Patents

Literature

37results about How to "Good viscosity performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricant additive

ActiveUS20120101017A1Good viscosity performanceIncrease VISolid-state devicesLiquid carbonaceous fuelsBase oilButadiene-styrene rubber

A hydrogenated styrene butadiene star copolymer is incorporated in a lubricant additive package. The star copolymer can include about 3 to 25% and about 97 to 75% butadiene. The star copolymer may further be incorporated in a lubricant additive in the amount of about 12 wt % of the star copolymer as compared to the base oil.

Owner:AFTON CHEMICAL

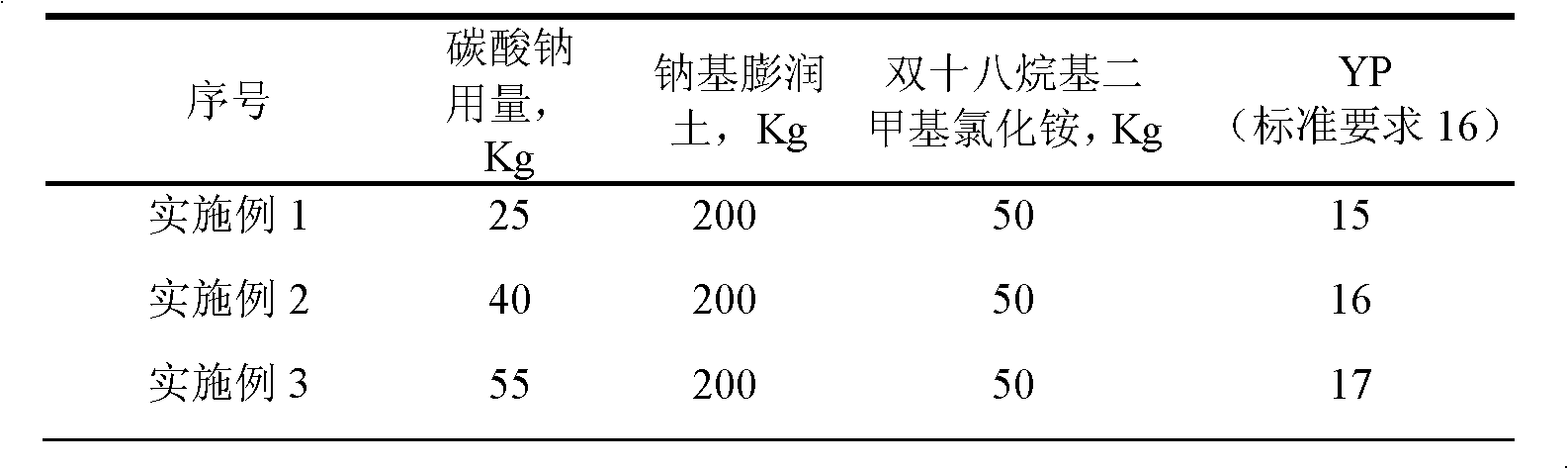

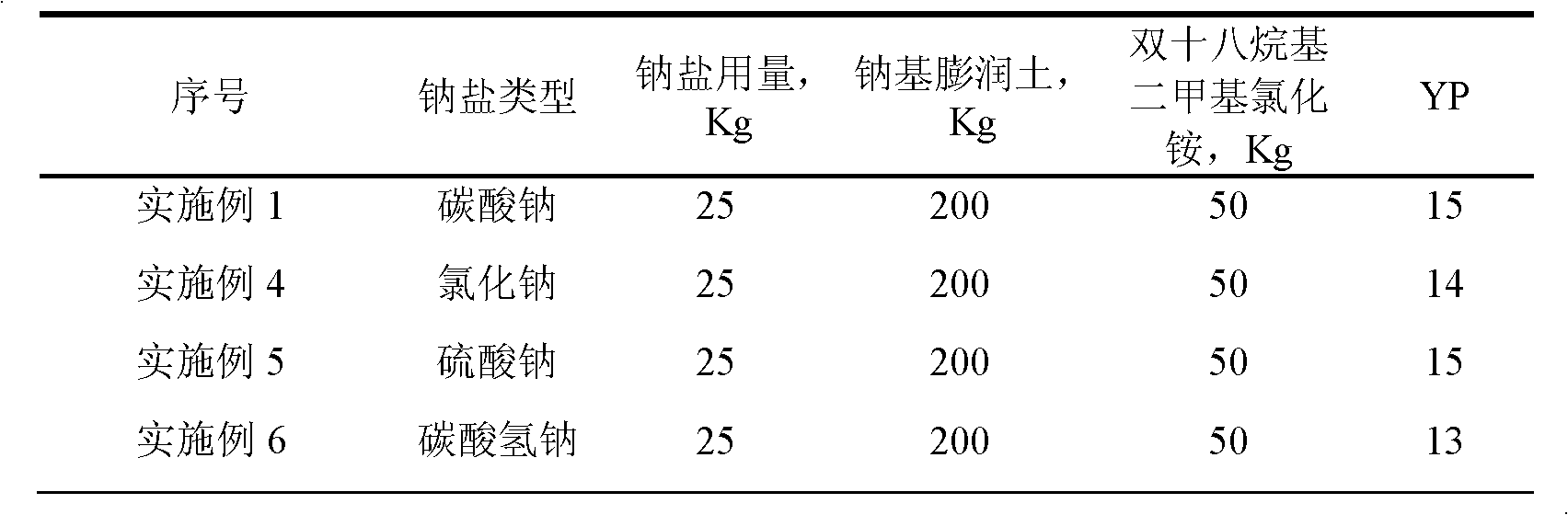

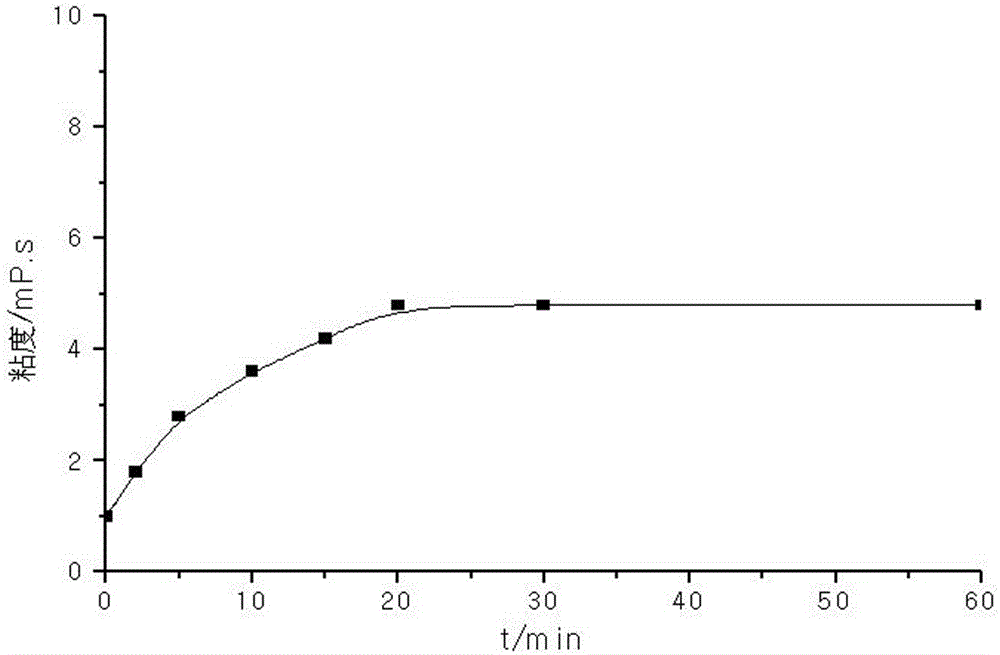

Novel process for producing organically modified bentonite

InactiveCN101817536AViscosifying effect is equivalentGood viscosity performanceSilicon compoundsChemistryAmmonium

The invention relates to a novel process for producing organically modified bentonite, which is characterized by sequentially comprising the following steps of: 1) performing sodium modification on calcium base bentonite with a sodium base salt; 2) performing organic modification on the bentonite obtained by the step 1) with a quaternary ammonium salt; and 3) modifying the bentonite obtained by the step 2) with octadecanoic acid fatty acid. The final product obtained by modifying the common calcium base bentonite has the same viscosifying effect as the American natural sodium base bentonite.

Owner:淄博联技化工有限公司

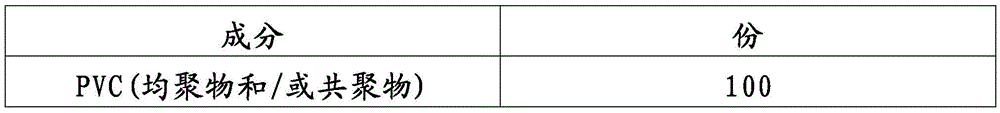

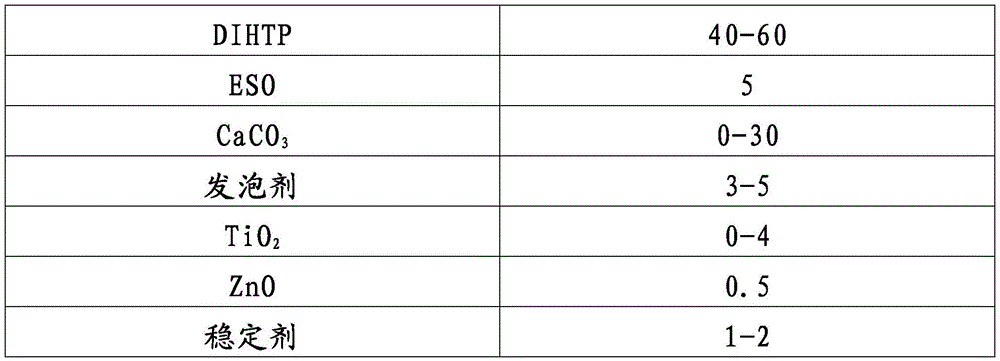

Polymer composition comprising terephthalate

The invention is directed to plasticized compositions comprising esters of terephthalic acid, particularly PVC compositions.

