Integral process for oil shale drying, heating, refining and semicoke burning

An oil shale and semi-coke technology, applied in the field of comprehensive utilization of oil shale resources, can solve the problems of low energy utilization rate, no consideration of using flue gas to dry wet oil shale, complicated layout, etc., so as to improve resource utilization rate, The effect of improving wide applicability and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

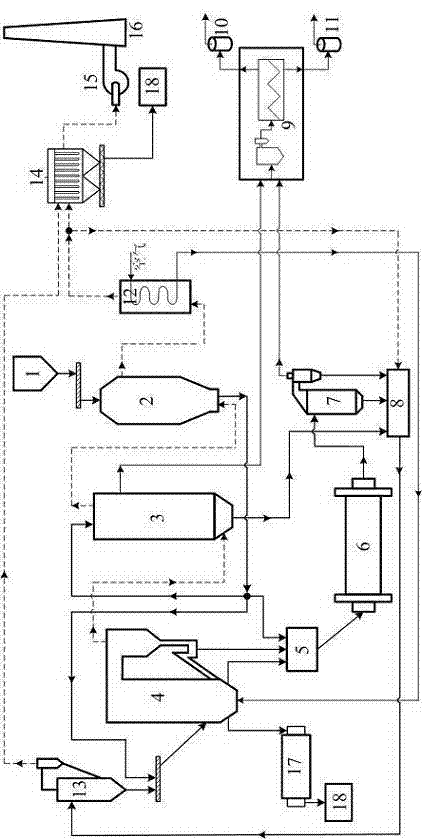

[0021] The present invention will be further described below using the accompanying drawings and examples.

[0022] refer tofigure 1 , an integrated process of oil shale drying, heating, oil refining, and semi-coke combustion of the present invention is to send the oil shale crushed to ≤15mm from the storage bin 1 to the medium-temperature gas indirect or direct heat exchange drying heater 2 In the process, the heating temperature is 50-150°C, and the oil shale after heating and drying is divided into three ways for transportation as required. The first path is mixed with the semi-coke falling from the semi-coke bin 13 and sent to the circulating fluidized bed combustion furnace 4 for combustion; The rock ash is mixed through the shale mixer 5. The weight ratio of oil shale: circulating shale ash is 1:2~3. ~30 minutes to complete carbonization and refining; the third oil shale is sent to the high-temperature gas indirect carbonization reactor 3, and conducts indirect heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com