Patents

Literature

58results about How to "Improve broad applicability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data-driving control process monitoring method based on dynamic component analysis

InactiveCN103488091AImprove broad applicabilityImprove monitoring efficiencyAdaptive controlData descriptionPerformance index

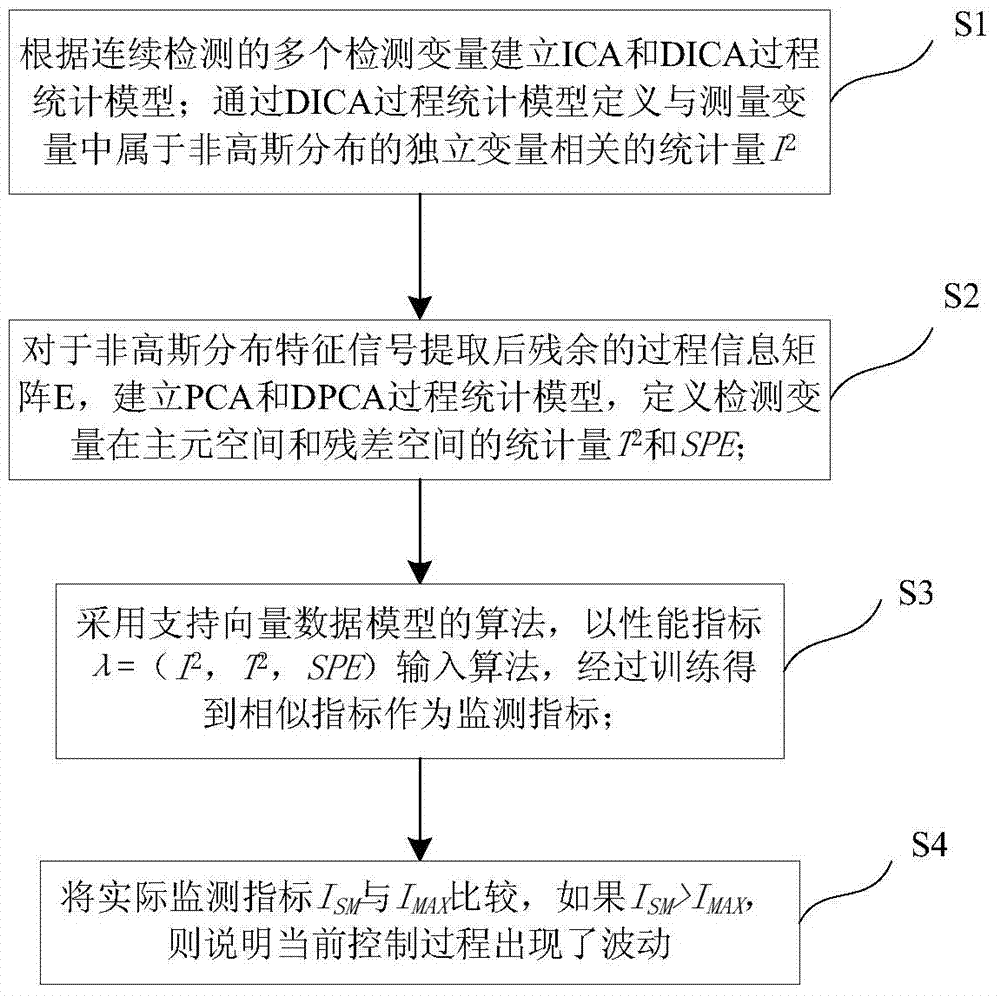

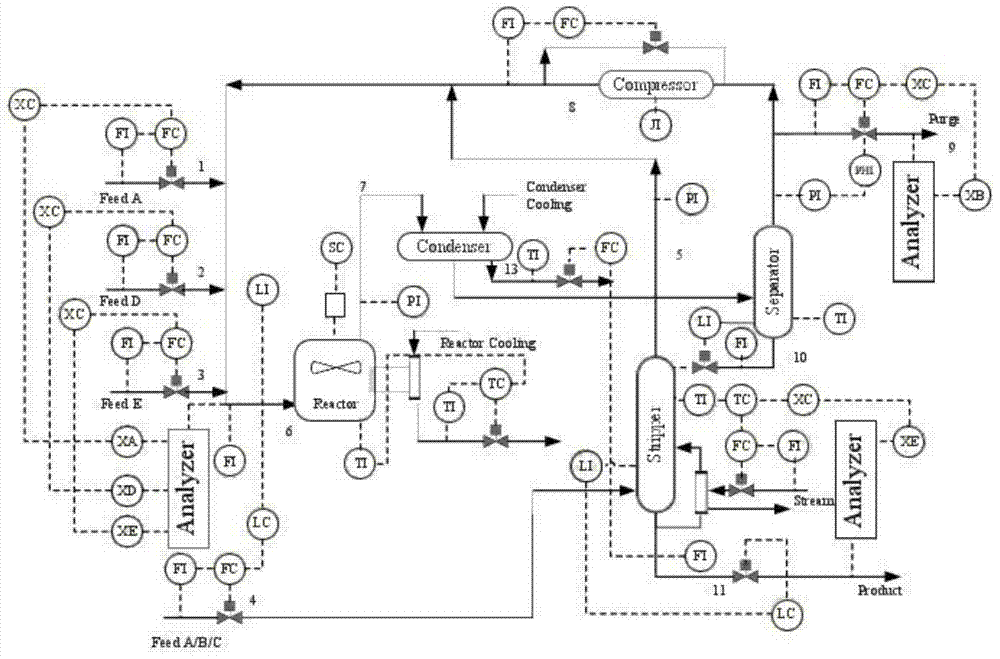

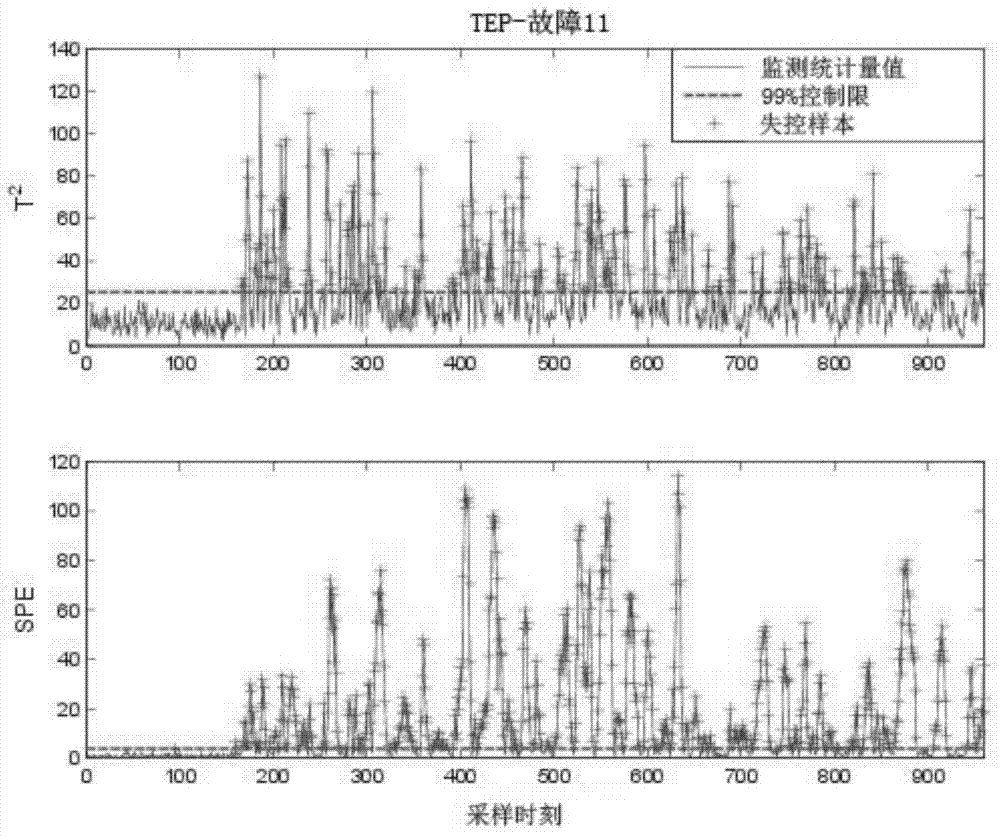

The invention provides a data-driving control process monitoring method based on dynamic component analysis. The method comprises the steps of (1) establishing ICA and DICA process statistics models according to multiple detection variables obtained from continuous detection, and defining statistics I2 relevant to independent variables belonging to non-Gaussian distribution in measured variables according to the DICA process statistics model; (2) establishing PCA and DPCA process statistics models for a process information matrix E left over after non-Gaussian distribution measured variable extraction, and defining statistics T2 and SPE of the detected variables in pivot element space and residual space; (3) obtaining similarity indexes ISM to serve as monitoring indexes through training by means of the support vector data description algorithm which is input by the performance indexes Lambda = (I2, T2, SPE); (4) comparing actual monitoring indexes ISM with IMAX and getting the conclusion that faults appear in the current control process if ISM>IMAX. According to the data-driving control process monitoring method based on dynamic component analysis, the number of monitoring diagrams can be reduced, and monitoring efficiency can be improved. The data-driving control process monitoring method based on dynamic component analysis can be widely used for multivariable control system monitoring such as industrial process control.

Owner:SHANGHAI JIAO TONG UNIV

Virtual desktop system and method for refreshing on-screen display of virtual desktop client

ActiveCN102566910AImprove experienceReduce transfer volumeTransmissionInput/output processes for data processingClient-sideData transmission

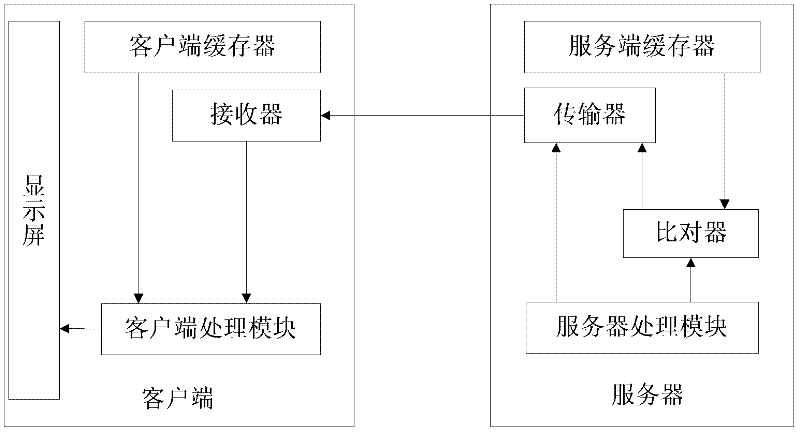

The invention provides a virtual desktop system and a method for refreshing on-screen display of a virtual desktop client. The virtual desktop system comprises a server and a client, the server comprises a server processing module, a server cache, a comparer and a transmitter, and the client comprises a receiver, a client cache, a client processing module, a display and a mobile detection module. The virtual desktop system and the method for refreshing on-screen display of the virtual desktop client are evidently advantageous in terms of mobile detection process and data transmission quantity reduction, mobile description instructions of pixel points / pixel blocks are used to indicate moving of existing on-screen display data of the client, retransmitting of existing pixels in the client cache through the network can be avoided, the process of updating single pixels in partial differential areas one by one is effectively substituted, the quantity of data to be transmitted is reduced, and consumption of network bandwidth can be effectively reduced while user experience is improved by using the method in the current network environment with the bandwidth limited.

Owner:GCI SCI & TECH

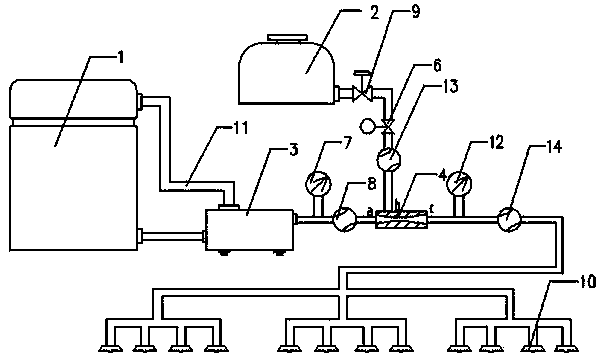

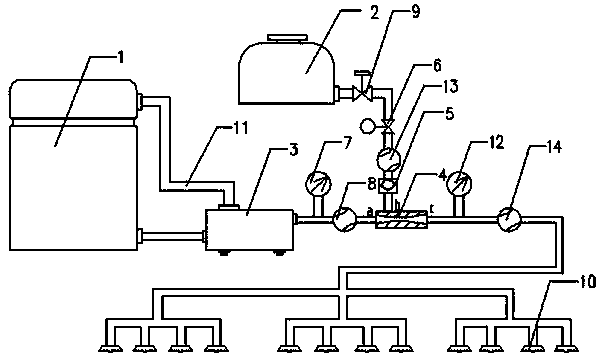

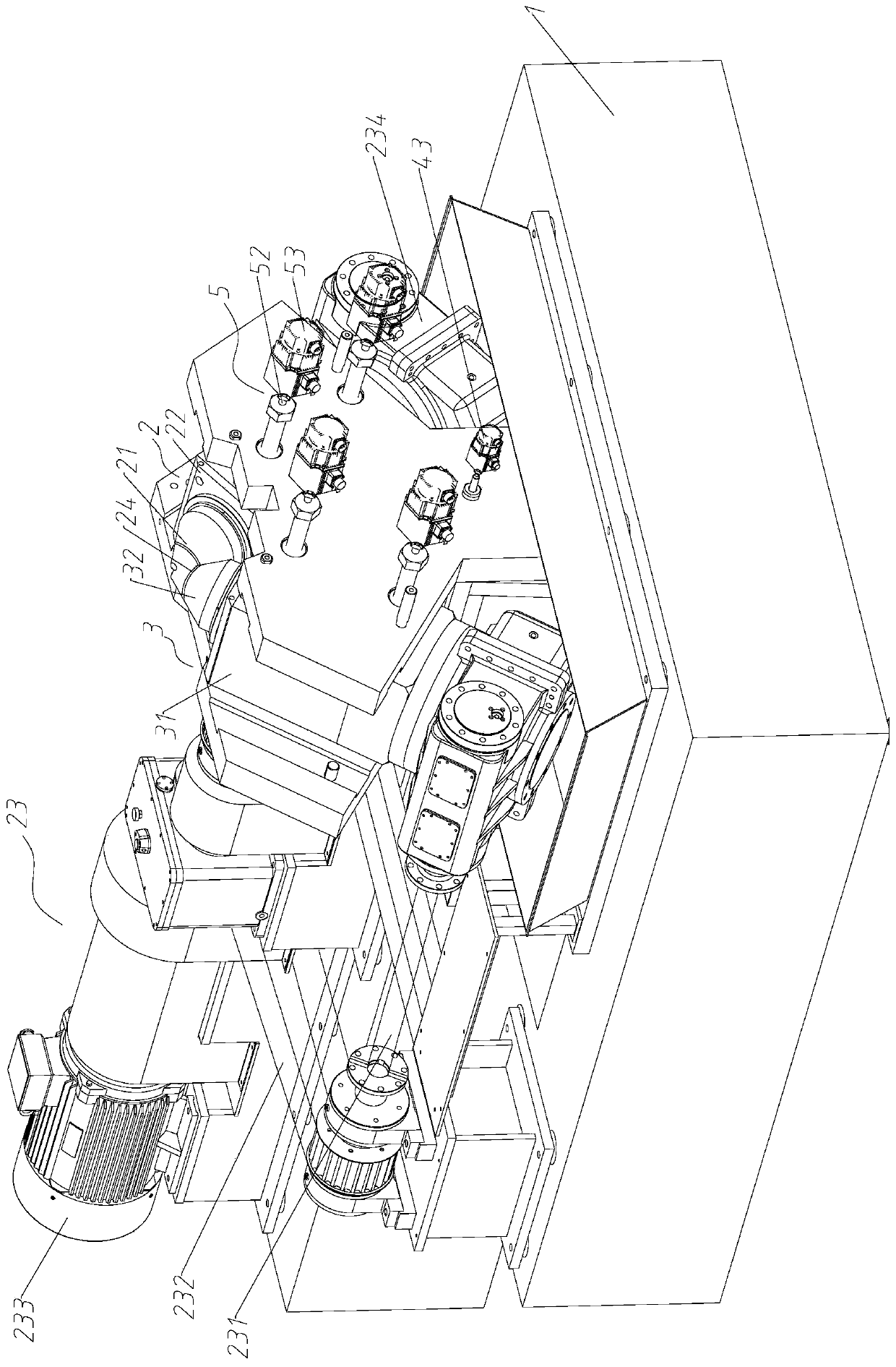

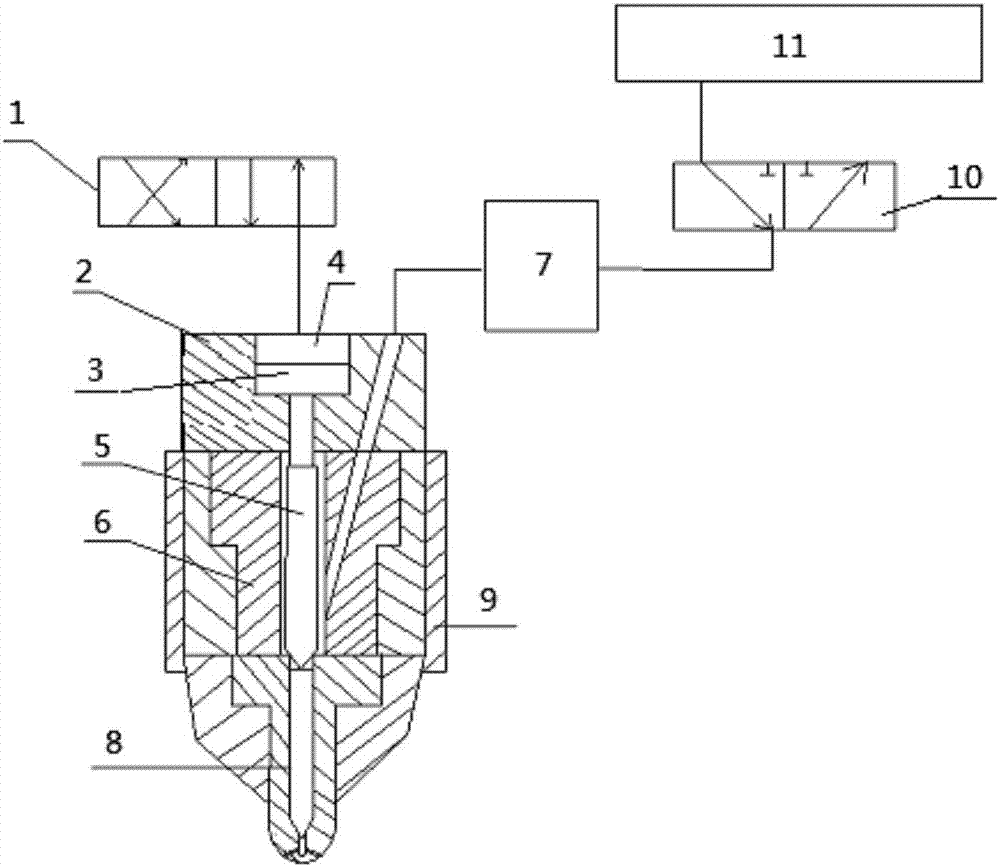

Variable amount spraying device capable of automatically mixing pesticide

InactiveCN103404500AImprove broad applicabilityWidely used and convenientInsect catchers and killersSpray nozzlePlunger pump

The invention relates to a variable amount spraying device capable of automatically mixing pesticide. The variable amount spraying device capable of automatically mixing the pesticide can adjust the amount of the automatically-sucked pesticide according to the requirements of spraying to change the concentration of spray, and can achieve the purpose that the pesticide and water are separately stored. The variable amount spraying device capable of automatically mixing the pesticide comprises a water tank for storing the water, a pesticide tank for storing liquid pesticide, a solenoid valve playing a role in protection, a mode backflow check valve, a jet flow pesticide mixing device, a pressure gauge, a plunger pump for providing power needed by spraying, a flow meter, pipelines and spraying nozzles. The pesticide and the water are independently stored, the variable amount spraying device capable of automatically mixing the pesticide can automatically and stably carry out pesticide suction in the process of spraying, on-line uniform mixing can be carried out, and real-time control over the amount of the sprayed pesticide can be carried out. In order to meet the requirement for developing high-efficiency agriculture, the variable amount spraying device capable of automatically mixing the pesticide can be mounted on a vehicle, and can be hung on an ordinary agricultural machine, and power of the variable amount spraying device capable of automatically mixing the pesticide can be provided by the ordinary agricultural machine, and large-area high-efficiency spraying operation can be achieved.

