Patents

Literature

383results about How to "Short mixing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

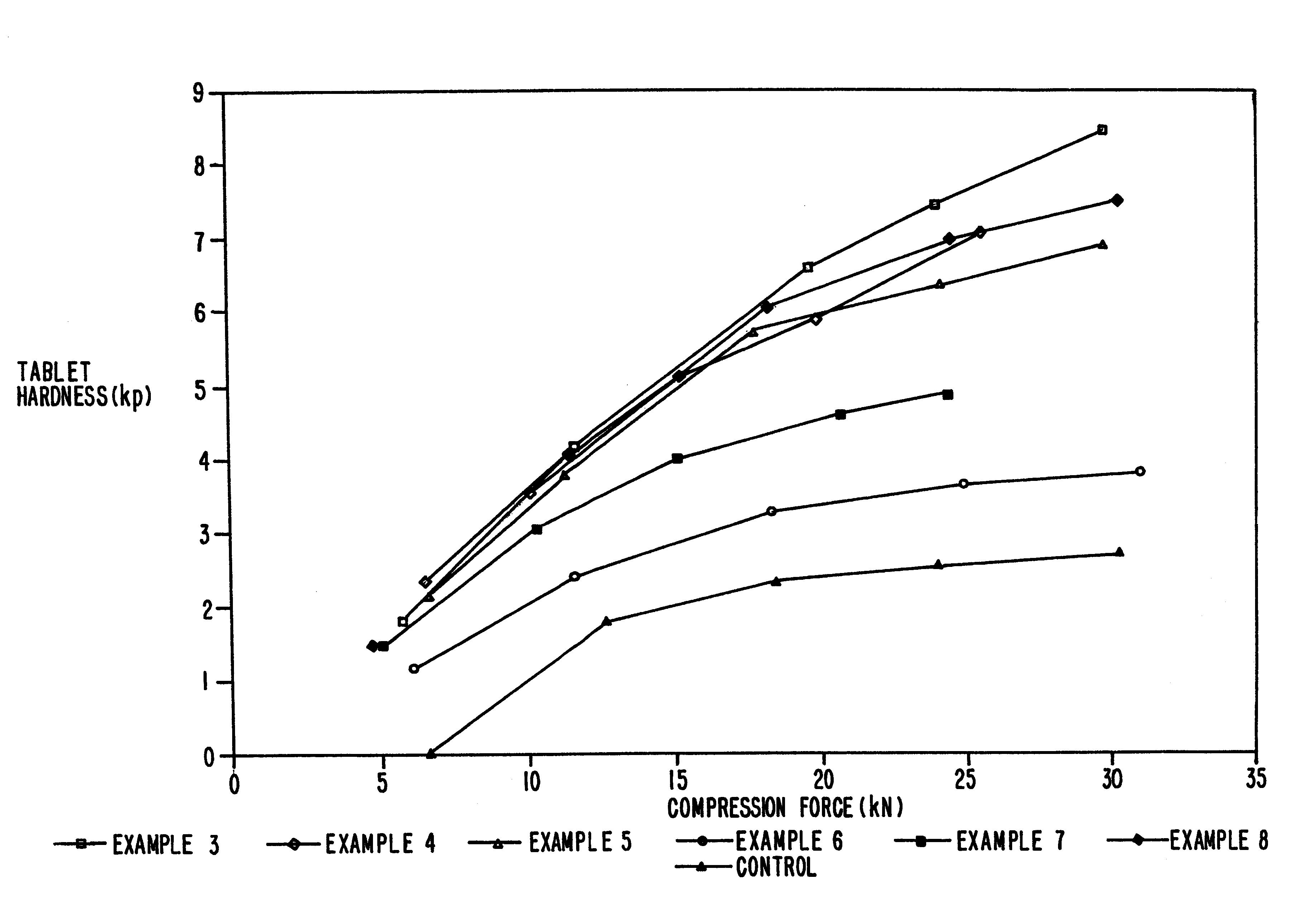

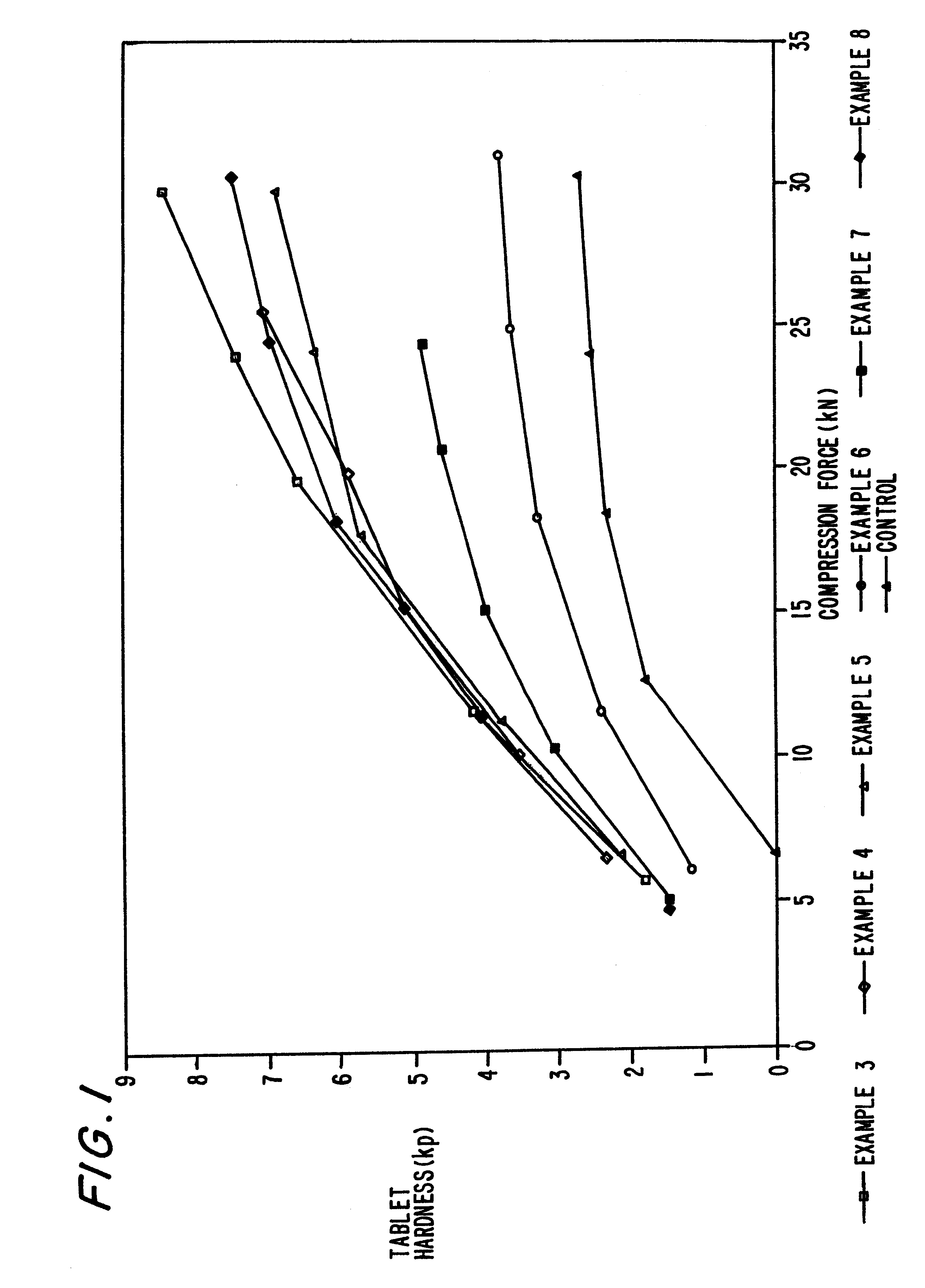

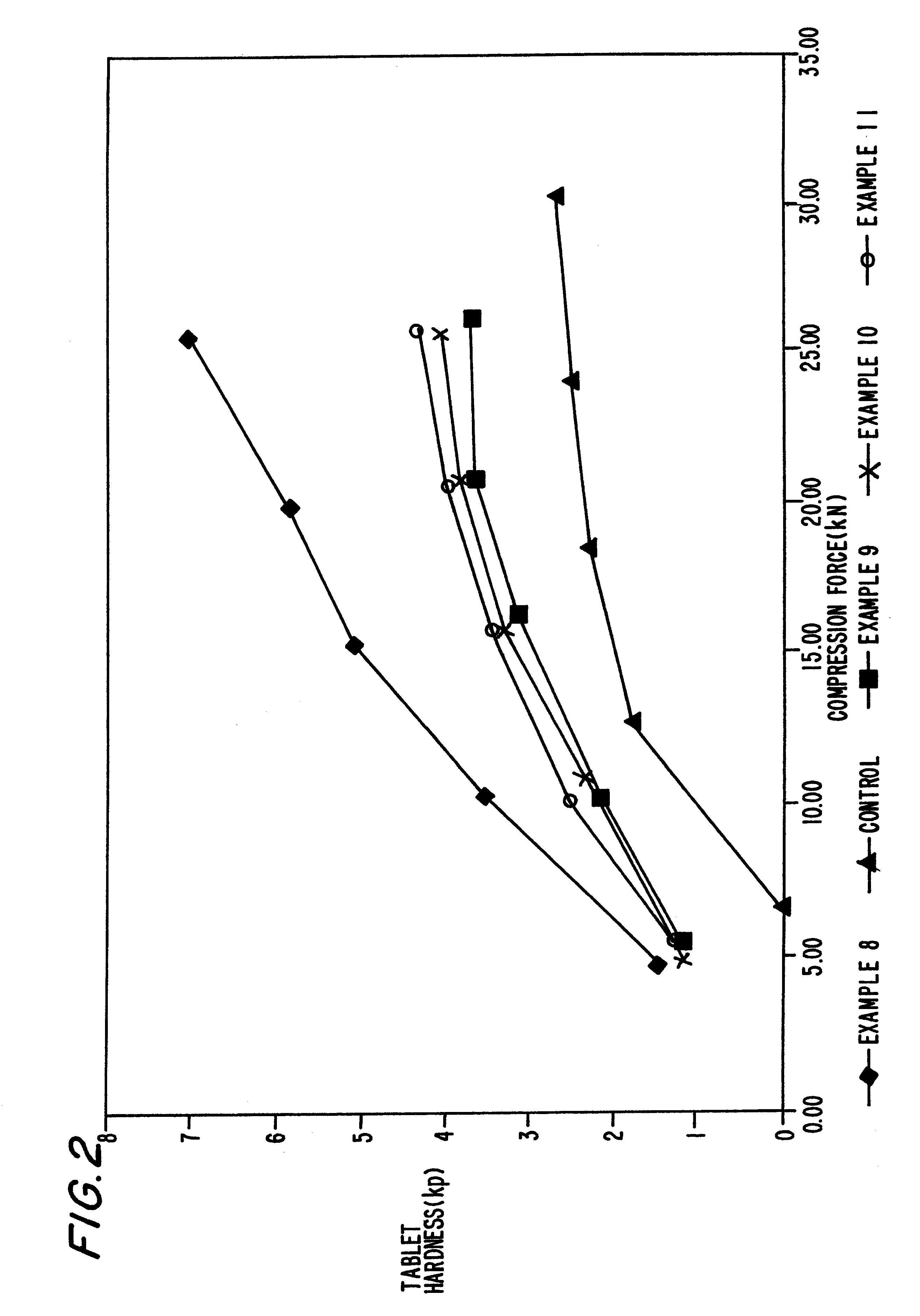

Directly compressible high load acetaminophen formulations

InactiveUS6217907B1High loadShort mixing timeOrganic active ingredientsPowder deliveryEngineeringMicrocrystalline cellulose

Direct compressed solid pharmaceutical dosage forms containing:a) from about 40 to about 95% by weight acetaminophen;b) from about 1 to about 60% by weight of a direct compression vehicle comprising microcrystalline cellulose; andc) from about 0.01 to about 4.0% by weight of a pharmaceutically-acceptable lubricant are disclosed. The acetaminophen and direct compression vehicle are combined under high shear conditions which are sufficient to transform acetaminophen and direct compression vehicle into a homogenous granulate without degradation. In preferred aspects of the invention, the lubricant is also combined with the acetaminophen and direct compression vehicle under high shear conditions. Methods of preparing the directly compressed solid pharmaceutical dosage forms and methods of treatment with the dosage forms are also disclosed. The methods are particularly well suited for preparing directly compressed dosage forms containing high load (i.e., up to 80% or greater) amounts of acetaminophen based on the weight of the total tablet.

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

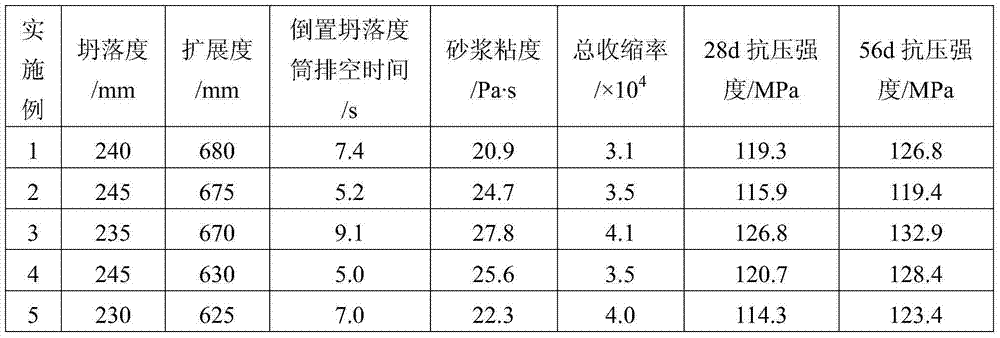

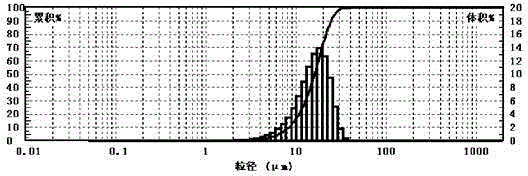

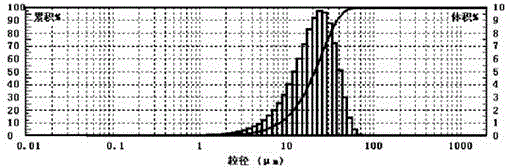

Low-shrinkage, low-viscosity and ultrahigh strength concrete

ActiveCN104844099AReduce hydration temperature riseReduce shrinkage cracksSolid waste managementWork performanceMicrosphere

The invention belongs to the technical field of building materials and particularly relates to low-shrinkage, low-viscosity and ultrahigh strength concrete. Based on a single formula proportional dosage, the low-shrinkage, low-viscosity and ultrahigh strength concrete comprises the following components by weight: 250-300kg of cement, 120-180kg of microspheres, 90-120kg of mineral powder, 820-860kg of machine-made sand, 950-1000kg of gravels, 7-11kg of a water reducer and 115-125kg of water. The components are mixed with stirring for 1.5-2 minutes to obtain a concrete mixture. The concrete provided by the invention is less in binding material use, the total shrinkage percentage is less than (0.03-0.04per mill), the emptying time of an inverted slump cone is 5-10 seconds, the viscosity of mortar in same proportion is 20-28 Mp.s, the 28d compressive strength is 110-130MPa, and the 56d compressive strength is 120-135MPa. The concrete has the characteristics of being low in bonding material use, short in stirring time, excellent in working performance and low in comprehensive cost, and can be produced on a large scale and has a broad application prospect.

Owner:中建商品混凝土(福建)有限公司 +1

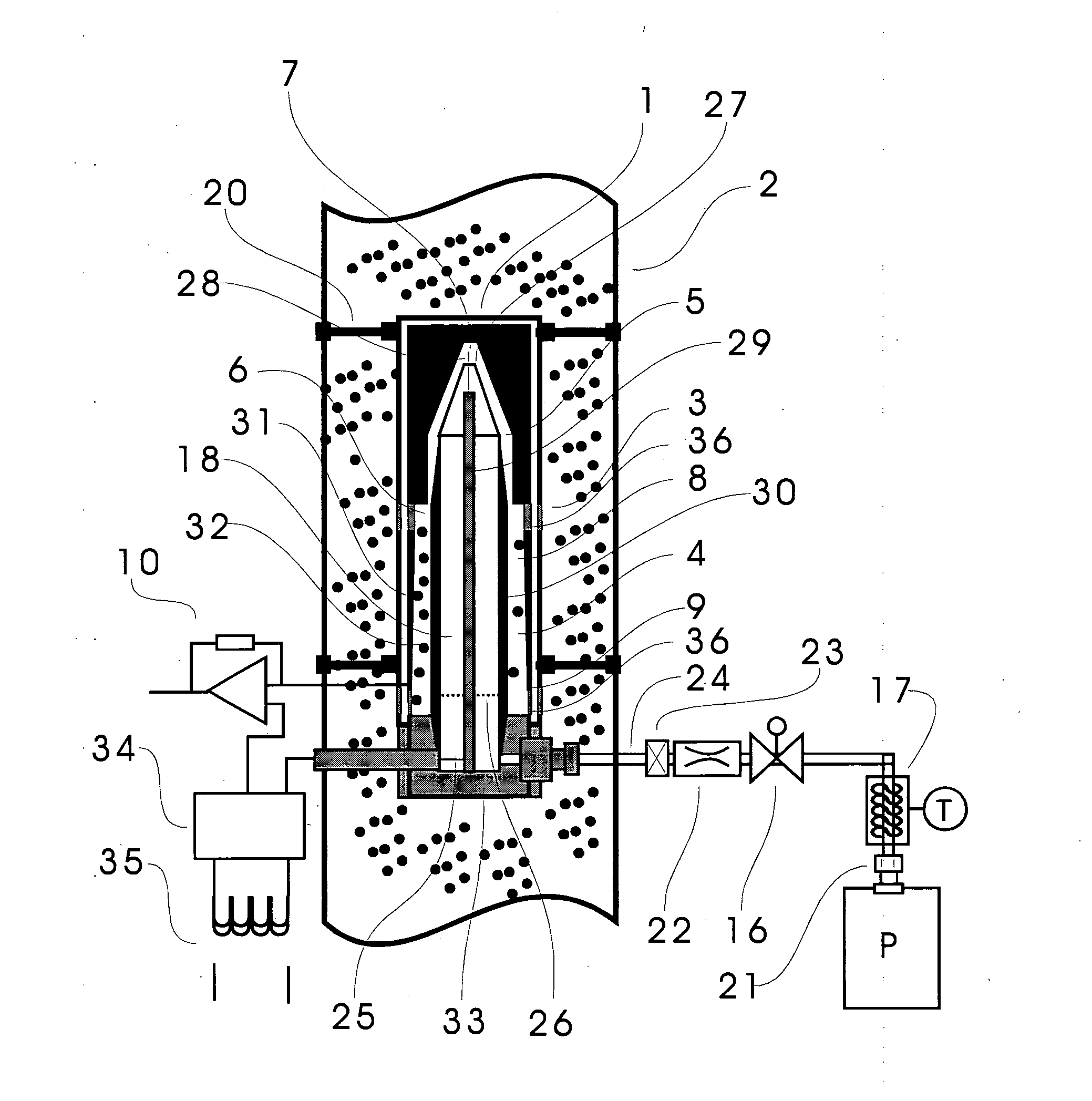

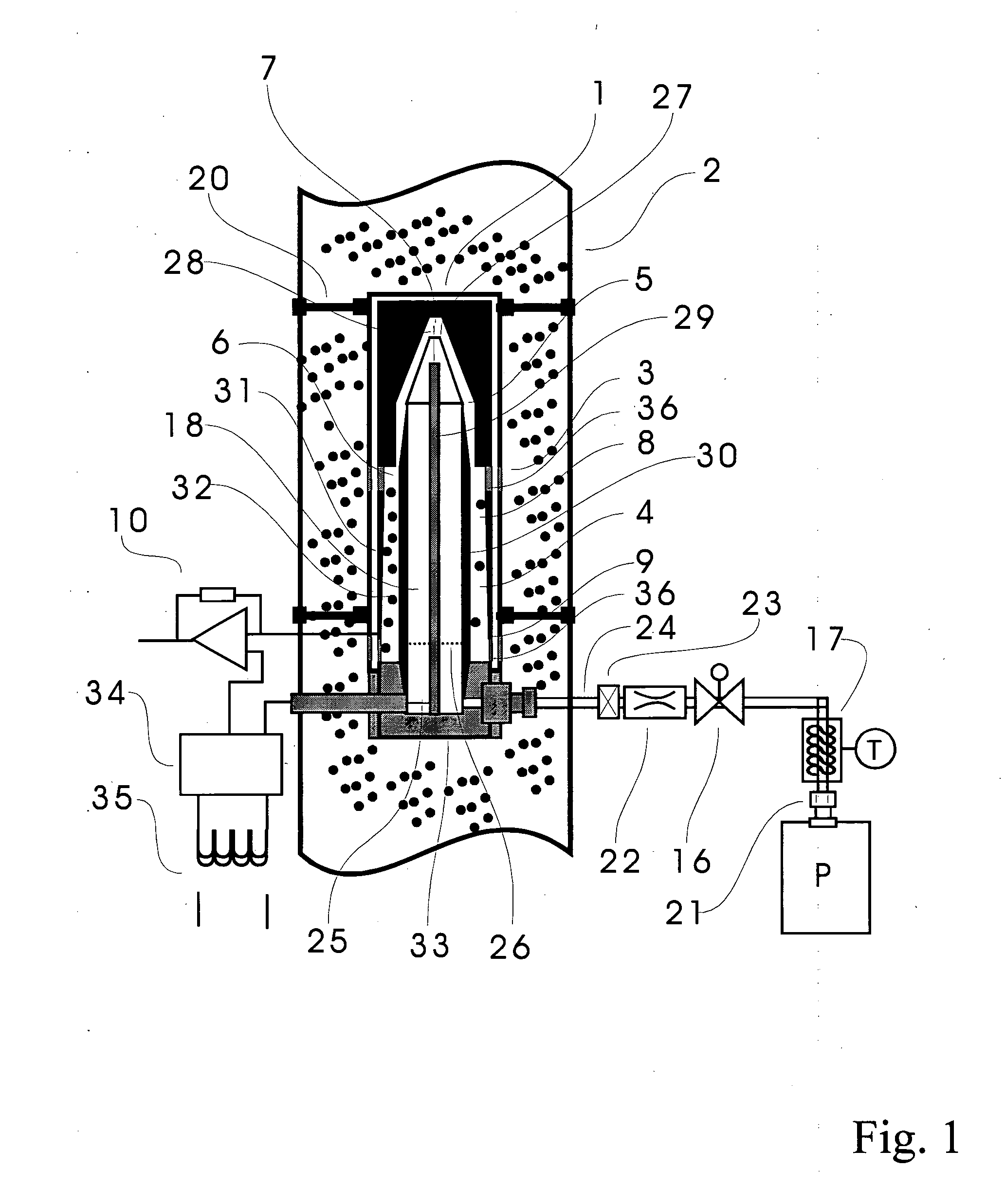

Particle Measurement Process and Apparatus

ActiveUS20110050243A1Increase ion productionDecrease ion lossSamplingMaterial analysis by electric/magnetic meansCombustionInternal combustion engine

A process for measuring particle concentrations in a gas using an ejector for producing an essentially constant sample flow and for efficient mixing of the particle-containing sample and and essentially clean, ionized gas. The invention also relates to an apparatus implementing such process. The process and the apparatus can be utilized for example in measuring particle concentrations in an exhaust system of a combustion engine.

