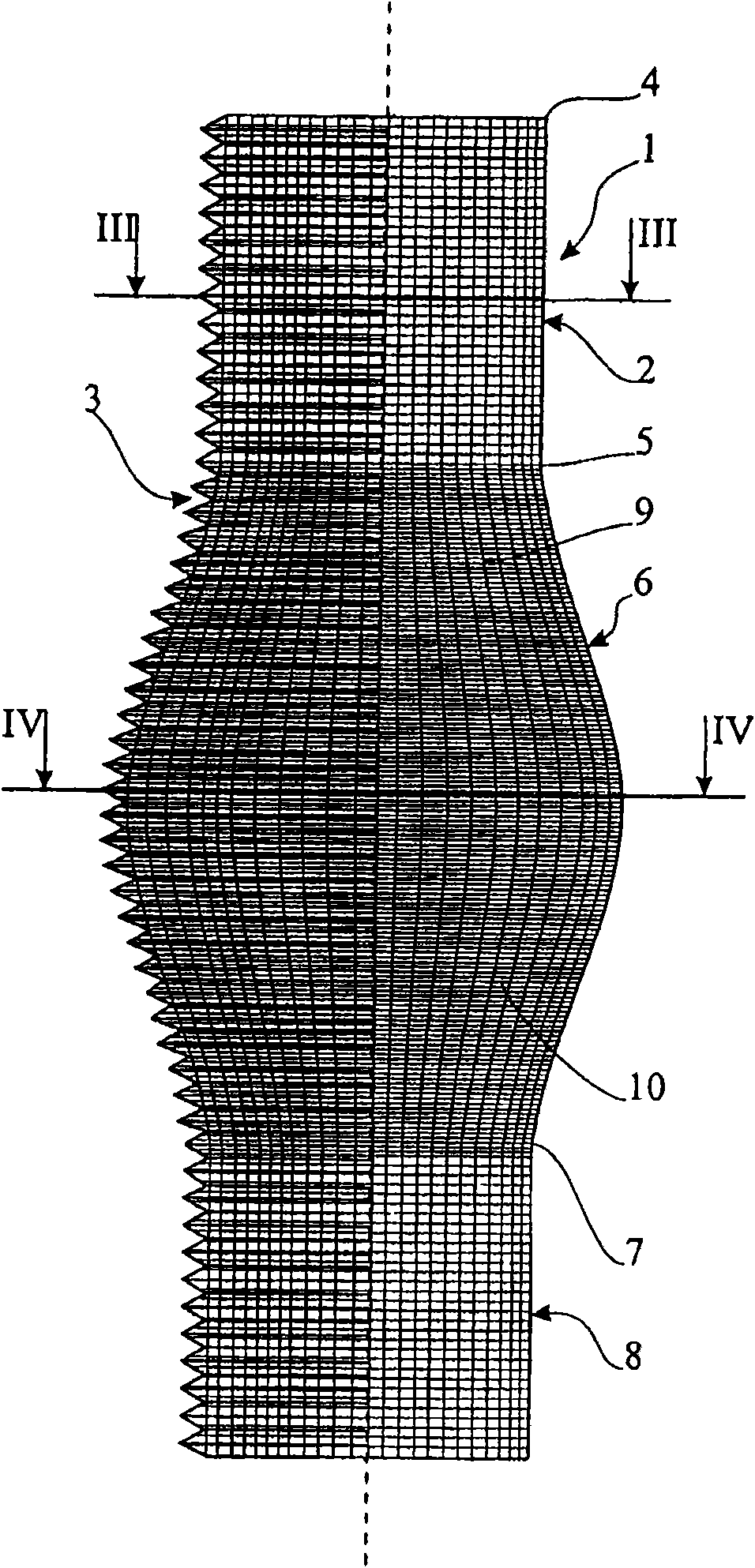

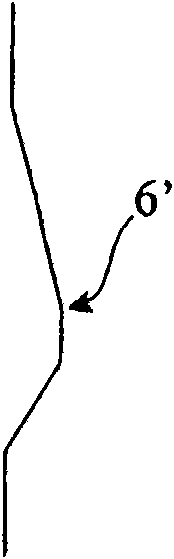

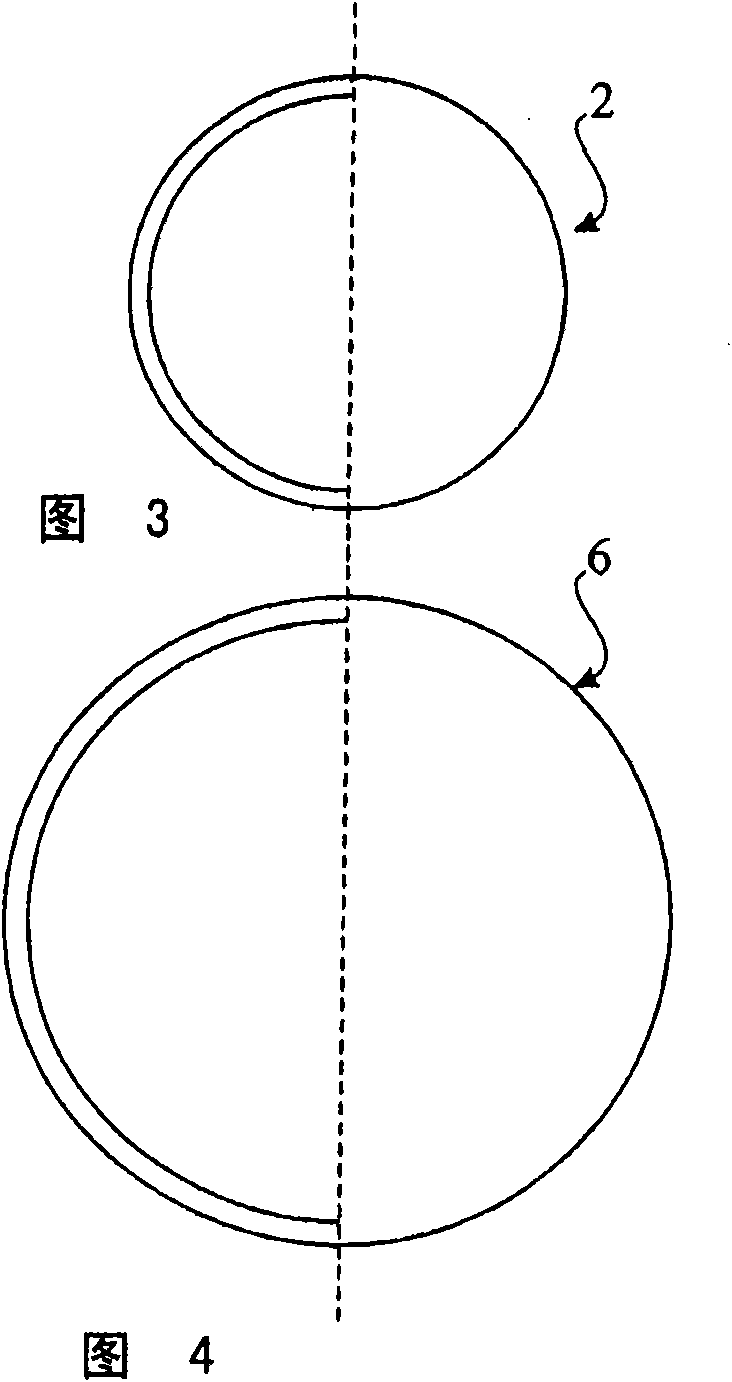

Woven aortic sinus prosthesis having a bulb

The invention relates to a woven aortic sinus prosthesis (1) having a first substantially cylindrical section (2) not close to the heart, which possibly transitions into an aortic arch, a second section (6) forming a bulb, which is expanded in comparison to the first section with regard to the diameter and which connects to the first section (2), and possibly a third substantially cylindrical section (8) close to the heart, which connects to the bulb section (6).