Owner:JIANGSU UNIV

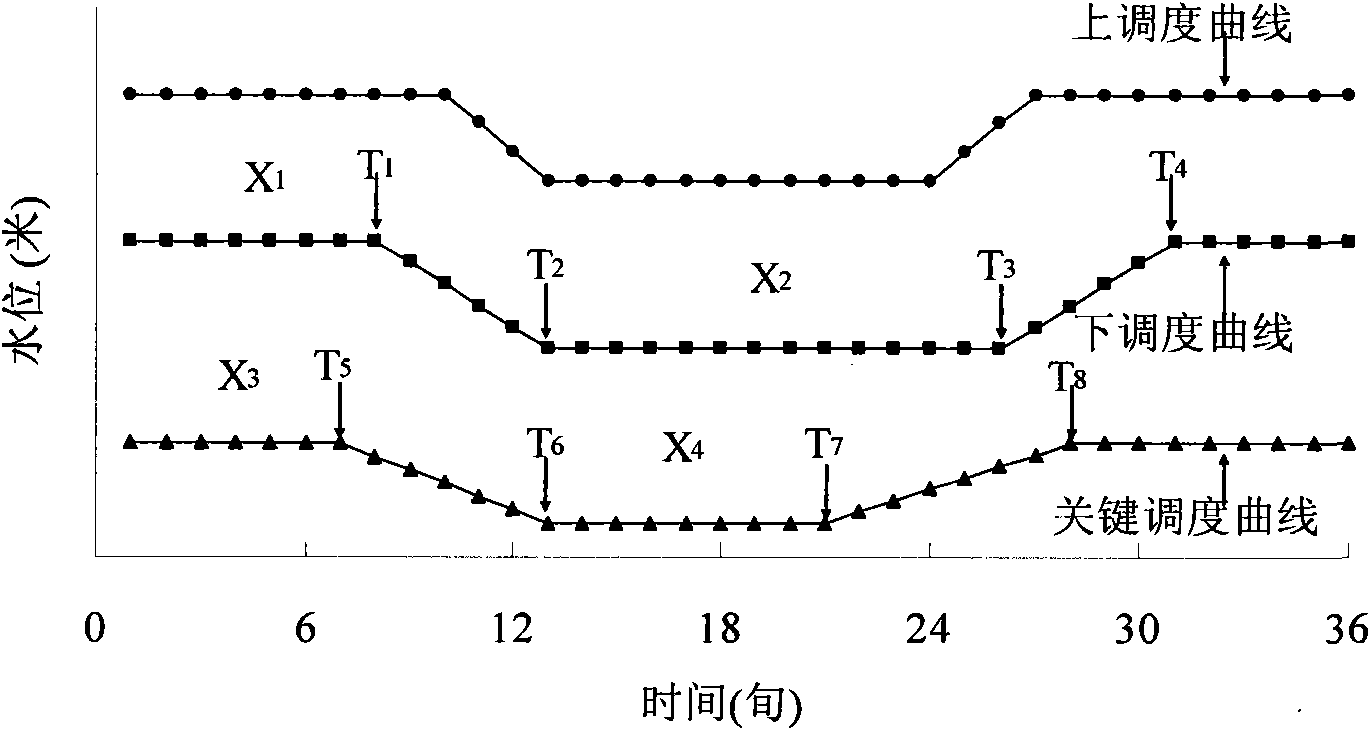

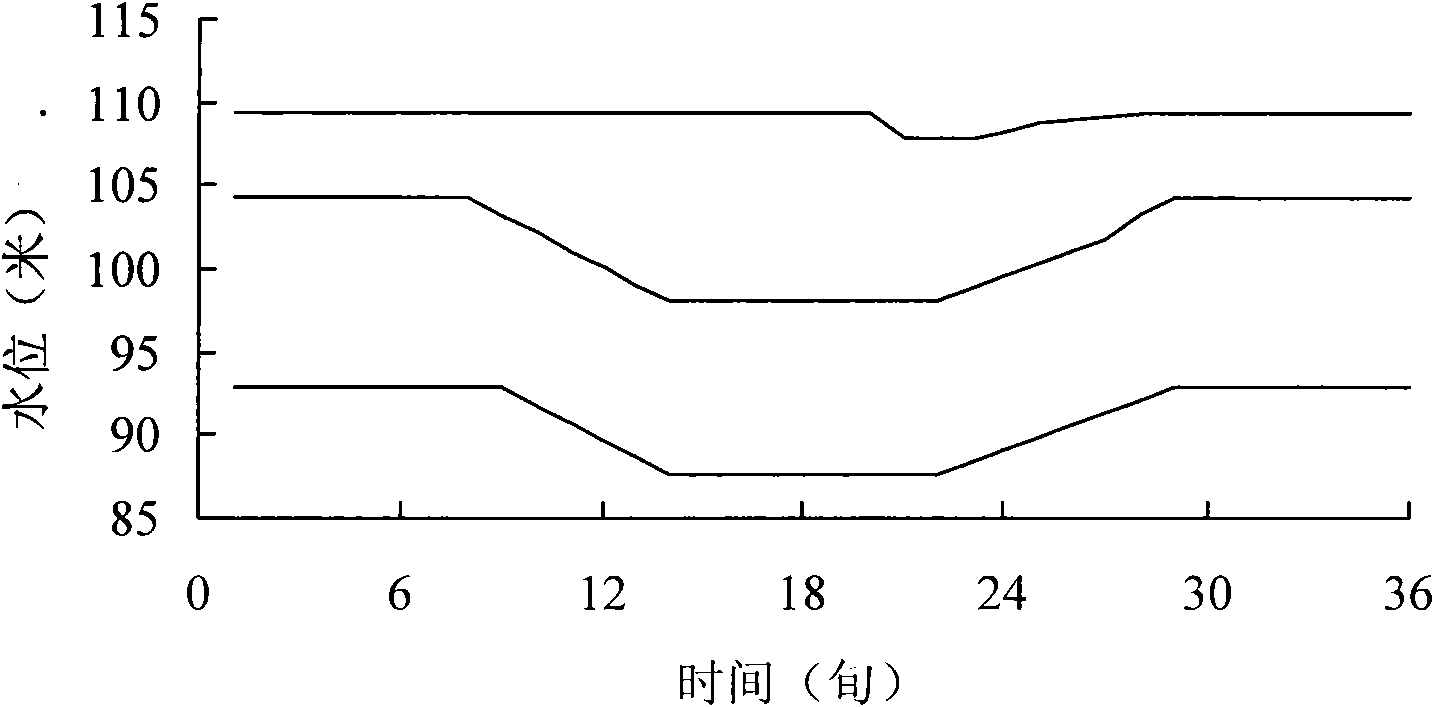

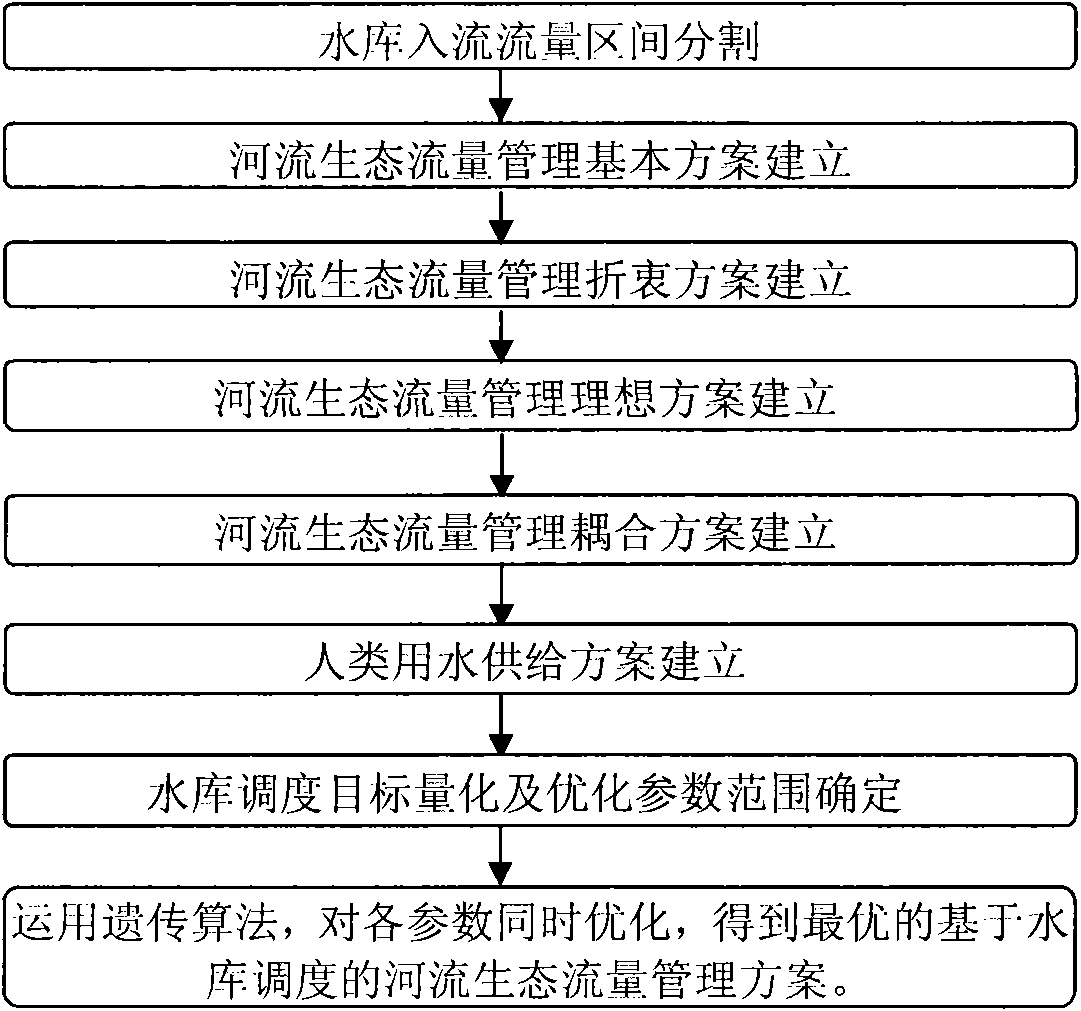

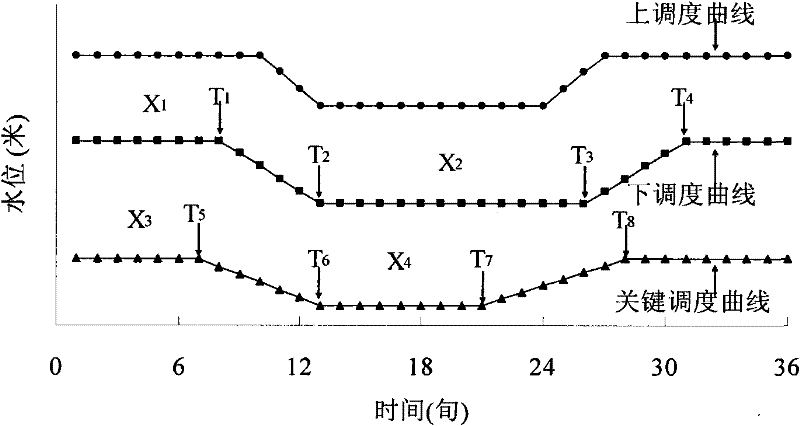

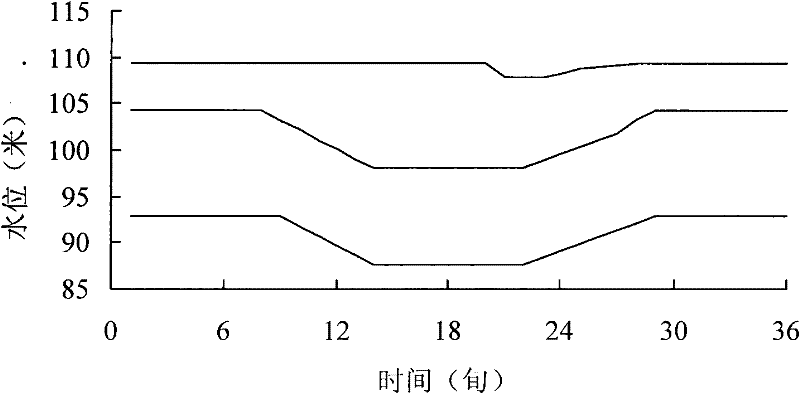

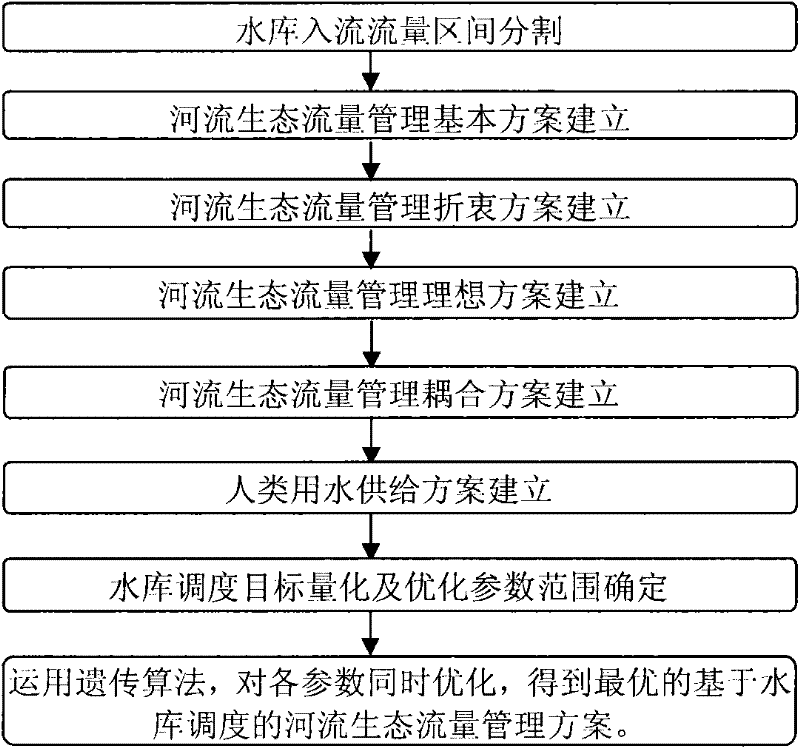

Management method of river ecological flows based on reservoir operation

InactiveCN101892647AReduce supplyAchieve protectionHydraulic engineering apparatusGenetic algorithmEngineering

The invention provides a management method of ecological flows river based on reservoir operation. The management method comprises the following steps: firstly, establishing a basic scheme, a compromise propose and an ideal scheme on the ecological flows management to be respectively suitable for the demands of high, medium and low water supply guarantee rate, and maintain health state of the basic, good and ideal ecological system of the river, simultaneously, dividing the capacity space of the reservoir to correspond to the management scheme of the ecological flows from top to down in sequence; then adopting a reservoir operation curve to guide so as to supply the water for the people and forming an integral reservoir ecological operation scheme by combining with the management scheme of the ecological flows; and finally applying a genetic algorithm, taking the water supply guarantee rate meeting the plan as the basic constrains and taking disturbance which reduces hydrologic regime of the river as an optimal target to optimize parameters of the reservoir capacity partition, dispatch curves and the like, so that the management scheme of ecological flows of the river based on the reservoir operation is obtained. The method can be suitable for demands of the different water supply guarantee rates, provide the optimized ecological flows process and effectively protect the ecological system of the river.

Owner:BEIJING NORMAL UNIVERSITY

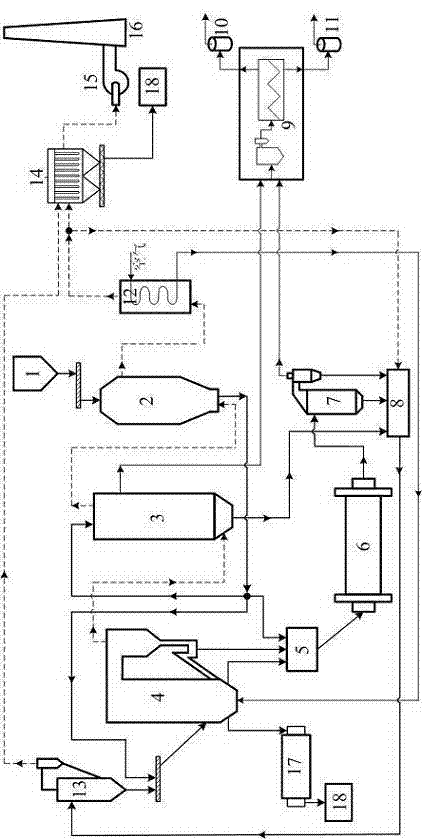

Integral process for oil shale drying, heating, refining and semicoke burning

ActiveCN102952558AImprove broad applicabilityTake advantage ofDirect heating destructive distillationEnergy inputHeat carrierSlag

The invention relates to an integral process for oil shale drying, heating, oil refining and semicoke burning. The integral process is characterized in that the oil shale crushed into the diameter smaller than or equal to 15mm is subjected to the direct or indirect heat exchange by moderate-temperature gas and the heating and drying by a drying heater, and is delivered with hot ash slag burned generated by burning of a circulating fluid bed burning furnace into a solid heat carrier dry distillation reactor to carry outbe subjected to mixed heat exchange and complete dry distillation oil refining; high-temperature smoke burned byfrom the circulating fluid bed burning furnace is delivered into the high-temperature gas indirect dry distillation reactor to exchange heat with the oil shale to realize the dry distillation oil refining of the solid fuels; oil shale semicoke from the solid heat carrier dry distillation reactor, through a semicoke bin hopper, and solid semicoke discharged from the circulating fluid bed burning furnace, are delivered to the circulating fluid bed burning furnace to be burned continue toously burn, and the excessive hot ash slag discharged from the circulating fluid bed burning furnace is cooled by a slag cooler, and is discharged and delivered to building material factories. The integral technology can be used for completing the oil shale fuel drying, heating, oil refining and semicoke burning, and also can also be used for coals, oil sands, waste and scrape tires, petroleum cokes, organic waste materials and biomasses.

Owner:NORTHEAST DIANLI UNIVERSITY

Radiation proof composite metallic yarn and weaving method thereof

The invention discloses an anti-radiation composite metal yarn comprising textile fiber bundle and metal filament. The diameter of metal filament is 15-80mum. The metal filament and the textile fiber bundle are doubled and twisted. The range of twist is 100-2200TPM. The textile fiber bundle is single yarn, plied yarn or long yarn. The invention also discloses the spinning process for anti-radiation composite metal yarn. At first, metal filaments with the diameter of 20-80mum and textile fiber bundle according with demands are selected and then selected metal filaments and textile fiber bundle are doubled and twisted on doubling and twisting machine. The tension of doubling and twisting is controlled in 15-80g and the twist of doubling and twisting is controlled in 100-2200TPM. Because metal filaments are used, the yarn and fabrics spun with the yarn are smooth. In fabric, longitude and latitude metal filaments are connected with each other in effect to form current loop. It can play a very good anti-radiation effect and improve the wide application of anti-radiation composite metal yarn.

Owner:CHANGZHOU POLYACE TEXTILE & YARN

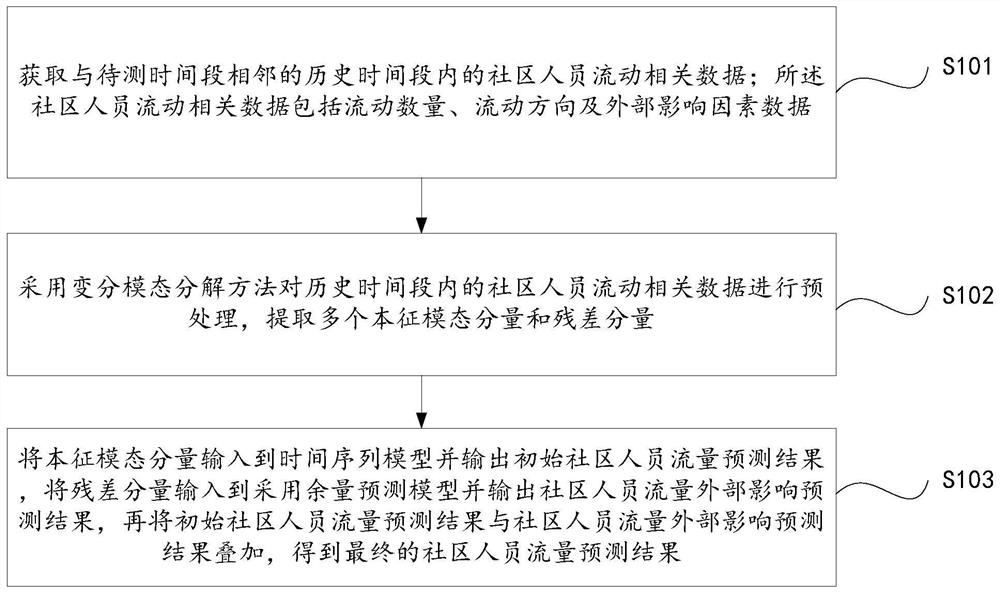

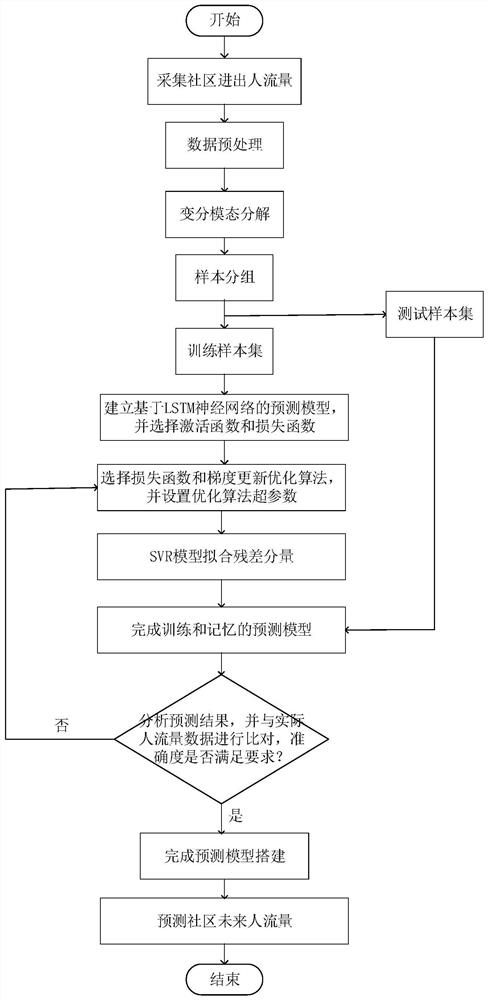

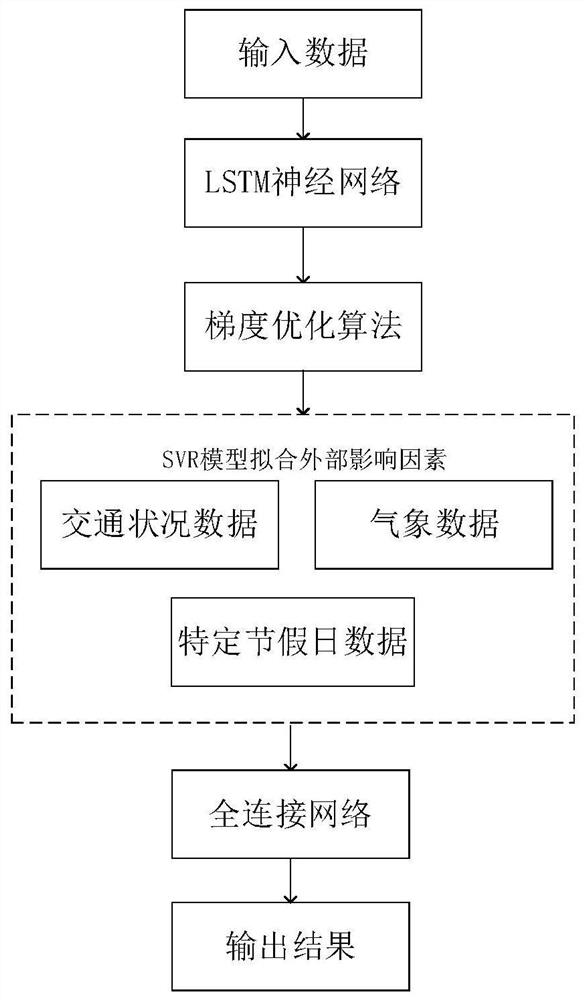

Community personnel flow prediction method and system, storage medium and equipment

PendingCN112381320AAccurate analysisStrong computing powerForecastingNeural architecturesData packTraffic prediction

The invention belongs to the technical field of personnel flow prediction, and provides a community personnel flow prediction method and system, a storage medium and equipment. The community personnelflow prediction method comprises the steps of obtaining community personnel flow related data in a historical time period adjacent to a to-be-tested time period, wherein the community personnel flowrelated data comprises flow quantity, flow direction and external influence factor data; preprocessing the community personnel flow related data in the historical time period by adopting a variationalmode decomposition method, and extracting a plurality of intrinsic mode components and residual components; inputting the intrinsic mode component into a time sequence model and outputting an initialcommunity personnel flow prediction result, inputting the residual component into an allowance prediction model and outputting a community personnel flow external influence prediction result, superposing the initial community personnel flow prediction result and the community personnel flow external influence prediction result, and obtaining a final community personnel flow prediction result. Thecommunity personnel flow prediction precision and resource allocation can be improved.

