Concrete wet shotcreting equipment for roadway

A concrete and wet spraying technology, which is applied to mining equipment, shaft equipment, clay preparation devices, etc., can solve the problems of reducing the progress of concrete wet spraying projects, being unable to adapt to construction operations, and being bulky, achieving ideal mixing effects and reducing labor intensity. , the effect of short mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

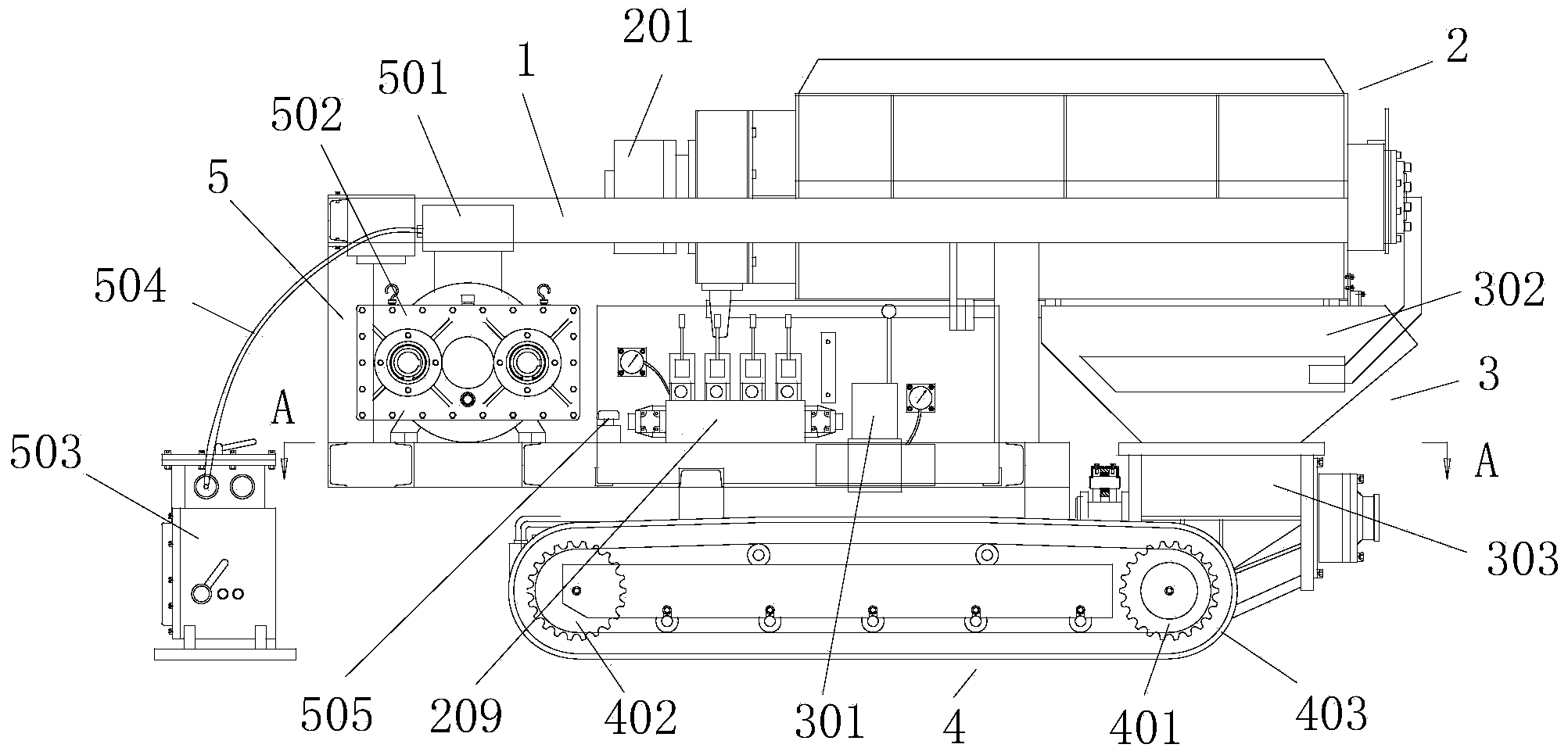

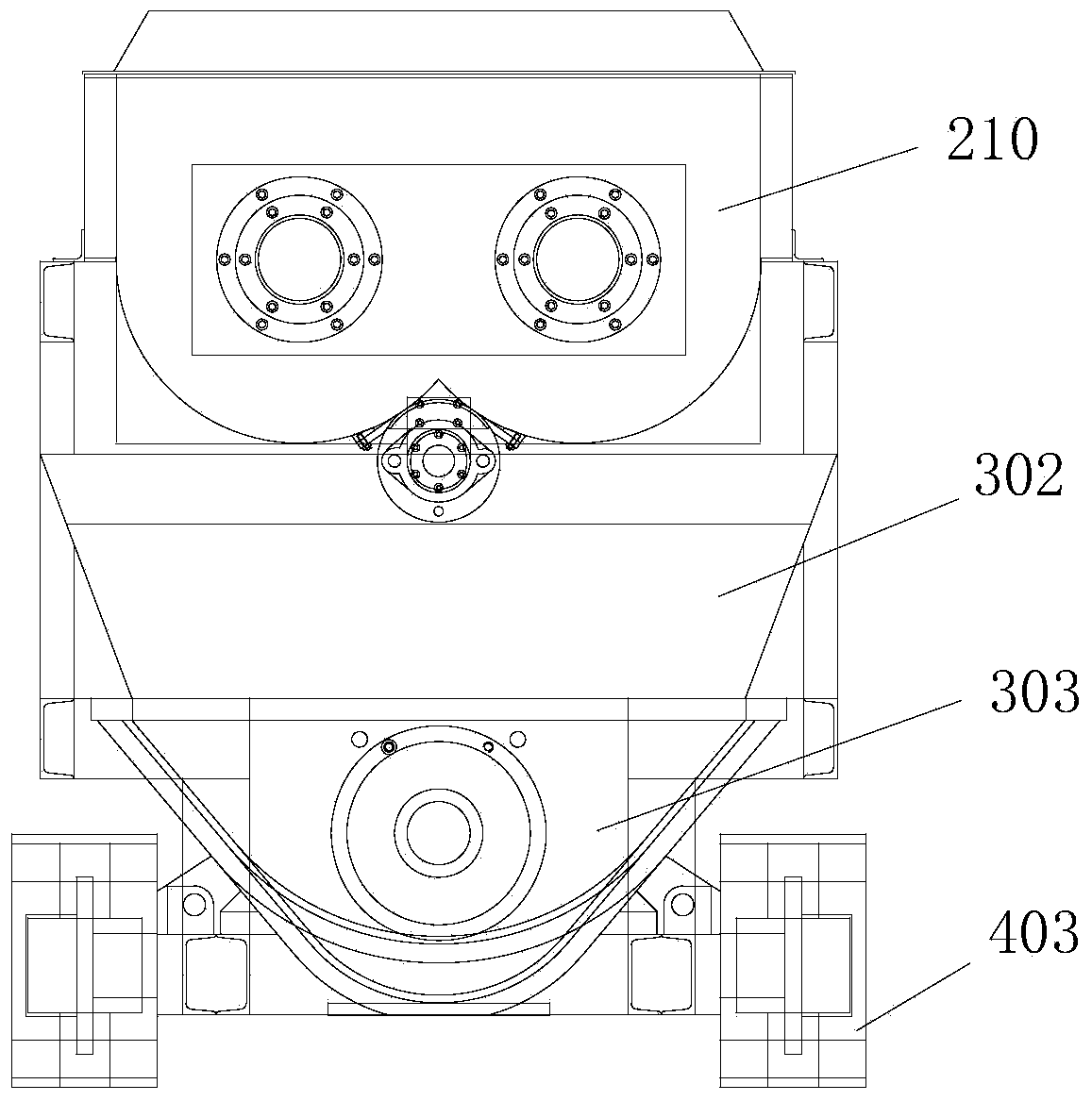

[0034] Such as figure 1 and figure 2 As shown, a concrete wet spraying equipment for shafts includes a fuselage 1 on which a batching machine 6 , a mixer 2 , a pumping mechanism 3 and a power mechanism 5 are arranged, and a running mechanism 4 is arranged below the fuselage 1 .

