Drilling fluid cleaning system device

A purification system and drilling fluid technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc., can solve problems such as unreasonable structure layout, poor mixing uniformity, serious sedimentation, etc., and achieve favorable mud mixing efficiency, The effect of large stirring force and short mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

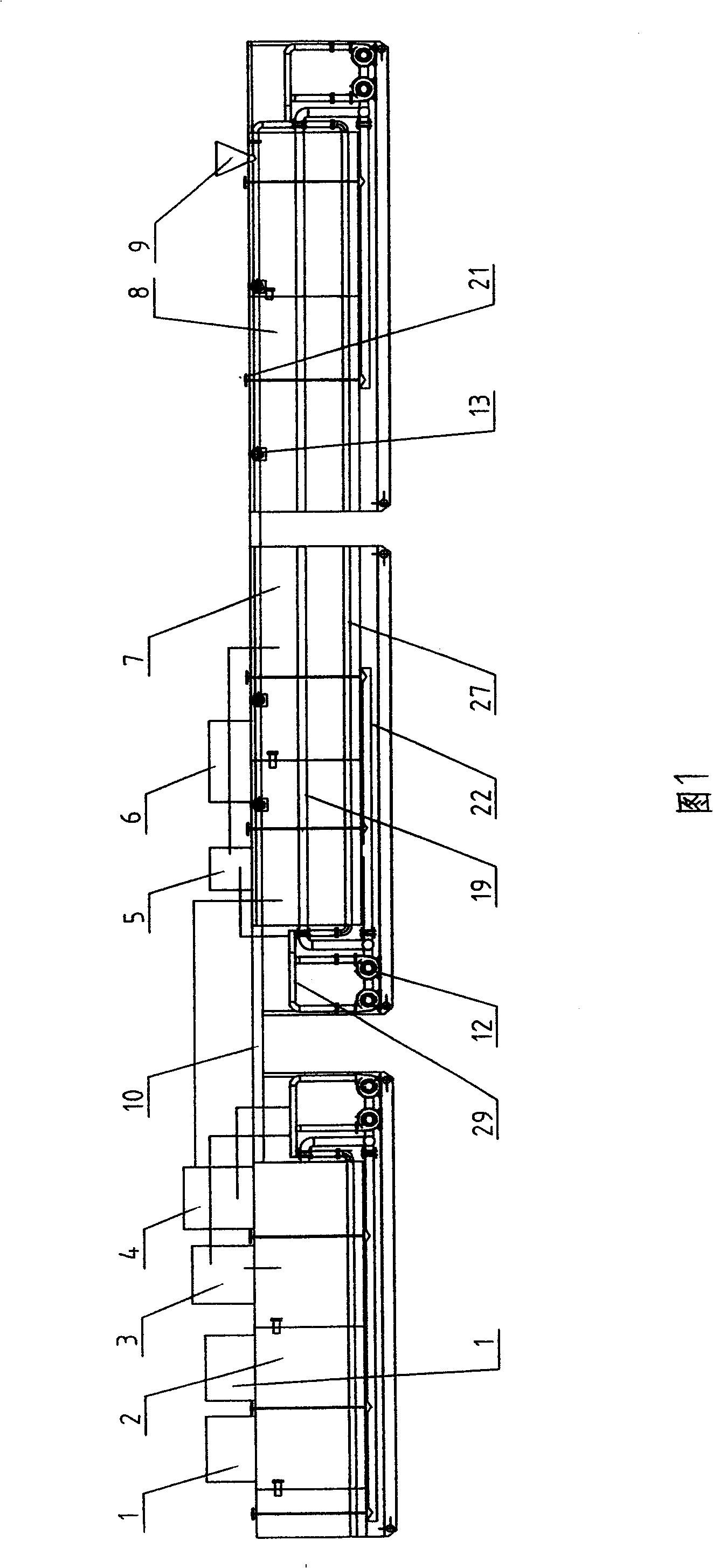

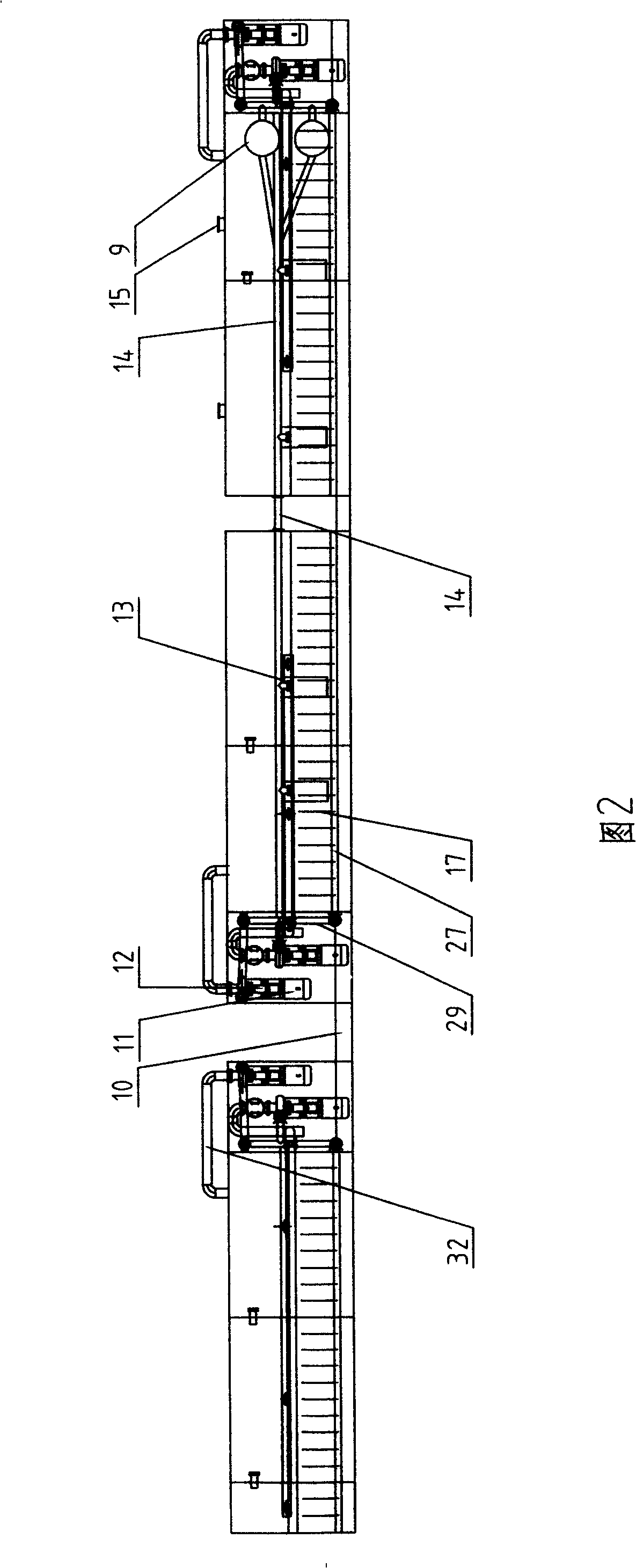