Owner:AESCULAP AG

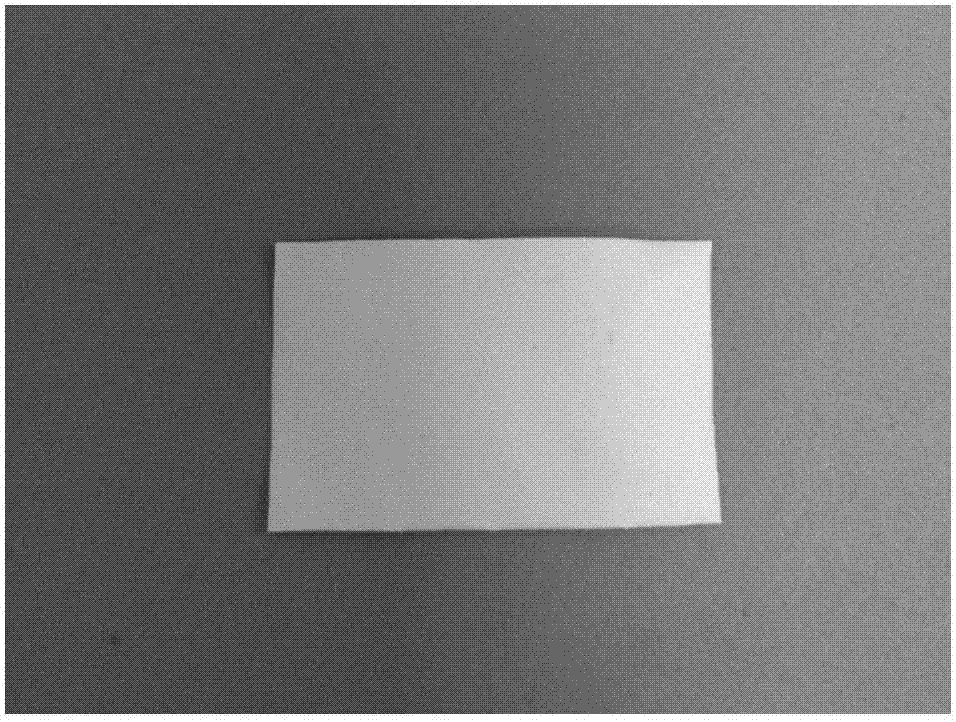

Preparation method of medical fiber wound dressing prepared through composition of natural polysaccharide derivatives and natural polymers

InactiveCN107469127AReduce stimulationImprove regenerative abilityRadioactive element fibre treatmentPharmaceutical delivery mechanismElectrospinningBiocompatibility Testing

The invention provides a preparation method of medical fiber wound dressing prepared through composition of natural polysaccharide derivatives and natural polymers and belongs to the field of medical dressing preparation. The preparation method of the medical fiber wound dressing prepared through composition of the natural polysaccharide derivatives and the natural polymers comprises steps as follows: natural polysaccharides are chemically modified, the modified natural polysaccharide derivatives and natural polymers are composited, the modified natural polysaccharide derivatives are obtained, fibers are prepared with an electrostatic spinning technology, the composite fibers are subjected to a crosslinking reaction under the irradiation of an ultraviolet lamp, cobalt-60 gamma ray radiation sterilization, segmentation and packaging are performed, and the medical fiber wound dressing prepared through composition of the natural polysaccharide derivatives and the natural polymers is obtained. The medical wound dressing is prepared from natural and renewable raw materials, is rich in source, adopts a simple preparation process, can realize extensive production, is controllable in strength, safe, environment-friendly and good in breathability and biocompatibility and has the functions of stopping bleeding, diminishing inflammation, resisting allergy and the like.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Virtual wireless multitrack recording system

Disclosed are systems and methods for wirelessly recording multi-track audio files without the data corruption or loss of data that typically occurs with wireless data transmission. In some aspects of the present invention, each performer is equipped with a local audio device capable of locally recording the respective performer's audio while also transmitting it to a master recorder. The locally recorded audio may then be used to repair or replace any audio lost or corrupted during transmission to the master recorder. Such repair or replacement may be performed electronically or via playback of the locally recorded audio. In other aspects of the present invention, a master recorder is not required since all locally recorded audio may be combined or otherwise processed post-recording. Locally recorded audio may include identifiers to aid in post-recording identification of such audio. A multi-memory unit is also provided to facilitate manipulation and processing of audio files.

Owner:ZAXCOM

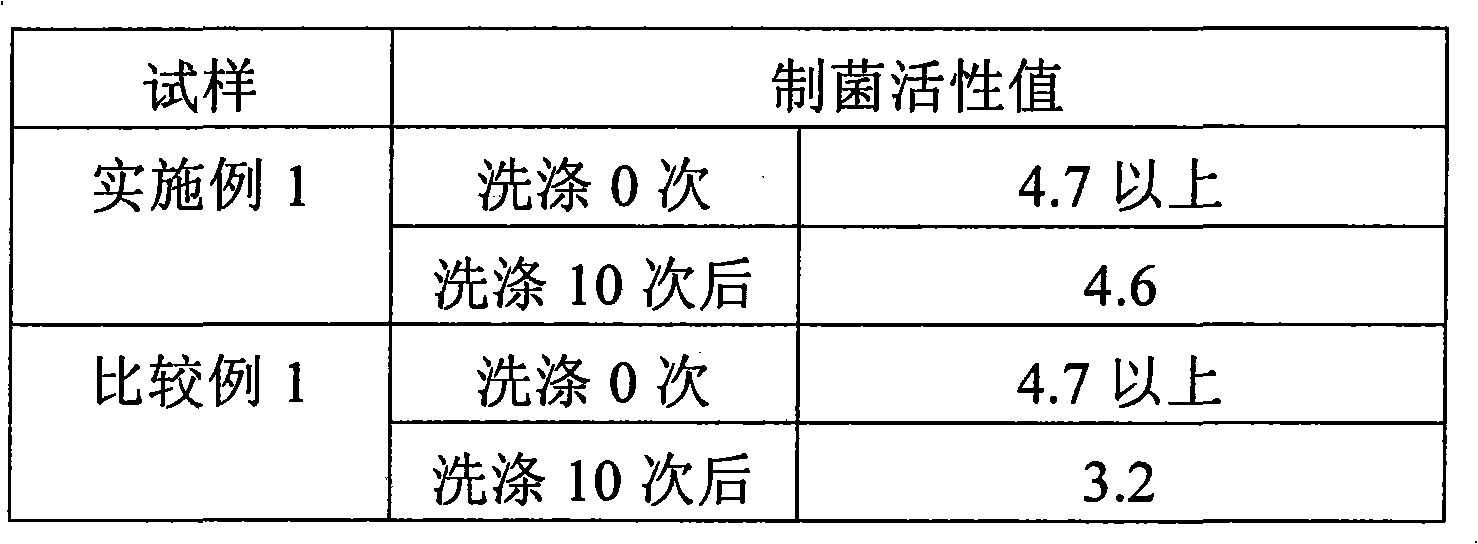

Method for antimicrobial treatment of fiber, process for production of antimicrobial fiber, and antimicrobial fiber

InactiveCN101896663AFirmly attachedImprove wash resistanceRadioactive element fibre treatmentChemicalsIridiumRhenium

Disclosed are a method for the antimicrobial treatment of a fiber and a process for the production of an antimicrobial fiber, each of which is characterized by immersing the fiber in an aqueous solution containing a noble metal ion or a noble metal complex and irradiating the aqueous solution with gamma-ray or electron beam. In the method for the antimicrobial treatment of a fiber and the processfor the production of an antimicrobial fiber, the noble metal constituting the noble metal ion or the noble metal complex is at least one noble metal selected from the group consisting of gold, silver, platinum, palladium, ruthenium, rhodium, iridium and rhenium. Also disclosed is an antimicrobial fiber produced by the process.

Owner:OSAKA UNIV

Surface treatment method for recycled carbon fibers

InactiveCN111235864AImprove surface activityImprove broad applicabilityRadioactive element fibre treatmentUltrasonic/sonic fibre treatmentFiberPolymer science

The invention relates to a surface treatment method for recycled carbon fibers. The method comprises the following steps of (1) carrying out cleaning and drying on a carbon fiber fabric to be recovered to obtain carbon fiber fibrils; and (2) placing the carbon fiber fibrils or a pretreatment liquid containing the carbon fiber fibrils in an electron irradiation source to be subjected to electron beam irradiation processing to complete. Compared to the prior art, the method is applicable to recycled carbon fibers with different surface residual resins and obtained through different recycling methods, has high wide applicability, and can shorten the treatment time, reduce the energy consumption in the surface modification reaction process, and effectively improve the interface performance between the carbon fibers and a resin matrix; and in addition, the modified recycled carbon fibers have relatively high surface activity and relatively low surface damage, are suitable for being used asa reinforcement to be re-prepared into a composite material for reuse, and the development of the high value-added reuse technology of the recycled carbon fibers is effectively promoted.