Owner:EXXONMOBIL CHEM PAT INC

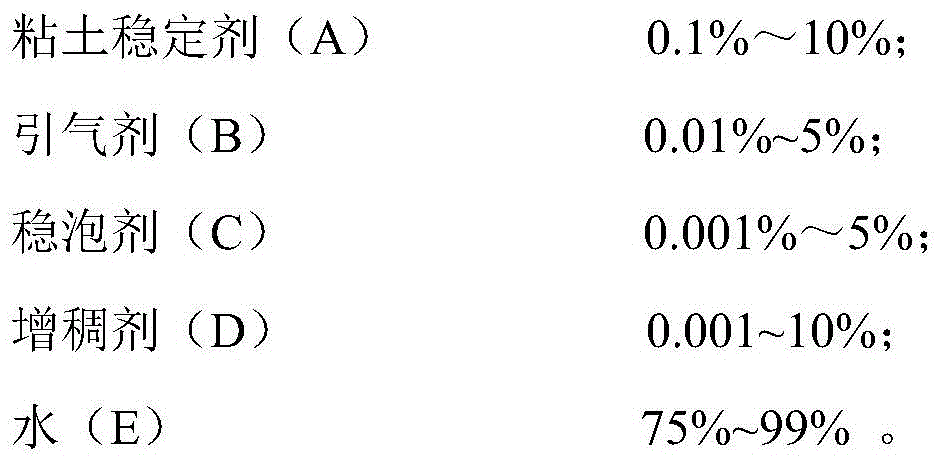

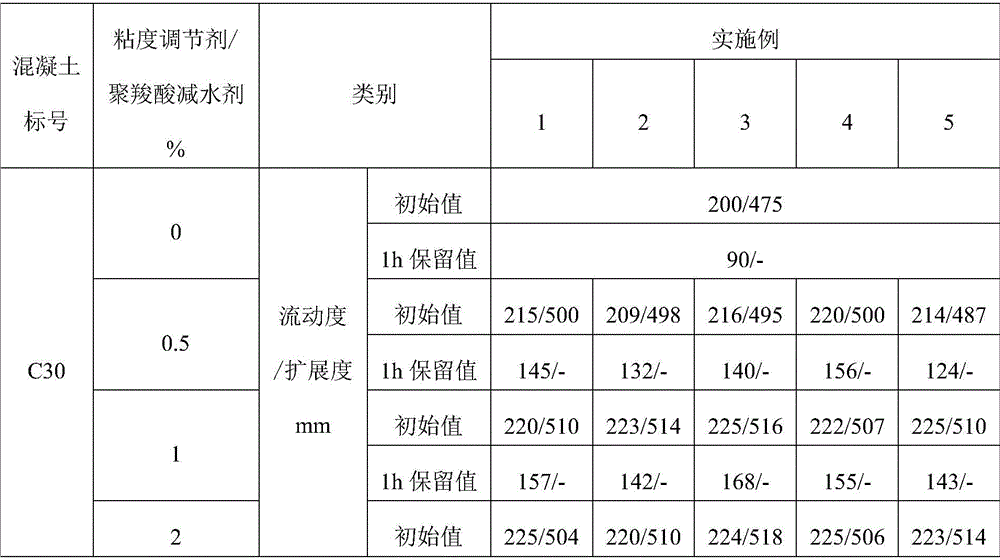

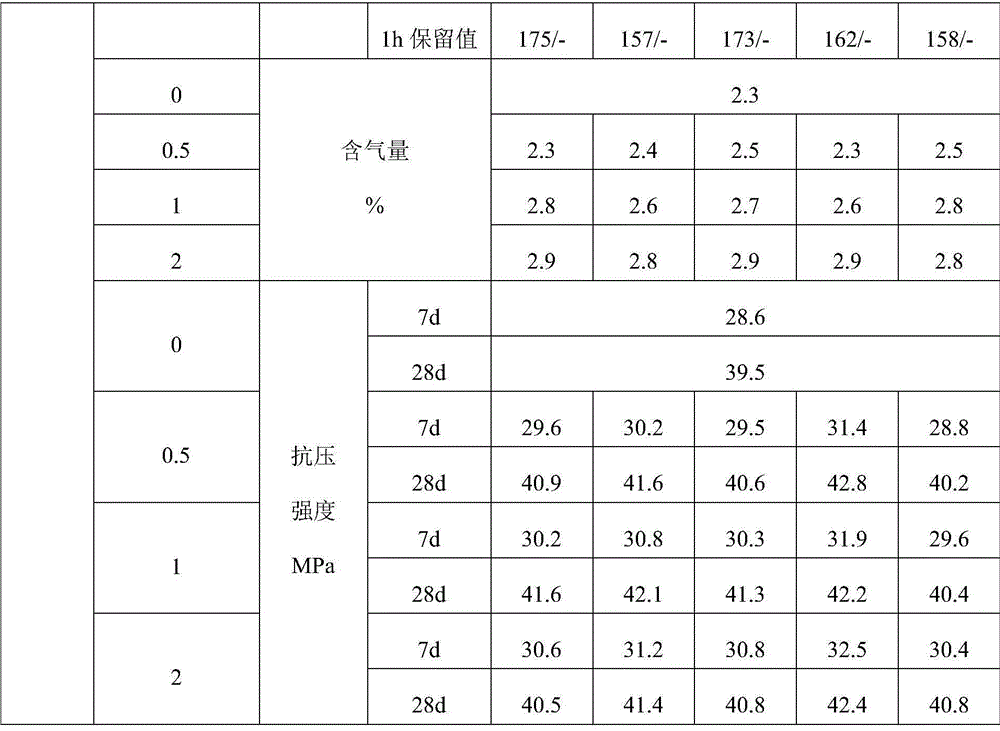

A concrete viscosity modifier suitable for use in combination with polycarboxylate water reducer and preparation method thereof