Owner:SHANDONG JIANZHU UNIV

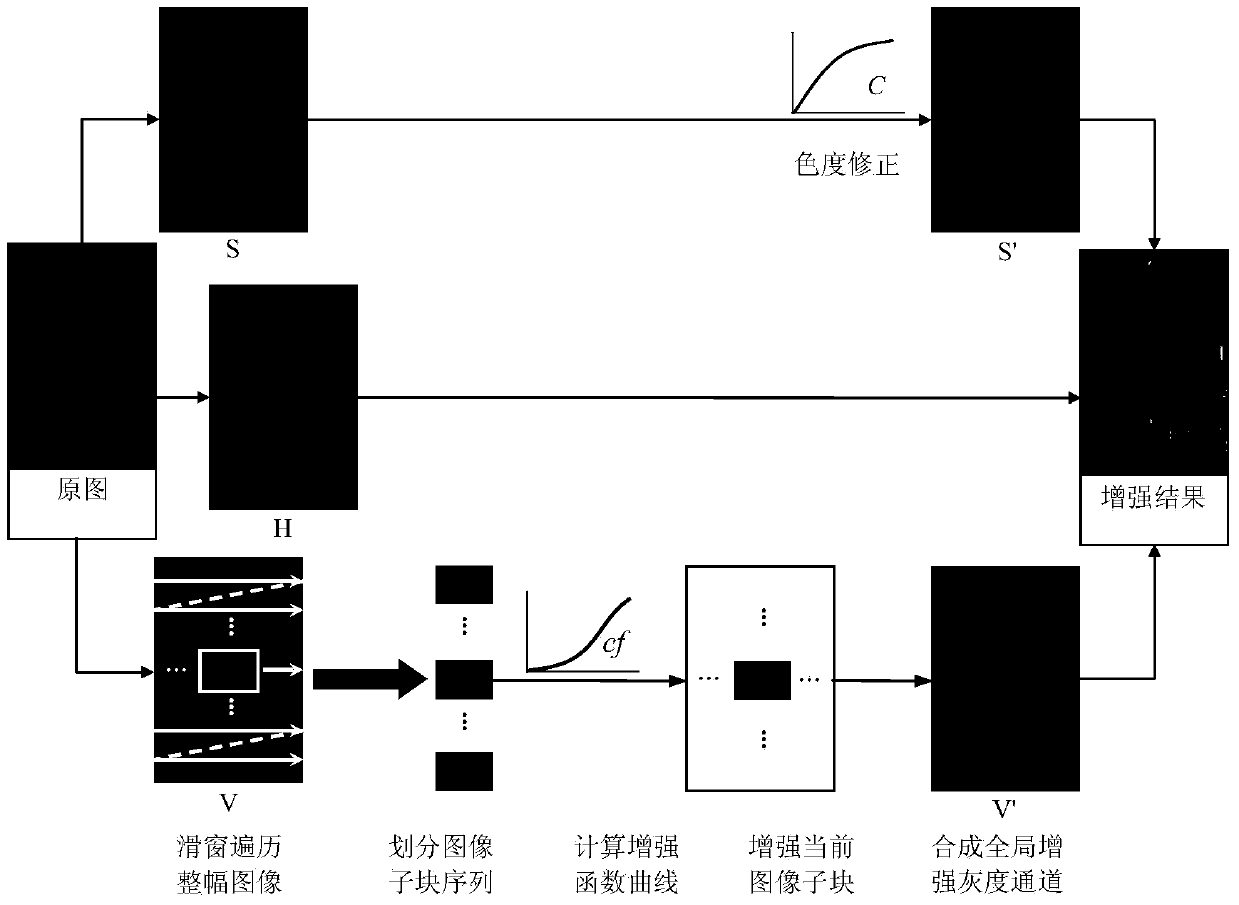

Highly adaptive image contrast enhancing method based on data driving technology

ActiveCN104463806AEnhancement effect is goodObvious advantagesImage enhancementImage contrastContrast enhancement

The invention discloses a content-based block adaptive image contrast enhancing algorithm to solve the problem that adaptive processing of various degraded images with different characteristics can not be achieved in the prior art by the adoption of the data driving idea. According to the method, by means of block analysis and processing, images are better processed by means of the details and local information of the images; a parameterized enhancement function is established and can change the characteristic of an enhancement curve by adjusting relevant parameters, and then a corresponding enhancement function curve is generated for each image according to the characteristic of the image; features relevant to the enhancement function are extracted through content analysis of image subblocks, and matched enhancement parameters are automatically generated according to the features and assigned to the enhancement function to enable the features of the images to be organically related with the characteristics of the enhancement function. By the adoption of the method, adaptive processing of various degraded images with different characteristics can be achieved without manual intervention.

Owner:NANJING UNIV OF SCI & TECH

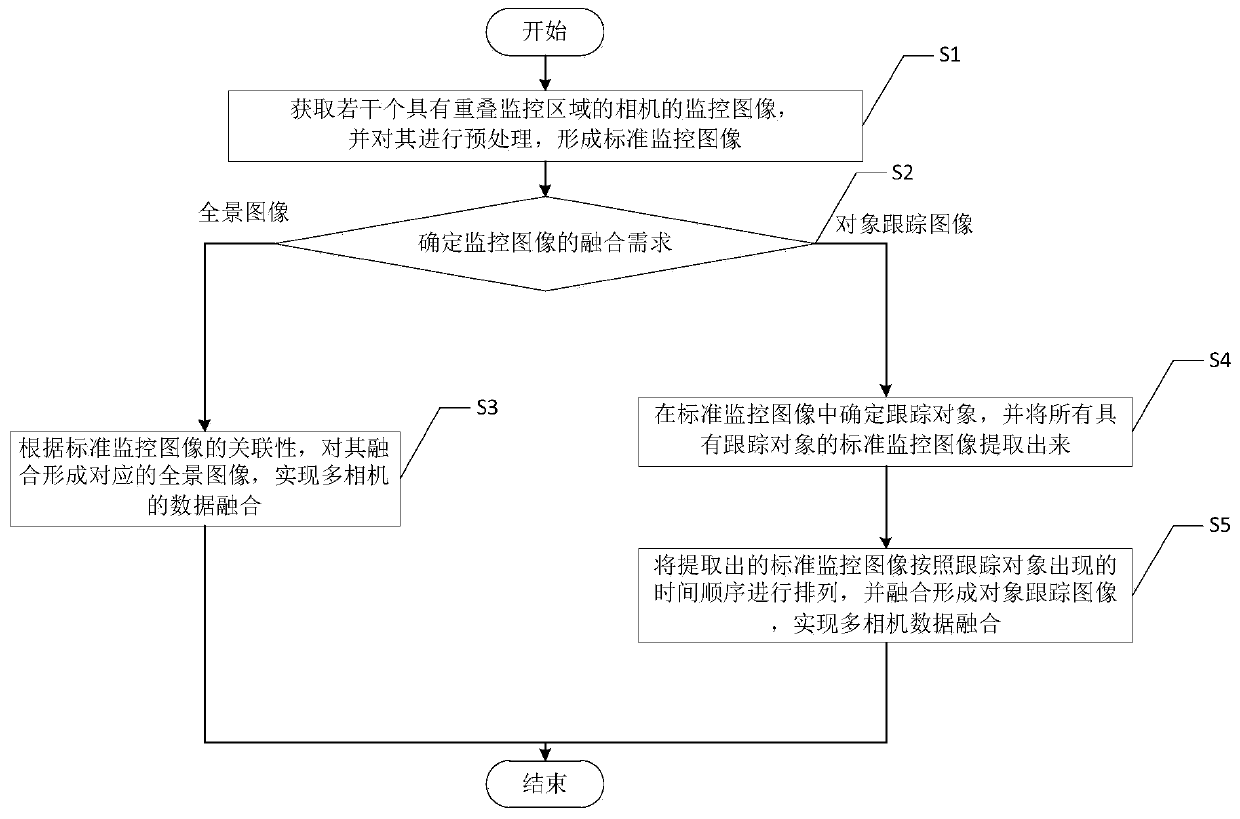

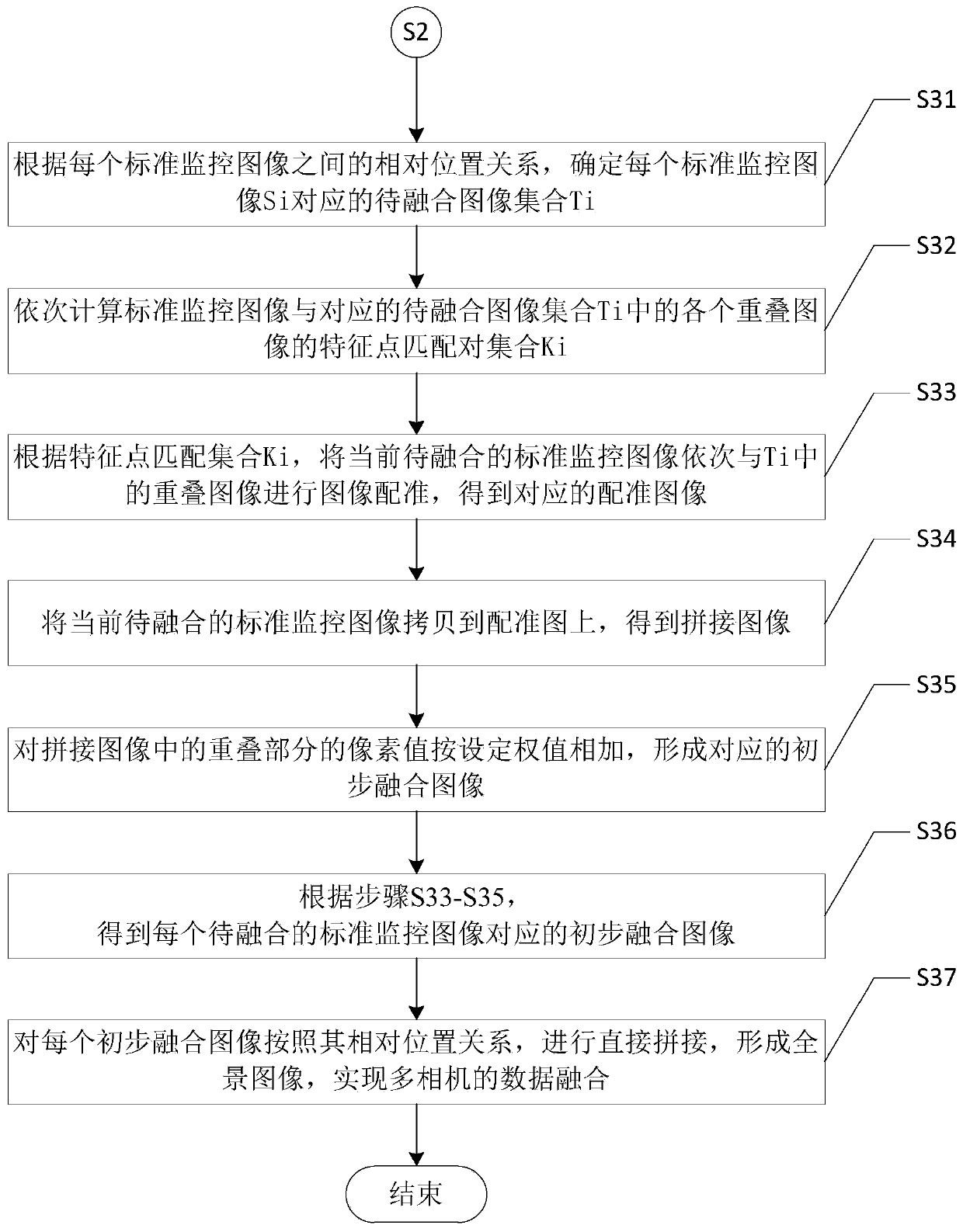

Multi-camera data fusion method in monitoring system

PendingCN110866889AImprove broad applicabilityEnhanced Processing Fusion EfficiencyImage enhancementImage analysisRadiologyMonitoring system

The invention discloses a multi-camera data fusion method in a monitoring system, and the method comprises the steps: S1, carrying out the preprocessing of a monitoring image with an overlapped monitoring region, and forming a standard monitoring image; S2, determining a fusion demand of the monitoring image; if the demand is fusing to form a panoramic image, entering S3; if the demand is fusing to form an object tracking image, entering S4; S3, according to the relevance of the standard monitoring images, fusing the standard monitoring images to form corresponding panoramic images; S4, determining a tracking object, and extracting all standard monitoring images with the tracking object; and S5, arranging the extracted standard monitoring images according to the appearing time sequence ofthe tracking object, and fusing to form an object tracking image. The multi-camera data fusion method suitable for different scenes is provided for presentation of panoramic images and tracking of specific objects in an existing monitoring system, the calculated amount during image data fusion is reduced, and the image data fusion efficiency and the presentation effect of fused images are improved.

Owner:成都威爱新经济技术研究院有限公司

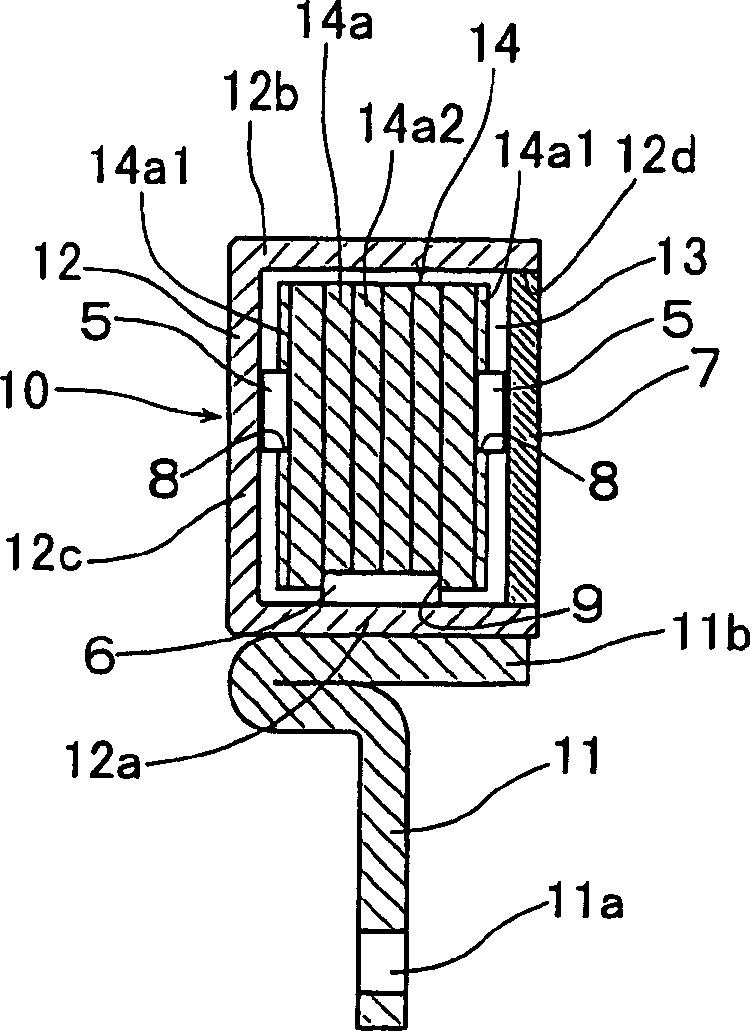

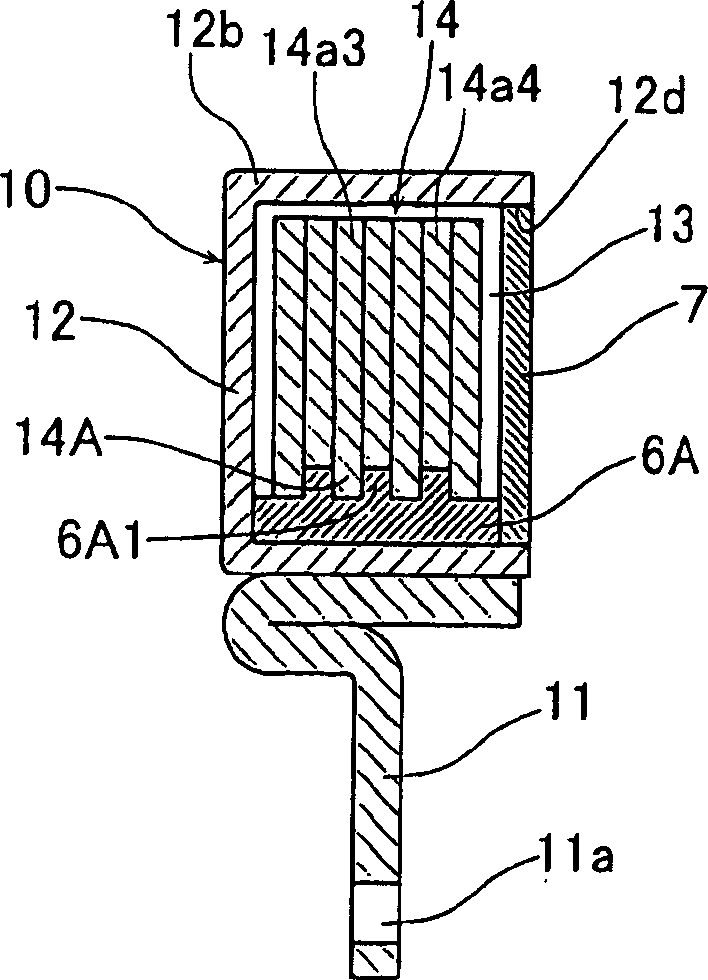

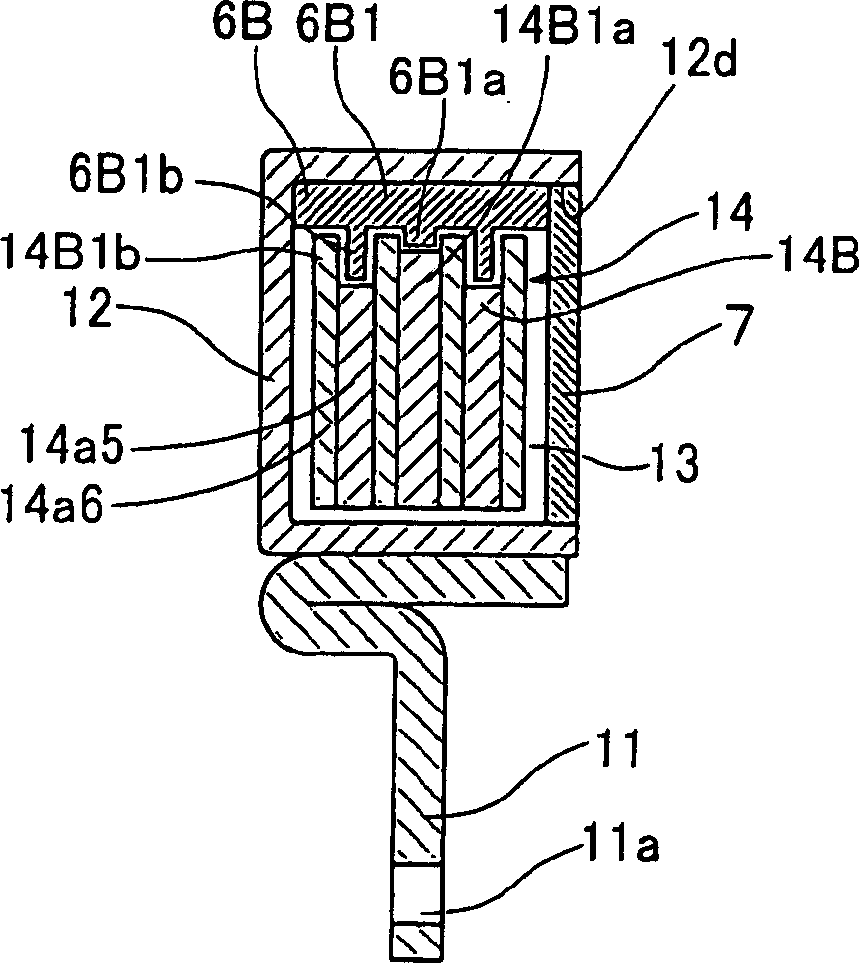

Viscous damper

InactiveCN1666035AImprove broad applicabilityQuality adjustmentMachines/enginesEngine componentsManufacturing cost reductionInertial mass

A viscous damper having improved versatility, easy to produce, capable of reducing production cost The viscous damper comprises an annular inertial mass body (14) received in a case (10) together with a damping liquid, and a hub (11) for fixing the case on the rotary shaft of an internal combustion engine. The case comprises a case main body (12) of substantially U-shaped cross section, and a cover (7) for liquid-tightly closing an opening (12d) directed to one axial side of the main body, and defining a sealed chamber (13) in the inside. The inertial mass body is made by superposing and joining a plurality of annular plates (14a). By thrust bearings (5) attached in holes (8) in the annular plate on both axial sides of the inertial mass body and by a journal bearing (6) attached in a recessed groove (9) in the inner periphery of the inertial mass body, the inertial mass body is supported on both axial sides and radially and disposed for peripheral rotation in the sealed chamber (13).