Owner:PEGASOR OY

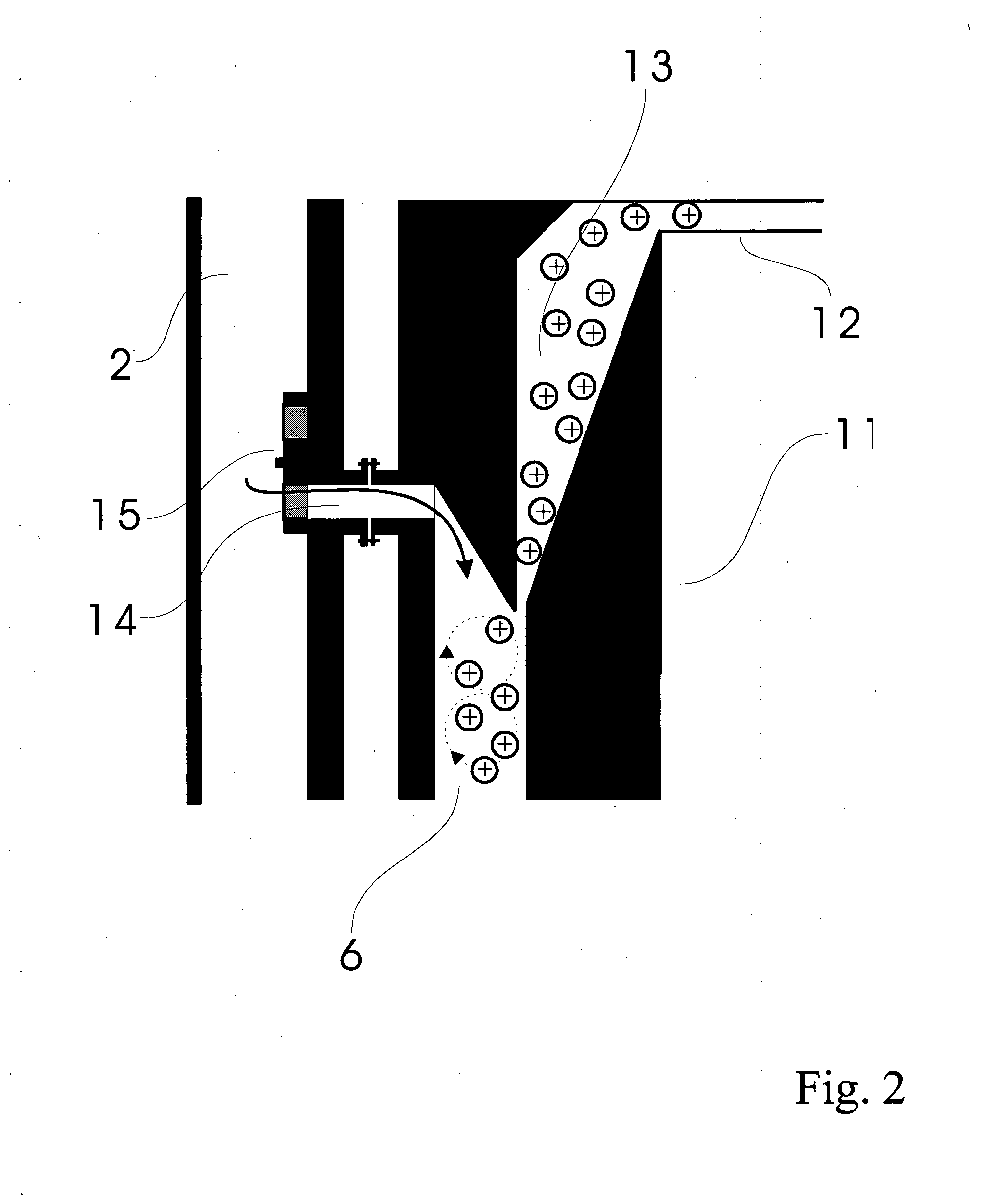

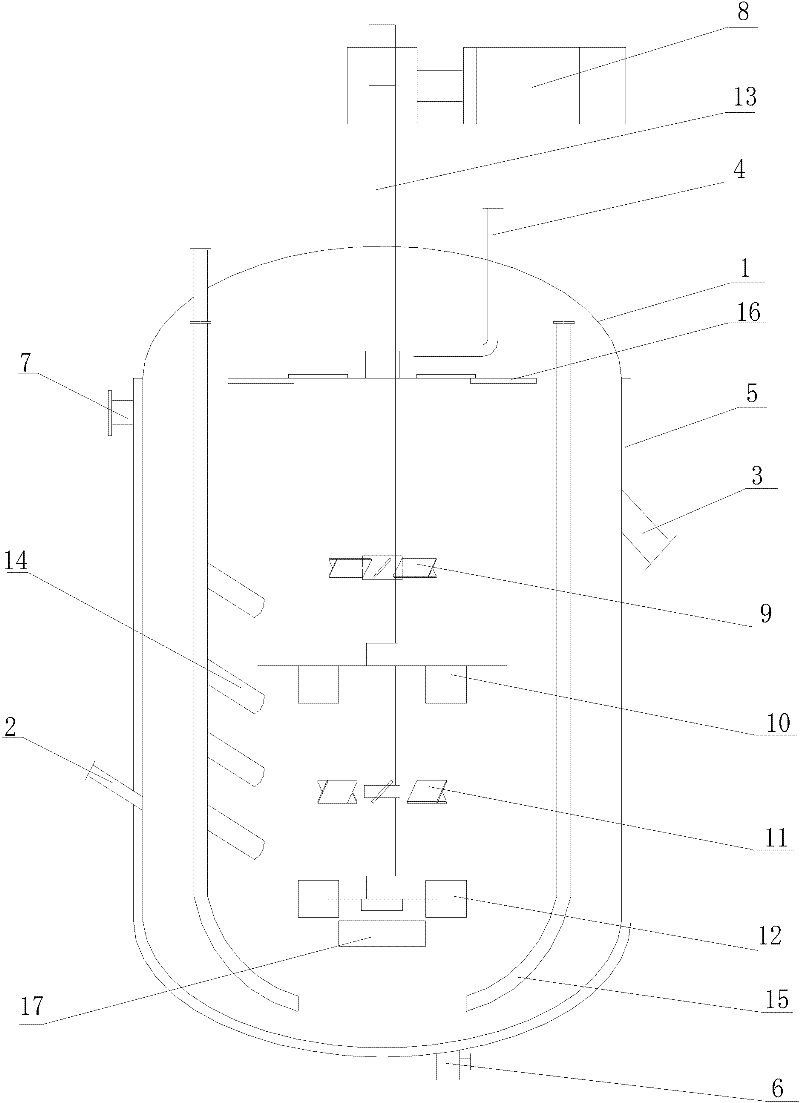

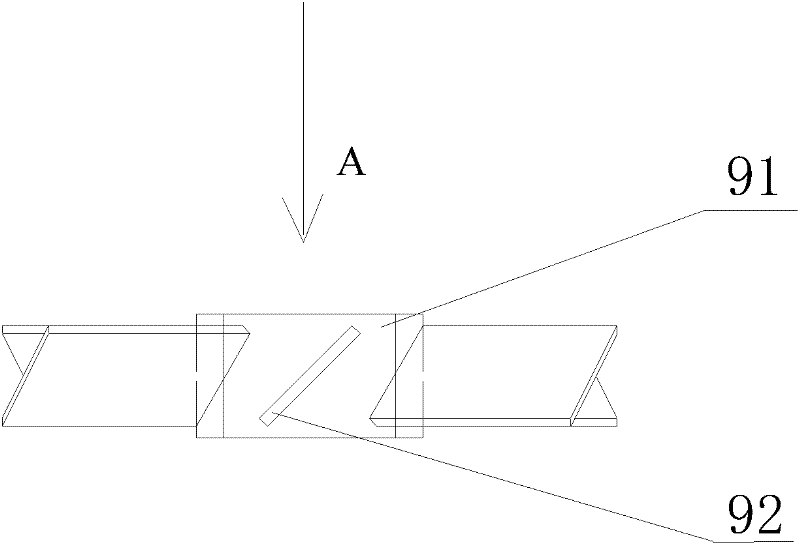

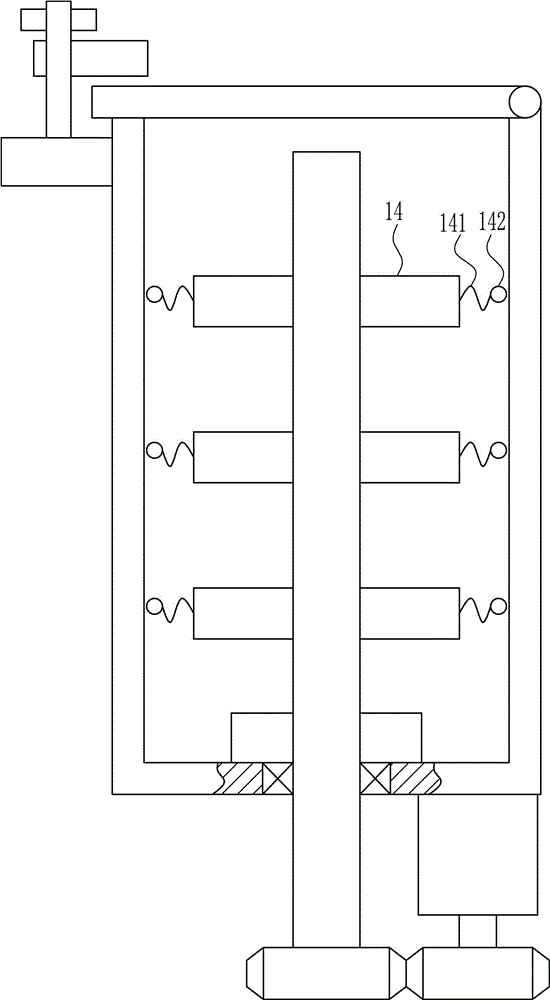

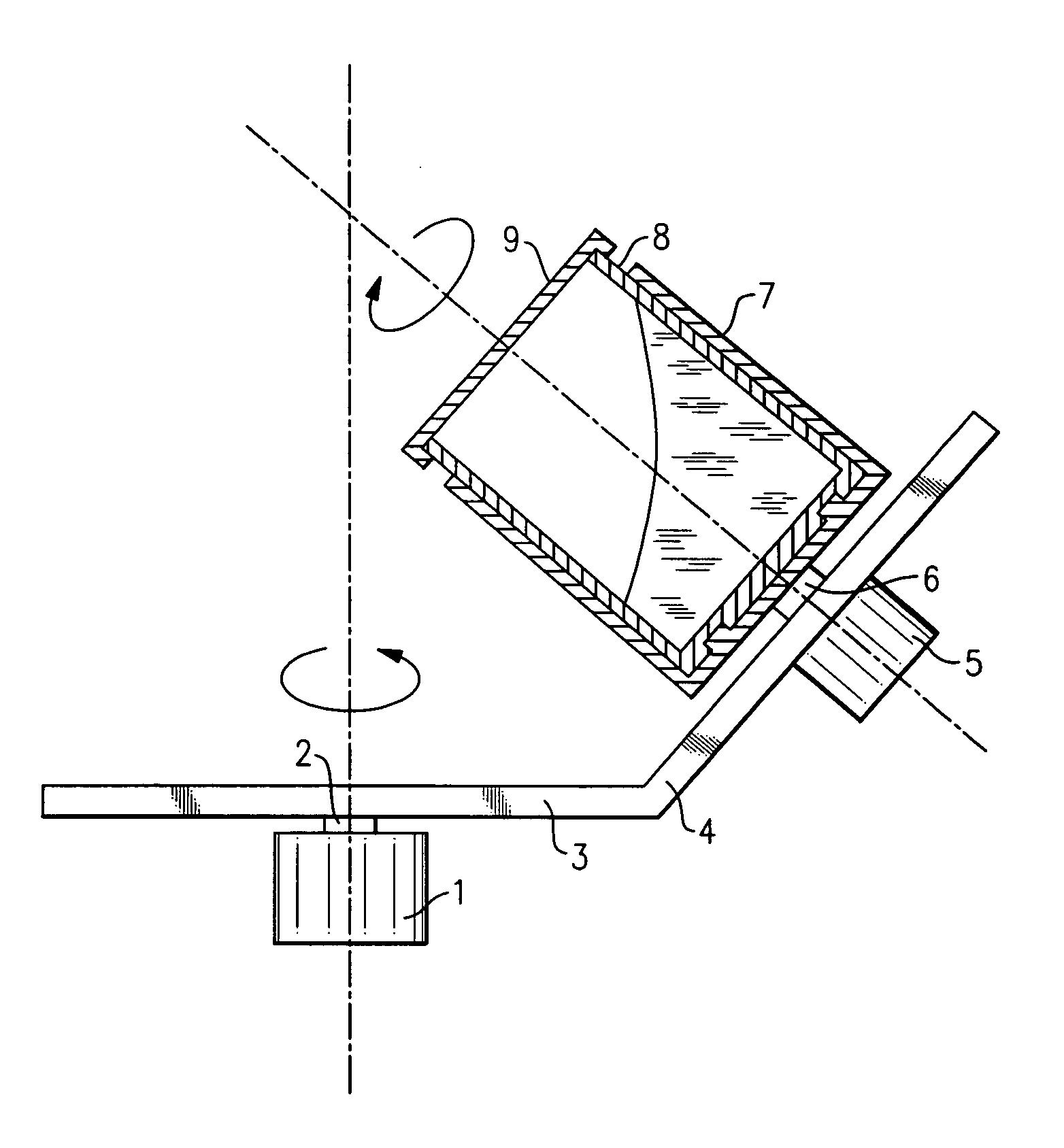

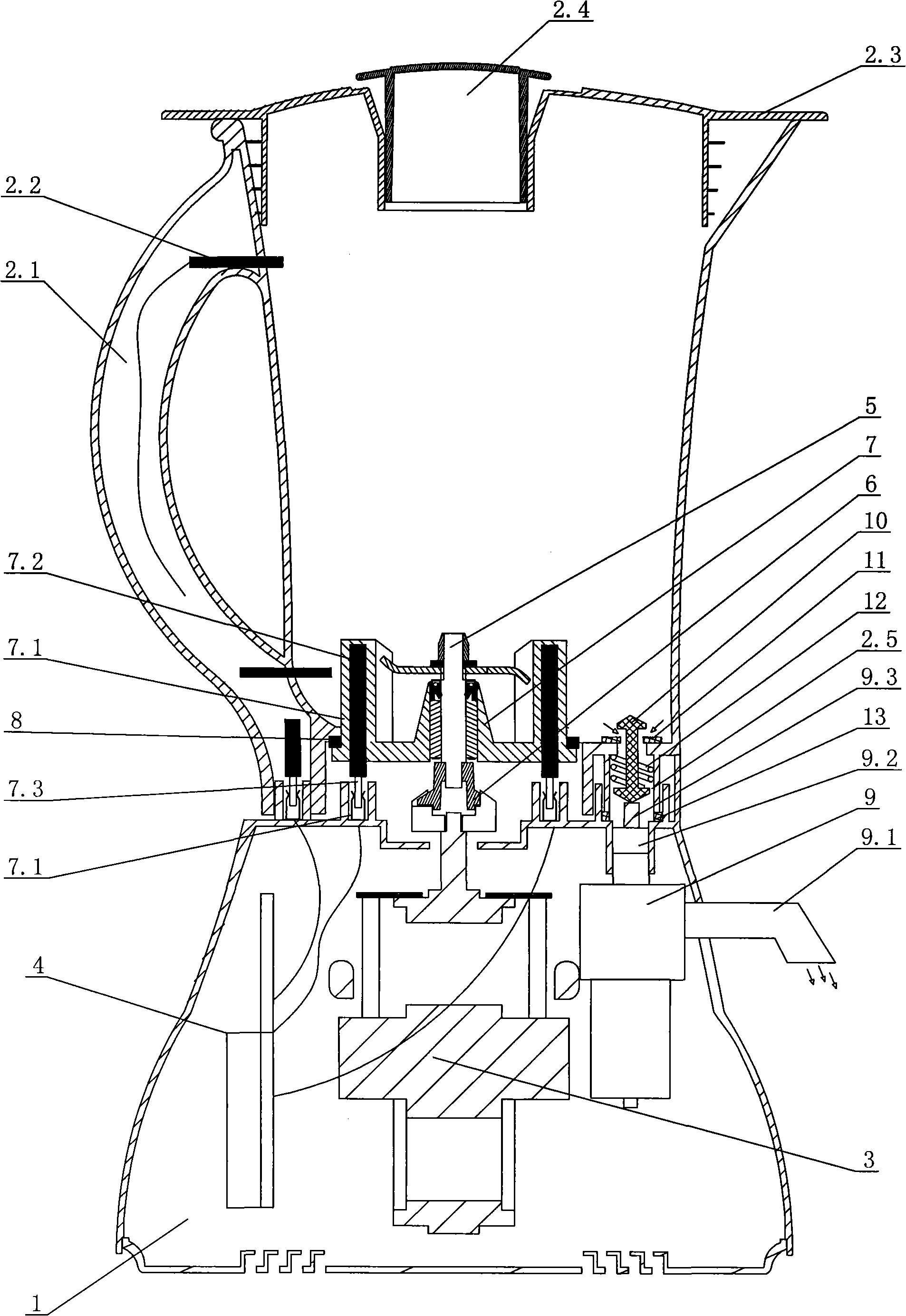

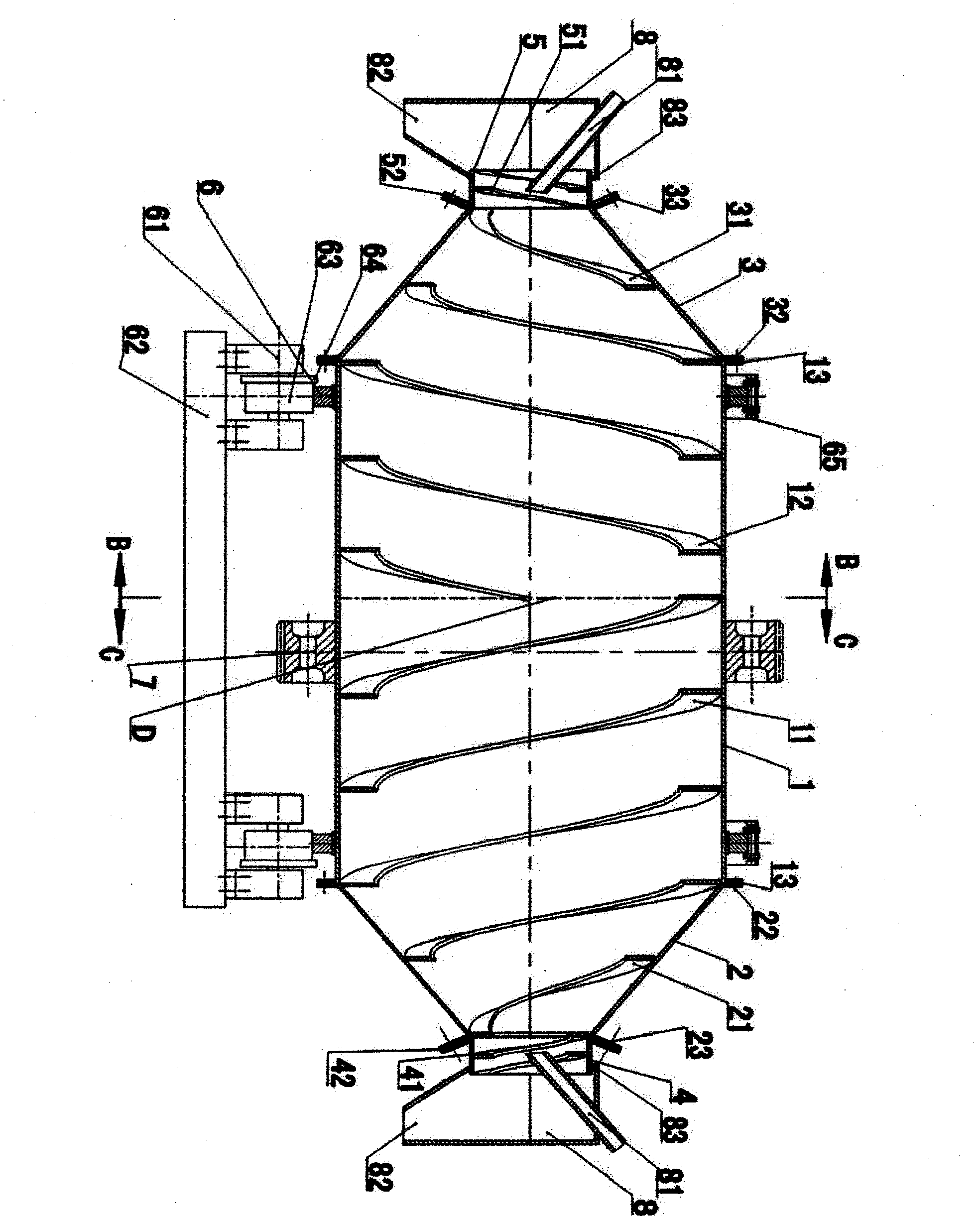

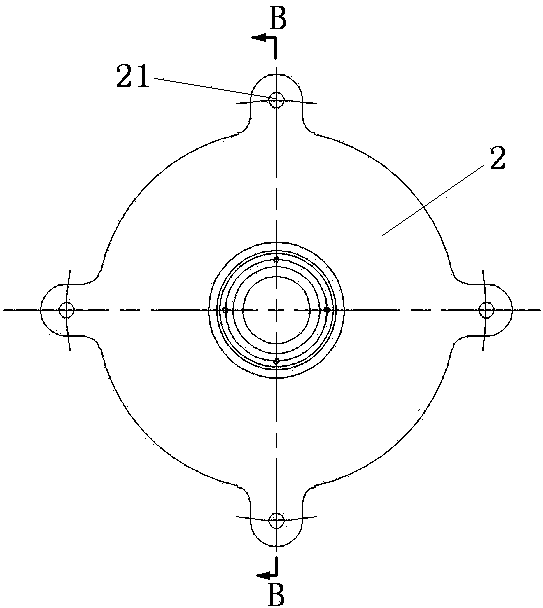

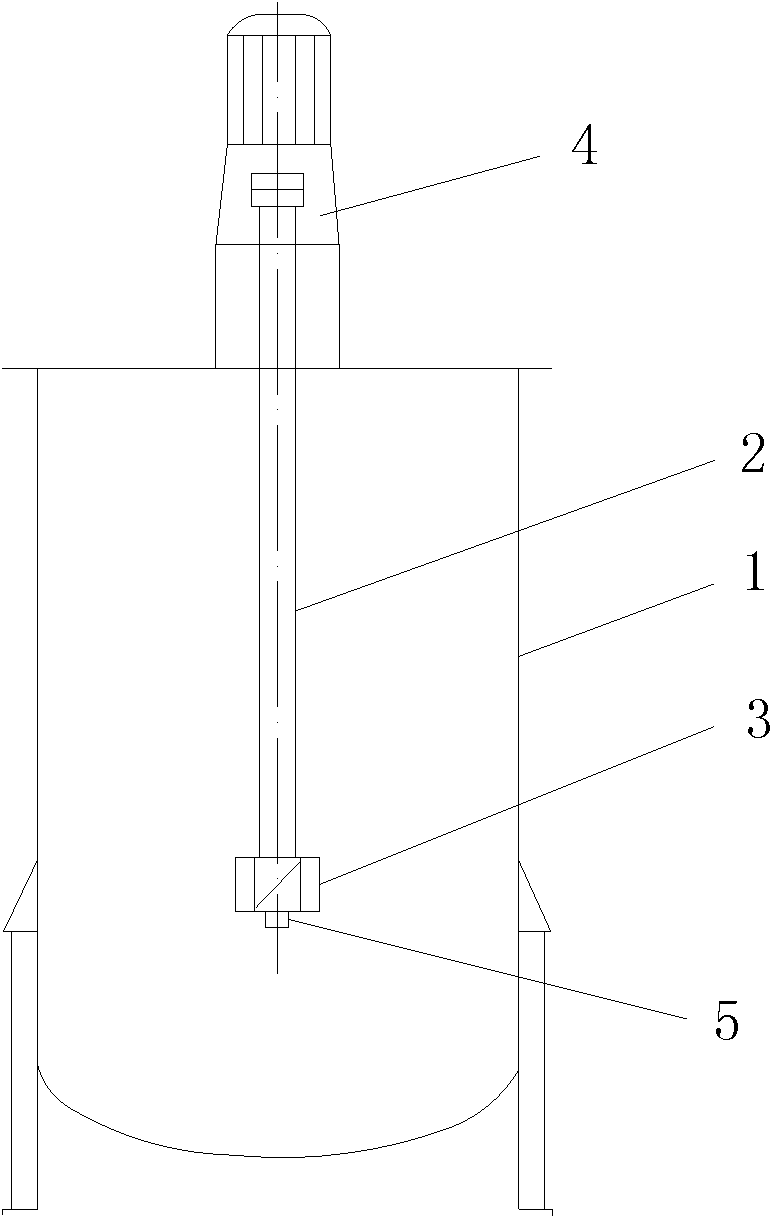

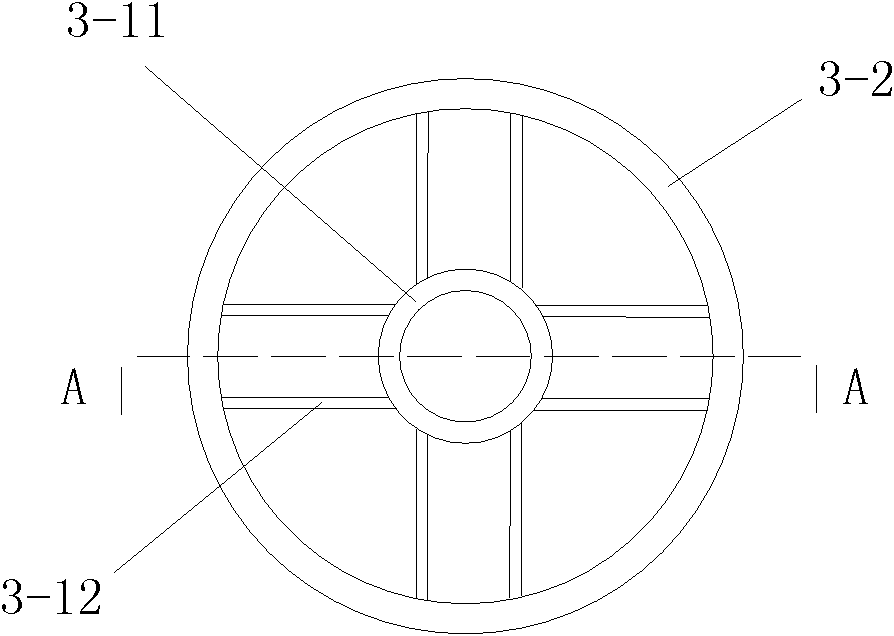

Stirred tank reactor

InactiveCN102358760ALarge circulationShort mixing timeRotary stirring mixersChemical/physical/physico-chemical stationary reactorsSizingProcess engineering

The invention discloses a stirred tank reactor and aims at improving a stirring turbine in the stirred tank reactor by using a four-layer combination stirring turbine. The stirring turbine comprises a first layer turbine, a second layer turbine, a third layer turbine and a fourth layer turbine which are arranged from the middle to the bottom of a stirring shaft sequentially. The first layer turbine is an upward axial flow turbine, the second layer turbine is a disk type turbine, the third layer turbine is an upward axial flow turbine, and the fourth layer turbine is a radial flow turbine. Radial circulation close to a liquid level, radial circulation close to a middle area of a stirred tank and radial circulation in a bottom area of the stirred tank are formed, so that circulation quantity inside the stirred tank is big and mixing time is short. Poor mixing area does not exist, and solid containing rate and gas containing rate are evenly distributed. A mass transfer condition of air and liquid is good, and single transfer efficiency is high. Entrainment quantity of sizing is greatly reduced, fouling of a heat exchanger is reduced, and service life is long. Operation cost is lowered, and production cost is saved.

Owner:ZHEJIANG UNIV

L-polylactide filler for injection and preparation method thereof

ActiveCN105879124AExtended shelf lifeGood stabilityPharmaceutical delivery mechanismProsthesisSodium hyaluronateAloin

The invention discloses an L-polylactide filler for injection and a preparation method thereof. Active ingredients of the filler are L-polylactide particles, honeycomb HA and a synergist, the honeycomb HA is obtained by alcohol precipitation and drying of a water solution formed by mixing sodium hyaluronate high in molecular weight and sodium hyaluronate low in molecular weight in an alkaline condition, and the synergist is mannitol or a mixture of mannitol and aloe polysaccharide with a mass ratio of 1:0.05-0.12. The filler is simple to prepare, shorter in re-suspension time, long in validity period and more convenient to use.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

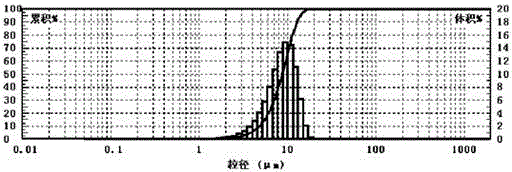

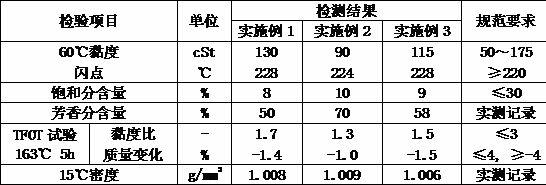

Asphalt recycling agent for hot recycling of asphalt on asphalt road surface

The invention discloses an asphalt recycling agent for hot recycling of asphalt on an asphalt road surface. The recycling agent comprises the following components by weight: 19-70% of an aromatic oil, 20-60% of heavy oil, 5-30% of liquid petroleum resin and 0.2-1% of a stabilizer. The invention also provides a preparation process of the asphalt recycling agent and a method for preparing recycled asphalt by use of the asphalt recycling agent. The recycling agent disclosed by the invention is good in recycling effect, easy for raw materials purchase, stable in quality, low in equipment investment, simple in processing steps, short in processing time of finished products, good in storage stability, stable in physicochemical property, and convenient for on-site operation, and is suitable for on-site hot recycling construction as a special recycling agent.