Owner:SHANGHAI JIAO TONG UNIV

Method for Functionalization of Nanoscale Fiber Films

InactiveUS20100028639A1Increase modulusHigh tensile strengthMaterial nanotechnologyCarbon compoundsFiberFluence

Methods are provided for functionalizing a macroscopic film comprised of nanoscale fibers by controlled irradiation. The methods may include the steps of (a) providing a nanoscale fiber film material comprising a plurality of nanoscale fibers (which may include single wall nanotubes, multi-wall nanotubes, carbon nanofibers, or a combination thereof); and (b) irradiating the nanoscale fiber film material with a controlled amount of radiation in the open air or in a controlled atmosphere. The step of irradiating the nanoscale fiber film material is effective to functionalize the plurality of nanoscale fibers. Irradiated nanoscale fiber films are also provided having improved mechanical and electrical conducting properties.

Owner:FLORIDA STATE UNIV RES FOUND INC

Flame retardant processing method, and cellulosic fiber material imparted with flame retardancy

InactiveCN101932766AImprove flame retardant performanceSufficiently maintain the feelRadioactive element fibre treatmentHeat resistant fibresFiberCellulose

Owner:KURASHIKI BOSEKI KK

A modifying method of soft wollastonite fibers

InactiveCN105544206AGood flexibilityIncrease profitInorganic fibres/flakesRadioactive element fibre treatmentPaper sheetSiloxane

The invention belongs to the field of inorganic mineral fibers and particularly relates to a modifying method of soft wollastonite fibers. The method is characterized in that the soft wollastonite fibers are prepared by adding wollastonite fibers into a sodium hydroxide solution, performing alkaline treatment to allow surfaces of the wollastonite fibers to be in a honeycomb microcellular structure, adding polydimethylsiloxane, stirring, mixing to obtain the modified wollastonite fibers, subjecting the modified wollastonite fibers, polyethyleneimine and polymaleic acid to gamma-ray radiation under functions of an initiator to allow the polymaleic acid and the polyethyleneimine to be subjected to copolymerization and to be grafted to the surfaces of the wollastonite fibers, and adding a cationic surface modifying agent for surface covering. Surface activity of the wollastonite fibers can be improved through the method, softness and dispersity of the wollastonite fibers are improved, and bonding force between the wollastonite fibers and plant fibers is increased. The soft wollastonite fibers are capable of obviously improving softness of paper and allowing paper to be good in hand feel and light in weight when the soft wollastonite fibers are used for papermaking.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