Owner:FUKOKU CO LTD

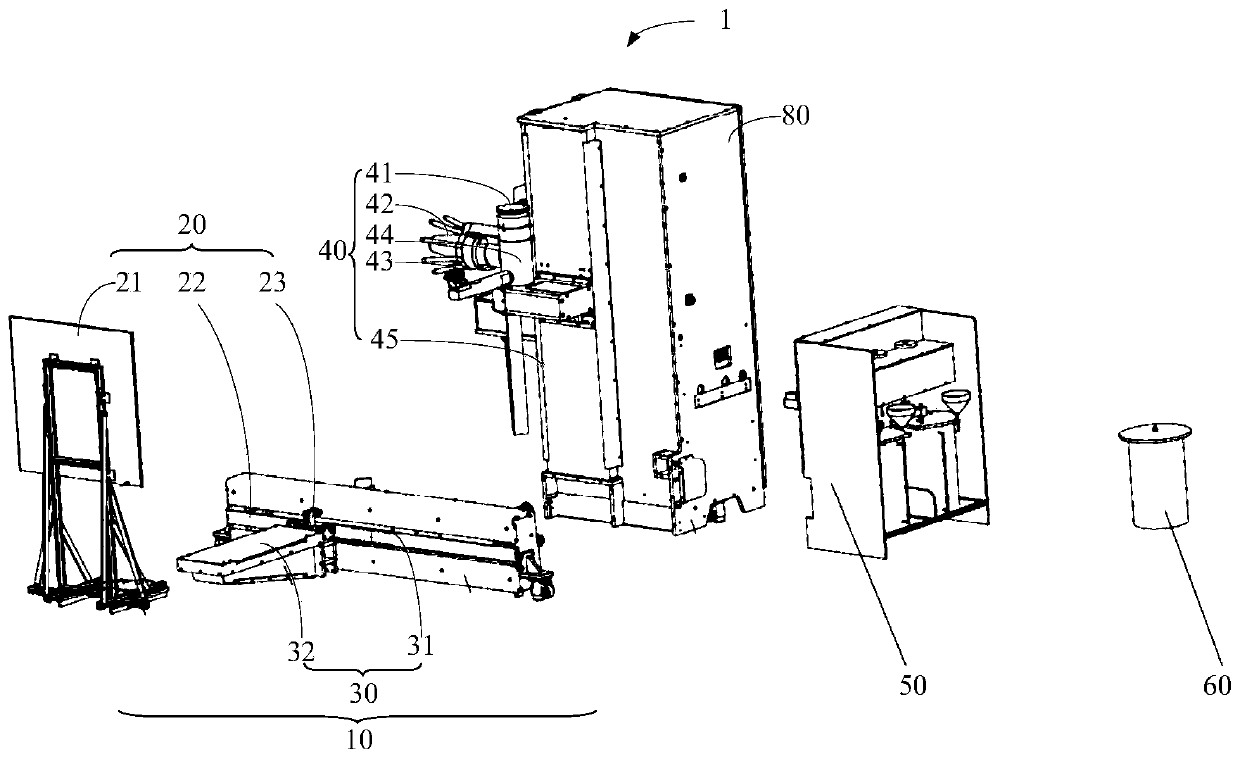

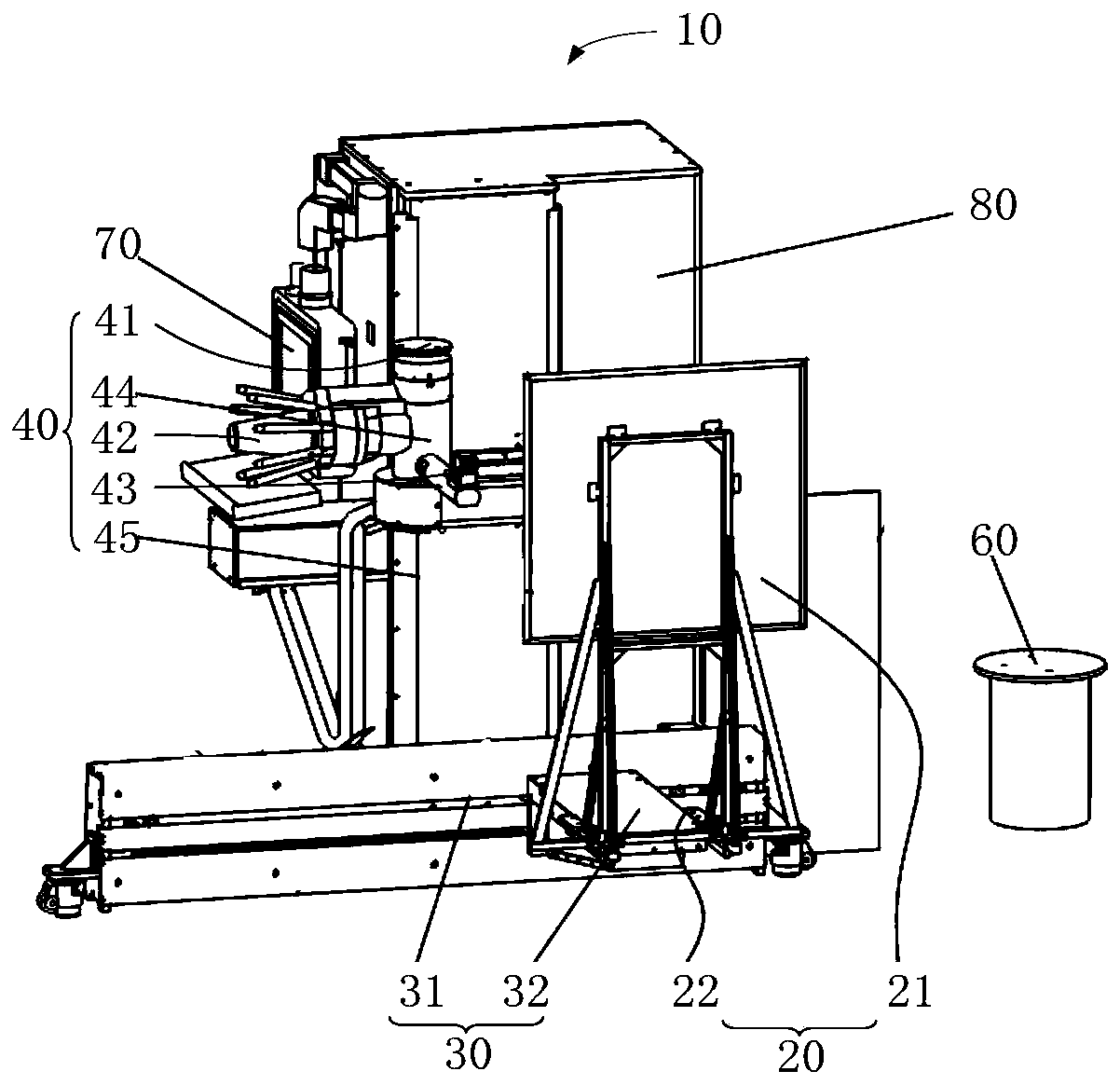

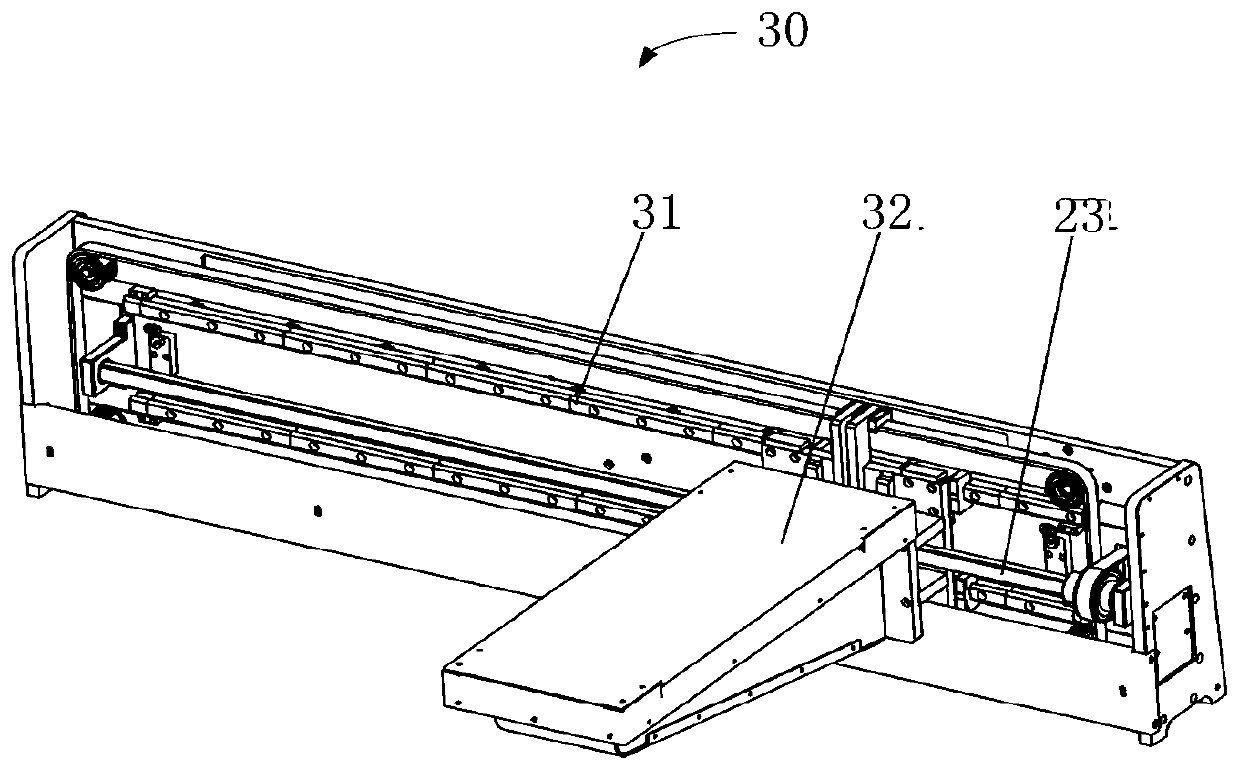

Reciprocating spraying robot and control device and spraying control method thereof

ActiveCN111250313AImprove broad applicabilityImprove applicabilitySpraying apparatusControl engineeringControl cell

The invention provides a reciprocating spraying robot and a control device and a spraying control method thereof. The reciprocating spraying robot comprises a three-axis motion mechanism, a paint supply device and a control device; the control device comprises a control unit and a touch screen, a keyboard and a control switch connected with the control unit; and the control unit comprises a spraying program setting module used for driving the touch screen to display a program setting interface and generating a spraying program according to received spraying control information input by the touch screen, the keyboard or the control switch, and further comprises a paint spraying module for calling the spraying program, driving the three-axis motion mechanism to move according to a spraying track and controlling the paint supply device, an atomizer or a spraying gun to perform spraying according to a spraying formula and spraying parameters. Through the reciprocating spraying robot, the effect of flexibly setting and adjusting spraying actions according to spraying demands is achieved, so that the wide applicability of the reciprocating spraying robot is improved.

Owner:安捷睿(厦门)机器人有限公司

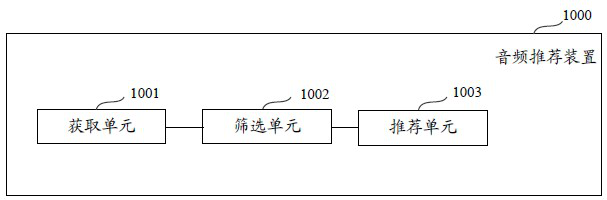

Audio recommendation method and device, electronic equipment and computer storage medium

ActiveCN112380377ARealize personalized recommendationImprove accuracyDigital data information retrievalSpecial data processing applicationsPersonalizationEngineering

The invention provides an audio recommendation method and device, electronic equipment and a computer storage medium, and relates to the technical field of artificial intelligence. According to the embodiment of the invention, in response to a page display request triggered by a target account, the reference audio corresponding to the target account is acquired according to the historical behaviordata of the target account, and at least one to-be-recommended audio is screened out from the candidate audio set according to the sound spectrum information of the reference audio and the sound spectrum information of each candidate audio in the candidate audio set, and the at least one screened to-be-recommended audio to a target account is recommended, according to the embodiment of the invention, the reference audio needs to be determined according to the historical behaviors of the user, and the to-be-recommended audio is screened from the candidate audio set according to the determinedreference audio, so that different audios can be flexibly recommended to the account for different accounts, thereby realizing personalized recommendation of the audios, and improving the user experience. Moreover, the historical behaviors of the target account and the content of the audio are considered at the same time, so that the accuracy of recommending the to-be-recommended audio to the target account is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

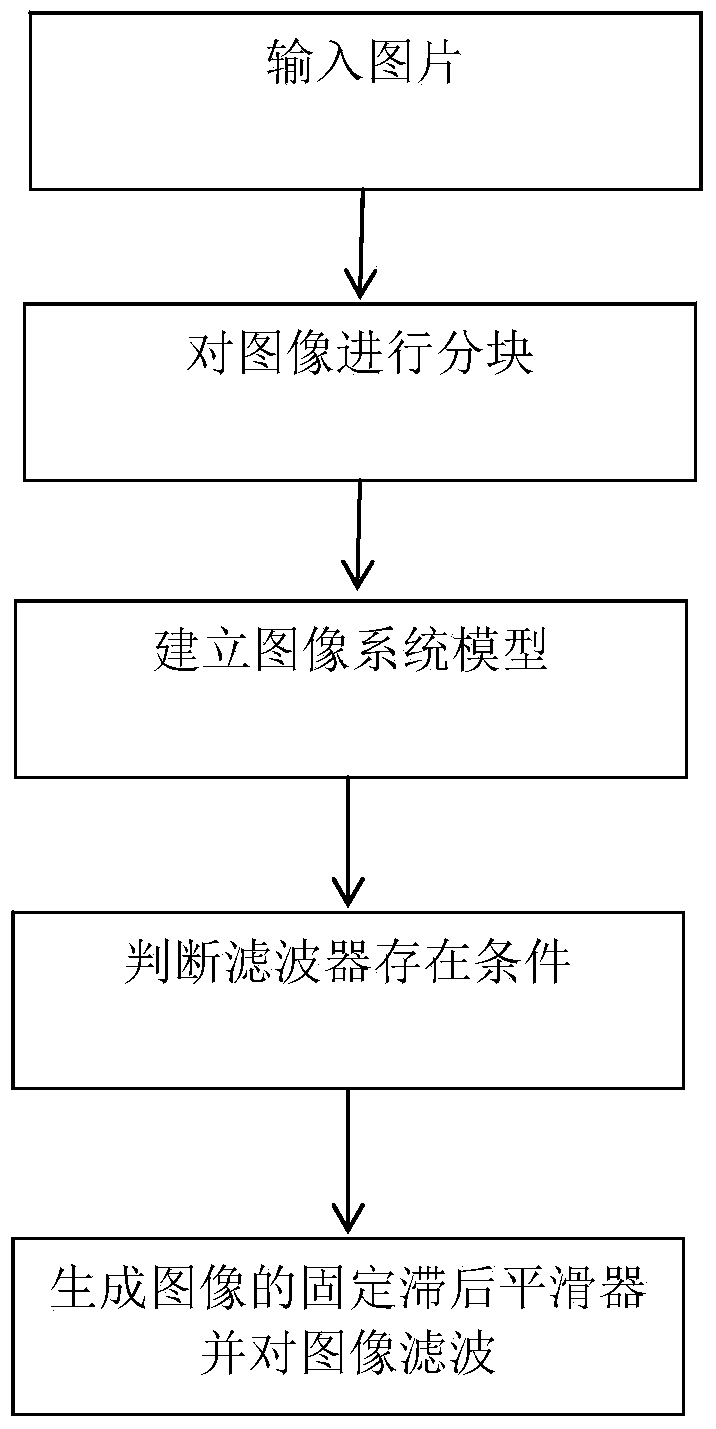

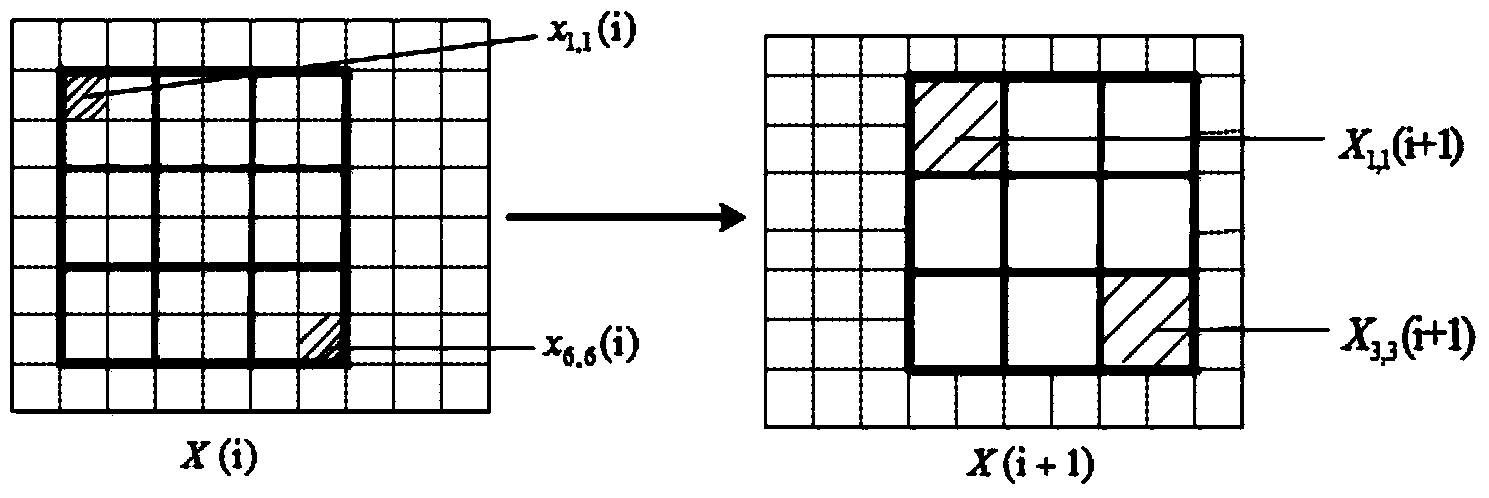

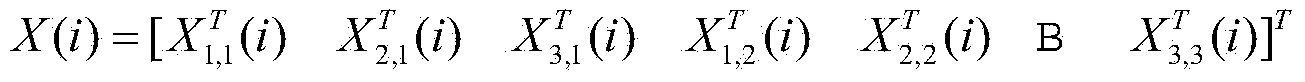

Filtering method in image recovery

ActiveCN103514589ATroubleshoot image recovery issuesImage Restoration ImplementationImage enhancementImaging processingState space

The invention discloses a filtering method in image recovery. The filtering method comprises the following steps of 1, carrying out blocking preprocessing on an image to be processed; 2, establishing a state space model of the image in a green space; 3, generating a fixed delay smoother of the image and carrying out filtering processing on the image. According to the invention, a filtering calculation method of the green space is applied to image processing; compared with the calculated amount of the augmentation Kalman filtering algorithm, the calculated amount of the filtering method is greatly reduced; image recovery is implemented under the condition of not knowing the noise statistic characteristic; applicability of image noise filtering processing and robustness of image recovery are effectively improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

