Patents

Literature

33results about How to "Fast viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All-solid low-energy-curing matte UV coating for PVC plastic and preparation method for UV coating

The invention discloses an all-solid low-energy-curing matte UV (ultraviolet) coating for a PVC (polyvinyl chloride) plastic and a preparation method for the UV coating. The coating contains the following components: 25-30% of special modified acrylic resin, 5-10% of urethane acrylate, 20-25% of high-functionality active monomers, 20-25% of a reactive diluent, 2-5% of a photoinitiator 1, 1-4% of a photoinitiator 2, 3-6% of a photoinitiator 3, 0.3-1.0% of a dispersant, 5-10% of extinction powder, 0.5-1.0% of wax powder, 0.1-0.5% of a defoamer and 0.1-0.5% of a leveling agent. The UV coating does not contain a solvent and can be cured to form a low-luster, high-scratch-resistant and pollution-resistant paint film only by 150-200 mj / m<2> of UV energy; and the UV coating is applied to soft PVC and can enable a base material not to be thermally damaged in a curing process, so that the application range of the UV coating is greatly expanded.

Owner:HUNAN JINHAI SCI & TECH

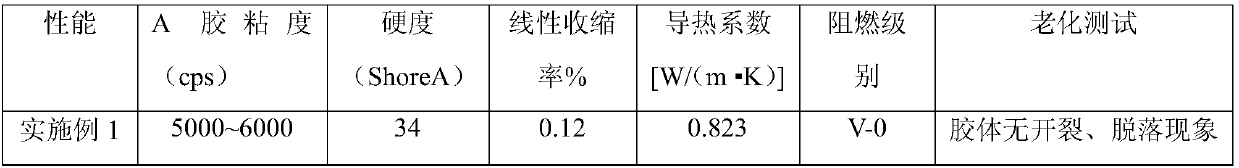

Low-shrinkage heat-conducting flame-retardant double-component condensed type organosilicone pouring sealant, and preparation method and application thereof

InactiveCN107760256AFast curingHigh copy numberNon-macromolecular adhesive additivesMacromolecular adhesive additivesHeat conductingPlasticizer

The invention belongs to the technical field of encapsulating materials, and discloses a low-shrinkage heat-conducting flame-retardant double-component condensed type organosilicone pouring sealant, and a preparation method and application thereof. The organosilicone pouring sealant consists of a component A and a component B, of which the weight ratio of (10:1) to (5:1), wherein the component A consists of the following raw materials in parts by weight: 100 parts of a base adhesive, 30 to 80 parts of a plasticizer A, 0.01 to 3 parts of a coloring material and 0.1 to 1 part of a curing accelerant; and the component B consists of the following raw materials in parts by weight: 80 to 300 parts of a crosslinking agent, 10 to 60 parts of a coupling agent, 0.5 to 1.5 parts of a catalyst and 100to 500 parts of a plasticizer B. The base adhesive consists of the following raw materials in parts by weight: 100 parts of liquid silicone rubber, 3 to 10 parts of reinforcing filler, 20 to 80 partsof heat-conducting filler, 20 to 100 parts of flame-retardant filler, 3 to 10 parts of a surface treating agent and 3 to 20 parts of functional filler.

Owner:GUANGZHOU MECHANICAL ENG RES INST

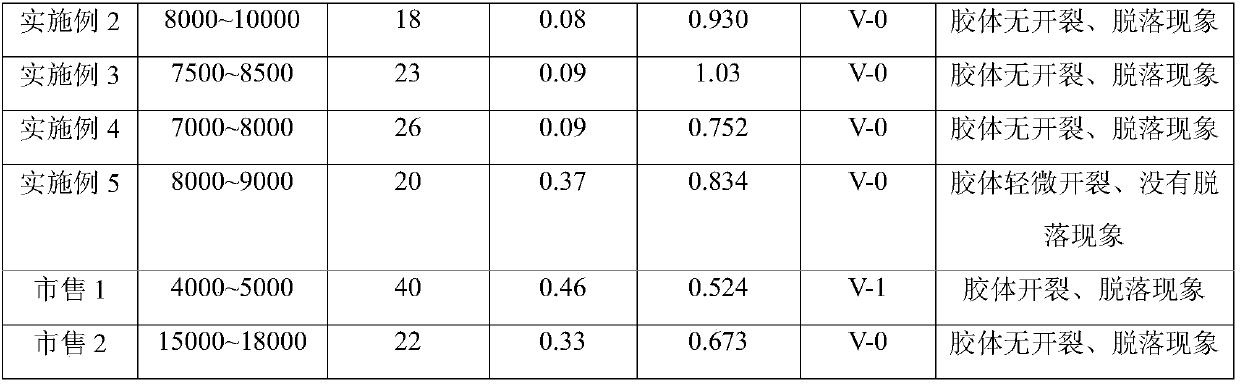

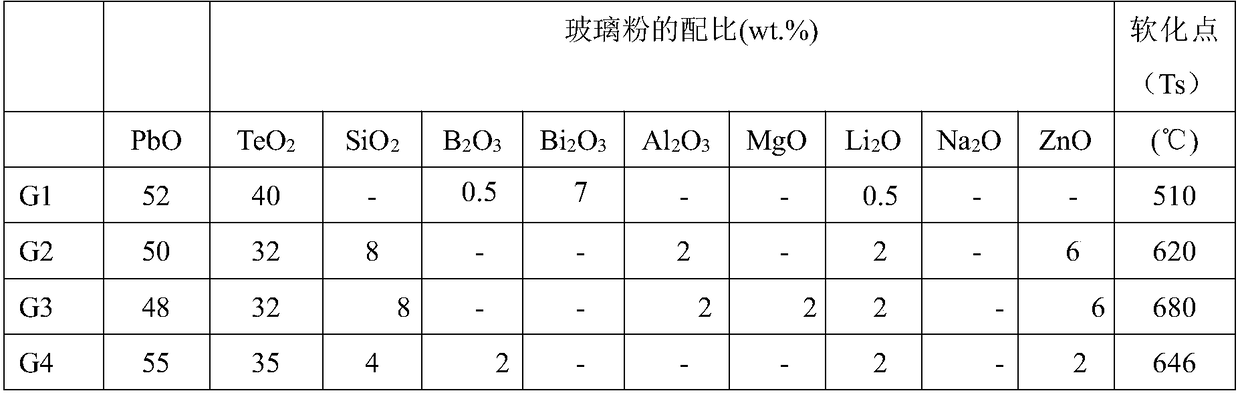

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

High viscosity asphalt modifier and preparation method thereof

InactiveCN101457009AImprove solubilityPromote decompositionBuilding insulationsSolubilityPolymer science

The invention discloses a high-viscosity asphalt modifier and preparation thereof, wherein, the mass proportion of the material composition and components of the high-viscosity asphalt modifier refers to that 100 proportion of SIS, 60-100 proportion of coumarone resin and 40-60 proportion of oleamide. The high-viscosity asphalt modifier of the invention modifies basic asphalt and has excellent dispersion and solubility, and moreover, modified asphalt being correspondingly prepared has better adhesion and high temperature property.

Owner:TONGJI UNIV

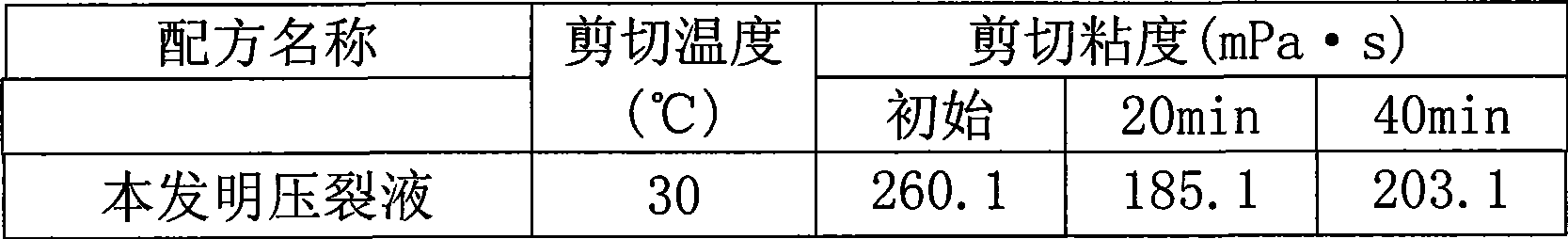

Ultra low temperature super guanidine gum fracturing fluid

ActiveCN101531892AFast swellingGuaranteed gel-forming propertiesDrilling compositionOrganosiliconEther

The invention relates to ultra low temperature super guanidine gum fracturing fluid, comprising the ingredients with mass percents as follows: 0.20% of super guanidine gum, 0.12% of organopolysiloxane, 0.07% of polyoxypropylene polyoxyethylene polyoxypropylene octadeyl alcohol ether, 0.32% of cationic organic amino, 0.09% of cationic long chain polymer, 0.03% of organic silicone oil, 0.0003% of borax, 0.00027% of persulfate, 0.00009% of hyper-valent oxysalt, 0.00014% of peroxide and balance of water. The fracturing fluid has good anti-shearing property and breaks gum completely.

