Readily water-miscible beta-glucan suspensions

A technology of suspension and dextran, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as insufficient viscosity establishment and poor filterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Various aspects of the invention may be better understood with reference to the following examples, which are provided by way of illustration. The invention is not limited to the examples given herein.

[0064] Stir Plate Shear Rate Calculation. The diameter of the shear element used was about 2.5-10 cm with a gap of about 1-2 mm between the shear element and the bottom of the beaker. The shear rate is about 700 rpm. D*π*rpm*(1 min / 60 sec) = distance traveled by the outer edge of the shearing element per second, which can be divided by the gap distance to estimate the shear rate. (2.5 to 10cm)*π*700rpm*(1 minute / 60 seconds) / 0.1 to 0.2cm=about 460s -1 to about 3,670s -1 .

[0065] Part I. Preparation of β-glucan.

[0066] Using a moderately agitated 5000 liter jacketed vessel, commercial CS6 (coarse powder blend of scleroglucan and Sclerotinia neat organisms powder) was added to 2400 liters of 11.8°C water and mixed for 1 hour. After mixing for 1 hour, the vess...

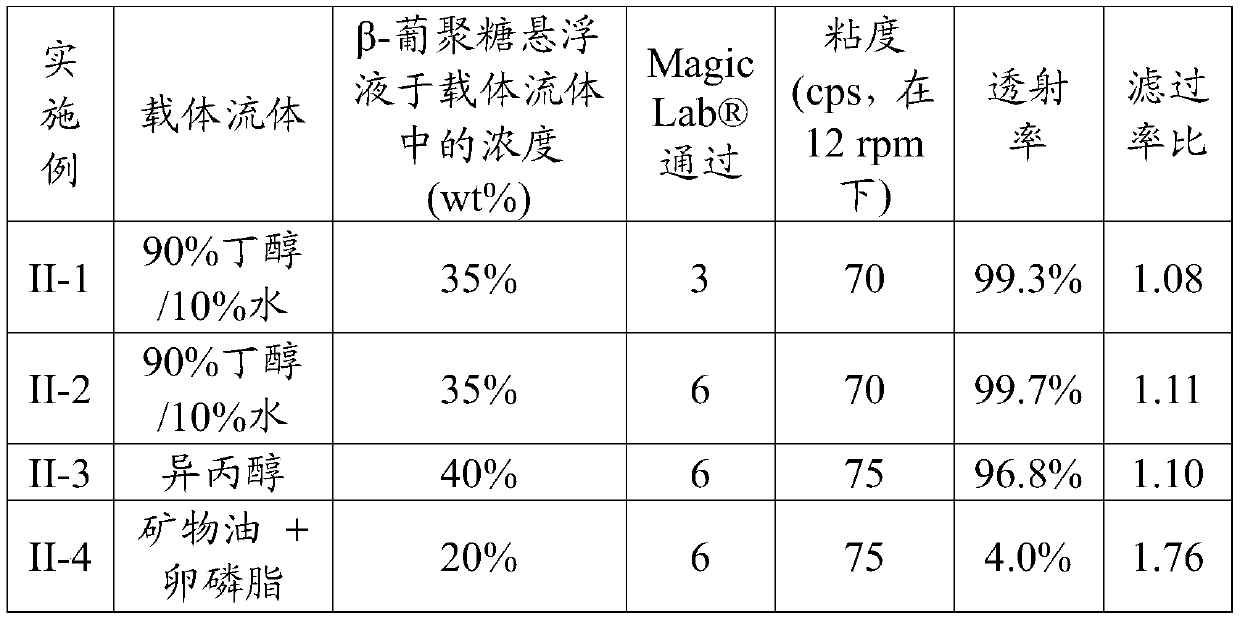

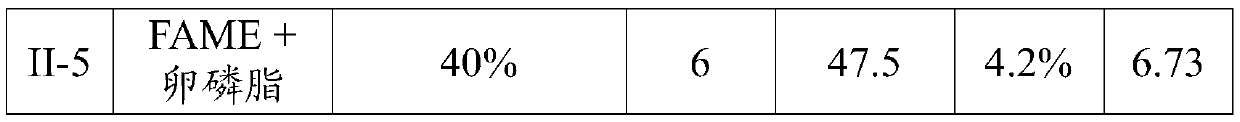

Embodiment II-1 to II-5

[0082] The various solvents or solvent mixtures shown in Table 1 were used to form β-glucan suspensions, which were then dispersed in synthetic seawater.

Embodiment II-1 and II-2

[0083] For Examples II-1 and II-2, by hydrating an appropriate weight of butanol and hydrating and at about 460s- 1 to about 3,670s- 1 A solvent mixture of 90% butanol, 10% deionized water by weight was prepared under agitation on a stir plate for about 1-5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com