Patents

Literature

42results about How to "Efficient pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

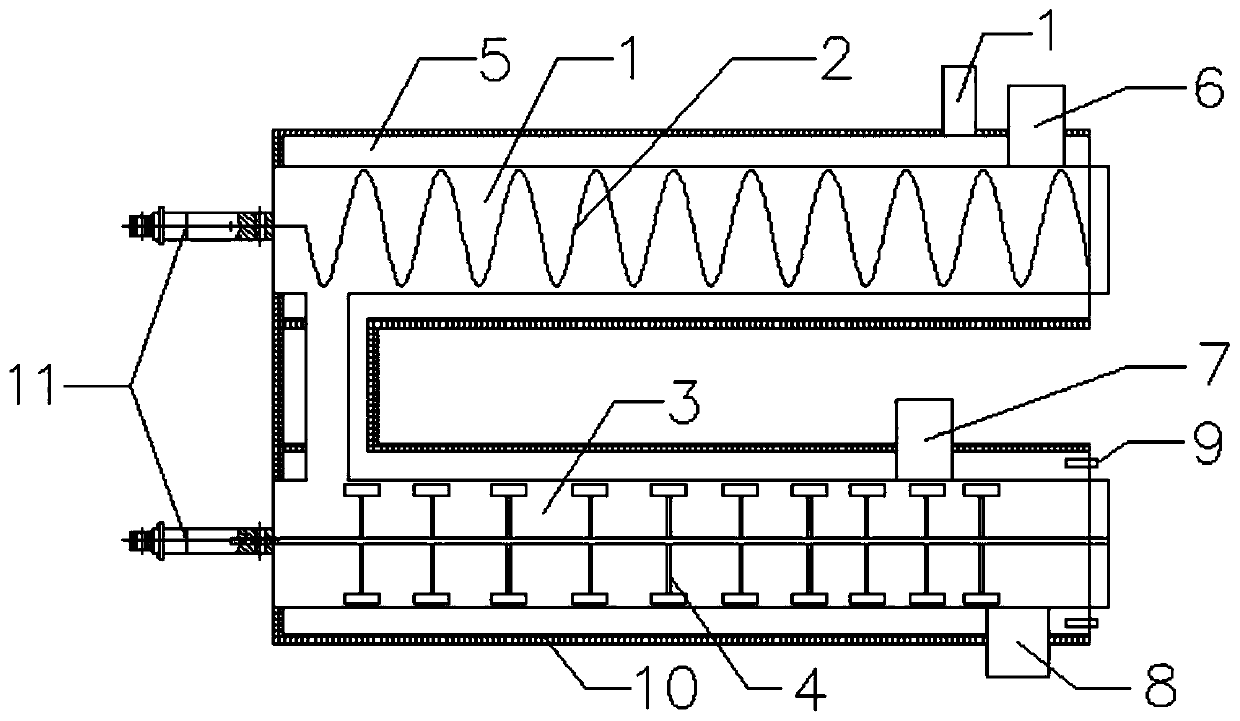

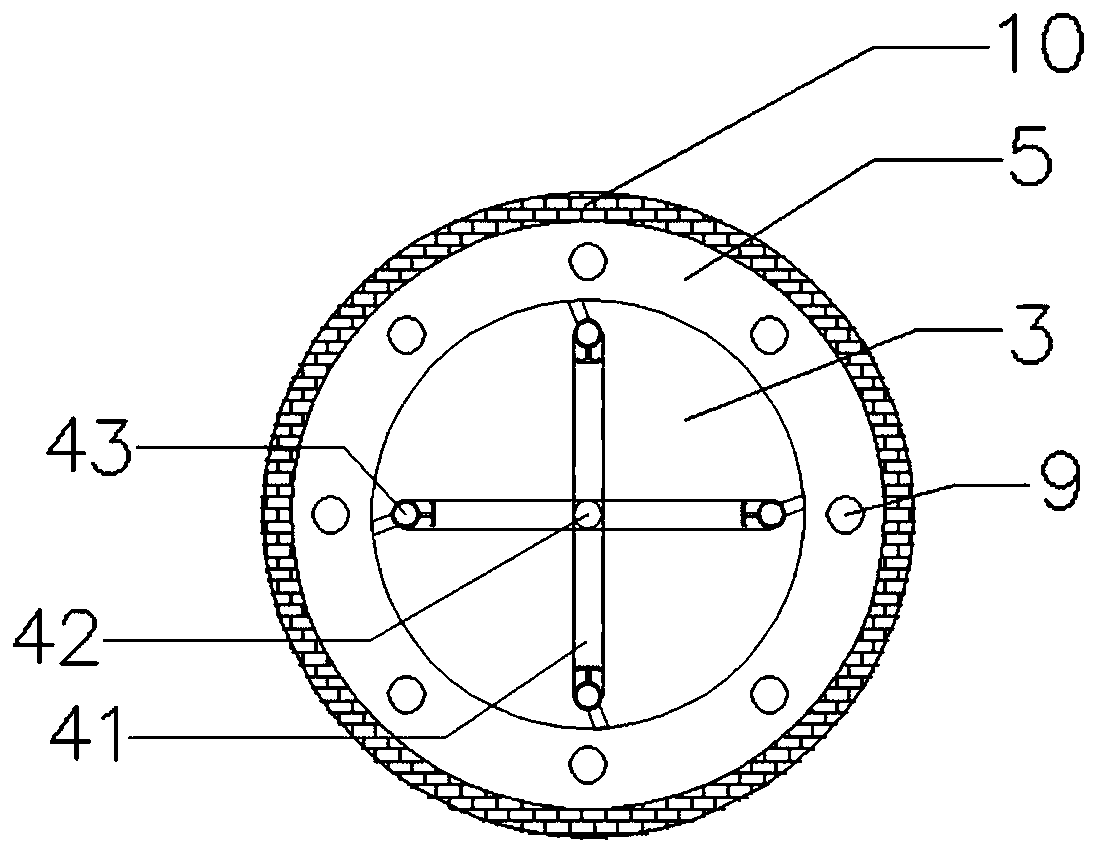

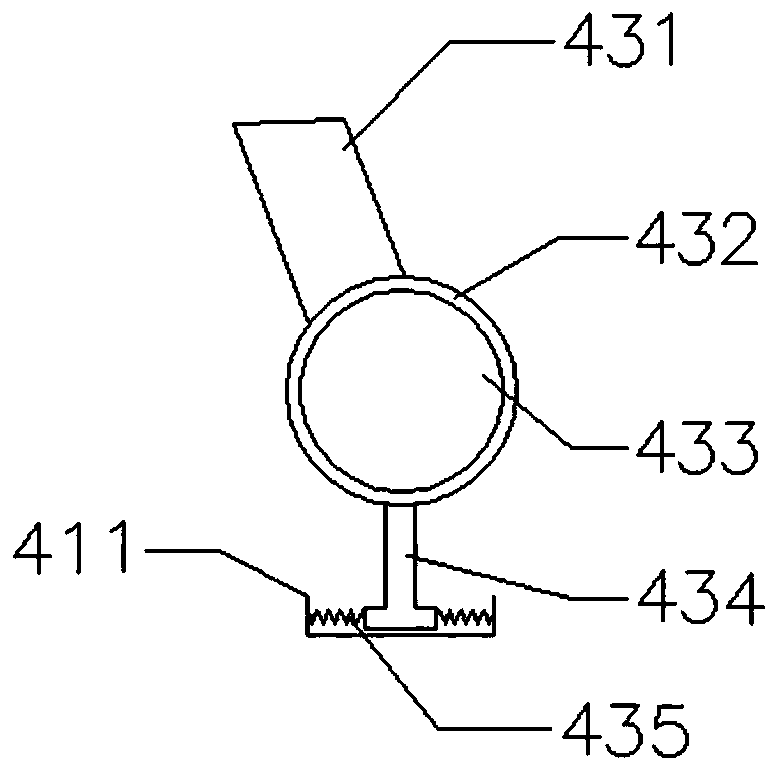

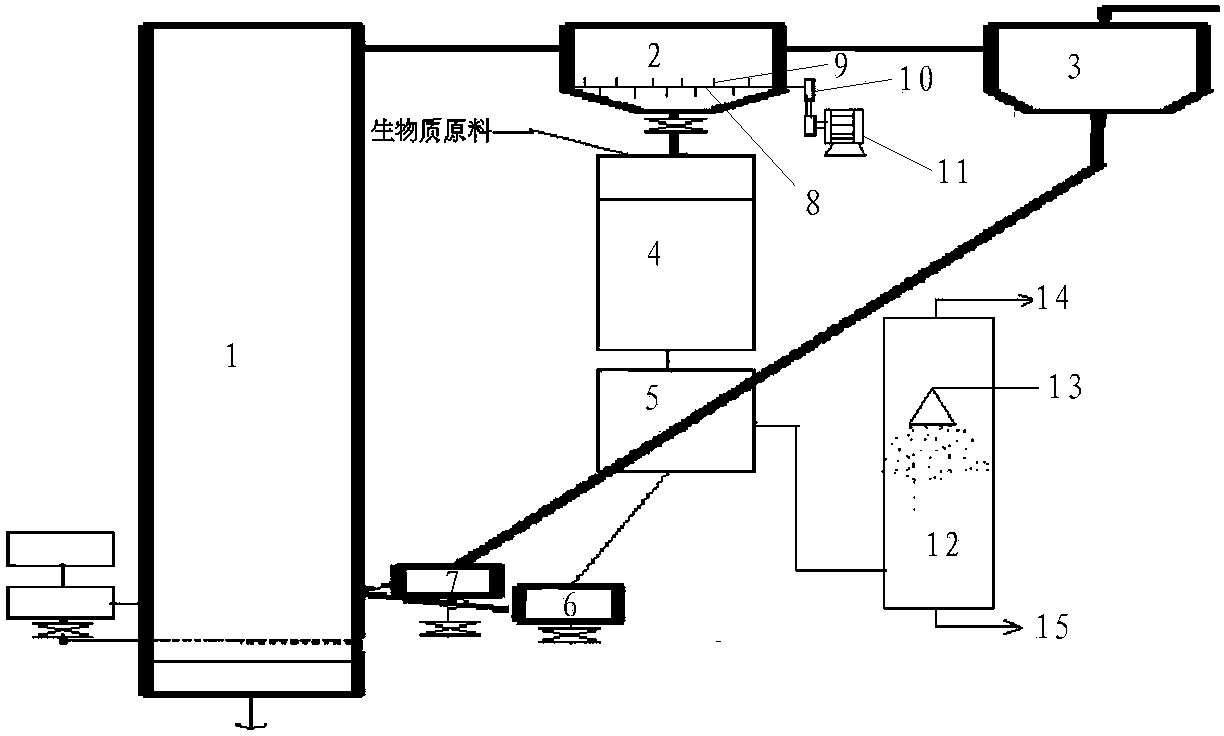

Industrial continuous agricultural and forestry biomass fast pyrogenation oil refining method and device thereof

InactiveCN101525545AAvoid settingSimple structureLiquid hydrocarbon mixture productionProduct gasEngineering

