Novel process for producing organically modified bentonite

A technology of bentonite and new technology, applied in inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve problems such as poor applicability and difficulty in starting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

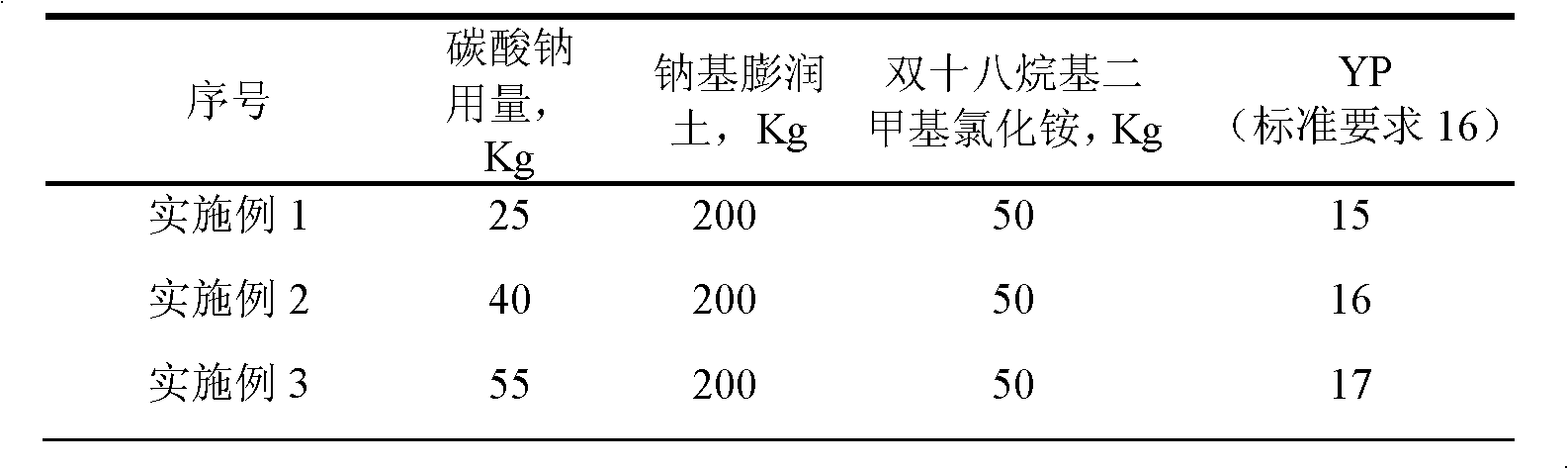

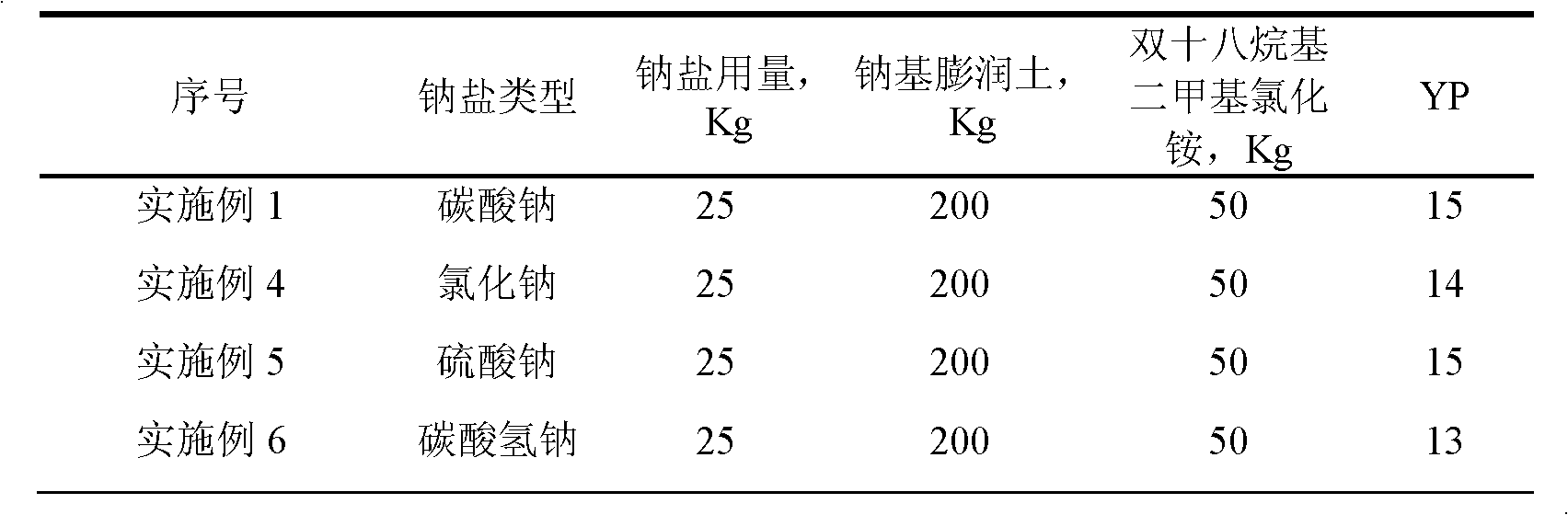

Embodiment 1

[0035] Put 200Kg of domestic calcium-based bentonite into the reactor, add 25Kg of sodium carbonate at the same time, add 30Kg of water by spraying, stir thoroughly for 30 minutes, add 55Kg of dioctadecyldimethyl ammonium chloride, and continue stirring for 10 minutes. After the stirring was completed, the temperature was rapidly raised to 90°C, and the reaction was sealed for 20 minutes. After the reaction finishes, add the methanol solution of stearic acid in a spray mode. Unloading, transfer to drying program.

[0036] Configure it as an oil-based mud system, measure the readings of R600 and R300 with a Fann35 viscometer, and calculate the YP value according to YP=2*R300-R600.

Embodiment 2

[0038] Put 250Kg of domestic calcium-based bentonite into the reactor, add 40Kg of sodium carbonate at the same time, add 30Kg of water by spraying, stir thoroughly for 30 minutes, add 50Kg of dioctadecyldimethylammonium chloride, and continue stirring for 10 minutes. After the stirring was completed, the temperature was rapidly raised to 90°C, and the reaction was sealed for 20 minutes. After the reaction finishes, add the methanol solution of stearic acid in a spray mode. Unloading, transfer to drying program.

[0039] Configure it as an oil-based mud system, measure the readings of R600 and R300 with a Fann35 viscometer, and calculate the YP value according to YP=2*R300-R600.

Embodiment 3

[0041] Put 150Kg of domestic calcium-based bentonite into the reactor, add 55Kg of sodium carbonate at the same time, add 30Kg of water by spraying, stir thoroughly for 30 minutes, add 50Kg of dioctadecyldimethylammonium chloride, and continue stirring for 10 minutes. After the stirring was completed, the temperature was rapidly raised to 90°C, and the reaction was sealed for 20 minutes. After the reaction finishes, add the methanol solution of stearic acid in a spray mode. Unloading, transfer to drying program.

[0042] Configure it as an oil-based mud system, measure the readings of R600 and R300 with a Fann35 viscometer, and calculate the YP value according to YP=2*R300-R600.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com