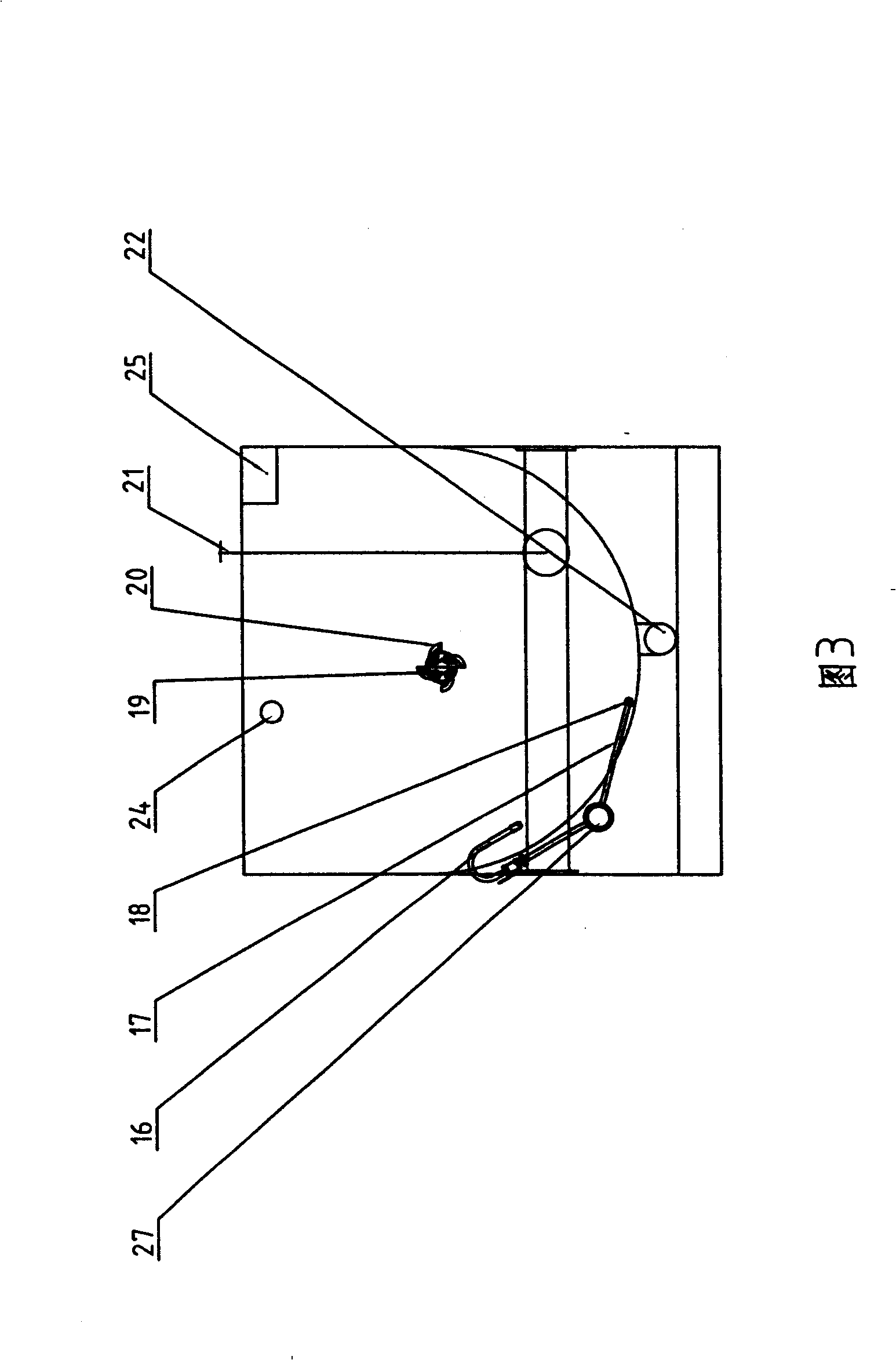

[0022] Referring to Fig. 1, Fig. 2 and Fig. 3, the drilling fluid purification system device includes a primary treatment tank 2 with a vibrating screen 1, a degasser 3 and a desander 4 on the top, a desilter 5, a centrifuge The post-treatment tank 7 of 6 is provided with the mud mixing tank 8 of the mixing funnel 9. According to the size of the drilling rig and the required drilling fluid reserve, a reserve tank can also be added between the post-processing tank and the mud mixing tank, and the mud can be filled between the tanks. Groove 10 communicates. In the system, each drilling fluid tank is provided with intercommunicating compartments, and each tank is provided with a central suction pipe 19 in the inner cavity that runs through each compartment of the tank, and a spraying main pipe 27 along each compartment of the tank is provided outside the tank. Two rows of inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com