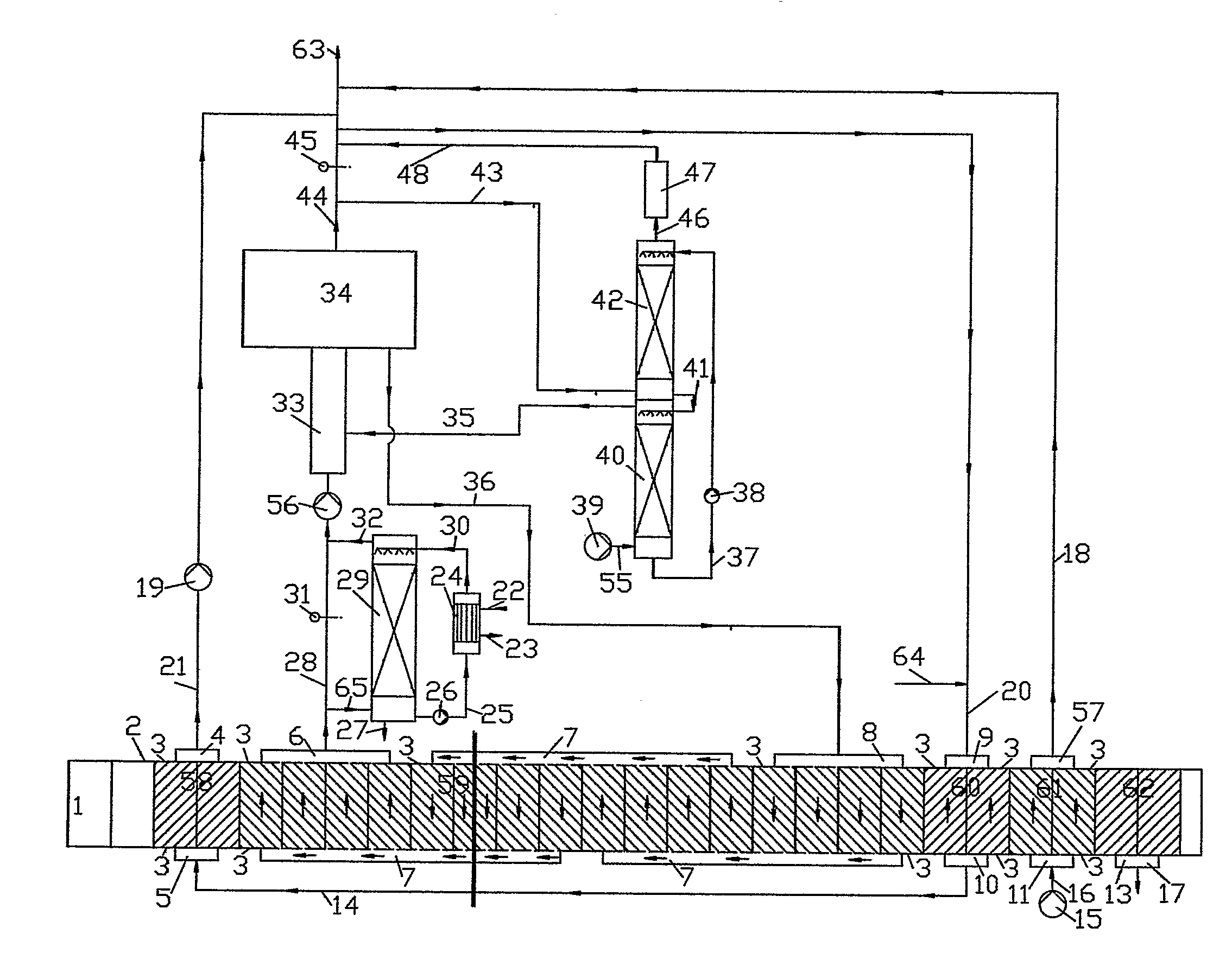

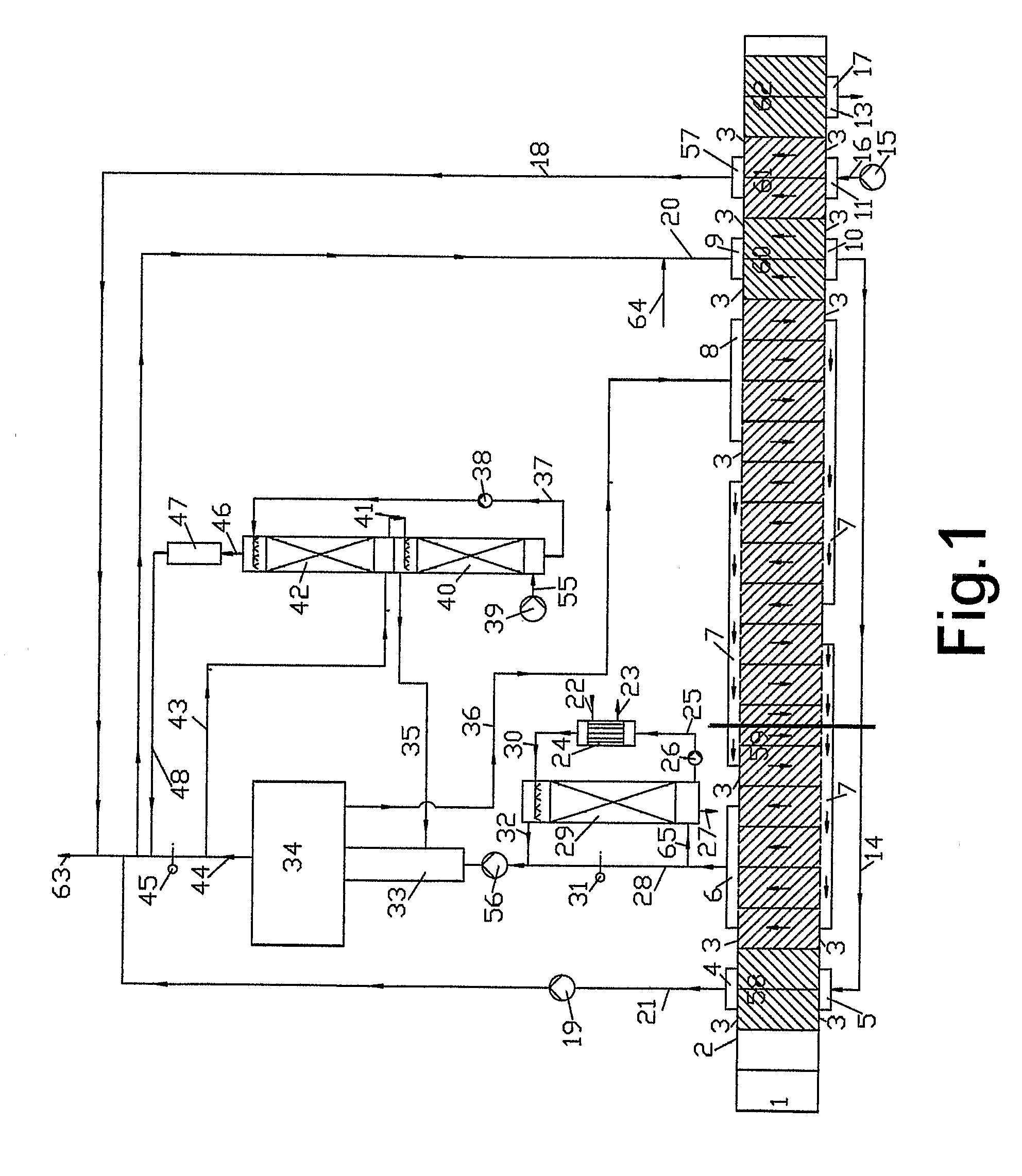

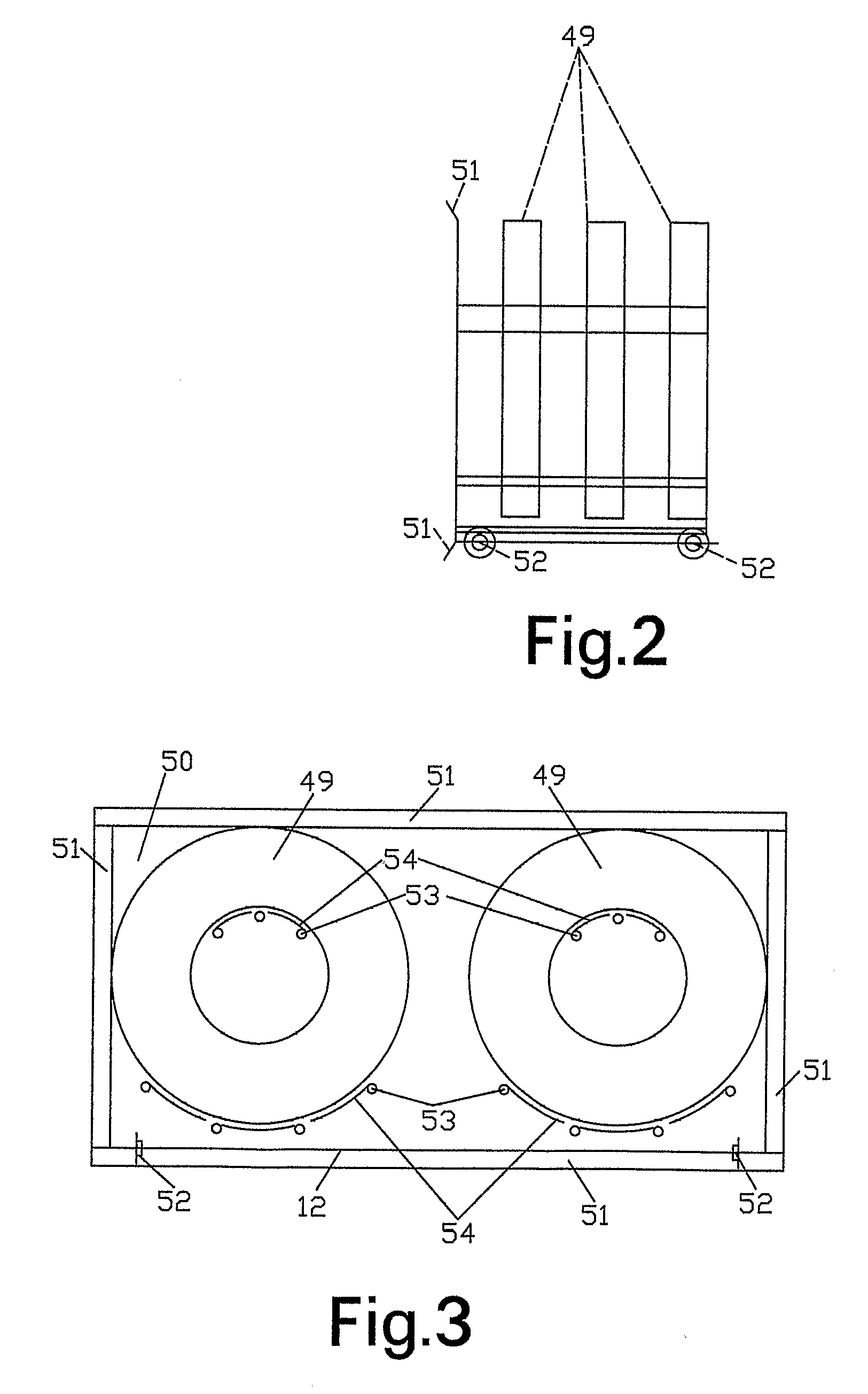

The present invention relates to an industrial continuous agricultural and forestry biomass fast pyrogenation oil refining method and a device thereof. The invention belongs to the technical field of biomass regeneration utilization and changing into energy. The crushed and dried agricultural and forestry biomass material is delivered into a pyrolysis reactor from the base for reacting. The carbon and pyrolysis are generated, wherein the pyrolysis enters a condenser along with the circulating gas. The bio-oil obtained after condensing the pyrolysis gas and incoagulable gas enter a reacting system for being heated by a combustion furnace for recycling. The fast pyrogenation oil refining method and the device of the invention use the incoagulable gas generated in the system as circulating fluidizing agent gas and heat supplying gas for high-efficiently executing the fast pyrogenation, gas-solid separation, condensing oiling of agricultural and forestry biomass and furthermore realizing the excellent circulation in the system. The device of the invention also has the advantages of reasonable structure of reactor, compact mechanism, stable operation of whole device, and suitability for industrial continuous production.

Owner:北京海润川投资咨询有限公司

Method for treating phthalate wastewater by means of catalyzing persulfate by utilization of supported activated carbon in microwave inducement manner

ActiveCN105565465AGood stabilitySimple process operationWater/sewage treatment by irradiationWater contaminantsActivated carbonEnvironmental chemistry

The invention relates to a method for treating phthalate wastewater by means of catalyzing persulfate by utilization of supported activated carbon in a microwave inducement manner, belonging to the technical field of phthalate wastewater treatment. The method comprises the following steps of adding a sodium persulfate solution with a concentration of 0.3 to 0.4 mM into phthalate wastewater with a concentration of 1500 to 3500 (mu)g / L according to a volume ratio of 0.5 to 1 percent, adjusting a pH value of the solution to be 6.0 to 9.0, then adding an activated carbon supported metal catalyst according to a proportion of 1 to 2 permillage, uniformly stirring, putting in a frequency conversion microwave reactor, setting a temperature of 70 to 80 DEG C, continuously reacting for 25 to 30 minutes, and taking a mixed solution to measure a phthalate concentration, wherein the phthalate removal rate reaches above 90 percent. The method disclosed by the invention has the advantages that microwave, supported activated carbon and persulfate act synergistically; the thermal effect and non-thermal effect of the microwave, the strong oxidation effect of the persulfate as well as the adsorptive catalysis and heat sensitization effects of the supported activated carbon are sufficiently exerted; the effects of simplicity and high efficiency in technological operation, easiness in implementation, freeness from secondary pollution, high oxidation efficiency and good removal effect are achieved.

Owner:广州中德环境技术研究院有限公司

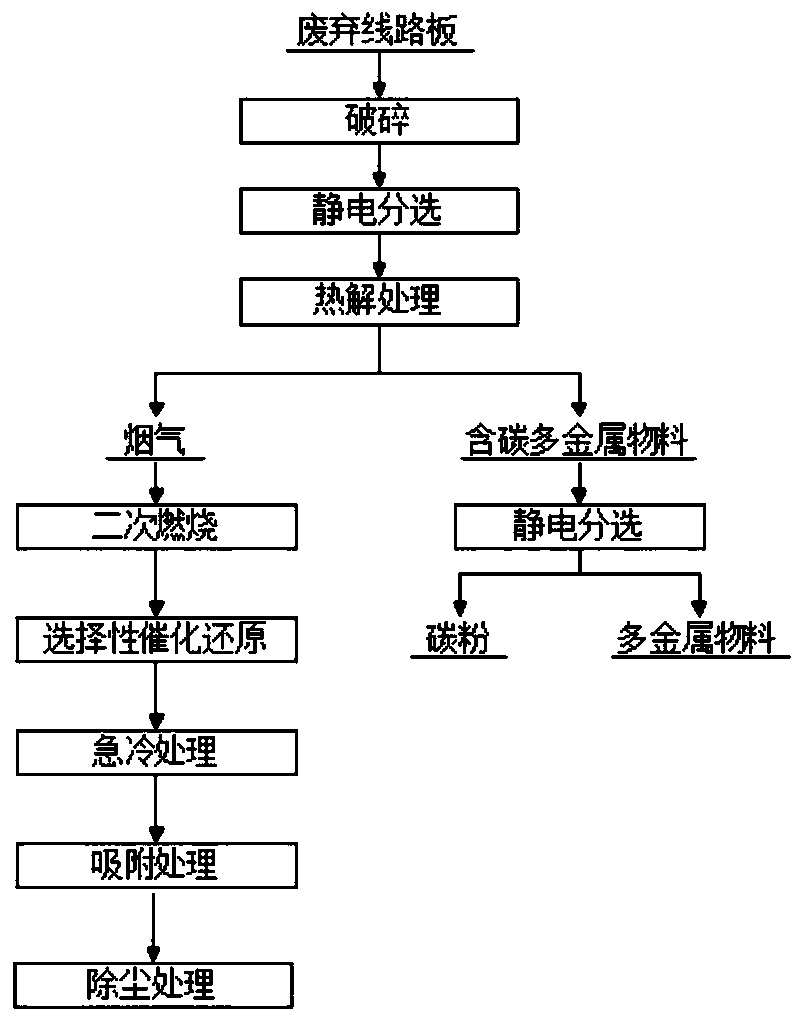

Treatment method for waste circuit board pyrolysis recovery

InactiveCN107866437AReduce productionReduce processing costsSolid waste disposalTransportation and packagingReduction treatmentCombustion

The invention discloses a treatment method for waste circuit board pyrolysis recovery. The method comprises the following steps that waste circuit boards are subjected to crushing, electrostatic separation and pyrolysis treatment to obtain flue gas and carbon-containing multi-metal materials, the carbon-containing multi-metal materials are subjected to electrostatic separation to obtain carbon powder and multi-metal materials, and the flue gas is subjected to secondary combustion, selective catalytic reduction treatment, quenching treatment, adsorption treatment and dust removal treatment to obtain the flue gas superior to the emission standard. By means of the treatment method, metal and non-metal substances in the waste circuit boards can be effectively separated, industrial continuous treatment of the waste circuit boards and recycling of resources are achieved, and the metal recovery rate reaches nearly 99.9%; besides, dioxin can be effectively prevented from being generated, and the dioxin removal efficiency is higher than 99.9%.