Owner:YINGDA HEAT REGENERATION

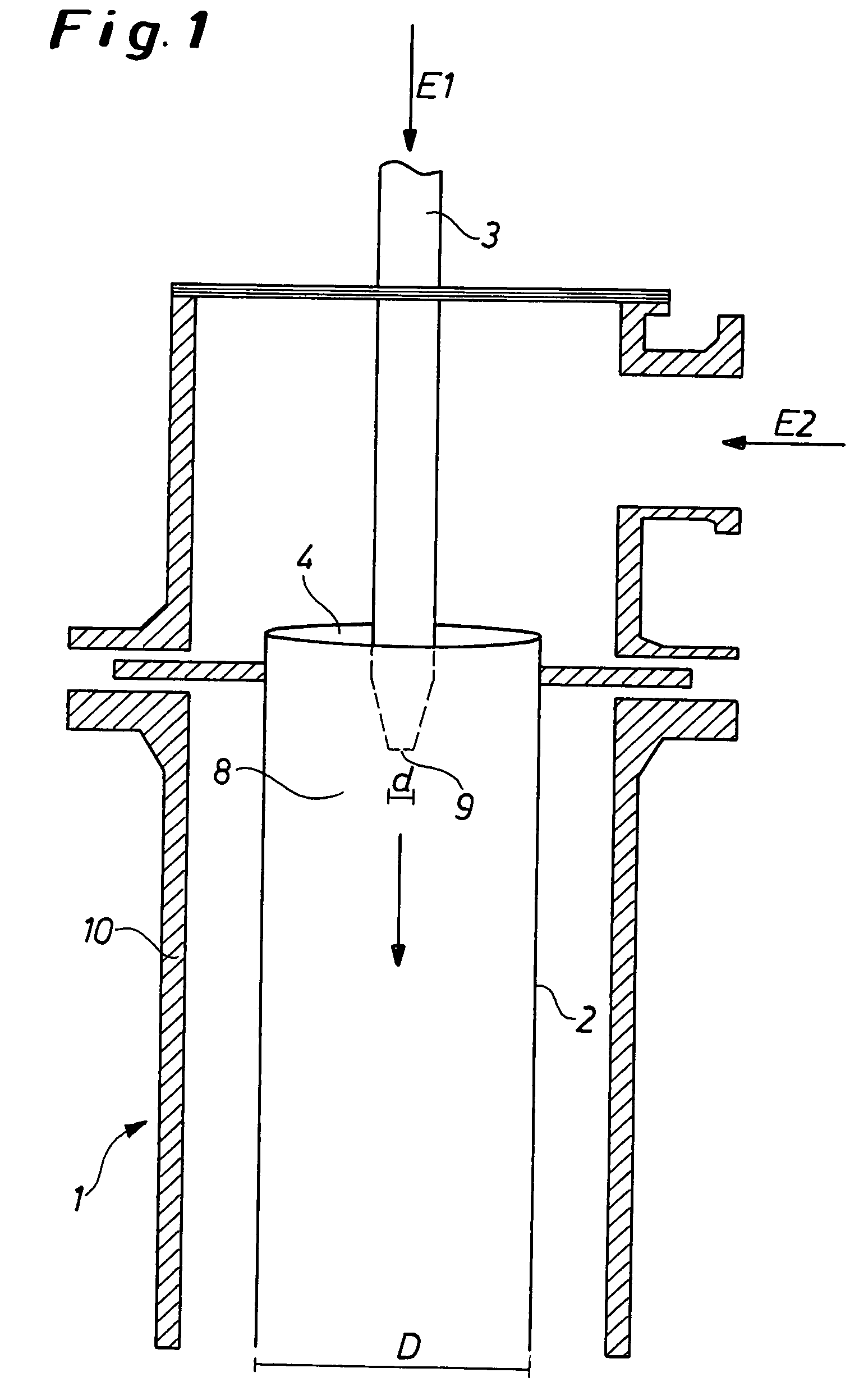

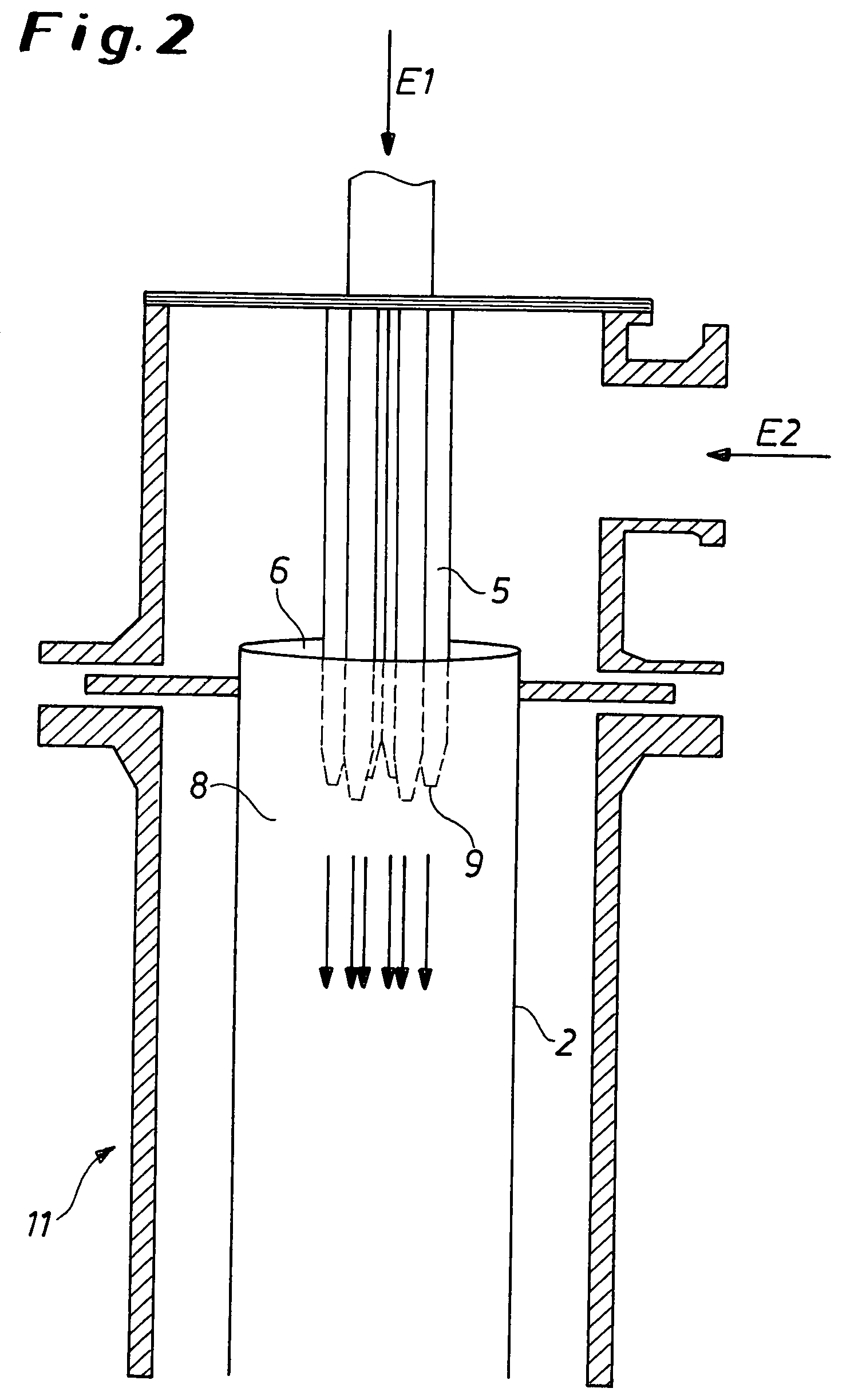

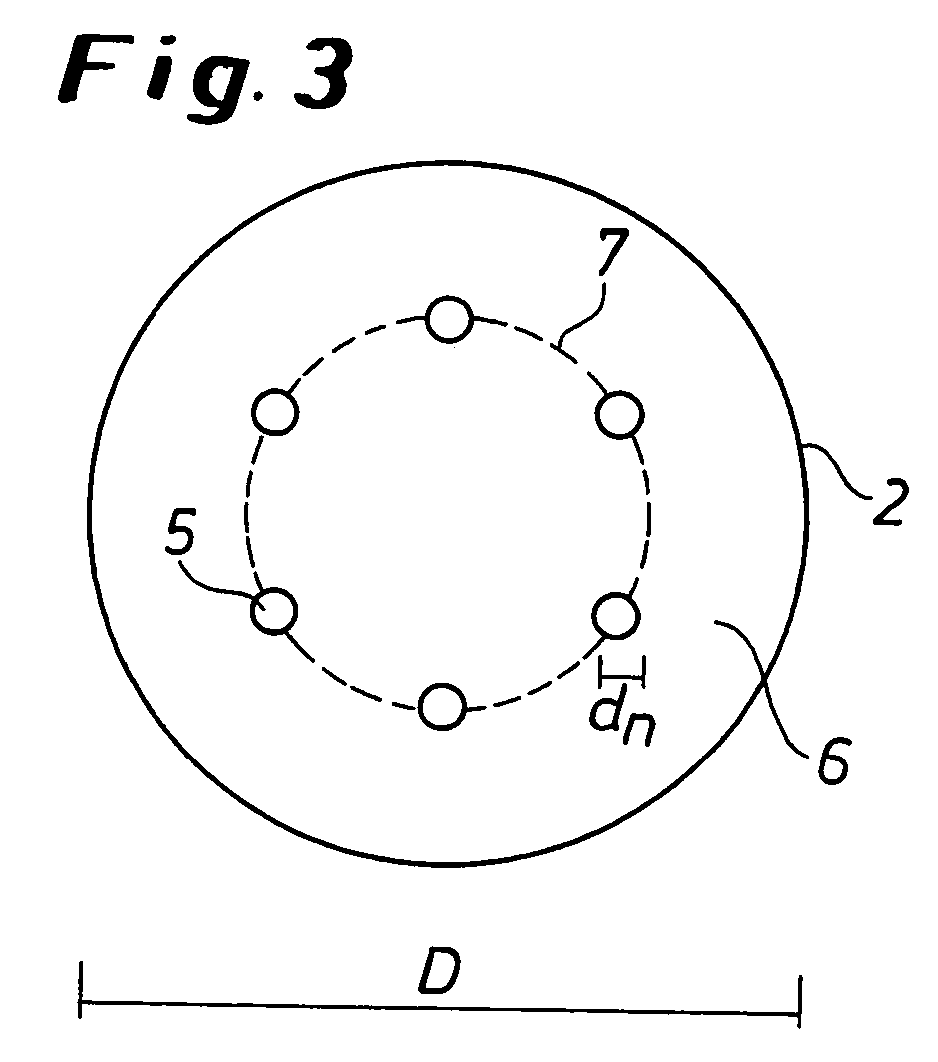

Process for the manufacture of (poly-)isocyanates in the gas phase

ActiveUS6974880B2High yieldShort mixing timeIsocyanic acid derivatives preparationLiquid-gas reaction as foam/aerosol/bubblesDiamineIsocyanate

The present invention relates to a process for the manufacture of diisocyanates by phosgenation of the corresponding diamines in which the vaporous diamines, optionally rarefied with an inert gas or with the vapors of an inert solvent, and phosgene are heated separately to temperatures of about 200° C. to about 600° C. and mixed and reacted in a tube reactor characterized in that a number n≧2 of nozzles directed parallel to the axis of the tube reactor are arranged in the tube reactor, the diamine-containing stream being fed into the tube reactor through the n nozzles and the phosgene stream being fed into the tube reactor through the remaining free space.

Owner:COVESTRO DEUTSCHLAND AG

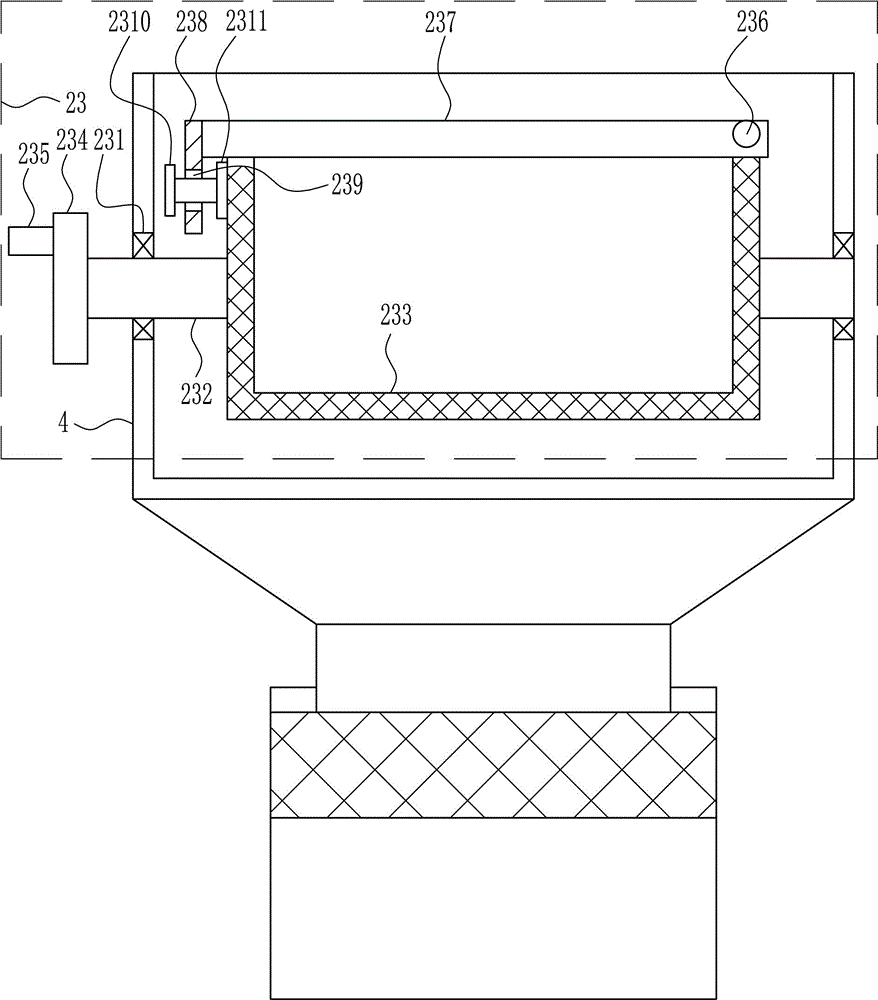

Full-automatic composite self-insulation building block production method

InactiveCN103612318AIncrease profitImprove thermal insulation performanceMixing operation control apparatusCeramic shaping plantsSocial benefitsFoaming agent

The invention discloses a full-automatic composite self-insulation building block production method. The full-automatic composite self-insulation building block production method includes distributing, building block forming, maintenance, supporting plate returning and product conveying. Distributing includes shell material distribution and thermal insulation material distribution. Shell materials are made of 15% of cement, 50% of coal cinders, 18% of sand, 10% of rubble and 7% of water. Thermal insulation materials are made of, by mass, 54% of PO42.5 cement, 10% of fly ash, 0.5% of foam stabilizer and fortifiers, 31.5% of water and 4% of foaming agents. The stirred raw materials are conveyed into a forming machine (4) so that forming can be carried out; a formed building block shell is conveyed into a maintenance kiln (8) to be maintained four hours; filling cores are poured, and the building block shell is conveyed into the maintenance kiln again to be maintained five to eight hours; maintained building blocks are piled, packaged and stacked. All the steps of the production method are coordinated, automatic control is achieved, and production efficiency is improved; the full-automatic composite self-insulation building block production method has good ecological benefit and social benefit.

Owner:连太吉 +3

Method for innocent treatment of arsenic sulfide residues

InactiveCN105963902ARealize harmless treatmentReduce arsenic leaching concentrationChemical protectionRoom temperatureArsenic sulfide

The invention discloses a method for harmless treatment of arsenic sulfide slag, which comprises the following steps: adding water to arsenic sulfide slag at room temperature, mixing to obtain mixture I, adding sodium sulfide to react to obtain mixture II, and then Add oxidant to carry out oxidation reaction to obtain mixture III, then add iron salt or aluminum salt for reaction to obtain mixture IV, and then add cement. The invention has the advantages of being able to effectively reduce the arsenic leaching concentration of the arsenic sulfide slag, the treated arsenic sulfide slag meets the requirements for hazardous waste landfill, simple process flow, small volume increase, strong operability, short stirring time, and low consumption.

Owner:云南大地丰源环保有限公司

Oxidation polysilacidiron coagulant and preparation thereof

InactiveCN1778701AImprove the efficiency of removing organic matter (especially dissolved organic matter)Improve the coagulation effectWater/sewage treatment by flocculation/precipitationSulfateSilicic acid

An oxidized polysilicate iron coagulating agent and its production are disclosed. The process is carried out by mixing activating silicic acid with low-polymerization degree with acid ferrous sulfate solution, adding into oxidant, additive and stabilizer, aging to obtain liquefied product or curing to obtain product. Its advantages include short period, better stability, simple process and good coagulating effect.

Owner:HARBIN INST OF TECH +2

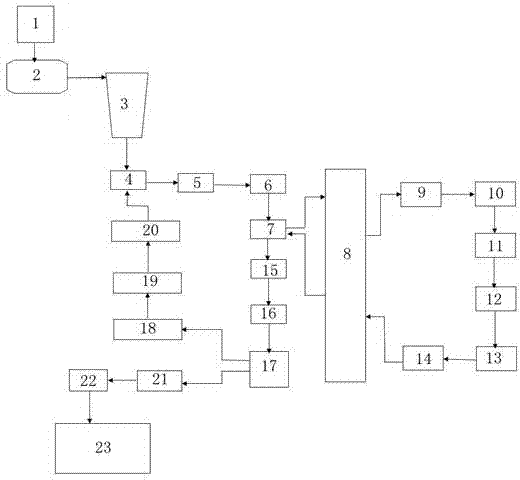

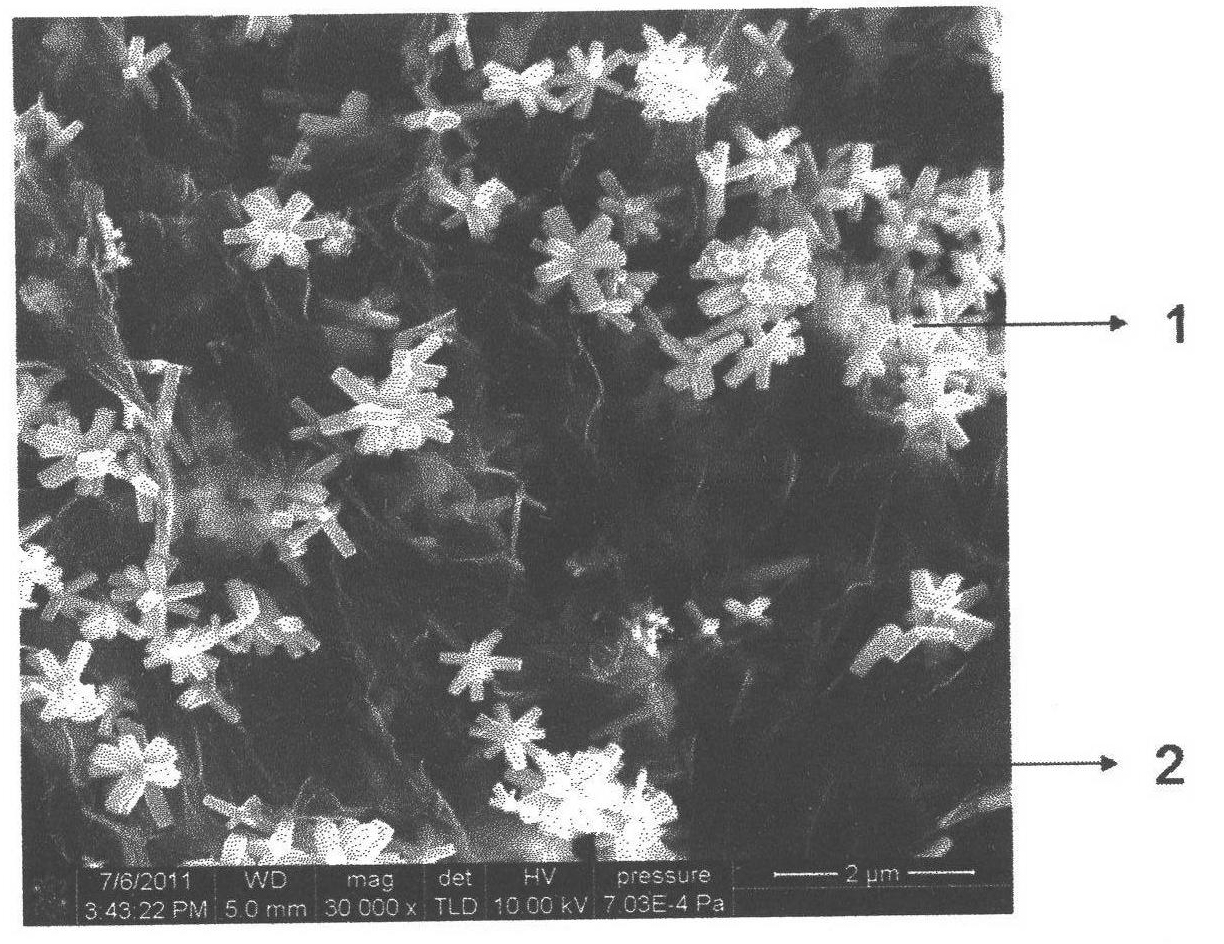

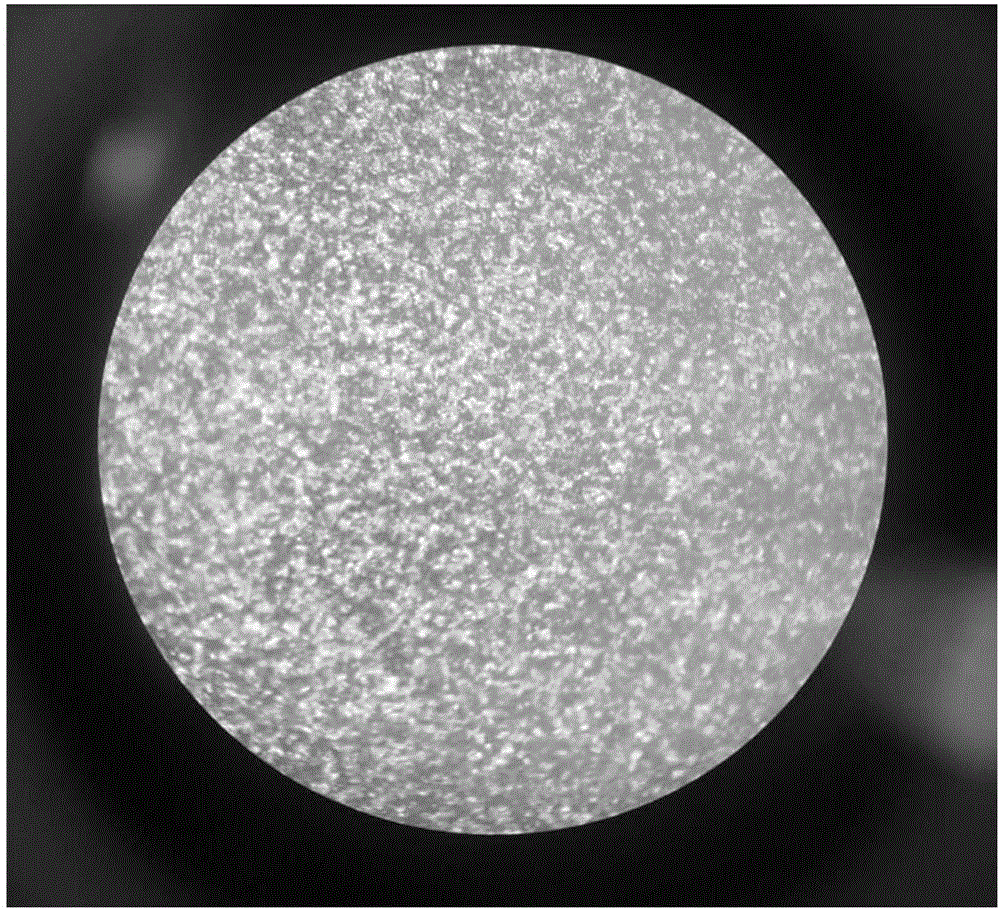

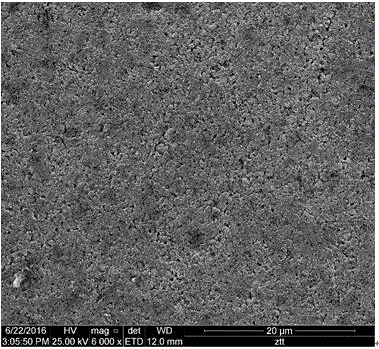

Preparation method of flower-like tin dioxide and graphene composite material

The invention discloses a preparation method of a flower-like tin dioxide and graphene composite material, belonging to the technical field of functional composite materials. According to the preparation method disclosed by the invention, the flower-like tin dioxide and graphene composite material with controllable morphology is prepared from graphene oxide, tin chloride pentahydrate and sodium hydroxide as raw materials by adopting the steps of mixed stirring, hydro-thermal synthesis, solid-liquid separation, cleaning and drying. The method disclosed by the invention has the advantages of simpleness, convenience for operation, lower production cost, no influence on the environment and convenience for popularization and application; and in the method, water is used as solvent and no surfactant is used. The flower-like tin dioxide and graphene composite material prepared by adopting the method can be widely applied to new energy source devices such as a lithium ion battery, a solar cell, a super capacitor and the like, or can be applied to the fields of catalyst carriers, information materials and the like.

