Method to prepare straw fiber/PBAT (poly(butylene adipate-co-terephthalate)) composite based on radiation modification

A technology of straw fiber and composite materials, which is applied in the field of straw fiber/PBAT composite materials prepared after radiation improves the surface of straw fiber, and in the field of straw fiber/PBAT composite materials, which can solve the problems of poor tensile strength, serious environmental pollution, and low efficiency. Achieve the effects of improving interface compatibility, improving mechanical properties, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of irradiated modified straw fibers

[0035] Dissolve 30g of silane coupling agent (KH-550) in 200ml of acetone solvent, spray evenly on 1.0kg of straw fibers dried at 80°C for 10h in a vacuum drying oven, and then dry them naturally with polyethylene. Vacuum packaging, irradiation treatment with 10kGy dose of gamma rays at normal temperature to obtain surface modified straw fibers.

Embodiment 2

[0036] Example 2: Preparation of irradiated modified straw fibers

[0037] Dissolve 20g of silane coupling agent (KH-550) in 150ml of acetone solvent, spray evenly on 1.0kg of straw fiber after drying in a vacuum oven at 70°C for 12h, and then dry it naturally with polyethylene. Vacuum packaging and irradiation treatment with 8kGy gamma rays at normal temperature to obtain surface modified straw fibers.

Embodiment 3

[0038] Embodiment 3: Preparation of straw fiber / PBAT composite material

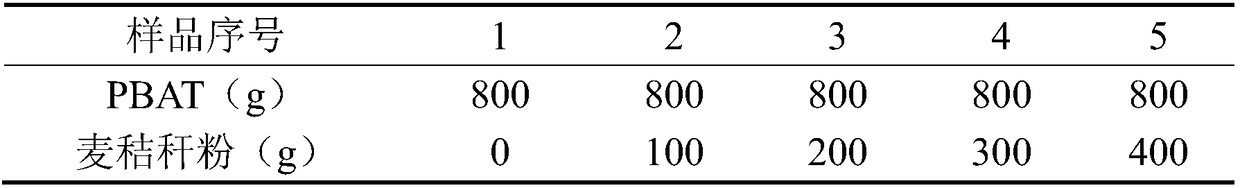

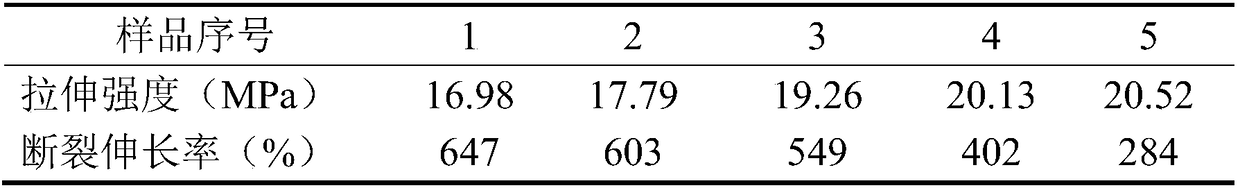

[0039] (1) Raw material pretreatment: ①In a vacuum drying oven, dry PBAT and the irradiated modified straw fibers prepared in Example 1 at 80°C for 20h; According to the modified straw fiber according to the ratio in Table 1, 25g of stearic acid and 15g of antioxidant were stirred in a high-speed mixer at room temperature for 5min.

[0040] Table 1 Straw fiber / PBAT composites with different compositions

[0041]

[0042] (2) Twin-screw extrusion granulation

[0043]Put the mixed raw materials into a twin-screw extruder for extrusion and granulation. The extrusion conditions are 115°C for the first stage, 120°C for the second stage, 122°C for the third stage, 124°C for the fourth stage, and 120°C for the fifth stage. ℃, the six-stage temperature is 120℃, the head temperature is 115℃; the speed of the screw host is 4.0Hz, and the speed of the feeder is 3.0Hz.

[0044] (3) Sample preparation

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com