Owner:PETROCHINA CO LTD +1

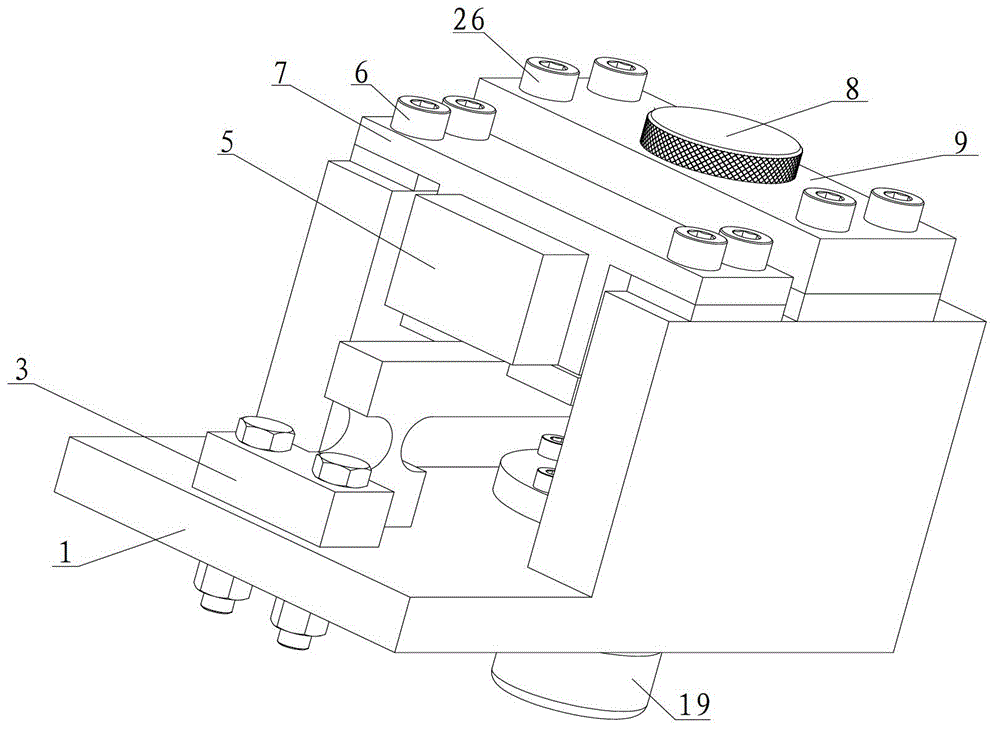

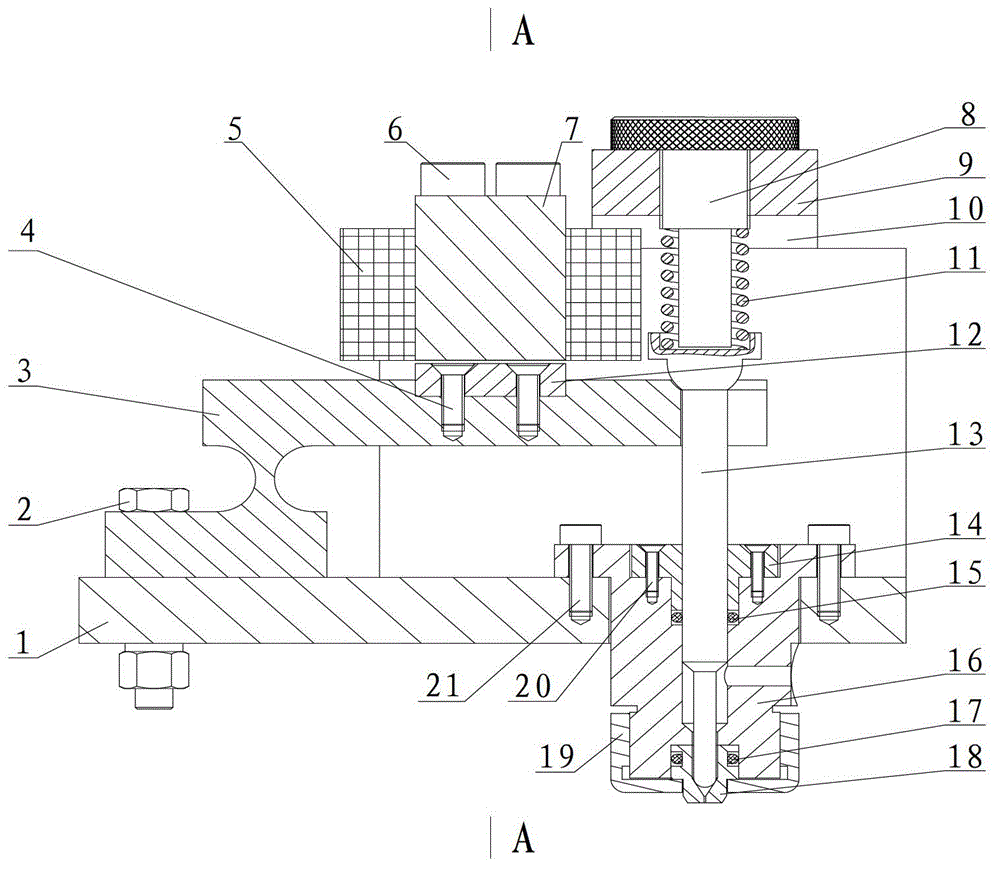

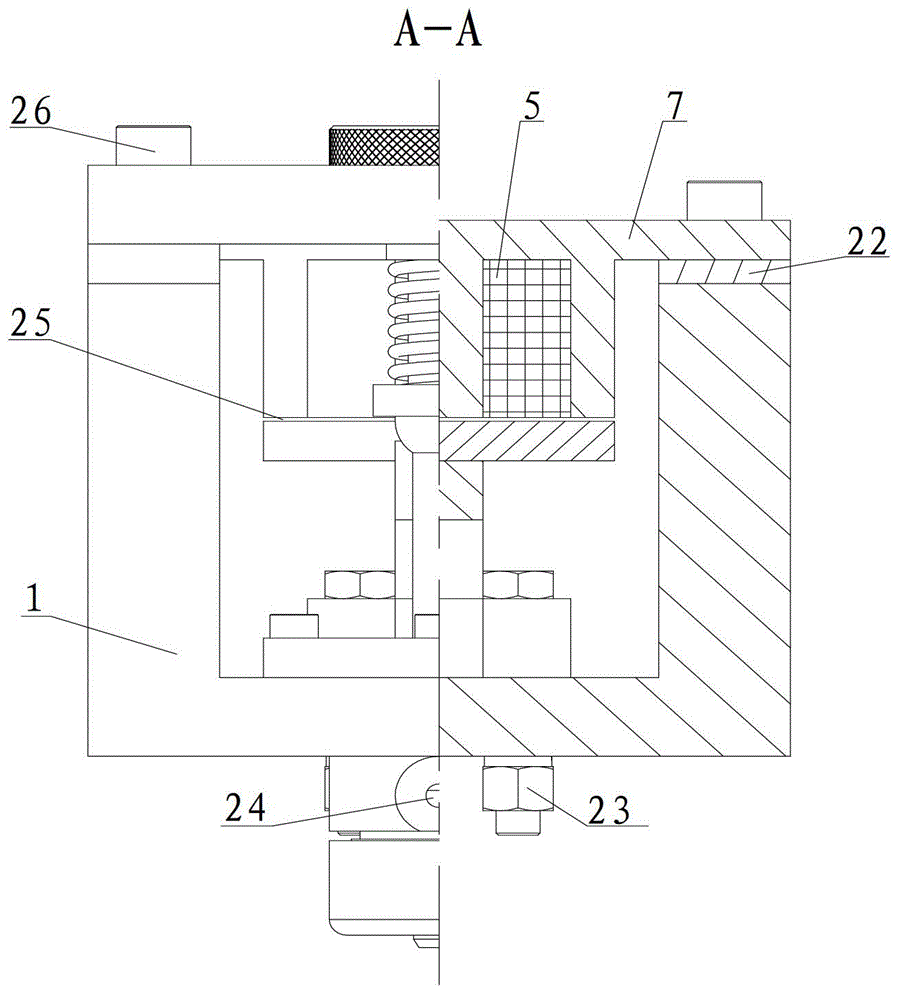

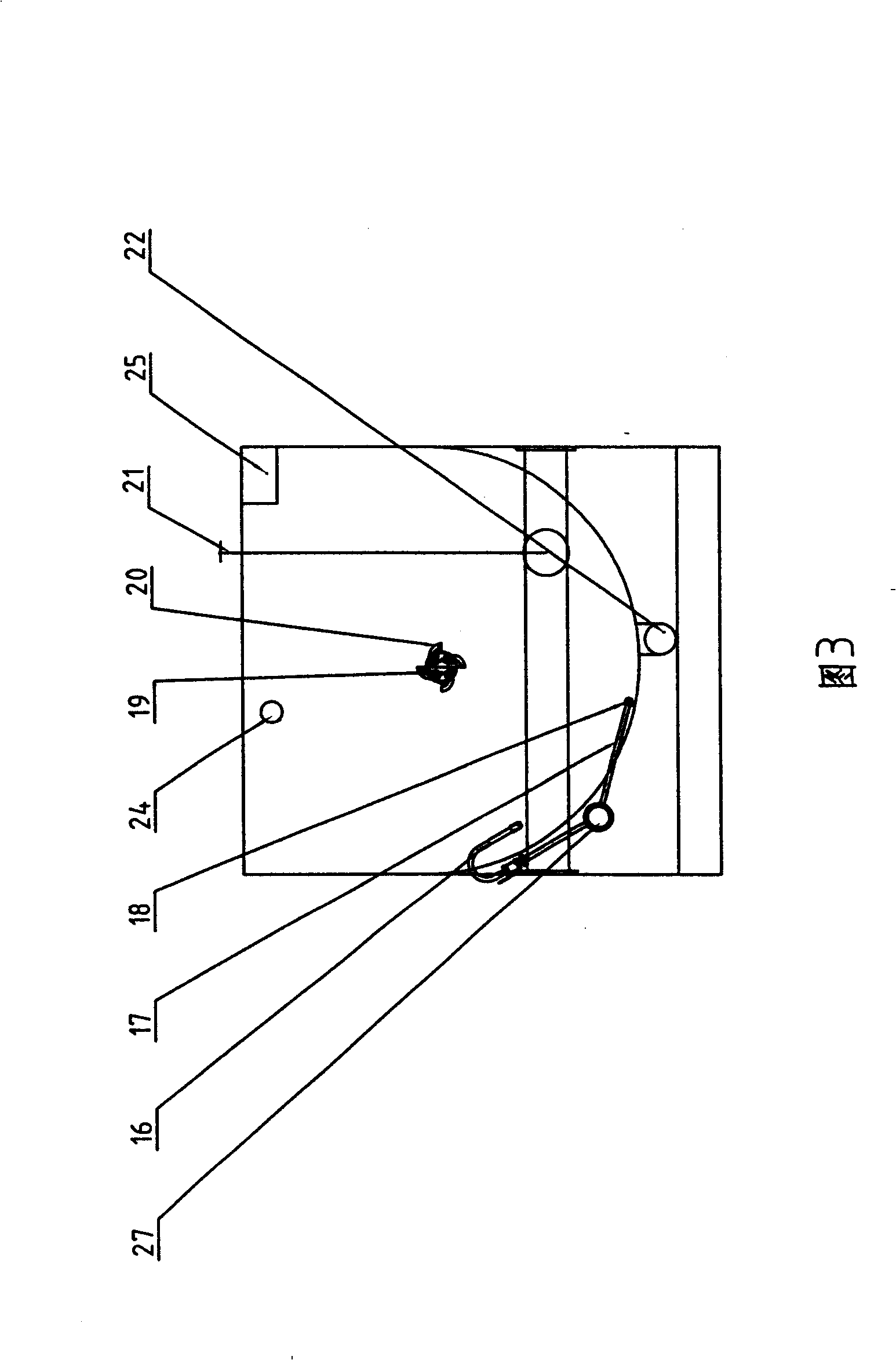

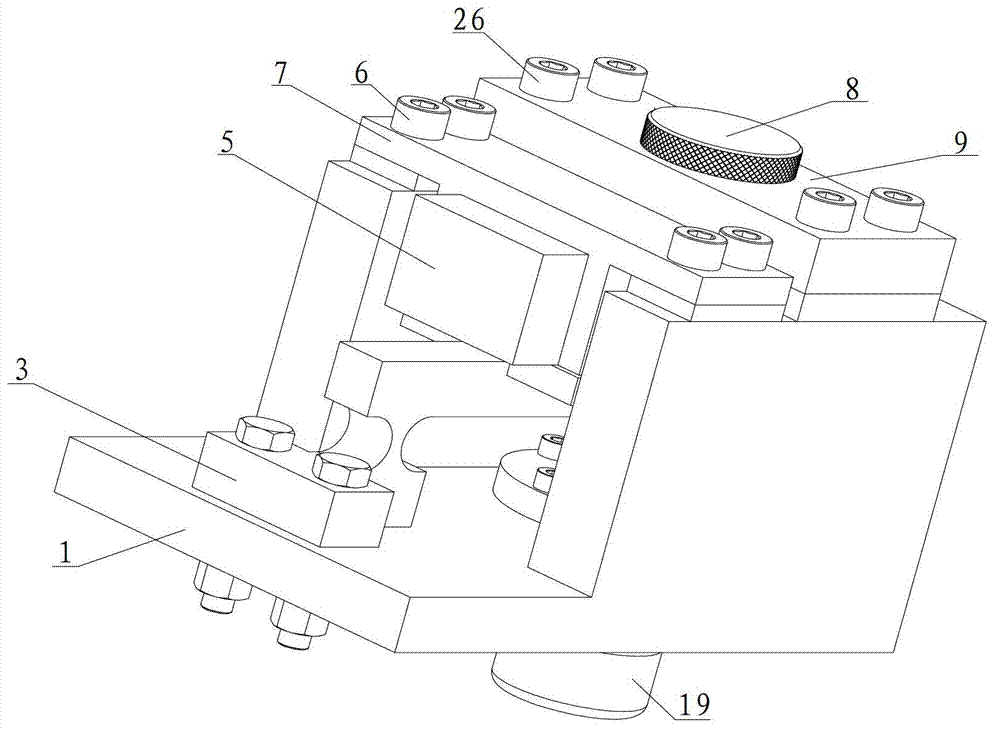

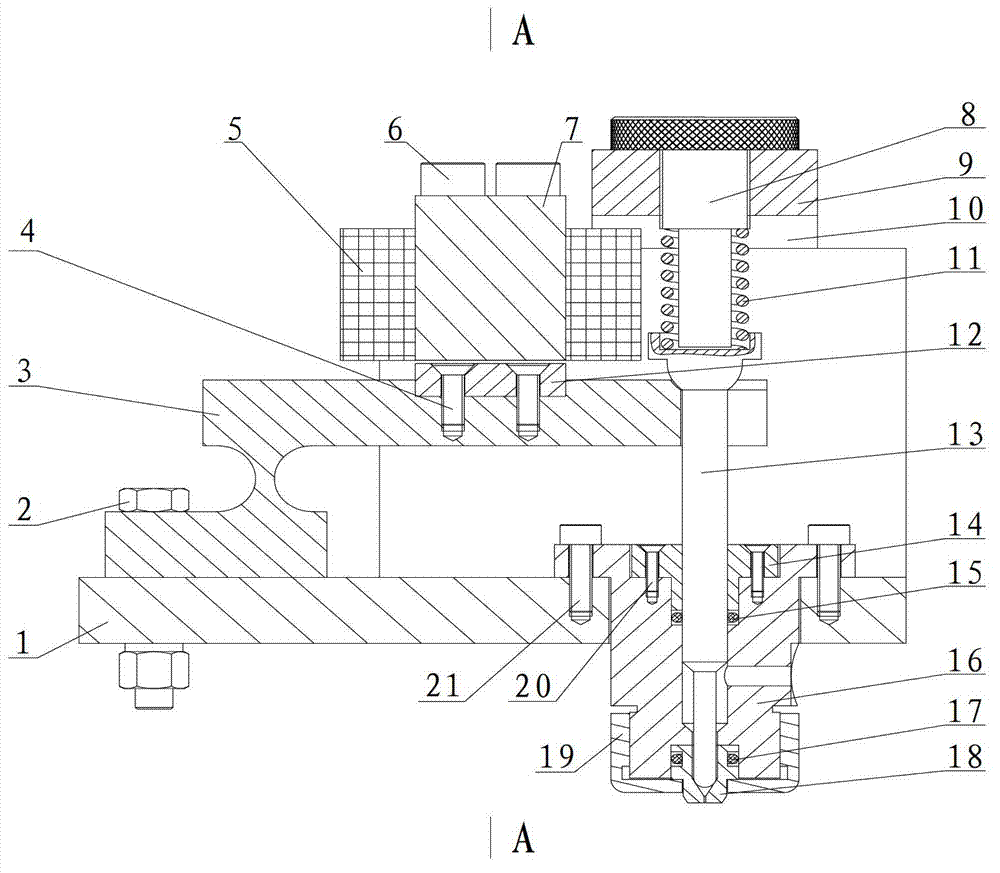

Electromagnetic drive adhesive dispensing valve comprising flexible amplification arm

InactiveCN102941183AHigh response frequencySimple structureLiquid surface applicatorsCoatingsMagnetAdhesive

The invention discloses an electromagnetic drive adhesive dispensing valve comprising a flexible amplification arm. The electromagnetic drive adhesive dispensing valve comprising the flexible amplification arm comprises an adhesive cavity (16), a nozzle (18) and an ejecting needle (13), the adhesive cavity (16), the nozzle (18) and the ejecting needle (13) are installed at one end of a support (1), one end of the flexible amplification arm (3) is installed at the other end of the support (1), the other end of the flexible amplification arm (3) is in transmission connection with the ejecting needle (13), a supporting horizontal plate (9) is arranged on the support (1), a regulating screw (8) is arranged on the supporting horizontal plate (9), a compression spring (11) is arranged between the ejecting needle (13) and the regulating screw (8), an armature (12) is installed on the flexible amplification arm (3), and an electric magnet acting on the armature (12) is installed on the support (1). The electromagnetic drive adhesive dispensing valve comprising the flexible amplification arm is rapid in response, simple in structure, large in sprayable adhesive viscosity and adjustable in spraying speed and adhesive spraying amount.