Owner:NANJING HYDRAULIC RES INST

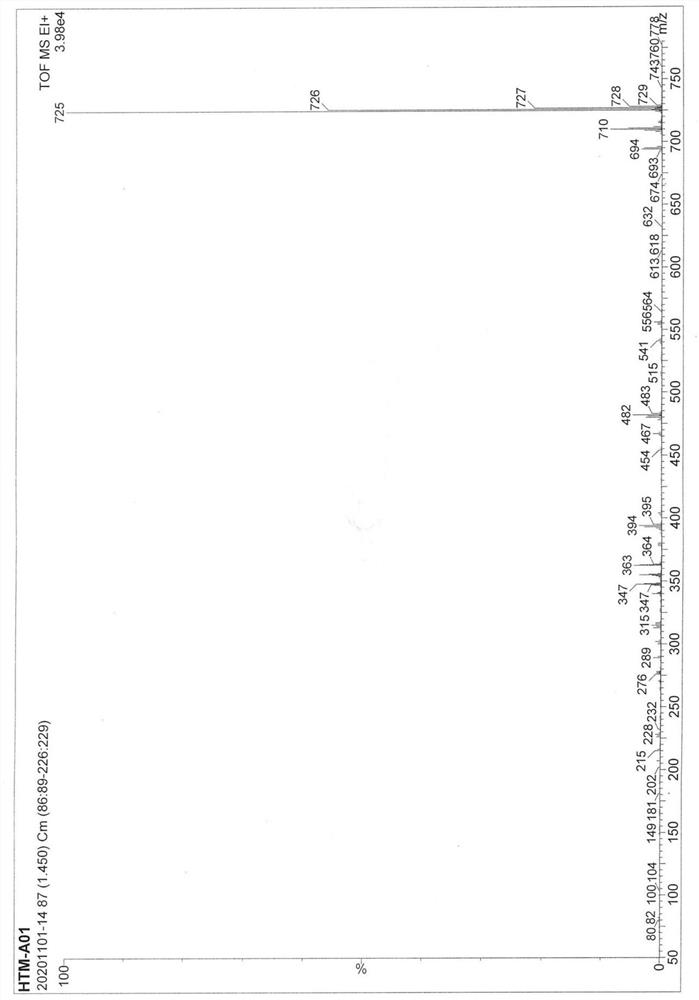

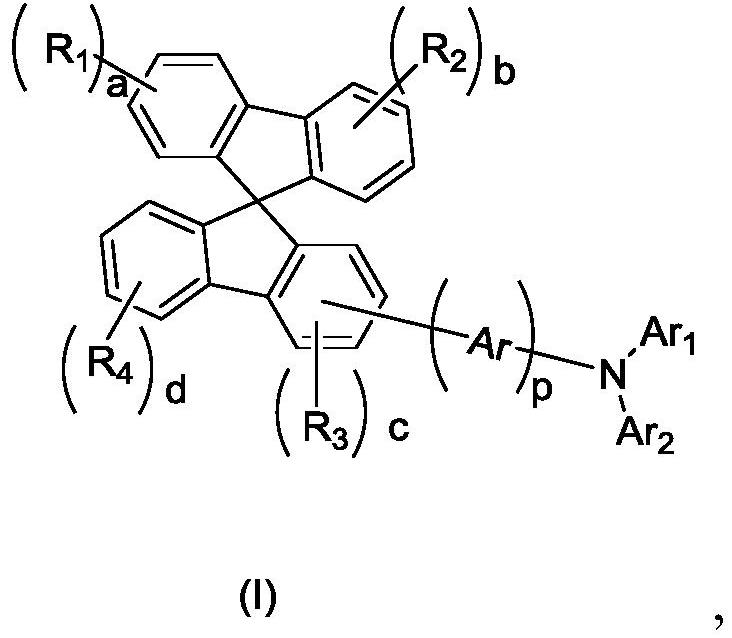

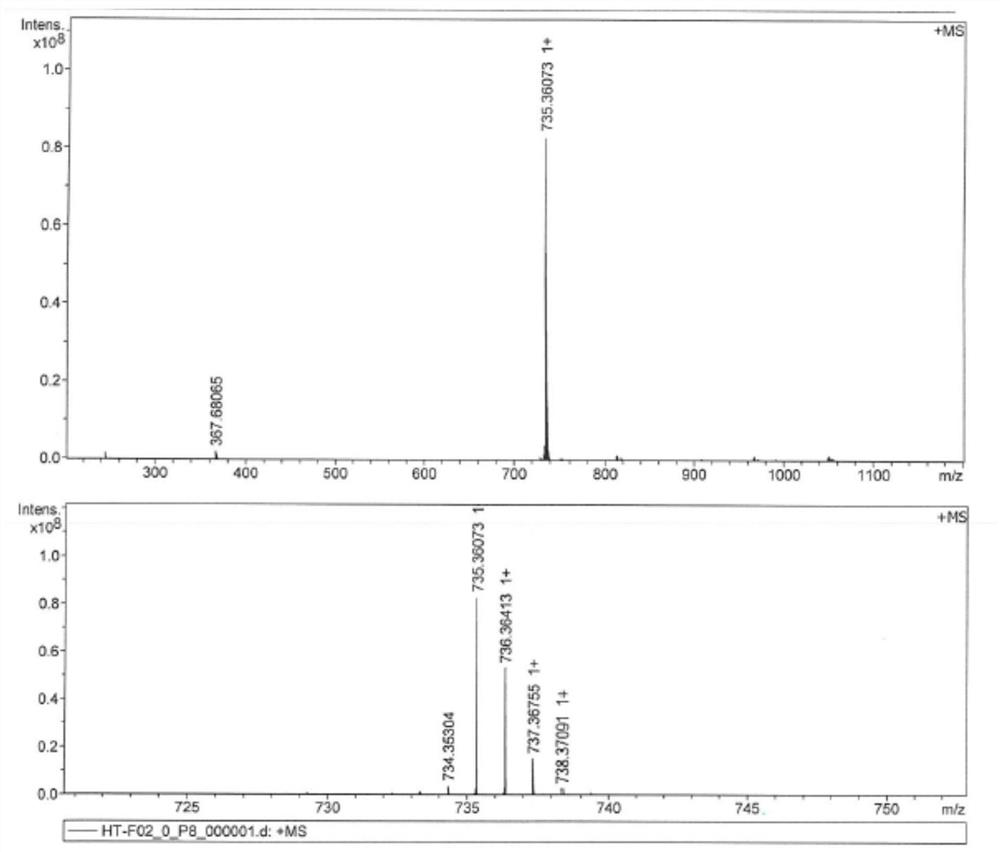

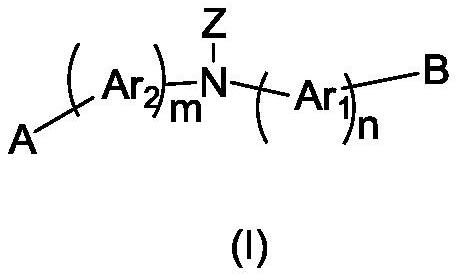

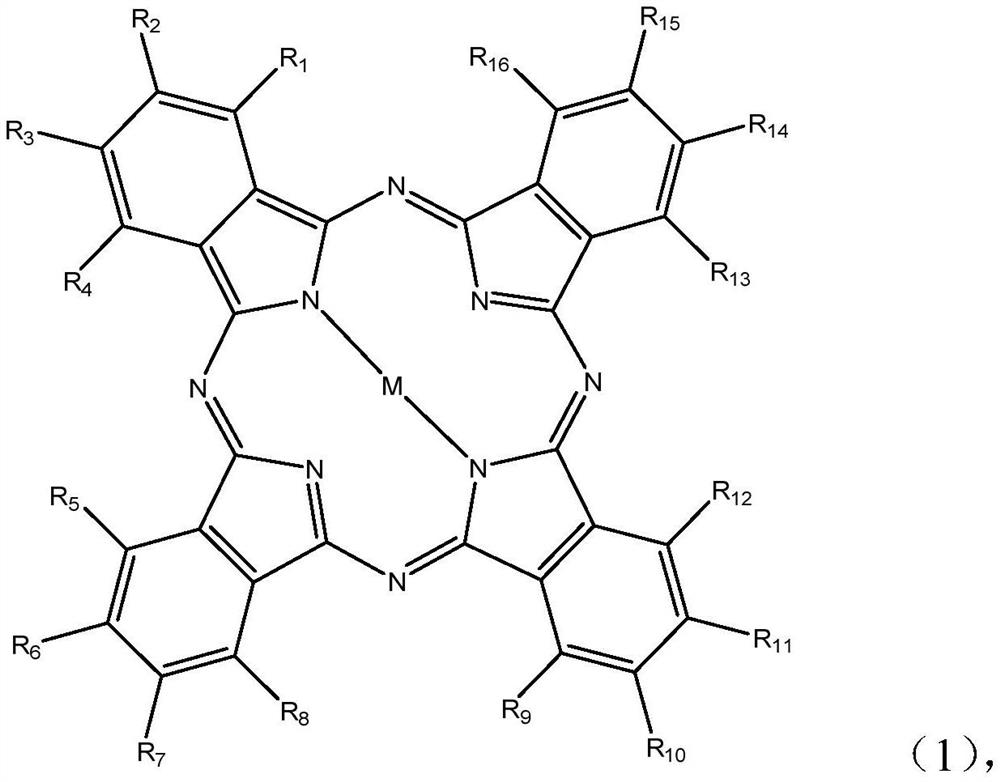

Compound, organic electroluminescent device and display device

InactiveCN112457201AReduce the driving voltageImprove current efficiencyOrganic chemistrySolid-state devicesDisplay deviceOrganic electroluminescence

The invention relates to the field of electroluminescence, and discloses a compound, an organic electroluminescent device and a display device. The structural formula of the compound is represented bya formula (I). The organic electroluminescent device made of a material of the compound has low driving voltage and high current efficiency, and meanwhile, a transmission layer or an injection layerof the organic electroluminescent device can be prepared by using the compound through a solution method.

Owner:FUYANG XINYIHUA MATERIAL TECH +2

Bag side needle-pricking oil formula

InactiveCN107130067ARetouching is effectiveImprove aestheticsLeather surface finishingEmulsionViscosity

The invention discloses a bag side needle-pricking oil formula. The bag side needle-pricking oil formula mainly comprises, by weight, 45 to 55 kg of acrylic emulsion, 25 to 35 kg of polyurethane, 1 to 3 kg of a defoaming agent, 7 to 9 kg of matte powder, 1 to 3 kg of an addition agent, 1 to 3 kg of a thickening agent, 4 to 6 kg of mill base and 2 to4 kg of a bonding material. According to the bag side needle-pricking oil formula, through acrylic emulsion and polyurethane, the effect of residue side modifying is achieved, through the defoaming agent, the effect of removing harmful gas in the formula is achieved, through the matte powder, attractiveness of the bag side needle-pricking oil increased, through the addition agent, the material can be better fused, through the thickening agent, viscosity of the bag side needle-pricking oil is increased, through the mill base, the color of the formula can be changed, through the bonding material, bonding of bag side needle-pricking oil for leather replacement is facilitated, the viscosity effect of the bag side needle-pricking oil is good, the residual side can be effectively modified, and a user can conveniently use the oil.

Owner:浙江威利达新材料有限公司

Antibacterial low-melting-point hot melt adhesive and preparation method thereof

ActiveCN105542698ALow melting pointCrystallize fastNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterPolymer science

The invention relates to an antibacterial low-melting-point hot melt adhesive. The antibacterial low-melting-point hot melt adhesive is processed from the following raw materials in parts by weight: 40-80 parts of a polyester hot melt adhesive, 20-30 parts of polyamide resin, 3-8 parts of paraffin, 0.5-1 part of an antioxidant 164 and 0.5-1 part of an inorganic antibacterial agent. A preparation method of the antibacterial low-melting-point hot melt adhesive comprises the following steps: uniformly mixing the polyester hot melt adhesive, the polyamide resin, the paraffin, the antioxidant and the inorganic antibacterial agent according to the formula ratio, adding the mixture into a screw extruder granulator, carrying out melt blending extrusion, cooling and granulating the extruded mixture, and carrying out vacuum drying on the aggregates to remove moisture, so as to obtain the antibacterial low-melting-point hot melt adhesive. By mixing the low-melting-point polyester hot melt adhesive with the polyamide resin, the paraffin, the antioxidant and the inorganic antibacterial agent, the prepared hot melt adhesive is stable in binding power, high in curing speed and convenient to use and does not easily mildew, the environmental influence is low, and particularly, the curing rate is prior to that of the hot melt adhesive in the prior art in a low-temperature environment; the production efficiency is greatly improved, the cooling curing time is substantially shortened after the coating of the hot melt adhesive, and the coating efficiency is remarkably improved.