Owner:CENT SOUTH UNIV

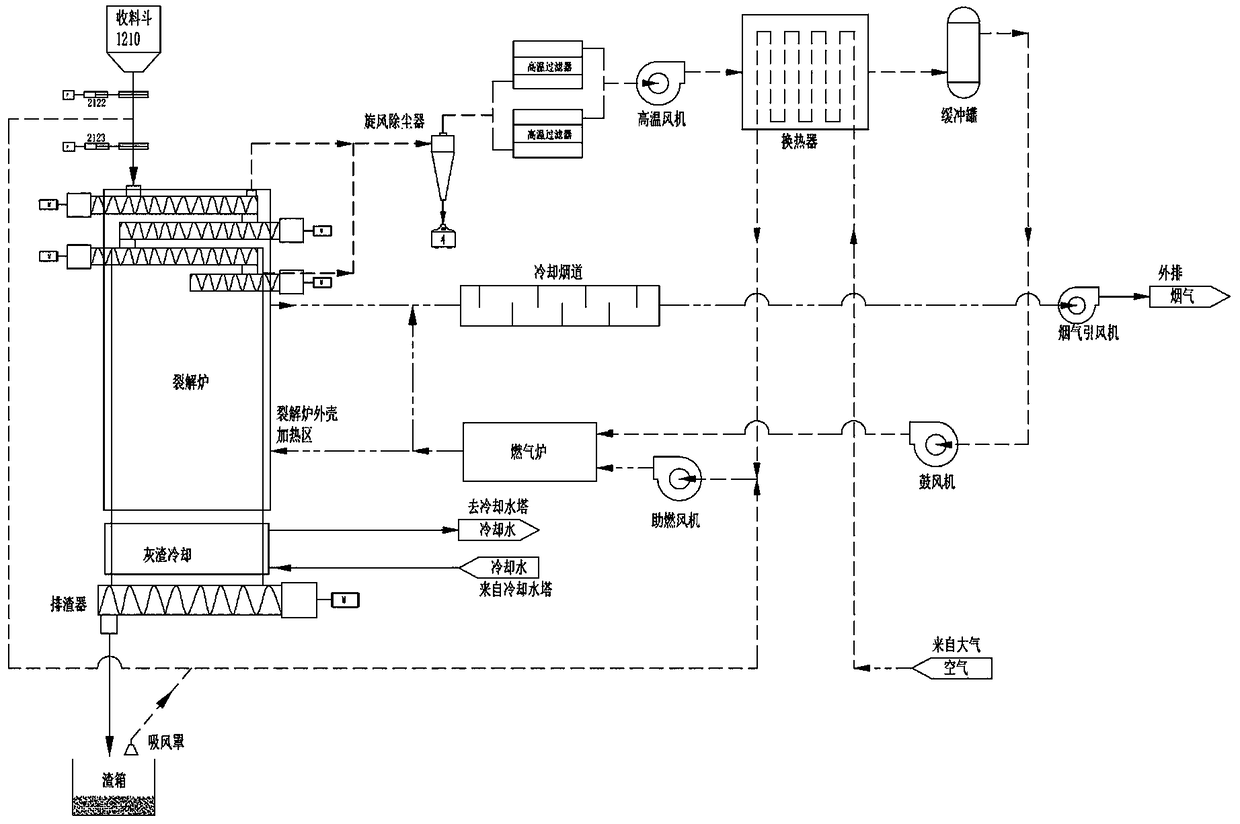

Oxygen-free sticky garbage pyrolyzing method and system

PendingCN108165287AEliminate cloggingEfficient pyrolysisProductsReagentsTemperature controlDecomposition

The invention discloses an oxygen-free sticky garbage pyrolyzing method and an oxygen-free sticky garbage pyrolyzing system. The oxygen-free sticky garbage pyrolyzing method comprises the following steps: performing garbage pretreatment: softening outwardly transported garbage by afterheat, adding a recycling liquid with an additive to increase the fluidity of a material, and sending the materialto a cracking furnace through specific hydraulic conveying equipment; performing garbage cracking decomposition: distilling, carbonizing and decomposing solid waste in the cracking furnace through multi-stage temperature control under an anaerobic condition, and according to the technological temperature and the heating rate, under the action of a catalyst, decomposing organic matters of the solidwaste into combustible gas, carbon and liquid compounds; reprocessing a cracking decomposition product: separating, purifying and synthesizing inorganic matters, the combustible gas, the carbon and the liquid compounds into building materials, fuel gas, regenerated finished products and solvents / oils. Under medium-temperature and low-temperature, catalytic and completely oxygen-free conditions, complex mixed garbage can be treated, the material is continuously fed, high-efficiency pyrolysis is achieved, and the fuel gas, the carbon and other regenerated products are produced.

Owner:深圳新能极科技有限公司

Comprehensive utilization method of biomass material

InactiveCN110093172ADoes not destroy the chemical structureHigh catalytic efficiencyBiofuelsLiquid hydrocarbon mixture productionCelluloseWater vapor

The invention relates to a method for recycling a biomass material, in particular to a method for converting the biomass material into activated carbon, a hydrogen-rich gas and a liquid fuel under supercritical conditions by microwave assistance of a composite metal catalyst. According to the method, the biomass material is subjected to gas explosion and fragmentation under high-pressure steam, sothat cellulose and hemicellulose are retained to the greatest extent, and the method can be better used for preparing energy chemicals through pyrolysis. The addition of solvent dimethyl sulfoxide can increase the specific surface area of the prepared solid product activated carbon. The use of flux NaF can improve the yield of the hydrogen-rich gas, meanwhile the composite metal catalyst is supported on alumina and silica substrates with transition metals, so that improvement of catalytic efficiency is especially facilitated.

Owner:NANJING COJINA NEW MATERIAL INST CO LTD

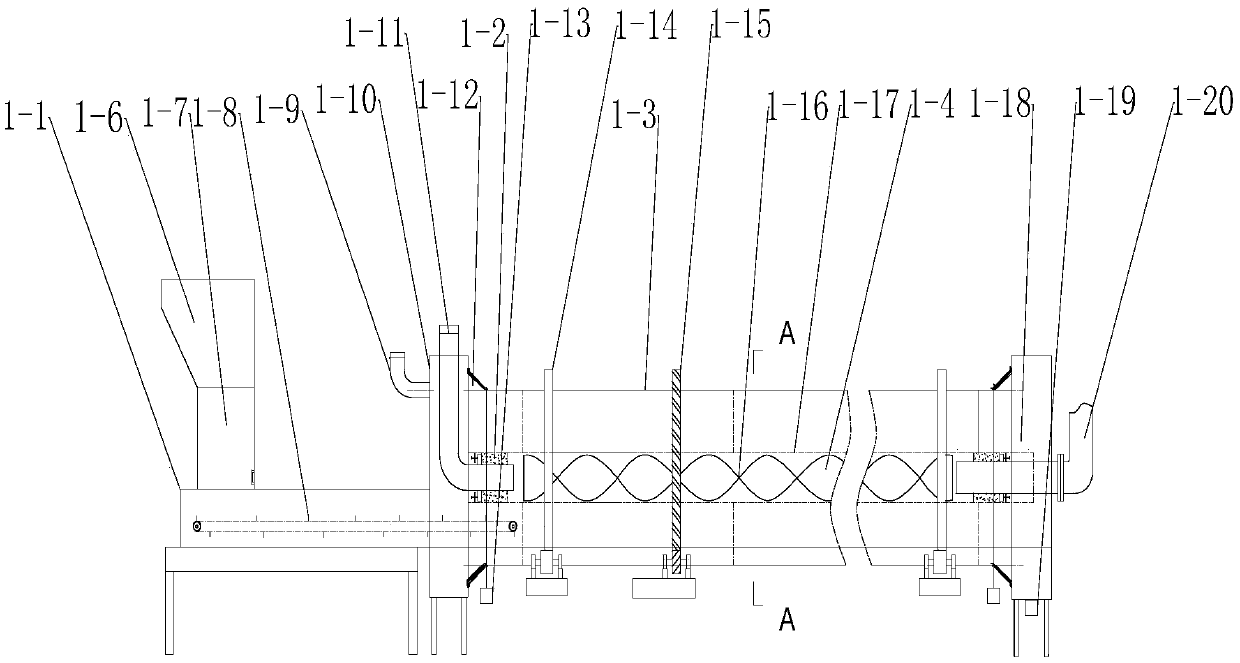

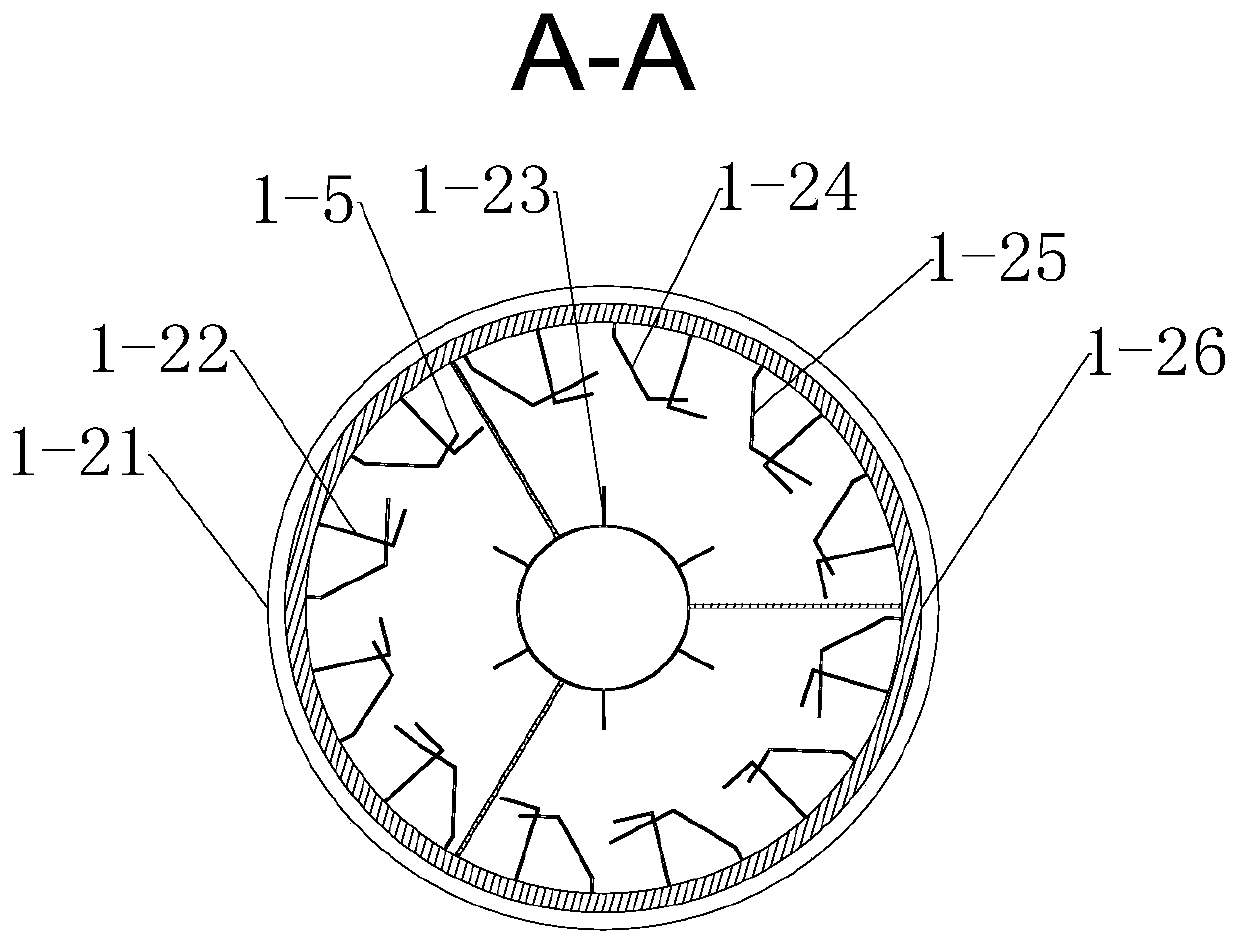

Multitube heating rotary pulverized coal pyrolysis system

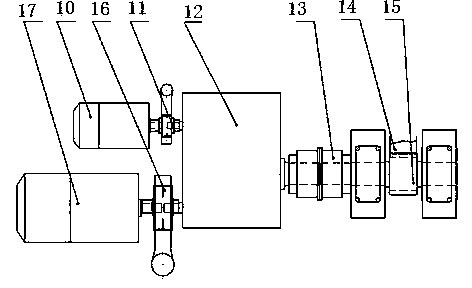

InactiveCN104017592ARealize large-scale pyrolysisAchieve recyclingIndirect heating destructive distillationSpecial form destructive distillationEngineeringCoal pyrolysis

The invention discloses a multitube heating rotary pulverized coal pyrolysis system, including a feeder, an outlet gas gathering and distribution box, a preheater, a transmission mechanism, a rotating cylinder body, a heating pipe, a riding wheel device, an air inlet gas gathering and distribution box and a gas guiding device. The rotating cylinder body supports on the riding wheel device, and is driven by the transmission mechanism; a feed end of the rotating cylinder body is provided with the outlet gas gathering and distribution box, and a discharging end of the rotating cylinder body is provided with the inlet gas gathering and distribution box; The rotating cylinder body is provided with the heating pipe, both ends of the heating tube are respectively connected with the inlet gas gathering and distribution box and the outlet gas gathering and distribution box; the feeder is connected with the charging end of the rotating cylinder body through the gas gathering and distribution box; the gas guiding device is connected with the discharge end of the rotating cylinder through the gas inlet gathering and distribution box; and the feeder is installed on the upper part of the preheater, and is connected with the gas outlet gathering and distribution box. The invention realizes the scale pyrolysis of pulverized coal, and creates conditions for improving the comprehensive utilization and economic value of pulverized coal.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Coal pyrolysis method and system