Owner:CENT SOUTH UNIV

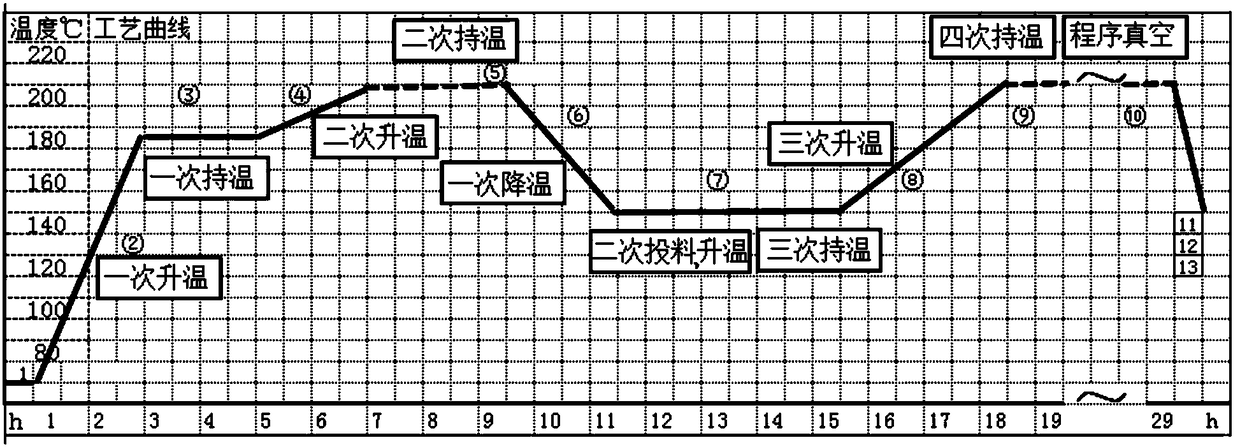

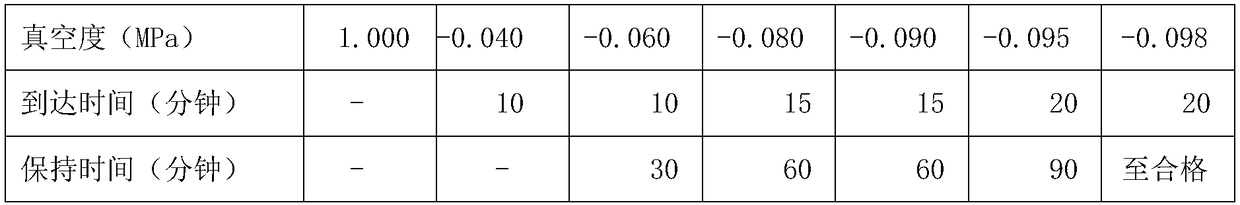

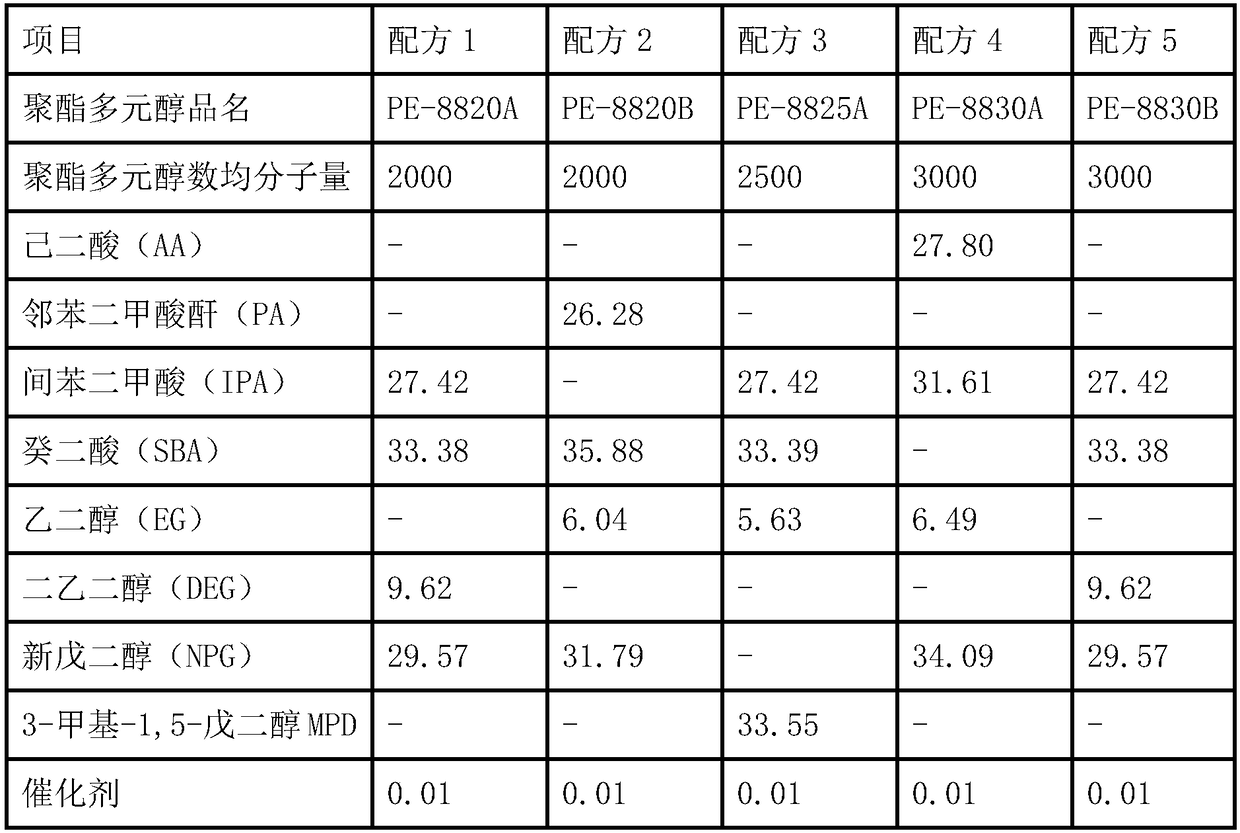

Preparation method of polyester polyol for laminated film adhesive

InactiveCN108424510AHigh bonding strengthHigh reactivityPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention provides a preparation method of polyester polyol for a laminated film adhesive. The preparation method comprises steps as follows: primary feeding is performed, 25.0%-35.0% of aromaticbinary carboxylic acid and 25.0%-40.0% of small-molecular diol are fed into a reaction kettle, programed heating is executed to promote esterification reaction, and after an acid value is reduced to 10-30 mgKOH / g, cooling is performed for secondary feeding; 25.0%-40.0% of aromatic binary carboxylic acid and 5.0%-15.0% of small-molecular diol are subjected to secondary feeding, the temperature is increased again, the esterification reaction is performed, water is produced, a tetrabutyl titanate or stannous octoate catalyst is added, programed heating and programmed vacuum are controlled, and atarget polyester polyol product containing both benzene ring aromatics and aliphatic hydrocarbon is obtained; the target polyester polyol product is primary hydroxyl terminated difunctional polyol andhas higher reactivity with isocyanate groups. The polyurethane adhesive prepared from polyester polyol as a main soft segment through polymerization is suitable for adhesion of food packaging laminated films which meet the high-temperature requirement and have steaming resistance for sterilization.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

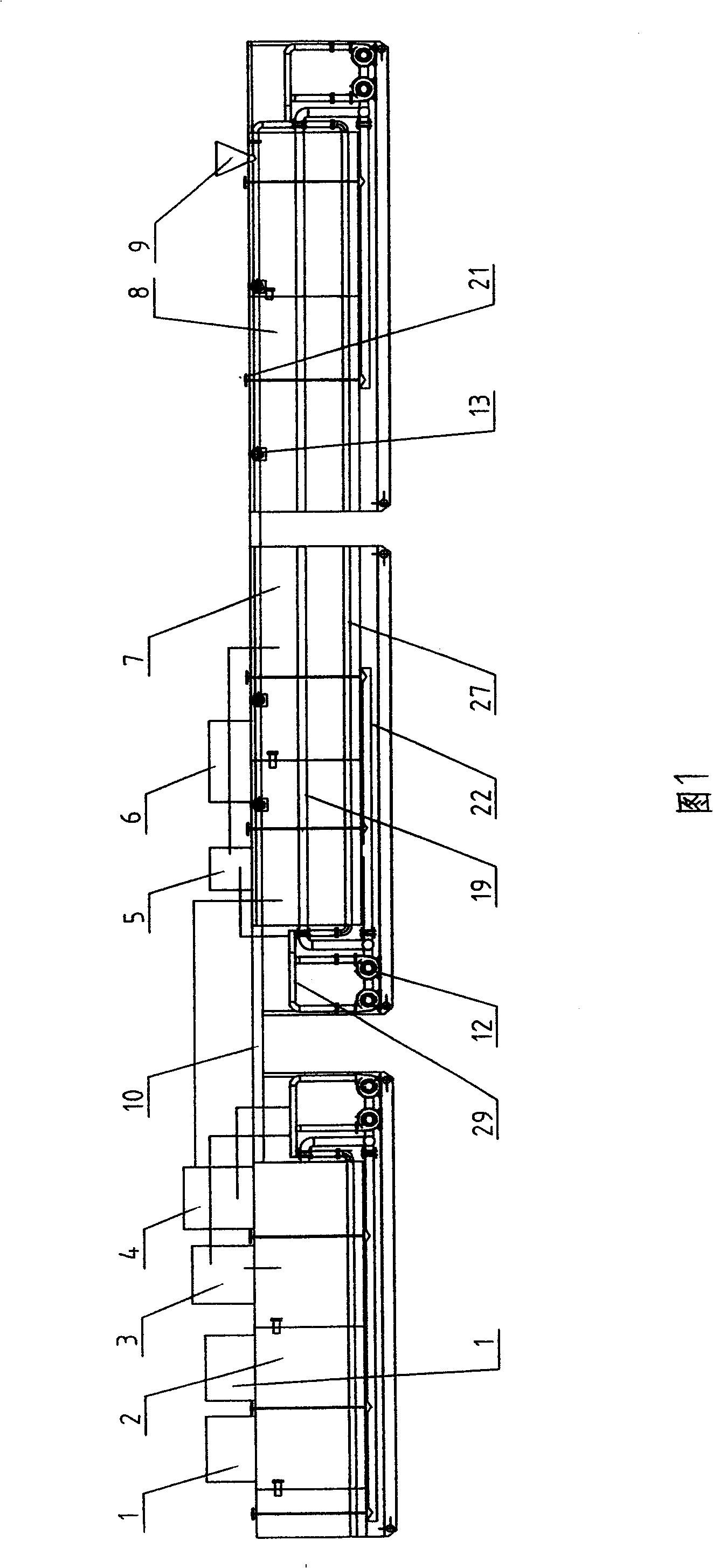

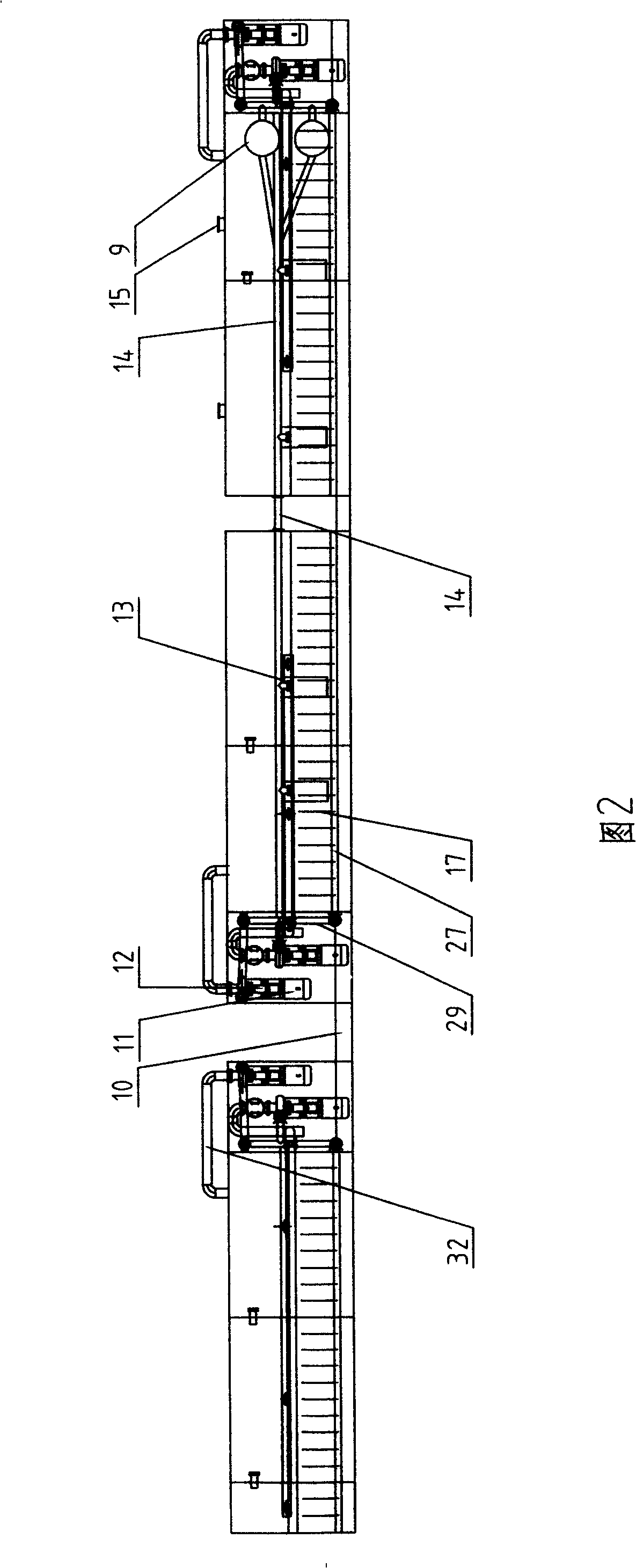

Drilling fluid cleaning system device

The invention discloses a drilling fluid purifying system and a device thereof, which are used for the circulating purification and ground configuration of the drilling fluid in the drilling operations of petroleum, geological exploration and non-excavation and the like. The drilling fluid purifying system and the device comprise an initial processing tank and a post processing tank which are provided with vibrating screens, deaeration devices, desanders, desilters and centrifugal machines as well as a slurry mixing tank provided with a mixing funnel, a central suction pipe penetrating through each bin of the tank is respectively arranged in the inner cavity of each tank, a main spraying pipe communicated with each bin of the tanks is arranged outside the tanks, a bottom suction pipe communicated with each bin of the tanks is arranged below the tanks, slurry dividing pipes connected to the mixing funnel are arranged at the top of the slurry mixing tank and the adjacent tank, a drilling fluid output pipe is arranged at the rear end of the system, the central suction pipe and the bottom suction pipe of each tank are connected into the suction end of a sand pump of each tank, the main spraying pipe of each tank and the related equipment on the tank top are connected into the paralleled discharging pipes of the sand pump, and the sand pump of each tank or each tank is respectively connected with the discharging ends of other sand pumps in parallel through the main spraying pipes. The invention aims to solve the defects of bad mixing uniformity, low efficiency and much sediment in the existing purifying device by utilizing a reasonable structure.