Owner:佛山市高达树脂有限公司

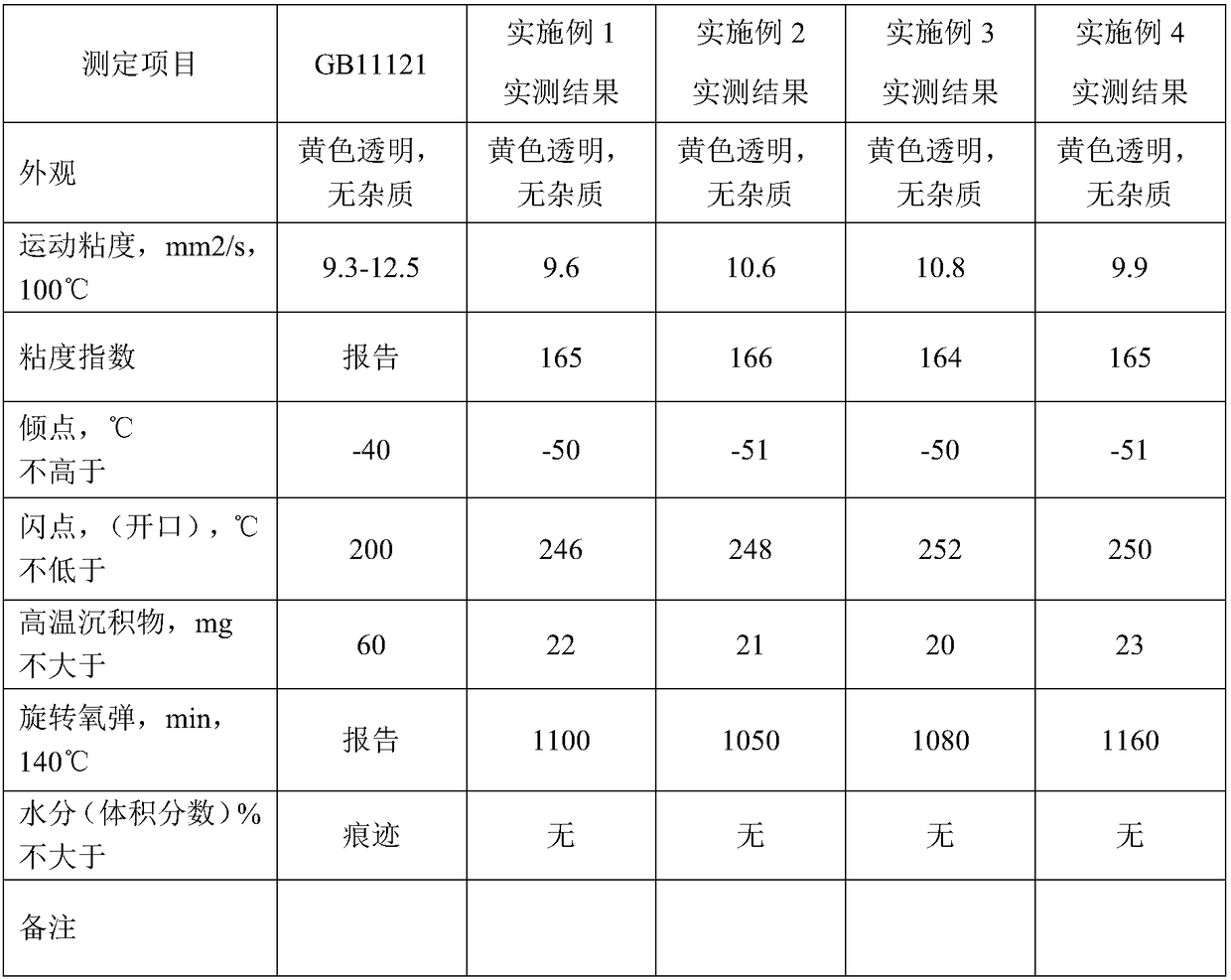

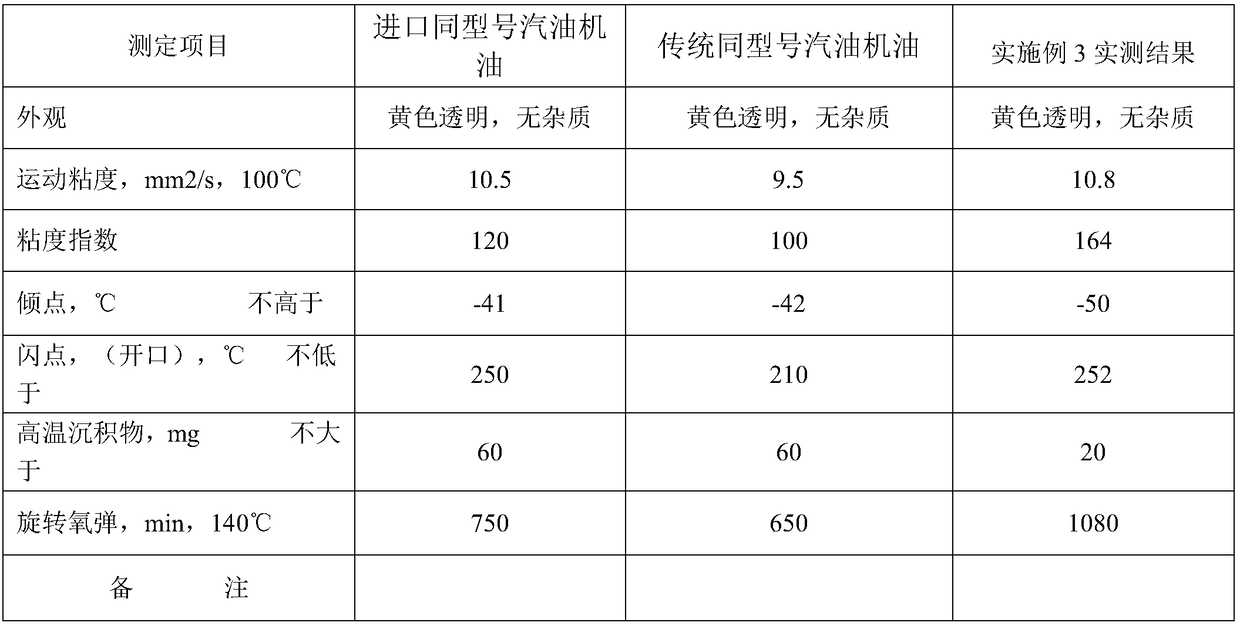

Environmentally-friendly energy-saving gasoline engine oil and preparation method thereof

InactiveCN109439416AReduce wearReduce consumptionTreatment with hydrotreatment processesLubricant compositionFuel oilEngineering

The invention discloses environmentally-friendly energy-saving gasoline engine oil. The environmentally-friendly energy-saving gasoline engine oil consists of poly alpha olefin, three-time-hydrogenation low-coagulation base oil, a viscosity index improver, a clearing agent, a non-ash dispersion agent, an oxidation and corrosion inhibitor and organic molybdenum. The invention also provides a preparation method of the environmentally-friendly energy-saving gasoline engine oil. The method comprises the following steps: weighing poly alpha olefin, three-time-hydrogenation low-coagulation base oil,the viscosity index improver, the clearing agent, the non-ash dispersion agent, the oxidation and corrosion inhibitor and organic molybdenum in percentages by weight; then adding poly alpha olefin ina reaction still, warming to 65 to 75 DEG C, adding three-time-hydrogenation low-coagulation base oil and the viscosity index improver in a stirring state, after stirring, and after adding the clearing agent, the non-ash dispersion agent, the oxidation and corrosion inhibitor and organic molybdenum in sequence, and then stirring to obtain the environmentally-friendly energy-saving gasoline engineoil. The environmentally-friendly energy-saving gasoline engine oil is high oxidation stability, long in service life, low in pour point and wide in operating temperature; and due to the organic molybdenum is contained in the environmentally-friendly energy-saving gasoline engine oil, so that the friction and friction heat are reduced, the consumption of fuel oil is saved, and the abrasion of anengine can be reduced.

Owner:上海中孚油品集团有限公司

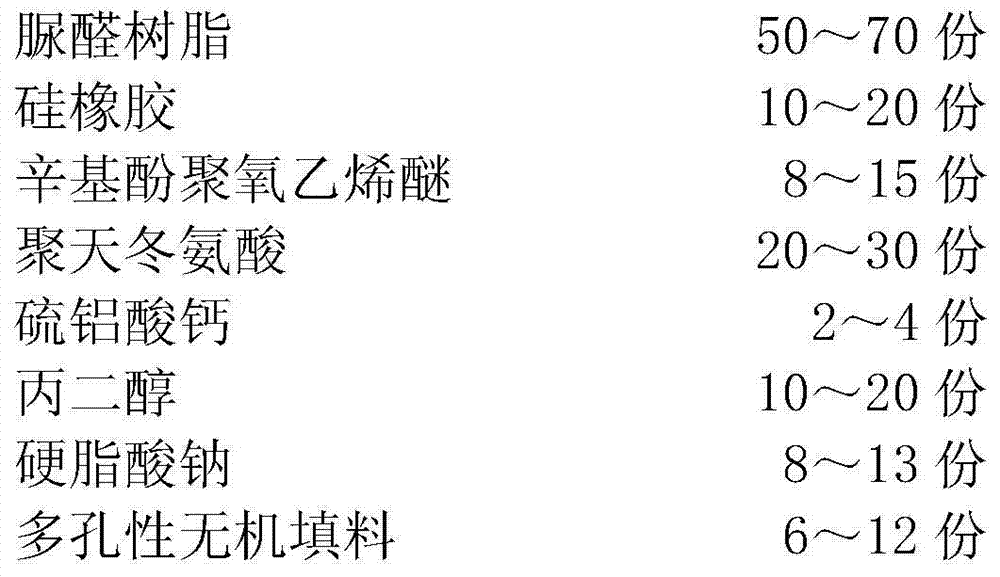

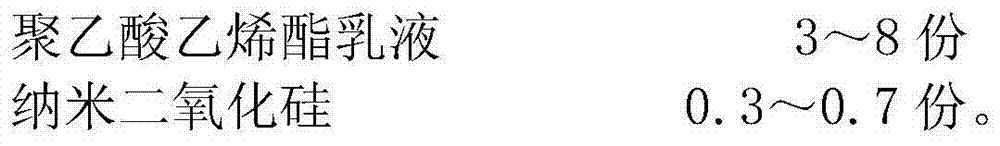

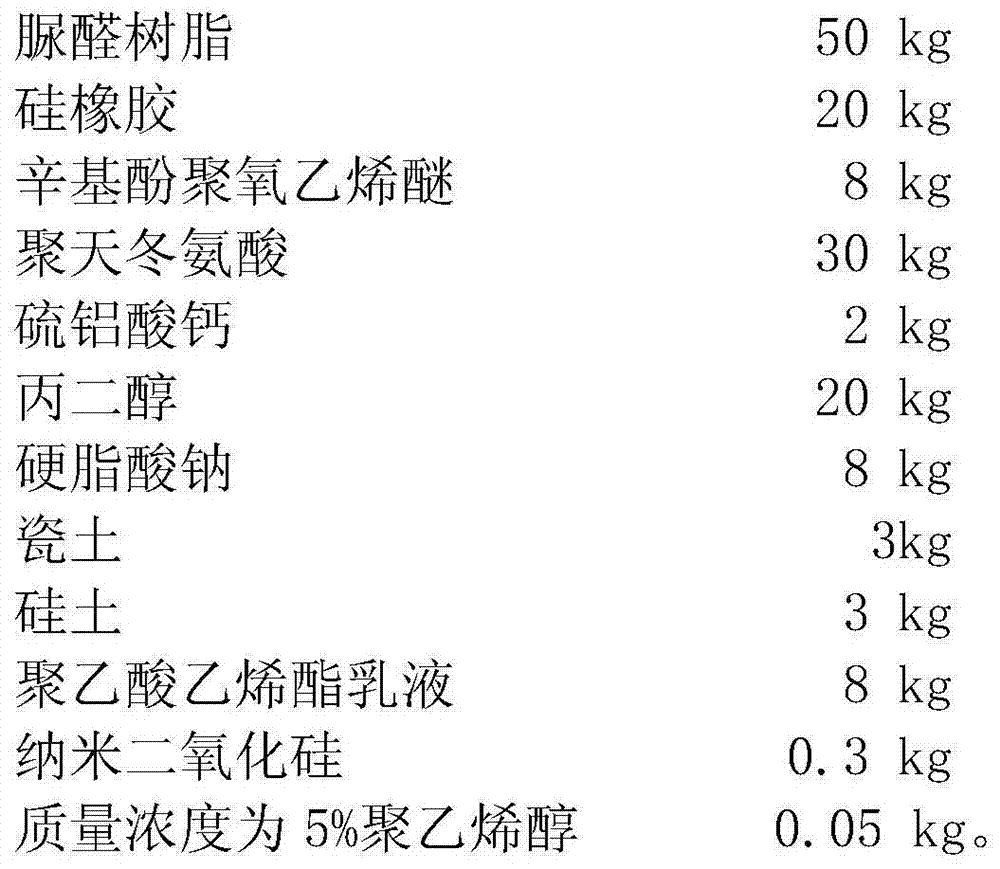

Adhesive for indoor plywood

InactiveCN104762039AIncrease productivityReduce formaldehydeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSodium stearateAdhesive

The invention relates to the technical field of adhesive, in particular to adhesive for indoor plywood. The adhesive comprises, by weight, 50-70 parts of urea resin, 10-20 parts of silicone rubber, 8-15 parts of octyl phenol polyoxyethylene ether, 20-30 parts of polyaspartic acid, 2-4 parts of calcium sulphoaluminate, 10-20 parts of propylene glycol, 8-13 parts of sodium stearate, 6-12 parts of porous inorganic filler, 3-8 parts of polyvinyl acetate emulsion, 1-5 parts of nano-silica and 5-10 parts of water. The adhesive for the indoor plywood is good in viscosity, has the antiseptic and anti-static functions and contains lower formaldehyde, the water resistance and aging resistance of the adhesive are improved greatly, and the service life of the adhesive is prolonged by half a year to one year. The adhesive is mainly applied to bonding of the inner plywood.

Owner:黄琳

Cold application water-blocking type optical power cable filling past and production method thereof

InactiveCN105989919AGood water blocking effectGood viscosity performanceInsulated cablesFibre mechanical structuresSuper absorbentOptical power

The invention discloses a cold application water-blocking type optical power cable filling past. The filling past comprises the following components in weight percentage: 70% to 80% of base oil; 2% to 5% of emulsifier; 5% to 10% of super absorbent polymer; 3% to 10% of thickener; 0.2% to 1% of antioxidant; and 0.2% to 0.8% of dispersant. The invention further provides a production method of the filling paste. The production method includes the following steps that: base oil is heated to 60 DEG C to 100 DEG C, a proper amount of an antioxidant, an emulsifier and a water resistance agent are added to the base oil, and an obtained liquid is fully stirred for 5 hours to 6 hours, and the liquid is completely emulsified, the liquid is fast cooled to room temperature through cooling equipment; a thickener and a dispersant are added into the liquid, and an obtained mixture is stirred uniformly for 0.5 hours to 1 hours; and polymer water-absorbent resin is added into the mixture, and a newly obtained mixture is stirred uniformly, air bubbles in the mixture are extracted through a vacuum pump, after air pumping, emptying is carried out. The filling paste produced by the production method of the invention has the advantages of good water resistance and lower production cost.