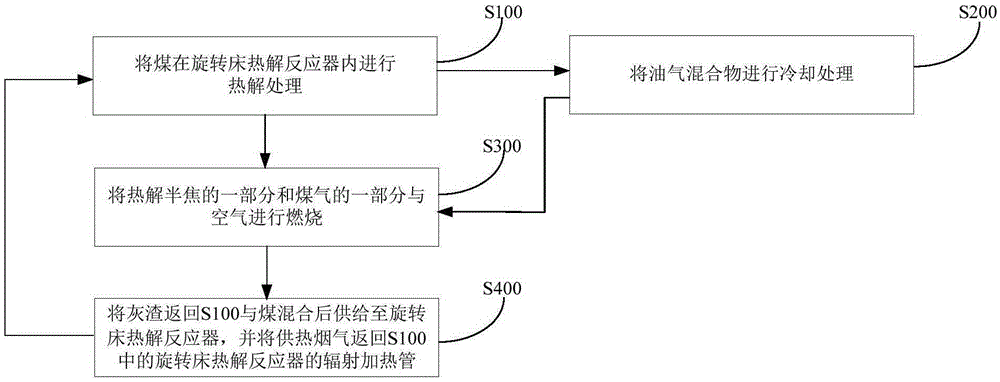

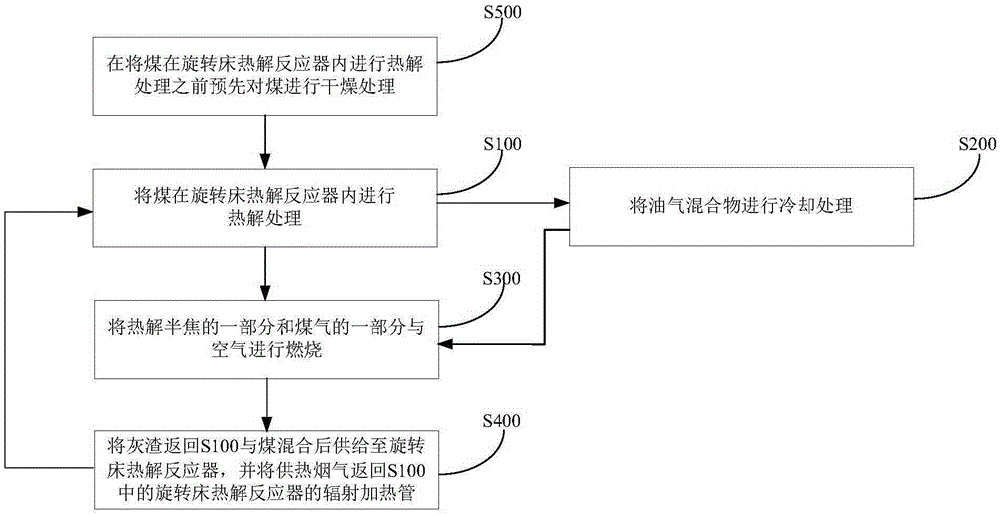

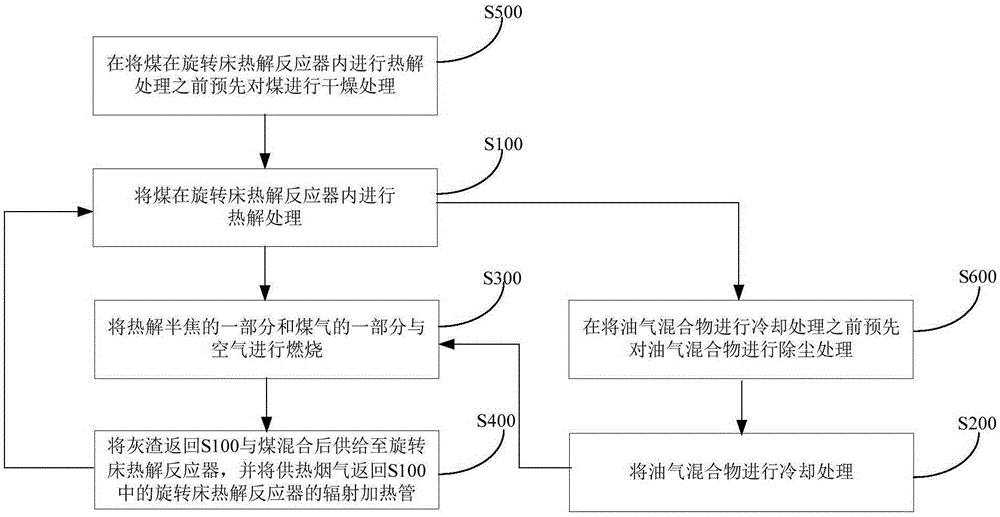

PendingCN105331377AEfficient pyrolysisIncrease tar yieldLighting and heating apparatusDispersed particle separationCoal pyrolysisProcess engineering

The invention discloses a coal pyrolysis method and system. The method comprises the steps that 1, coal is pyrolyzed in a revolving bed pyrolysis reactor to obtain a gas-oil mixture and pyrolysis semicoke; 2, the gas-oil mixture is cooled to obtain tar and coal gas; 3, some pyrolysis semicoke and some coal gas are combusted with air to obtain heat supply smoke and ash; 4, the ash is returned to the step 1 to be mixed with coal to be supplied to the revolving bed pyrolysis reactor, and the heat supply smoke is returned to a radiation heating pipe of the revolving bed pyrolysis reactor in the step 1 to be used as a heat source, so that cooled smoke is obtained. By the adoption of the method, efficient pyrolysis of coal is achieved, the tar yield is high, meanwhile, the problem of the high energy consumption in the prior art can be solved, and therefore the disposal cost is effectively reduced.

Owner:SHENWU TECH GRP CO LTD

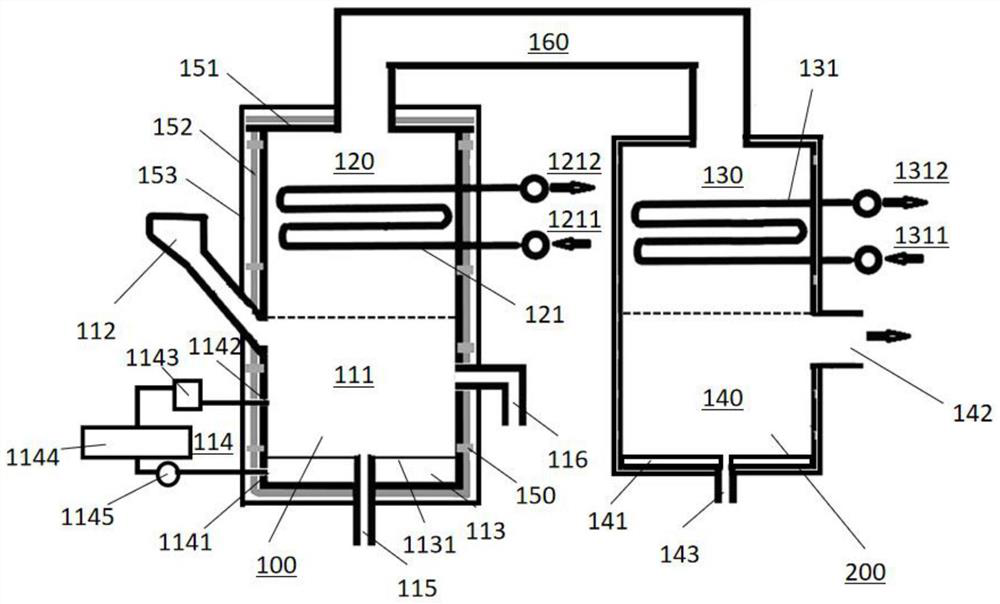

Organic garbage pyrolysis device and organic garbage pyrolysis treatment method

InactiveCN111040791AReduce thermal hysteresisEfficient pyrolysisSpecial form destructive distillationChemistryProcess engineering

The embodiment of the invention provides an organic garbage pyrolysis device. The device mainly comprises a low-temperature pyrolysis chamber, a high-temperature pyrolysis chamber, a smoke chamber, aheat preservation layer and a motor, wherein the low-temperature pyrolysis chamber adopts shaftless spiral stirring and garbage material conveying; a stirring scraper in the high-temperature pyrolysischamber mixes materials, and scrapes off coked materials on a heating surface; high-temperature oil gas generated by organic garbage pyrolysis is directly combusted, and hot smoke flows in the smokechamber in the direction opposite to the garbage material conveying direction and exchanges heat with the materials in the high-temperature pyrolysis chamber and the low-temperature pyrolysis chamberin sequence; a screw and a coke scraper are arranged in the pyrolysis chamber, so that materials are uniformly heated, and coking is reduced; segmented pyrolysis realizes high-temperature direct combustion of high-efficiency pyrolysis garbage pyrolysis oil gas of different kinds of garbage, high-temperature sensible heat is effectively utilized, the temperature of combustion smoke is increased, and pollution is reduced; and the smoke is indirectly heated, pyrolysis gas is not mixed with the smoke, the heat value is high, and subsequent utilization is easy. The embodiment of the invention further provides a garbage pyrolysis treatment method using the organic garbage pyrolysis device.

