Elastic meltblown laminate constructions and methods for making same

A melt-blown layer and melt-blown technology are applied in the direction of lamination, lamination devices, chemical instruments and methods, etc., which can solve the problems of airtightness and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

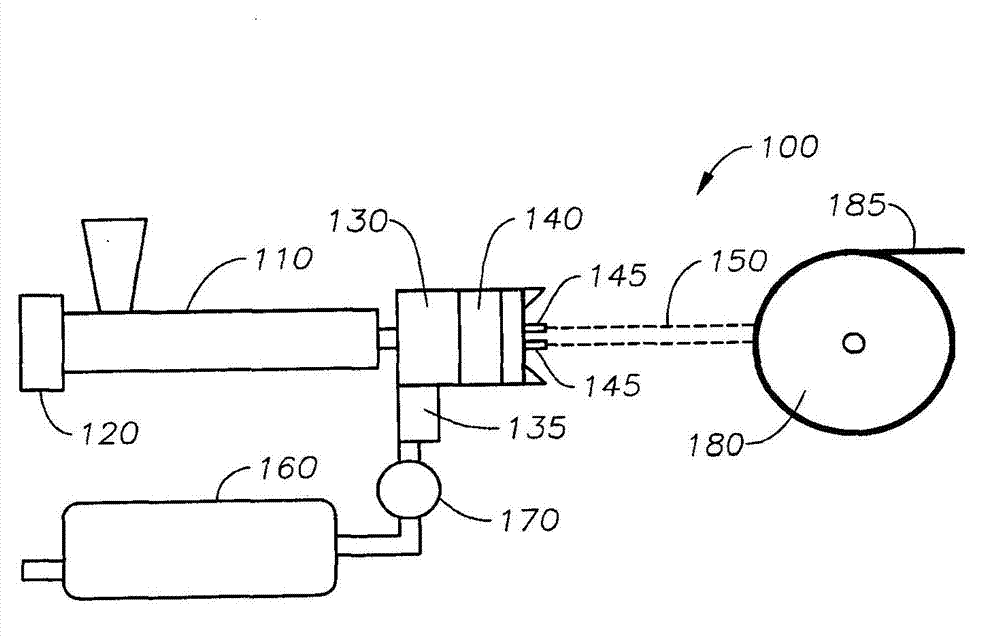

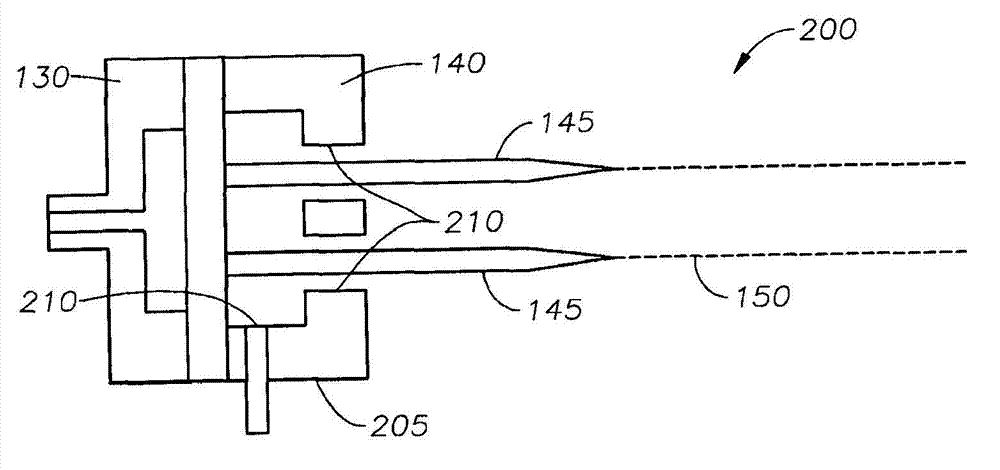

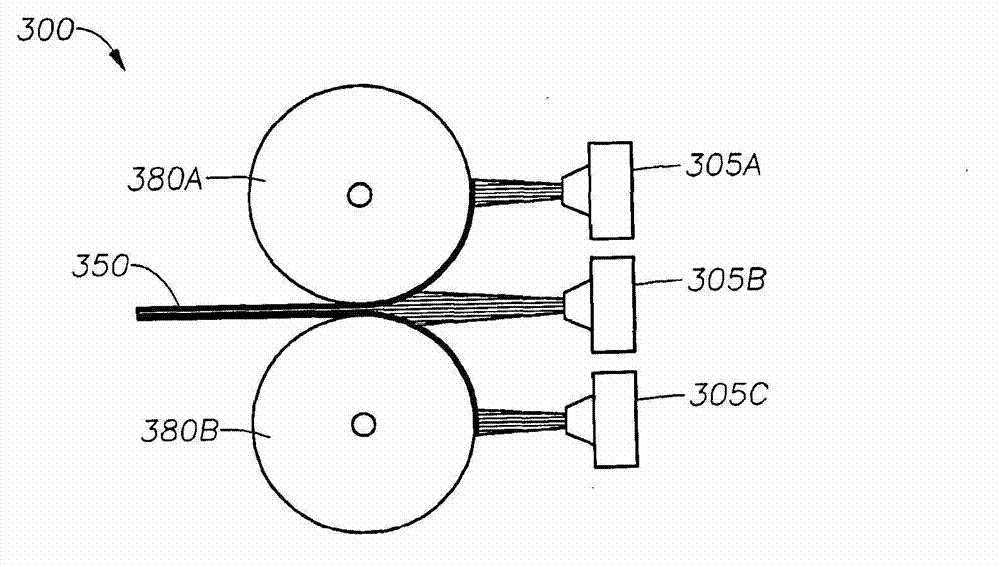

[0129] The above discussion can be further described with reference to the following non-limiting examples. In the examples provided, meltblown fabrics and polyoxymethylenes were formed using equipment and conditions similar to those of R. Zhao, "Meltblown Polyoxymethylene Copolymers", INT'L NONWOVENS J., pp. 19-24 (Summer 2005). layer structure. In particular, using Biax-Fiberfilm TM Meltblown fabrics and multilayer constructions are formed on a meltblown production line (Biax-Fiberfilm Corp., Greenville, WI) that operates at a melt pressure of 1200psi (6.89MPa) to 1700psi (10.34MPa) and a melt temperature of 200°C to 275°C. The temperature was operated using an array die with a spinneret hole density of 50-150 holes / inch. The line has an extruder, block and spinneret, and an air manifold to supply the spinneret with an air pressure of 5psi-20psi (34kPa-138kPa) and an air temperature of 220°C-260°C.

[0130] In each example, Biax-Fiberfilm was used under these conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base weigh | aaaaa | aaaaa |

| Mfr | aaaaa | aaaaa |

| Heat of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com