Owner:CHONGQING UNIV

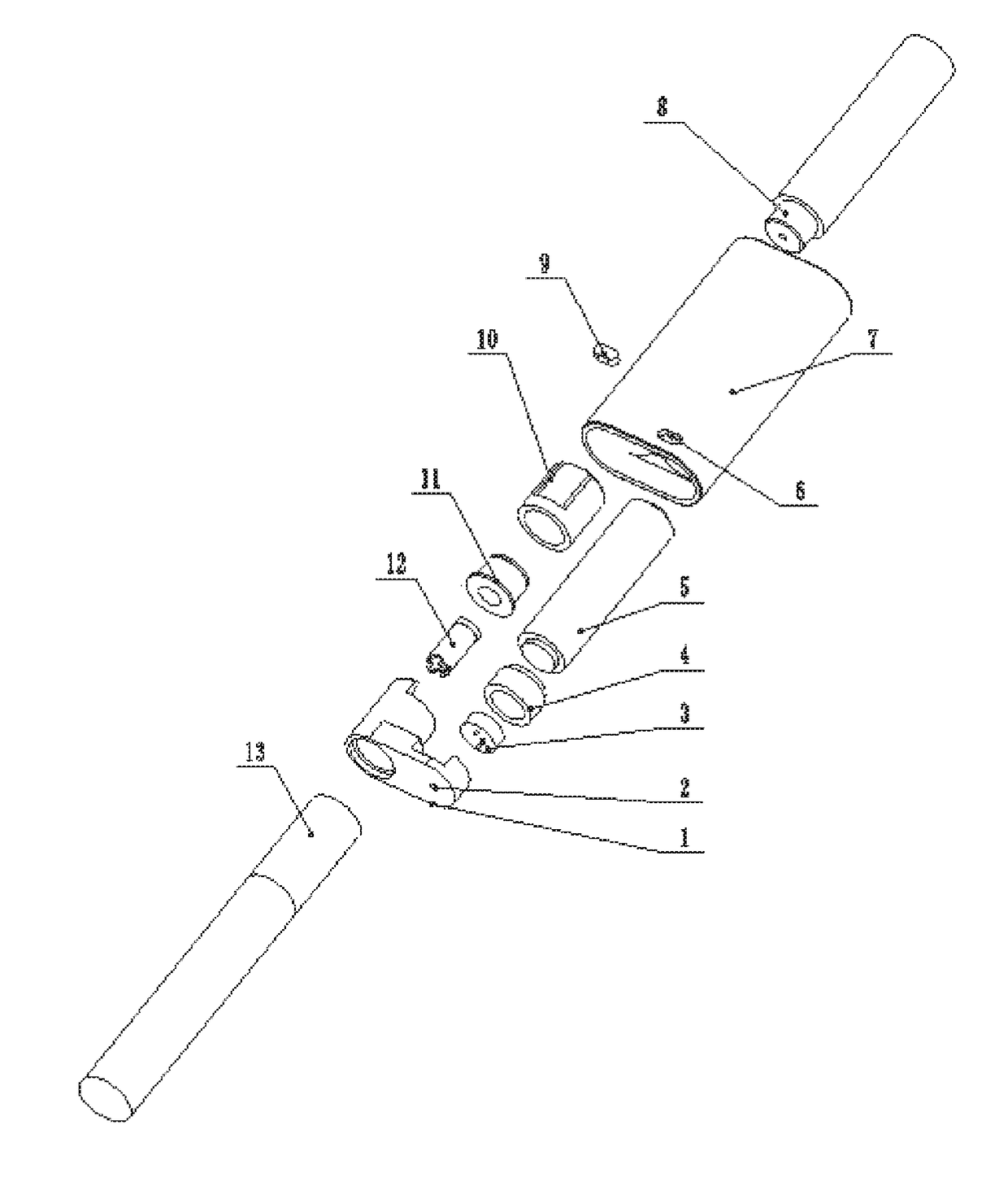

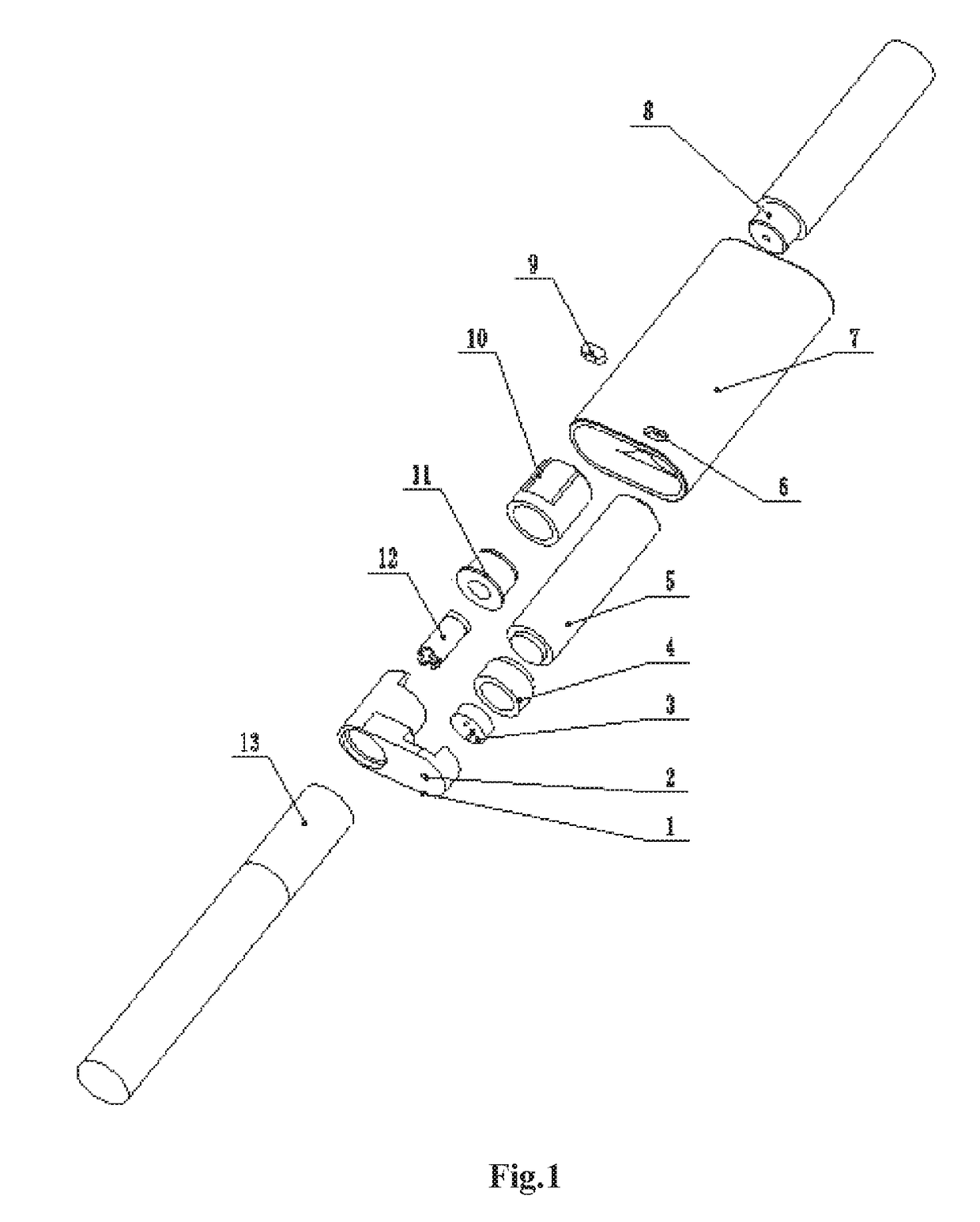

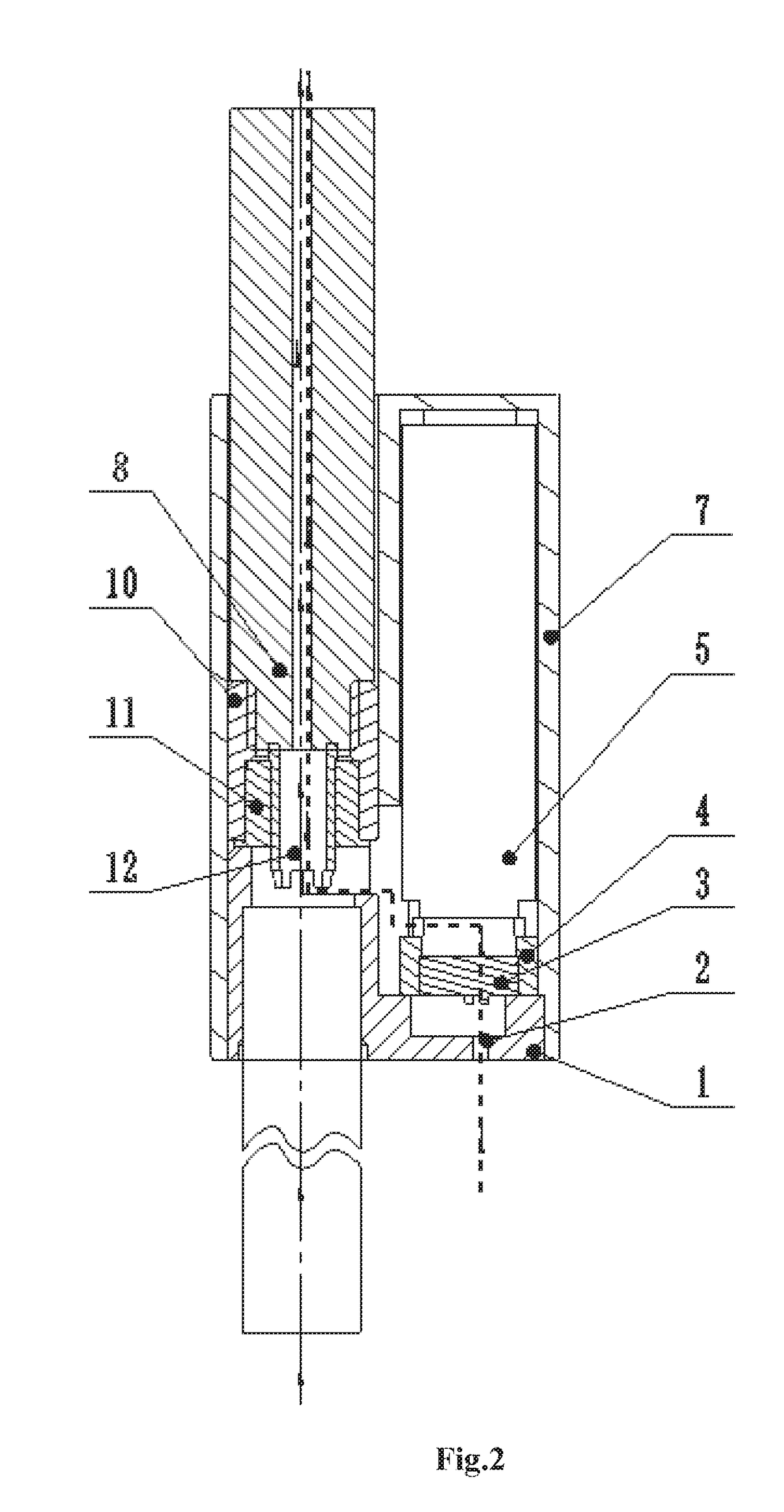

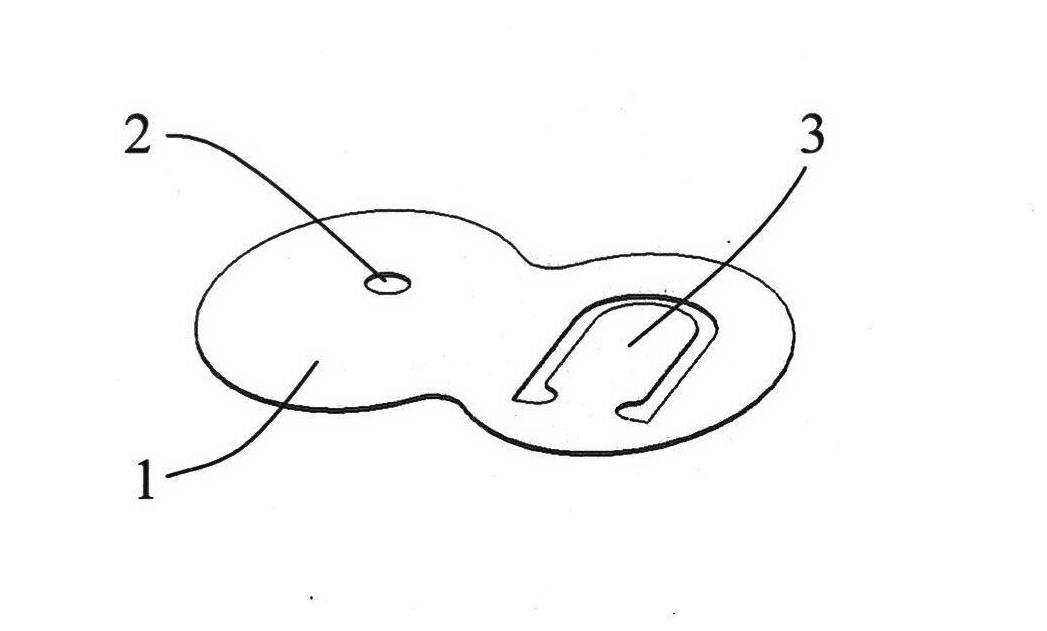

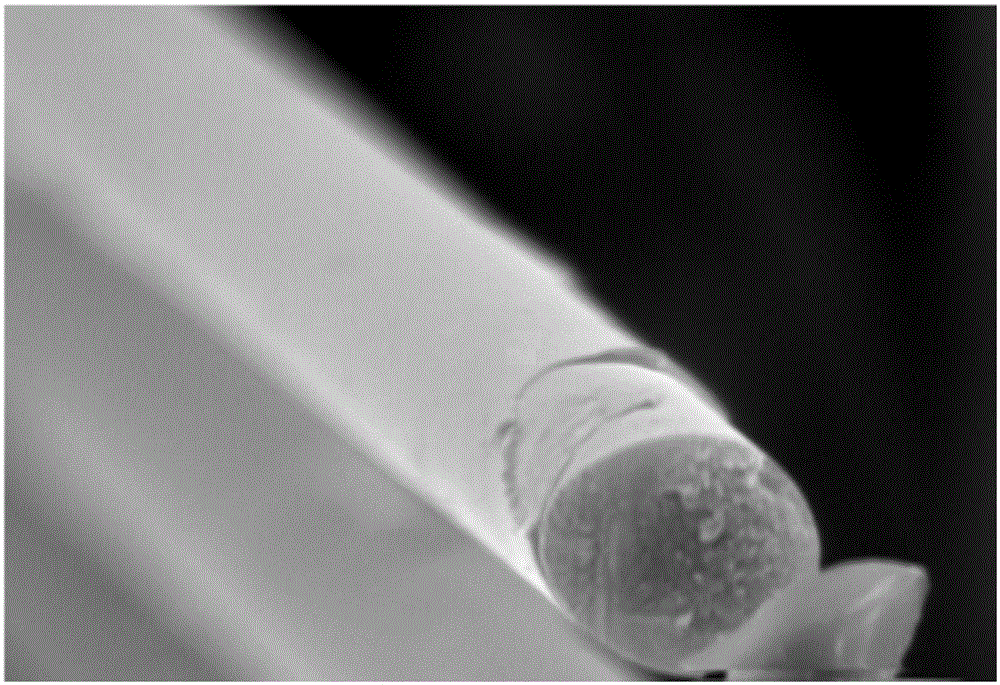

Cigarette smoking device having electronic atomization function and method for improving cigarette smoking quality

ActiveUS20180042299A1Reduce harmComplex extraction processTobacco pipesTobacco devicesEngineeringAirflow

The present invention relates to a cigarette smoking device having an electronic atomization function, including a cigarette holder and an electronic atomization component cooperatively assembled with one another, wherein the cigarette holder includes a cigarette holding cavity and an optional end cap for closing the open end of a shell; the electronic atomization component includes the shell and the following components located in the shell: a power supply, an airflow sensor switch and an atomizer provided with a central airflow channel; the cigarette holding cavity is in air communication with the central airflow channel of the atomizer; the cigarette smoking device further includes an airflow sensor switch air inlet penetrating the shell and / or the end cap of the cigarette holder. Also provided is a method for improving cigarette smoking quality, the method includes smoking after mainstream smoke generated by an end-lighting cigarette, dilution air and atomization vapor are mixed.

Owner:CHINA TOBACCO YUNNAN IND

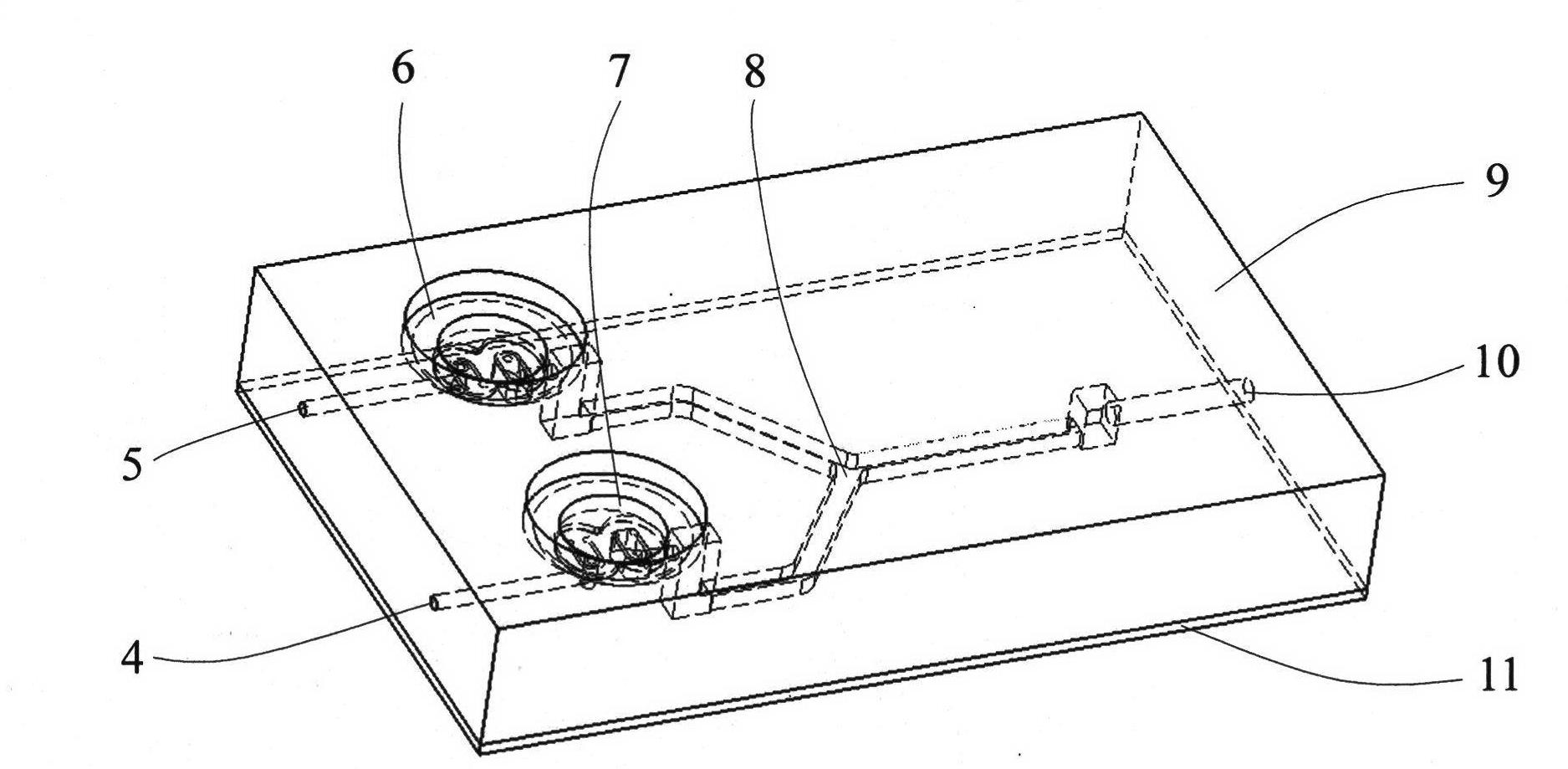

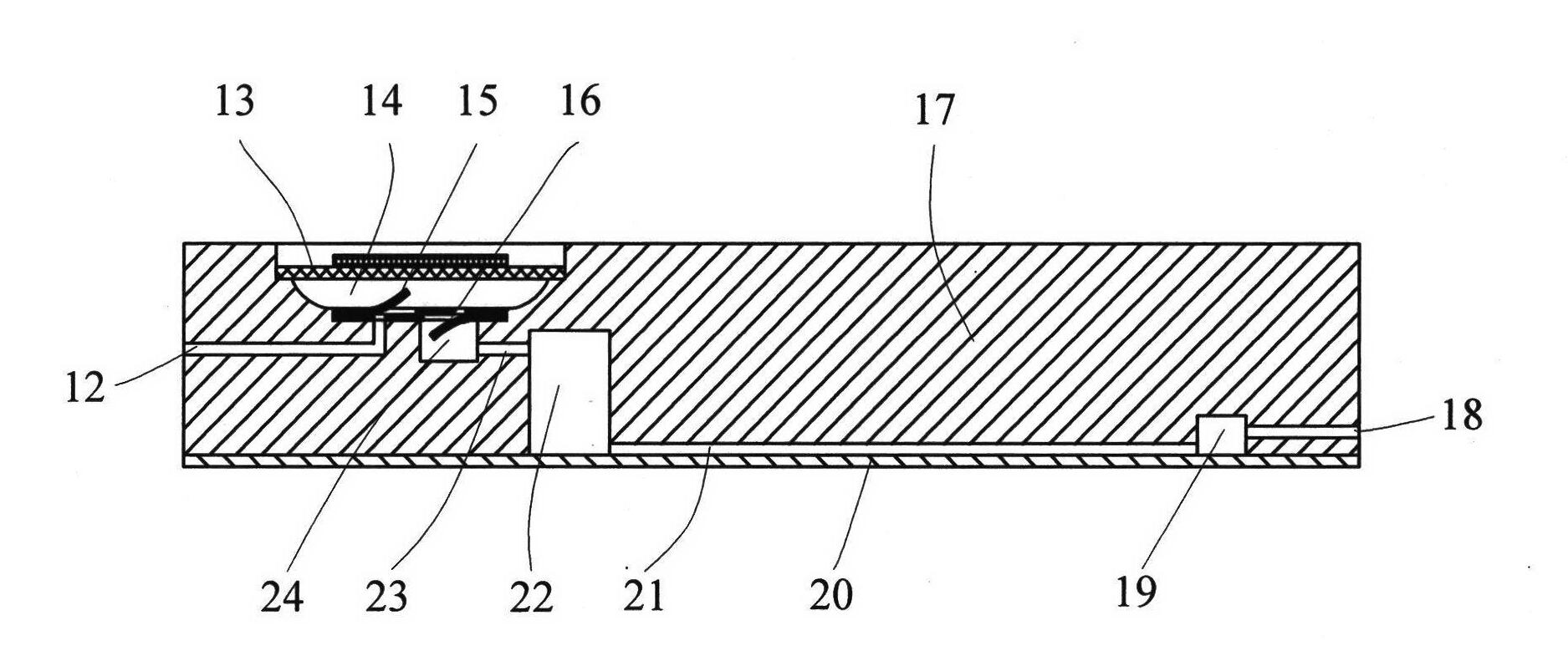

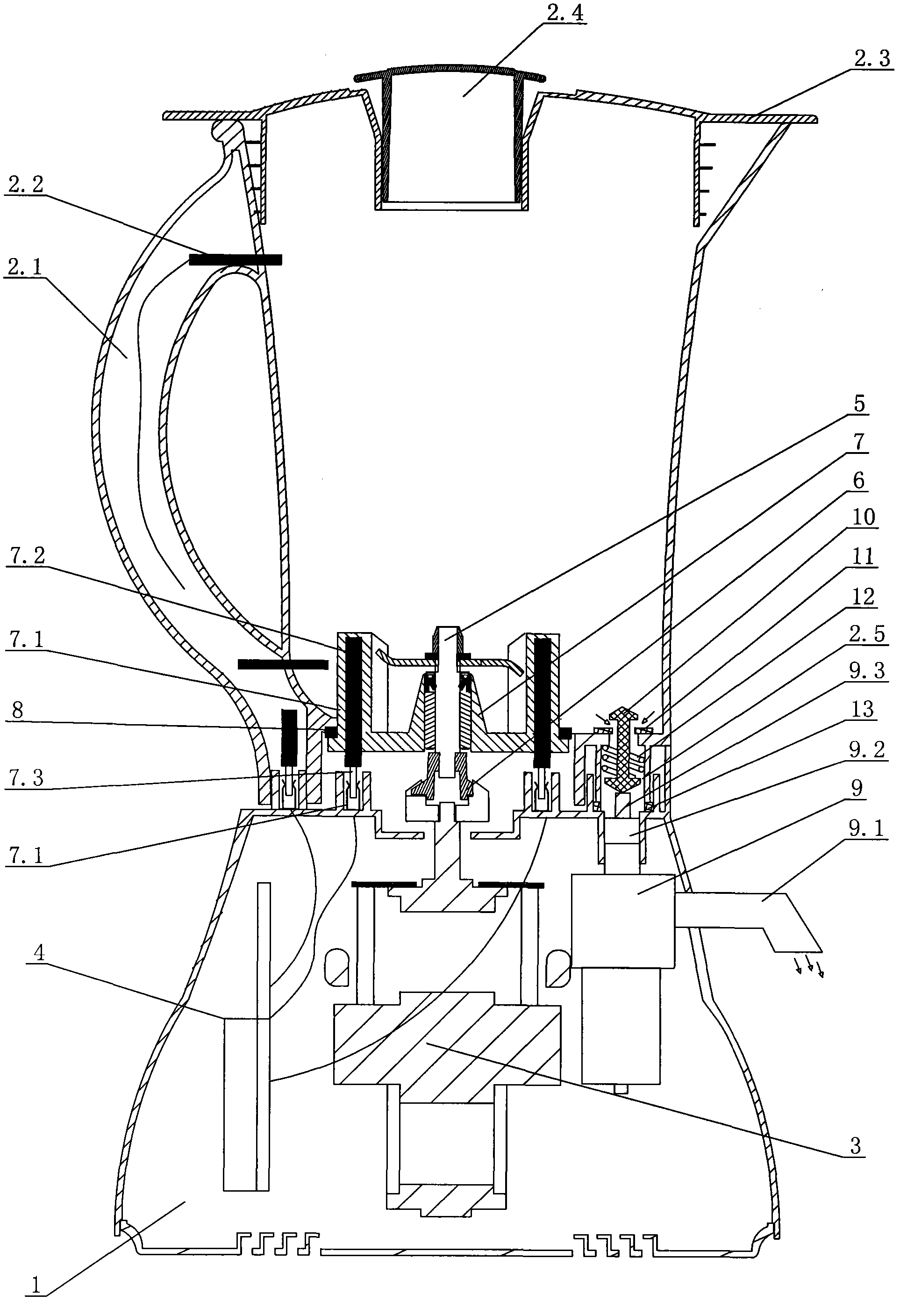

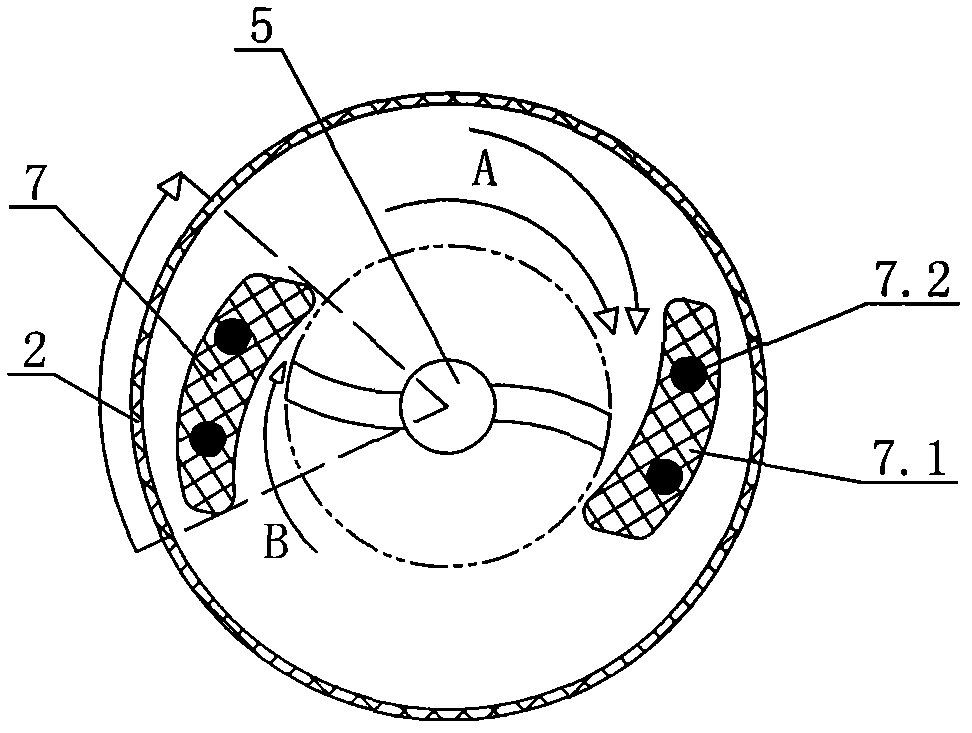

Piezoelectrically actuated micro-mixer, manufacturing method and control method of piezoelectrically actuated micro-mixer

InactiveCN102671572ALarge controllable rangeImprove mixing efficiencyMixer accessoriesPump controlElectricityEngineering

The invention discloses a piezoelectrically actuated micro-mixer, a manufacturing method and a control method of the piezoelectrically actuated micro-mixer, belonging to the technical field of a micro-mixer. With the adoption of the micro-mixer, a micro-fluid drive unit (namely a piezoelectric pump) and a micro-mixing unit (namely a mixing runner) are integrated into a whole via an overall PDMS (polydimethylsiloxan) substrate; a single chip piezoelectric vibrator and a one-way valve block are encapsulated together with the PDMS substrate to form the piezoelectric pump; a glass base plate is encapsulated together with the PDMS substrate to form the mixing runner; and the piezoelectric vibrator is stimulated by adopting different voltages, frequencies, different waveforms and phase staggered drive electric signals so as to achieve high-frequency pulsating displacement mixing of the micro-fluid in a micro-mixing runner. With the adoption of the piezoelectrically actuated micro-mixer, the defects of low mixing efficiency, long time and the like caused by that the micro-fluid is mixed by laminar diffusion under a micro-scale are effectively overcome, so that efficient turbulent mixing is realized. The piezoelectrically actuated micro-mixer disclosed by the invention has the advantages of being simple in manufacturing method, low in cost, high in mixing efficiency, short in time, small in volume and easy in integration, and capability of widely applying to the fields such as analytical chemistry, micro-chemical system, environment monitoring, life science and the like.