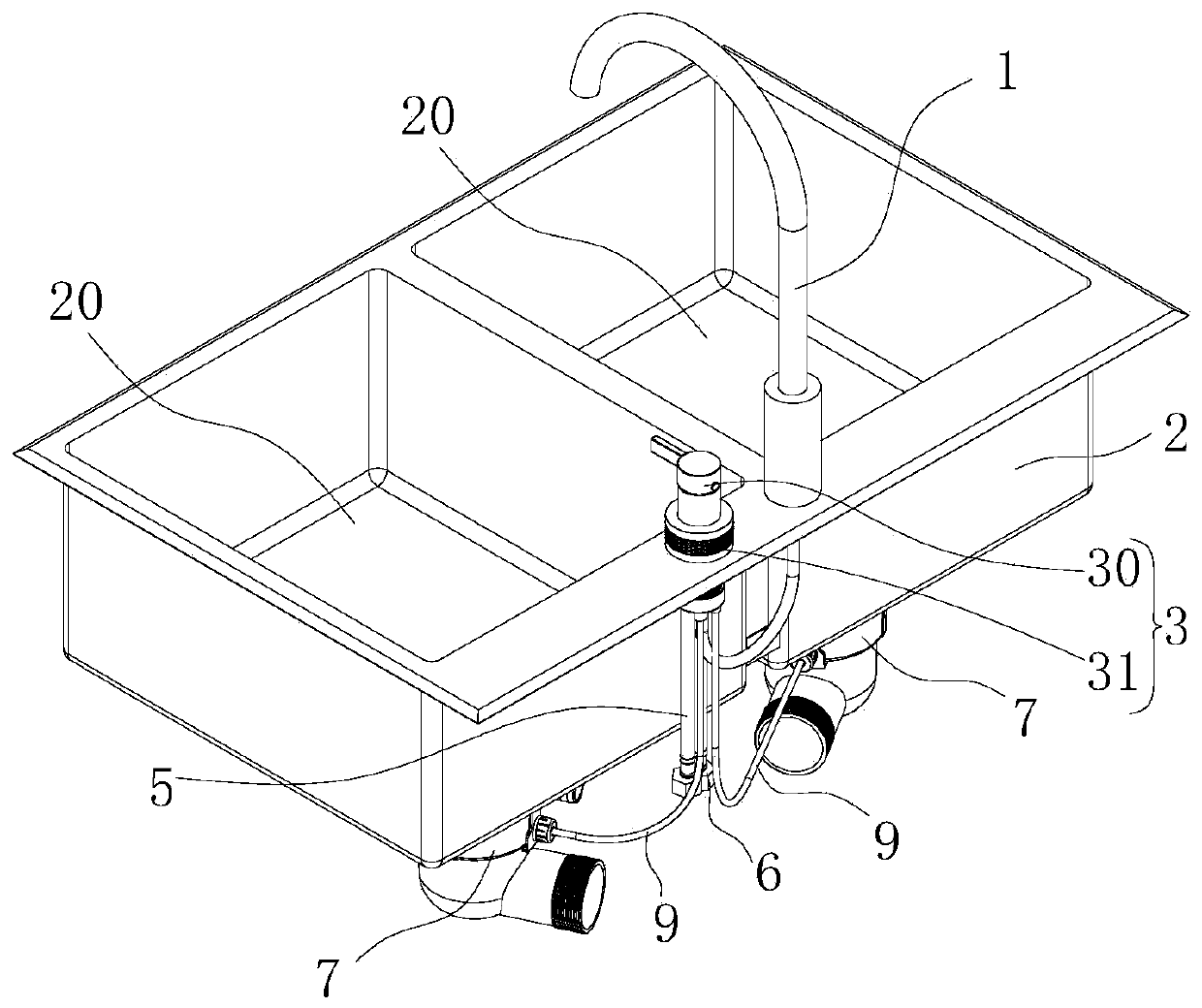

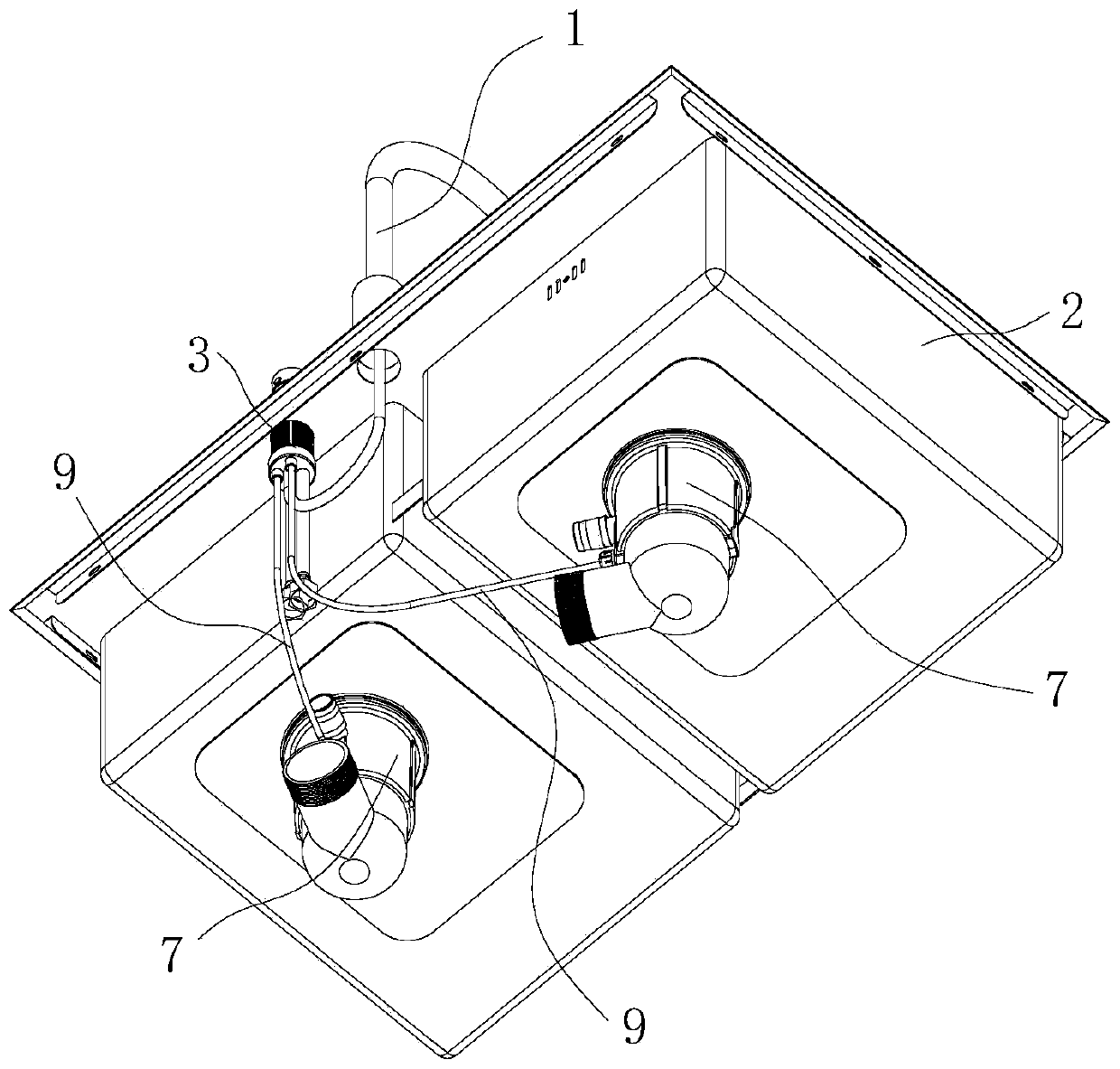

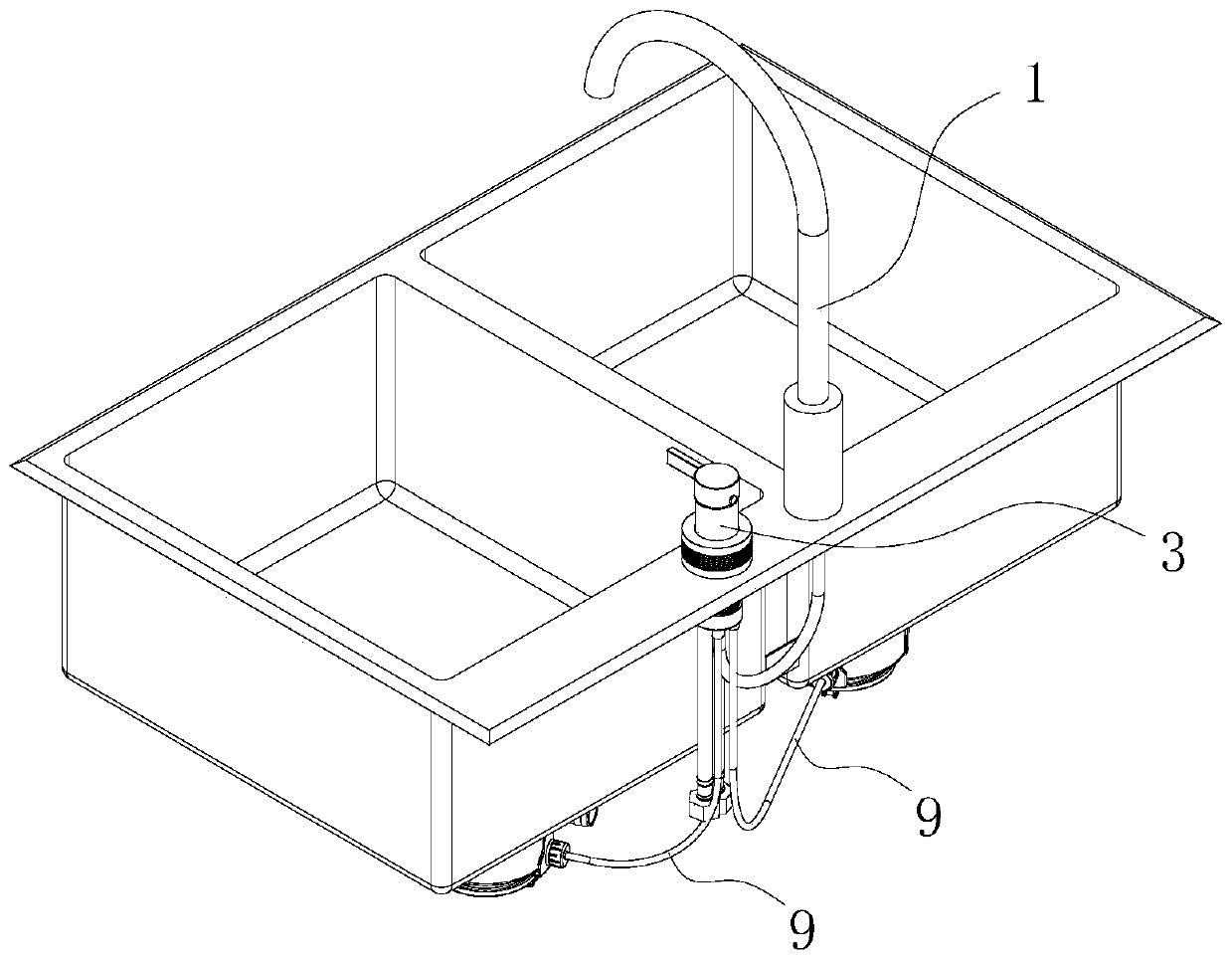

Control system for automatically controlling water intake and water drainage of water sink

PendingCN110629839ARealize automatic controlSave control spaceDomestic plumbingAutomatic controlControl system

The invention discloses a control system for automatically controlling water intake and water drainage of a water sink. The system comprises a water faucet, a water sink body and a switch control part, wherein at least one cavity is formed in the water sink, a drain outlet is formed in the bottom of each cavity located in the water sink body, a drainer is arranged at the drain outlet in each cavity located in the water sink body, and a sealing cover for opening and closing the drain outlet is arranged in each drainer; a faucet valve switch and a draining control switch for controlling each sealing cover to open or close the drain outlet are arranged at the switch control part; and a drive-by-wire pulling steel wire rope and a touch control part are arranged between the switch control partand each drainer, one end of each drive-by-wire pulling steel wire rope is connected to the draining control switch, and the other end of each drive-by-wire pulling steel wire rope is connected with the touch control part in each drainer and drives the touch control part to trigger opening and closing of the sealing cover in a linked manner when the draining control switch pulls each drive-by-wirepulling steel wire rope respectively.

Owner:ZHONGSHAN GABALU KITCHEN & BATHROOM PRODS

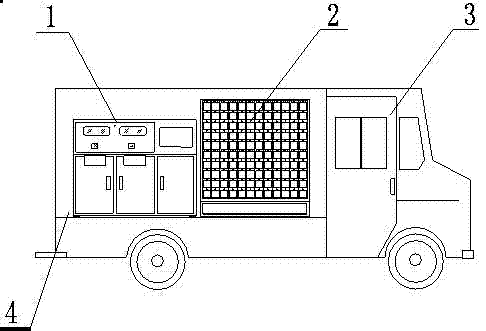

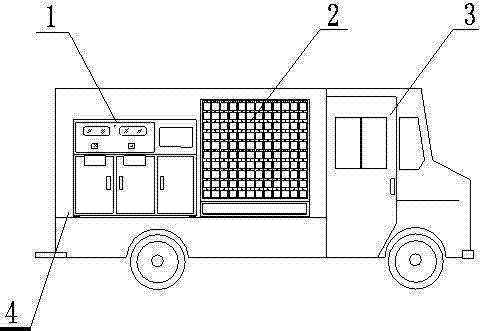

Mobile emergency drug dispensing system

InactiveCN102525776AImprove broad applicabilityImprove practicalityNursing accommodationDrug dispensingMedical emergency

The invention discloses a mobile emergency drug dispensing system. The system comprises a car body; a drug dispensing machine and a drug cabinet are arranged inside the carriage of the car body, are connected through data lines and are connected with a power source which is arranged inside a car through wires. The invention improves wide applicability and practicability of Chinese medicinal granules and drug dispensing devices, and allows more people to benefit from up-to-date modern Chinese medicine equipment in China.

Owner:SICHUAN NEO GREEN PHARMA TECH DEV

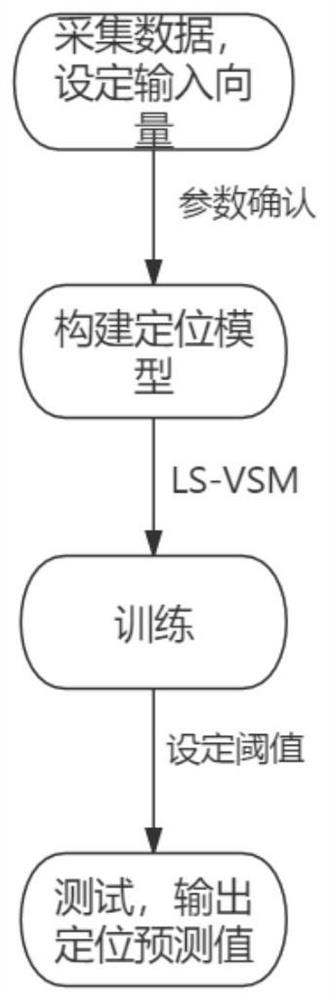

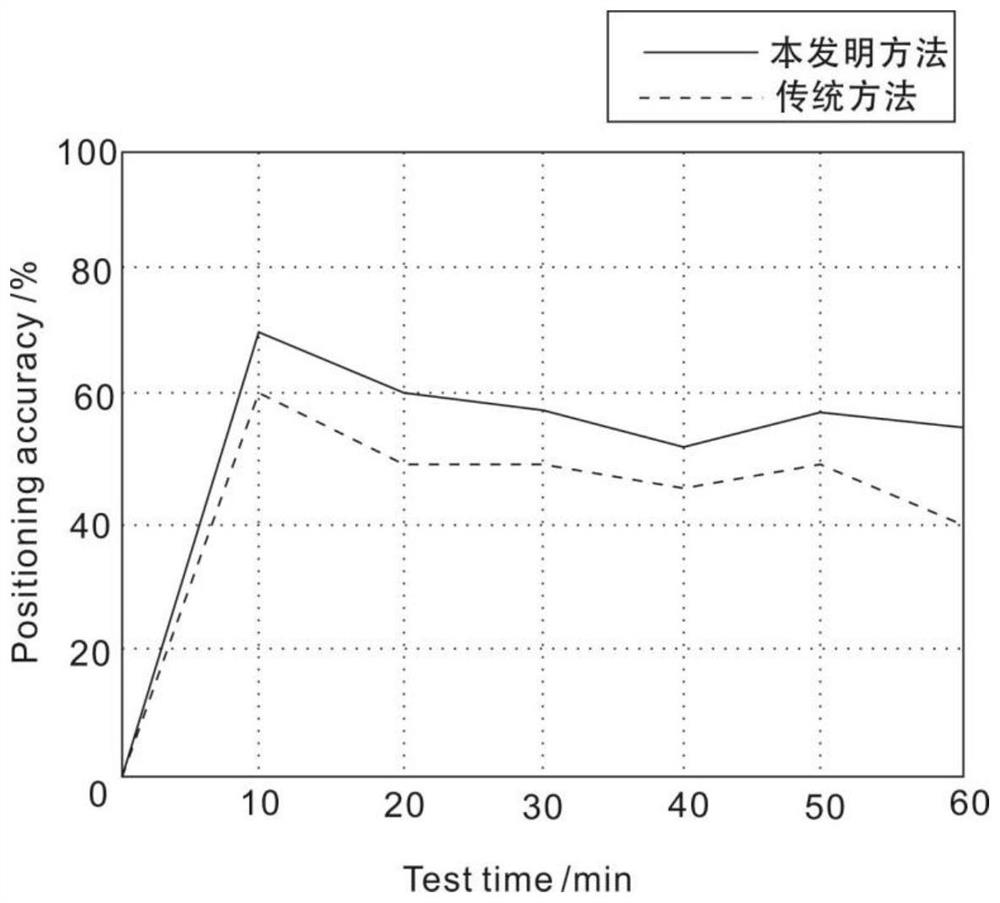

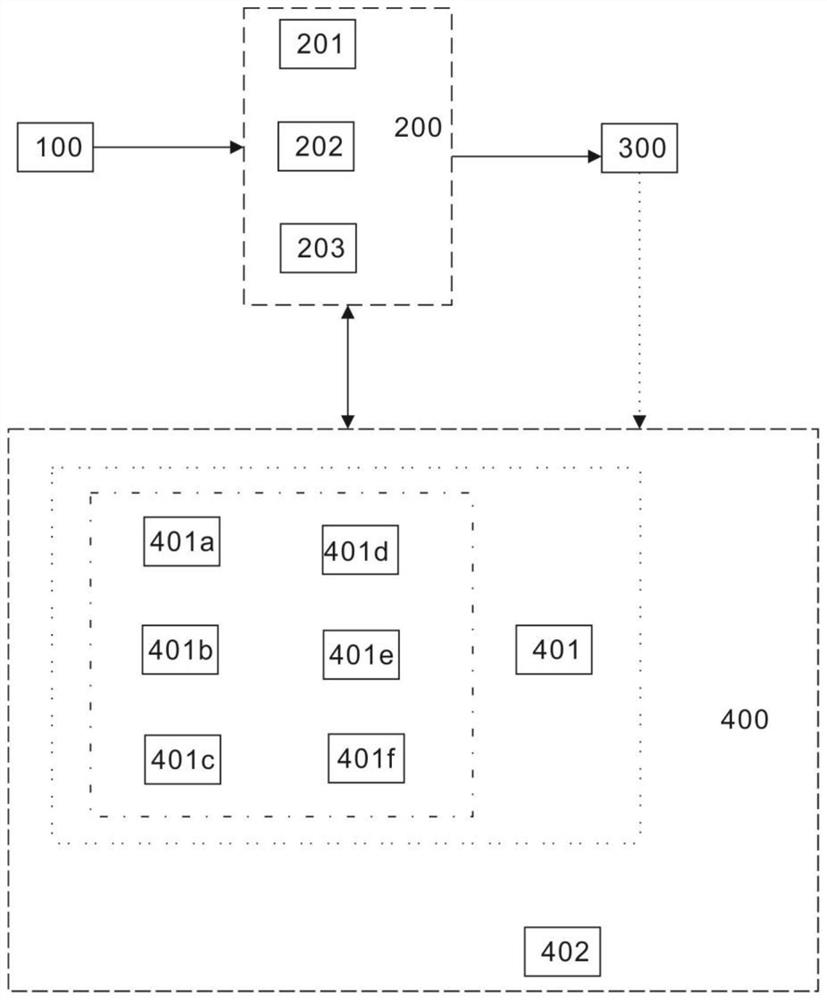

Positioning method and system based on hull attitude monitoring

ActiveCN112762935AHigh positioning accuracyImprove real-time performanceNavigational calculation instrumentsSustainable transportationData setSimulation

The invention discloses a positioning method and system based on hull attitude monitoring. The method comprises the steps of: collecting hull attitude monitoring data, carrying out preprocessing, dividing a data set, and setting an input vector; constructing a positioning model based on a time sequence strategy, and performing parameter confirmation on the input vector; performing positioning prediction training on the positioning model on the basis of an LS-VSM and the data set; and setting a positioning training threshold, if the positioning model satisfies the positioning training threshold, outputting the trained positioning model, and inputting a test set into the positioning model to perform testing to obtain a positioning predicted value. According to the positioning method and system of the invention, centimeter-level hull positioning is realized through the positioning model and RTK real-time differential positioning; hull attitude real-time monitoring, real-time hull attitude broadcasting, real-time transceiving, viewing and storage of data of a ground station are realized; data information used by each ship is stored in the cloud, can be called, viewed and analyzed; an IOT wireless data terminal and 5G can be supported; and the positioning precision of the hull is improved, the real-time performance and wide applicability of hull monitoring are improved.

Owner:赫星(厦门)电子有限公司

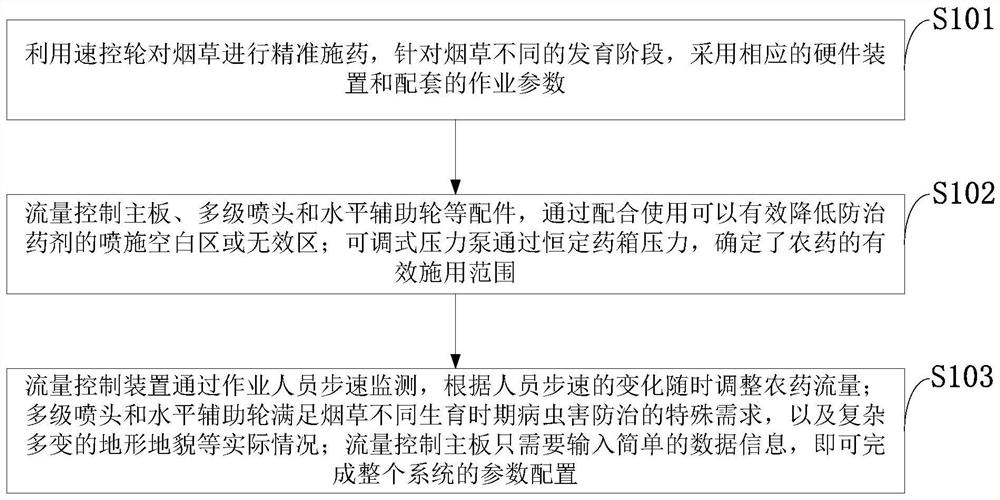

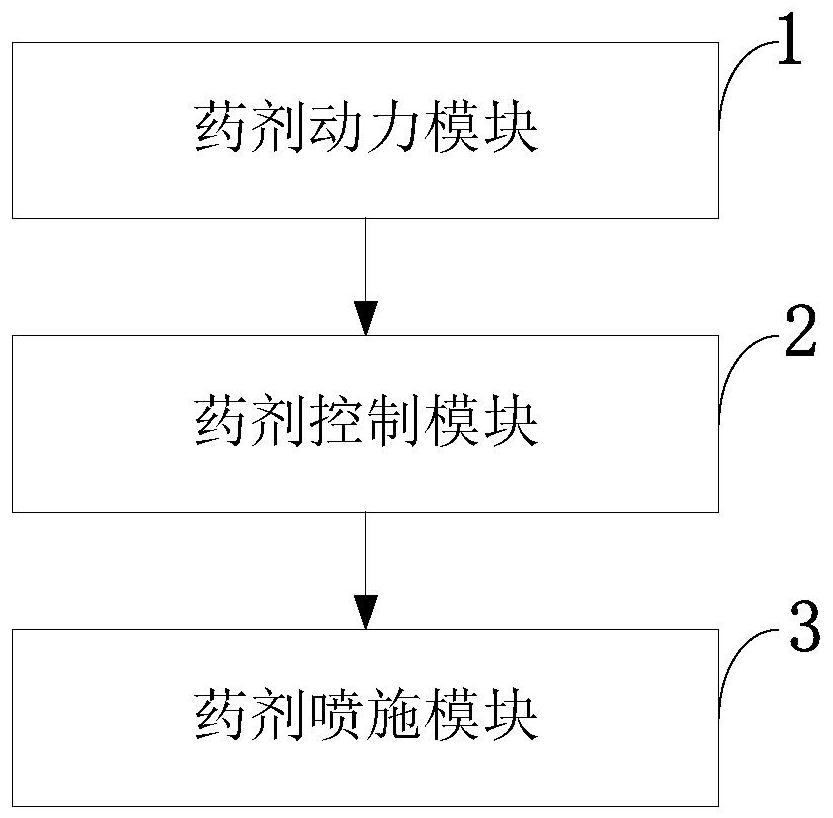

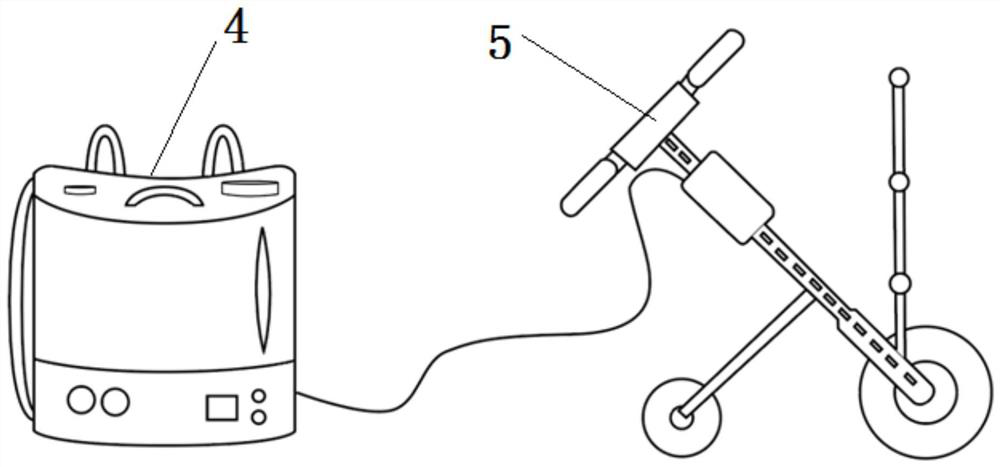

Control method, system and device for accurately applying pesticide to tobaccos and application

PendingCN111758707AImprove automationImprove the level of intelligenceTobacco cultivationPlant protectionAgricultural scienceNicotiana tabacum

The invention belongs to the technical field of tobacco pesticide application control, and discloses a control method, system and device for accurately applying pesticide to tobaccos and application.A speed control wheel is used for accurately applying the pesticide to the tobaccos, and corresponding hardware devices and matched operation parameters are adopted for different development stages ofthe tobaccos; accessories such as a flow control main board, a multi-stage spray head and a horizontal auxiliary wheel are matched for use to reduce a spraying blank area or an invalid area of the prevention and treatment pesticide; an adjustable pressure pump determines the effective application range of the pesticide through the constant pesticide box pressure; the flow control device adjusts the pesticide flow at any time according to the change of the step speed of an operator through the step speed monitoring of the operator; the multi-stage spray head and the horizontal auxiliary wheelmeet the special requirements of pest control in different growth periods of the tobaccos; and the flow control mainboard only needs to input simple data information to complete parameter configuration of the whole system. The requirements of current precise pesticide application technicians, instruments, sites and the like are reduced, and the requirements of different tobacco planting productionareas can be met.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