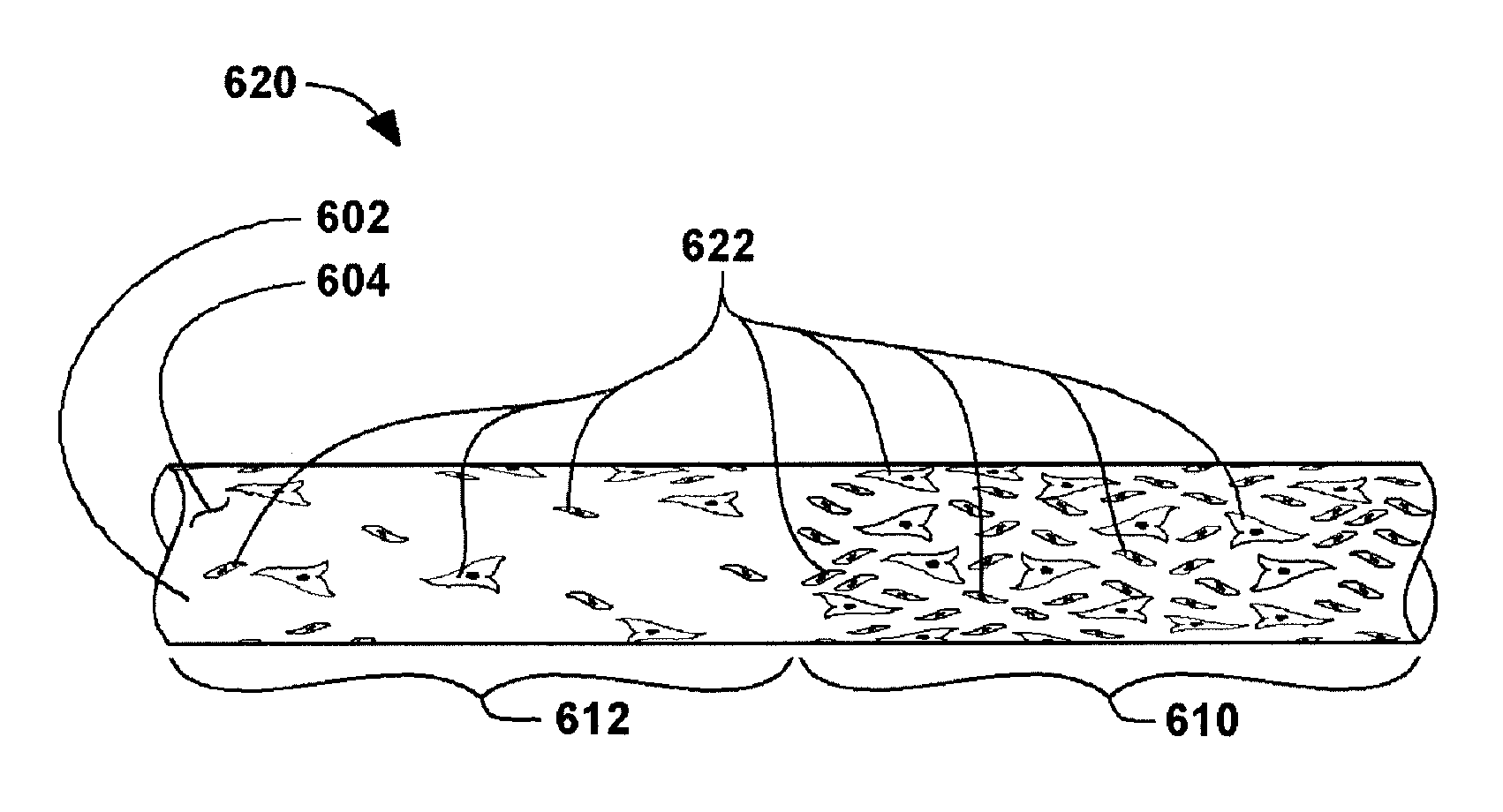

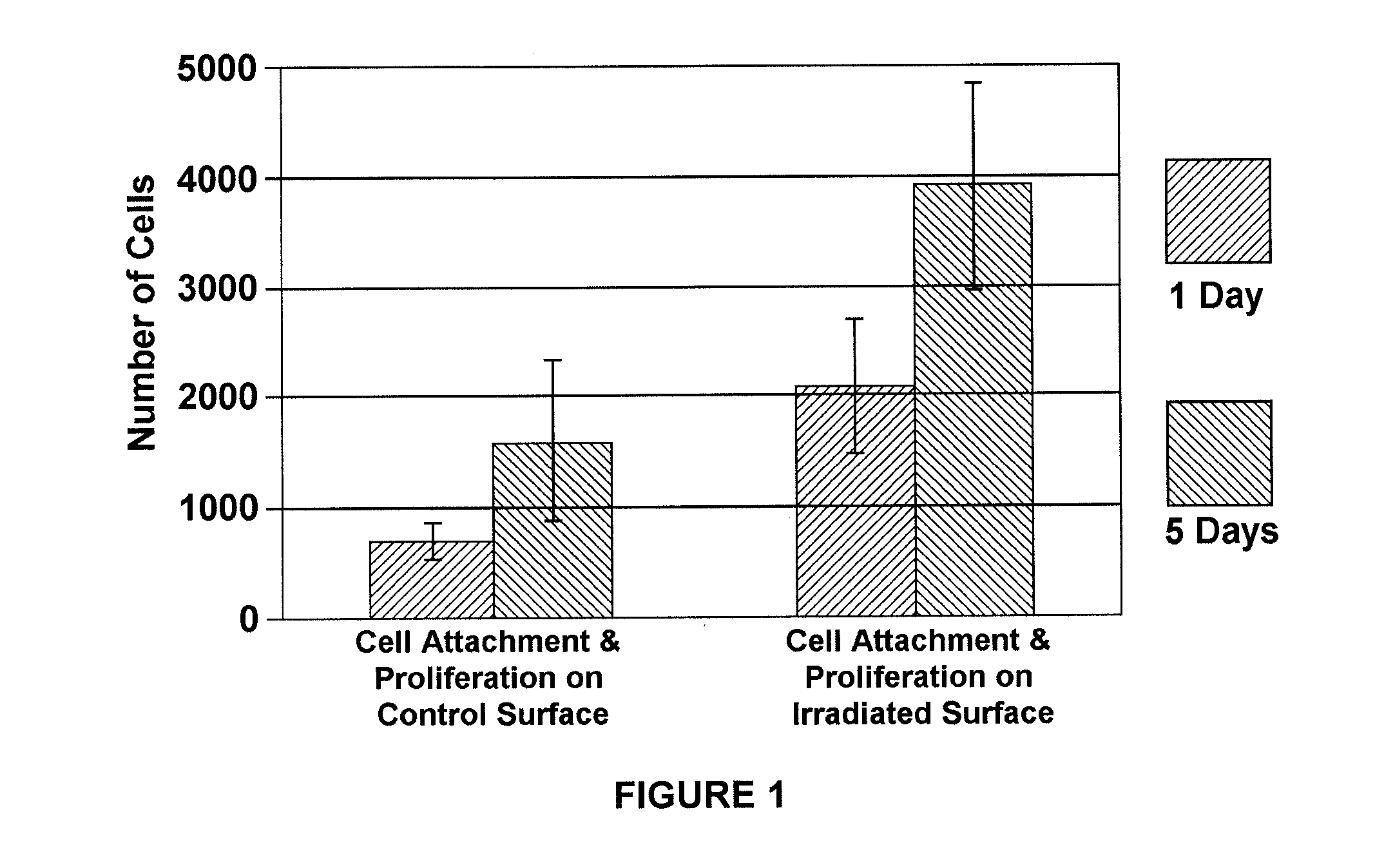

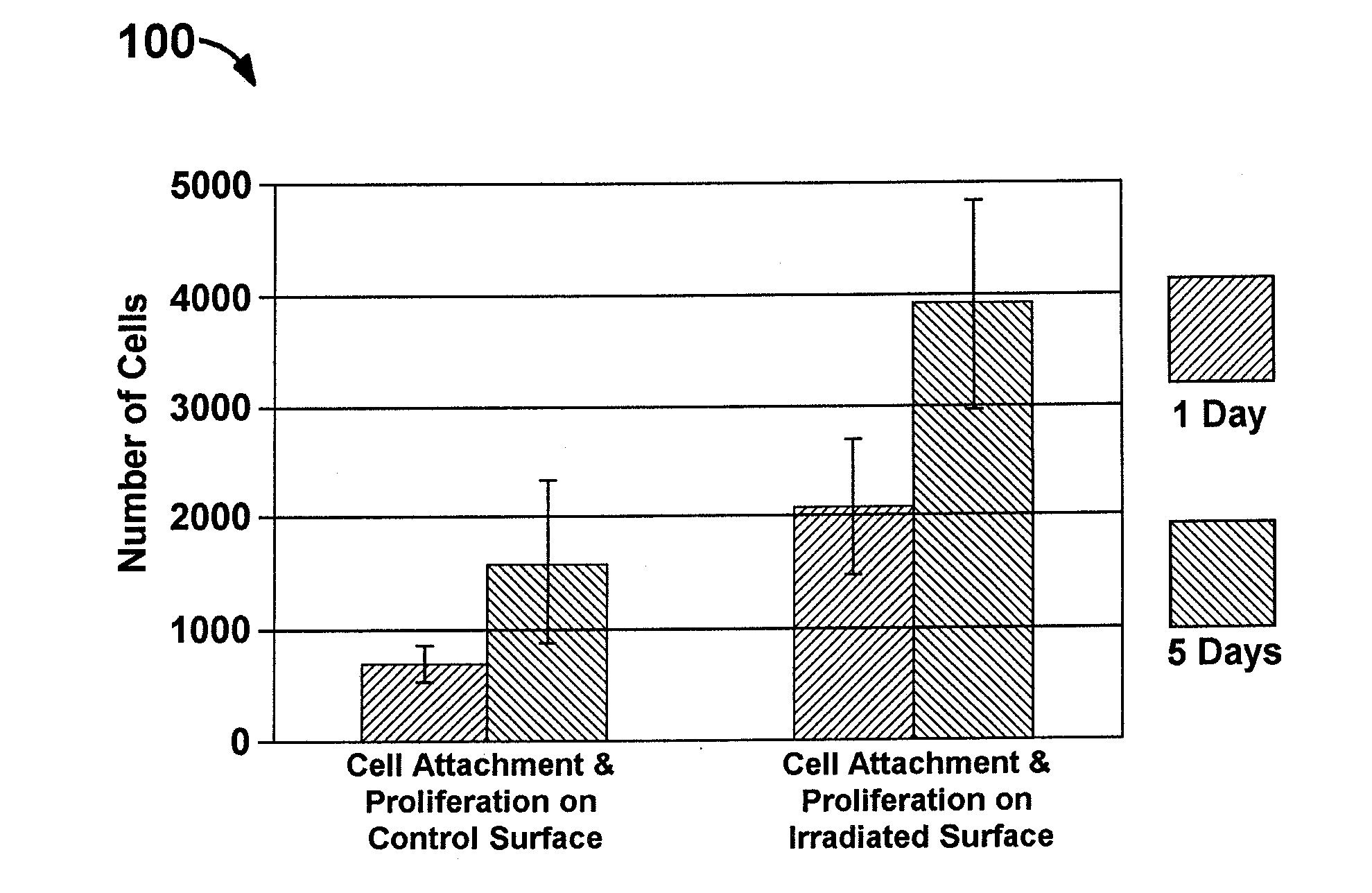

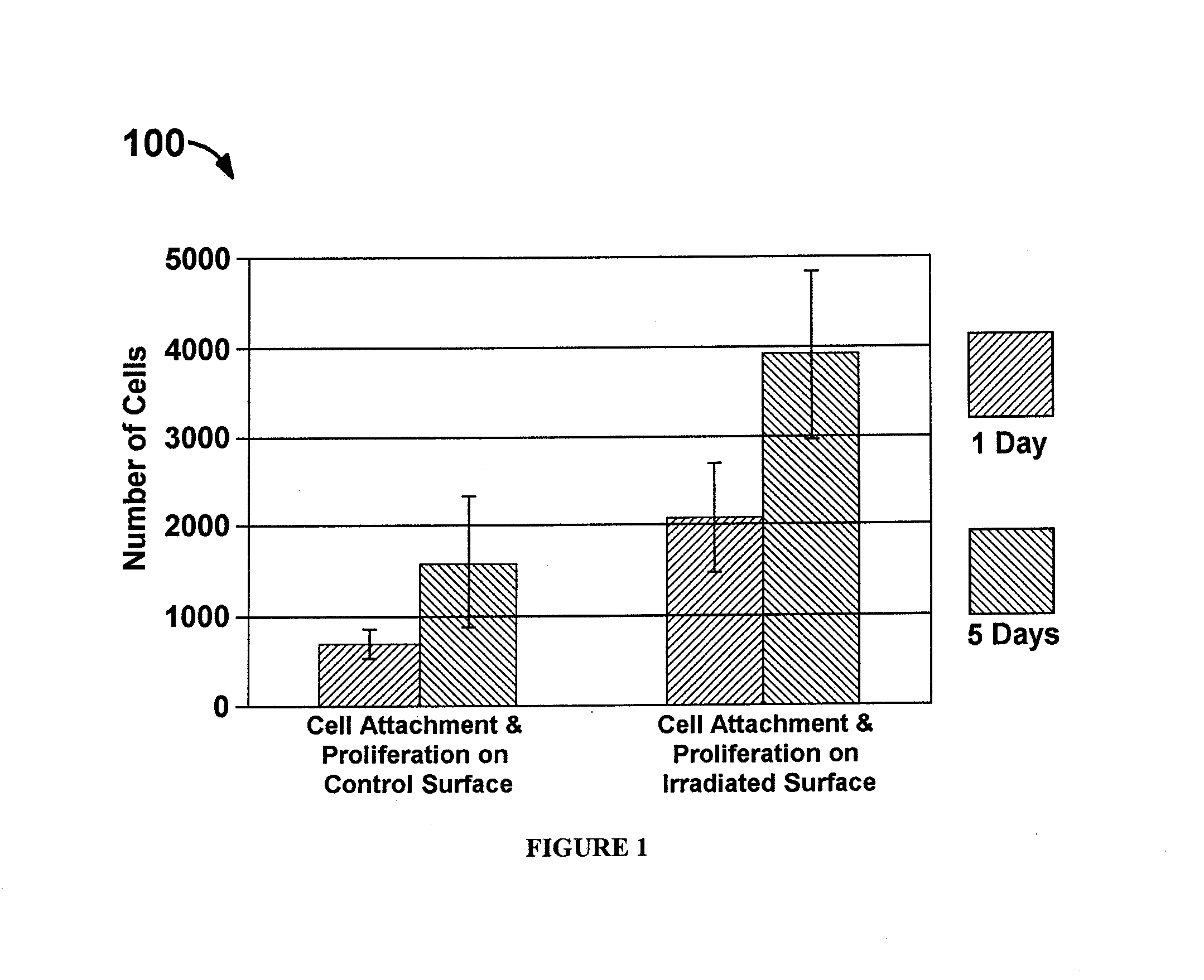

Methods for improving the bioactivity characteristics of a surface and objects with surfaces improved thereby

InactiveUS20140074159A1Avoid excessive controlAvoid problemsSuture equipmentsPharmaceutical delivery mechanismGas cluster ion beamGeneral surgery

A method for improving bioactivity of a surface of a surgical suture and sutures prepared thereby provides forming a gas-cluster ion-beam (GCIB) in a reduced-pressure chamber, introducing a surgical suture into the reduced-pressure chamber, and irradiating at least a first portion of the surface of said surgical suture with a GLIB derived beam.

Owner:EXOGENESIS CORP

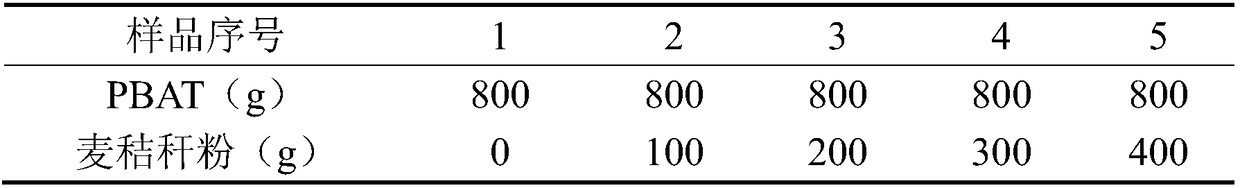

Method to prepare straw fiber/PBAT (poly(butylene adipate-co-terephthalate)) composite based on radiation modification

ActiveCN108410145ASimple processImprove surface activityRadioactive element fibre treatmentVegetal fibresFiberAdipate

The invention discloses a method to prepare straw fiber / PBAT (poly(butylene adipate-co-terephthalate)) composite based on radiation modification, wherein after a coupling agent is sprayed to straw fiber, the straw fiber is treated by means of radiation modification; the radiation modification process has the advantages of good simplicity, environmental friendliness, and availability for reaction at normal temperature; the straw fiber is treated via radiation modification, surface gloss of the straw fiber is decreased, and surface activity of the straw fiber is improved; by adding the straw fiber to PBAT resin, it is possible to effectively improve straw fiber and PBAT interfacial compatibility. The straw fiber-reinforced PBAG composite prepared herein has improved mechanical properties andhas a wider applicable range.

Owner:河南省科学院同位素研究所有限责任公司

Increasing the specific strength of spun carbon nanotube fibers

Owner:TRIAD NAT SECURITY LLC

Wear-resistant bacteriostatic bamboo-fiber rib fabric and processing method thereof

InactiveCN110714265AImprove comfortGood flexibilityRadioactive element fibre treatmentWeft knittingBiotechnologyCarbon fibers

The invention discloses a wear-resistant bacteriostatic bamboo-fiber rib fabric and a processing method thereof. The rib fabric is prepared from, by weight, 38-44 parts of cotton fiber, 45-50 parts ofbamboo fiber, 20-25 parts of flax fiber, 12-15 parts of bacteriostatic anti-odor fiber, 8-10 parts of polyimide fiber, 6-8 parts of algae carbon fibre, and 4-8 parts of modal fiber. The rib fabric isprepared from various fibers, the bamboo fiber has good breathability, water absorptivity, high wear resistance, good dying property and the like, and has functions such as natural antibacterial property, bacteriostat, mite controlling, deodorizing and ultraviolet resistance; particularly, the average bacteriostasis rate of the bacteriostatic anti-odor fiber to staphylococcus aureus, candida sporogenes and colibacillus is equal to or higher than 99%, and thus excellent antibacterial and deodorizing effect can be achieved.