Owner:湖南华仁宏顺科技有限公司

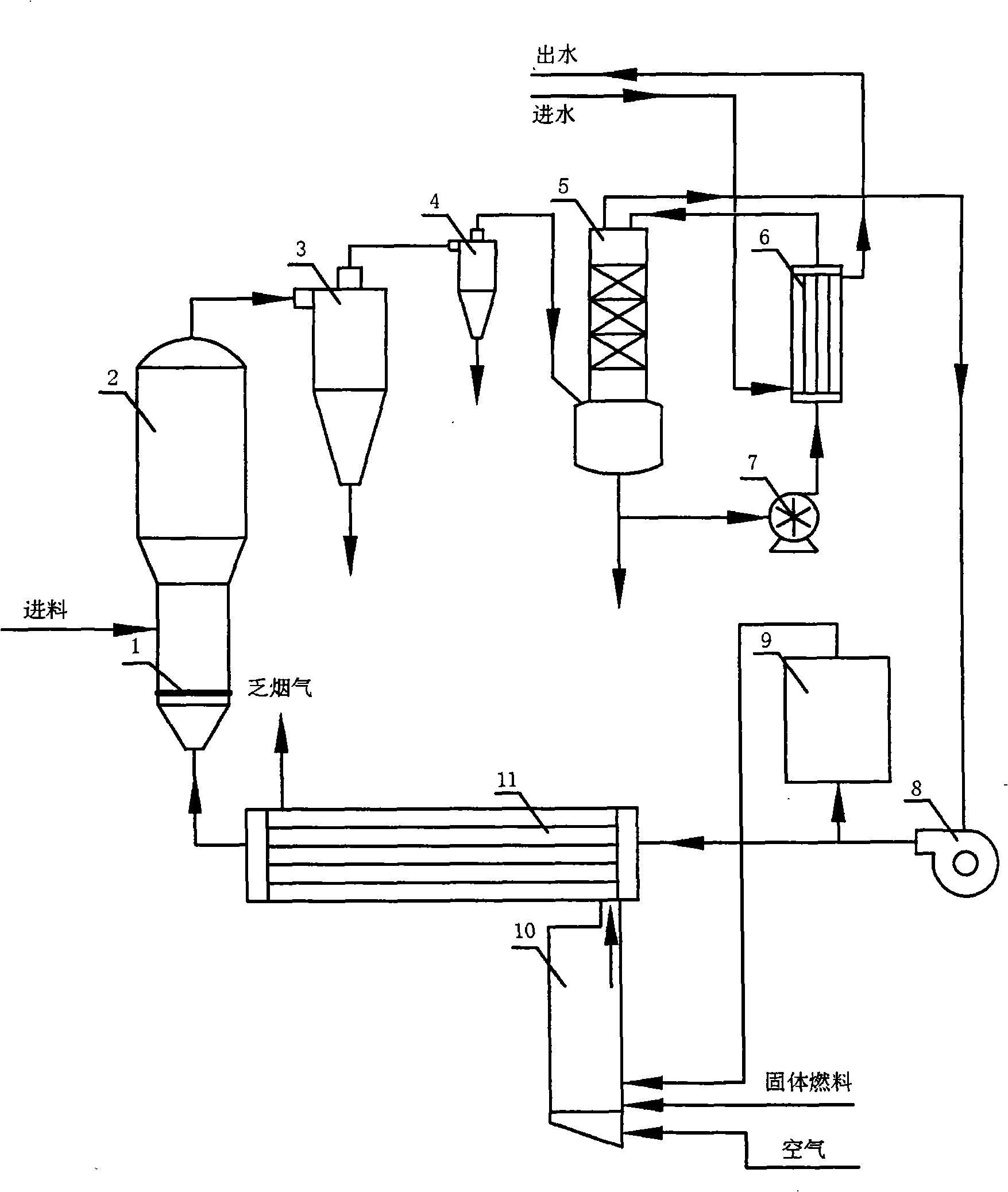

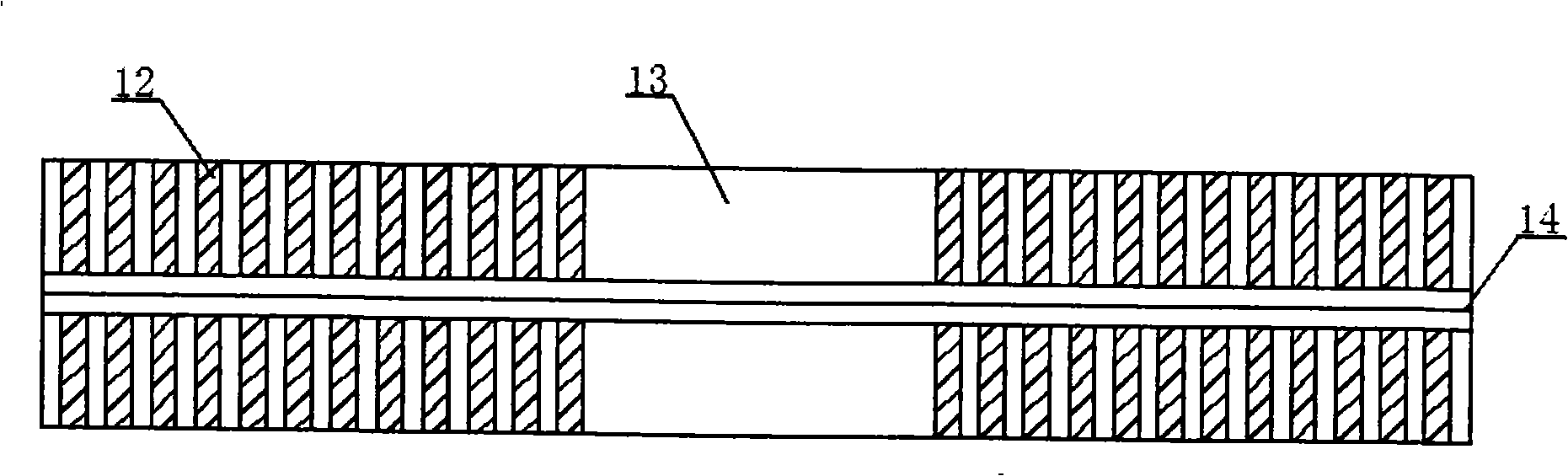

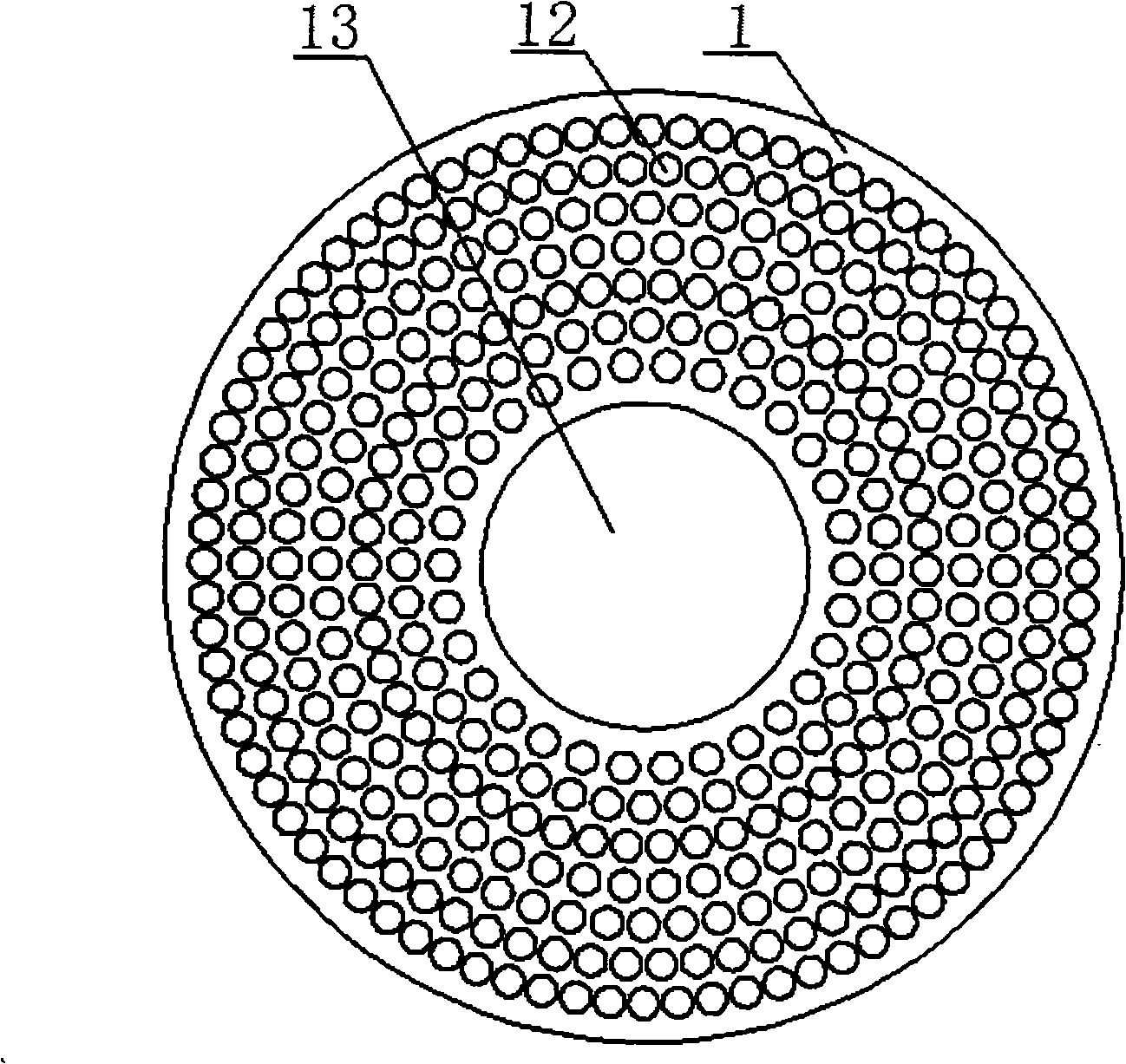

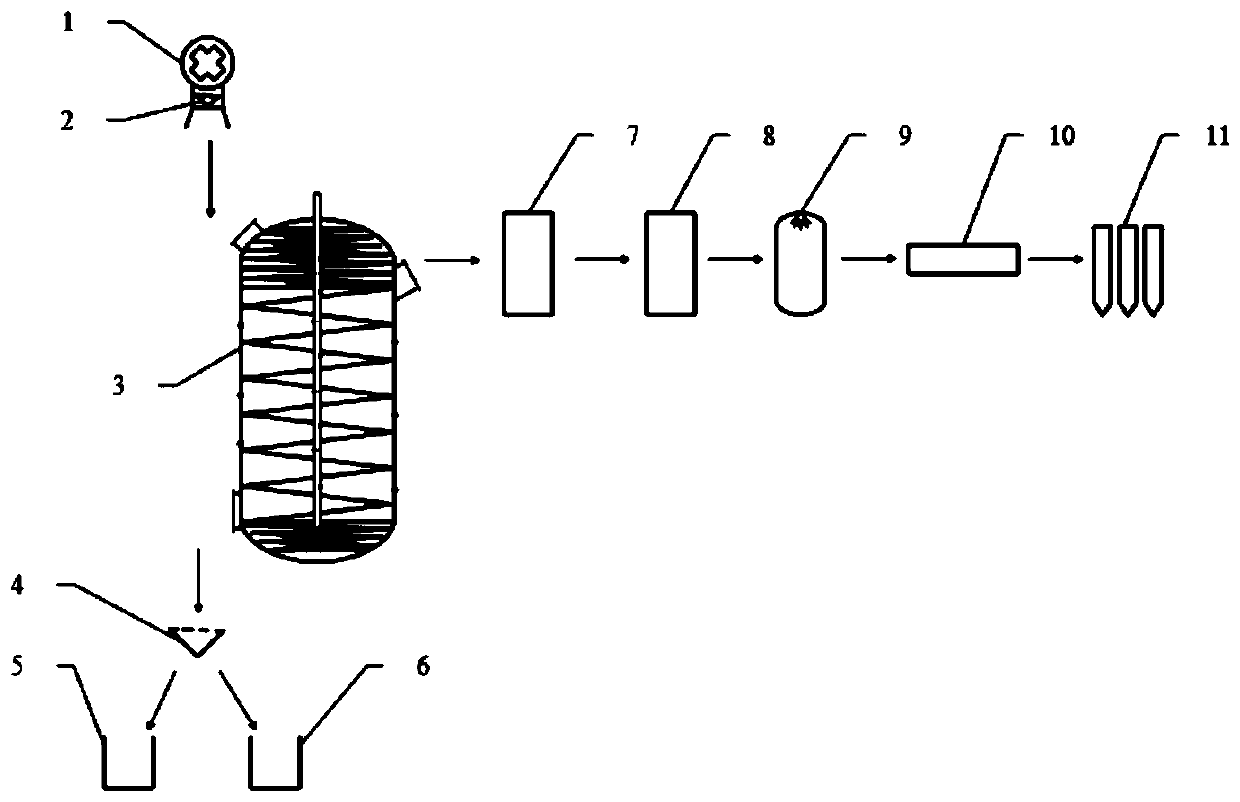

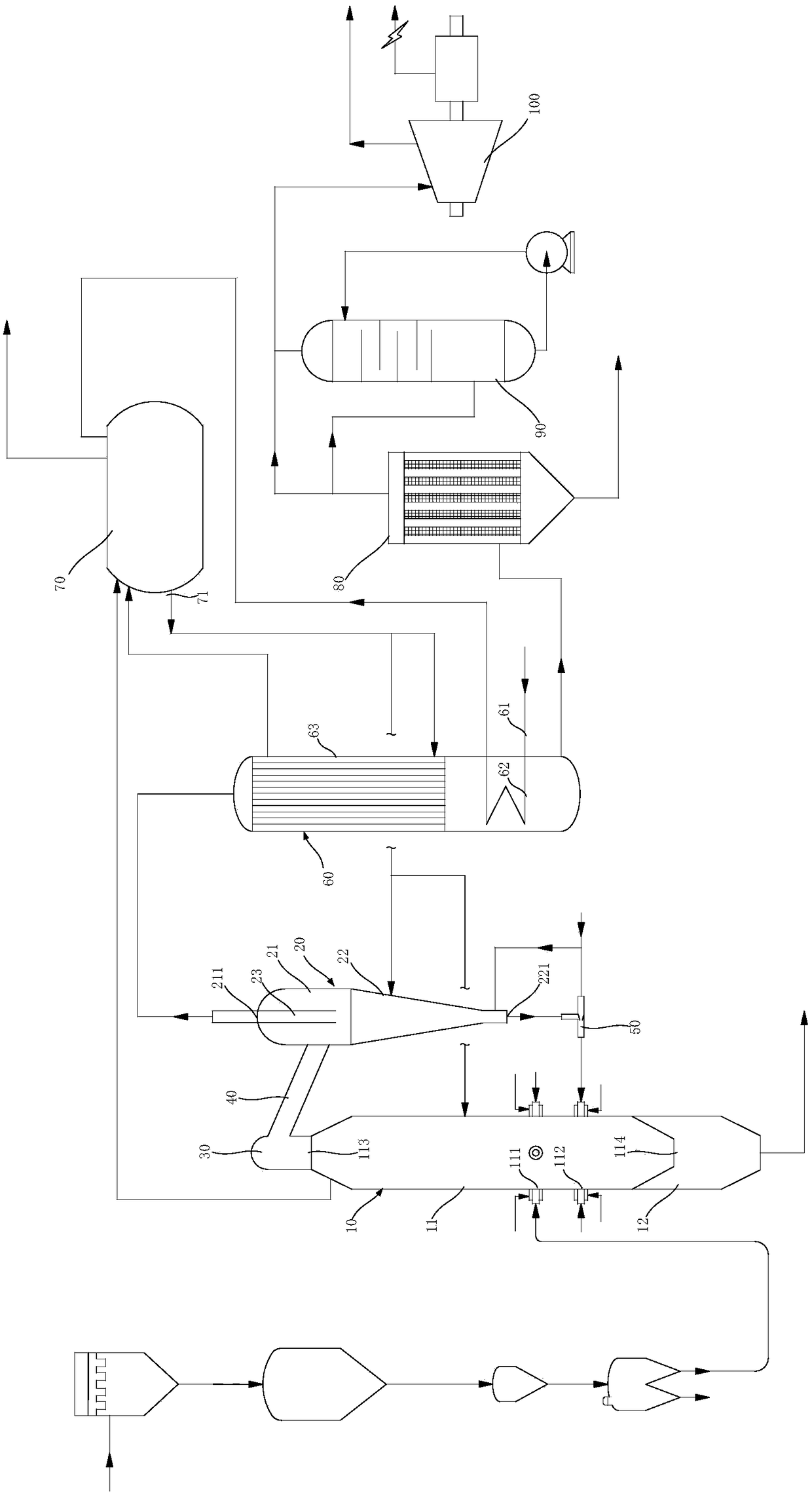

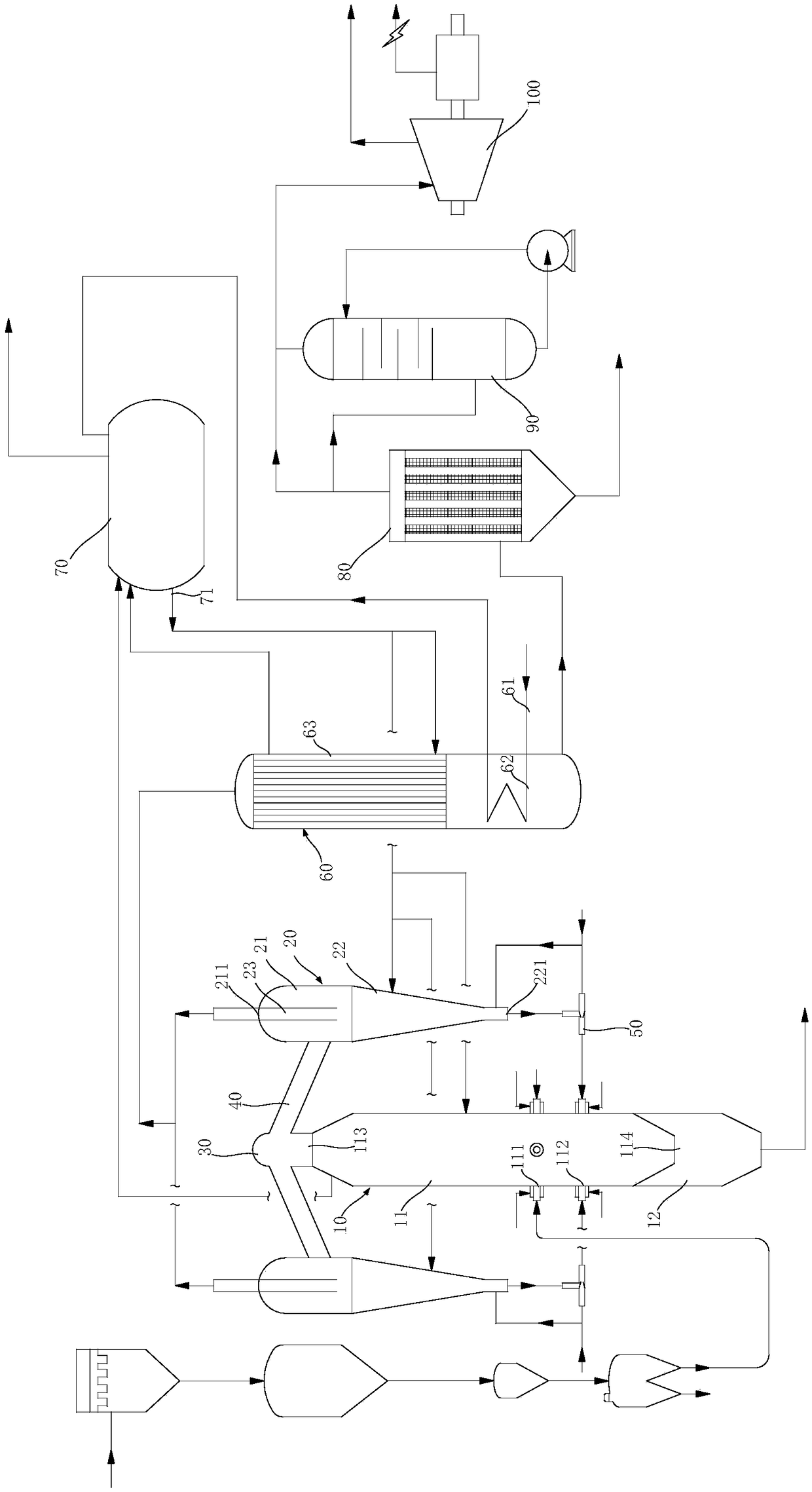

High-efficiency production technique for preparing fuel oil by pyrolyzing biomass

ActiveCN103396824AOptimizing the pyrolysis processEfficient pyrolysisLiquid hydrocarbon mixture productionInternal pressureEngineering

The invention relates to a high-efficiency production technique for preparing fuel oil by pyrolyzing biomass, which adopts a circulating fluid bed reactor. The production technique comprises the following steps: (1) pulverizing the raw material pine wood into granules with the granule size of 1-3 millimeters, and drying until the relative water content is less than 8% for later use; (2) pyrolyzing every 12 tons of absolute dry material for one hour, wherein the reactor temperature is kept at 480-530 DEG C in the pyrolysis process, and the internal pressure is kept at 0 to -500 Pa; and (3) carrying out spray cooling on the reaction pyrolytic gas to lower than 60 DEG C, separating and cooling to obtain the fuel oil, wherein the spray pressure is controlled at -1000 Pa. The invention aims to optimize the biomass pyrolysis technique on the premise of not changing the existing equipment and traditional technical process, so that the biomass is pyrolyzed efficiently, and the yield of fuel oil is greatly enhanced.