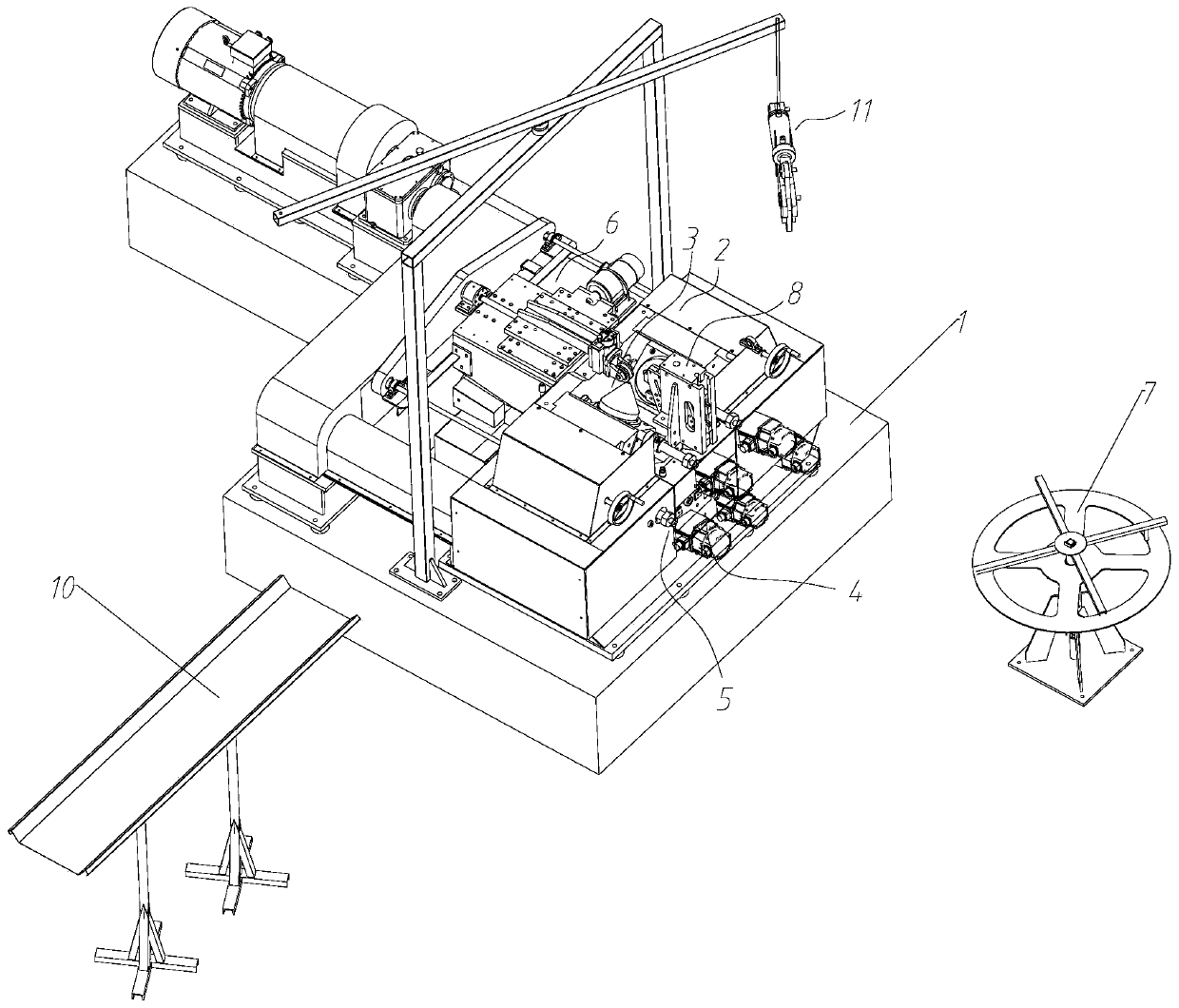

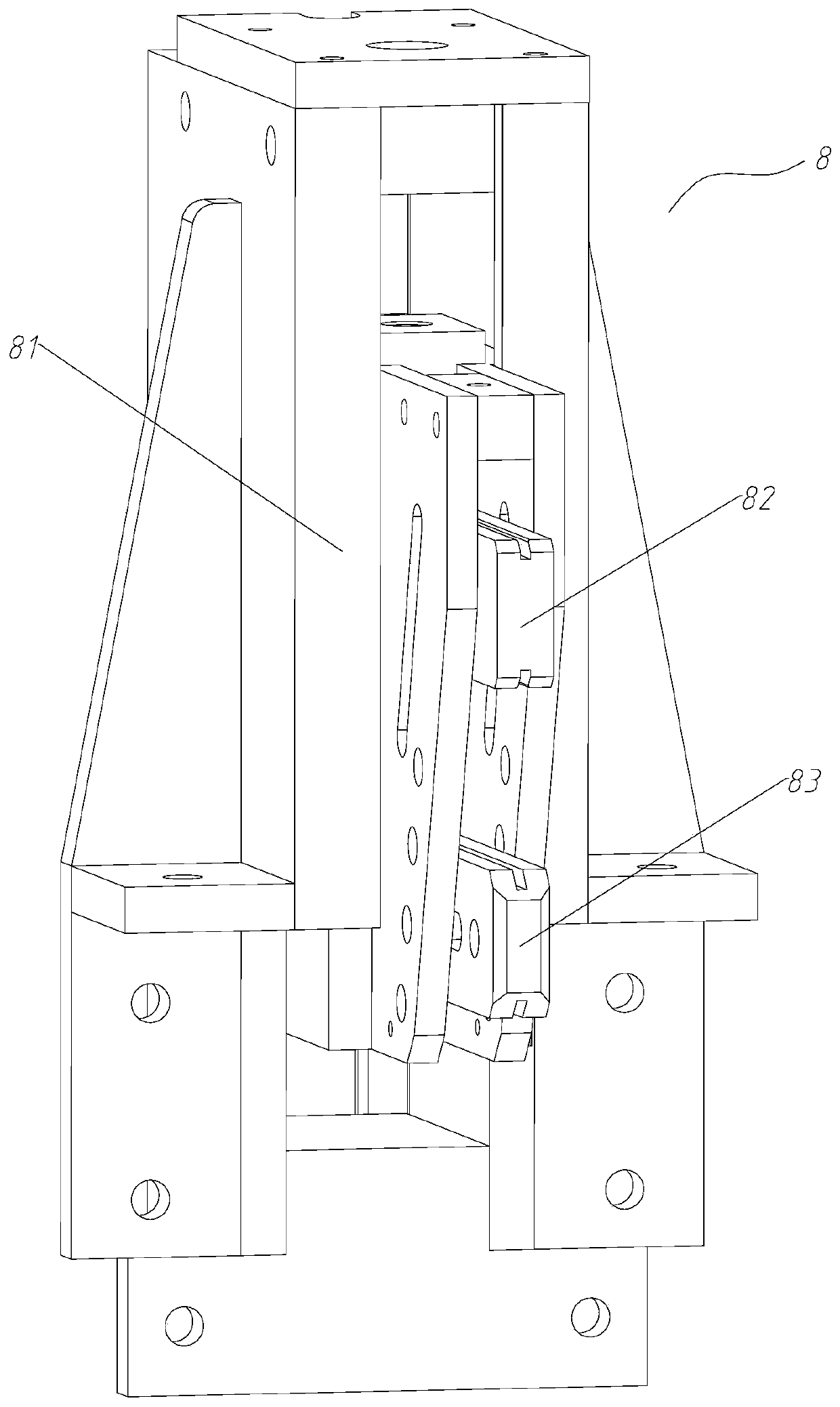

Screw blade cold-rolling mill

ActiveCN110976725AQuality improvementReduce scrap rateMetal-working feeding devicesMetal rolling stand detailsSpiral bladeStructural engineering

The invention belongs to the technical field of screw blade production equipment, and provides a screw blade cold-rolling mill. The screw blade cold-rolling mill comprises a main machine frame, a first roller, a second roller and a roller angle adjusting member, the first roller is arranged on the main machine frame, the second roller is arranged on the main machine frame, and the roller angle adjusting member is arranged on the main machine frame and used for bearing the first roller and the second roller. Through the technical scheme, the problem of poor product quality caused by difficult adjustment of the roller seam in the prior art is solved.

Owner:石家庄旭东机械制造有限公司

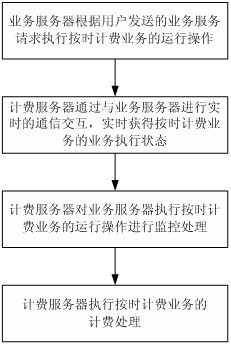

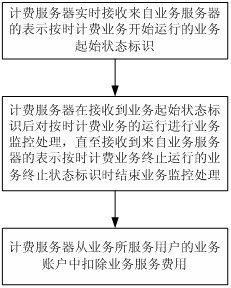

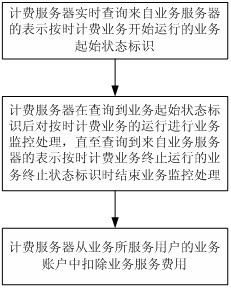

On-time charging service monitoring method based on charging server

InactiveCN102694661AReduce cost inputRealize real-time billing controlMetering/charging/biilling arrangementsThird partyReal-time charging

The invention provides an on-time charging service monitoring method based on a charging server, which comprises the following steps: a service server executes a running operation of an on-time charging service according to a service request sent by a user; and a charging server obtains the executing state of the on-time charging service in real time through carrying out real-time communication interaction with the service server, and monitors the running operation that the service server executes the on-time charging service, and executes the charging processing of the on-time charging service. Therefore, the charging server can obtain the executing state of the on-time charging service in real time, so that the running of the on-time charging service is correspondingly monitored in time according to the specific service management demand, so that a third party completely monitors and manages the on-time charging service by virtue of the charging server and possibly realizes on-time charging control; and meanwhile, the cost input of a third party operator for performing the on-time charging service management is greatly reduced.

Owner:CHONGQING SUNTEL TECH

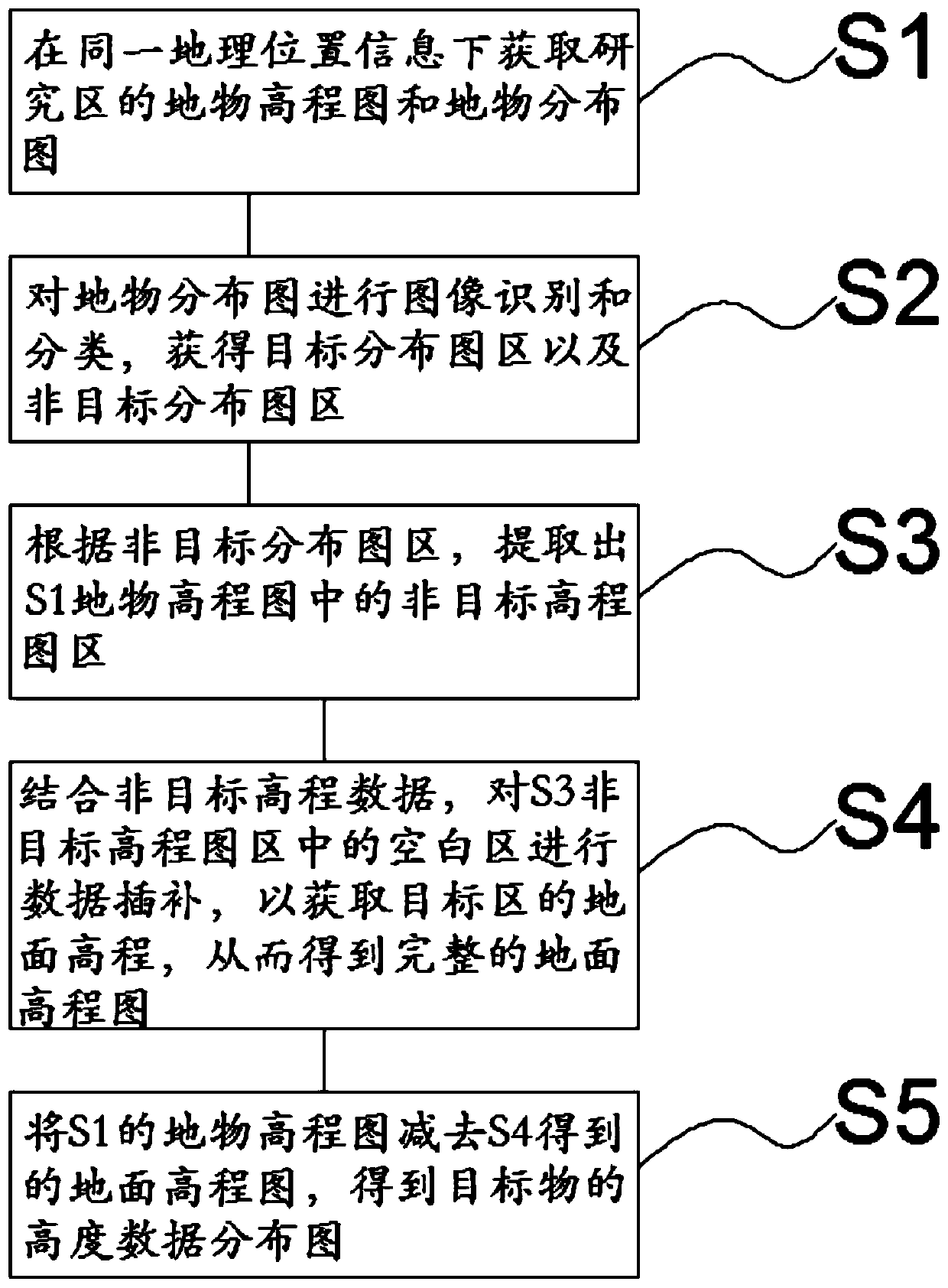

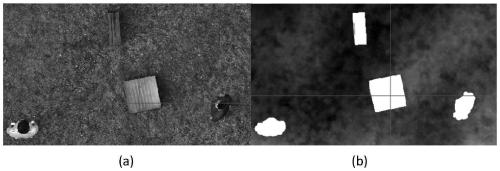

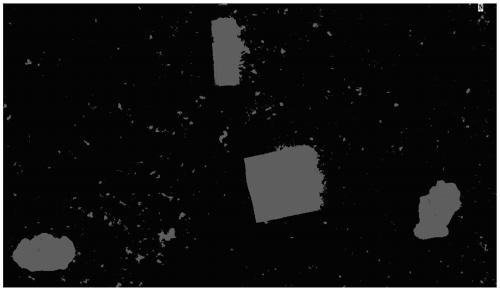

Target object height centralized measurement and calculation method

PendingCN111429509ATargetedImprove calculation efficiencyImage enhancementImage analysisElevation mapElevation data

The invention relates to a centralized measurement and calculation method for the height of a target object. The method comprises the following steps: S1, acquiring a ground object elevation map and aground object distribution map of a research area under the same geographic position information; s2, performing image recognition and classification on the ground object distribution diagram to obtain a target distribution diagram area and a non-target distribution diagram area; s3, according to the non-target distribution map area, extracting a non-target elevation map area in the ground objectelevation map in S1; s4, in combination with the non-target elevation data, performing data interpolation on the blank area in the non-target elevation map area in S3 to obtain the ground elevation of the target area so as to obtain a complete ground elevation map; and S5, subtracting the ground elevation map obtained in the step S4 from the ground object elevation map obtained in the step S1 toobtain height data distribution of the target object. The measuring and calculating method provided by the invention relates to an image recognition and interpolation algorithm, so that the target object pertinence of the method is strong, the centralized measurement and calculation of the height information can be realized, the measuring and calculating efficiency is high, the precision is high,the application is wide, the flexibility is strong, and the dynamic target object height measurement and calculation of different scales can be realized.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Management method of river ecological flows based on reservoir operation

InactiveCN101892647BReduce supplyAchieve protectionHydraulic engineering apparatusGenetic algorithmEngineering

The invention provides a management method of ecological flows river based on reservoir operation. The management method comprises the following steps: firstly, establishing a basic scheme, a compromise propose and an ideal scheme on the ecological flows management to be respectively suitable for the demands of high, medium and low water supply guarantee rate, and maintain health state of the basic, good and ideal ecological system of the river, simultaneously, dividing the capacity space of the reservoir to correspond to the management scheme of the ecological flows from top to down in sequence; then adopting a reservoir operation curve to guide so as to supply the water for the people and forming an integral reservoir ecological operation scheme by combining with the management scheme of the ecological flows; and finally applying a genetic algorithm, taking the water supply guarantee rate meeting the plan as the basic constrains and taking disturbance which reduces hydrologic regimeof the river as an optimal target to optimize parameters of the reservoir capacity partition, dispatch curves and the like, so that the management scheme of ecological flows of the river based on thereservoir operation is obtained. The method can be suitable for demands of the different water supply guarantee rates, provide the optimized ecological flows process and effectively protect the ecological system of the river.

Owner:BEIJING NORMAL UNIVERSITY

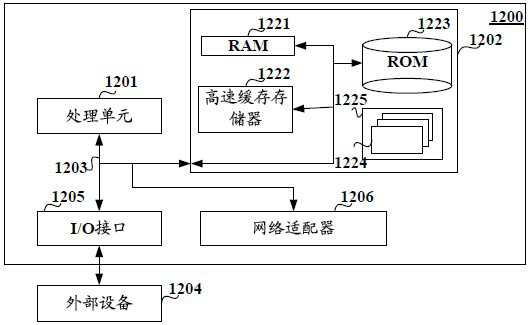

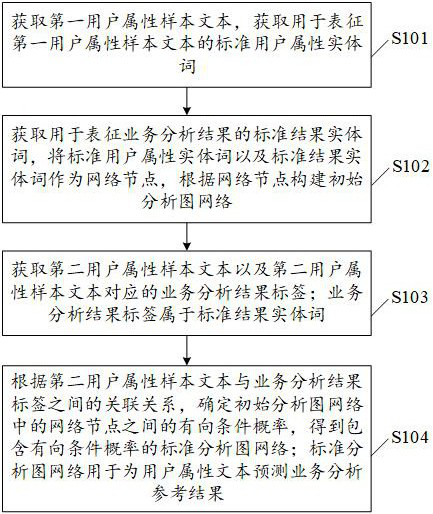

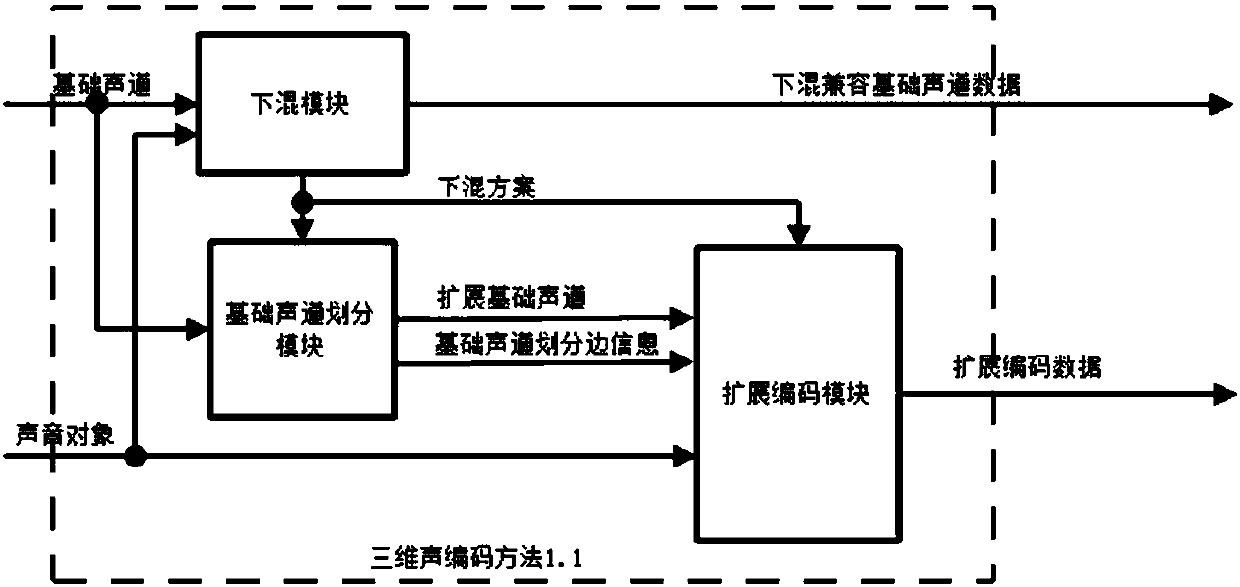

Data processing method, equipment and computer readable storage medium

ActiveCN112182253AImprove broad applicabilityDifferential expression eliminationNatural language data processingNeural architecturesTheoretical computer scienceEngineering

The embodiment of the invention discloses a data processing method, equipment and a computer readable storage medium, and the method comprises the steps: obtaining a first user attribute sample text,and obtaining a standard user attribute entity word for representing the first user attribute sample text; obtaining a standard result entity word used for representing a service analysis result, taking the standard user attribute entity word and the standard result entity word as network nodes, and constructing an initial analysis graph network according to the network nodes; obtaining a second user attribute sample text and a service analysis result label corresponding to the second user attribute sample text; and determining a directed conditional probability between network nodes in the initial analysis graph network according to an association relationship between the second user attribute sample text and the service analysis result label to obtain a standard analysis graph network containing the directed conditional probability. The standard analysis graph network is used for predicting a service analysis reference result for the user attribute text. By adopting the method, equipment and storage medium, the accuracy of a service analysis result can be ensured in service data analysis.