Owner:苏州神马织针器材有限公司

Fiber-based adsorbents having high adsorption capacities for recovering dissolved metals and methods thereof

A fiber-based adsorbent and a related method of manufacture are provided. The fiber-based adsorbent includes polymer fibers with grafted side chains and an increased surface area per unit weight over known fibers to increase the adsorption of dissolved metals, for example uranium, from aqueous solutions. The polymer fibers include a circular morphology in some embodiments, having a mean diameter of less than 15 microns, optionally less than about 1 micron. In other embodiments, the polymer fibers include a non-circular morphology, optionally defining multiple gear-shaped, winged-shaped or lobe-shaped projections along the length of the polymer fibers. A method for forming the fiber-based adsorbents includes irradiating high surface area polymer fibers, grafting with polymerizable reactive monomers, reacting the grafted fibers with hydroxylamine, and conditioning with an alkaline solution. High surface area fiber-based adsorbents formed according to the present method demonstrated a significantly improved uranium adsorption capacity per unit weight over existing adsorbents.

Owner:UT BATTELLE LLC

Preparation method of antifouling and antibacterial polypropylene non-woven fabric finished with silk fibroin for bandages

InactiveCN109137479AImprove breathabilityGood moisture permeabilityStain/soil resistant fibresRadioactive element fibre treatmentPolyhexamethyleneguanidine hydrochlorideNonwoven fabric

The invention discloses a preparation method of an antifouling and antibacterial polypropylene non-woven fabric finished with silk fibroin for bandages. The method includes the steps that a grafting solution is dropwise added to the surface of a polypropylene non-woven fabric obtained after irradiation-plasma pretreatment; the polypropylene non-woven fabric is covered with a quartz plate, placed in an ultraviolet lamp box for irradiation, taken out, ultrasonically washed with ultrapure water and ethanol alternately, put into a polyhexamethylene guanide hydrochloride aqueous solution, taken outafter a reflux reaction, ultrasonically washed with ultrapure water and ethanol alternately, and then subjected to vacuum drying; the obtained surface-functionalized antifouling and antibacterial polypropylene non-woven fabric is dipped in a silk fibroin solution and subjected to two-dipping and two-rolling, and the dipped and rolled cloth specimen is dried, treated with an ethanol solution, dried to a constant weight and then placed in a dryer for balance; the obtained silk fibroin functionally-modified polypropylene non-woven fabric is dipped in a graphene finishing liquid, and the non-woven fabric is treated with a small padder, dried and then baked.