Owner:JILIN UNIV

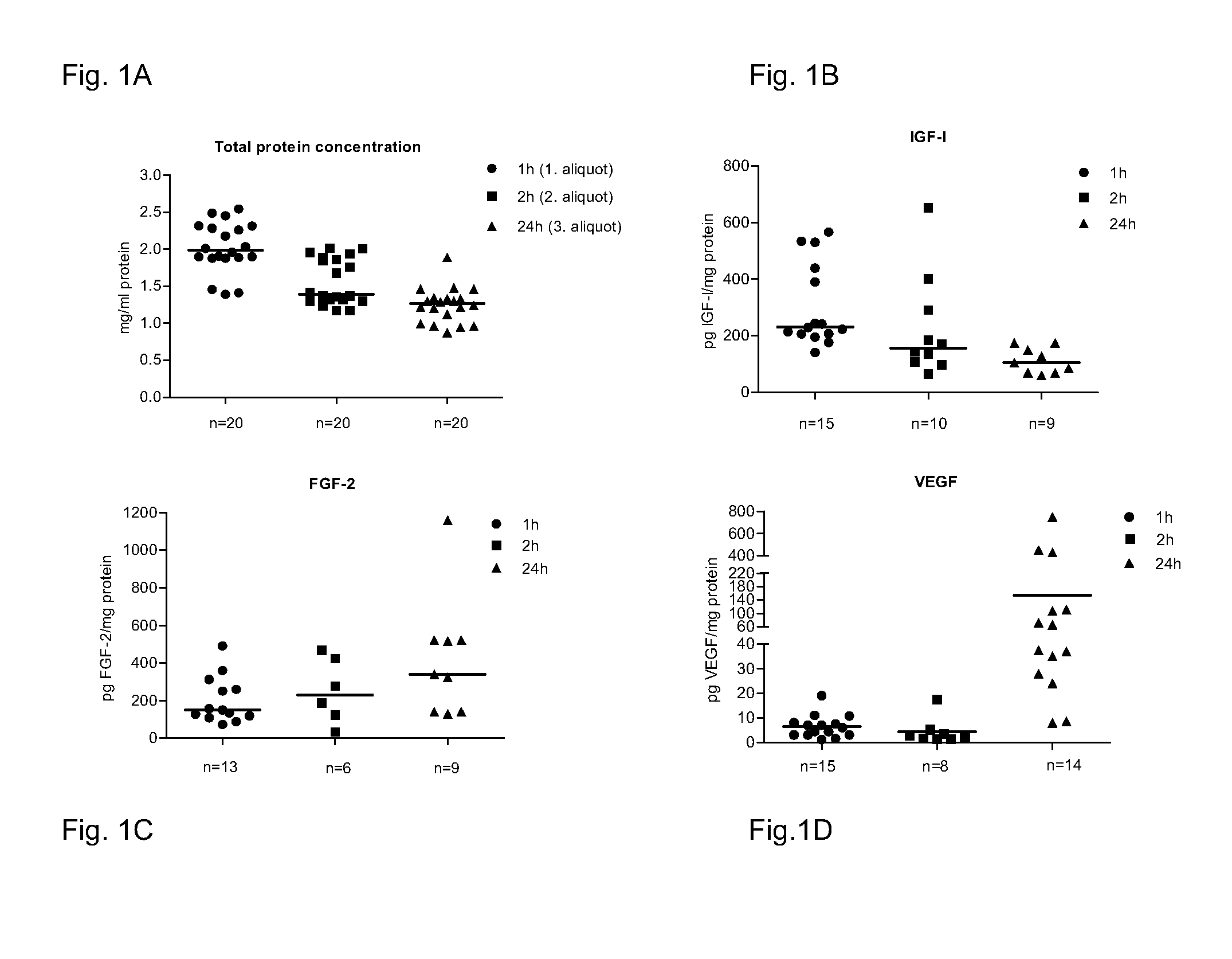

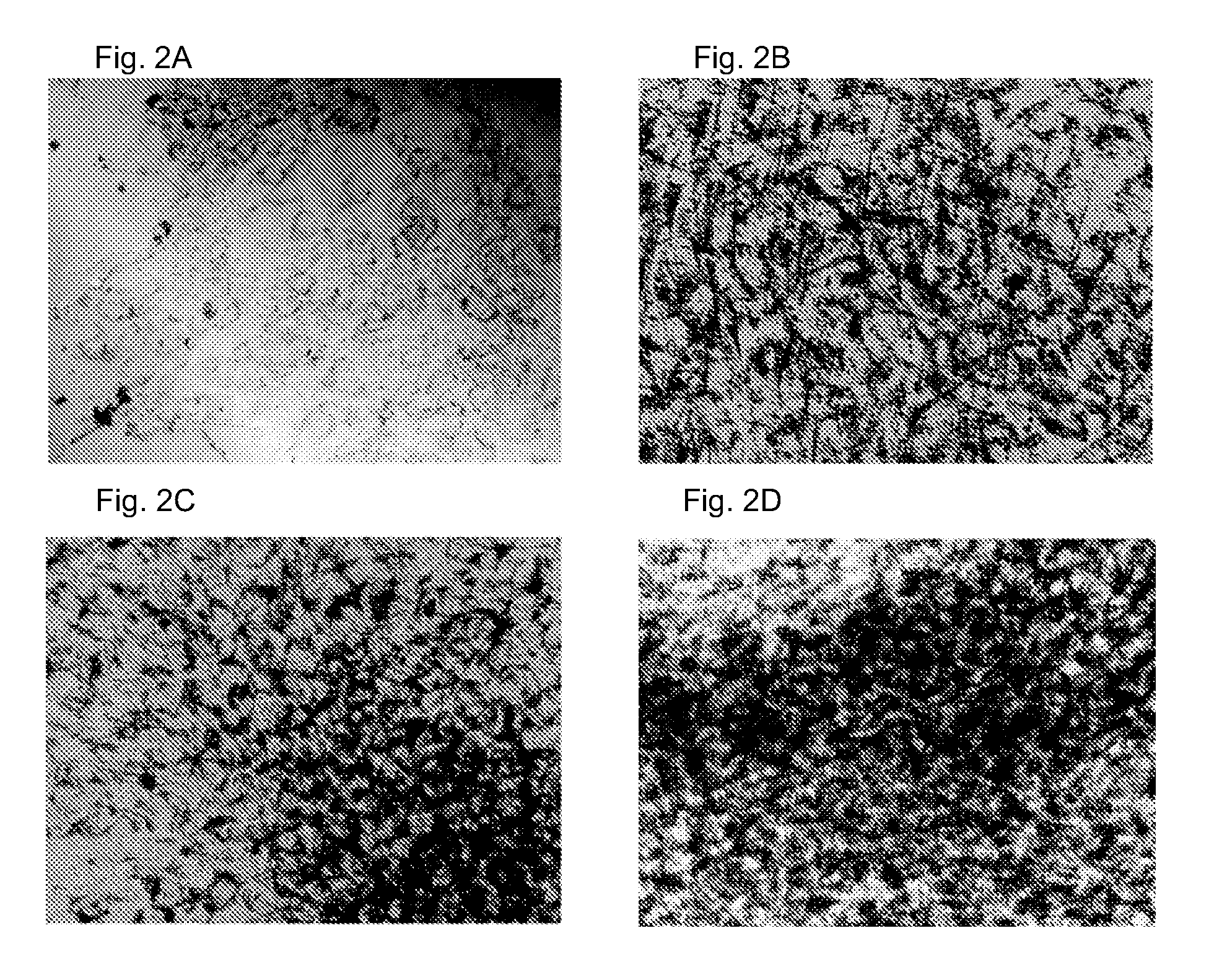

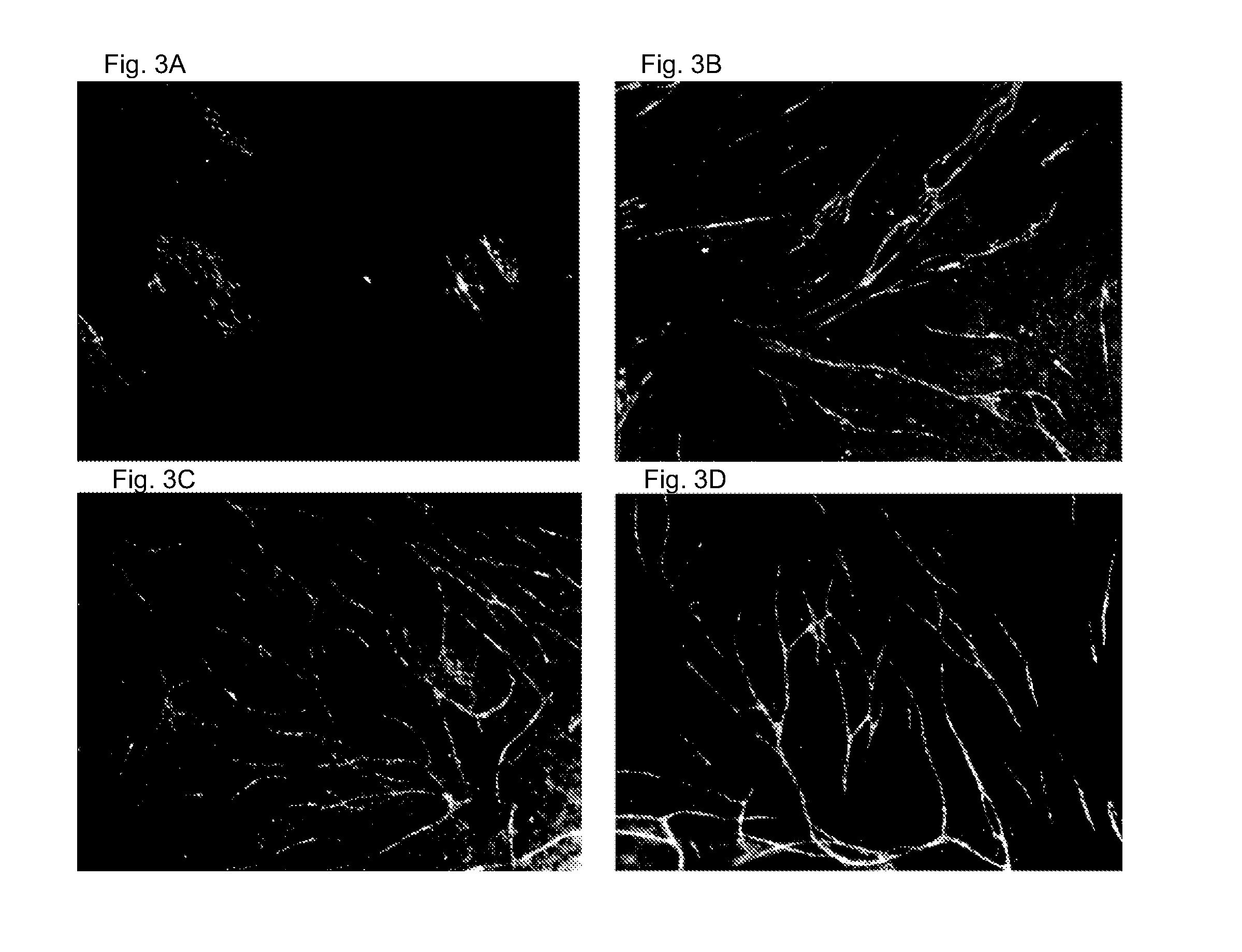

Methods and means for soft tissue engineering

ActiveUS20110151005A1Tailoring is fastShort incubation timePowder deliveryPeptide/protein ingredientsWound healingAdipogenesis

Cellfree adipose tissue extracts, implants including the same and methods for the preparation thereof. The extracts and implants are capable of inducing adipogenesis and angiogenesis and are, thus, useful in applications including soft tissue repair and engineering and angiogenesis induction, e.g., in wound healing, treatment of burn injuries and ischemic conditions.

Owner:LINIO BIOTECH OY

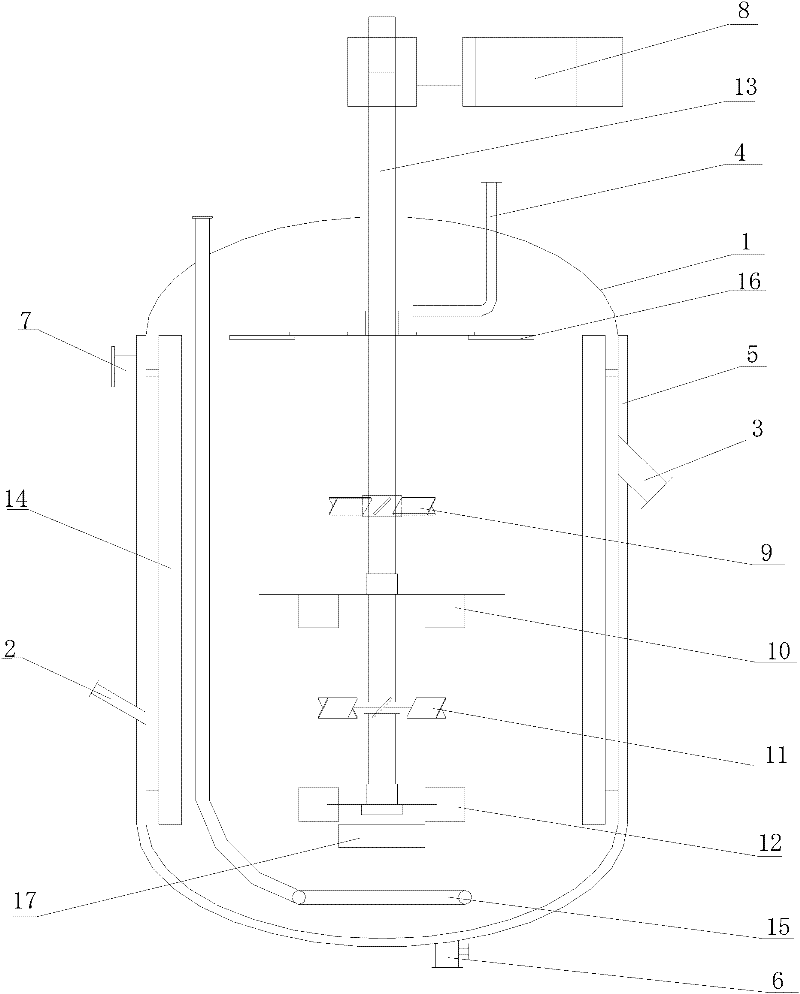

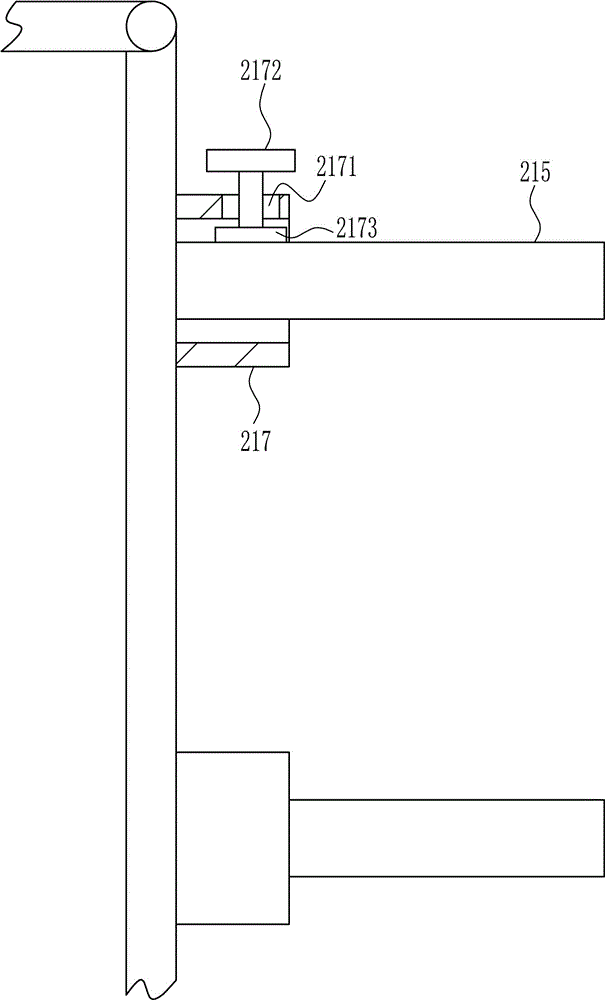

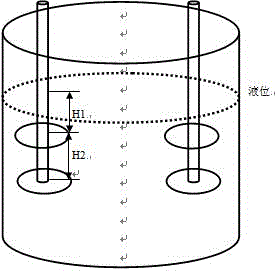

Efficient rare earth extracting device for rare earth processing

ActiveCN106834672AShort mixing timeImprove efficiencyProcess efficiency improvementRare earthMaterials science

The invention relates to a rare earth processing device and especially relates to an efficient rare earth extracting device for rare earth processing. The technical problem to be solved by the invention is to provide the efficient rare earth extracting device for rare earth processing, with capability of simultaneously stirring multi-batch materials, shorter stirring time and higher efficiency. In order to solve the technical problem, the efficient rare earth extracting device for rare earth processing, provided by the invention, comprises a base plate, a settling tank, a filter screen, a first funnel, a support plate, a first connecting rod, a first bearing base, stirring boxes, a second bearing base, a first rotating rod and a first gear, wherein the settling tank is arranged on a middle part on the upper side of the base plate in the manner of bolt connection, and the filter screen is arranged on the upper side in the settling tank in the manner of bolt connection. The efficient rare earth extracting device for rare earth processing can achieve the effects of capability of simultaneously stirring multi-batch materials, shorter stirring time and higher efficiency. A first guide sleeve and a first guide rail are adopted for loading a plurality of stirring boxes for stirring.

Owner:平湖市宸信机械有限责任公司

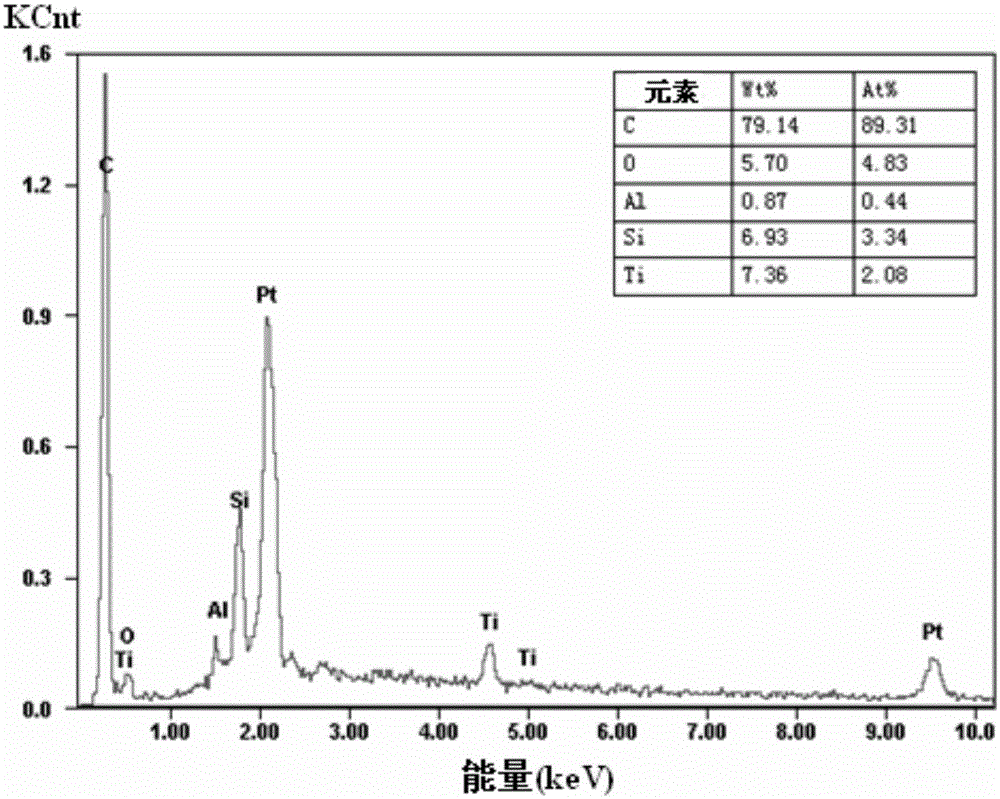

Method for preparation of antioxidant composite coating on carbon fiber surface

ActiveCN105113213ASimple preparation processReduced total preparation timeCarbon fibresFiberCarbon fibers

The invention relates to a method for preparation of an antioxidant composite coating on a carbon fiber surface. The antioxidant composite coating is an Al2O3-SiO2-TiO2 composite coating. The method is sol-gel method, which includes: composite sol preparation, carbon fiber surface activation treatment, coating, drying and heat treatment. The composite sol is prepared under room temperature, and the preparation process includes: firstly preparing a water-alcohol solution of tetraethyl orthosilicate and acetic acid into a mixed solution A, then pouring the mixed solution A into an alcohol solution of butyl titanate to prepare a mixed solution B, then under stirring, pouring an alcohol solution of aluminum nitrate nonahydrate into the mixed solution B to prepare a mixed solution C, finally adding an alcohol-water mixed solvent into the mixed solution C, and performing stirring to obtain the composite sol. With the ternary composite sol prepared by the method provided by the invention, a uniform and complete antioxidant coating with good adhesion and thickness within 3 micrometers can be prepared on the carbon fiber surface.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

