Arch bridge abutment tunnel type large-angle inclined pile construction method

A construction method and large-angle technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of difficulty in excavating and retaining wall support for inclined piles, large cross-sectional size of inclined piles, and high safety risks, so as to improve output Improve slag work efficiency, improve work efficiency, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Arch bridge abutment tunnel-type large-angle inclined pile construction method, the construction of inclined piles adopts the excavation construction of the upper and lower steps, and the reciprocating cycle slag discharger is used to discharge slag, and the retaining wall is anchored and sprayed. The excavation of each step is completed. Complete the retaining wall support in time, and the specific construction steps for each step are as follows:

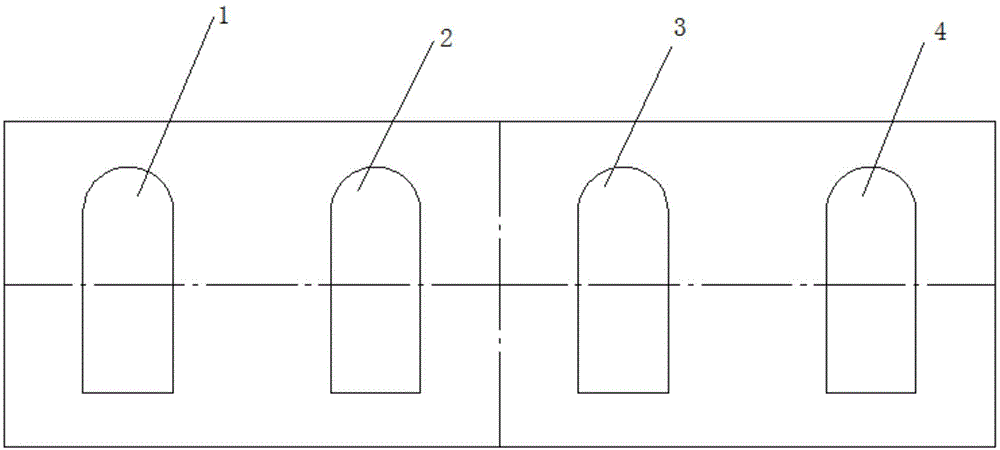

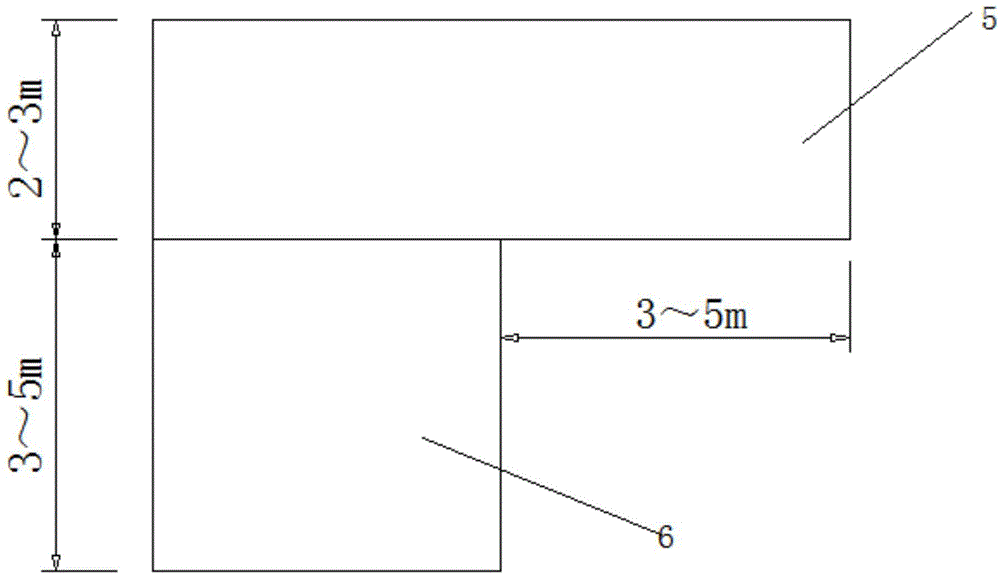

[0022] 1. The inclined pile is excavated by the weak blasting method in two steps, the upper and lower steps. The semicircle at the top and the straight wall totaling 2-3m are used as the upper step for excavation construction. dig;

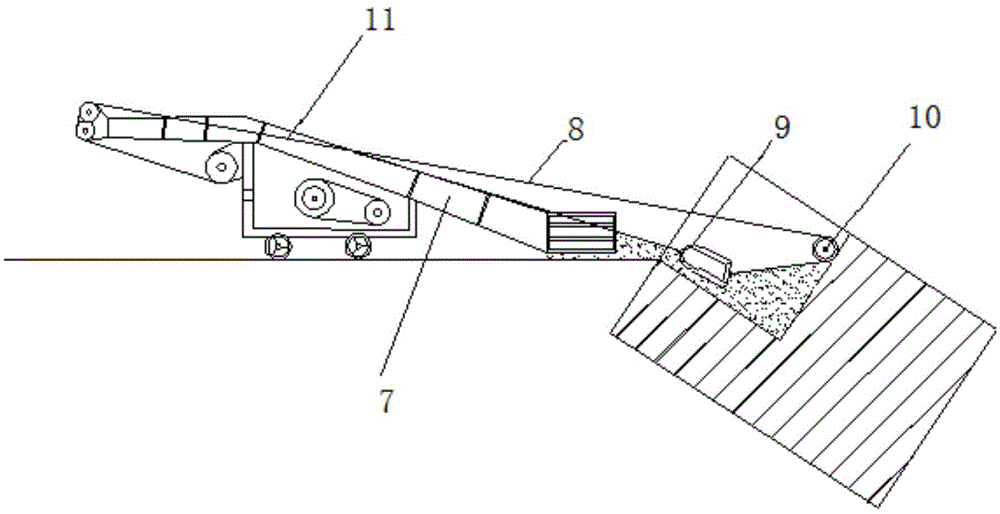

[0023] 2. The slag of the inclined pile is discharged by a reciprocating cycle type slag discharge machine, and the pile slag of the upper step is transported to the bottom of the lower step by the slag discharge machine, and then transported from the bottom of the lower step to the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com