Owner:上海明翼光电科技有限公司

Preparation method of liquid butadiene-acrylonitrile rubber with high nitrile content

The invention discloses a preparation method of liquid butadiene-acrylonitrile rubber with a high nitrile content. The preparation method comprises the steps of mixing a carbon nano tube and water, stirring at a high speed to allow the carbon nano tube to be dispersed uniformly, adding the dispersed carbon nano tube in a reactor containing ester, an emolsifier and the water, controlling the temperature at 50-100 DEG C to allow the ester to coat and polymerize the carbon nano tube to form a seed solution, dropwise adding the ester to prepare functional composite emulsion, adding the water, acrylonitrile, cellulose and the emolsifier into a polymerization kettle, then adding butadiene and the functional composite emulsion, start the polymerization kettle to stir, then cooling the polymerization kettle, when cooling the polymerization kettle to 15-25 DEG C, adding an initiator and a molecular weight regulator, performing polymerization reaction for 10-16h, then adding a terminator, and allowing latex to be degassed and cohered to form a product. According to the liquid butadiene-acrylonitrile rubber with the high nitrile content prepared by the method, the mass percentage of combined acrylonitrile is 28-35%.

Owner:之江(四川)高新材料应用技术研究院有限公司

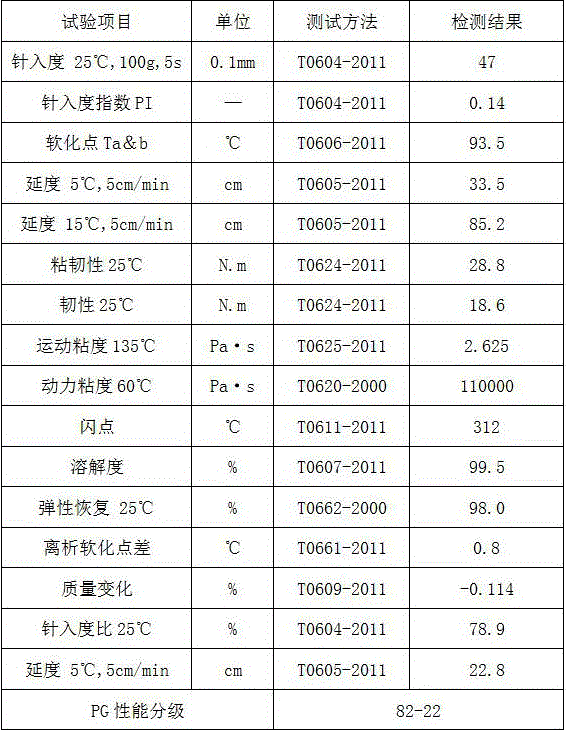

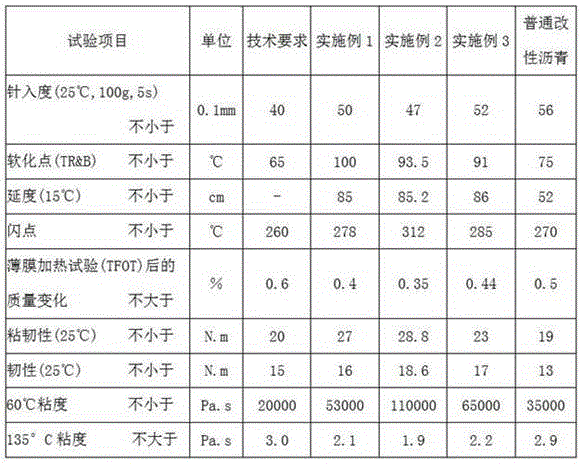

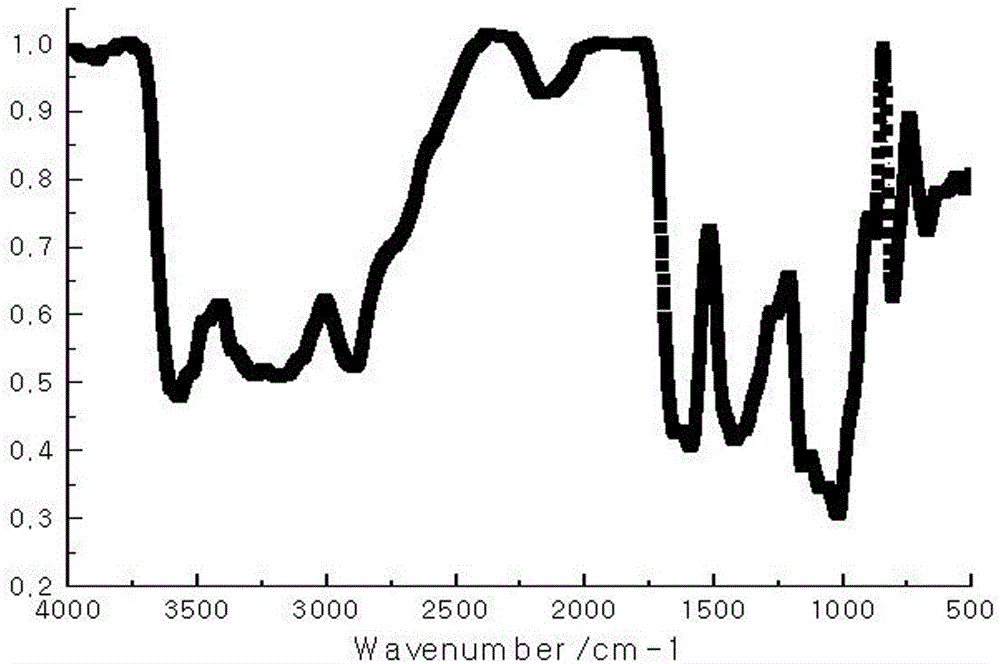

High-performance modified asphalt and preparation method thereof

The invention provides high-performance modified asphalt, consisting of the following raw materials in parts by weight: 70-100 parts of asphalt, 3-7 parts of a styrene-butadiene-styrene copolymer (SBS), 0.01-2 parts of ethylene bis-stearamide (EBS), 0.1-1 part of a vulcanizing agent, 0.1-1.5 parts of an antioxidant, 2-4 parts of methyl ethyl ketone, 2-3 parts of an anti-aging agent, 1-2.5 parts of methyl phenol type phenolic resin, 0.5-1 part of epoxidized vegetable oil, 2-4 parts of propyl acetic acid, 1-3 parts of nickel acetylacetonate, 1-3 parts of dibutyl ester, and 1-3 parts of pentaerythritol tetrastearate. The high-performance modified asphalt provided by the invention has excellent high-temperature stability, salt fog resistance and ageing resistance, and the high-temperature viscosity of the modified asphalt can be reduced; and the modified asphalt meets a high-viscosity modification index requirement, and can be applied to special occasions including OGFC (Open Graded Friction Course) drainage asphalt pavements, heavy-loaded traffic road asphalt pavements and the like.

Owner:漳州新立基沥青有限公司

Antistatic modified hot melt adhesive and preparation method thereof

ActiveCN105482755BLow melting pointCrystallize fastMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolyesterPetroleum resin

The invention relates to an antistatic modified hot melt adhesive. The hot melt adhesive is prepared by processing the following raw materials in parts by weight: 40-60 parts of polyester hot melt adhesive, 20-50 parts of polyamide resin, 20-30 parts of conductive carbon black, 5-10 parts of petroleum resin and 0.5-1 part of an antioxidant 164. The antistatic modified hot melt adhesive is obtained by uniformly mixing the polyester hot melt adhesive, polyamide resin, petroleum resin, the antioxidant and conductive carbon black in a formula ratio, then adding the mixture to a screw extruder pelletizer to undergo melt blending and extrusion, cooling and pelletizing the extruded mixture and removing moisture from pellets obtained through pelletizing through vacuum drying. The hot melt adhesive with stable adhesion, good antistatic property and high crystallization and curing rates is prepared by selecting the polyester hot melt adhesive with low melting point to be mixed with polyamide resin, conductive carbon black, petroleum resin and the antioxidant 164, is convenient to use, is slightly affected by the environment and has higher crystallization and curing rates than hot melt adhesives in the prior art especially in a low-temperature environment, thus greatly improving the production efficiency.

Owner:南通恒华粘合材料科技有限公司

Antistatic modified hot melt adhesive and preparation method thereof

ActiveCN105482755ALow melting pointCrystallize fastMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolyesterPolymer science

The invention relates to an antistatic modified hot melt adhesive. The hot melt adhesive is prepared by processing the following raw materials in parts by weight: 40-60 parts of polyester hot melt adhesive, 20-50 parts of polyamide resin, 20-30 parts of conductive carbon black, 5-10 parts of petroleum resin and 0.5-1 part of an antioxidant 164. The antistatic modified hot melt adhesive is obtained by uniformly mixing the polyester hot melt adhesive, polyamide resin, petroleum resin, the antioxidant and conductive carbon black in a formula ratio, then adding the mixture to a screw extruder pelletizer to undergo melt blending and extrusion, cooling and pelletizing the extruded mixture and removing moisture from pellets obtained through pelletizing through vacuum drying. The hot melt adhesive with stable adhesion, good antistatic property and high crystallization and curing rates is prepared by selecting the polyester hot melt adhesive with low melting point to be mixed with polyamide resin, conductive carbon black, petroleum resin and the antioxidant 164, is convenient to use, is slightly affected by the environment and has higher crystallization and curing rates than hot melt adhesives in the prior art especially in a low-temperature environment, thus greatly improving the production efficiency.

Owner:南通恒华粘合材料科技有限公司

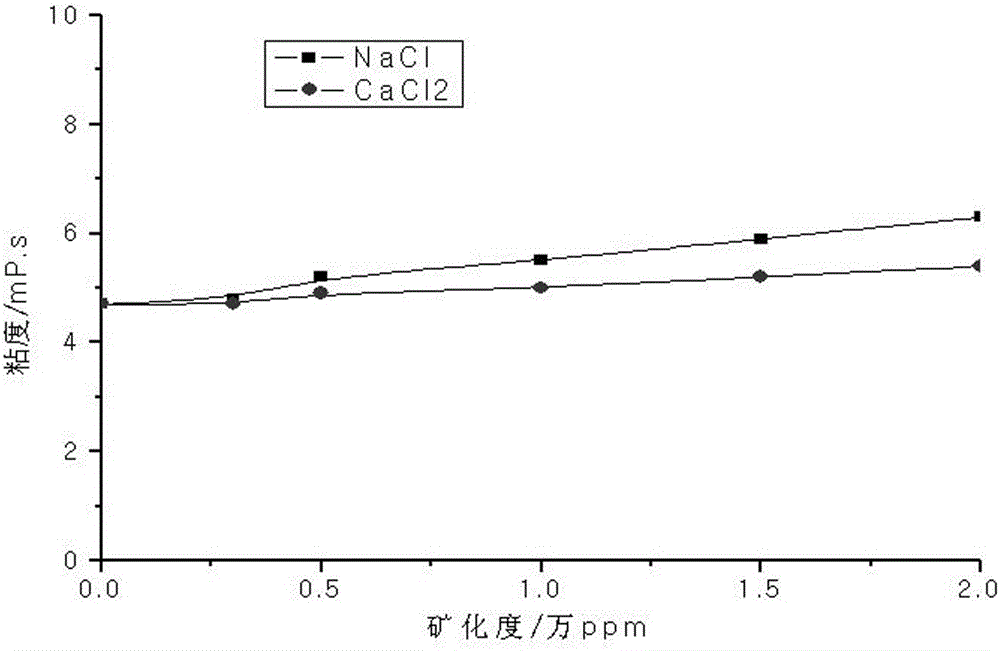

Novel instant salt-tolerant guar gum and preparation method therefor

The invention discloses a novel instant salt-tolerant guar gum and a preparation method therefor, and relates to a guar gum modification method. Aiming at the defects that solubility and salt tolerance cannot be met at the same time during the preparation of guar gum, the invention provides an instant salt-tolerant guar gum with good solubility and salt tolerance and a preparation method thereof. The method comprises the following three steps: (1) adding the guar gum into an alcohol-water mixed solvent, adding alkyleneoxide after normal temperature alkalization for 0.5-2 h, and stirring for 0.5-2 h; (2) dropwise adding N,N-dimethyl-3-chloropropylamine, adjusting the pH value to be grater than or equal to 8, raising the temperature to 30-50 DEG C, and performing reflux condensation for 2-4 h; and (3) adding sodium chloroacetate and sodium hydroxide, performing reflux condensation for 2-4 h at the temperature of 50-70 DEG C, cooling the product to room temperature, adjusting the pH to be 7, washing, performing suction filtration and drying to obtain the instant salt-tolerant guar gum. The preparation method is mild in condition, the preparation process is simple, the prepared instant salt-tolerant guar gum is high in dissolution rate, and the novel instant salt-tolerant guar gum has good viscosity performance in salt water.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Polymer compositions comprising terephthalates

InactiveCN105566812AGood viscosity performanceReduce volatilityCoatingsPolymer scienceTerephthalic acid

The invention is directed to plasticized compositions comprising esters of terephthalic acid, particularly PVC compositions.

