Method for constructing subway tunnel with complicated geology and without shield launching site

A technology for complex geology and tunnel construction, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of not being able to provide the starting site for the shield on time, accelerate tool wear, and reduce the speed of excavation, so as to avoid opening and changing Knives, reducing the wear of the cutterhead, and improving the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

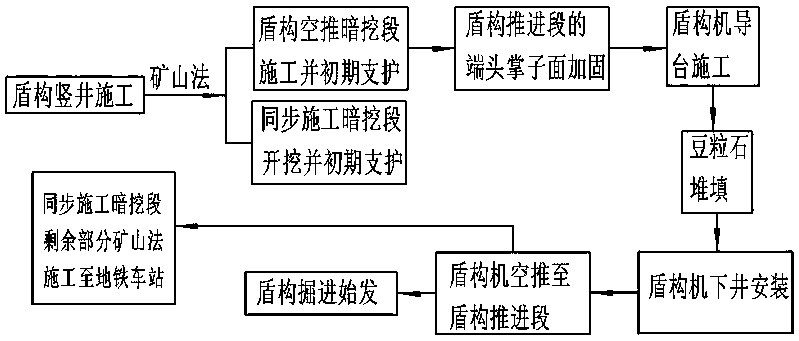

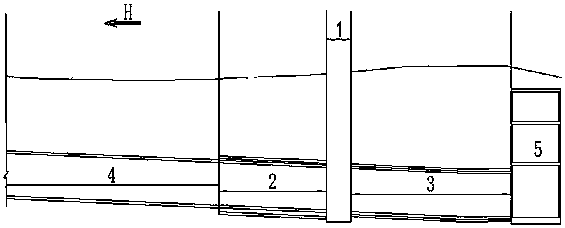

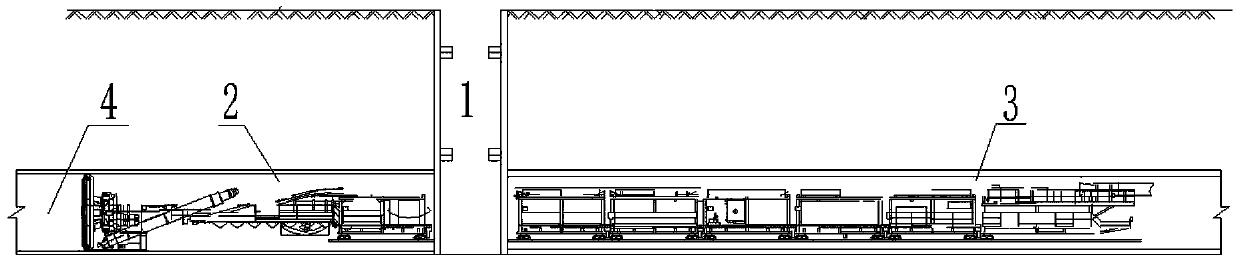

[0020] refer to Figure 1 to Figure 5 Further elaborating the present invention, a subway tunnel construction method with complex geology and no shield starting site, a shield shaft 1 is set in the preset tunnel section, and shield tunneling is constructed at both ends of the shield shaft 1 using the mining method Empty thrust underground excavation section 2 and synchronous construction underground excavation section 3 and the initial support 7 are implemented in time, the air thrust underground excavation section 2 of the shield machine faces the shield advancing direction H, and the synchronous construction underground excavation section 3 faces the opposite direction of shield tunneling, The shield tunneling section 2 is connected with the shield tunneling section 4, and the main body 11 of the shield machine and the supporting equipment that are lowered and assembled through the shield shaft 1 arrive at the shield tunneling section 2 in a separate way. After the shield tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com