Owner:TENCENT TECH (SHENZHEN) CO LTD

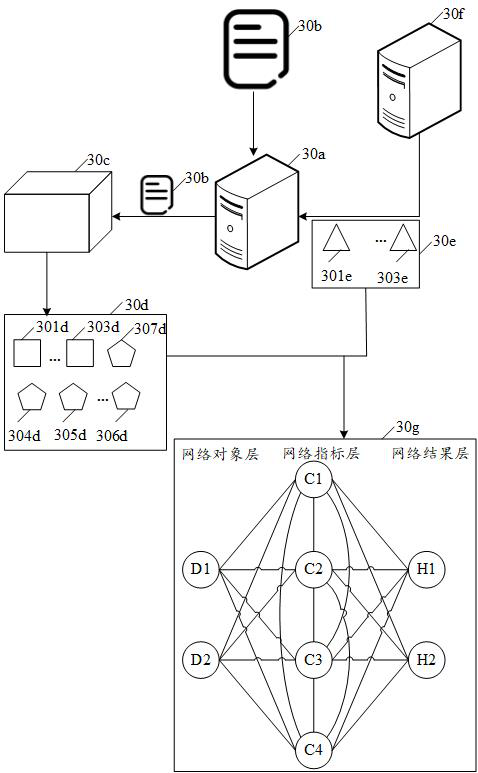

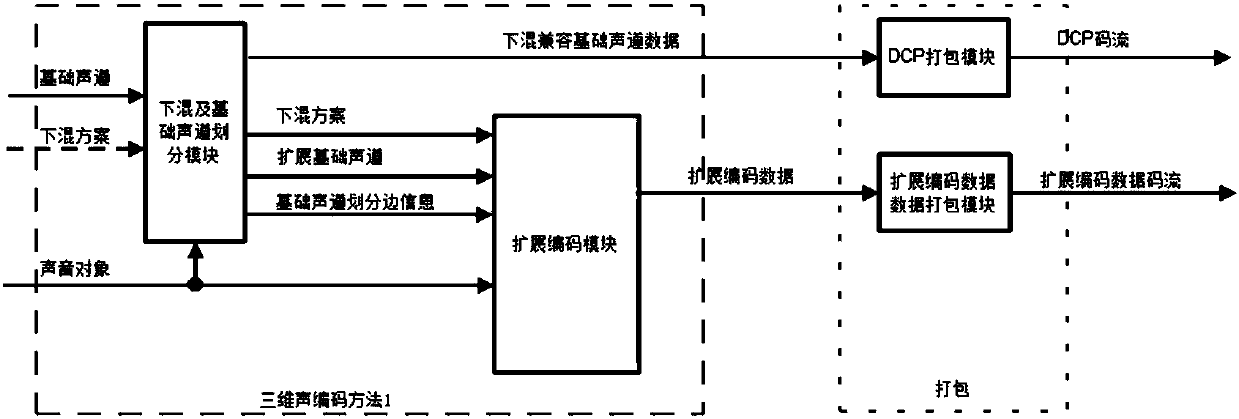

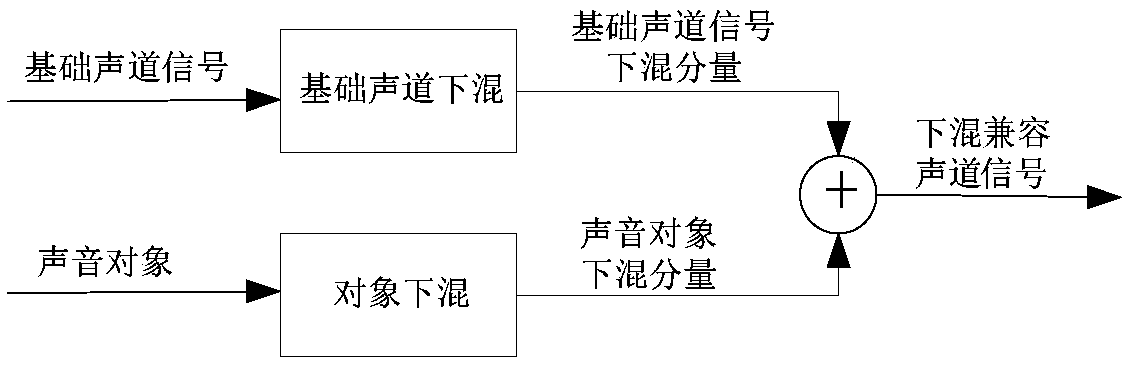

Encoder and decoder for transmitting three-dimensional sound signals by using multiple channels, coding method and decoding method of encoder and decoder

ActiveCN108206984ADiversified transmission methodsRealize three-dimensional sound playbackPseudo-stereo systemsChannel dataData packing

The invention discloses an encoder and decoder for transmitting three-dimensional sound signals by using multiple channels, a coding method and decoding method of the encoder and decoder. The encodercomprises a down-mixing and base channel division module, an extended coding module, a DCP packing module and an extended coded data packing module; the down-mixing and base channel division module isused for receiving a base channel and / or a sound object, performing down-mixing and base channel division operation according to a down-mixing scheme and outputting down-mixed compatible base channeldata, an extended base channel and base channel division side information; the extended coding module is used for receiving the sound object, the down-mixing scheme, the extended base channel and thebase channel division side information and outputting extended coded data; the DCP packing module is used for receiving the down-mixed compatible base channel data and packing the down-mixed compatible base channel data into DCP code streams according to a DCP standard; and the extended coded data packing module is used for receiving the extended coded data and outputting extended coded data streams. The encoder, decoder, coding method and decoding method of the invention are compatible with movie servers according with the DCP protocol so as to realize direct playing and can realize three-dimensional sound playback of cinemas when three-dimensional sound processors are adopted to perform playing.

Owner:WAVARTS TECH CO LTD

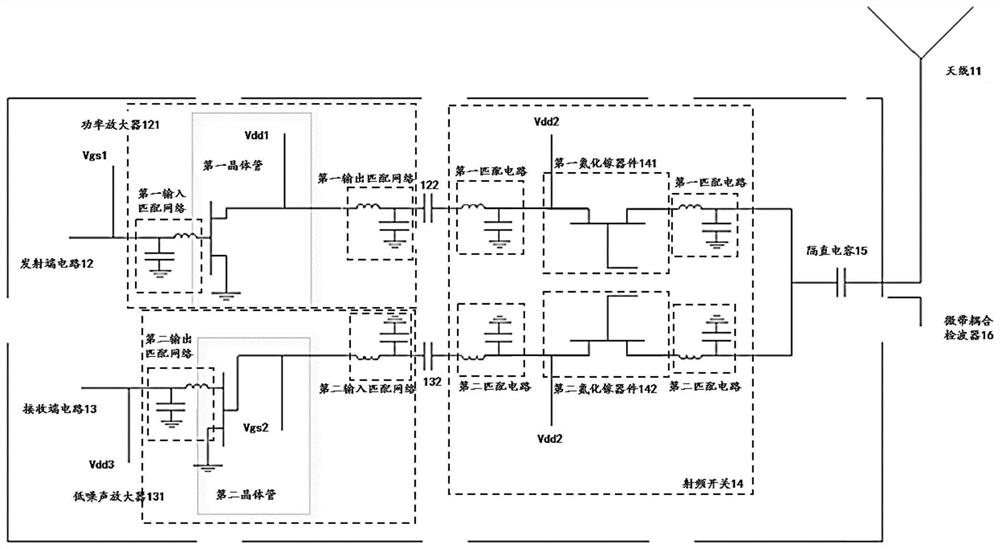

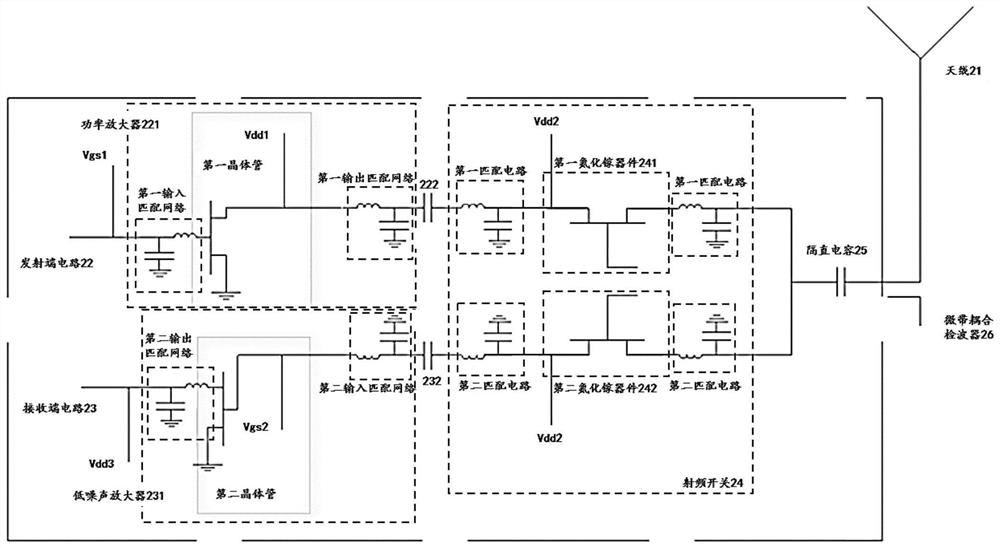

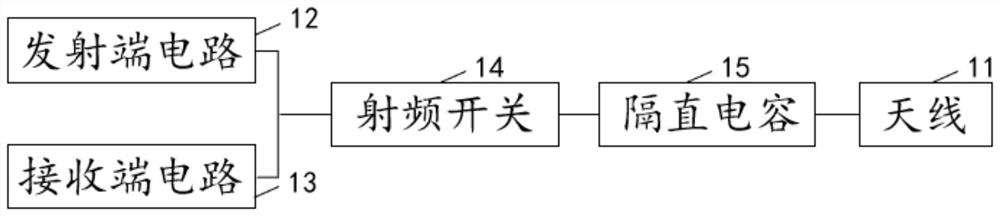

Radio frequency transceiving front end

The invention provides a radio frequency transceiving front end, and the front end comprises an antenna, a transmitting end circuit, a receiving end circuit, a radio frequency switch and a blocking capacitor; the radio frequency switch is connected to the transmitting end circuit and the receiving end circuit, the antenna is connected to two ends of the radio frequency switch through the blocking capacitor, the transmitting end circuit is used for amplifying the power of a radio frequency signal to be transmitted, the receiving end circuit is used for reducing the noise interference of the system and amplifying the received radio frequency signal, and the transmitting end circuit and the receiving end circuit are integrated in a package. The radio frequency switch is connected in series with the transmitting end circuit of the radio frequency transceiving front end, and the transmitting end circuit and the receiving end circuit are integrated together, so that the size of the radio frequency transceiving front end is obviously reduced, and the portability and wide applicability of the radio frequency transceiving front end are improved.

Owner:深圳市时代速信科技有限公司

Electronic control fuel injection system with adjustable injection starting pressure for low-speed two-stroke diesel engine

PendingCN107355329AIncrease jetting flexibilityThe spray pressure is flexible and adjustableFuel injection apparatusMachines/enginesPressure stabilizationDieseling

The invention relates to an electronic control fuel injection system with adjustable injection starting pressure for a low-speed two-stroke diesel engine, The electronic control fuel injection system with adjustable injection starting pressure for the low-speed two-stroke diesel engine comprises a high-pressure fuel supply module, a fuel injection valve, a fuel injector and a gas regulation control unit, wherein the high-pressure fuel supply module is used for providing high-pressure fuel with stable and reliable pressure; the fuel injection valve is connected with the high-pressure fuel supply module and used for controlling starting and stopping of fuel injection; the gas regulation control unit is used for providing driving gas, and the pressure of the driving gas is regulated in advance according to the need of the rotating speed or the load of the diesel engine and an injection starting pressure is set so that the control over the injection starting pressure is achieved; the upper portion of the fuel injector is connected with the gas regulation control unit, and the lower portion of the fuel injector is connected with the fuel injection valve; and when the pressure of the high-pressure fuel entering the lower portion of the fuel injector through the fuel injection valve exceeds the pressure of the driving gas in the gas regulation control unit, the fuel injector starts fuel injection at the preset injection starting pressure. The electronic control fuel injection system with adjustable injection starting pressure for the low-speed two-stroke diesel engine achieves the adjustability of the injection starting pressure, improves the response speed of a needle valve, ensures the stability of the fuel injection pressure, has the advantages of being simple in structure and wide in application range, and can be applied to different diesel engines.

Owner:CSSC POWER INST CO LTD +1

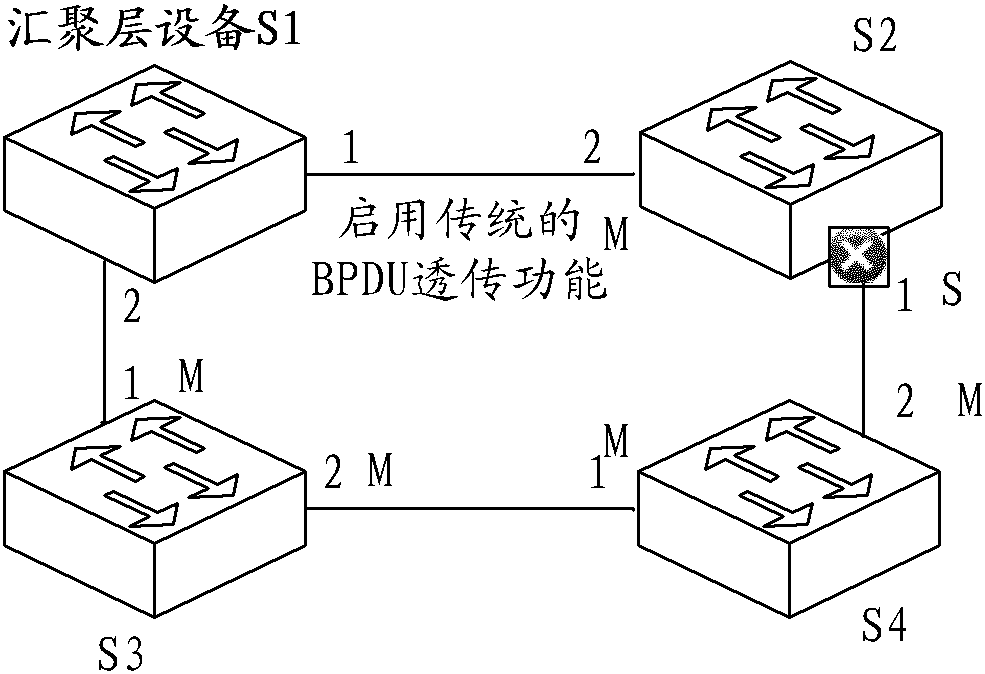

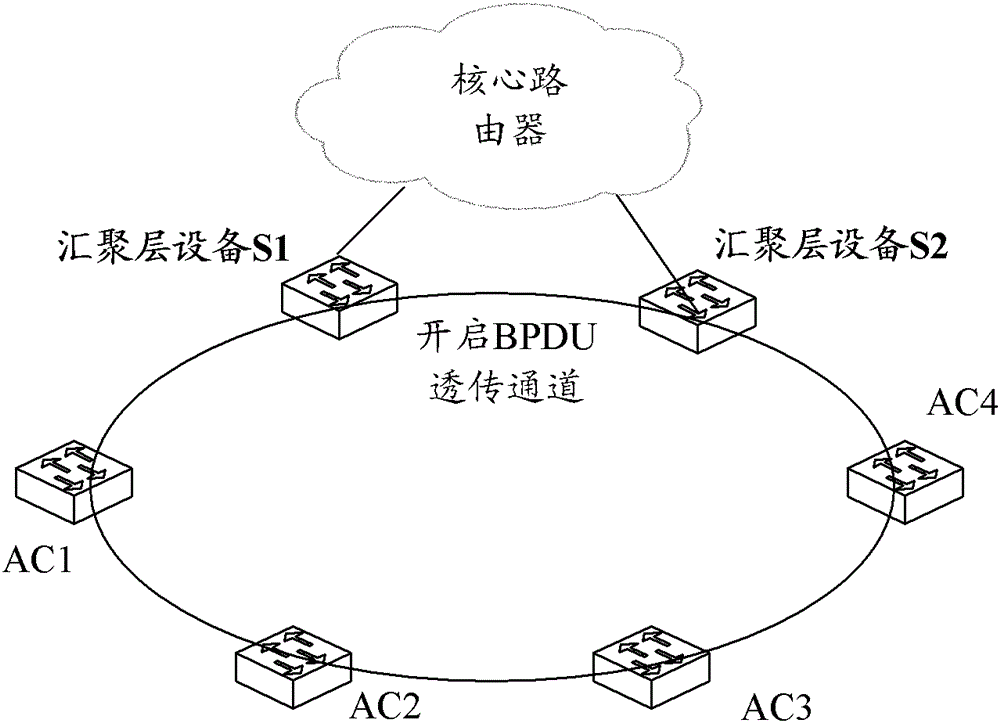

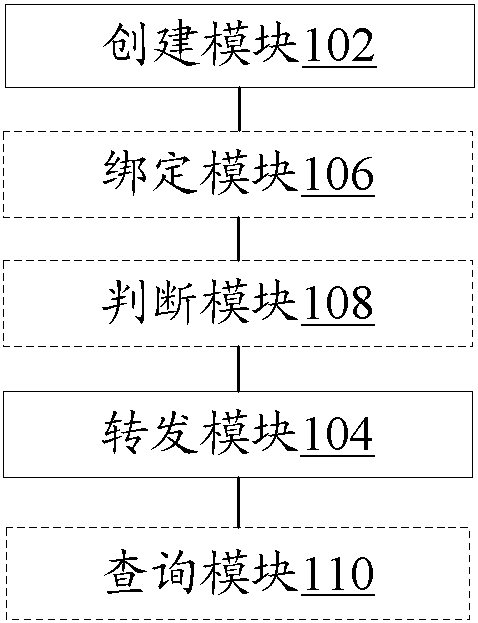

Method, device and system for transparently transmitting protocol data unit bpdu message

InactiveCN102130835BRealize requirementsGuaranteed stabilityData switching networksComputer networkProtocol data unit

The invention discloses a method, device and system for transparently transmitting a protocol data unit BPDU message. Wherein, the method includes: using the label distribution protocol LDP to create one or more transparent transmission channels on the first device, and setting an external tunnel label for each transparent transmission channel; the BPDU message on the first device is transparently transmitted The channel is forwarded to the second device. Through the present invention, user requirements can be better realized, the stability, versatility and security of the spanning tree protocol can be guaranteed, and the extensive application capability of the spanning tree protocol in actual networking can be improved.