Owner:广饶县泽润环保科技有限公司

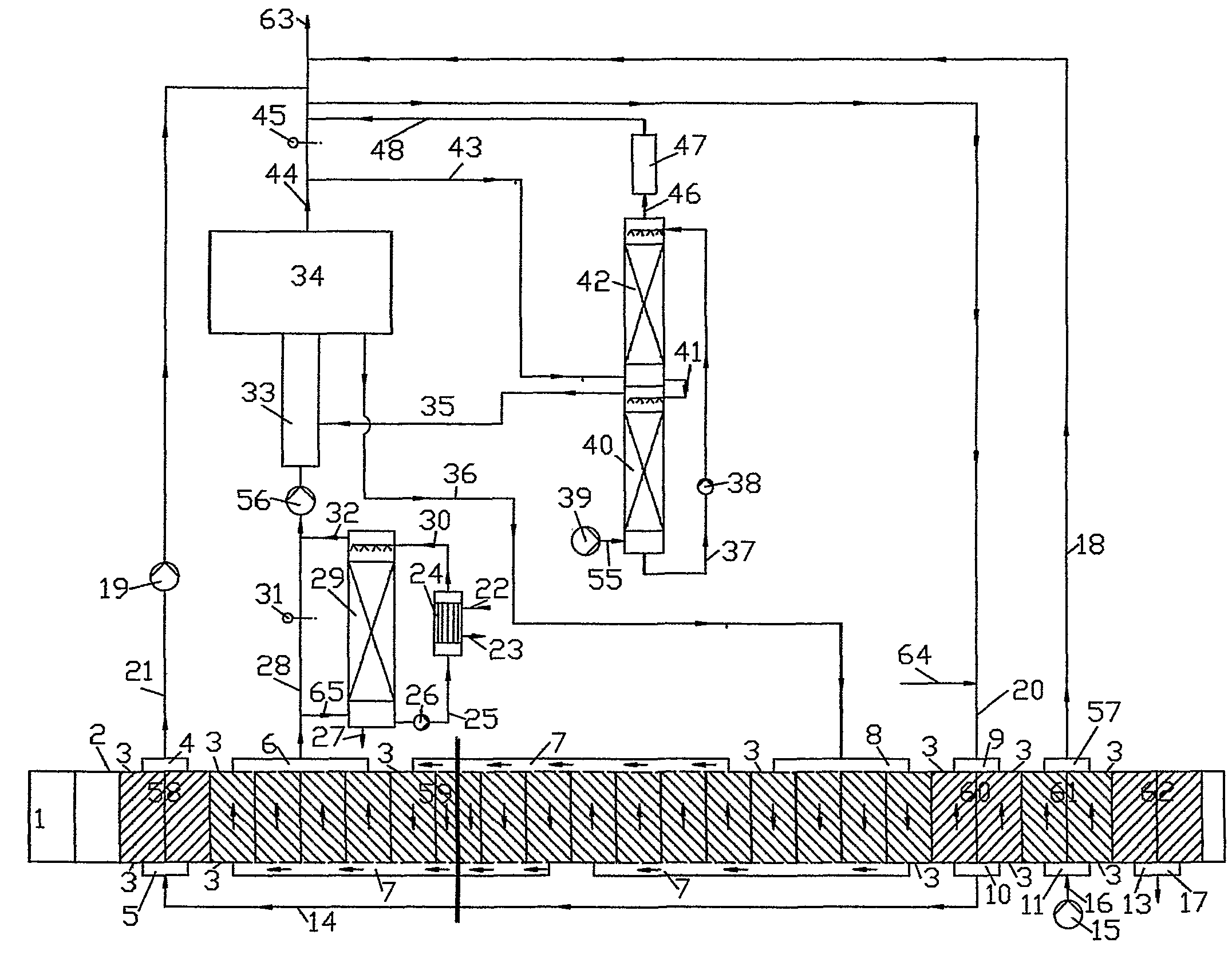

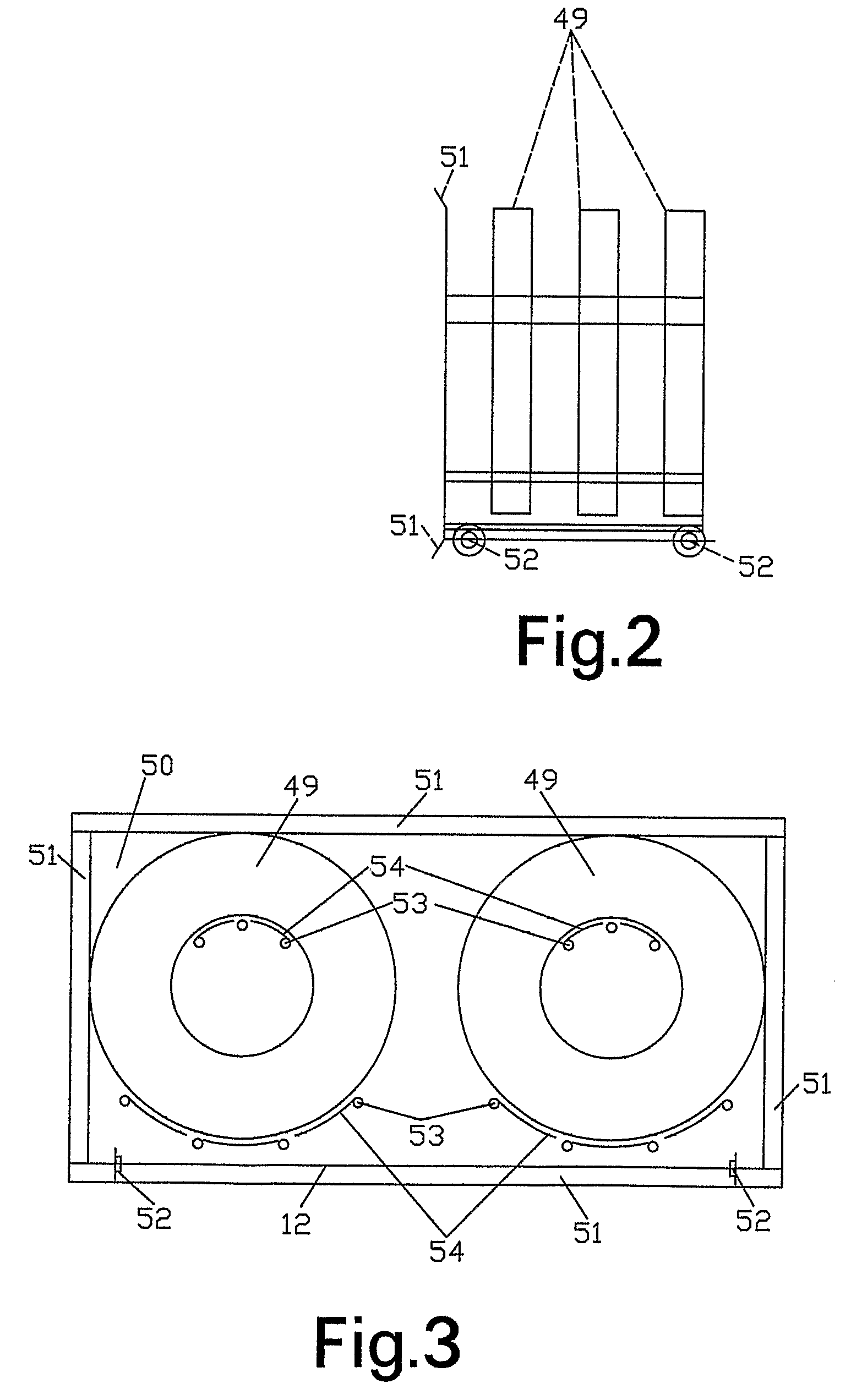

Method and Installation for Pyrolisis of Tires

InactiveUS20080202913A1Reduce energy expenseReduce harmful effectsPigmenting treatmentDirect heating destructive distillationThermal energyAtmospheric air

The present invention relates to a method and apparatus for waste tyres pyrolysis wherein whole tyres are directly heated with flue gases from the combustion of pyrolysis gases, in a tunnel type furnace. The process produces thermal energy, carbon black and mineral oil; the cooled flue gases are cleaned from sulfur oxides before released into the atmosphere.

Owner:KOLEV DIMITAR NIKOLAEV +2

Fluidized bed hierarchical coal pyrolysis reactor and coal pyrolysis method

InactiveCN103031135BImprove heat transfer performanceImprove heat transfer effectDirect heating destructive distillationBiofuelsFluidized bedMixed materials

The invention discloses a fluidized bed hierarchical coal pyrolysis reactor. The fluidized bed hierarchical coal pyrolysis reactor comprises a pyrolysis chamber, a separating wall, a pyrolytic gas waste heat recovery device, a coal conveying device, a large granule outlet, a mixed material outlet and an ash conveying device, wherein the pyrolysis chamber comprises a low-temperature pyrolysis chamber and a high-temperature pyrolysis chamber. The invention further discloses a method for performing coal pyrolysis by using the device. By the method, the yield of gas is high, the yield of tar is low, high-efficiency and complete pyrolysis of coal is realized, the gas flow is less fluidized, and excellent fluidized heat exchange and conveying of coal, semicoke and circulating ash are realized, so that energy consumption and heat loss caused by fluidized gas are reduced. Low-temperature pyrolytic gas and high-temperature pyrolytic gas are mixed, so secondary pyrolysis of the lightweight tar of the low-temperature pyrolytic gas is realized, the yield of the pyrolytic gas is increased and the amount of the tar is reduced; and the temperature of the medium-temperature gas after mixing is reduced compared with the pyrolysis final temperature of the coal pyrolysis reactor, so the capacity and the flowing resistance of the pyrolytic gas waste heat recovery device can be reduced, the cost of equipment materials is reduced and the reliability of the equipment is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

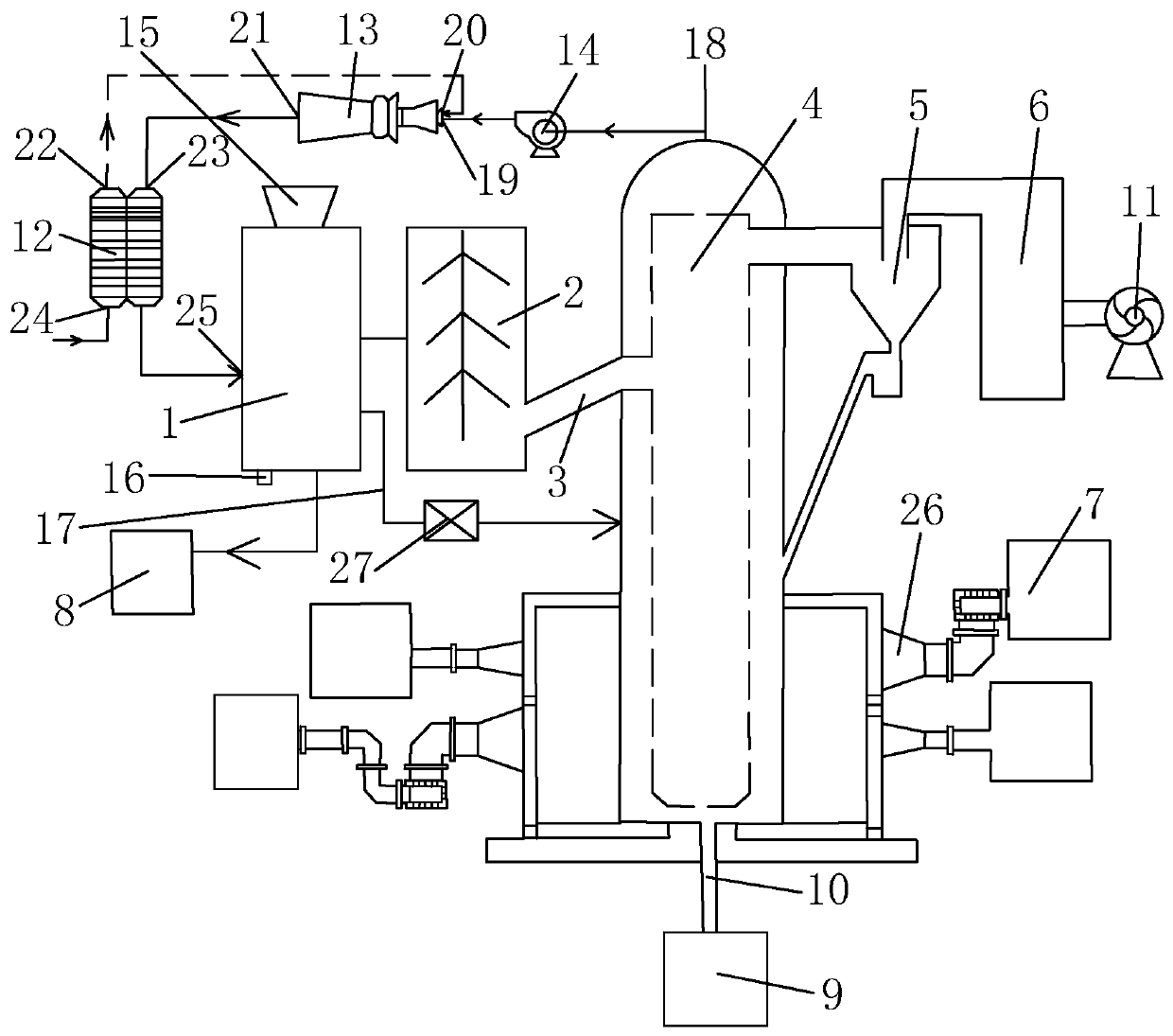

Fluidized bed microwave pyrolysis rural domestic garbage device and use method thereof