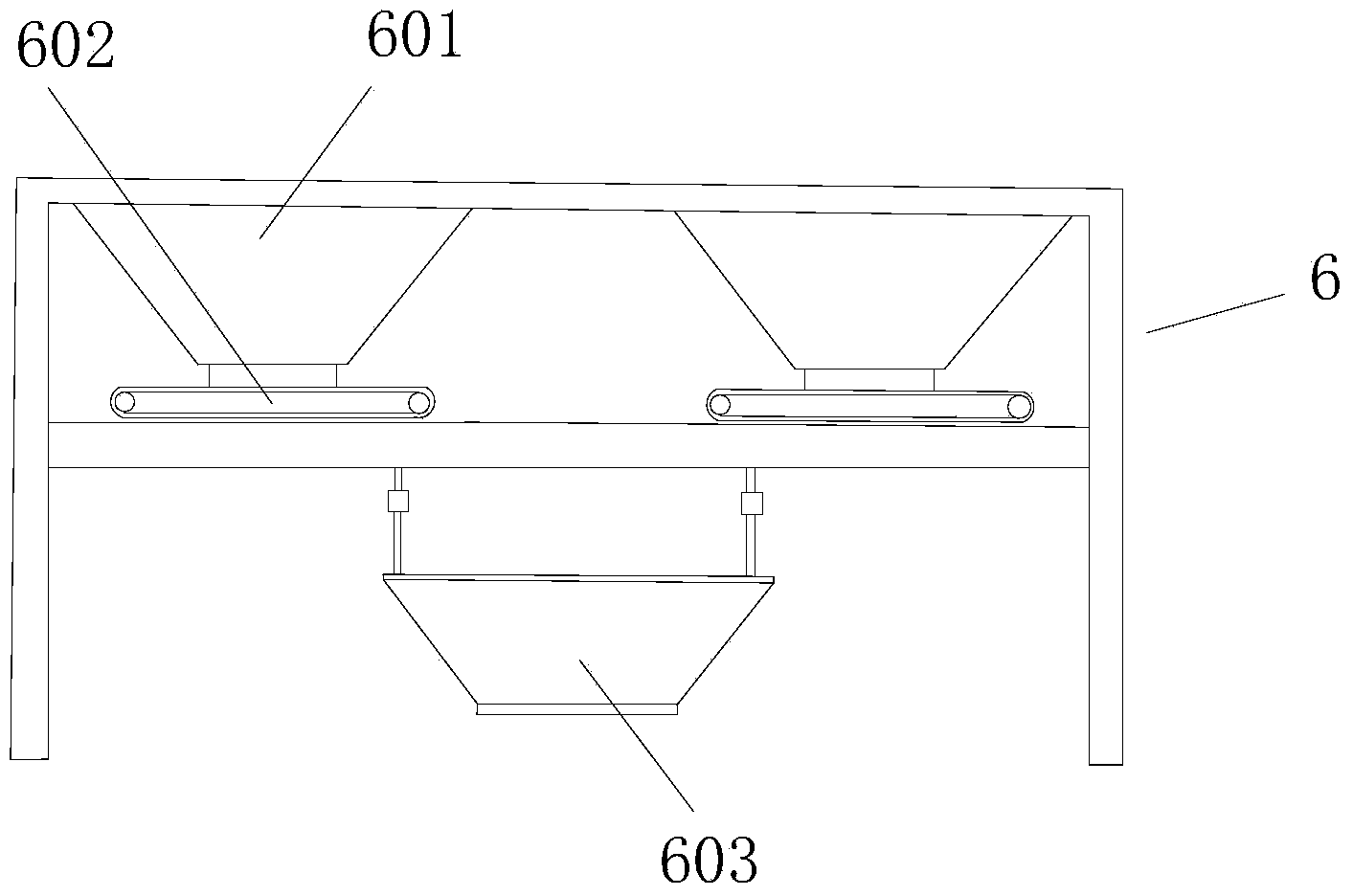

[0035] Such as image 3 As shown, the batching machine 6 includes two or more than two storage bins 601, each storage bin 601 below is provided with a conveyor belt mechanism 602 for feeding materials to one place, and the blanking of each conveyor belt mechanism 602 A weighing hopper 603 is correspondingly provided below the end, and a blanking port is provided below the weighing hopper 603 .

[0036] Such as figure 1 , Figure 5 , Figure 6 and Figure 9 As shown, the mixer 2 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com