Owner:安徽玉然经编科技有限公司

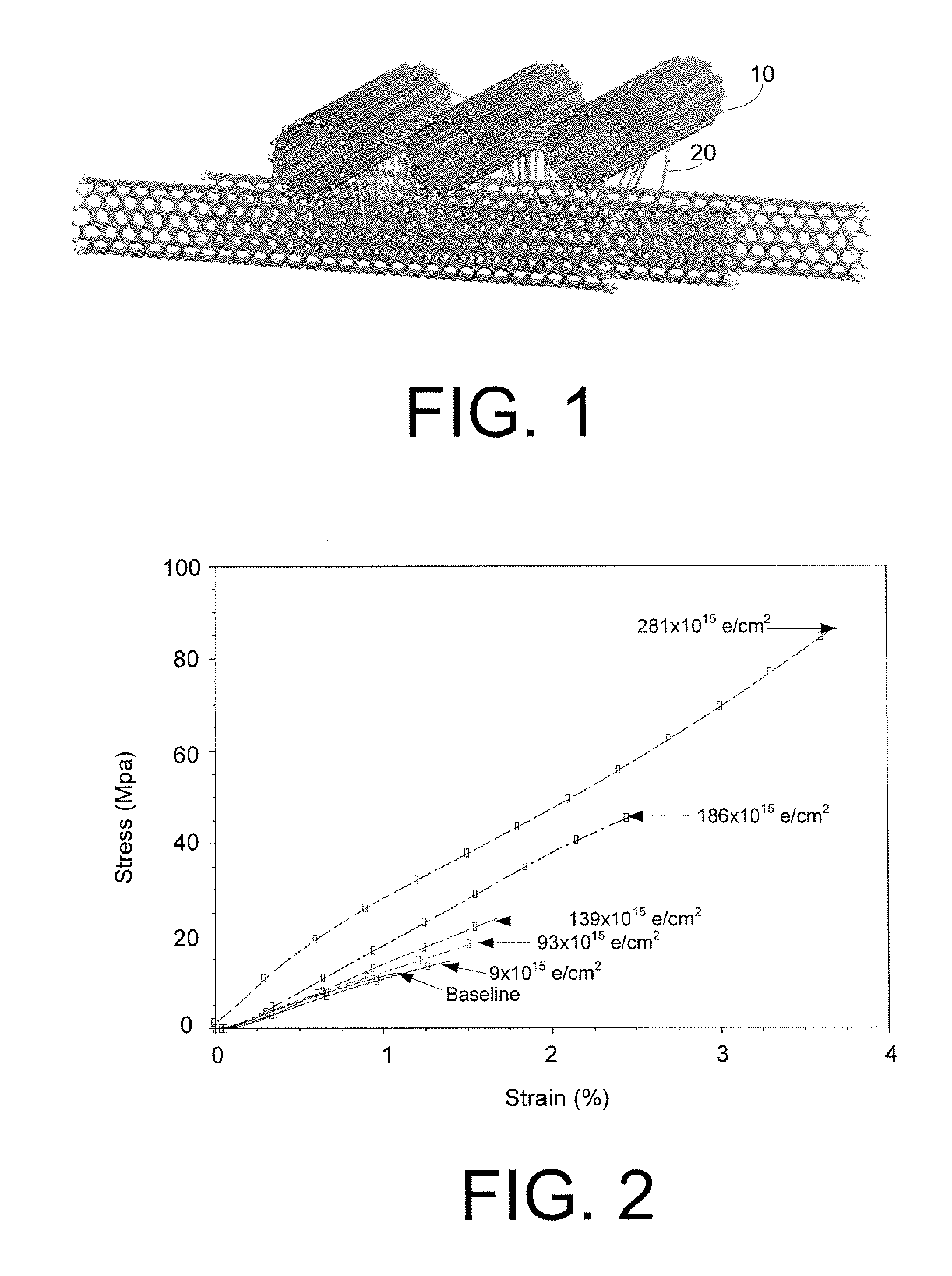

Increasing the specific strength of spun carbon nanotube fibers

InactiveUS20100284896A1Material nanotechnologyRadioactive element fibre treatmentFiberCarbon nanotube

A spun fiber of carbon nanotubes is exposed to ion irradiation. The irradiation exposure increases the specific strength of the spun fiber.

Owner:TRIAD NAT SECURITY LLC

Methods for improving the bioactivity characteristics of a surface and objects with surfaces improved thereby

InactiveUS20100234948A1Improve biological activityImprove adhesionSurgeryPharmaceutical delivery mechanismBiomedical engineeringLaboratory facility

Owner:EXOGENESIS CORP

Treatment method for improving coloring characteristic of nylon fishing net line

ActiveCN107687087AImprove mechanical performanceGood colorRadioactive element fibre treatmentFibre typesEconomic benefitsEngineering

The invention discloses a treatment method for improving a coloring characteristic of a nylon fishing net line. The treatment method comprises the following steps: (1) etching; (2) cleaning; (3) drying; (4) soaking modification; (5) irradiation. According to the method disclosed by the invention, the nylon fishing net line is subjected to special improvement treatment, the coloring performance andthe dyeing effect of the nylon fishing net line are obviously improved, the mechanical property of the nylon fishing net line is improved, the overall quality is high, and the economic benefits and popularization value are high.

