Viscous damper

一种粘性阻尼器、惯性质量的技术,应用在弹簧/减震器、机器/发动机、发动机元件等方向,能够解决制造工艺复杂等问题,达到提高广泛应用性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

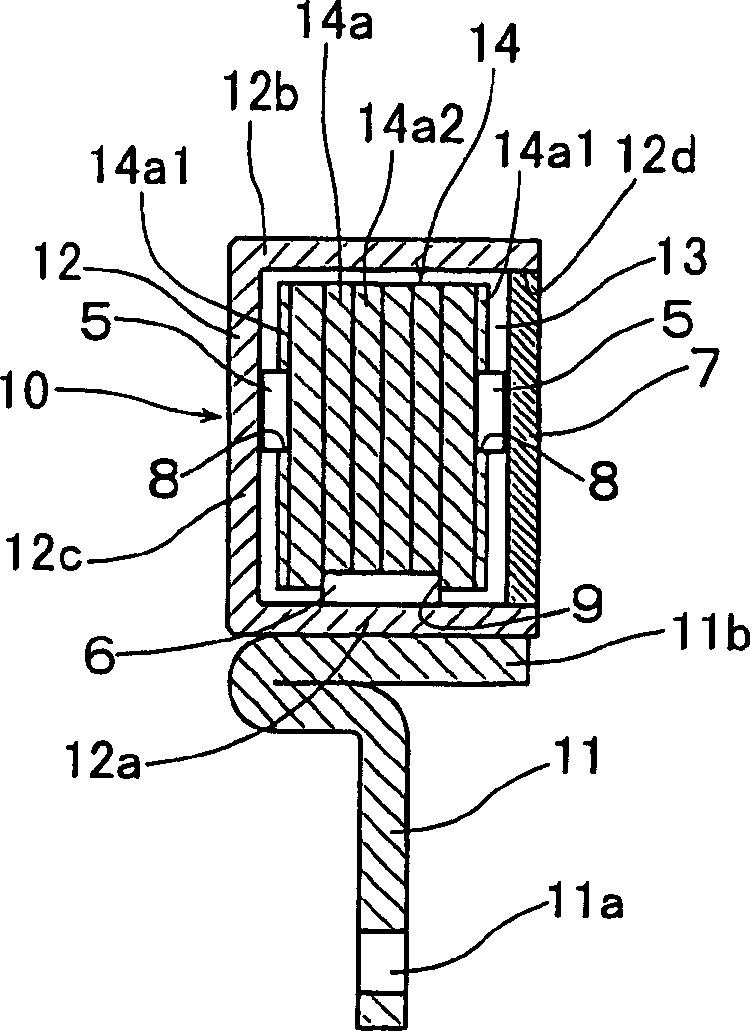

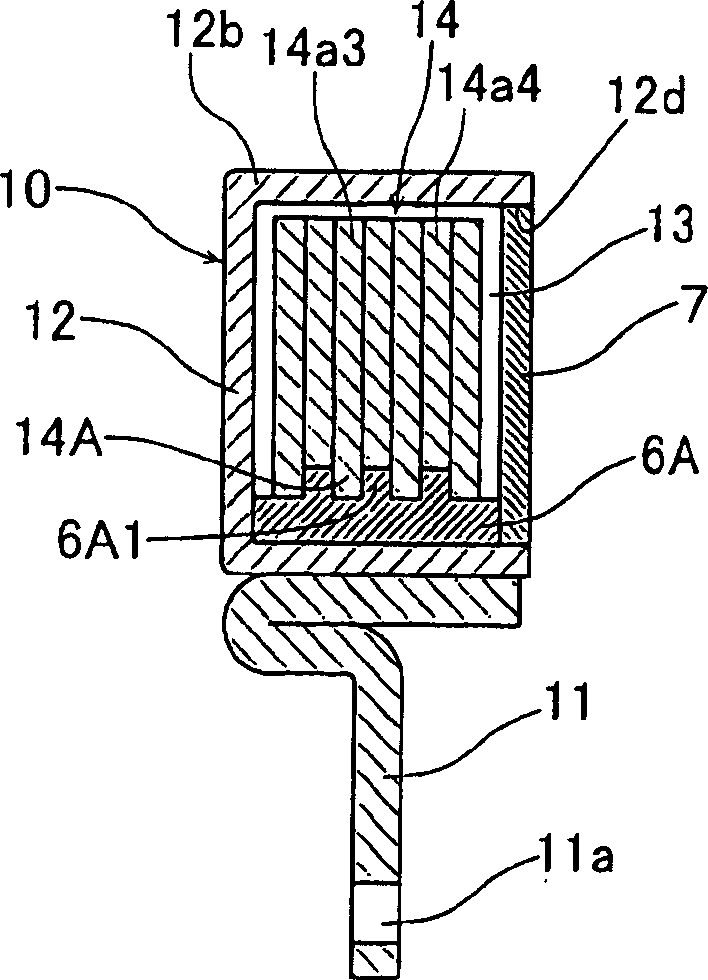

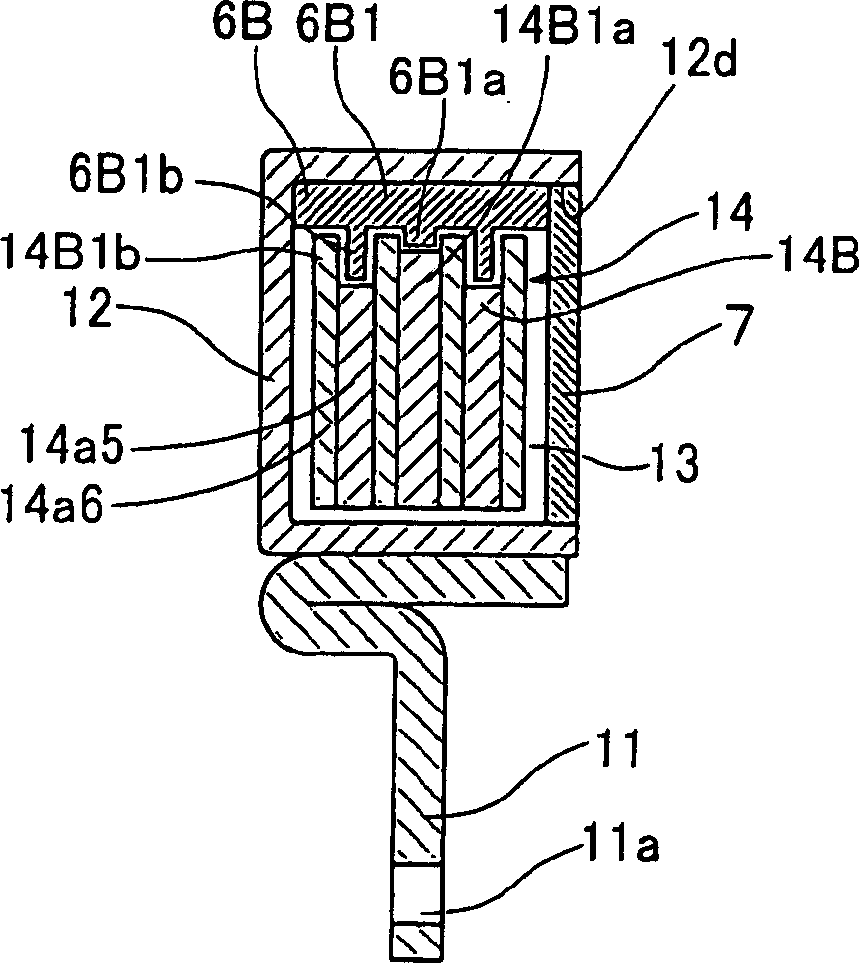

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0031] figure 1 It is a sectional view showing a main part of an embodiment of the viscous damper of the present invention, figure 2 yes means figure 1 A top view of the annular plate portion used by the inertial mass of the damper. In the present embodiment, the viscous damper is composed of the following parts: the casing 10 that liquid-tightly closes the opening 12d of the ring-shaped casing body 12 with a substantially "U"-shaped cross-section and the opening 12d toward one side of the axial direction with the cover 7; An annular inertial mass body 14 housed together in the casing 10 ; and a hub 11 that fixes the casing 10 to a rotating shaft of an internal combustion engine, for example, a crankshaft (not shown) of an automobile engine.

[0032]The hub 11 has an annular fixing part 11b on the outer periphery, which is made of punched sheet material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com