Owner:孙泽义

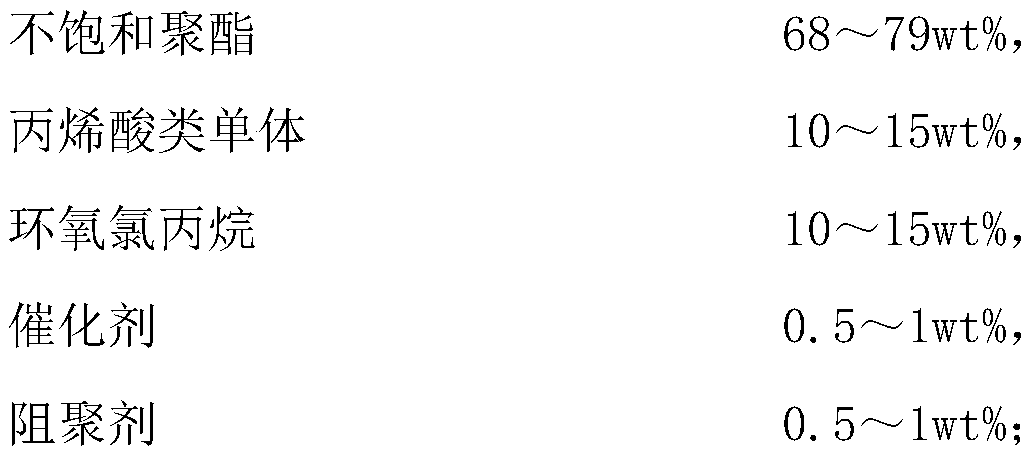

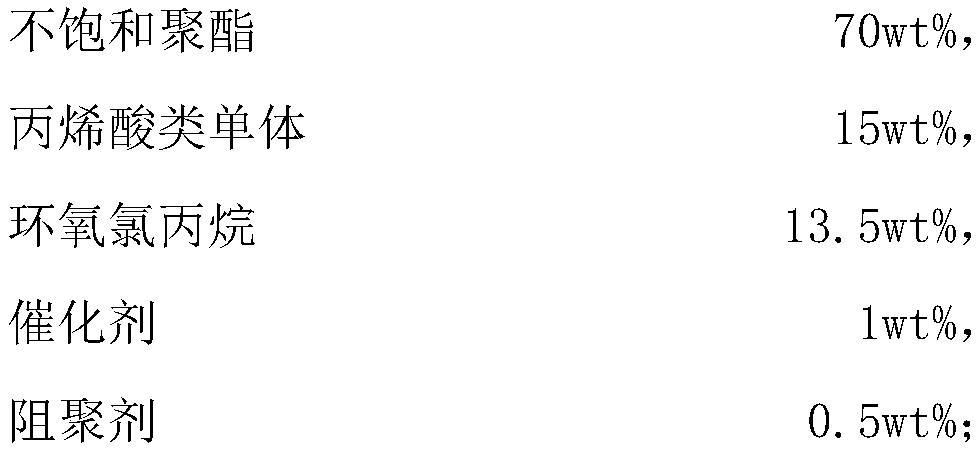

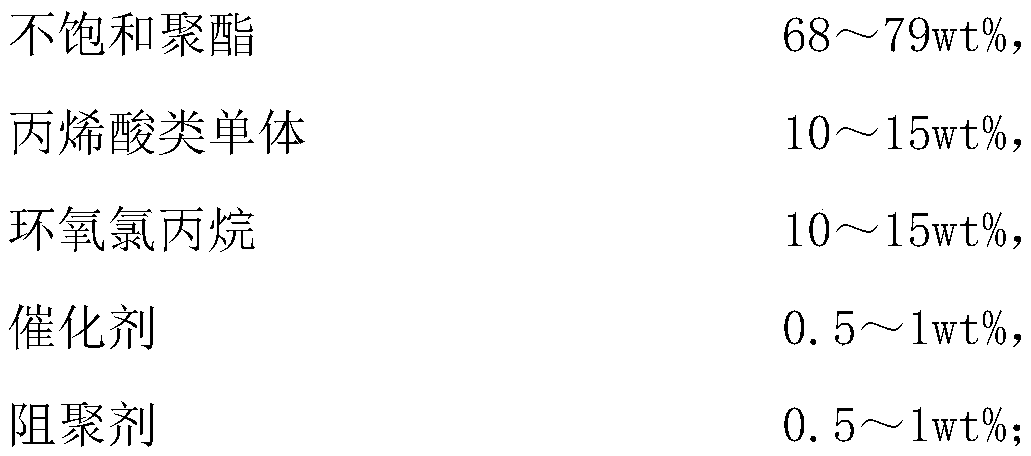

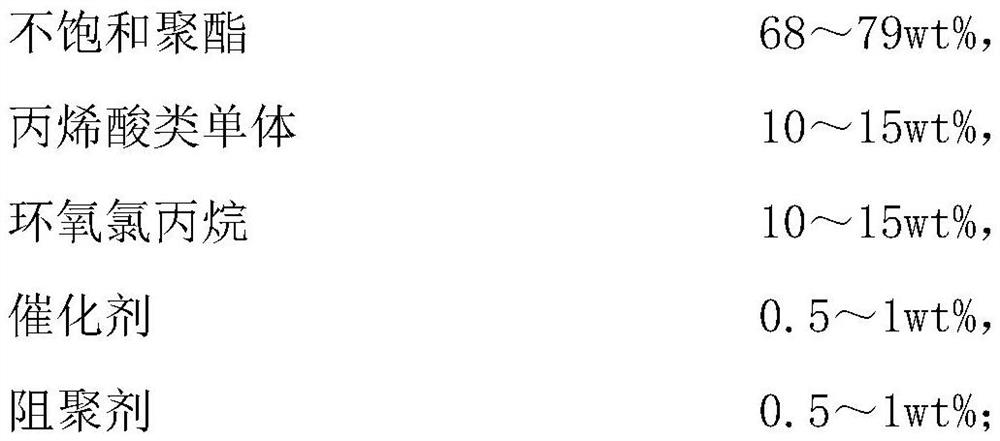

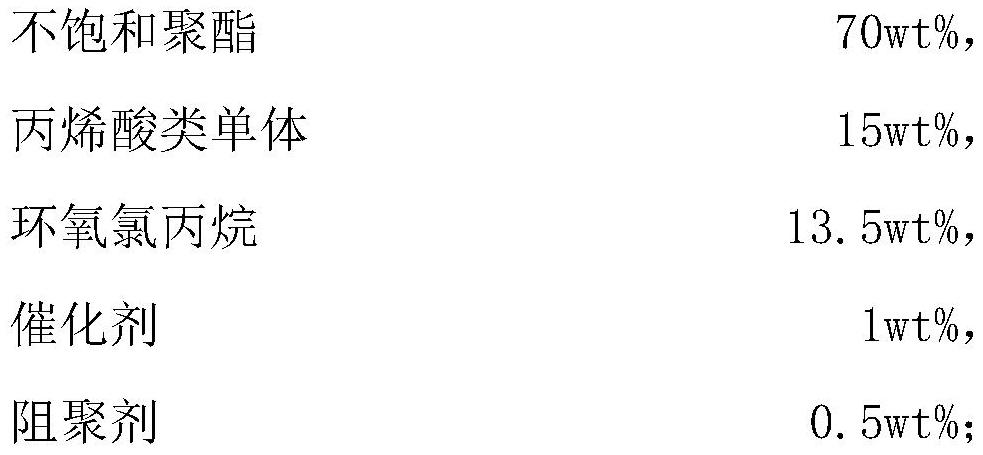

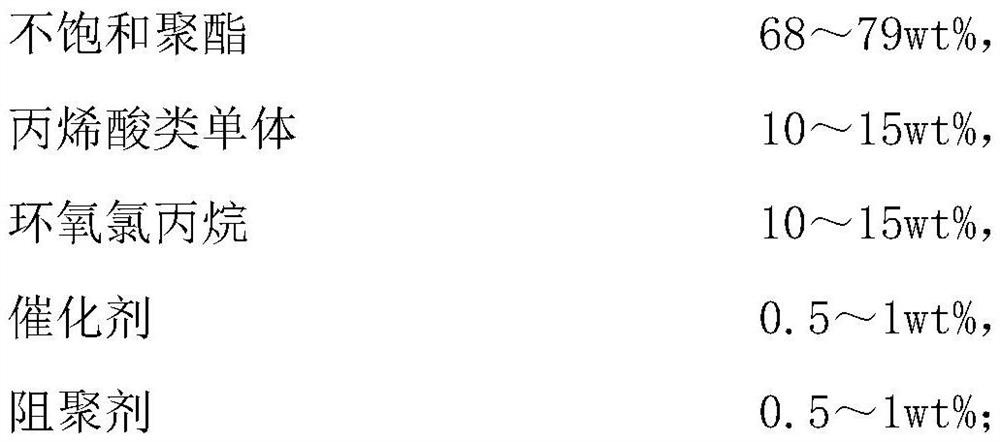

Low-viscosity fast curing UV polyester acrylate and preparation technology thereof

ActiveCN110105851AReduce resin viscosityFast curingPolyester coatingsPhosphinic AcidsMaleic anhydride

The invention relates to the technical field of fine chemical preparation, and discloses a low-viscosity fast curing UV polyester acrylate and a preparation technology thereof. The low-viscosity fastcuring UV polyester acrylate is prepared from 68-79 wt% of unsaturated polyester, 10-15 wt% of an acrylic monomer, 10-15 wt% of epichlorohydrin, 0.5-1 wt% of a catalyst and 0.5-1 wt% of a polymerization inhibitor; and the unsaturated polyester comprises, by weight, 20 parts of maleic anhydride, 10.1 parts of phthalic anhydride, 5.8 parts of deionized water, 0.1 part of hypophosphorous acid, 30 parts of dicyclopentadiene, 20 parts of diethylene glycol, 14.4 parts of pentaerythritol, 8 parts of fumaric acid and 1.5 parts of toluene. The UV polyester acrylate of the invention has the advantagesof low viscosity, fastness in curing, high reaction activity, good economical property, and facilitation of large-scale preparation and promotion of UV paints; and the preparation technology is simple, and is convenient to operate.

Owner:YINGDE YAJIA PAINT

High viscosity asphalt modifier and preparation method thereof

InactiveCN101457009BIncreased difficulty in dissolutionImprove solubilityBuilding insulationsSolubilityPolymer science

The invention discloses a high-viscosity asphalt modifier and preparation thereof, wherein, the mass proportion of the material composition and components of the high-viscosity asphalt modifier refers to that 100 proportion of SIS, 60-100 proportion of coumarone resin and 40-60 proportion of oleamide. The high-viscosity asphalt modifier of the invention modifies basic asphalt and has excellent dispersion and solubility, and moreover, modified asphalt being correspondingly prepared has better adhesion and high temperature property.

Owner:TONGJI UNIV

Preparation method of PVC foam glove

The invention relates to a preparation method of a PVC foam glove. The method comprises the steps of: S1: preparing a material A: mixing 30-55 parts of PVC resin powder, 35-65 parts of a plasticizer,0.2-4 parts of a stabilizer, 0.3-8 parts of a viscosity reducer and 0.2-5 parts of a foaming agent, and fully stirring the substances to obtain a material A, and conducting standing for 15-50h for standby use; S2: preparing a material B: firstly adding 0.1-5 parts of butyronitrile powder into 35-65 weight parts of the material A, then adding 0.1-3 parts of PVC resin powder, 0.1-3 parts of a foaming aid and 0.1-2 parts of an anti-sagging agent, and conducting further stirring, finally pouring 5-25 parts of water and 3-20 parts of oil agent, stirring the substances evenly, then conducting standing for 4h or more for standby use; S3: impregnating a glove blank in the material B, and carrying out rubber dripping and homogenizing; and S4: performing drying and plasticizing to obtain the wear-resistant PVC foam glove. The method provided by the invention can prepare the PVC foam glove with breathability, softness, comfortable hand feel, excellent wear resistance, tear resistance and punctureresistance, improves the comprehensive performance of the PVC glove and expands the scope of application.