Owner:马鞍山天顺农业科技有限公司

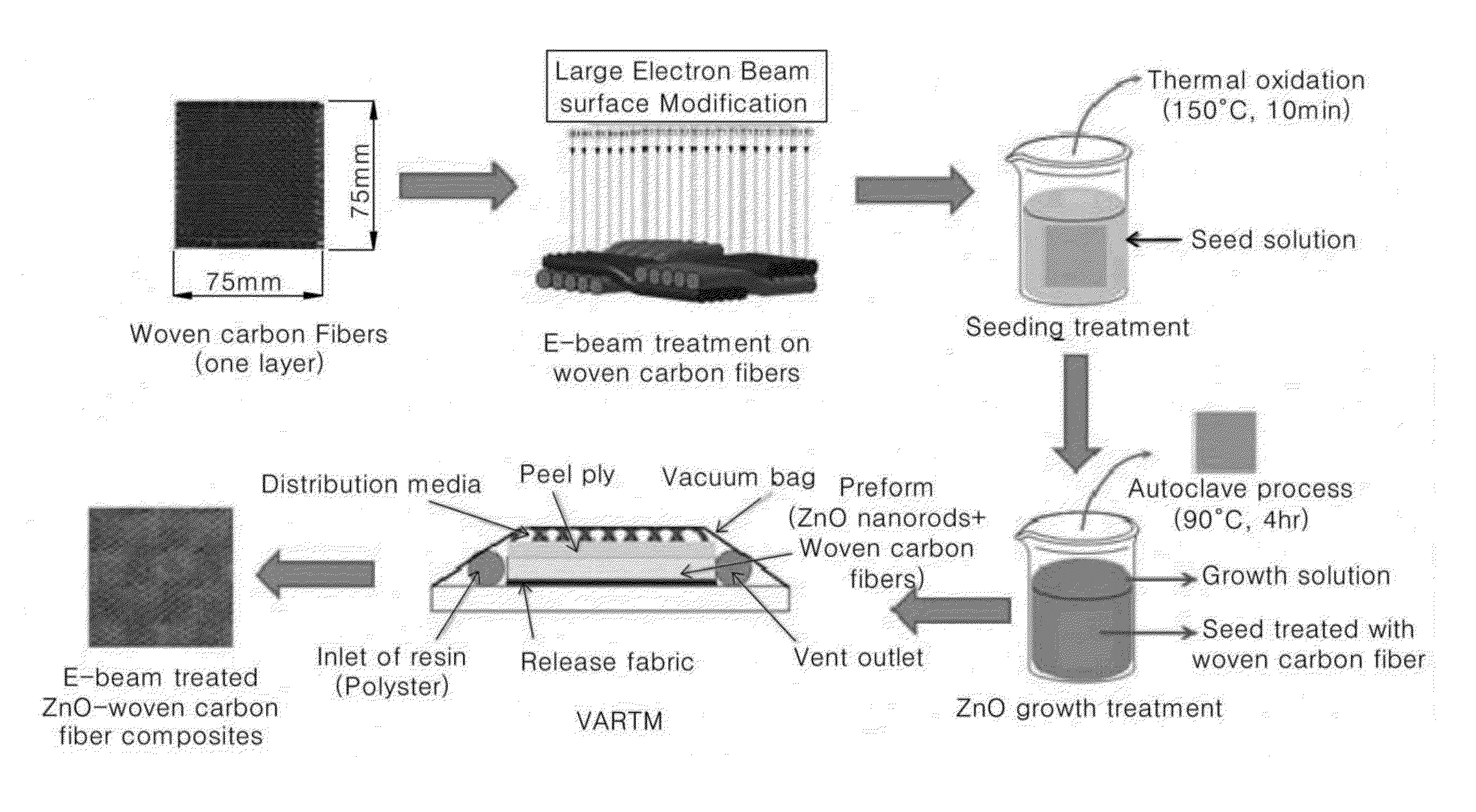

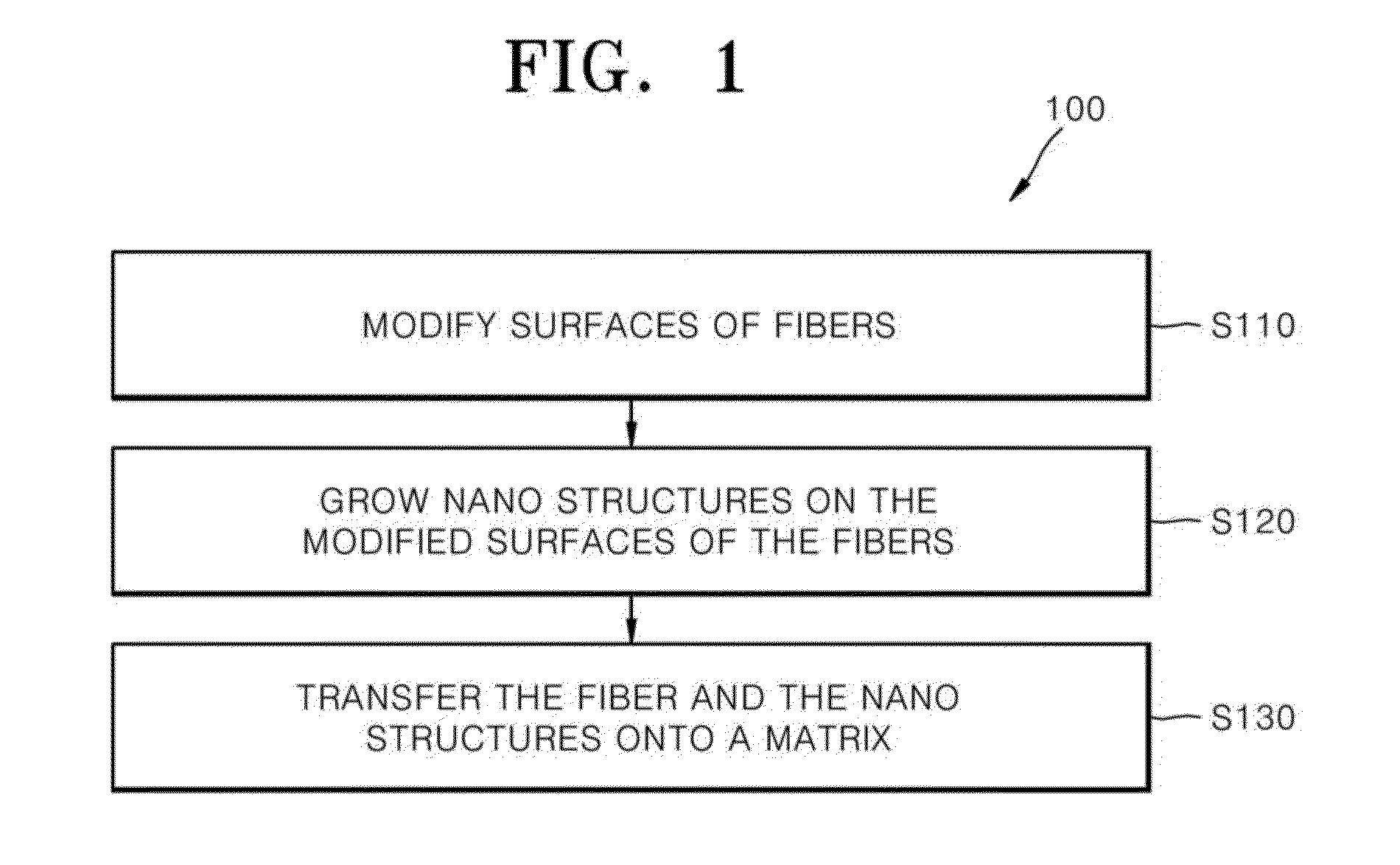

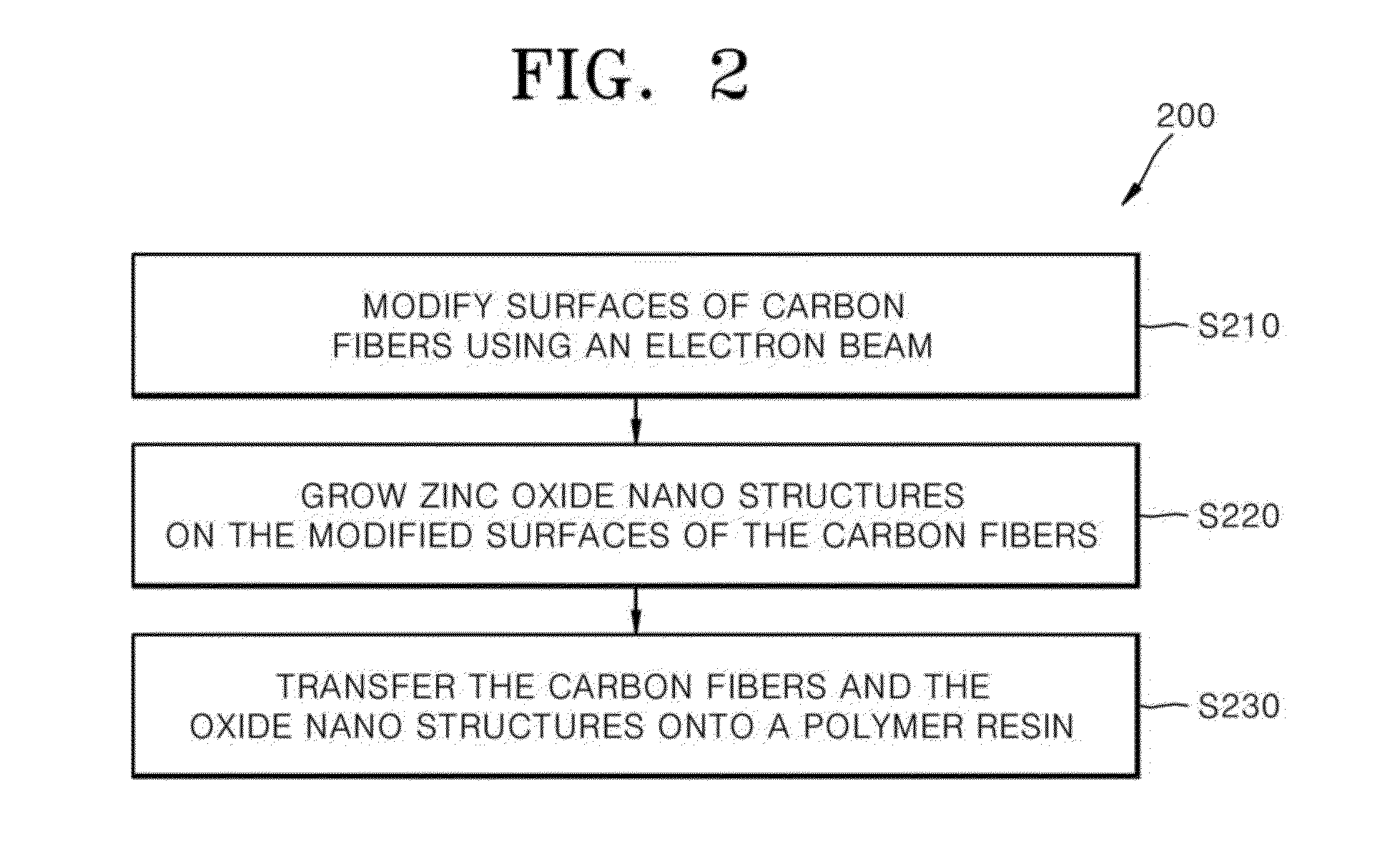

Method of manufacturing composite material having NANO structure grown on carbon fiber and composite material having NANO structure manufactured using the same

InactiveUS20150119494A1High densityPolycrystalline material growthFrom normal temperature solutionsFiberHigh density

Provided is a composite material having a nano structure grown on a carbon fiber with a high density. A method of manufacturing a composite material includes: modifying a surface of a carbon fiber by using an electron beam; growing a zinc oxide (ZnO) nano structure on the modified surface of the carbon fiber; and transferring the carbon fiber and the zinc oxide nano structure onto a polymer resin.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

Elastic meltblown laminate constructions and methods for making same

InactiveCN102791481ARadioactive element fibre treatmentSynthetic resin layered productsCopolymerEthylene

Multilayer meltblown composites, articles made therefrom, and methods for making same are provided. The meltblown composite can include a first meltblown layer comprising one or more resins having an Ultimate Elongation (UE) of from about 50% to about 250%, as measured according to ASTM D412; and a second meltblown layer comprising a propylene-a-olefm copolymer having an ethylene content of about 5 wt% to about 20 wt%; a MFR (ASTM-1238D, 2.16 kg, 2300 DEG C) of about 10 g / 10 min to about 30 g / 10 min; and a heat of fusion of 75 J / g or less.