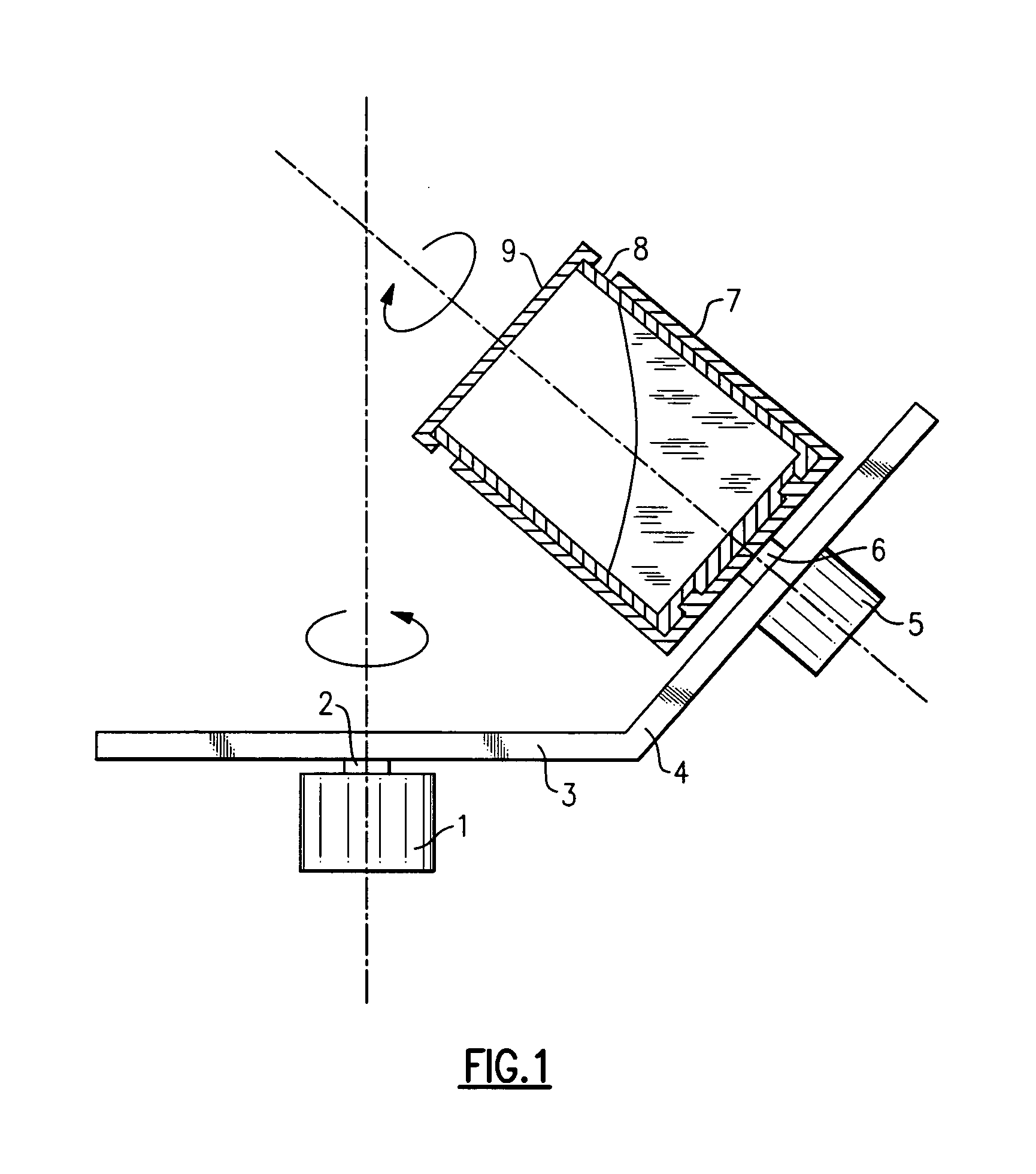

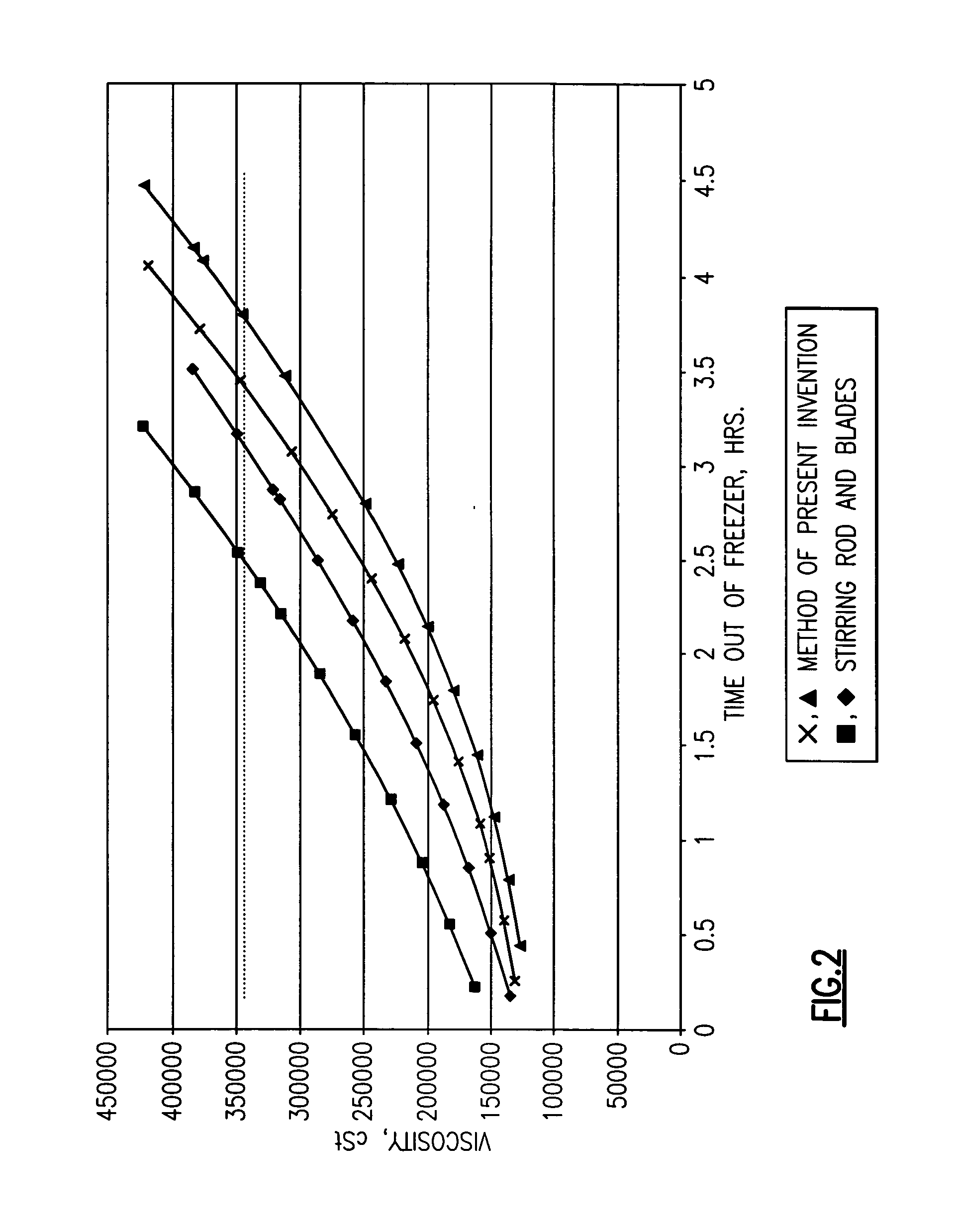

Method of producing mixtures of thermally labile materials

InactiveUS20070002680A1Extend working lifeShort mixing timeRotating receptacle mixersShaking/oscillating/vibrating mixersMaterials scienceHeat labile

Owner:BAUSCH & LOMB INC

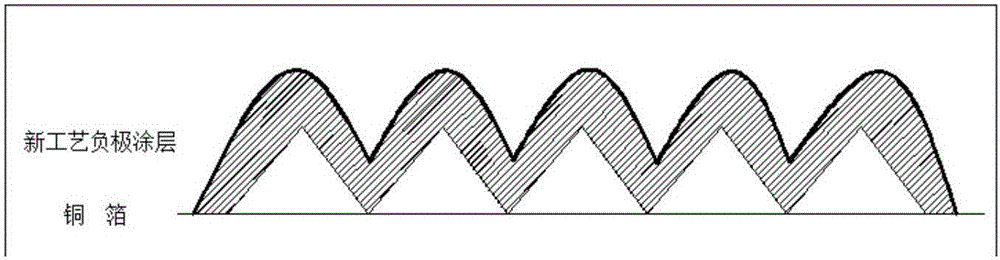

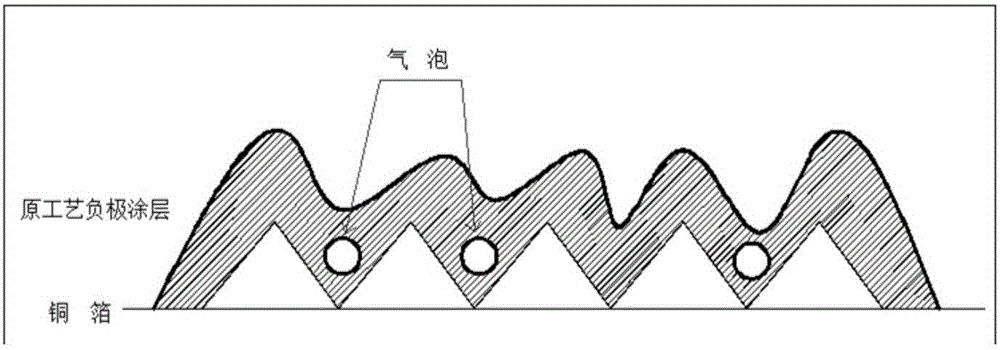

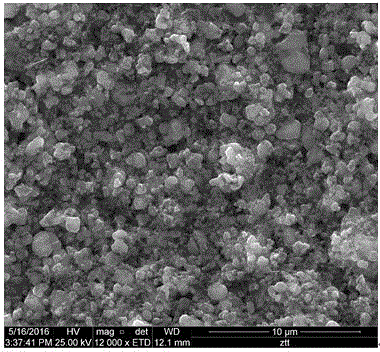

Preparation method of lithium ion power battery cathode

ActiveCN106848205AImproved mixing schemeShorten mixing timeElectrode collector coatingSodium carboxymethylcelluloseButadiene-styrene rubber

The invention relates to the field of power lithium ion batteries, in particular to a preparation method of a lithium ion power battery cathode. The preparation method comprises the following steps: first preparing sodium carboxymethylcellulose glue solution in a number 1 stirring machine, adding conducting carbon black and dry graphite powder in a number 2 stirring machine, uniformly mixing, and then adding the sodium carboxymethylcellulose glue solution in the number 1 stirring machine into the number 2 stirring machine; and adding little alcohol, vacuumizing, defoaming, adding styrene-butadiene latex, mixing, finally vacuum defoaming, and obtaining the lithium ion power battery cathode material. By improving a stirring scheme, the stirring time of the cathode slurry is shortened, the moisturizing coating performance of the cathode slurry is improved, and a bubble-free purpose is achieved.

Owner:HEFEI HENGNENG NEW ENERGY TECH

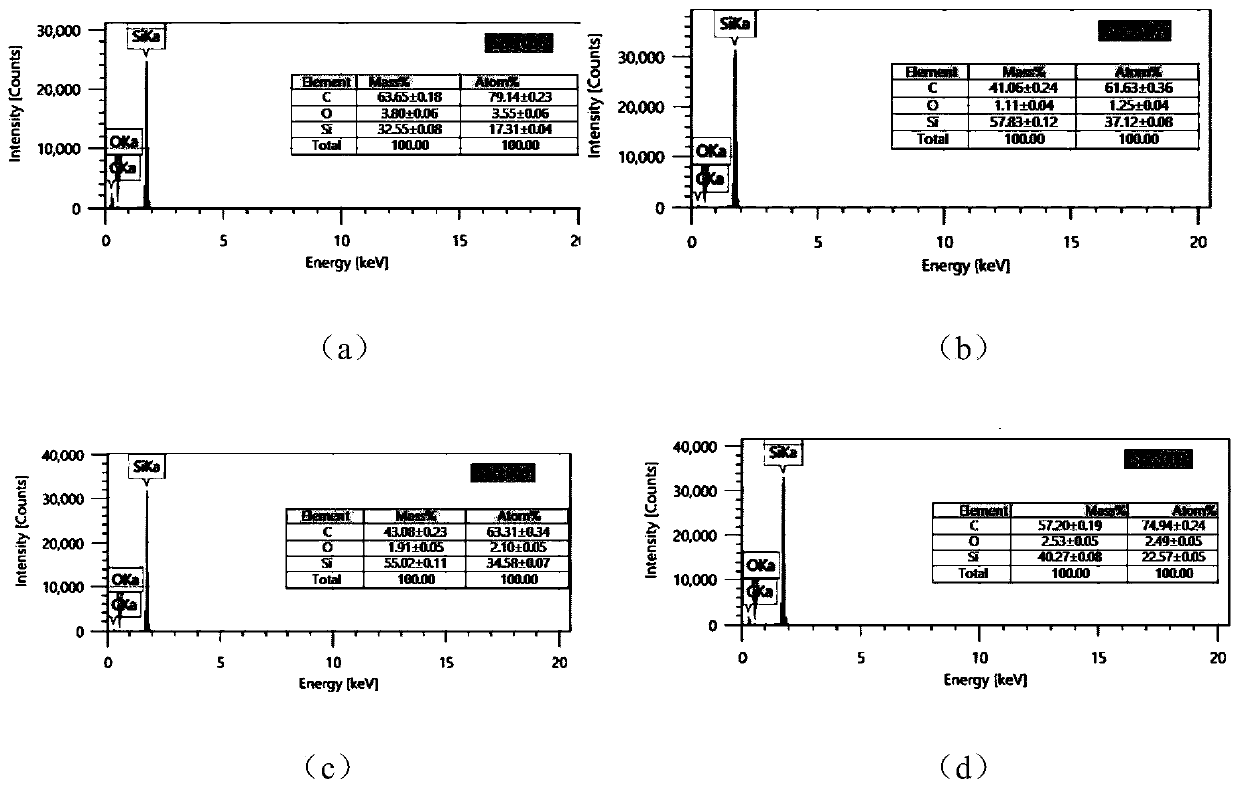

Silicon carbide ceramic paste for photocuring and preparation method thereof

InactiveCN110451985AImprove curing depthReduce clumpingAdditive manufacturing apparatusCeramic sinteringDispersity

The invention discloses silicon carbide ceramic paste for photocuring and a preparation method thereof. The paste is prepared by mixing SiC mixed powder, a dispersing agent, a monomer, a compatilizerand a photoinitiator, wherein the surface of the SiC mixed powder is coated with a SiO2 layer, so that the refractive index difference between the final paste and light-cured resin is reduced, and then printing efficiency is further improved. SiO2 can improve the solid phase content of the whole slurry, so that the sintering density of sintered ceramic and the mechanical property of finally formedceramic can be improved during subsequent ceramic sintering. Through addition of the dispersing agent into the slurry, the agglomeration phenomenon of the slurry can be reduced, the dispersity is improved, and the solid phase content of the whole slurry can be increased. Verification finds that the solid phase content in the paste can finally reach 40%-60%.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

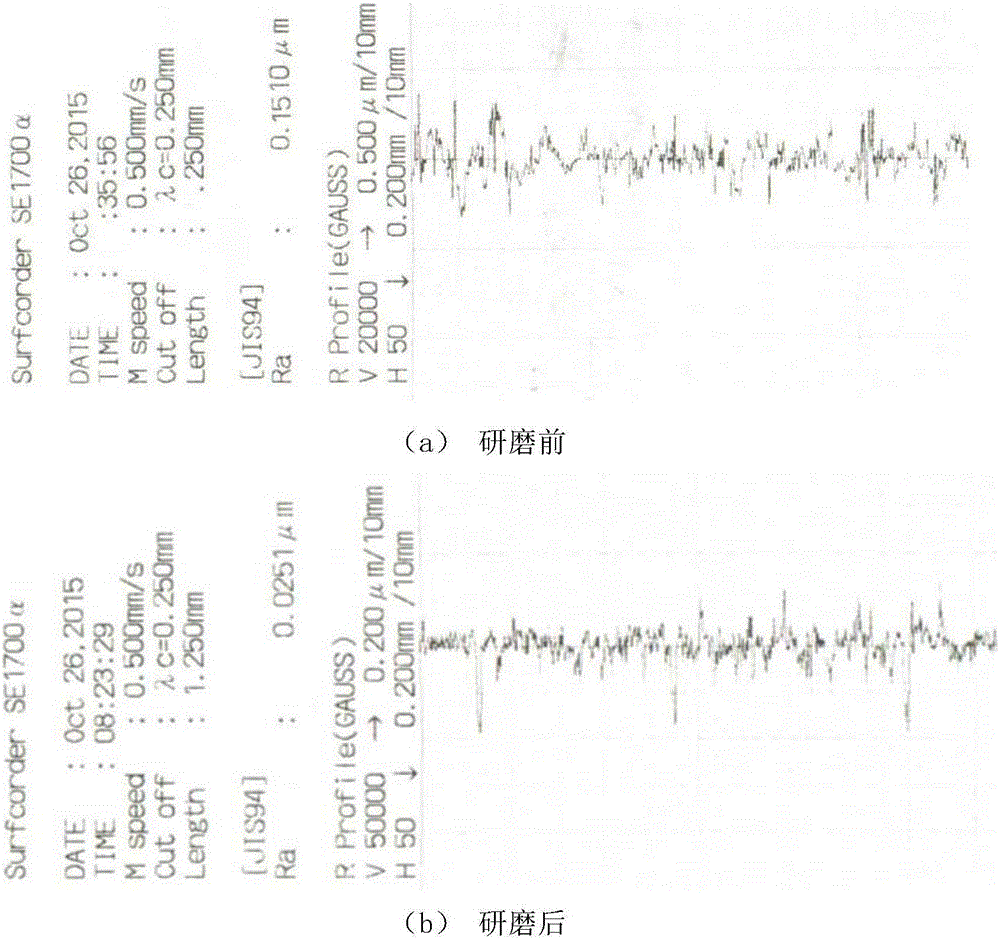

Grinding tool of rubber resin compound binding agent and preparation method of grinding tool

InactiveCN106826591AImprove heat resistanceImprove toughnessAbrasion apparatusGrinding devicesPorosityHeat resistance

The invention discloses a wet-process blended rubber resin composite binder abrasive tool and a preparation method thereof. The abrasive tool is composed of the following components: by weight, 25-100 parts of abrasive grains, 5-30 parts of rubber bond, 10-35 parts of resin bond, 15-55 parts of filler, 20-50 parts of solvent, 1-30 parts of wetting agent 3 parts, 0.5-3 parts of pore-forming agent, 0.1-1 part of curing agent. The rubber resin composite binder mixture is obtained by wet blending the rubber powder and the resin powder in a solvent, and the obtained rubber resin composite binder mixture is mixed with abrasives, fillers and pore-forming agents, dried, pulverized, and sieved to obtain The mixed powder is added with a curing agent and then hot-pressed and solidified to prepare a rubber resin composite binder abrasive tool. The abrasive tool combines rubber and resin organically to make a composite bond that has both advantages and avoids the disadvantages of both. It has good heat resistance and corrosion resistance, large porosity, easy to maintain contour, high strength and high elasticity. , At the same time, wet blending is adopted, the mixing is more uniform, and it is not easy to agglomerate.

Owner:QUZHOU UNIV

Multifunctional heating stirrer

The invention relates to a multifunctional heating stirrer, which comprises a stirring cup arranged on a main body in a split manner, wherein a motor and a control device is arranged in the main body, the motor is coupled and connected with a stirring cutter assembly of the stirring cup through a transmission assembly, the bottom of the stirring cup is provided with an opening, a compression guide flow heater is connected to the bottom of the opening, at least two group of guide flow blocks extending into the stirring cup is arranged on the compression guide flow heater, the feeding channel of the guide flow blocks and the stirring cutter assembly is gradually narrowed, heating pipes are arranged inside the guide flow blocks, and a water pump assembly is arranged in the main body and can be detachably connected with the stirring cup. During the working, under the action of the guide flow blocks, liquid food in the stirring cup generates turbulence along the stirring direction of the stirring cutter assembly and is compressed, so that the stirring effect of the stirrer is greatly improved; and the heating pipes are arranged in the guide flow blocks, the liquid food in the stirring cup can be heated and boiled, a user can pour liquid in the stirring cup without taking down the stirring cup, and conveniently drinks the liquid foods.

Owner:周林斌

Dispersion method for positive electrode slurry of lithium ion battery

The invention discloses a dispersion method for positive electrode slurry of a lithium ion battery. The dispersion method comprises the following steps in sequence: pre-preparing a water system or oil system adhesive solution at certain concentration through an adhesive making tank; adding the adhesive solution, a conductive agent, a dispersing agent and a solvent into a stirring bucket, performing full pre-mixing by a high-speed dispersing machine to obtain a pre-dispersed solution; adding a positive electrode active material in two times, performing pre-mixing in the first time, and performing high-speed dispersing and mixing after adding in the second time, performing high-speed dispersing for a certain time to obtain a high-viscosity dispersing turbid liquid; and adding a certain amount of solvent to further perform high-speed dispersing until the slurry reaches proper viscosity and solid content to obtain the positive electrode slurry with excellent performance and to complete the overall process. By making full advantage of a mechanical relation between high-viscosity heterogeneous fluids, and by adopting the simple and convenient method, the dispersing effect of a stirrer is given into full play, uniform applying of shearing force on super-fine powder in the slurry in the stirring process is promoted, the stirring time is saved, and the uniformity, the stability and the consistency of the slurry are improved.

Owner:ZHONGTIAN ENERGY STORAGE TECH

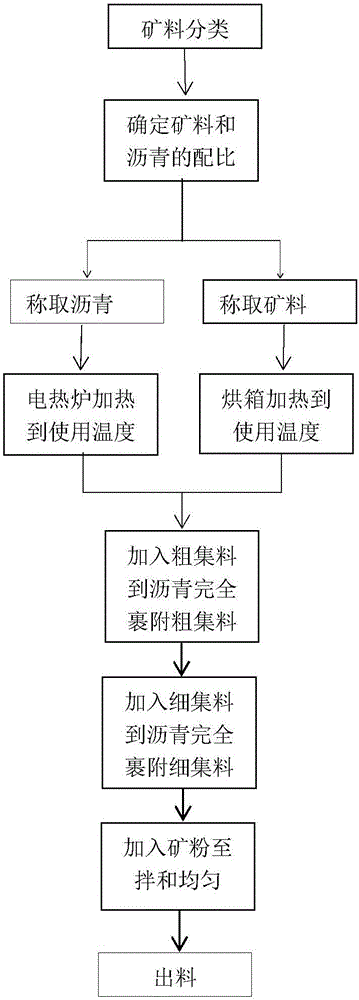

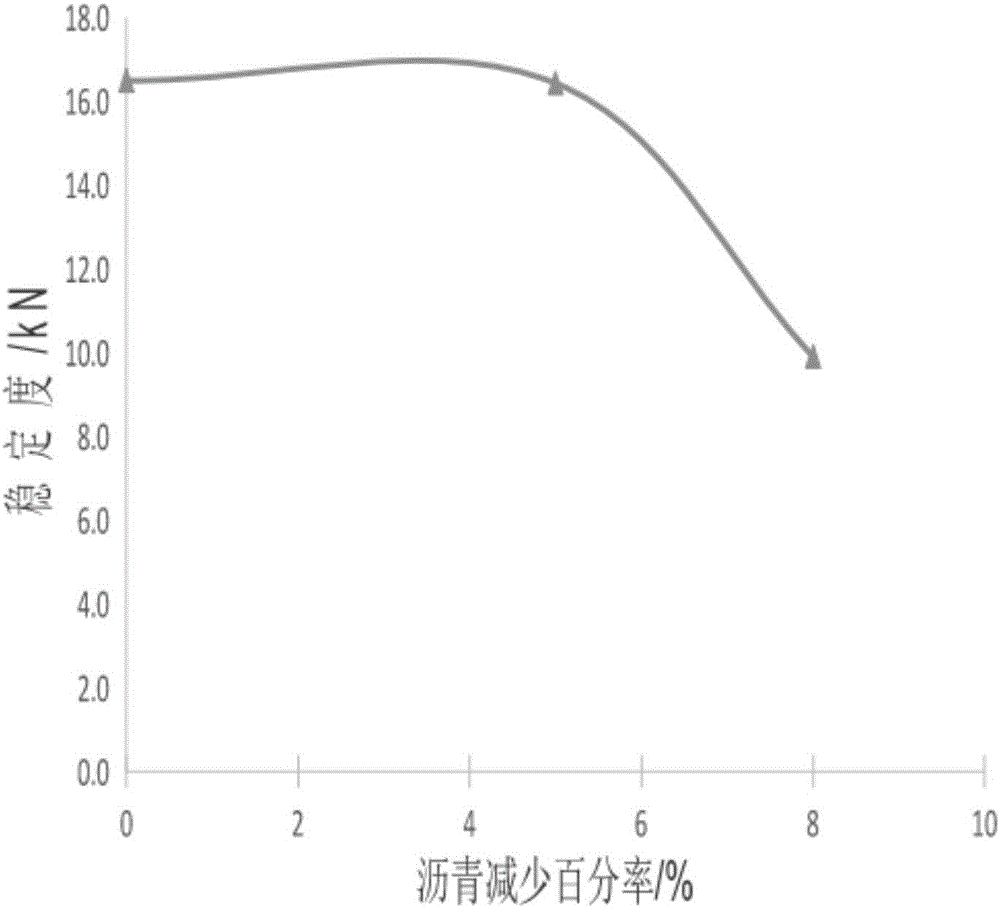

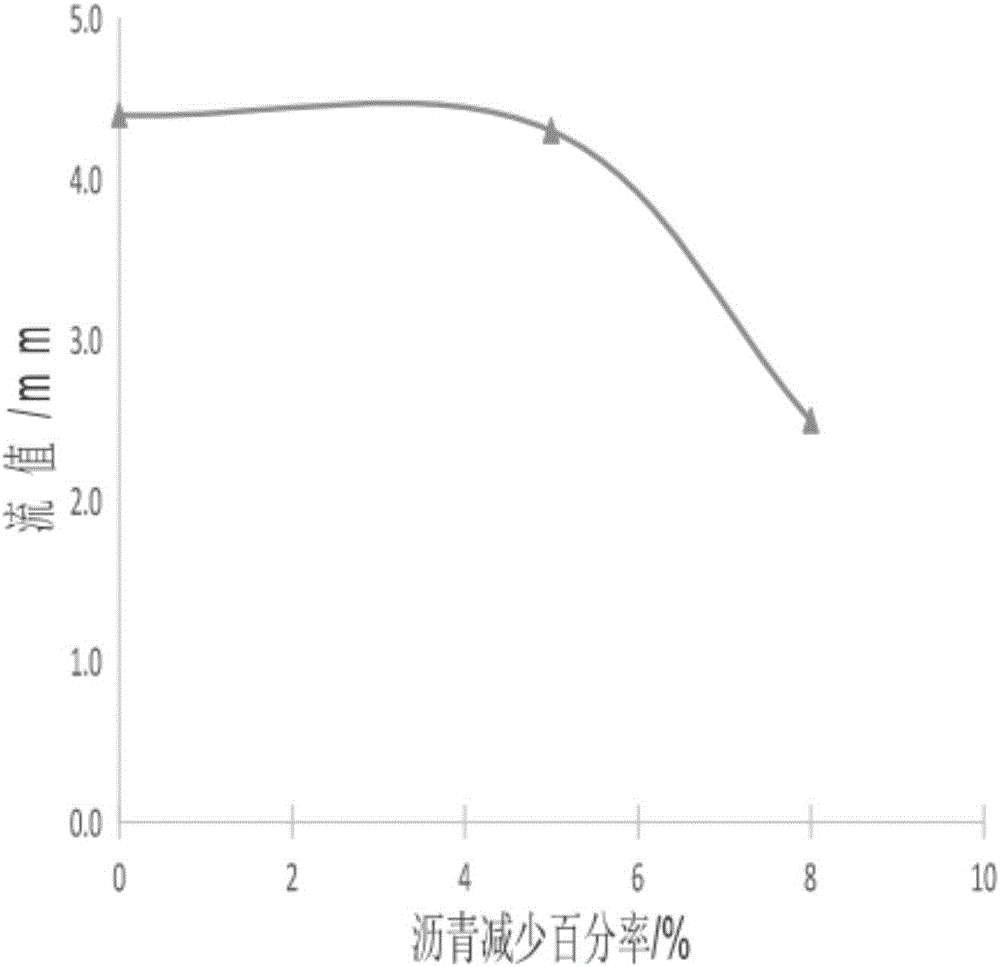

Asphalt mixture blending method

The invention discloses an asphalt mixture blending method which comprises the following steps of (1) dividing mineral aggregates into coarse aggregates, fine aggregates and mineral powder; (2) determining the mass ratios of the coarse aggregates, the fine aggregates and the mineral powder according to the mineral aggregate gradation requirements, and determining the mass ratios of asphalt and the mineral aggregates according to the variety of the asphalt; (3) weighing the coarse aggregates, the fine aggregates and the mineral powder according to the total mass of to-be-mixed mineral aggregates, and separately arranging the coarse aggregates, the fine aggregates and the mineral powder; (4) heating the weighed coarse aggregates, fine aggregates and mineral powder to the operating temperature; and (5) adding the heated coarse aggregates and fine aggregates to a blending device for blending, completely coating the coarse aggregates with the asphalt and then adding the fine aggregates for further blending, adding the mineral powder after the fine aggregates are completely coated with the asphalt, and blending evenly to obtain a finished product asphalt mixture. The problems that asphalt oil films coating the surfaces of the coarse aggregates, the fine aggregates and the mineral powder are not uniform and the performance of the asphalt mixture is affected in the prior art are solved; and the uniform oil films can be formed on the surfaces of the coarse aggregates, the fine aggregates and the mineral powder, so that the quality of the asphalt mixture is improved.