InactiveCN110332544AImprove energy and heat utilization efficiencyEmission reductionIncinerator apparatusPulverizerPhencyclone

The invention discloses a fluidized bed microwave pyrolysis rural domestic garbage device and a use method thereof. The fluidized bed microwave pyrolysis rural domestic garbage device comprises a roller dryer, a chain crusher and a spiral feeder, wherein the roller dryer is connected with the chain crusher; the chain crusher is connected with a feed port of a fluidized pyrolysis chamber through the spiral feeder; a discharge port of the fluidized pyrolysis chamber is connected with a cyclone separator; the top end of the cyclone separator is connected with a dust remover, and a solid outlet atthe bottom end of the cyclone separator is connected with the fluidized pyrolysis chamber; microwave reflection diffusion cavities are symmetrically arranged on the left side and the right side of the fluidized pyrolysis chamber; and microwave waveguides are connected with a microwave generator and uniformly arranged in the longitudinal direction of the microwave reflection diffusion cavities. The use method comprises the steps of drying, crushing, and vulcanizing pyrolysis. According to the device and the method, domestic garbage can be efficiently treated, no secondary pollution is generated, the garbage pyrolysis is more thorough, and the treatment efficiency is higher.

Owner:SHANDONG POLYTECHNIC COLLEGE

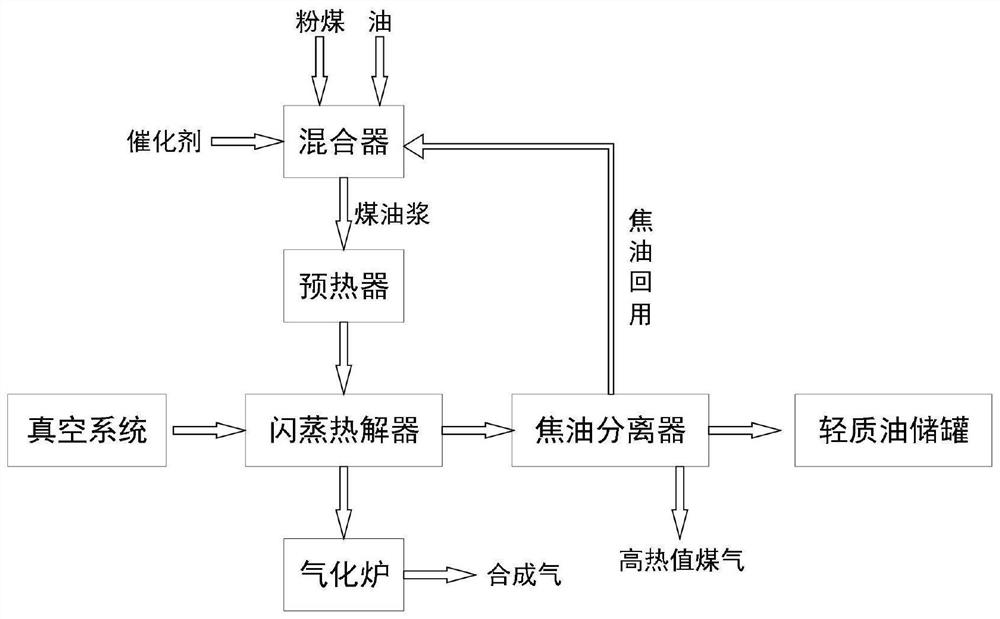

Kerosene co-catalytic pyrolysis-semicoke catalytic gasification method

PendingCN113214874ALower gasification temperatureImprove gasification efficiencyGasification processes detailsCombustible gas productionCatalytic pyrolysisSyngas

The invention discloses a kerosene co-catalytic pyrolysis-semicoke catalytic gasification method which comprises the following steps: mixing low-rank coal, oil and a catalyst to obtain kerosene slurry, preheating the kerosene slurry to 300-500 DEG C, feeding the preheated kerosene slurry into a flash pyrolysis device, maintaining the pressure of the flash pyrolysis device at 0.5-60kPa, and feeding volatile components generated by flash pyrolysis of the kerosene slurry into a tar separator; after volatile components obtained by flash evaporation and pyrolysis of the kerosene slurry escape, carrying out condensation polymerization on residual components through a flash evaporation and pyrolysis device to obtain solid semi-coke, crushing the solid semi-coke to 1-200 meshes, feeding the crushed solid semi-coke to a gasification furnace, heating the crushed solid semi-coke to 900-1200 DEG C at a speed of 10 DEG C / min in the gasification furnace, and taking CO2 as a gasification agent to obtain synthesis gas CO and H2; and condensing and separating volatile components obtained by flash evaporation and pyrolysis of the kerosene slurry through a tar separator to obtain light tar and high-calorific-value coal gas. According to the method disclosed by the invention, the yield and the quality of the pyrolysis tar are improved, meanwhile, the gasification temperature of the semicoke is reduced, and the gasification efficiency of the semicoke is improved.

Owner:XIJING UNIV

Method and system for the pyrolysis of whole tires

InactiveUS7922870B2Reduce harmful effectsEfficient pyrolysisPigmenting treatmentDirect heating destructive distillationThermal energyCombustion