Owner:SHANDONG XINGYU GLOVES

Special continuous casting crystallizer casting powder for ESP low carbon

The invention relates to special continuous casting crystallizer casting powder for ESP low carbon, and belongs to the field of metallurgy accessories. The casting powder comprises chemical componentsincluding, by weight, 28-33 parts of CaO, 22-29 parts of SiO2, 4.5-7.5 parts of MgO, 4.5-7 parts of Al2O3, 7-10 parts of Na2O, 8-11 parts of F, 0.3-1.5 parts of B2O3, 0.5-1 part of Li2O and 1-3.5 parts of C. The casting powder has the low melting temperature, low viscosity and high melting speed, the casting powder can be rapidly consumed when the continuous casting pulling rate is 5-7 m / min, andaccordingly heat transfer and lubricating performance between a continuous casting blank shell and a crystallizer copper plate are guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Method for preparing HMW (High Molecular Weight) p-aramid polymer through ternary co-condensation

InactiveCN108359091AEasy to solveFast activation energyMonocomponent copolyamides artificial filamentPolymer scienceDiaminodiphenyl ether

The invention discloses a method for preparing HMW (High Molecular Weight) p-aramid polymer through ternary co-condensation. The method comprises the following steps: 1, preparing an NMP (N-Methyl Pyrrolidone)-CaCl2 solvent system; 2, cooling the NMP-CaCl2 solvent system, and adding 3,4'-diaminodiphenyl ether and p-phenylenediamine under the protection of nitrogen, thus obtaining a p-phenylenediamine-NMP-CaCl2 solution system; 3, adding p-phthaloyl chloride in the p-phenylenediamine-NMP-CaCl2 solution system, thus obtaining a raw material solution system; carrying out first-step copolycondensation; 4, after colloid appears in a solution of the first-step copolycondensation, rising the reaction temperature, and carrying out second-step copolycondensation, thus obtaining the p-aramid polymer. According to the method disclosed by the invention, a two-step copolycondensation reaction method which is carried out at a high temperature after a low temperature is adopted, ordered proceeding ofreaction is ensured, increment of side effects is avoided, and the intrinsic viscosity of the obtained p-aramid polymer in a dissolved state is 1.95 to 2.13 dL / g.

Owner:THE NORTHWEST RES INST OF CHEM IND

Nutrition balanced feed for chicken

InactiveCN106819531AGood Absorption Conversion RateHigh absorption conversion rateFood processingAnimal feeding stuffYeast ProteinsPotato starch

The invention discloses nutrition balanced feed for chicken. The nutrition balanced feed is prepared from the following raw materials in parts by weight: 20 to 40 parts of fermented animal fat dreg, 5 to 13 parts of fish meal, 8 to 12 parts of meat and bone meal, 3 to 7 parts of blood worm meal, 6 to 12 parts of yeast protein meal, 10 to 16 parts of sweet potato starch, 4 to 10 parts of fermented soybean meal, 15 to 25 parts of cottonseed meal, 10 to 18 parts of grape seed meal, 20 to 30 parts of buckwheat bran, 4 to 6 parts of a Chinese medicinal herb additive, 2 to 4 parts of peanut oil, 1 to 4 parts of rice bran oil, 0.1 to 0.2 part of methionine, 0.3 to 0.7 part of tryptophan, 0.4 to 0.8 part of beta-glucan, 2 to 6 parts of maltose, 2 to 4 parts of choline chloride, 6 to 10 parts of a guar gum compound, 4 to 8 parts of talcum powder and 2 to 4 parts of calcium dihydrogen phosphate. The nutrition balanced feed disclosed by the invention has the advantages of easiness of obtaining raw materials, low cost, good palatability and high nutrient value; the nutrition balanced feed can guarantee protein and energy requirements of the chicken and the feed absorption conversion rate is extremely high.

Owner:ANHUI TIANZE FEED

Novel application of hexafluoroisobutylene

InactiveCN108586792AEffective protectionLow vapor phase thermal conductivityFoaming agentBoiling point

The invention provides an application of hexafluoroisobutylene as a foaming agent in polyurethane foaming. The hexafluoroisobutylene can be used as a new generation of foaming agent and meets the following requirements: the ozone depletion potential (ODP) is 0, the global warming potential (GWP) is as low as possible, the foaming agent is not flammable, the boiling point is suitable, the gas-phaseheat conduction coefficient is low, the foaming agent is safe and reliable, and the like. The hexafluoroisobutylene can effectively protect the earth that we depend on for existence, and achievementsare gained for the present and benefits are gained for the future. The foaming agent and composite foaming agent can be applicable to the foaming of hard polyurethane insulation materials in the fields of household appliances, building heat preservation, cold-chain transportation, industrial heat preservation and the like. The hexafluoroisobutylene is not flammable, so that safety improvement oforiginal foaming equipment is not required in any aspects.

Owner:张振宽

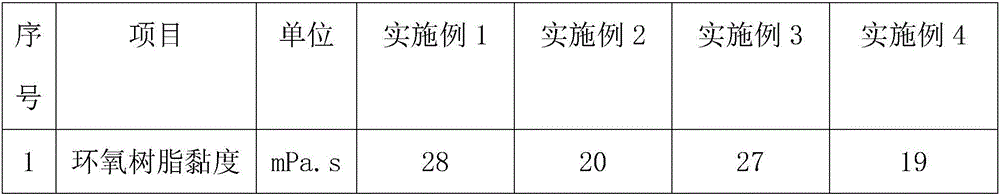

Ballastless track CA (cement and asphalt) mortar layer damage repair resin material and preparation method thereof

The invention relates to a ballastless track CA (cement and asphalt) mortar layer damage repair resin material and a preparation method thereof, belonging to the field of high-speed railway engineering materials. The resin material is prepared from the following raw materials in parts by weight: 100 parts of epoxy resin, 30-60 parts of furfural, 20-40 parts of acetone, 0.1-0.3 part of saturated ammonia water, 3-10 parts of toughener, 1-3 parts of accelerator, 0.5-2 parts of coupling agent, 0.5-2 parts of surfactant and 20-50 parts of composite amine curing agent. The obtained product has the characteristics of high binding force and high corrosion resistance in the common epoxy-furfural-acetone resin grouting material, also has the advantages of high permeability, environment friendliness, low toxicity, higher glass transition temperature, low shrinkage, high normal-temperature curing rate and the like, and is applicable to wet basal plane construction.