Owner:EXXONMOBIL CHEM PAT INC

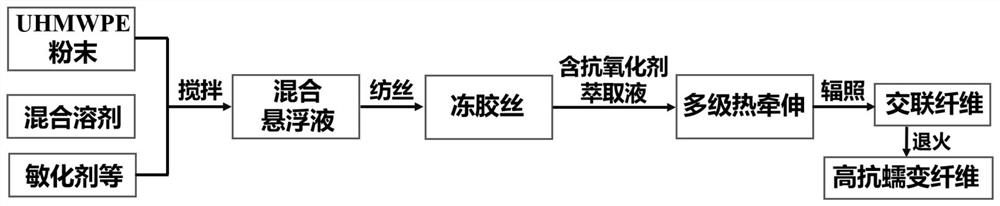

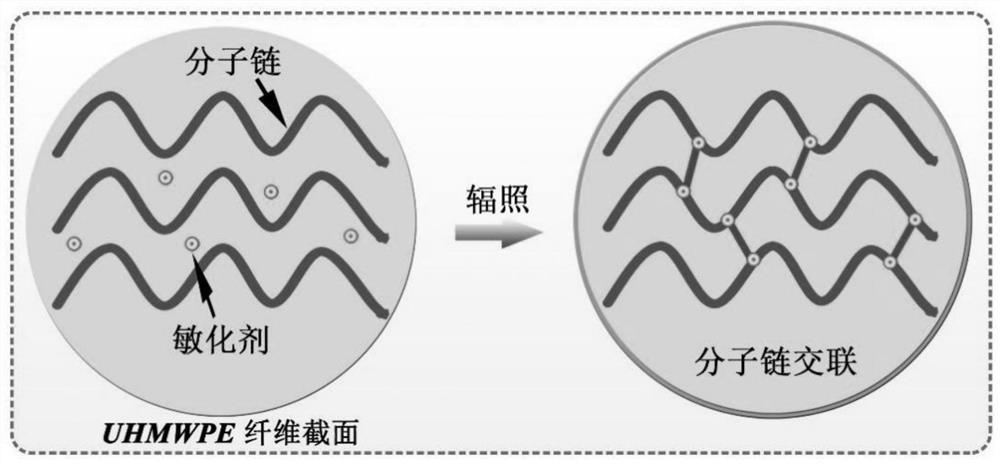

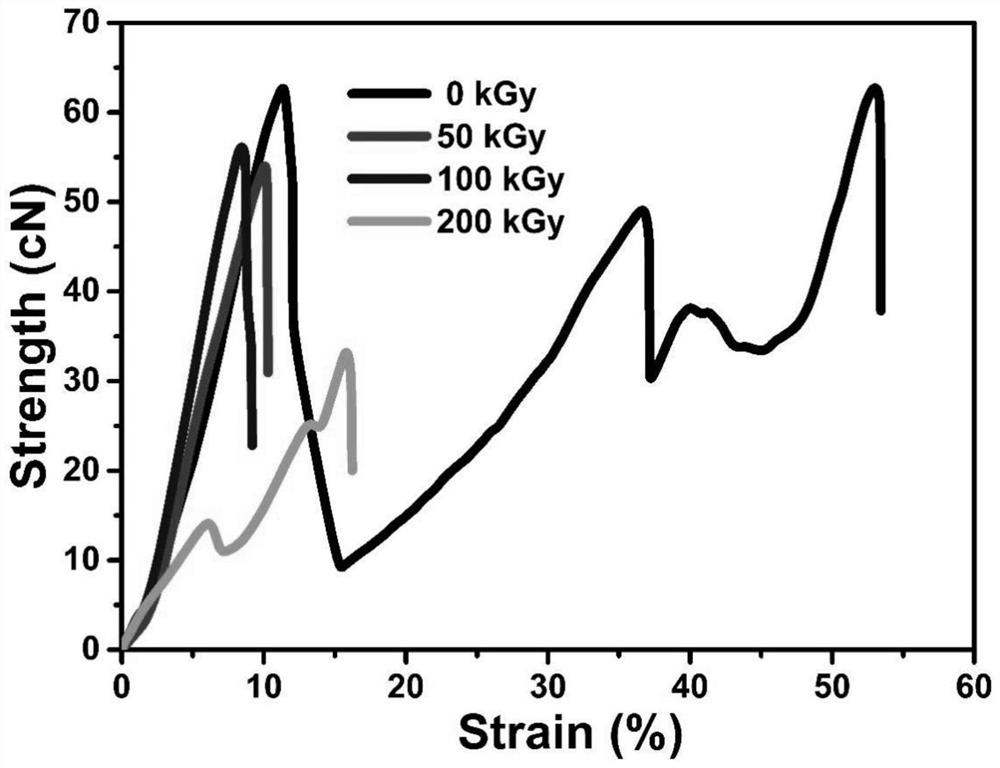

High-creep-resistance ultra-high molecular weight polyethylene fiber and preparation method thereof

ActiveCN113502556AReduce oxidationPrevent oxidationRadioactive element fibre treatmentMonocomponent polyolefin artificial filamentFiberPolymer science

The invention provides high-creep-resistance ultra-high molecular weight polyethylene fiber and a preparation method thereof. The preparation method comprises the following steps of S1, mixing ultra-high molecular weight polyethylene powder, a mixed solvent, an antioxidant and a sensitizer according to a preset proportion, and performing stirring to obtain a uniform mixed suspension; S2, putting the mixed suspension into a double-screw extruder for spinning treatment, then obtaining primary gel filament through a cooling water bath, extracting the primary gel filament through a mixed extraction solution containing the antioxidant, performing drying, and then obtaining a primary fiber product through multi-stage hot drafting and multi-stage drying in a drying oven; and S3, performing irradiation crosslinking: performing irradiation treatment of a predetermined dose on the primary fiber product, and finally performing annealing treatment under a nitrogen condition to obtain the high-creep-resistance ultra-high molecular weight polyethylene fiber. Compared with conventional ultra-high molecular weight polyethylene fiber, the creep elongation of the high-creep-resistance ultra-high molecular weight polyethylene fiber prepared by the invention is reduced by 50% or above.

Owner:WUHAN TEXTILE UNIV +2

Antibacterial treatment method for fiber, method for producing antibacterial fiber and antibacterial fiber

InactiveUS20110135846A1Low costImprove washabilityRadioactive element fibre treatmentVacuum evaporation coatingRheniumPlatinum

Disclosed are a method for the antimicrobial treatment of a fiber and a process for the production of an antimicrobial fiber, each of which is characterized by immersing the fiber in an aqueous solution containing a noble metal ion or a noble metal complex and irradiating the aqueous solution with γ-ray or electron beam. In the method for the antimicrobial treatment of a fiber and the process for the production of an antimicrobial fiber, the noble metal constituting the noble metal ion or the noble metal complex is at least one noble metal selected from the group consisting of gold, silver, platinum, palladium, ruthenium, rhodium, iridium and rhenium. Also disclosed is an antimicrobial fiber produced by the process.

Owner:OSAKA UNIV

Surface field electron emitters using carbon nanotube yarn and method of fabricating carbon nanotube yarn thereof

ActiveUS8193692B2Improve homogeneityGood reproducibilityCarbon fibresThermionic cathodesCarbon nanotube yarnLight emitting device

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com