Industrial continuous agricultural and forestry biomass fast pyrogenation oil refining method and device thereof

An oil refining device and biomass technology, applied in the field of biomass regeneration and energy, can solve the problems of industrial scale-up difficulty, high operating cost, unstable operation, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

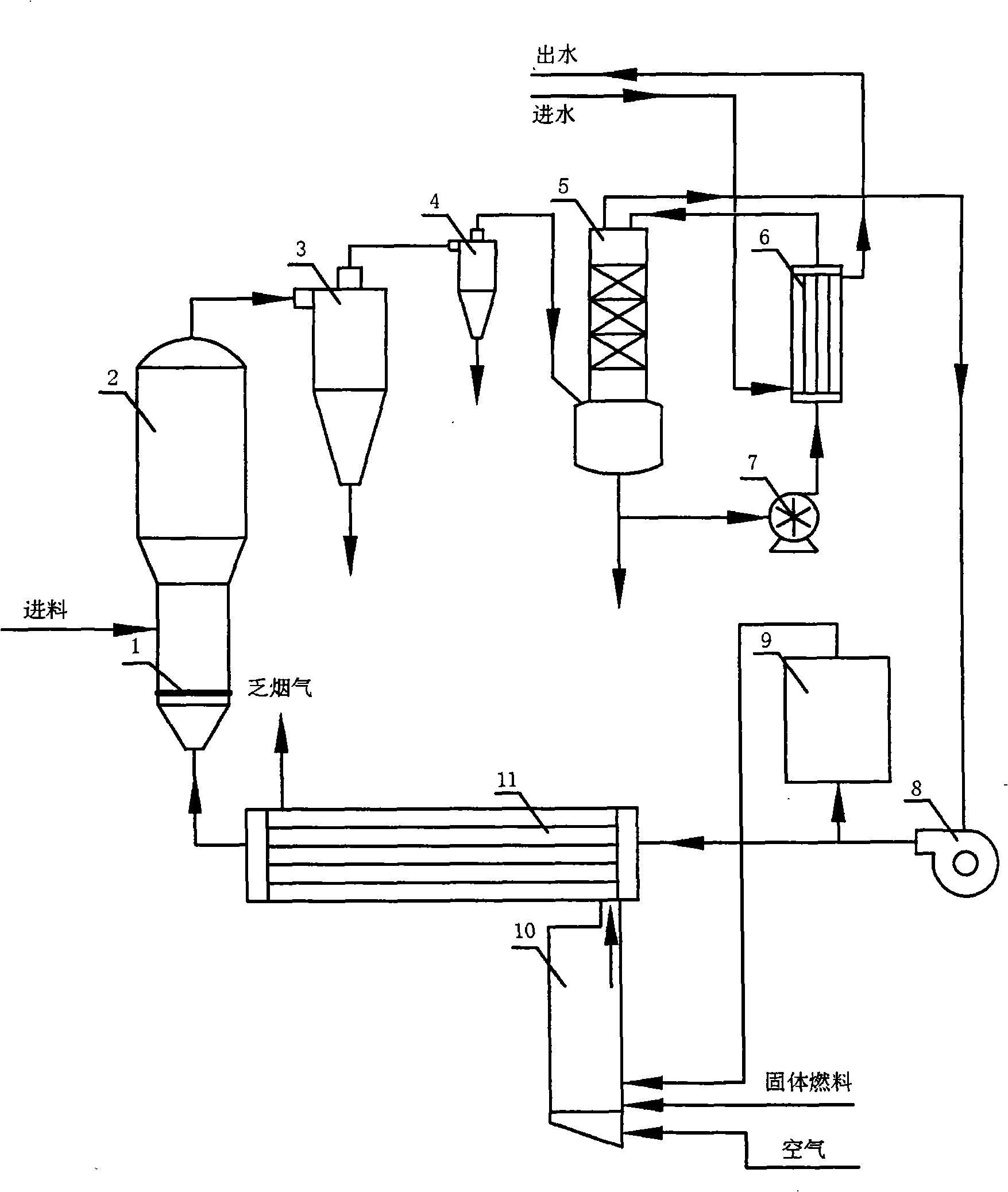

[0055] A fast pyrolysis refinery with a capacity of 100Kg / h is used to process cotton stalks to refine bio-oil. A two-stage cyclone separator is used in the device to improve the classification effect of solid and pyrolysis gas.

[0056] Its specific process operation method is as follows:

[0057] Turn on the co-firing furnace, run the heating system, and set the heating temperature to 550°C. Turn on the Roots blower, open the valve in the connecting pipeline, run the fluidized gas circulation system, and set the circulation gas flow rate in the system to 20m 3 / h. Turn on the circulation pump of the condenser and the external condensate water circulation pipeline to run the condensate system. After the interior of the fast pyrolysis reactor is heated to the required set temperature, run the feeding system, set the frequency of the inorganic frequency modulation motor to 25Hz, and gradually feed the cotton straw particles with a moisture content of 8% and a particle size o...

Embodiment 2

[0059] A fast pyrolysis refinery with a capacity of 150Kg / h is used to process larch sawdust to refine bio-oil. A two-stage cyclone separator is used in the device to improve the classification effect of solid and pyrolysis gas.

[0060] Its specific process operation method is as follows:

[0061] Turn on the co-firing furnace, run the heating system, and set the heating temperature to 560°C. Turn on the Roots blower, open the valve in the connecting pipeline, run the fluidized gas circulation system, and set the circulation gas flow rate in the system to 25m 3 / h. Turn on the circulation pump of the condenser and the external condensate water circulation pipeline to run the condensate system. After the interior of the spouted fluidized bed reactor is heated to the required set temperature, run the feeding system, set the frequency of the inorganic frequency modulation motor to 30Hz, and feed the cotton straw particles with a moisture content of 10% and a particle size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com