Owner:北京中德新亚建筑技术有限公司

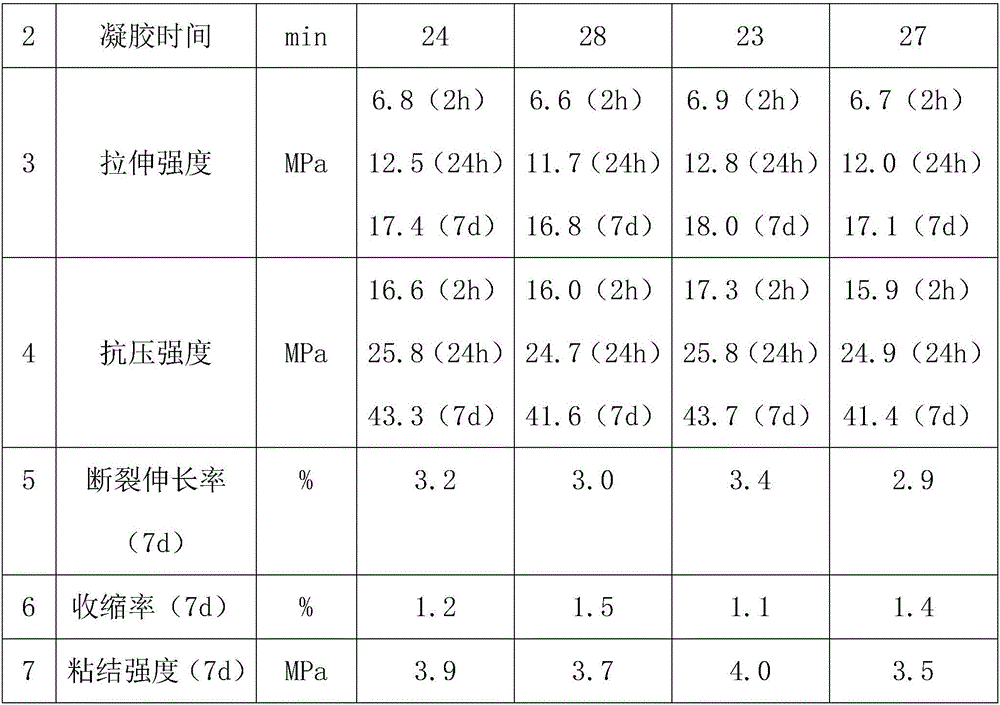

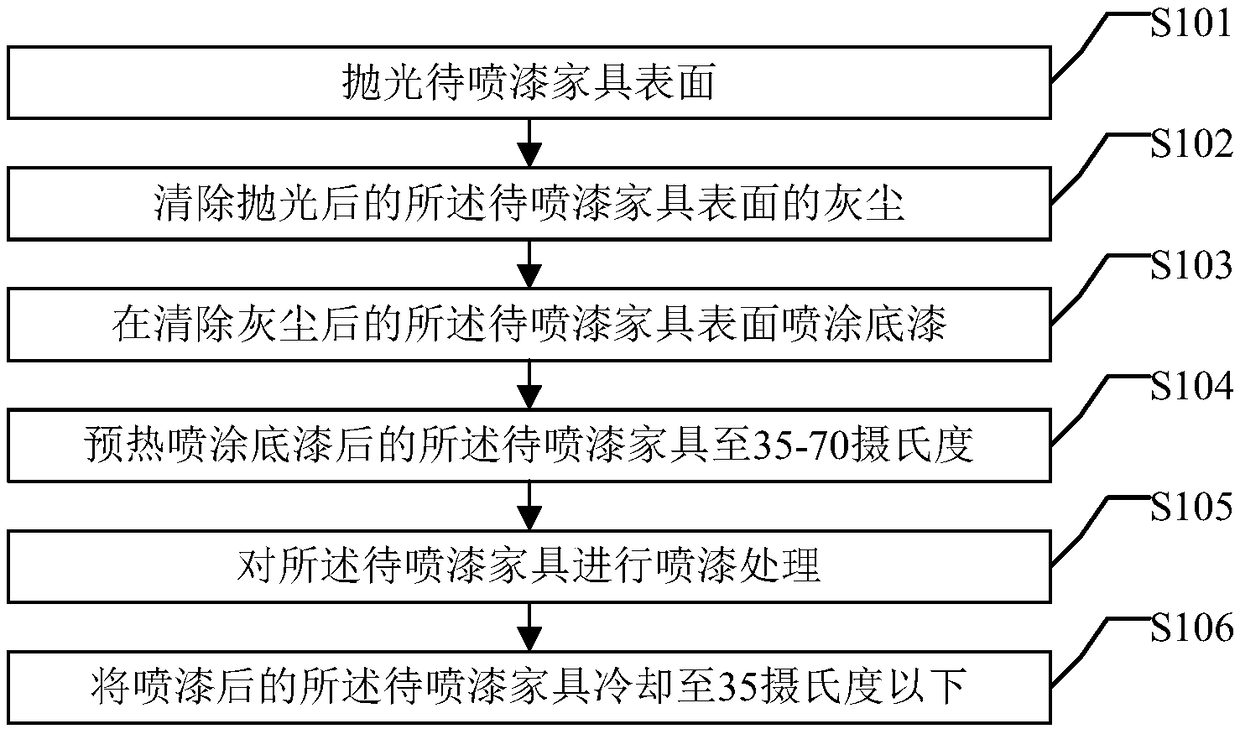

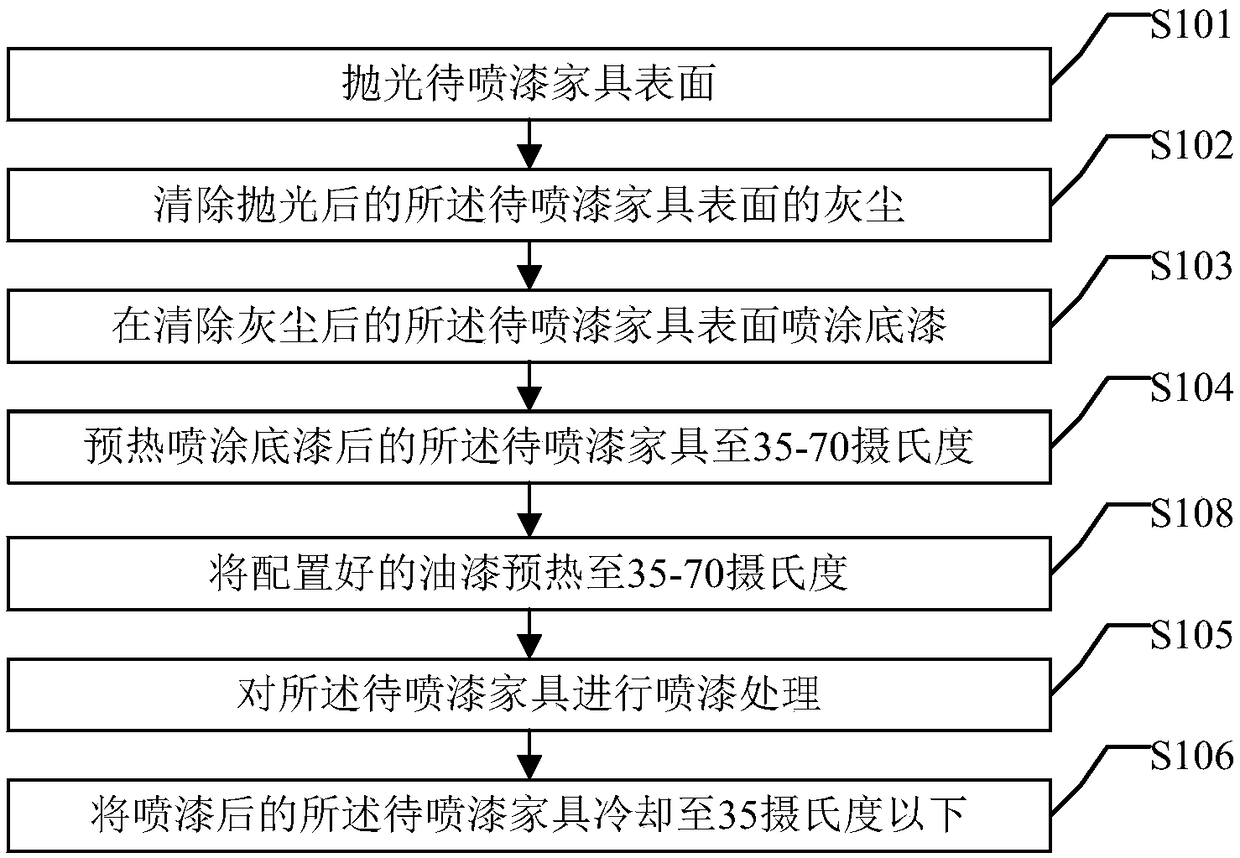

Furniture paint spraying method and lacquer furniture

The invention discloses a furniture paint spraying method and lacquer furniture. The method comprises the steps of polishing the surface of to-be-painted furniture, removing dust on the surface of thepolished to-be-painted furniture, painting primer on the surface of the to-be-painted furniture subjected to dust removing, preheating the to-be-painted furniture subjected to primer painting to 35 DEG C to 70 DEG C, conducting painting treatment on the to-be-painted furniture, and cooling the painted to-be-painted furniture to below 35 DEG C. By means of the furniture paint spraying method and the lacquer furniture, the yield of the furniture can be increased.

Owner:ANHUI DONGPING WOOD GRP

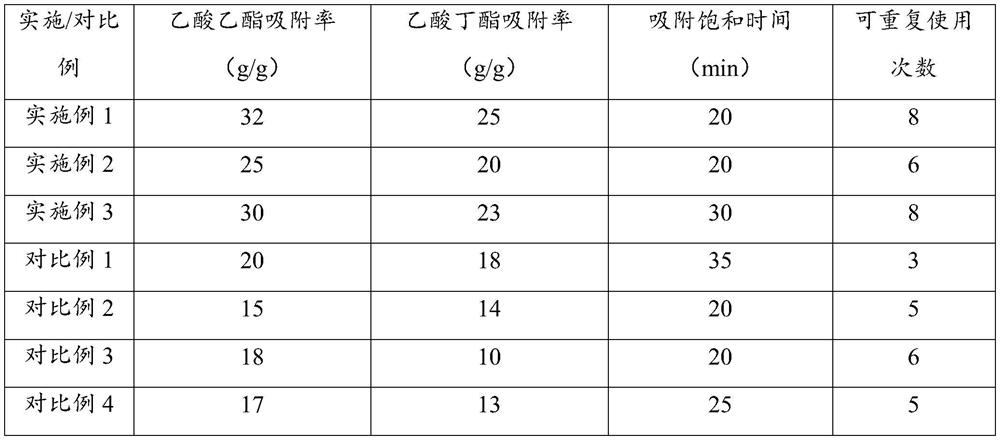

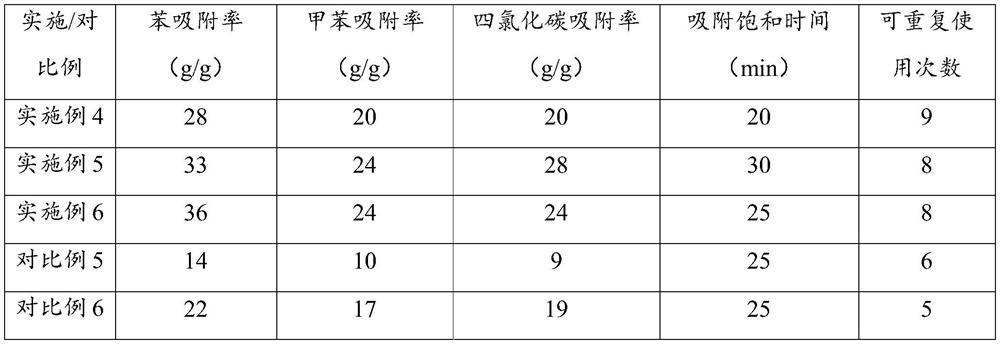

High-adsorbability resin and preparation method thereof

ActiveCN111957303AImprove adsorption capacityEasy regenerationOther chemical processesSolid sorbent liquid separationMethacrylateAcetic acid

The invention discloses high-adsorbability resin which comprises the following raw material components in parts by weight: 1-15 parts of water, 15-30 parts of methacrylate, 5-15 parts of acrylate, 15-50 parts of acrylate and 10-30 parts of styrene. The high-adsorbability resin also comprises a pore-foaming agent and an initiator. The product is stable in polarity, easy to store and moderate in viscosity, has the advantages of being high in adsorption rate, high in adsorption capacity, good in mechanical strength, simple in regeneration mode and the like, and can effectively adsorb an organic poison solvent and solve the leakage problem of the organic poison solvent. The invention further discloses a preparation method of the high-adsorbability resin. The preparation method is simple to operate, safe in preparation process, free of by-products, high in repeatability and beneficial to large-scale preparation. The invention also discloses an application of the high-adsorbability resin inorganic poison adsorption. The product can be used for adsorption treatment of organic toxicants such as acetic acid short-chain ester, benzene compounds and chlorides.

Owner:谦信化工集团有限公司 +1

A kind of bead-shaped ultra-high viscosity water-soluble cationic polymer and its preparation method

The invention belongs to the technical field of preparation of high-molecular compounds, and particularly relates to a bead-shaped hyperviscosity water-soluble cationic polymer and a preparation method thereof. The preparation method of the bead-shaped hyperviscosity water-soluble cationic polymer adopts the technical scheme that the preparation method comprises the following steps of according to parts by mass, adding 1 to 5 parts of dispersant into a reaction kettle, adding 200 to 500 parts of organic hydrocarbon solvent of aviation kerosene, putting into a water bath pot at room temperature, stirring, and filling a nitrogen protection reaction system under liquid level. The bead-shaped hyperviscosity water-soluble cationic polymer has the advantages that the dissolving speed is high, the viscosity is high, the cationic degree can be adjusted, and the like; the bead-shaped hyperviscosity water-soluble cationic polymer is widely applied into water treatment, papermaking, petroleum production, textile printing and dyeing, daily chemical engineering, and the like.

Owner:山东聚发生物科技有限公司

A kind of method for preparing high molecular weight p-aramid polymer by terpolymerization

InactiveCN108359091BEasy to solveFast activation energyMonocomponent copolyamides artificial filamentPolymer scienceDiaminodiphenyl ether

Owner:THE NORTHWEST RES INST OF CHEM IND

Solenoid-actuated dispensing valve with flexible amplifier arm

InactiveCN102941183BIncrease movement speedHigh response frequencyLiquid surface applicatorsCoatingsAdhesiveEngineering

Owner:CENT SOUTH UNIV

A kind of mold powder for esp low carbon special continuous casting mold

The invention relates to special continuous casting crystallizer casting powder for ESP low carbon, and belongs to the field of metallurgy accessories. The casting powder comprises chemical componentsincluding, by weight, 28-33 parts of CaO, 22-29 parts of SiO2, 4.5-7.5 parts of MgO, 4.5-7 parts of Al2O3, 7-10 parts of Na2O, 8-11 parts of F, 0.3-1.5 parts of B2O3, 0.5-1 part of Li2O and 1-3.5 parts of C. The casting powder has the low melting temperature, low viscosity and high melting speed, the casting powder can be rapidly consumed when the continuous casting pulling rate is 5-7 m / min, andaccordingly heat transfer and lubricating performance between a continuous casting blank shell and a crystallizer copper plate are guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

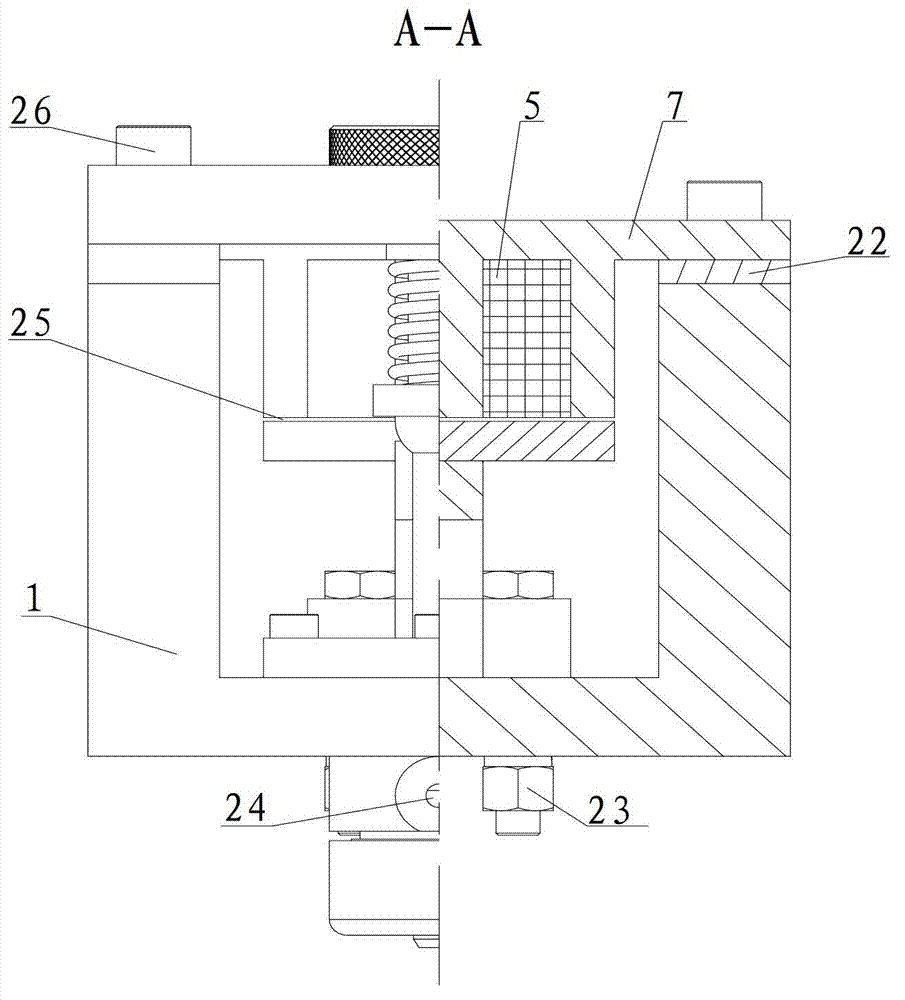

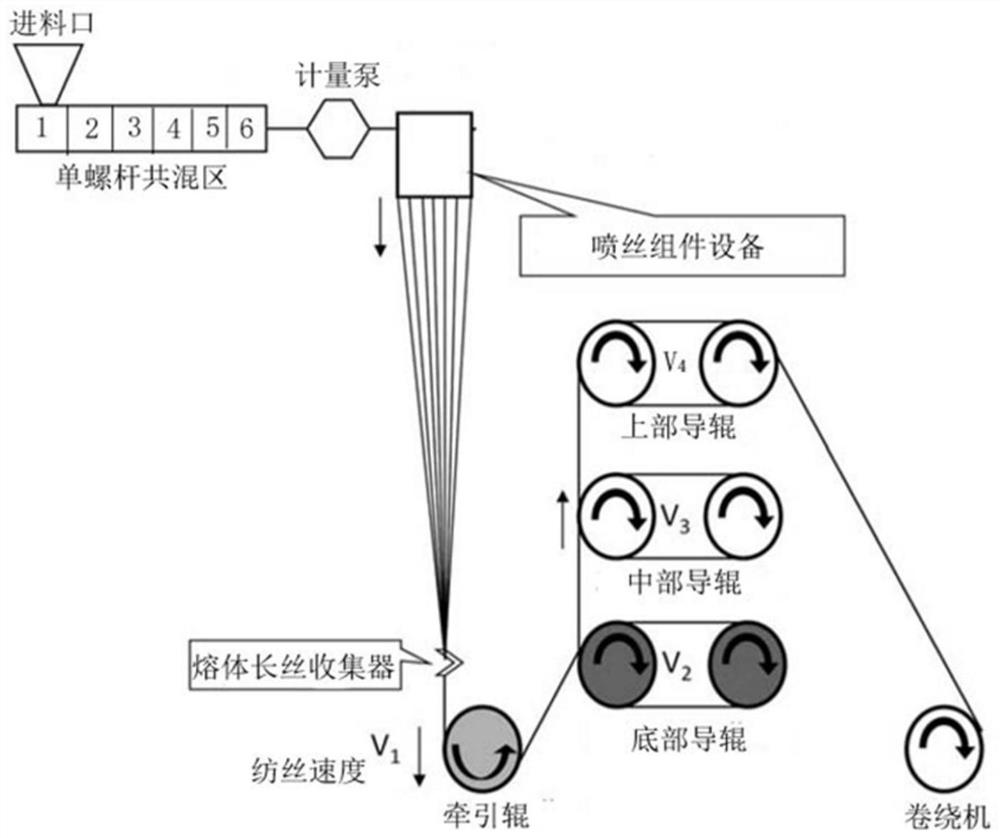

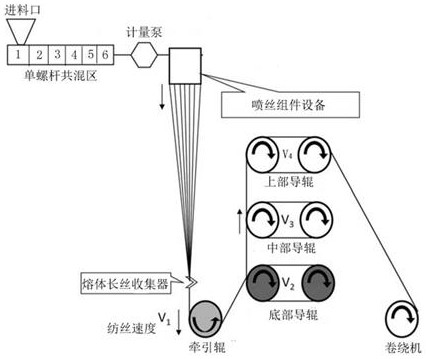

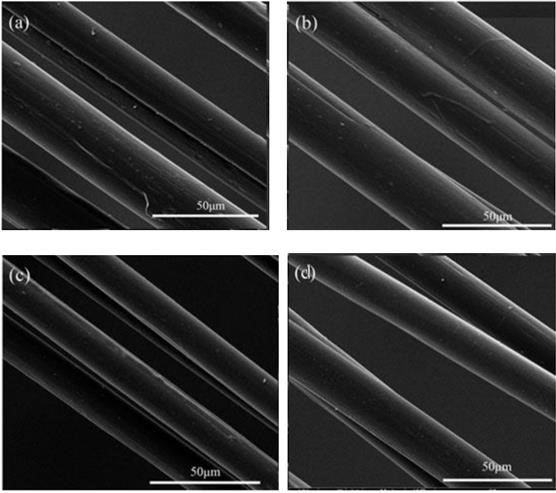

Preparation method and application of plasticized melt-spun commodity-grade active PAN precursors

