Method for antimicrobial treatment of fiber, process for production of antimicrobial fiber, and antimicrobial fiber

A treatment method and antibacterial technology, which are used in the antibacterial treatment of fibers, the manufacture of antibacterial fibers and the fields of antibacterial fibers, can solve the problems of reduced cost advantage, increased cost, and reduced product feel, and achieve excellent washing resistance. , Easy to adjust, the effect of the change control of the feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

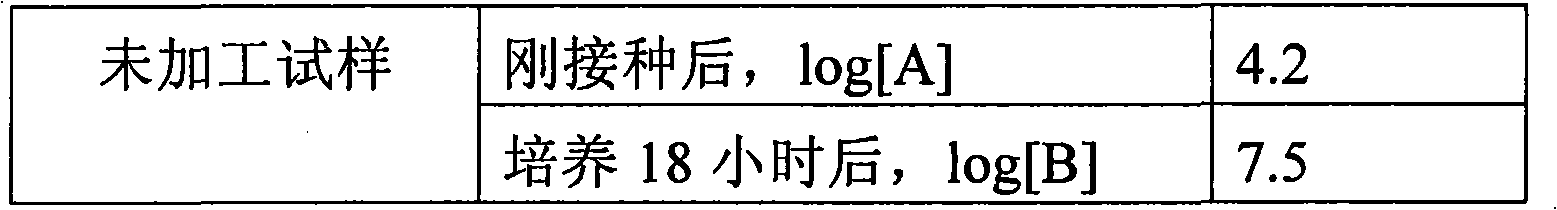

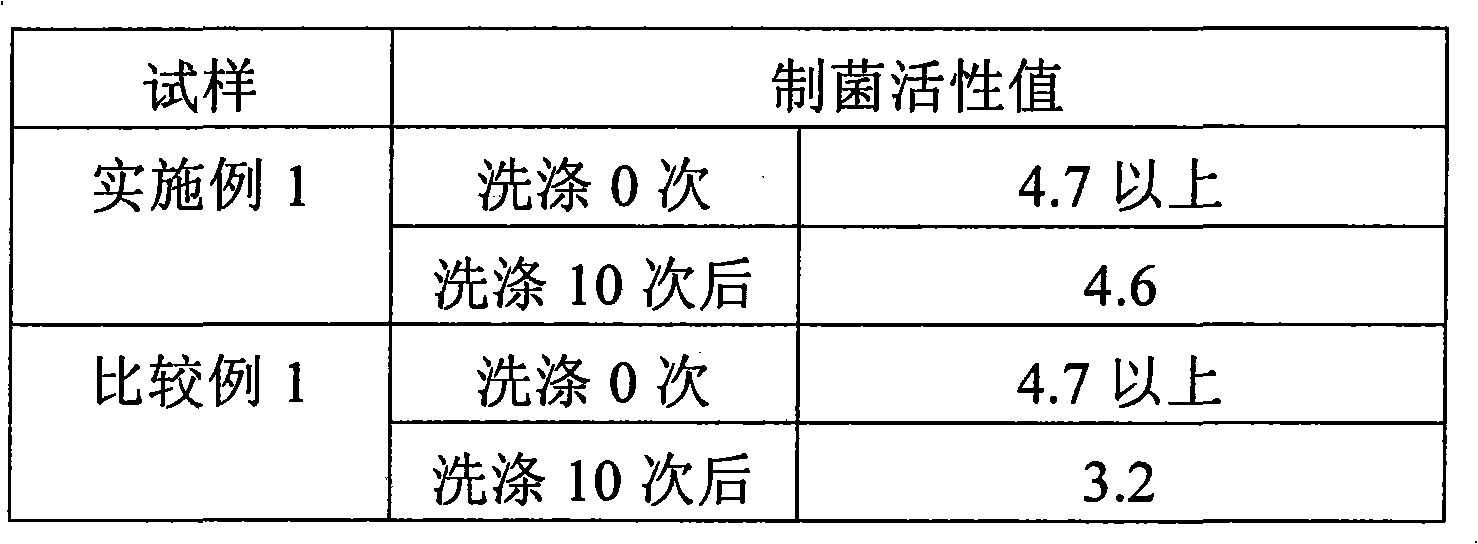

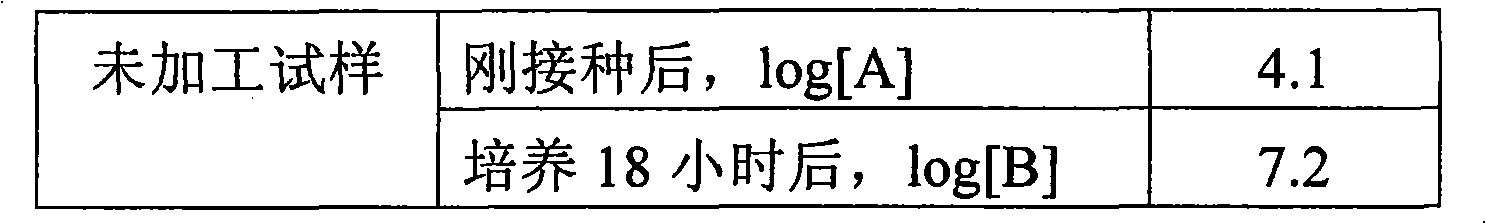

[0057] In Example 1 and Comparative Example 1, antibacterial treatment was performed using silver as a noble metal, and the obtained antibacterial performance was compared with a cloth made of commercially available antibacterial silver fibers.

Embodiment 1

[0059] (1) Preparation of antibacterial fiber samples

[0060] Silver nitrate was added to 800 mL of water, and the resulting silver nitrate aqueous solution with a concentration of 0.1 mM was put into a 1 L plastic bottle, and 8 mL of 2-propanol was added to promote the reduction reaction of silver ions. In the obtained aqueous solution, 8.6 mg of silver existed as ions.

[0061] A commercially available cotton cloth (50 cm×50 cm) was immersed in the obtained aqueous solution, the plastic bottle was sealed, and cobalt 60 gamma rays were irradiated under the following conditions using a cobalt 60 gamma ray irradiation device while stirring.

[0062] Radiation source: cobalt 60 gamma ray source (energy of gamma ray photon: 1.25MeV)

[0063] Ray source intensity: about 7000 Curies

[0064] Dose rate: 3kGy / h

[0065] Irradiation time: 2 hours

[0066] Then, the cotton cloth was taken out from the plastic bottle, washed with water, and dried to obtain the antibacterial fiber s...

Embodiment 2~5

[0079] In the following examples, silver ions were used as noble metal ions to test the relationship between concentration and antibacterial properties.

[0080] (1) Production of samples

[0081] Silver nitrate was added to 1 L of water, silver nitrate aqueous solutions of various concentrations shown in Table 2 were charged into the container, and 1 vol% of 2-propanol was added to promote the reduction reaction of silver ions.

[0082] A commercially available cotton cloth (50 cm x 50 cm) was immersed in the obtained aqueous solution, the container was sealed, and the same cobalt 60 gamma ray irradiation device as in Example 1 was used to irradiate cobalt 60 gamma rays with an absorbed dose of 10 kGy (10000 J / kg). In addition, stirring of the aqueous solution was not performed at the time of irradiation. Then, the cotton cloth was taken out from the container, washed with water, and dried to obtain each sample of Examples 2 to 5 in which silver nanoparticles adhered to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com