Owner:EXXONMOBIL CHEM PAT INC

Bearing anti-rust oil and preparation method thereof

InactiveCN106318575AGood rust resistanceGood viscosity performanceLubricant compositionHydroxyl-terminated polybutadienePetroleum

The invention discloses bearing anti-rust oil and a preparation method thereof. The preparation method includes the following steps of firstly, taking heavy calcium carbonate powder to be ground through a grinding machine; secondly, increasing the temperature in a stirring tank to be 90-120 DEG C, and adding 140-170 parts of mineral oil, 3-7 parts of petroleum sodium sulfonate, 2-4 parts of phytic acid, 3-6 parts of nonylphenol polyoxyethylene ether, 2-5 parts of calcium lignosulphonate and 1-5 parts of hydroxyl-terminated polybutadiene into the stirring tank to be stirred for 30-50 min; thirdly, adding 4-8 parts of starch sodium octenylsuccinate, 0.5-1 part of fluorocarbon resin, 1-4 parts of acetyl castor butyl alcohol acid, 1-3 parts of perfluorinated octyl ethyl acrylate and 1-3 parts of heavy calcium carbonate powder into the stirring tank to be stirred for 20-40 min, and cooling to prepare the bearing anti-rust oil. The prepared bearing anti-rust oil can effectively prevent bearings from rusting.

Owner:WUJIANG HUAWEI SPECIAL OIL

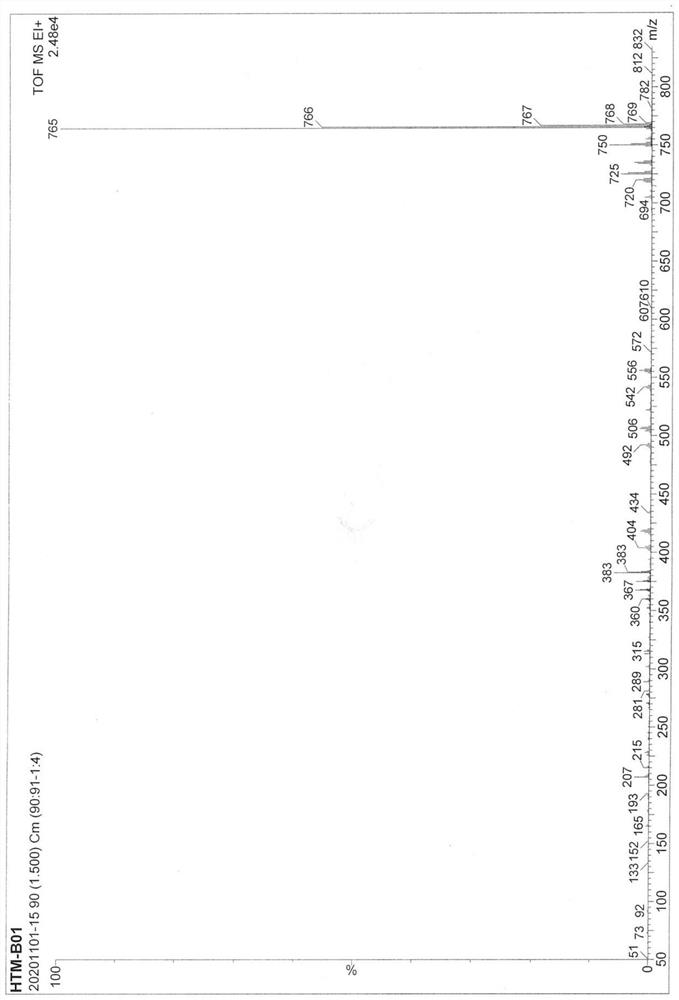

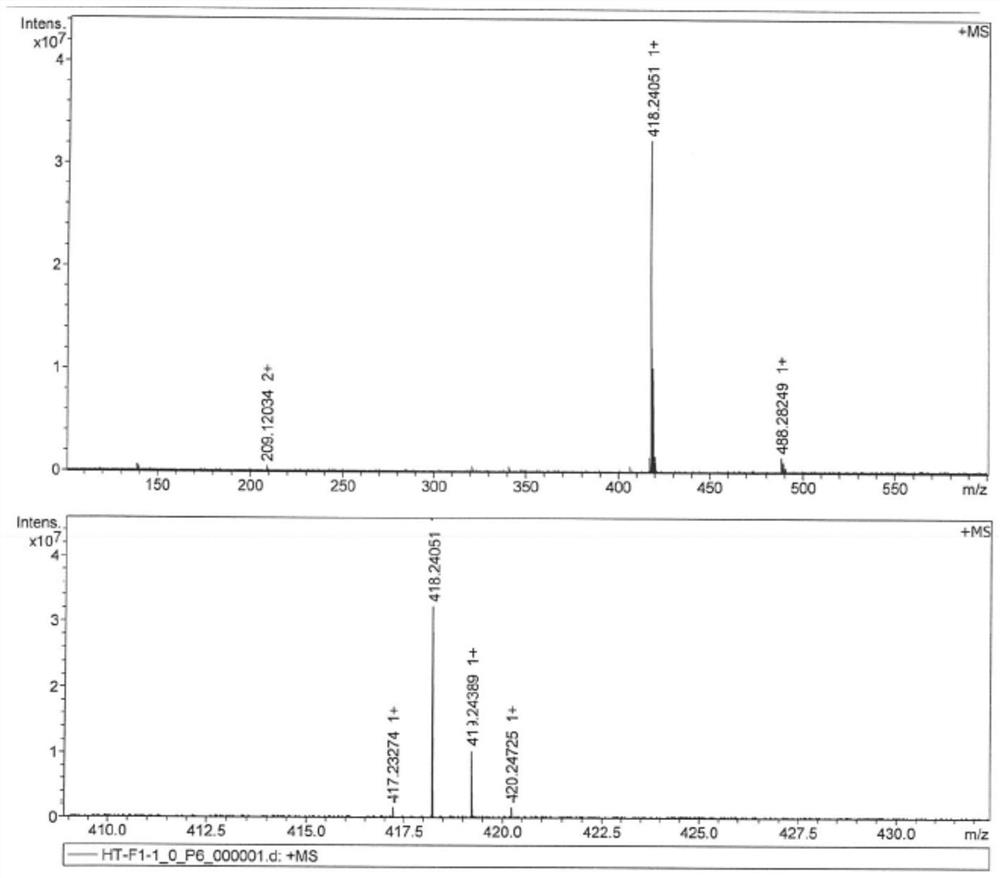

Compound and organic electroluminescent device

PendingCN113149889ASimple structureChange structureOrganic chemistrySolid-state devicesOrganic electroluminescenceMaterials science

The invention relates to the field of electroluminescence, and discloses a compound and an organic electroluminescent device. The structural formula of the compound is shown as a formula (I), so that the driving voltage and the current efficiency of the electroluminescent device are reduced, and meanwhile, the invention provides a compound capable of preparing a transmission layer of the electroluminescent device by using a solution method.

Owner:FUYANG XINYIHUA MATERIAL TECH +1

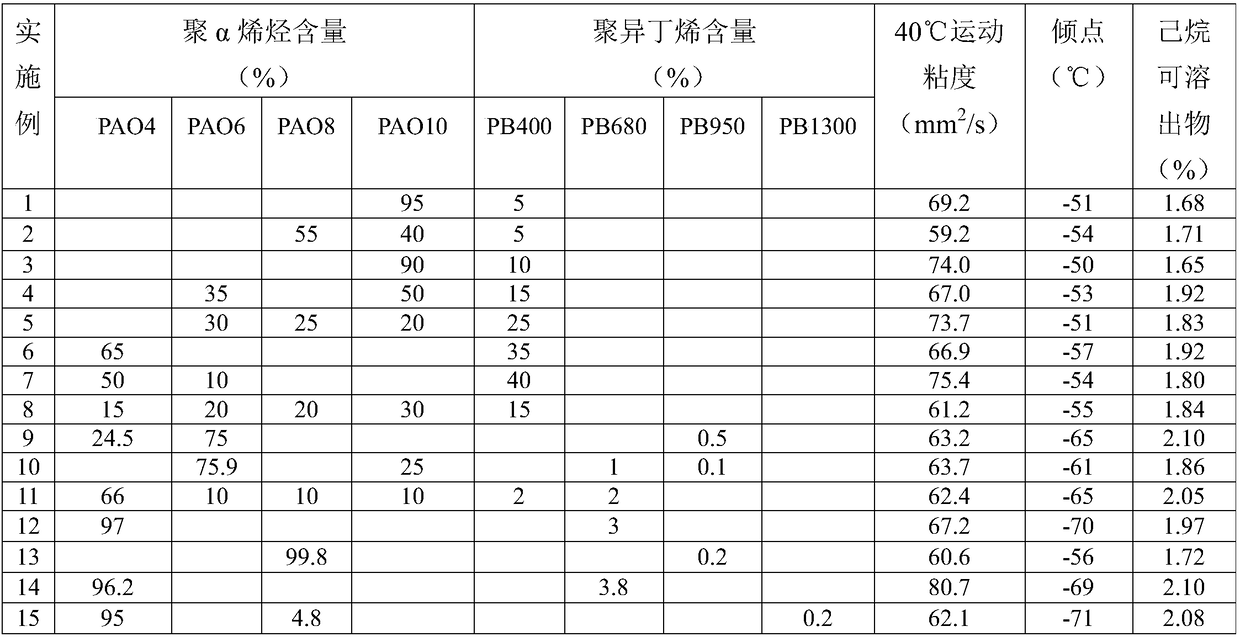

Dispersing agent for polyolefin catalyst

The invention relates to a dispersing agent for a polyolefin catalyst. The dispersing agent is composed of the following materials by weight percent: 60%-99.9% of poly alpha-olefin synthetic oil withkinematic viscosity not above 100mm2 / s at 40 DEG C and 0.1%-40% of polyisobutene. Due to the viscosity and dispersity of the dispersing agent disclosed by the invention, the prepared catalyst suspension is not easy to settle under the conditions of storage, transportation and polymerization process; compared with the mineral oil with same viscosity, the dispersing agent has lower flow point and better and more stable operation; poly alpha-olefin has high compatibility with polypropylene and is not easy to volatile; fuming phenomenon of polymer during the processing process is greatly reduced;the content of soluble substance in hexane is low; the dispersing agent is suitable for the production of packaging products of medical supplies and food and the production of aluminum laminated films.

