Desert sand compound type building dry-mixed mortar and manufacturing method thereof

A dry-mixed mortar and composite technology, applied in the field of building materials, can solve the problems of high quality, high mud content, high bonding strength, etc., and achieve the effects of high quality, improved bonding, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

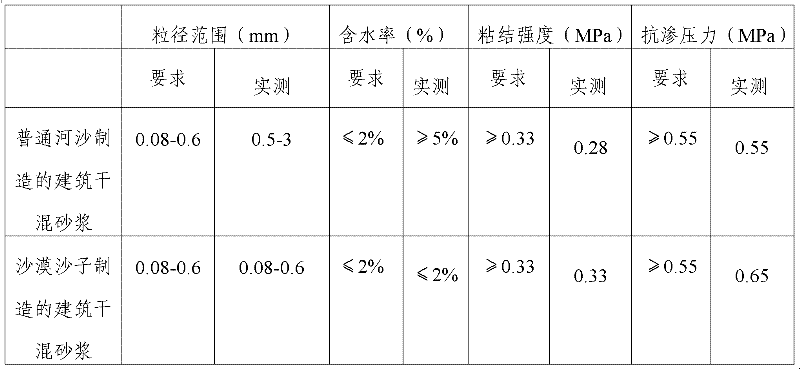

Image

Examples

Embodiment 1

[0032] A desert sand composite dry-mixed mortar for construction in this embodiment is composed of the following raw materials in mass percentage: 30% of desert sand, 2% of reinforcing agent, 2% of water retaining agent, 4% of plasticizer, 1.5% of anti-cracking agent, 0.5% of anti-seepage agent, 50% of curing agent, 10% of leveling agent, the described reinforcing agent is vinyl acetate-ethylene copolymer rubber powder, the described water-retaining agent is methyl cellulose ether, and the described plasticizer is Powdered polyvinyl alcohol 1788, the anti-cracking agent is powdered plant fiber, the anti-seepage agent is polymethylacrylate, the curing agent is ordinary Portland cement, and the leveling agent is fly ash.

[0033] The manufacture method of the desert sand composite type building dry-mixed mortar of the present embodiment comprises the following steps:

[0034] (1) Screening of desert sand: the desert sand is screened, and the fineness of the screened particles i...

Embodiment 2

[0043] This example is the same as Example 1, except that the reinforcing agent is ethylene-polyvinyl chloride-vinyl laurate ternary copolymer rubber powder, ethyl acetate-ethylene-higher fatty acid ethylene ester ternary copolymer glue Powder, vinyl acetate-higher fatty acid copolymer powder, acrylate-styrene copolymer powder, vinyl acetate-acrylate-higher fatty acid ester ternary copolymer powder, vinyl acetate homopolymer powder or styrene-butylene ethylene copolymer rubber powder, the water-retaining agent is ethyl cellulose ether, carboxymethyl cellulose ether, hydroxymethyl propyl cellulose ether, hydroxypropyl methyl cellulose ether, hydroxyethyl cellulose ether or hydroxy Ethyl carboxymethyl cellulose ether, the plasticizer is powdered polyvinyl alcohol 1792, powdered polyvinyl butyral or powdered polyvinyl alcohol 124, and the described anti-cracking agent is powdered animal fiber Or powdered mineral fiber, powdered rayon, powdered synthetic fiber or powdered inorgani...

Embodiment 3

[0046] A desert sand composite dry-mixed mortar for construction in this embodiment is composed of the following raw materials in mass percentage: 40% desert sand, 0.9% reinforcing agent, 0.08% water retaining agent, 4% plasticizer, 0.019% anti-cracking agent, 0.001% anti-seepage agent, 45% curing agent, 10% mineralizer, the reinforcing agent is ethylene-polyvinyl chloride-vinyl laurate ternary copolymer rubber powder, the water-retaining agent is ethyl cellulose ether, The plasticizer is powdered polyvinyl alcohol 1792, the anti-cracking agent is powdered animal fiber, the anti-seepage agent is polyethylacrylate, and the curing agent is high alumina cement. The mineralizer is quicklime.

[0047] The manufacturing method of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com