Owner:CHANGAN UNIV

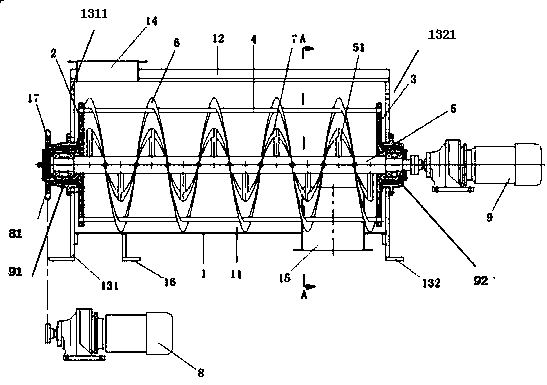

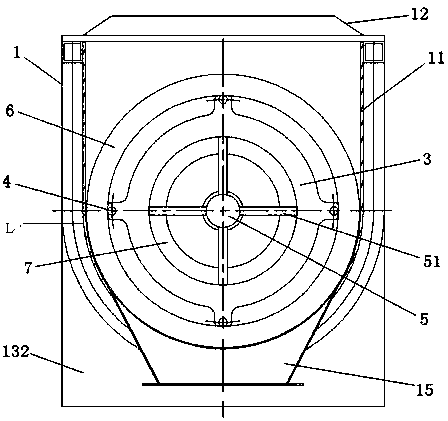

Double helix mixer

InactiveCN102974252ASimple structureReduce manufacturing costRotating receptacle mixersTransportation and packagingHelical bladeMixed materials

The present invention provides a double helix mixer for mixing different types of fine granular materials and solid-liquid mixing materials, specifically a double helix mixer adopting helical blades as a main mixing member. According to the double helix mixer, when a cylinder rotates, two materials entering the cylinder from both ends of the cylinder are rapidly conveyed to the middle position of the cylinder through inner helical blades having different rotation directions and distributed on the inner wall of the cylinder to carry out completely and repeatedly mix, after mixing is completed, the cylinder rotates in a reverse direction, and the mixed materials are conveyed to material outlets on both ends of the cylinder through the inner helical blades so as to enter a finished product material bin or be conveyed away. The double helix mixer has advantages of simple structure, low manufacturing cost, complete material mixing, short mixing time, low operation energy consumption, low maintenance cost, low operation cost and the like, wherein the advantages can not be provided by the existing mixing equipment.

Owner:李三济

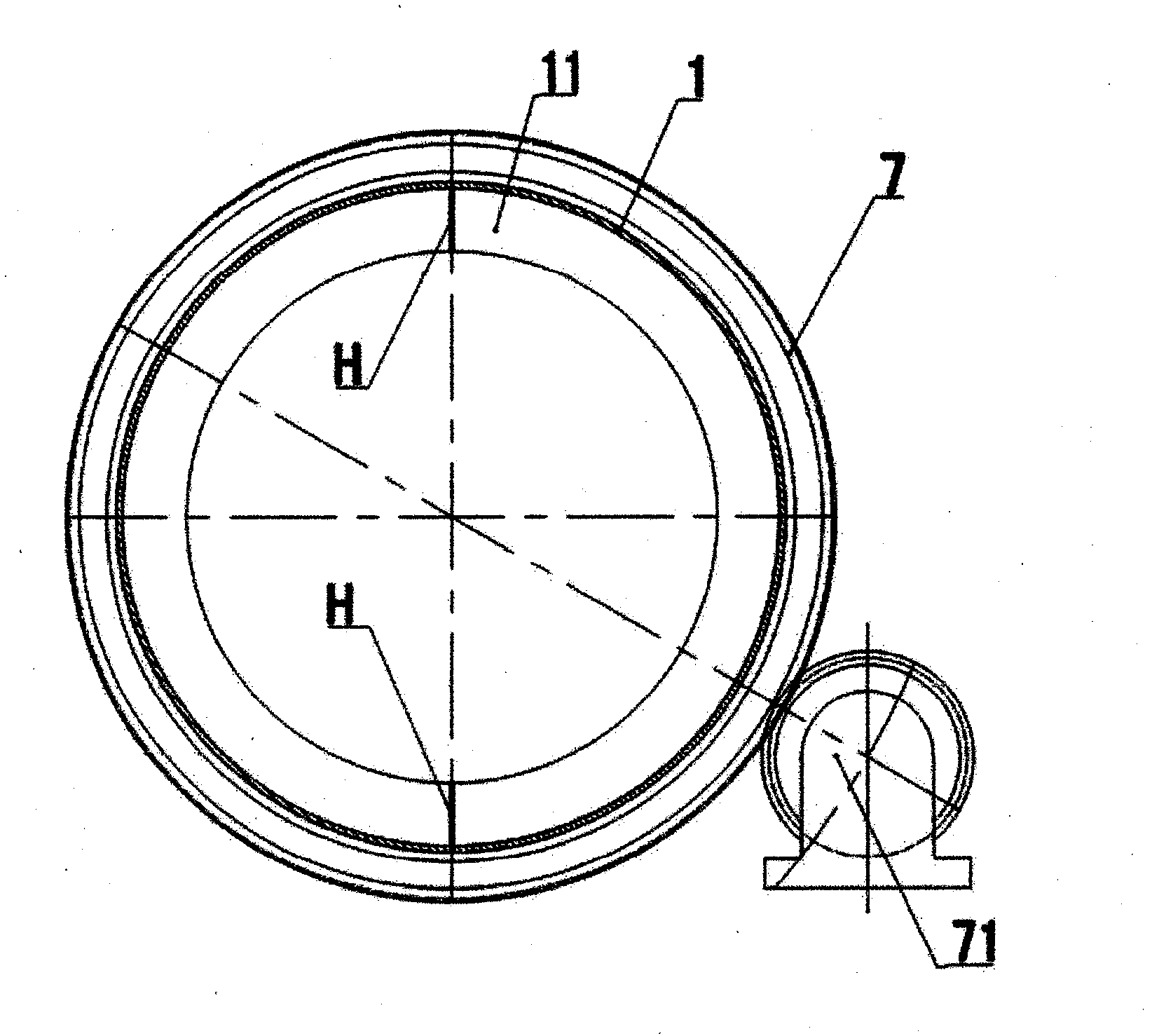

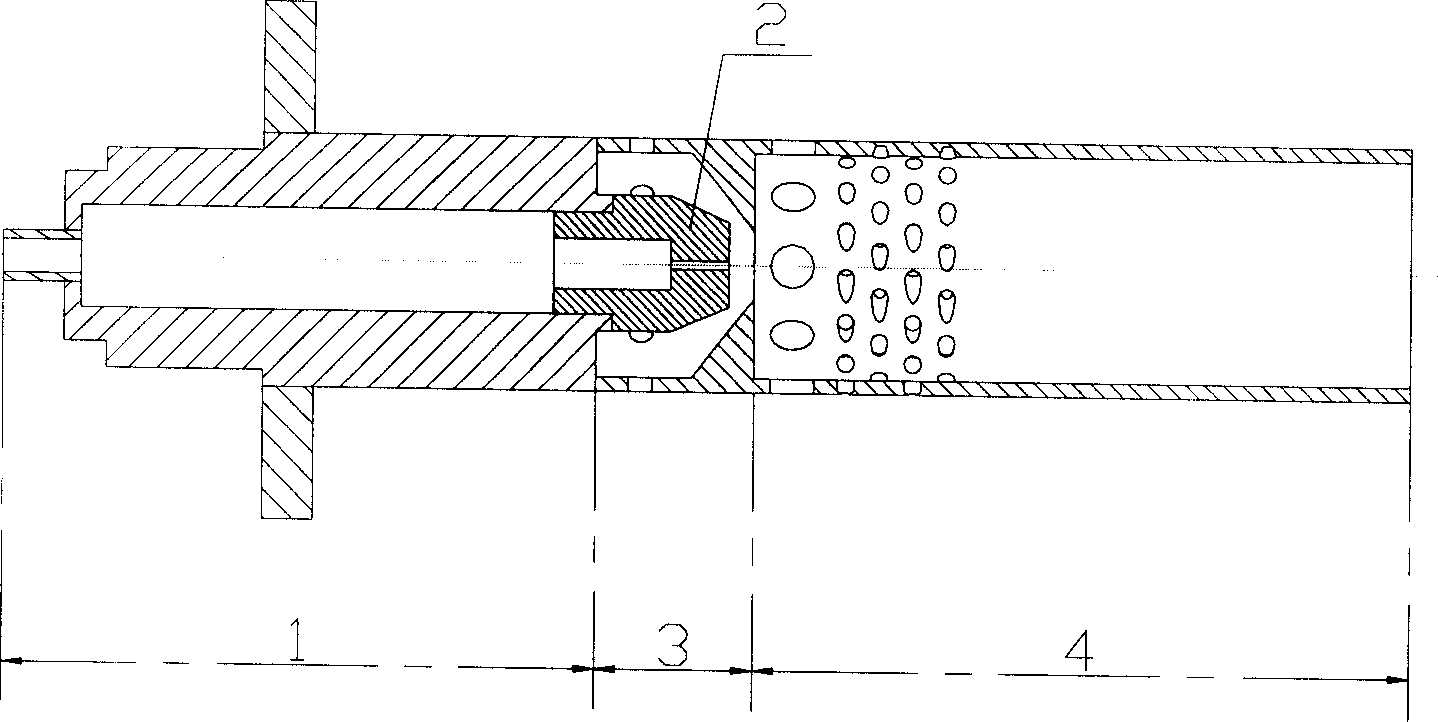

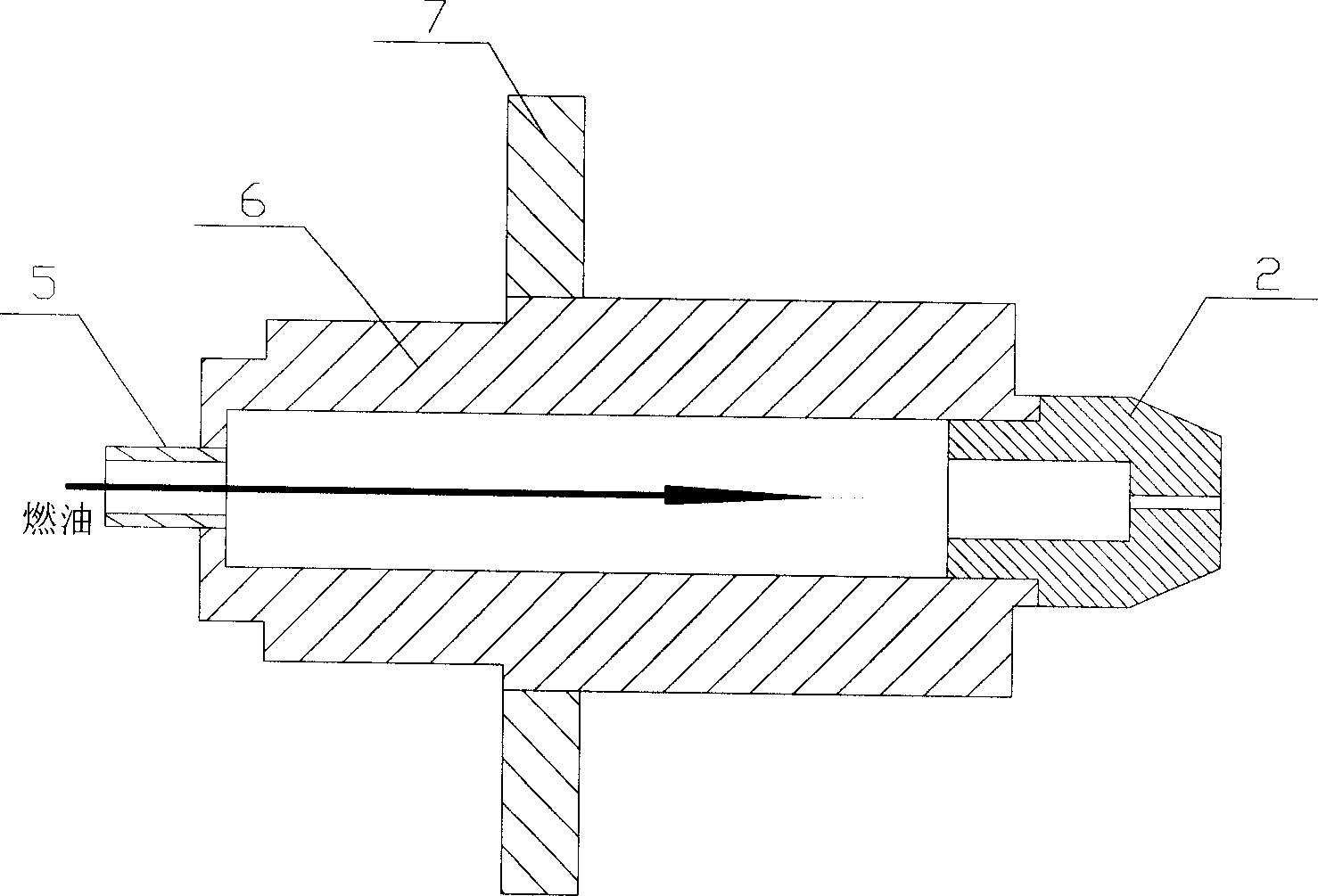

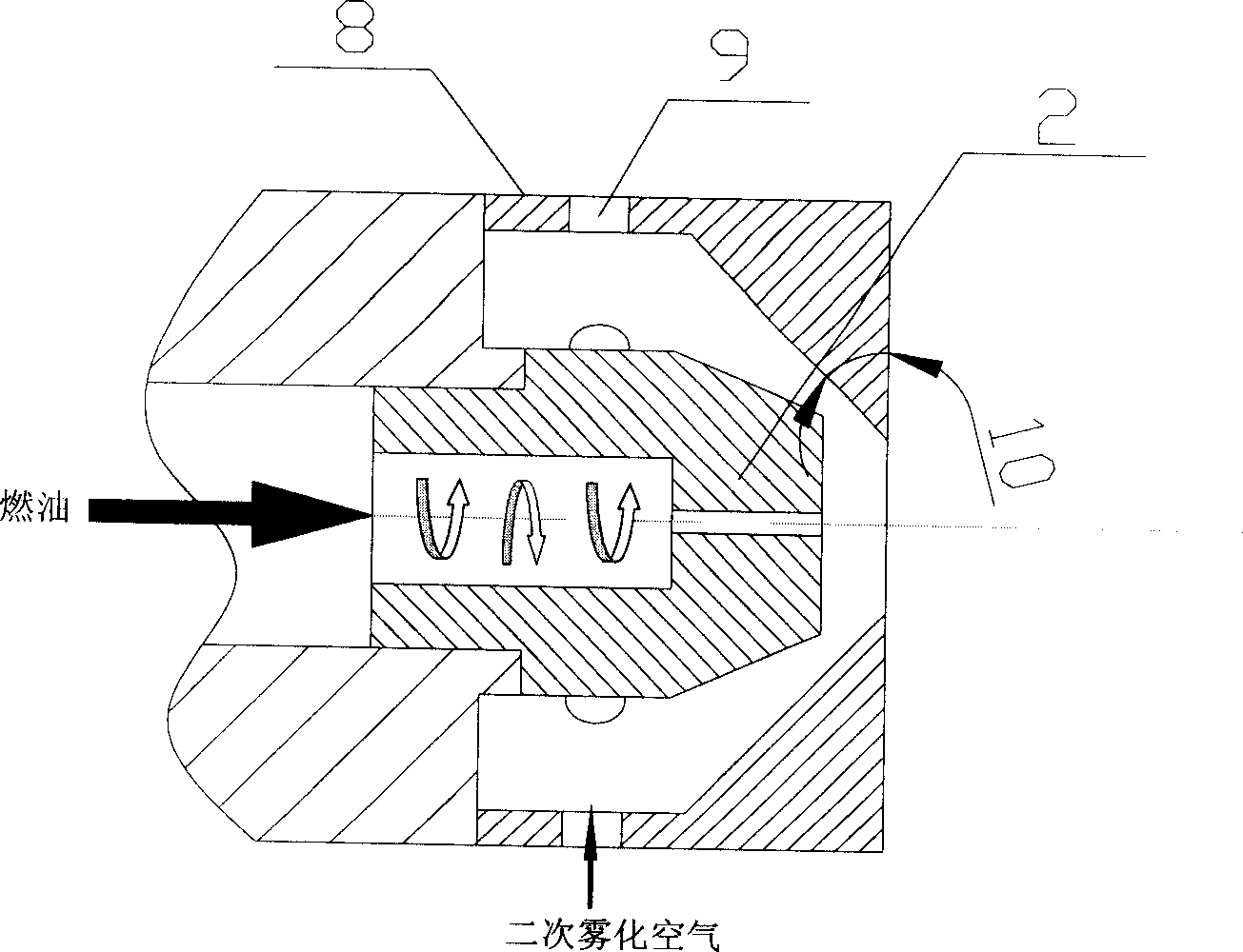

Fuel pre-evaporation and premix perforated pipe

InactiveCN1912368AFully contactedImprove atomization effectTurbine/propulsion fuel supply systemsCombustion chamberEvaporation

A preevaporating and premixing multihole tube of fuel oil is unit for preparing fuel oil of combustion chamber on gas turbine, which consists of oil supply unit, nozzle section and mixing section. It is featured as drilling straight holes on tube wall of nozzle section, setting outlet of nozzle section to be contraction form and drilling straight holes and slope holes on the wall of mixing section.