Owner:利和知信新材料技术有限公司

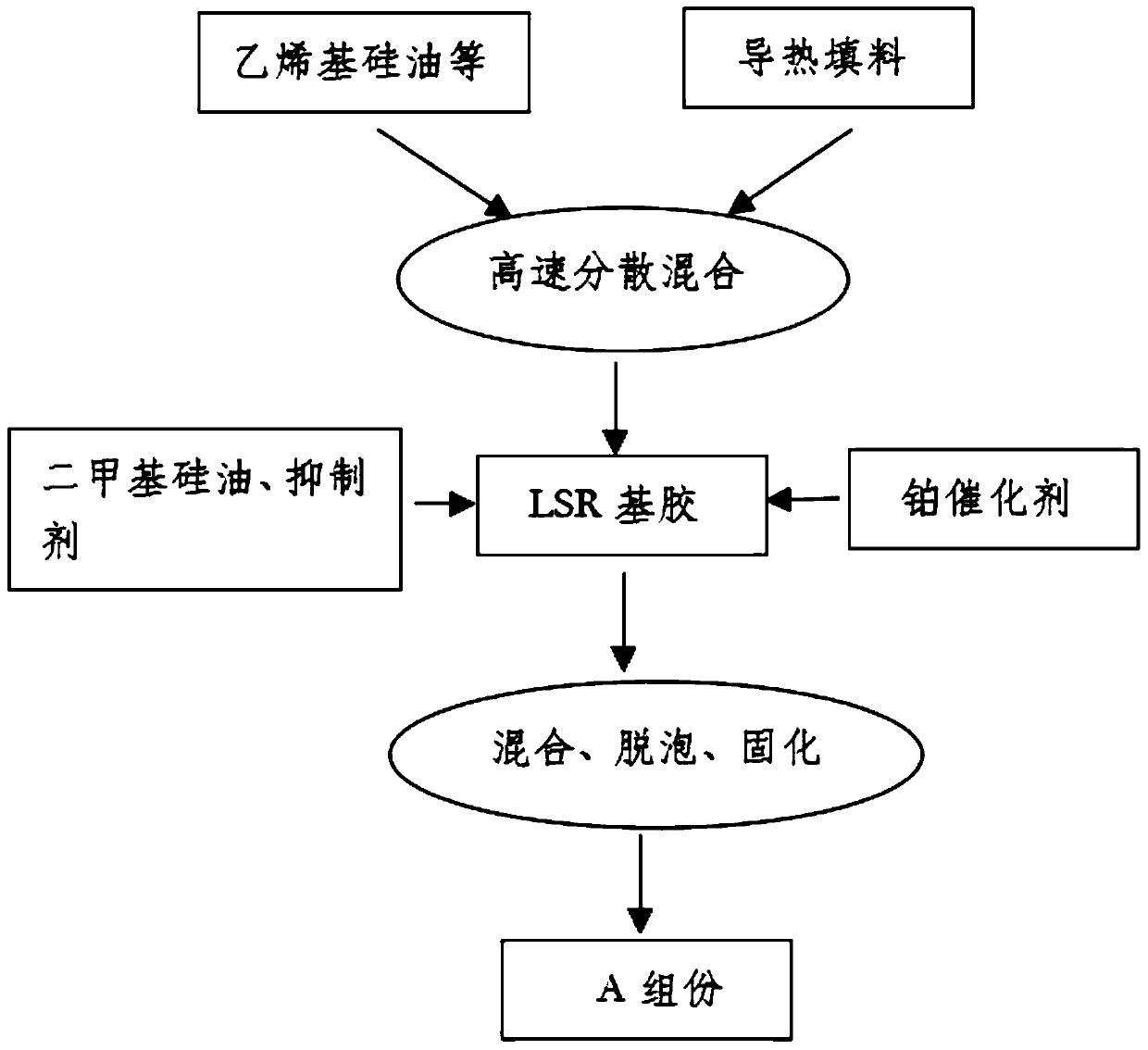

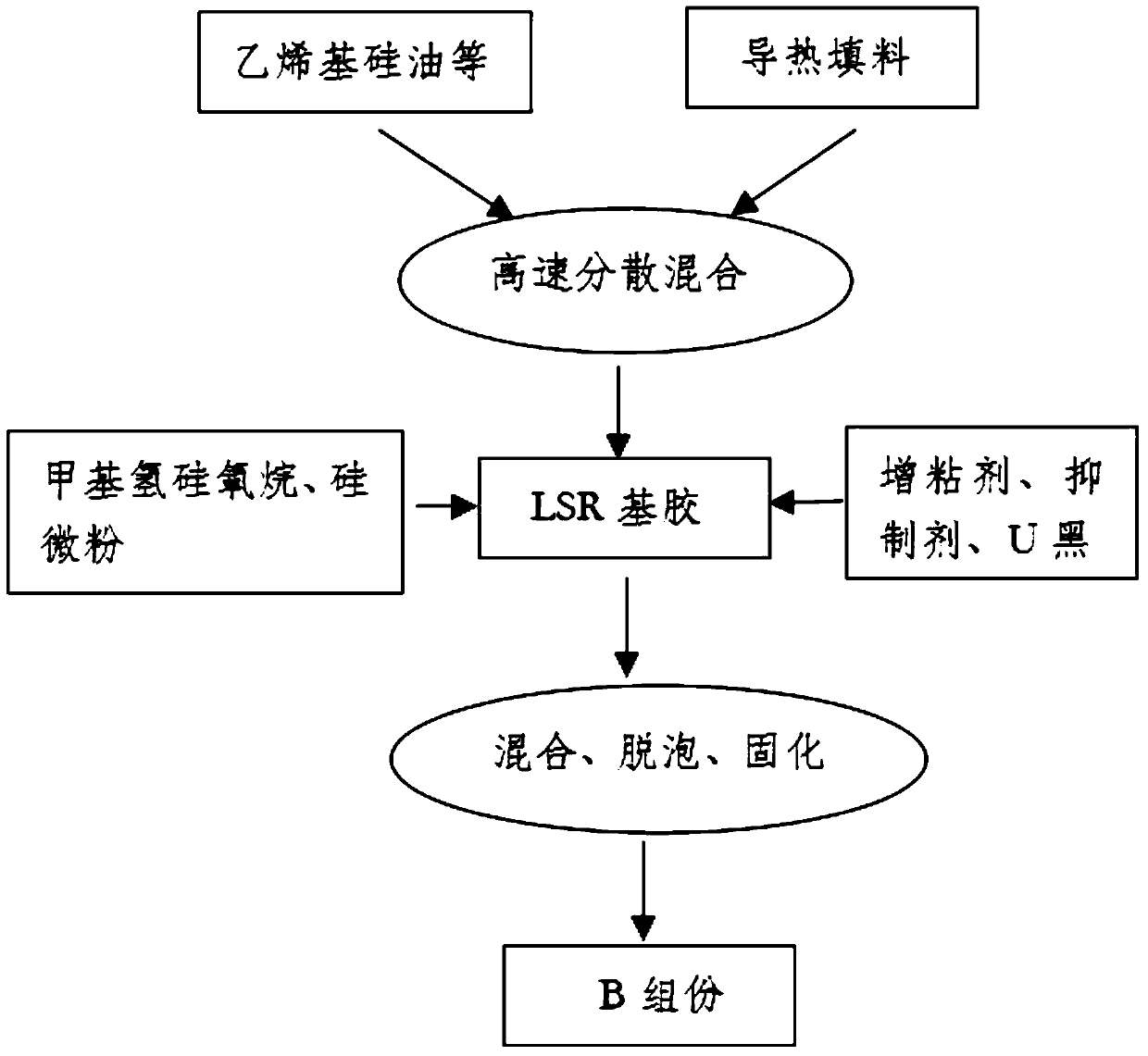

Two-component silicone potting compound and its preparation process

ActiveCN105754542BImprove thermal conductivityAchieve temperatureNon-macromolecular adhesive additivesSealantTackifier

The invention discloses a two-component organic silicon pouring sealant and a preparation process thereof. The two-component organic silicon pouring sealant comprises a component A and a component B, wherein the component A is prepared by mixing vinyl silicone oil, simethicone, silica powder, alumina, aluminum nitride, LSR base glue and a platinum catalyst in a certain weight ratio; and the component B is prepared by mixing vinyl silicone oil, simethicone, methyl hydrogen siloxane, silica powder, alumina, LSR base glue, white carbon black, a tackifier and an inhibitor in a certain weight ratio; and the mixing ratio of the component A and the component B is 1 to 1. The preparation process comprises the following steps: (1) preparing the component A; (2) preparing the component B; and (C) uniformly mixing the component A with the component B in a mass ratio of 1 to 1 under the high-speed shearing and dispersing, adding the mixture into a vacuum drying chamber, carrying out vacuum defoamation for 10 minutes, pouring the mixture into a mold, and curing at the room temperature or heating to cure.

Owner:深圳市欧普特工业材料有限公司

Preparation method of liquid nitrile rubber with high nitrile content

The invention discloses a preparation method of liquid butadiene-acrylonitrile rubber with a high nitrile content. The preparation method comprises the steps of mixing a carbon nano tube and water, stirring at a high speed to allow the carbon nano tube to be dispersed uniformly, adding the dispersed carbon nano tube in a reactor containing ester, an emolsifier and the water, controlling the temperature at 50-100 DEG C to allow the ester to coat and polymerize the carbon nano tube to form a seed solution, dropwise adding the ester to prepare functional composite emulsion, adding the water, acrylonitrile, cellulose and the emolsifier into a polymerization kettle, then adding butadiene and the functional composite emulsion, start the polymerization kettle to stir, then cooling the polymerization kettle, when cooling the polymerization kettle to 15-25 DEG C, adding an initiator and a molecular weight regulator, performing polymerization reaction for 10-16h, then adding a terminator, and allowing latex to be degassed and cohered to form a product. According to the liquid butadiene-acrylonitrile rubber with the high nitrile content prepared by the method, the mass percentage of combined acrylonitrile is 28-35%.