ActiveCN112695401AReduce pollutionSpeed up the stabilization reactionFilament forming substance formingMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention relates to a preparation method and application of plasticized melt-spun commodity-grade active PAN precursors. Copolymerized PAN with the viscosity-average molecular weight of (5-7)x10<4> g / mol is selected as a raw material, [Bmim]Cl is selected as a plasticizer, sodium dodecylbenzene sulfonate is selected as a dispersing agent, and mixing is performed in a mechanical blending mode. A single-screw spinning machine is adopted for spinning, and the temperature of a melt blending area needs to reach 270 DEG C. The number of holes in a spinneret plate is 36, the hole diameter is 0.3 mm, the pump supply amount is 35 g / min, and the screw speed is 100-200 r / min. The temperature of a spinning workshop is 10-20 DEG C, the spinning stroke is 3-5 m, a traction roller is 300-400 m / min, and the draft multiples of a bottom layer roller, a middle layer roller and an upper layer roller are 2-2.5, 1.5-2 and 1.2-1.5 respectively. The precursors are soaked in deionized water with the temperature of 20-30 DEG C for 12-24 hours, and drying is performed in a drying oven with the temperature of 40-50 DEG C. The precursors are perfect in structure and contain a large amount of active free radicals.

Owner:ZHENJIANG COLLEGE

Feed capable of realizing low mortality rate for laying hens

InactiveCN106819532AHigh absorption conversion rateGood dispersionFood processingAnimal feeding stuffBiotechnologyBetaine

The invention discloses feed capable of realizing low mortality rate for laying hens. The feed is prepared from the following raw materials in parts by weight: 15 to 25 parts of fermented animal oil residue, 15 to 25 parts of rice bran, 5 to 12 parts of rapeseed meal, 10 to 20 parts of fermented soybean meal, 2 to 8 parts of rice bran meal, 3 to 6 parts of bean worm powder, 1 to 5 parts of potato protein meal, 2 to 8 parts of yellow mealworm powder, 1 to 5 parts of expanded blood powder, 2 to 8 parts of high protein flour, 0.5 to 2.5 parts of corn oil, 1 to 2 parts of peanut oil, 1 to 3 parts of corn syrup, 0.5 to 0.9 part of tryptophan, 0.05 to 0.1 part of methionine, 0.2 to 0.4 part of betaine, 1 to 2 parts of calcium dihydrogen phosphate, 1 to 2 parts of choline chloride, 2 to 4 parts of zeolite powder, 4 to 8 parts of a guar gum compound and 2 to 3 parts of a Chinese medicinal herb additive. The feed disclosed by the invention has the advantages of easiness of obtaining the raw materials, low cost, good palatability and high nutrient value; protein and energy requirements of the laying hens are guaranteed and the absorption conversion rate of the feed is extremely high.

Owner:ANHUI TIANZE FEED

A kind of low-viscosity fast-curing uv polyester acrylate and its preparation process

The invention relates to the technical field of fine chemical preparation, and discloses a low-viscosity fast-curing UV polyester acrylate and a preparation process thereof, which is prepared from the following components: 68-79 wt% of unsaturated polyester, acrylic monomer 10-15wt%, epichlorohydrin 10-15wt%, catalyst 0.5-1wt%, polymerization inhibitor 0.5-1wt%; the unsaturated polyester includes 20 parts by weight of maleic anhydride, phthalic anhydride 10.1 parts of diformic anhydride, 5.8 parts of deionized water, 0.1 part of hypophosphorous acid, 30 parts of dicyclopentadiene, 20 parts of diethylene glycol, 14.4 parts of pentaerythritol, 8 parts of fumaric acid and 1.5 parts of toluene. The UV polyester acrylate of the present invention has the advantages of low viscosity, fast curing, high reactivity, etc., and has good economy, which is beneficial to the mass preparation and popularization of UV paints. The preparation process of the present invention is simple and easy to operate.

Owner:YINGDE YAJIA PAINT

A kind of preparation method and application of plasticized melt spinning commercial grade active pan precursor

ActiveCN112695401BReduce pollutionSpeed up the stabilization reactionFilament forming substance formingMonocomponent synthetic polymer artificial filamentPolymer sciencePlasticizer

The invention relates to a preparation method and application of plasticized melt-spun commercial-grade active PAN raw silk. Choose a viscosity average molecular weight of 5‑7×10 4 g / mol copolymerized PAN is used as raw material, [Bmim]Cl is used as plasticizer, and sodium dodecylbenzene sulfonate is used as dispersant, which is mixed by mechanical blending. Using a single screw spinning machine for spinning, the temperature of the melt blending zone should reach 270 °C. The number of spinneret holes is 36, the hole diameter is 0.3mm, the pump supply is 35g / min, and the screw speed is 100‑200r / min. The temperature of the spinning workshop is 10-20℃, the spinning distance is 3-5m, the pulling roller is 300-400m / min, and the draft ratios of the bottom, middle and upper rollers are 2-2.5, 1.5-2, 1.2-1.5 respectively. Soak the raw silk in deionized water at 20-30°C for 12-24h, and dry it in an oven at 40-50°C. The protofilament has a perfect structure and contains a lot of active free radicals.

Owner:ZHENJIANG COLLEGE

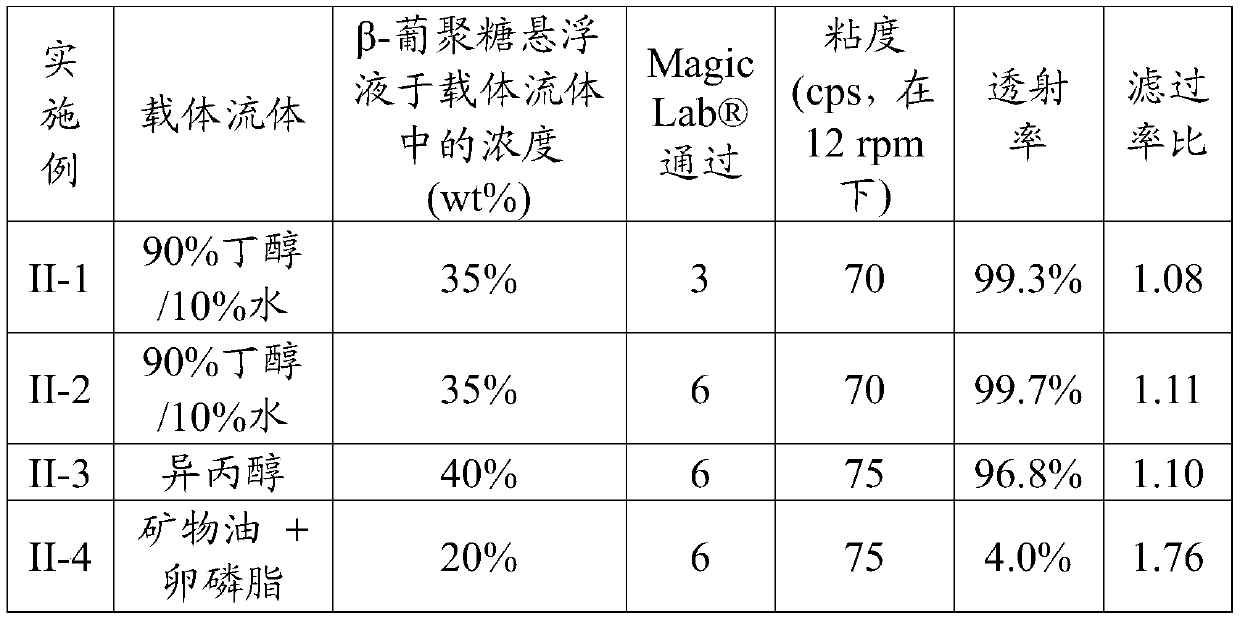

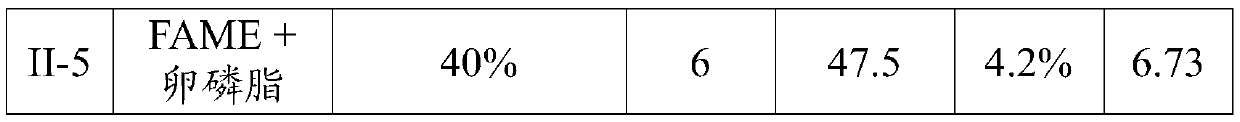

Readily water-miscible beta-glucan suspensions

Owner:CARGILL INC

Surface disinfector for edible fungus matrix

The invention discloses a surface disinfector for an edible fungus matrix. The surface disinfector comprises the following raw materials in parts by weight: 2-10 parts of Fumeiling, 1-6 parts of thiophanate, 400-650 parts of alcohol and 6-15 parts of filler. The filler is bentonite or / and calcium nitrate. The disinfector disclosed by the invention can conveniently sterilize the surface of an edible fungus cured matrix and has a high kill ratio to infectious microbes which are easy to breed on the surface of the matrix and quick degerming effect. The characteristic that alcohol can volatilize quickly is skillfully utilized, and a print area of a sterilizing zone is reserved on a sterilizing part, so that holes can be formed in the best positions to carry out inoculation, thereby guaranteeing a good sterilizing effect. Furthermore, the medicament resources are effectively saved, and the comprehensive utilization value of medicament raw materials and human resource is greatly improved, so that the surface disinfector is easy to popularize and use.