Owner:BEIHANG UNIV

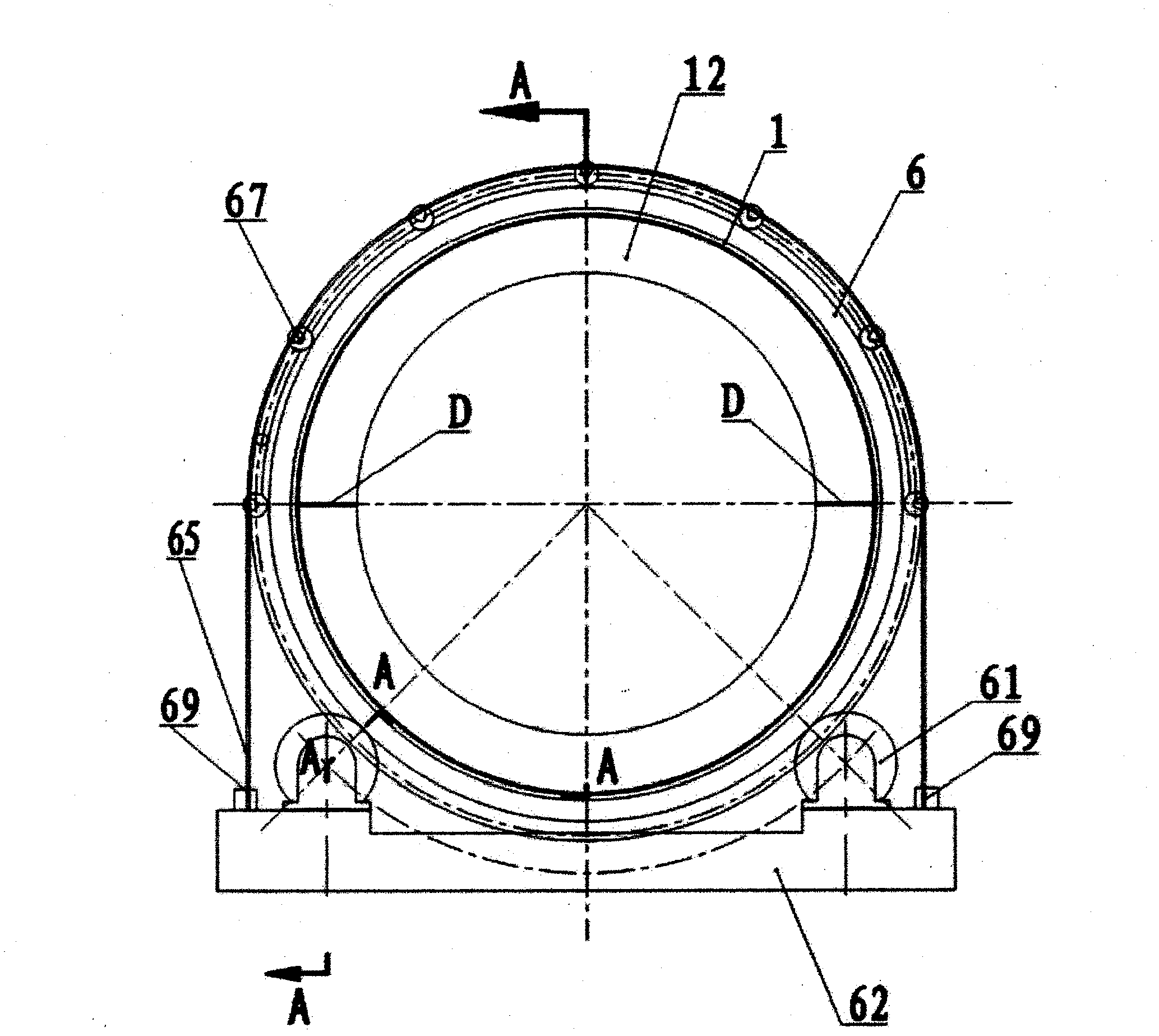

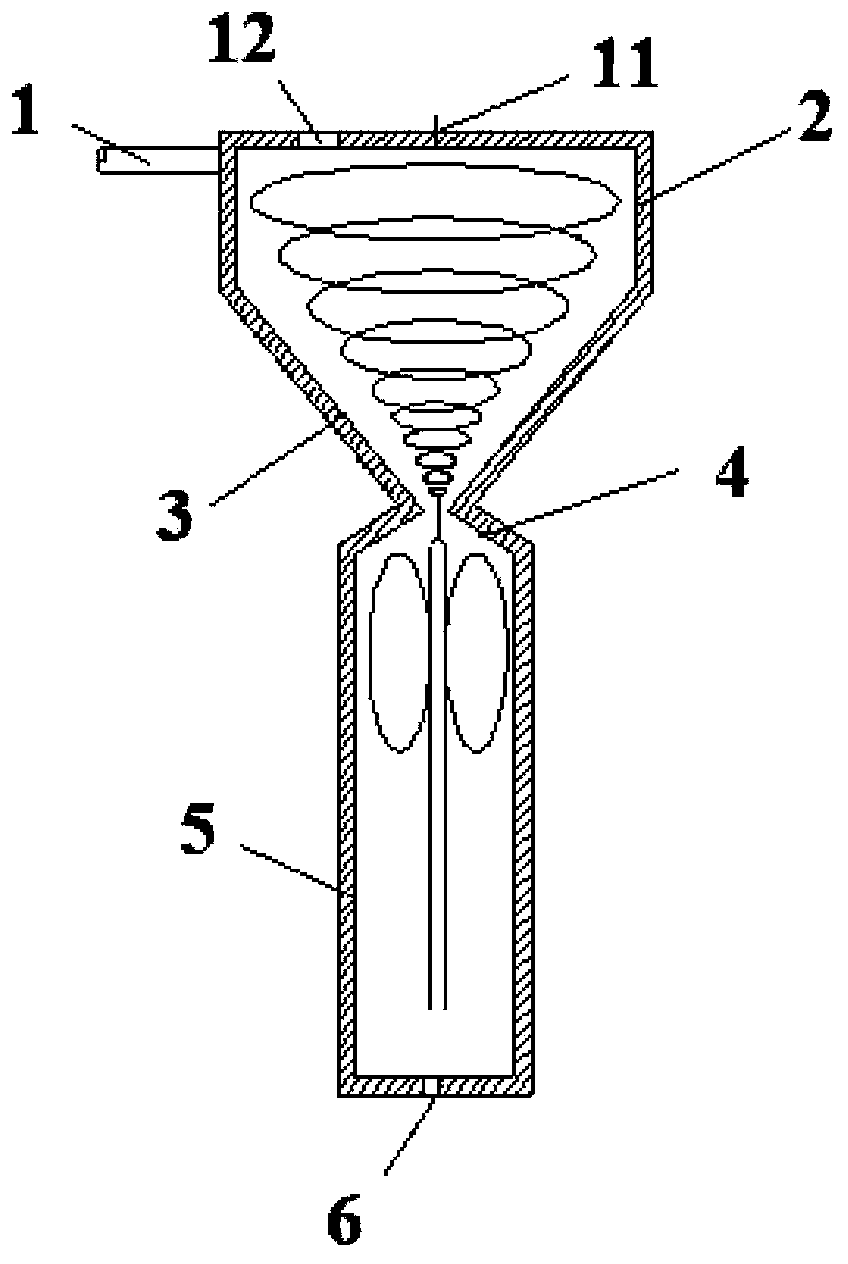

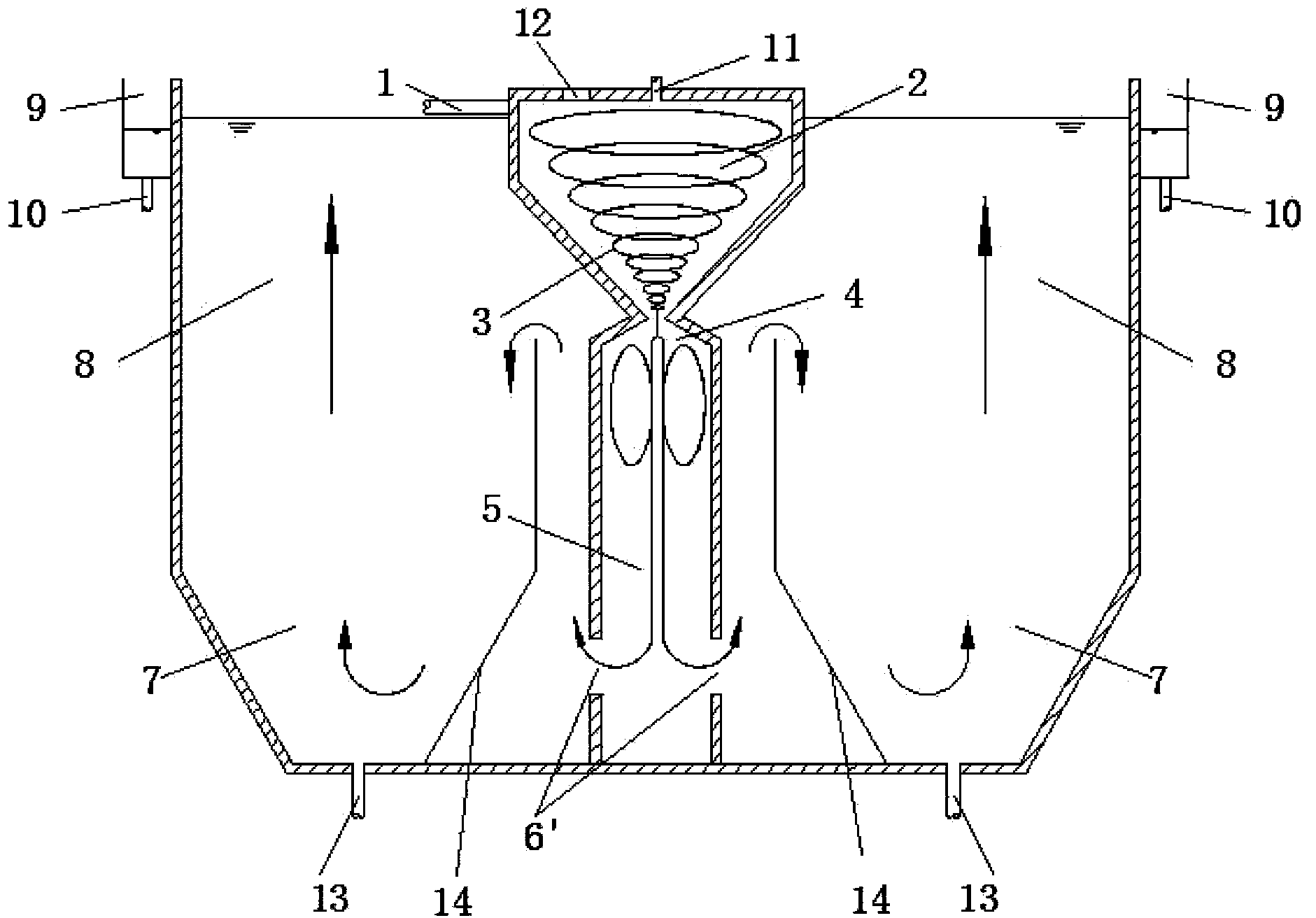

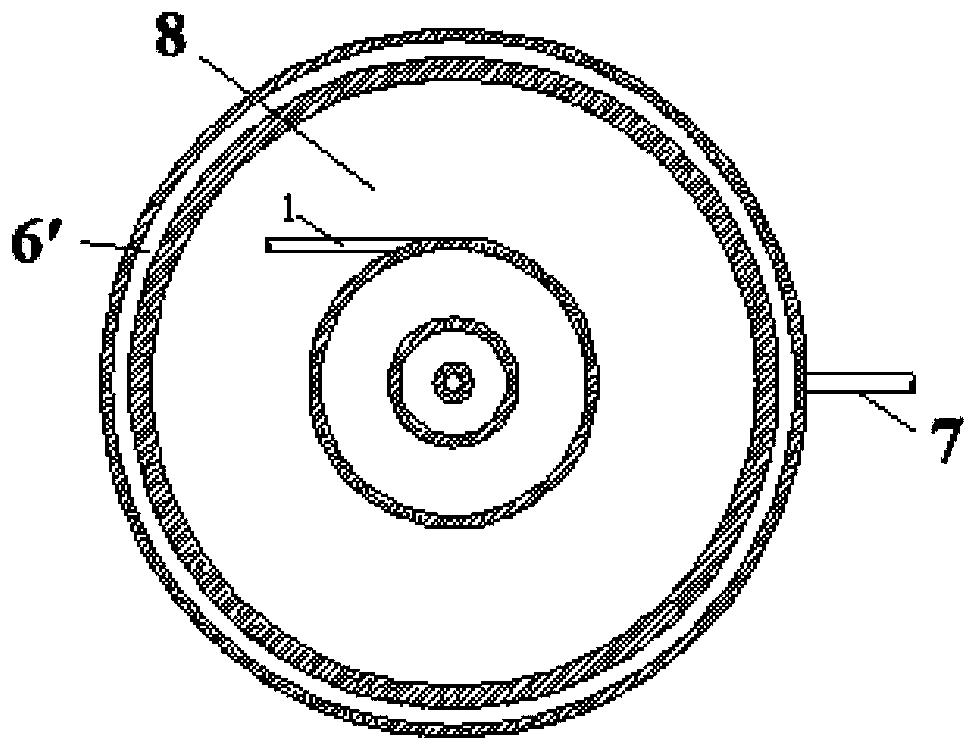

Vortex-type mixing sedimentation integrated reactor

InactiveCN103351043ASimple structureLow water speedWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationWater flowMechanical equipment

The invention discloses a vortex-type mixing sedimentation integrated reactor which comprises a first cylinder, a contraction cone, an expansion cone and a second cylinder, and the first cylinder, the contraction cone, the expansion cone and the second cylinder are mutually connected, or the second cylinder is connected with a precipitation zone through a guide plate. A water flow tangentially enters the first cylinder, and flows downward while rotation. In the part of the contraction cone the flow rate of the water flow becomes greater because the section becomes smaller. When the water flow enters into the expansion cone, because the section suddenly largens and because of longitudinal jet entrainment of water, a larger backflow zone appears at near-wall places of the expansion cone and the second cylinder and negative pressure is generated. In the process, drugs moves along with the water flow, and has an excellent contact effect with the water flow, so that the waste of the drugs can be reduced and the drug dosage can be reduced. The water flow passes through the part of the second cylinder, has an extremely low flow rate, and meets the requirements for getting into a sedimentation tank. Through use of integrated reactor, mechanical equipment for mixing is needless, energy consumption and maintenance difficulties are reduced, and the operation cost and repair cost are saved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Self-cleaning type double-helical-ribbon differential velocity mixer

InactiveCN103768973AAchieve cleaning effectImprove mixing uniformityRotary stirring mixersMixer accessoriesMotor driveEngineering

The invention relates to a self-cleaning type double-helical-ribbon differential velocity mixer. According to the self-cleaning type double-helical-ribbon differential velocity mixer disclosed by the invention, feeding and discharge holes are formed in the two ends of a U-shaped casing respectively, a spindle is fixed on left and right side plates of the casing respectively by virtue of left and right bearing seats, inside and outside helical ribbons are driven by two motors respectively, the spindle is provided with a plurality of support rods, and the inner helical ribbon is fixed at the spindle by virtue of the support rods and is driven by the corresponding motor; the outer helical ribbon is fixed at the peripheries of a plurality of connecting rods which are connected with drive discs; the drive discs are installed at the outer rings of the left and right bearing seats and include a driving disc with mounting holes and a driven disc with mounting holes, and the mounting holes are circumferentially formed in the driving disc and the driven disc uniformly with equal quantity; one end of each connecting rod is fixed on each mounting hole of the driving disc, and the other end of each connecting rod is fixed on each mounting hole of the driven disc, so that the plurality of connecting rods are arranged on the outer side of the spindle in parallel, and the other motor drives the driving disc to enable the outer helical ribbon to rotate; the outer helical ribbon is close to the lower part of the inner wall of the U-shaped casing. With the adoption of the self-cleaning type double-helical-ribbon differential velocity mixer, when materials are mixed, the rotational directions of the inner and outer helical ribbons are opposite, and a differential velocity can be adjusted; during discharging, the rotational directions of the inner and outer helical ribbons are the same so as to increase the discharge speed.

Owner:SHANGHAI TIANYI GAODE ELECTROMECHANICAL

Single-shaft mortar and high-viscosity fluid stirrer for axial turbulent flow pattern multi-wire cutting machine

InactiveCN102059068AReasonable structural designEasy to manufacture and installRotary stirring mixersTransportation and packagingFlow diversionWire cutting

The invention discloses a single-shaft mortar and high-viscosity fluid stirrer for an axial turbulent flow pattern multi-wire cutting machine, comprising a stirring shaft, a stirring assembly and a driving mechanism, wherein the stirring assembly comprises impellers and short flow diversion tubes, the impellers are used for driving a material to move up or down in an axial and spiral mode along the inner wall of a pot body of a stirring pot, the short flow diversion tubes are used for restricting the material flow direction to an axial movement along the axis of the stirring shaft when the material moves up or down in the axial and spiral mode, the impellers and the short flow division tubes are assembled into the stirring assembly which drives the material needed to be mixed and stirred to do an axial turbulent flow motion during stirring, the impellers are coaxially installed at the bottom end of the stirring shaft, the short flow division tubes are coaxially and fixedly sleeved at the outer sides of the impellers, and the stirring speed of the stirring shaft is 600-1500rmp. The single-shaft mortar and high-viscosity fluid stirrer has the advantages of simplicity in structure, high stirring capacity, small shearing force, high dispersing power and high effect, and can be used for solving the problem that silicon carbide is broken due to the shearing force during the high-speed stirring of various traditional stirrers. Moreover, a stuck phenomenon is difficult to generate.

Owner:XIAN HUAJING ELECTRONICS TECH

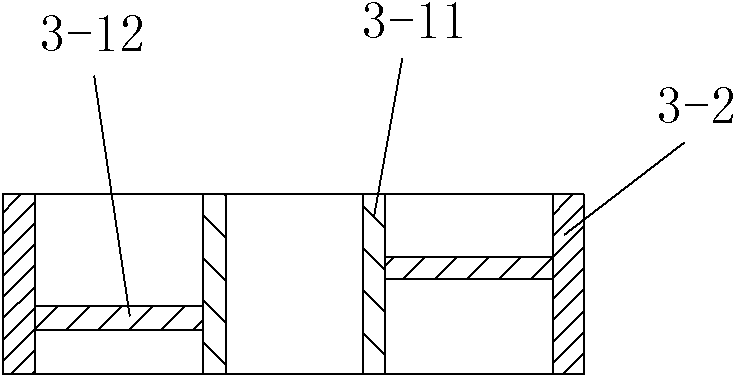

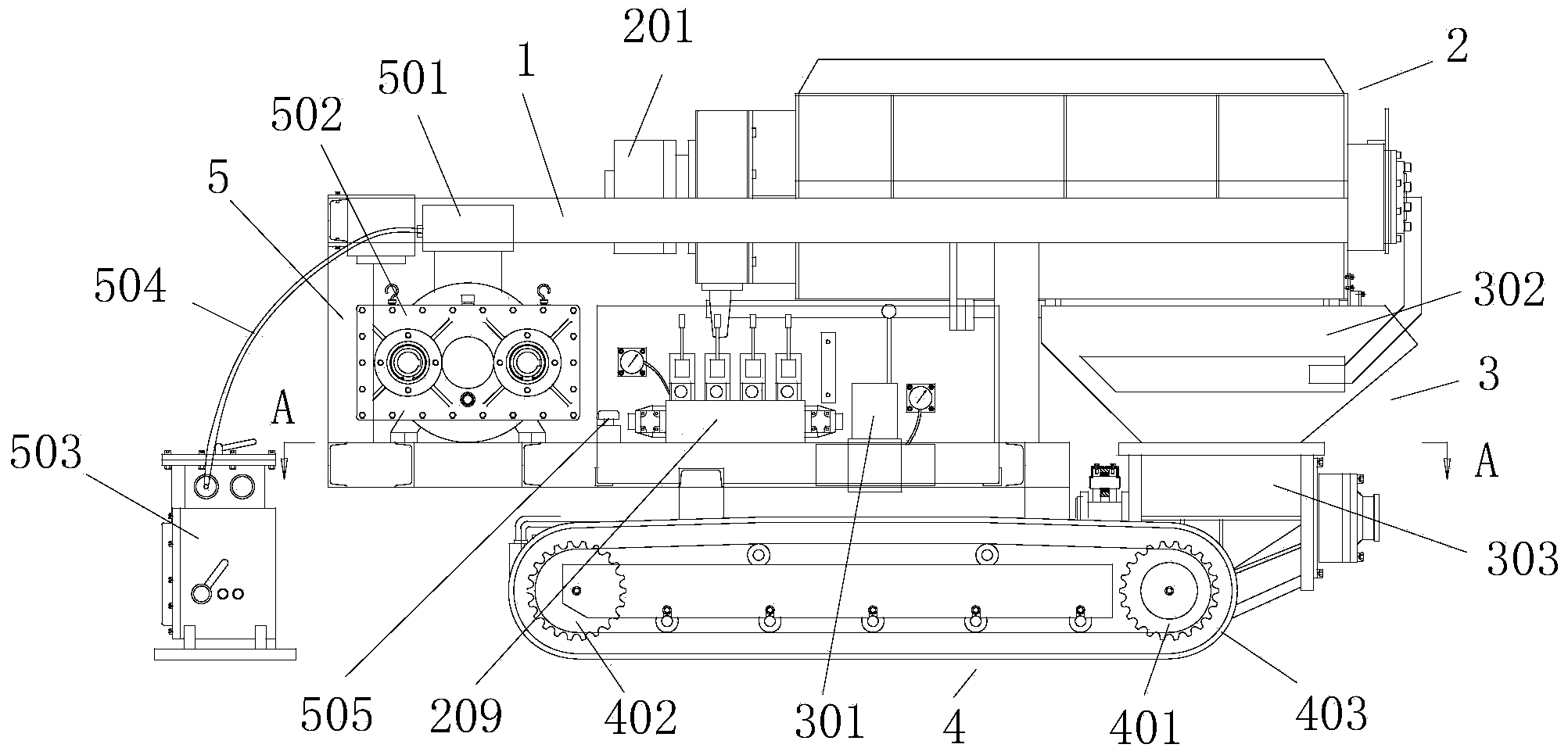

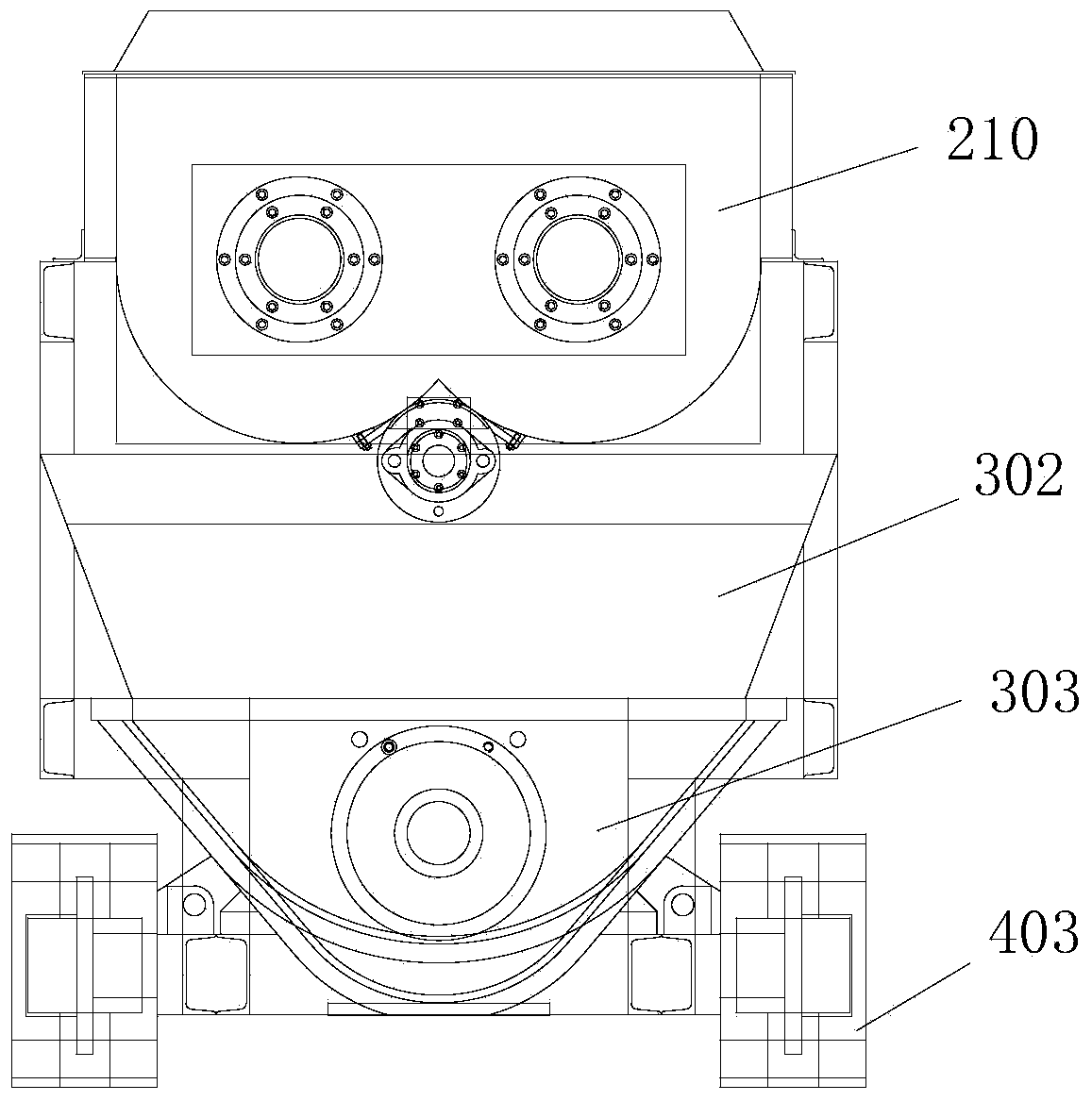

Concrete wet shotcreting equipment for roadway

ActiveCN104047615ASpeed up the progress of the projectShort mixing timeUnderground chambersCement mixing apparatusShotcreteBatch machine

The invention discloses concrete wet shotcreting equipment for a roadway. The concrete wet shotcreting equipment comprises a machine body, wherein a batching machine, a stirrer, a pumping mechanism and a power mechanism are arranged on the machine body; a walking mechanism is arranged below the machine body; the stirrer comprises a stirring cylinder and a stirring multi-path valve connected with the stirring cylinder; two parallel stirring shafts are arranged inside the stirring cylinder; the pumping mechanism comprises a wet shotcreting main valve block, a blanking copper and a wet shotcreting discharging copper communicated with the blanking copper; an S valve conveying pipeline is arranged inside the wet shotcreting discharging copper; one end of the S valve conveying pipeline is connected with a concrete conveying pump, and the other end of the S valve conveying pipeline is connected with a concrete wet shotcreting pipeline; a shower nozzle assembly is arranged at the tail end of the concrete wet shotcreting pipeline; the power mechanism comprises a mining anti-explosion motor and a transfer case; the transfer case is internally provided with a main pump and a secondary pump; the main pump is connected with the wet shotcreting main valve block; the secondary pump is connected with the stirring multi-path valve. With the adoption of the concrete wet shotcreting equipment provided by the invention, the functions of batching, stirring, discharging, wet shotcreting and walking can be realized. The concrete wet shotcreting equipment is particularly applicable to operations in underground engineering, shotcreting in the coal mine roadway and the like.

Owner:WIT LAB MINE EQUIP +1

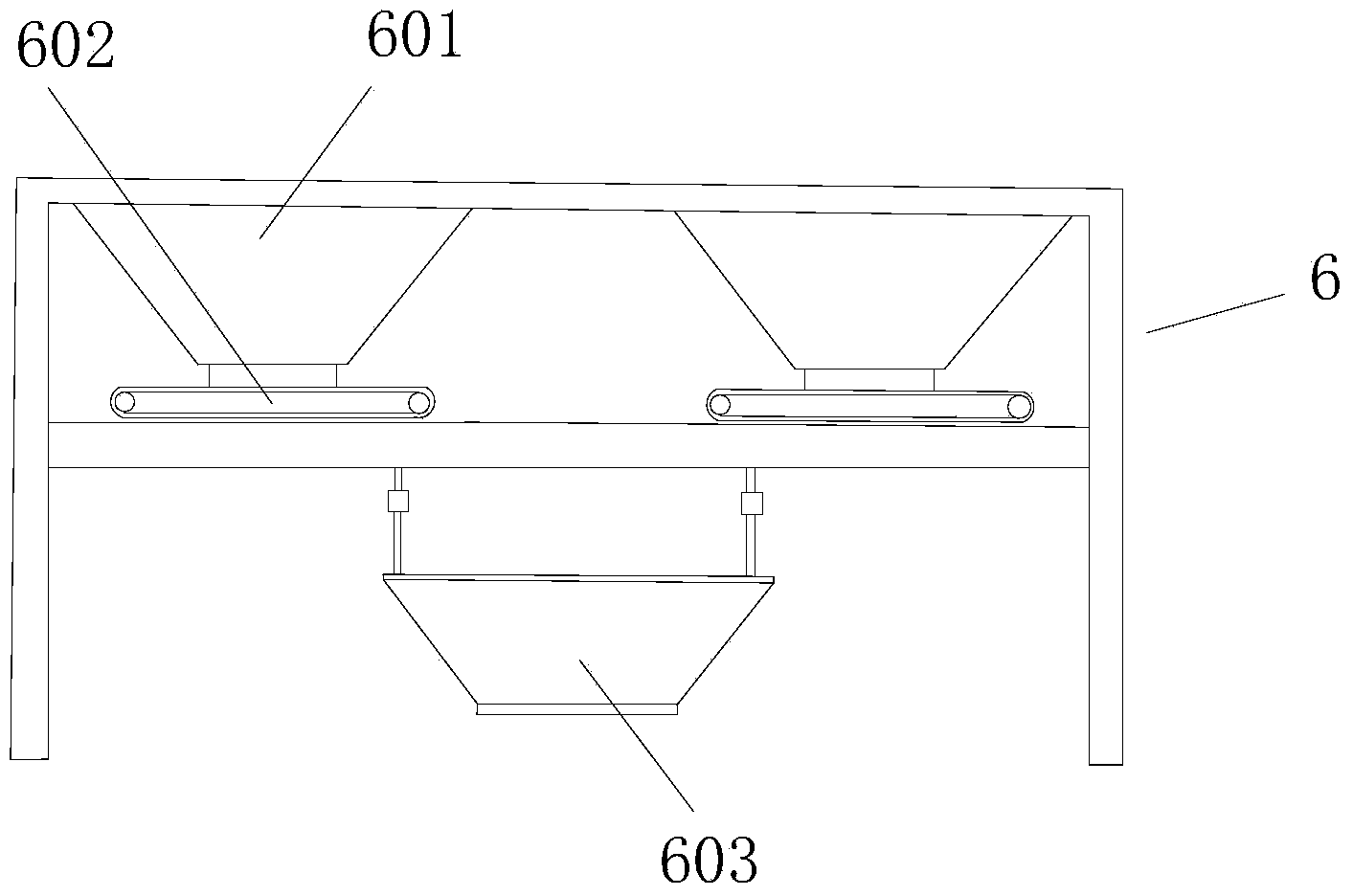

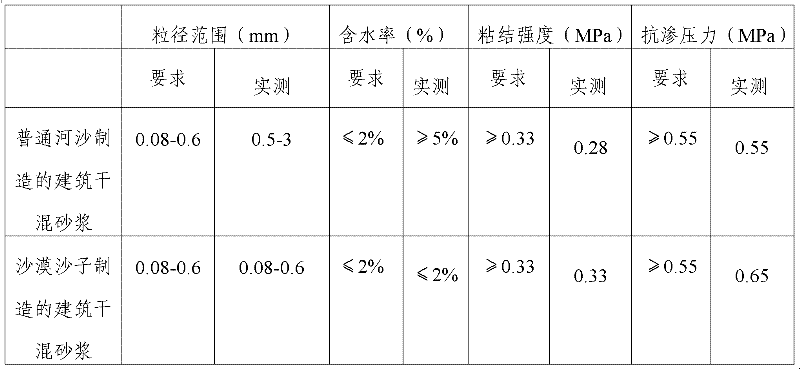

Desert sand compound type building dry-mixed mortar and manufacturing method thereof

ActiveCN102390962ASolve the use problemChange the status quo of lack of resourcesPlasticizerMaterials science

The invention relates to a desert sand compound type building dry-mixed mortar and a manufacturing method thereof. The dry-mixed mortar comprises the following raw materials by weight percent: 30%-60% of desert sand, 0.1%-2% of intensifier, 0.01%-2% of water-retaining agent, 0.1%-5% of plasticizer, 0.01%-2% of anti-cracking agent, 0.001%-2% of permeability admixture, 30%-60% of curing agent, 0%-10% of mineralizing agent and 0%-10% of flatting agent. The manufacturing method comprises the following steps: screening the desert sand; crushing, drying and screening the mineralizing agent; and dosing, mixing and stirring the raw materials, thereby obtaining the dry-mixed mortar. A long-term existing problem that the desert sand cannot be used as the sand for building because the desert sand contains superfine grains and is high in silt content is solved. The present problem of utilizing the large amount of desert sand is also solved. A novel method for manufacturing the dry-mixed mortar isprovided. The current situation that the resource of the sand for building is in insufficient is changed. Meanwhile, the production process is simple and the operation is convenient.

Owner:XIAN HONGFENG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com