Tunnel lining detection support with height and angle capable of being automatically adjusted

A technology for automatic adjustment and detection of brackets, applied in the direction of measuring devices, measuring instrument components, radio wave measuring systems, etc. The effects of erection and manual lifting, reducing the intensity of inspection work, and improving inspection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

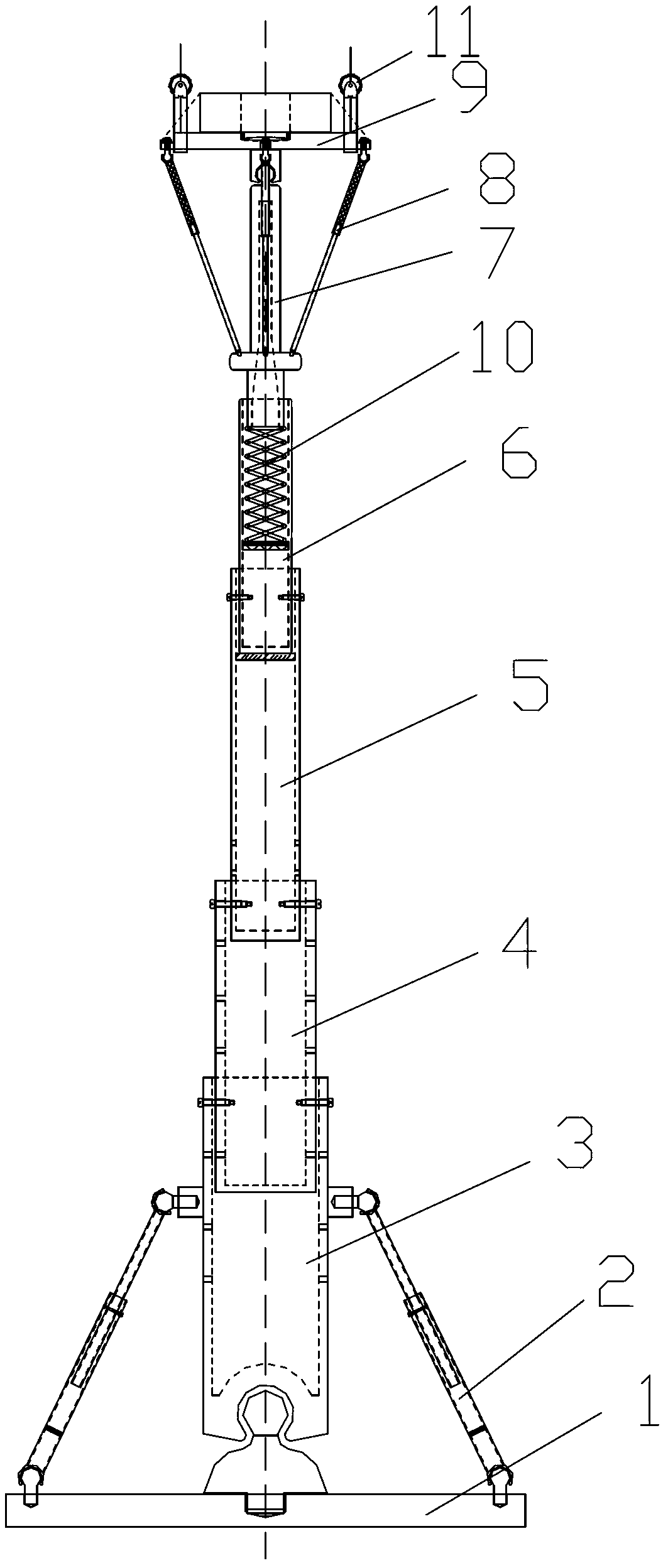

[0015] Such as figure 1 As shown, a tunnel lining detection bracket whose height and angle can be automatically adjusted includes a radar bracket 9, a plurality of pulleys 11 are arranged on the upper side of the radar bracket 9, and the axis position of the lower side of the radar bracket 9 A main support rod is installed on it, one end of the main support rod is connected with the radar bracket 9 through a universal joint, and the other end of the main support rod is installed on the fixed base 1 through a universal joint, and the main support rod The lower part of the rod is fixed on the fixed base 1 by at least three air supports 2 uniformly arranged around the main support rod, and the two ends of the air support 2 are respectively connected to the main support rod and the fixed base through universal joints. The base 1 is connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com