Owner:李书杰

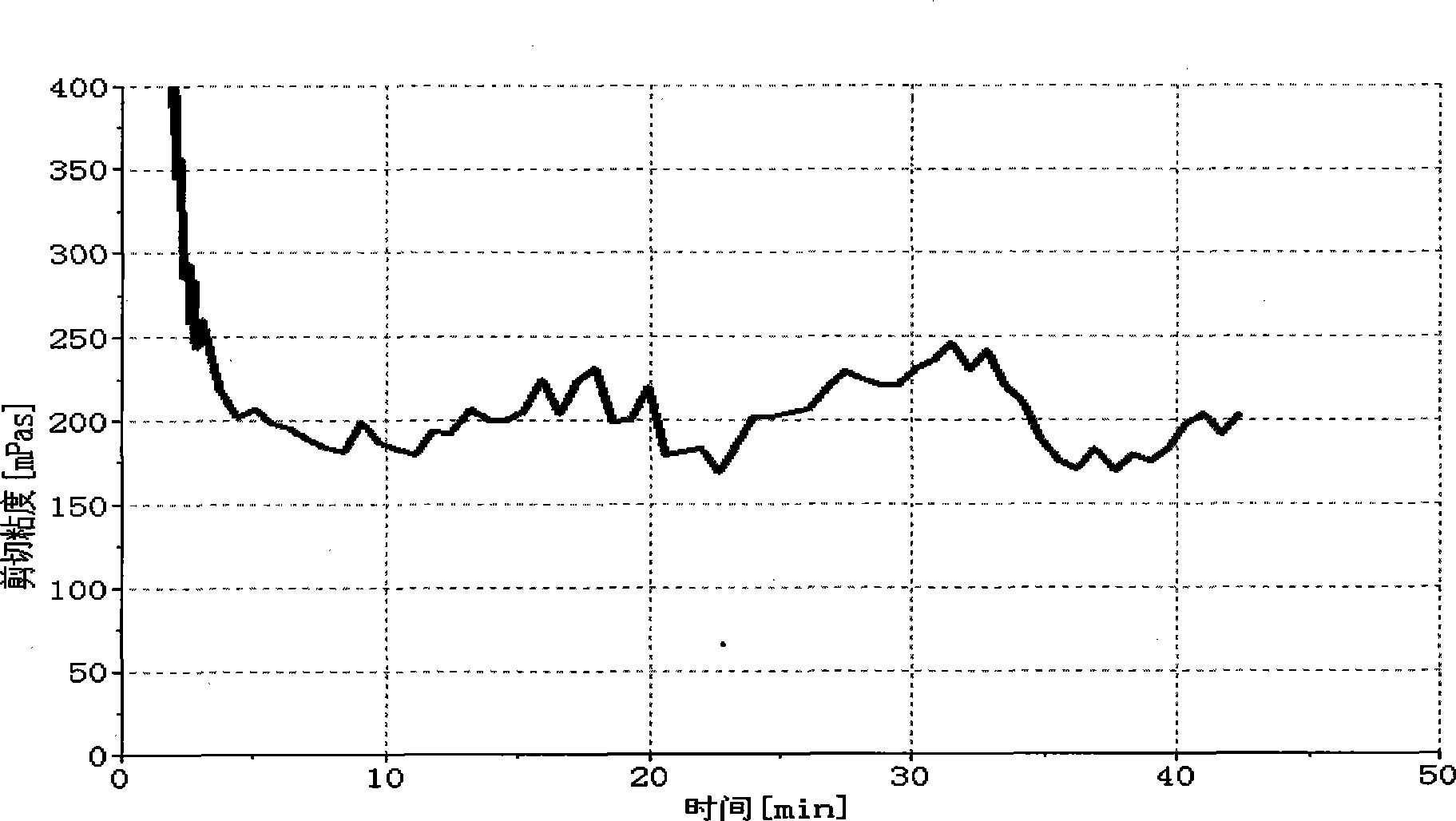

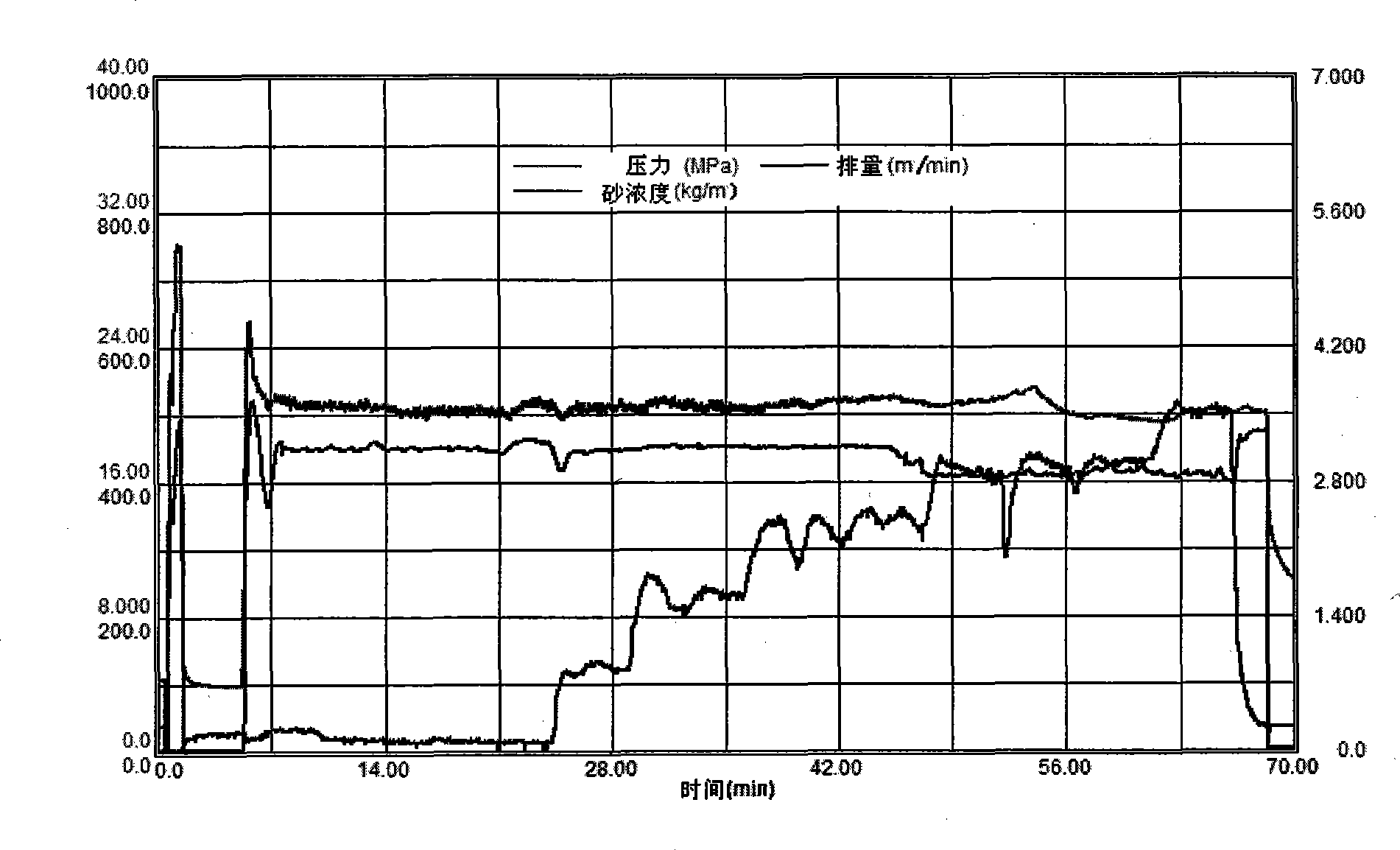

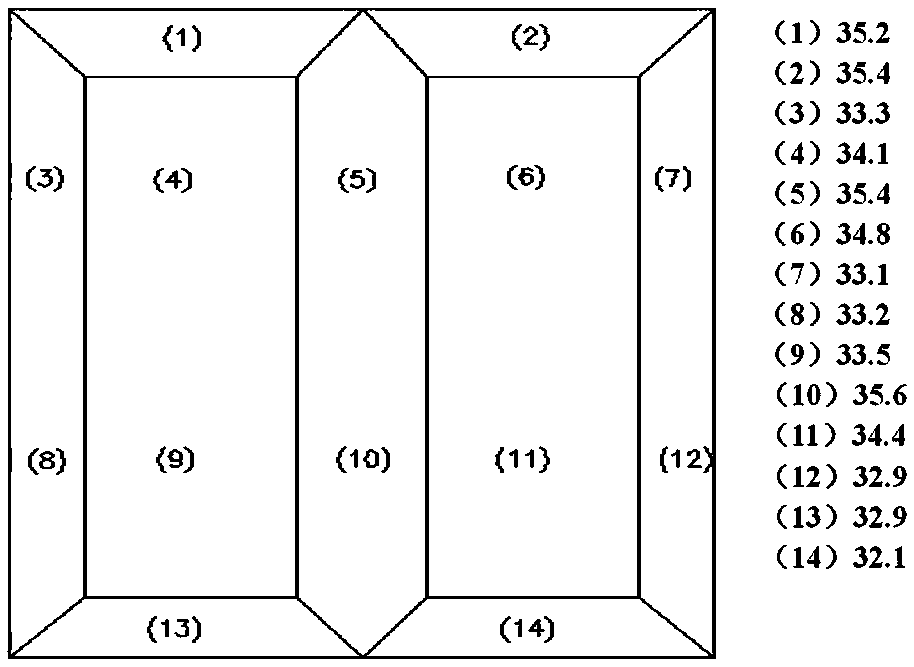

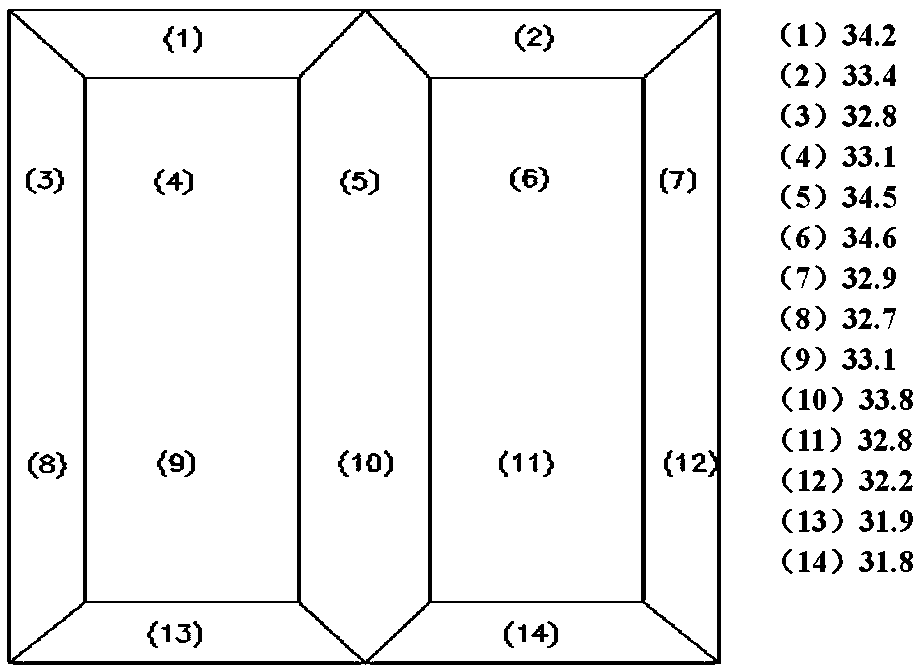

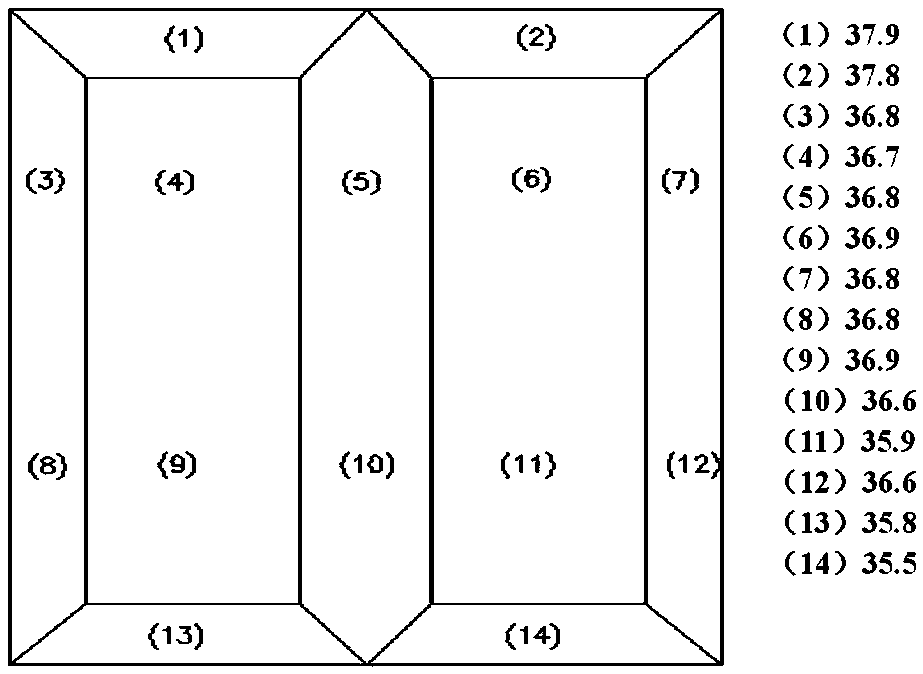

Readily water-miscible [beta]-glucan suspensions

The present invention provides readily water-miscible [beta]-glucan suspensions and methods of making and using the same. A readily water-miscible [beta]-glucan suspension includes a [beta]-glucan anda water-miscible organic fluid that comprises an alcohol, an alpha-hydroxy acid alkyl ester, a polyalkylene glycol alkyl ether, or a combination thereof, wherein the suspension is sufficient such that mixing with water at a shear rate of 40,000 s-1 or more forms a homogeneous mixture of the suspension and the water. The present invention also provides methods of dispersing the water-miscible [beta]-glucan suspension in water to form homogenous mixtures of the suspension and the water, methods of treating subterranean formations with such homogeneous mixtures, and methods of making the suspension.

Owner:CARGILL INC

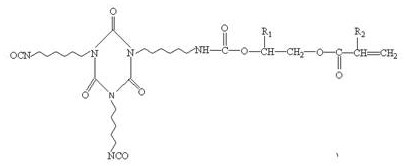

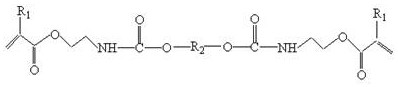

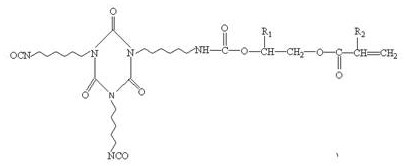

A kind of low-viscosity environment-friendly UV/moisture double-cured three-proof adhesive and preparation method thereof

ActiveCN109370507BHigh reactivityLow viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

A low-viscosity environmentally friendly UV / moisture dual-curing three-proof adhesive and a preparation method thereof, which consist of the following raw materials in parts by weight: 30-50 parts of self-made low-viscosity moisture-curable acrylate, 10-30 parts of functional polyurethane acrylate, 30-50 parts of acrylic reactive diluent, 3-8 parts of photoinitiator, 0.05-0.2 parts of polymerization inhibitor, and 1-3 parts of silane coupling agent. The invention provides a kind of viscosity lower than 50mPa.s, easy to spray, good leveling effect, good toughness, adhesion test can reach 5B, and in the area where ultraviolet light is difficult to irradiate, the low viscosity environmental protection UV / moisture Dual curing three-proof adhesive has lower viscosity, no volatile solvent, fast curing speed, good surface dryness, good toughness, high bonding reliability, and wide application range.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Readily water-miscible [beta]-glucan suspensions Readily water-miscible [beta]-glucan suspensions](https://images-eureka.patsnap.com/patent_img/bba5d2e8-ebd2-495e-8dfb-74642eb9e9fb/BDA0002218428770000261.png)

![Readily water-miscible [beta]-glucan suspensions Readily water-miscible [beta]-glucan suspensions](https://images-eureka.patsnap.com/patent_img/bba5d2e8-ebd2-495e-8dfb-74642eb9e9fb/BDA0002218428770000271.png)