Owner:ZTE CORP

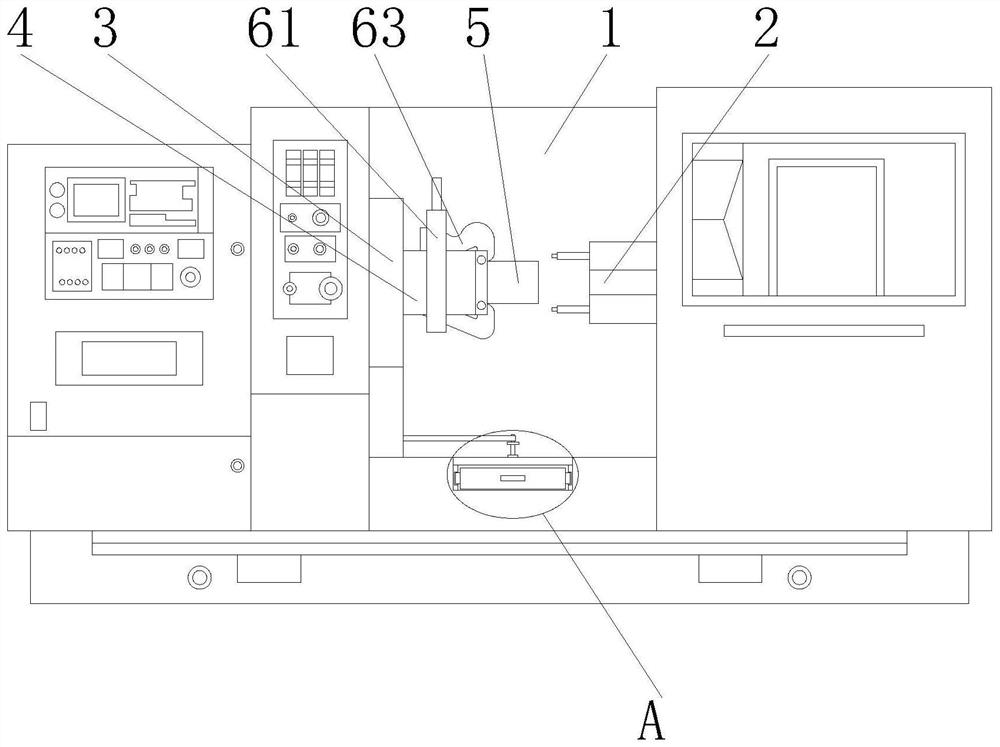

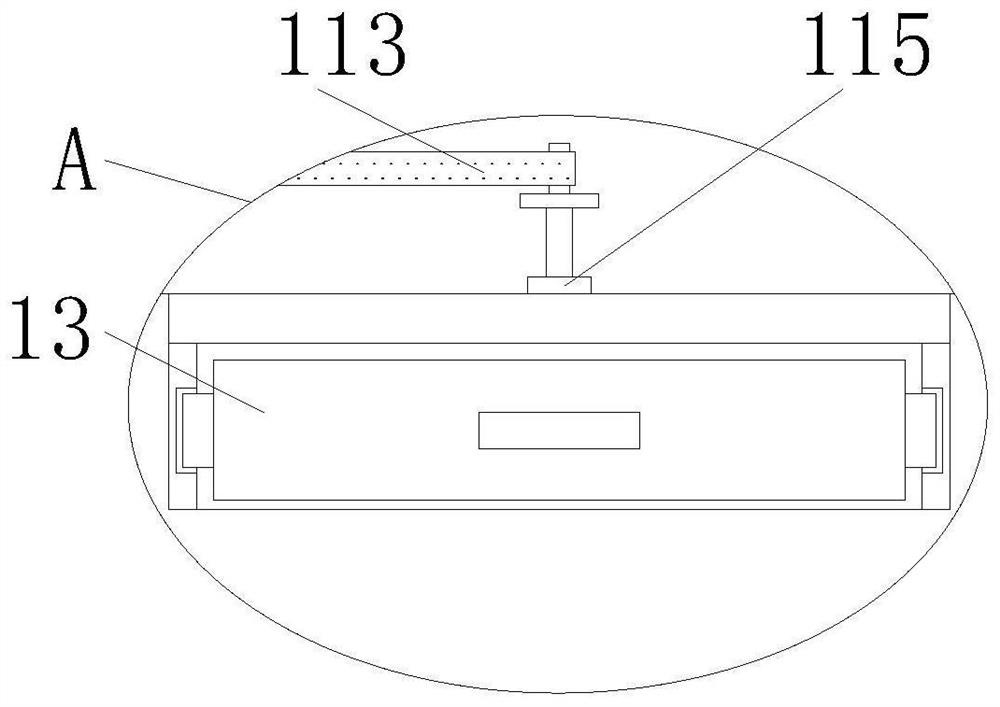

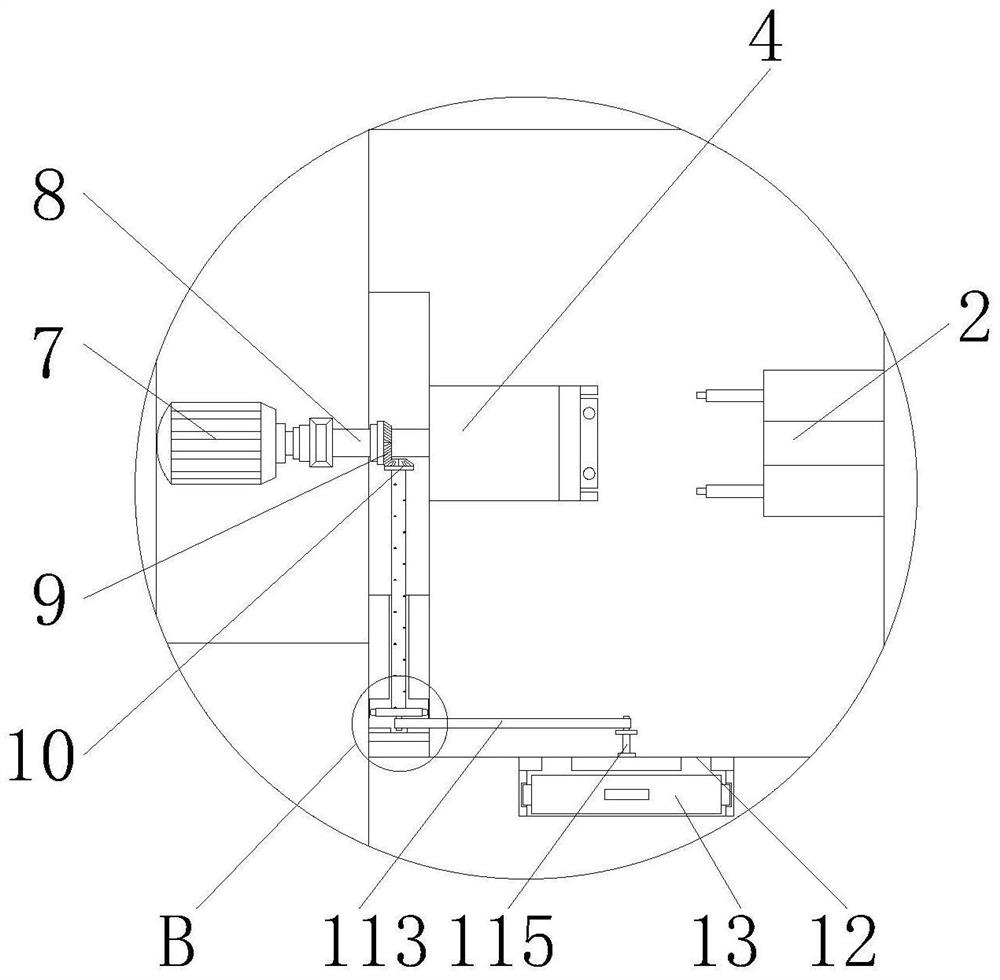

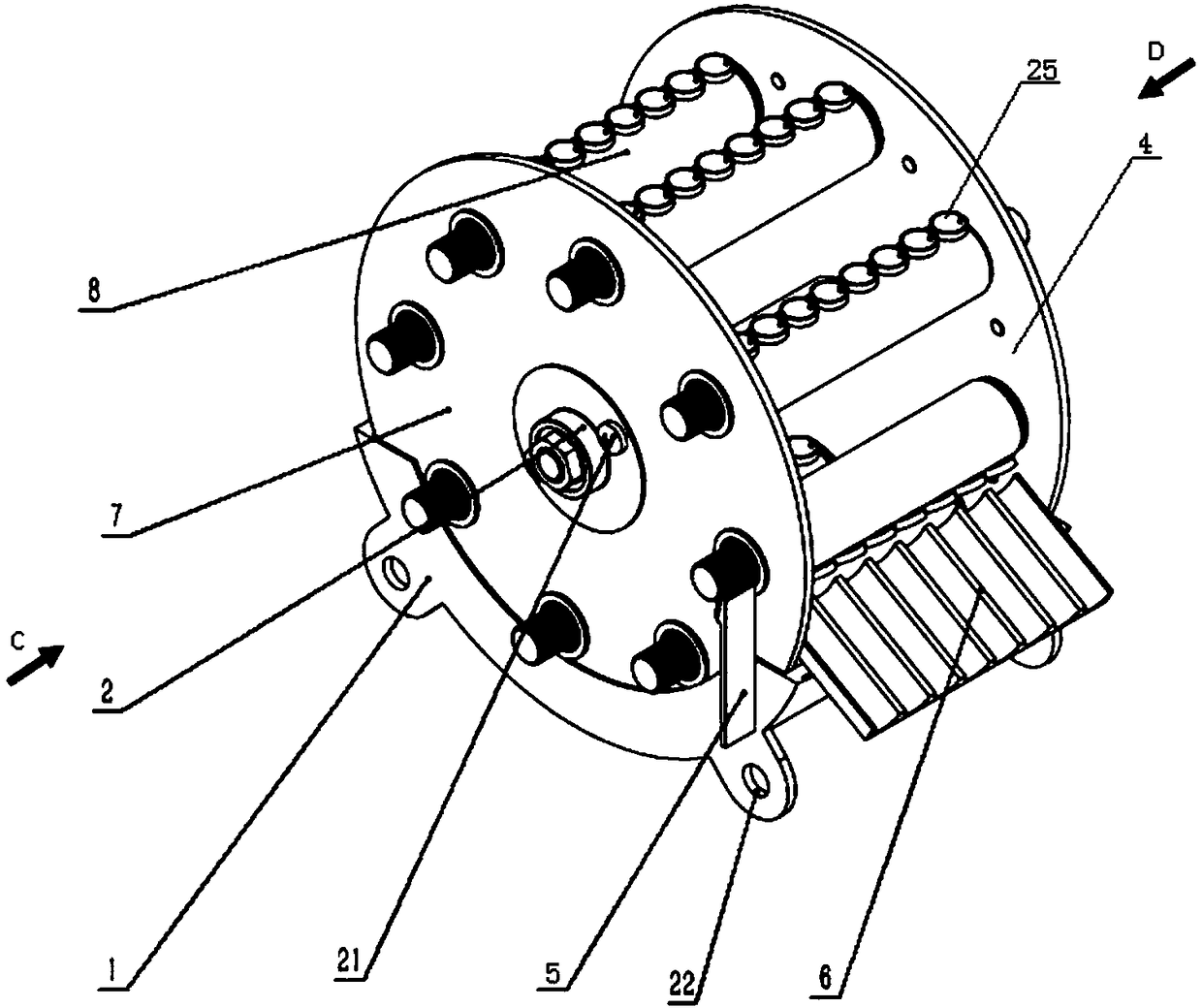

Composite multi-station ultra-precision numerical control machine tool

ActiveCN112705981AImprove broad applicabilityImprove cleanlinessPositioning apparatusMaintainance and safety accessoriesNumerical controlTool bit

The invention discloses a composite multi-station ultra-precision numerical control machine tool. The numerical control machine tool comprises a numerical control machine tool body, a tool bit and a driving motor, wherein the tool bit is connected into the numerical control machine tool body, a fixed block is fixedly connected into the numerical control machine tool body, one side of the fixed block is connected with a connecting base, one side of the connecting base is connected with a workpiece, the connecting base is connected with a fixing mechanism, and the driving motor is fixedly mounted in the numerical control machine tool body. According to the composite multi-station ultra-precision numerical control machine tool, a circular workpiece and an irregular workpiece can be clamped and fixed through the fixing mechanism, the numerical control machine tool can conveniently machine workpieces in different shapes, and the wide applicability of the numerical control machine tool can be better improved; and in the machining process of the workpieces, a clearing mechanism can clear up chippings generated in the workpiece machining process, and the cleanliness of the numerical control machine tool in the machining process can be better kept.

Owner:遂川天马数控有限公司

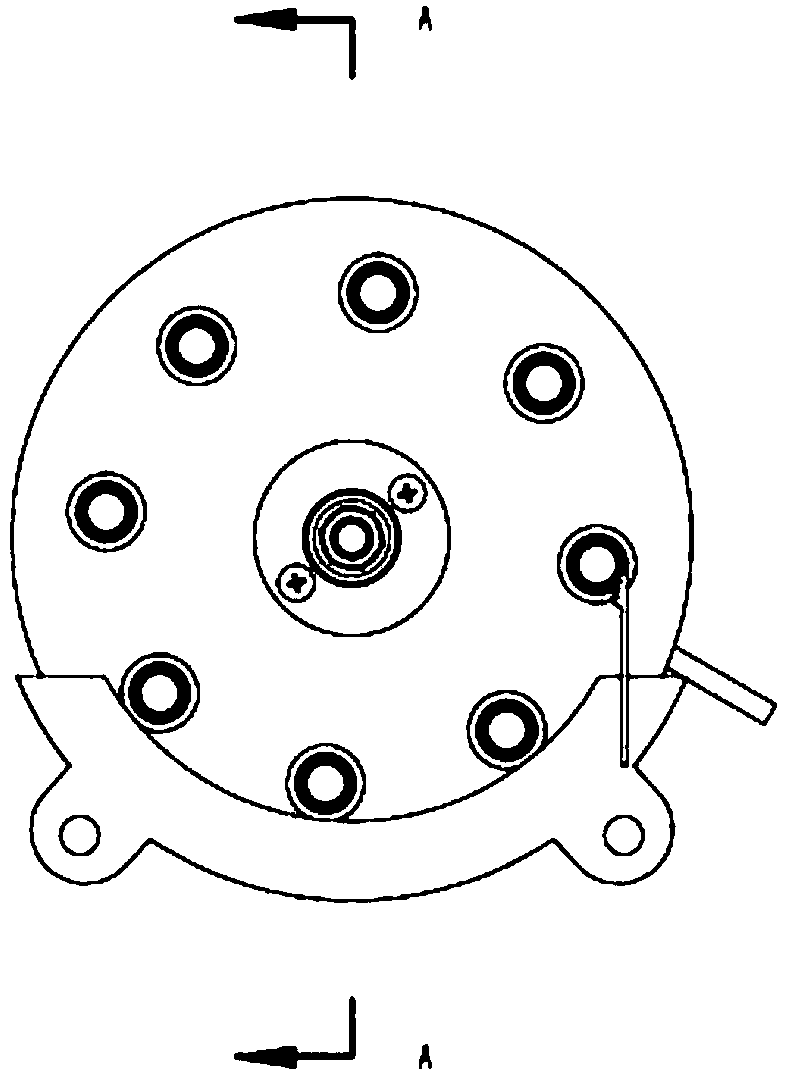

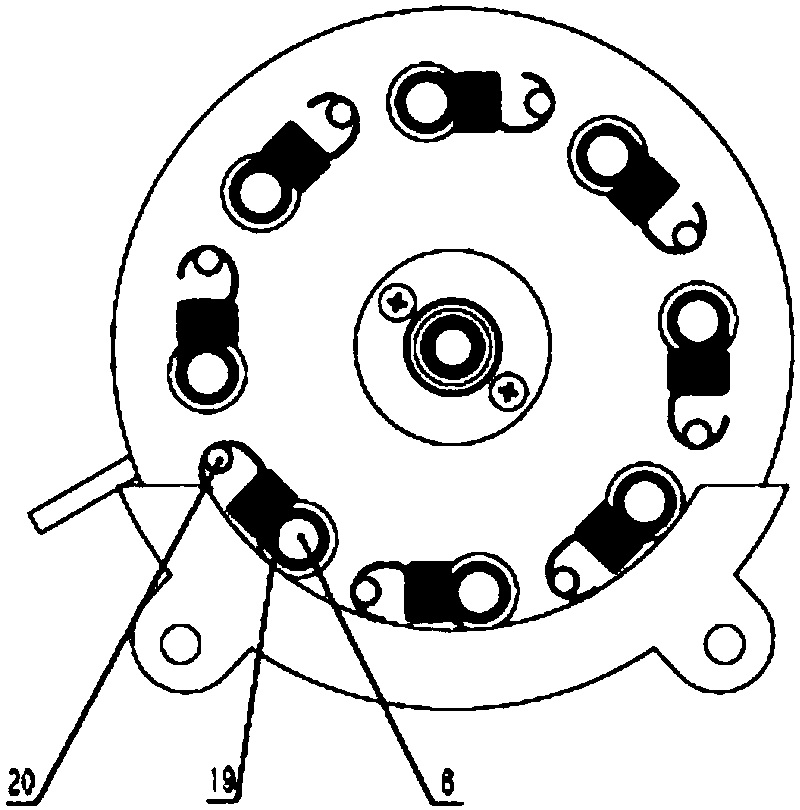

Waterwheel type single-seed precise seed-metering device

ActiveCN108243681AReduce porosityAvoid damageSeed depositing seeder partsAgricultural engineeringEngineering

The invention belongs to the technical field of agricultural machinery, provides a precise seed-metering device of the agricultural machinery and in particular relates to a waterwheel type single-seedprecise seed-metering device. The waterwheel type single-seed precise seed-metering device comprises a seed basin arranged at the bottom, a seed-metering device distributed above the seed basin and aguide rail distributed at the front part of the seed-metering device. By adopting the waterwheel type single-seed precise seed-metering device, seed filling and metering of a plurality of rows can realized in one step; a special hole spoon design is adopted so that single-seed seed filling is realized and surplus seeds are removed by gravity; under the action of an overturning mechanism, low-level seed metering is realized, seed falling caused by vibration is reduced and the voiding rate is reduced.

Owner:CHINA AGRI UNIV

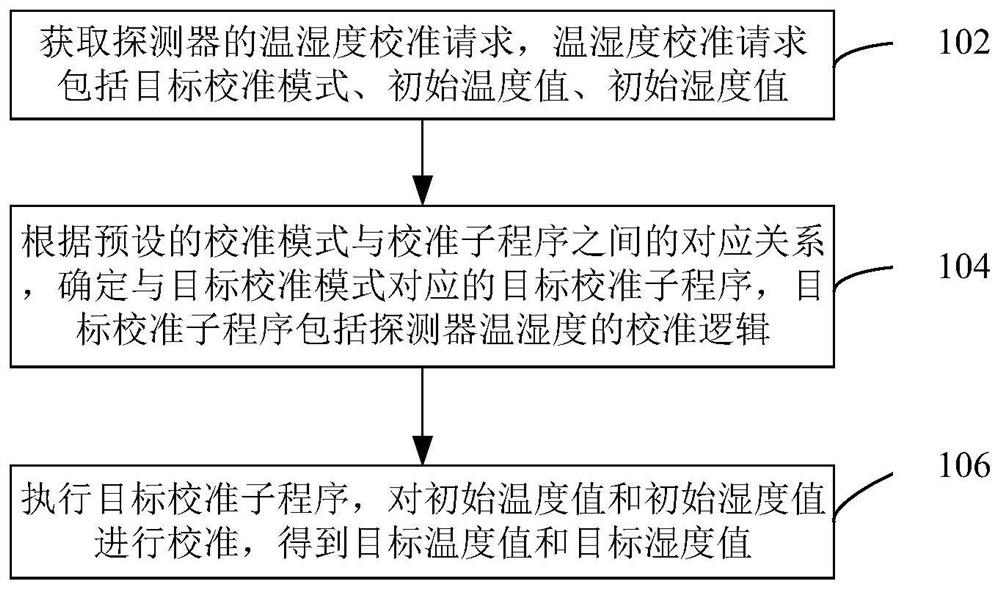

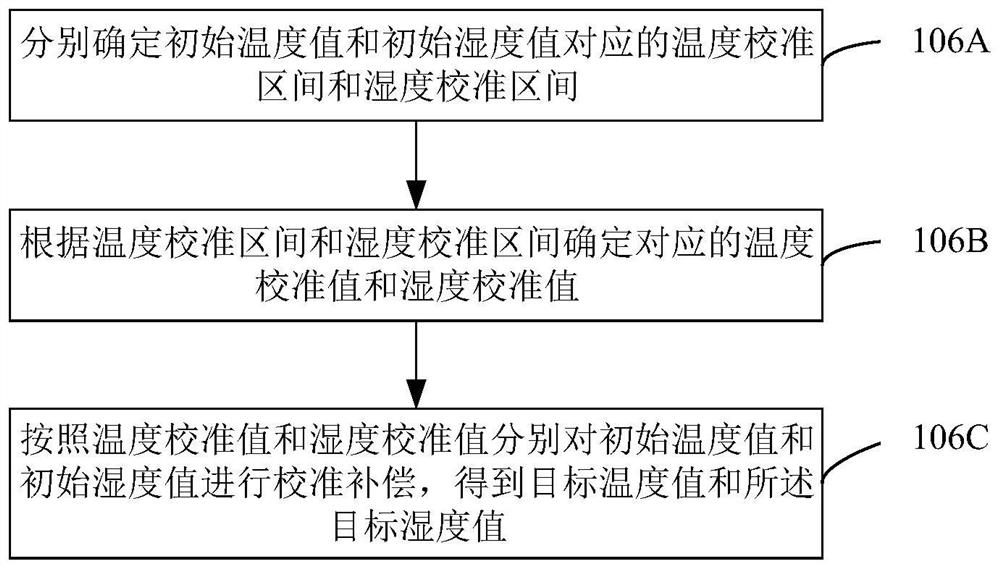

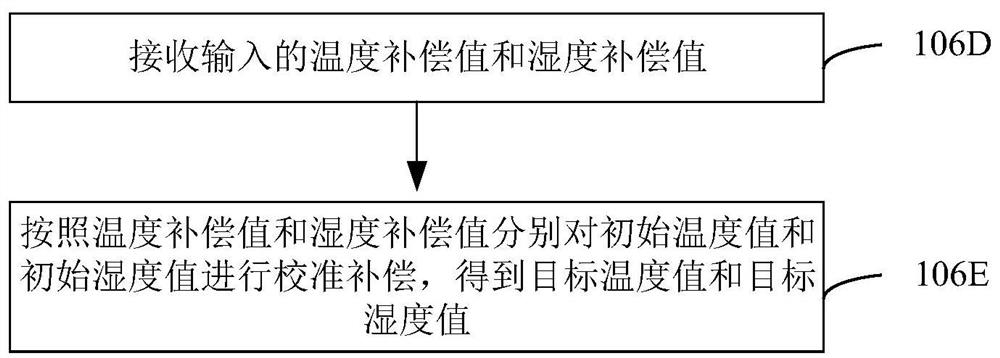

Temperature and humidity calibration method and device of detector, computer equipment and storage medium

PendingCN111735489AImprove the efficiency of temperature and humidity calibrationImprove calibration efficiencyThermometer testing/calibrationPhysicsProcess engineering

The embodiment of the invention discloses a temperature and humidity calibration method of a detector. The method comprises the steps of obtaining a temperature and humidity calibration request of thedetector; determining a target calibration subprogram corresponding to the target calibration mode according to a preset corresponding relationship between the calibration mode and the calibration subprogram, the target calibration subprogram comprising calibration logic of the temperature and humidity of the detector; executing a target calibration subroutine, calibrating the initial temperaturevalue and the initial humidity value; and obtaining a target temperature value and a target humidity value, so that accurate calibration of the temperature and humidity of the detector is realized, the consistency of the target temperature value and the target humidity value of the detector is ensured, the method can be suitable for detectors in different environments, the efficiency of temperature and humidity calibration of the detector is improved, and the wide applicability of the temperature and humidity calibration method of the detector is also improved. In addition, the invention further provides a temperature and humidity calibration device of the detector, computer equipment and a storage medium.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +2

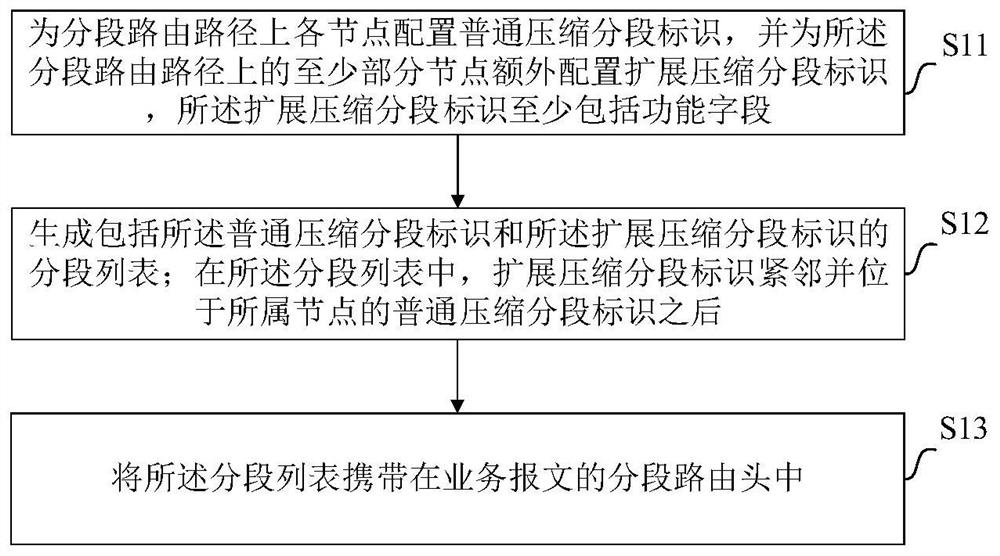

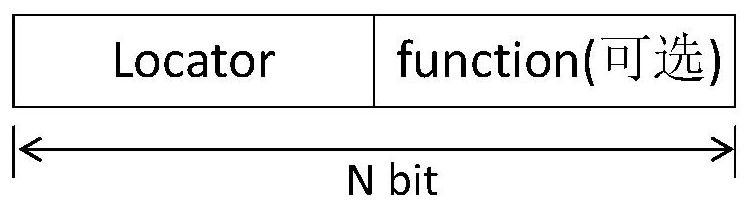

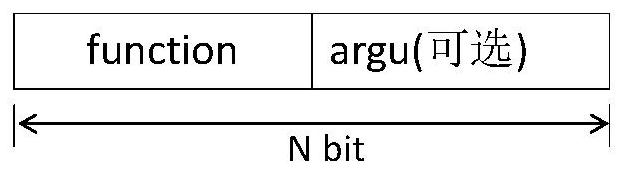

Segment routing header compression method and device, service processing method and device

PendingCN113497760ARealize business function expansionMaintain compression propertiesData switching networksPathPingEngineering

The invention provides a segment routing header compression method, which comprises the following steps: configuring a common compression segment identifier for each node on a segment routing path, and additionally configuring an extended compression segment identifier for at least part of nodes on the segment routing path, the extended compression segment identifier at least comprising a function field; generating a segment list comprising the common compression segment identifiers and the extended compression segment identifiers, wherein in the segment list, the extended compression segment identifier is adjacent to and located behind the common compression segment identifier of the node to which the extended compression segment identifier belongs; and carrying the segment list in a segment routing header of a service message. According to the embodiment of the invention, the extended compression segment identifier comprising the function field is used, the network programming capability of the node can be improved while the compression characteristic of the segment identifier is maintained, the node service function expansion is realized, and the wide applicability and flexibility of service processing are improved. The invention further provides a service processing method, a segment routing header compression device, a service processing device, computer equipment and a computer readable medium.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com