Owner:之江(四川)高新材料应用技术研究院有限公司

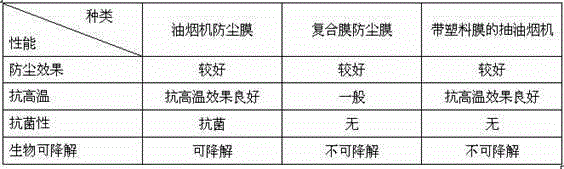

Range hood dustproof film and preparation method thereof

The invention relates to a range hood dustproof film and a preparation method thereof. The preparation method of the range hood dustproof film comprises purification of konjac glucomannan, preparation of modified konjac glucomannan, purification of a modified product, mixing, plate inversion and film preparation, and film opening. The range hood dustproof film takes the konjac glucomannan as a carrier and other auxiliary agents are added, so that the range hood dustproof film has good film forming property, water resistance, antibacterial property, large tensile strength and good flexibility; the product has the antibacterial property and the viscosity performance is very good; the stuck range hood dustproof film is not crimped, has biodegradability and does not pollute the environment. The range hood dustproof film takes the konjac glucomannan as a main material of the range hood dustproof film; compared with a plastic material, the range hood dustproof film has high tensile strength, acid and alkali resistance, high temperature resistance and antibacterial effect, can be completely biodegraded and is environment-friendly and low-carbon, and the materials are easy to obtain.

Owner:FUJIAN AGRI & FORESTRY UNIV

Green pigment dispersion liquid for color filter and preparation method of green pigment dispersion liquid

PendingCN114085549ASimple compositionGive full play to the adsorption effectOrganic dyesPhotosensitive materials for photomechanical apparatusColor gelPigment dispersion

The invention relates to a green pigment dispersion liquid for a color filter and a preparation method of the green pigment dispersion liquid. The dispersion liquid comprises the following components: phthalocyanine pigment, a dispersing agent, resin and a solvent. The dispersion liquid is simple in formula, and the pigment dispersion liquid with excellent viscosity performance and good storage stability is obtained on the premise of not using any derivative, so that the defects of complex synthesis and formula are overcome.

Owner:XIAN SMART MATERIALS CO LTD

Antibacterial low melting point hot melt adhesive and preparation method thereof

ActiveCN105542698BLow melting pointCrystallize fastNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterAntioxidant

Owner:佛山市高达树脂有限公司

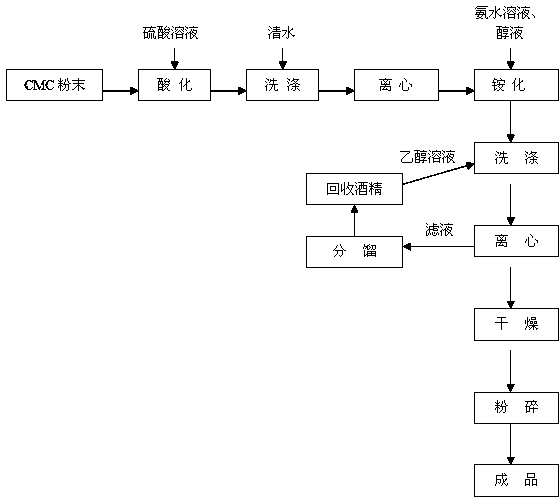

Preparation method of ammonium carboxymethylcellulose

The invention provides a preparation method of ammonium carboxymethylcellulose, which includes first evenly mixing sodium carboxymethylcellulose powder and dilute sulphuric acid solution in stirring mode, placing the mixture statically for a time, conducting acidification reaction, conducting washing and centrifuging, adding hartshorn to conduct ammonium compounding, finally conducting washing, centrifuging, drying and crushing to obtain a ammonium carboxymethylcellulose product. The whole production process is simple in process, short in reaction period, less in equipment investment and low in raw material consumption.

Owner:CHONGQING LIHONG FINE CHEM

Fireproof paint for interior wall decorative plywood and preparation method of fireproof paint

InactiveCN106634255AGood viscosity performanceWith anti-corrosion, anti-static functionFireproof paintsAntifouling/underwater paintsMelamine phosphatePolyvinyl alcohol

The invention discloses fireproof paint for interior wall decorative plywood and a preparation method of the fireproof paint. The fireproof paint is prepared from the following formula components in parts by mass: 10 to 20 parts of mineral wool, 7 to 9 parts of calcium sulfoaluminate, 10 to 12 parts of styrene-acrylic emulsion, 6 to 8 parts of melamine phosphate, 1 to 3 parts of a preservative, 6 to 10 parts of polyvinyl alcohol, 5 to 7 parts of polyaspartic acid, 15 to 25 parts of fly ash, 6 to 8 parts of nano zinc oxide, 10 to 12 parts of palm oil, 1 to 2 parts of a synergist, 6 to 8 parts of ash calcium powder and 60 to 80 parts of water. The paint disclosed by the invention is used to coat the surface of the plywood, and has excellent heat-preservation, heat-insulation, fireproof and mildew-proof effects.

Owner:浦北县建业胶合板有限责任公司

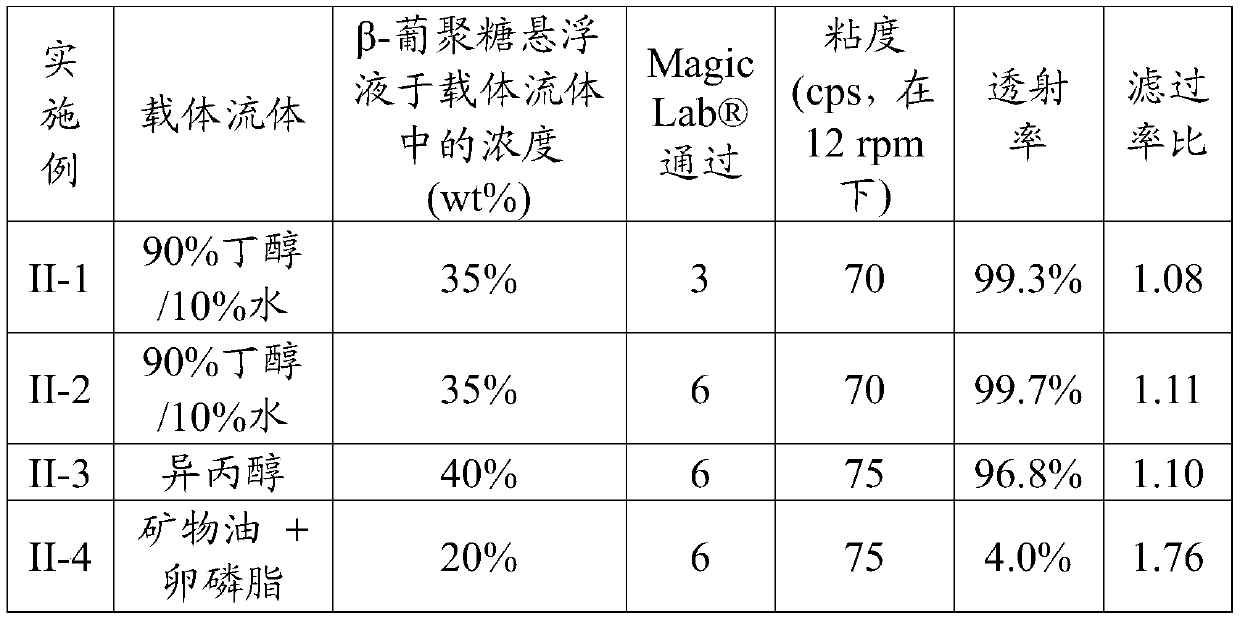

Readily water-miscible beta-glucan suspensions

Owner:CARGILL INC

Preparation method of modified silicon dioxide-epoxy resin composite slurry

InactiveCN114292614AUniform particle size distributionParticle size distribution can be adjustedNon-macromolecular adhesive additivesEpoxy resin adhesivesMeth-Silicic acid

The invention provides a preparation method of modified silicon dioxide-epoxy resin slurry, which comprises the following steps: adding an alkaline substance into a mixed solvent of alcohol and water, dropwise adding tetraethoxysilane and methyltrimethoxysilane, then adding at least two biped silane coupling agents, washing and drying to obtain in-situ modified silicon dioxide powder; adding the prepared silicon dioxide powder into an epoxy resin matrix prepared from epoxy resin and ethylene glycol diglycidyl ether, uniformly mixing by using a high-speed mixer, and removing bubbles to obtain the modified silicon dioxide-epoxy resin composite slurry. The preparation and surface in-situ modification of silicon dioxide are completed in one pot, the grafting rate of functional groups on the surface of silicon dioxide is increased, the problem that the viscosity of composite slurry is too high when existing silicon dioxide filler is small in particle size and high in filling amount is solved, and the epoxy resin composite slurry is ideal in the field of electronic packaging.

Owner:XILONG SCI CO LTD

Preparation method of permanent orange pigment

InactiveCN109593385AReduce aggregationNot easy to gatherMonoazo dyesInksDispersityReaction temperature

The invention provides a preparation method of permanent orange pigment and relates to the technical field of coating. The preparation method comprises the following steps: (1) sequentially adding thecomponents in parts by weight: 0.5 to 3 parts of hydrochloric acid and 8 to 14 parts of 3,3-dichlorobenzidine; pulping, diluting an cooling; adding 2.5 to 3.6 parts of sodium nitrite and carrying outdiazotization reaction; adding sulfamic acid to obtain a diazonium solution; (2) mixing 6 to 8 parts of 1,3,5-pyrazolone in parts by weight and 0.8 to 1.2 parts of an emulsifier in parts by weight and pulping to obtain a coupling solution; (3) mixing 2 to 6 parts of liquid alkali by weight and 2 to 3 parts of rosin by weight, so as to obtain a rosin solution; (4) synthesizing; adding the couplingsolution into the diazonium solution and carrying out coupling reaction, wherein the reaction temperature is 12 to 18 DEG C; then adding the rosin solution and mixing; and adding 3 to 4 parts of a dispersant to obtain the permanent orange pigment. According to the preparation method provided by the invention, a second component is introduced so that an aggregation effect of particles is reduced;in a utilization process, a system has good dispersity and the particles are not easy to aggregate; and the softnesss of the particles is increased and the pigment has good flowability in the utilization process.

Owner:宣城英特颜料有限公司

A kind of instant salt-resistant guar gum and preparation method thereof

An instant salt-resistant guar gum and a preparation method thereof relate to a modification method of guar gum. Aiming at the defect that the existing guar gum cannot satisfy the solubility and salt tolerance at the same time during preparation, an instant salt-tolerant guar gum with good solubility and salt tolerance and a preparation method thereof are provided. The method includes the following three steps: (1) Add guar gum to alcohol-water mixed solvent, alkalinize at room temperature for 0.5-2 hours, then add alkylene oxide, and stir for 0.5-2 hours; (2) Add N,N-dimethyl- 3-Chloropropylamine, adjust the pH value to ≥8, heat up to 30-50°C to condense and reflux for 2h-4h; (3) add sodium chloroacetate and sodium hydroxide, condense and reflux at 50-70°C for 2h-4h, and cool the product to room temperature, adjust the pH to 7, wash, filter with suction, and dry to obtain instant salt-resistant guar gum. The preparation method has mild conditions and simple operation process, and the prepared instant salt-resistant guar gum has a fast dissolution speed and good viscosity performance in salt water.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com