Owner:KOLEV DIMITAR NIKOLAEV +2

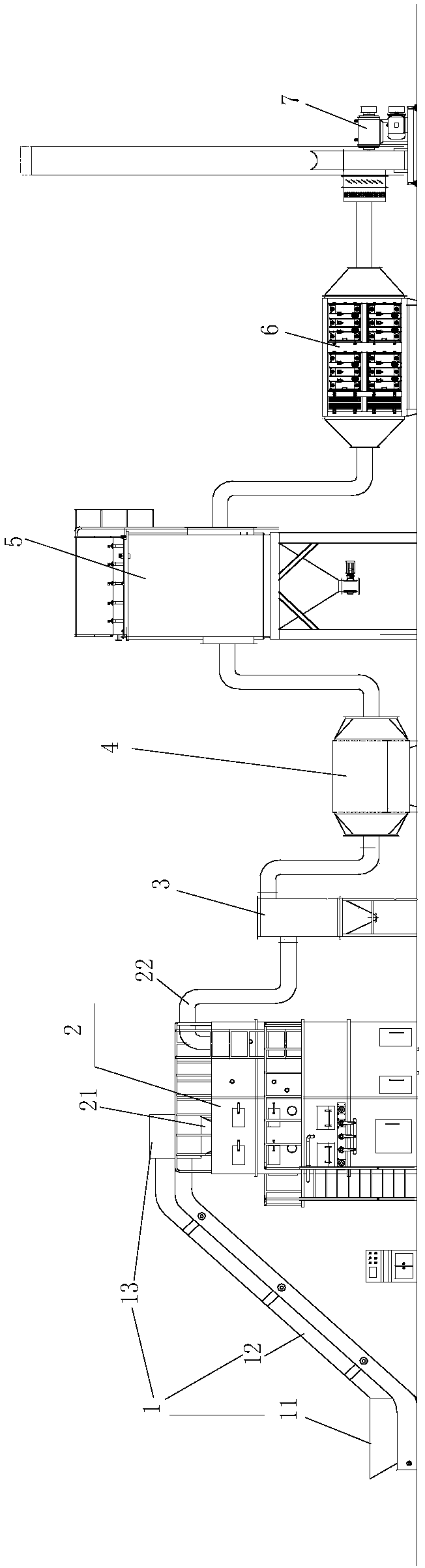

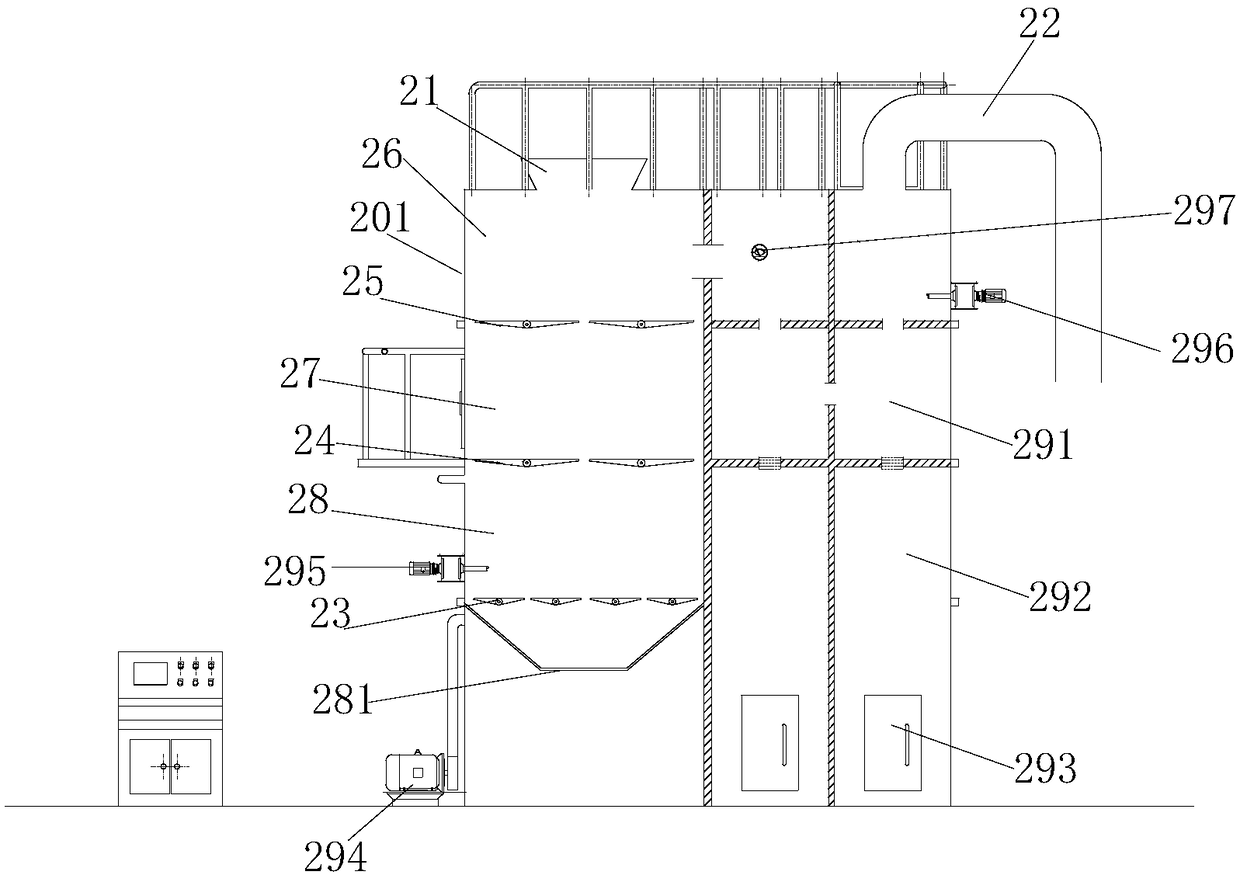

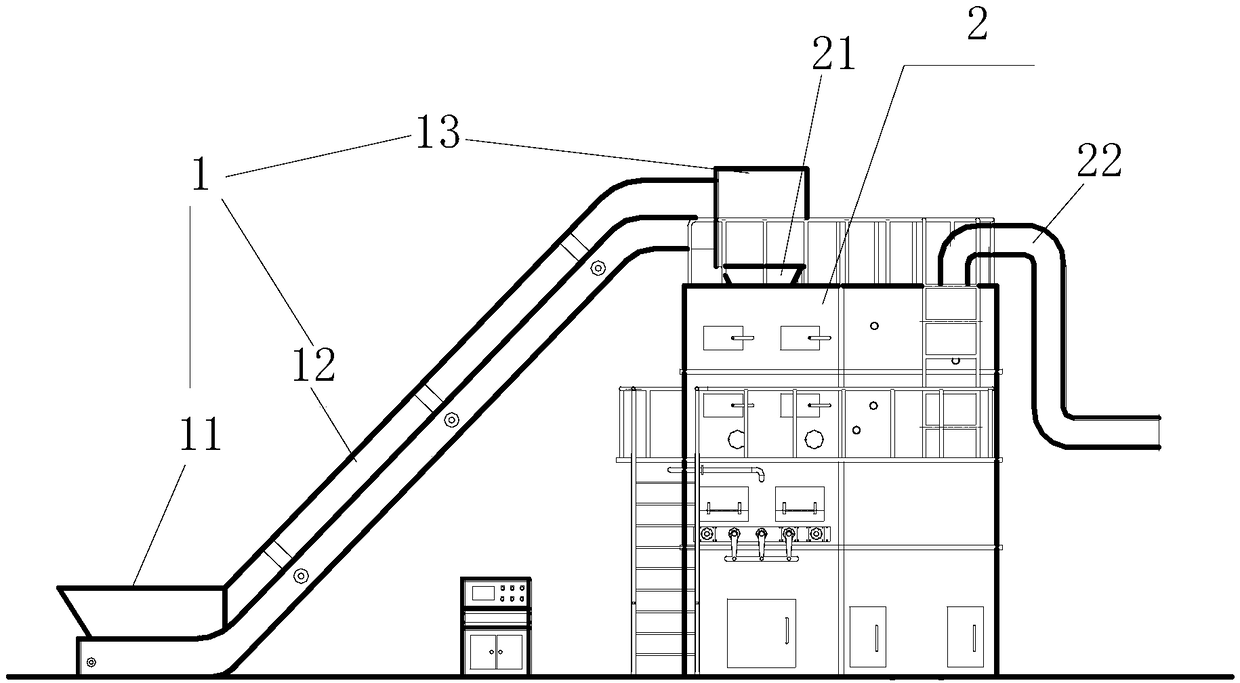

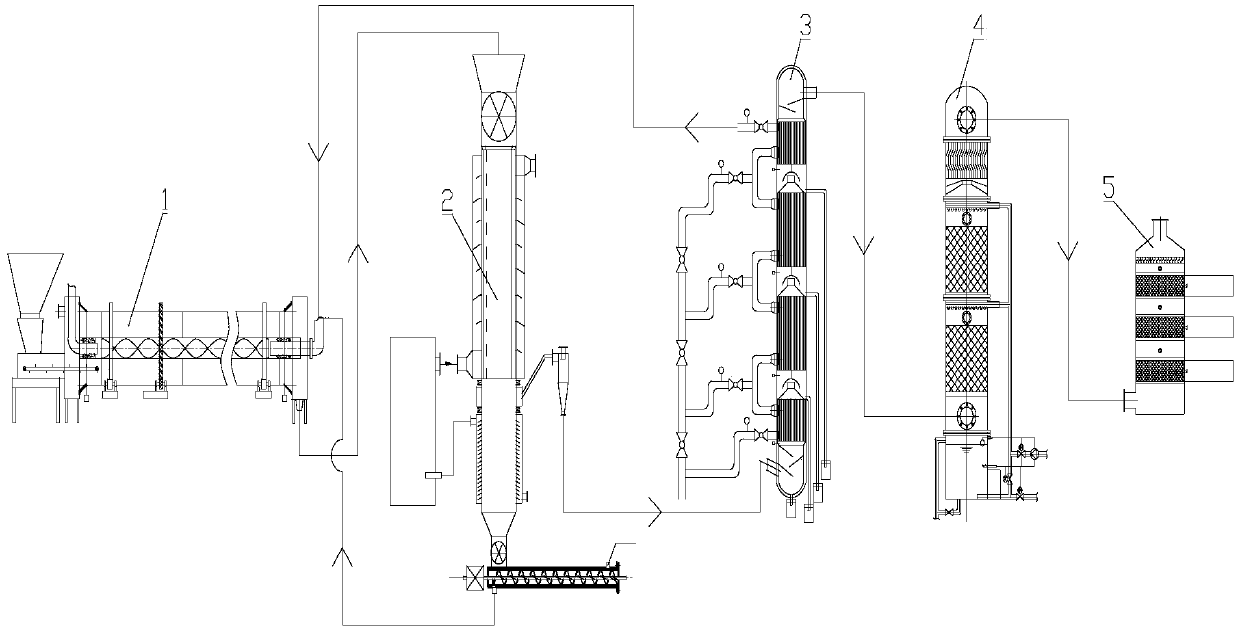

Household waste pyrolysis treatment equipment

PendingCN108286711AEfficient pyrolysisNo emissionsCombustion technology mitigationIncinerator apparatusBaghouseExhaust fumes

The invention relates to household waste pyrolysis treatment equipment. The equipment comprises an automatic feeding machine (1), a waste pyrolysis furnace (2), a ceramic cyclonic multi-pipe dust remover (3), a heat exchange condenser (4), a bag dust remover (5), a plasma dust remover (6) and an induced draft fan (7). According to the equipment, waste can be fed through the automatic feeding machine and then pyrolyzed in the waste pyrolysis furnace, large-particle matter in generated flue gas is removed through the ceramic cyclonic multi-pipe dust remover, small-particle matter is cooled through the heat exchange condenser and filtered through the bag dust remover, organic waste gas and Dioxin are removed through the plasma dust remover, therefore, efficient waste pyrolysis is achieved, and no harmful gas is exhausted.

Owner:云南朗润环境治理有限公司

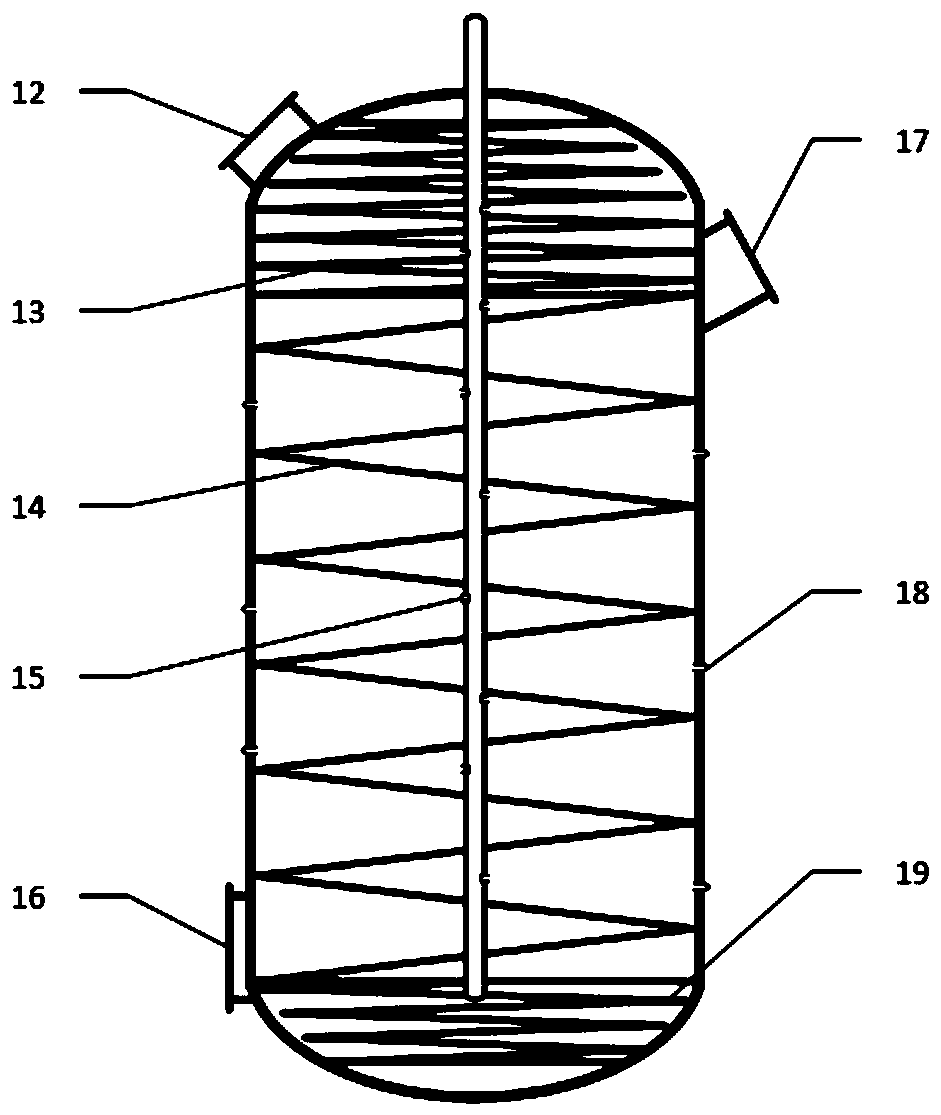

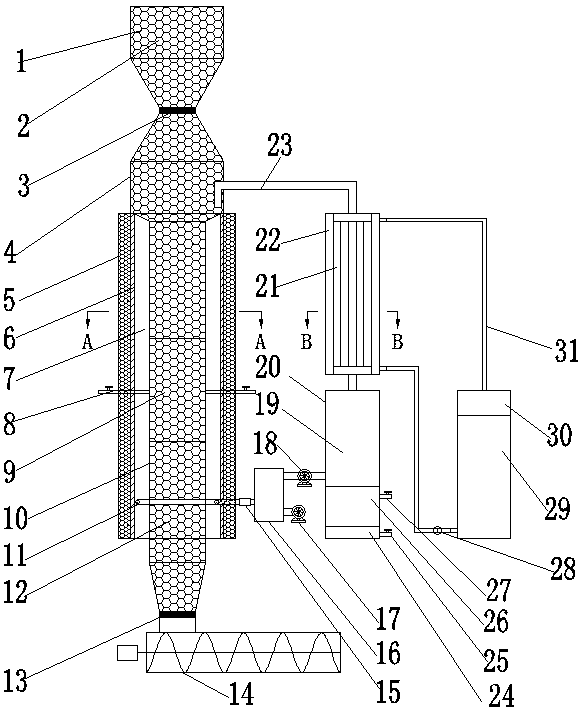

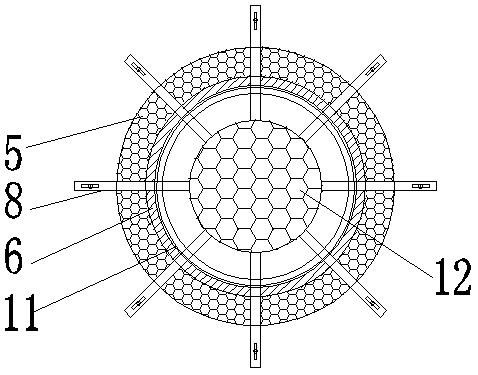

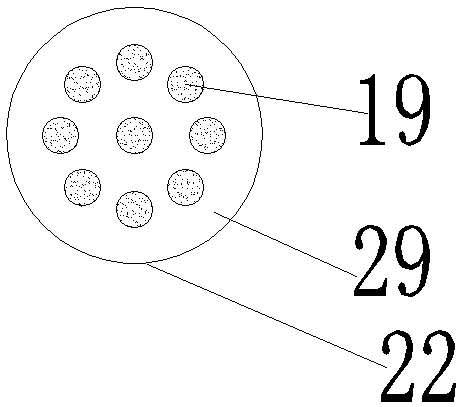

An internal-external heating type pyrolysis device

InactiveCN108949206AEfficient pyrolysisIncrease productivityBiofuelsIndirect and direct heating destructive distillationBiomassReaction tube

An internal-external heating type pyrolysis device is disclosed. The device includes a furnace body. The upper section of the furnace body includes a feeding hopper and a raw material settling chamber. The outmost layer of the middle section of the furnace body is a thermally insulating layer inside which a fireproof layer is arranged. The upper end of a pyrolysis reaction tube in the center of the furnace body is connected to the raw material settling chamber, and the lower end of the pyrolysis reaction tube is connected to a charcoal discharging device through a second brake valve. The cavity between the external wall and the fireproof layer is a hearth. A plurality of air pipelines communicating with the pyrolysis reaction tube are mounted in the middle of the furnace body. An annular combuster is mounted at the bottom of the hearth. A fuel gas outlet is connected to the raw material settling chamber, and the other end of the fuel gas outlet is connected to a fuel gas pipeline in acondenser. The fuel gas pipeline is connected to a gas liquid storage tank. A pyrolysis gas storing chamber is connected to a gas mixing chamber through a fuel gas draught fan and a pipeline. The gasmixing chamber communicates with the annular combuster through a flame arrester. A water tank communicates with and is connected to the condenser. The pyrolysis device overcomes a technical problem that the biomass pyrolysis efficiency is low, shortens the reaction period, and reduces production energy consumption.

Owner:NORTHWEST A & F UNIV

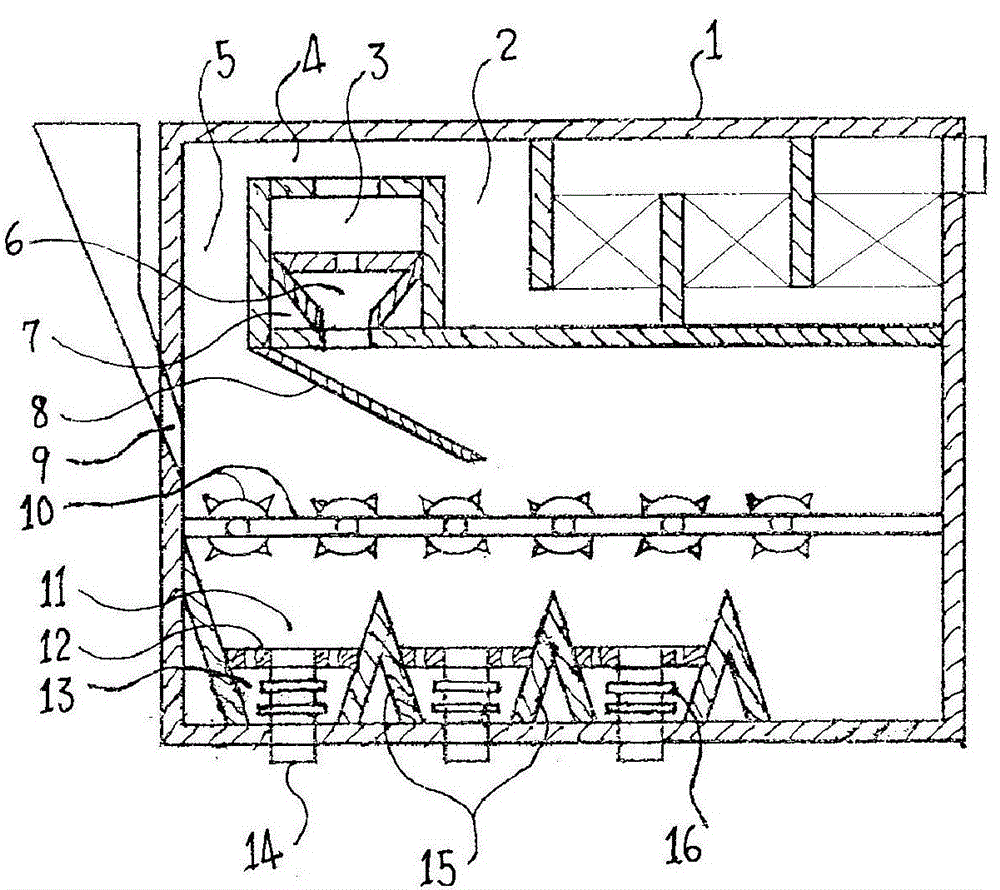

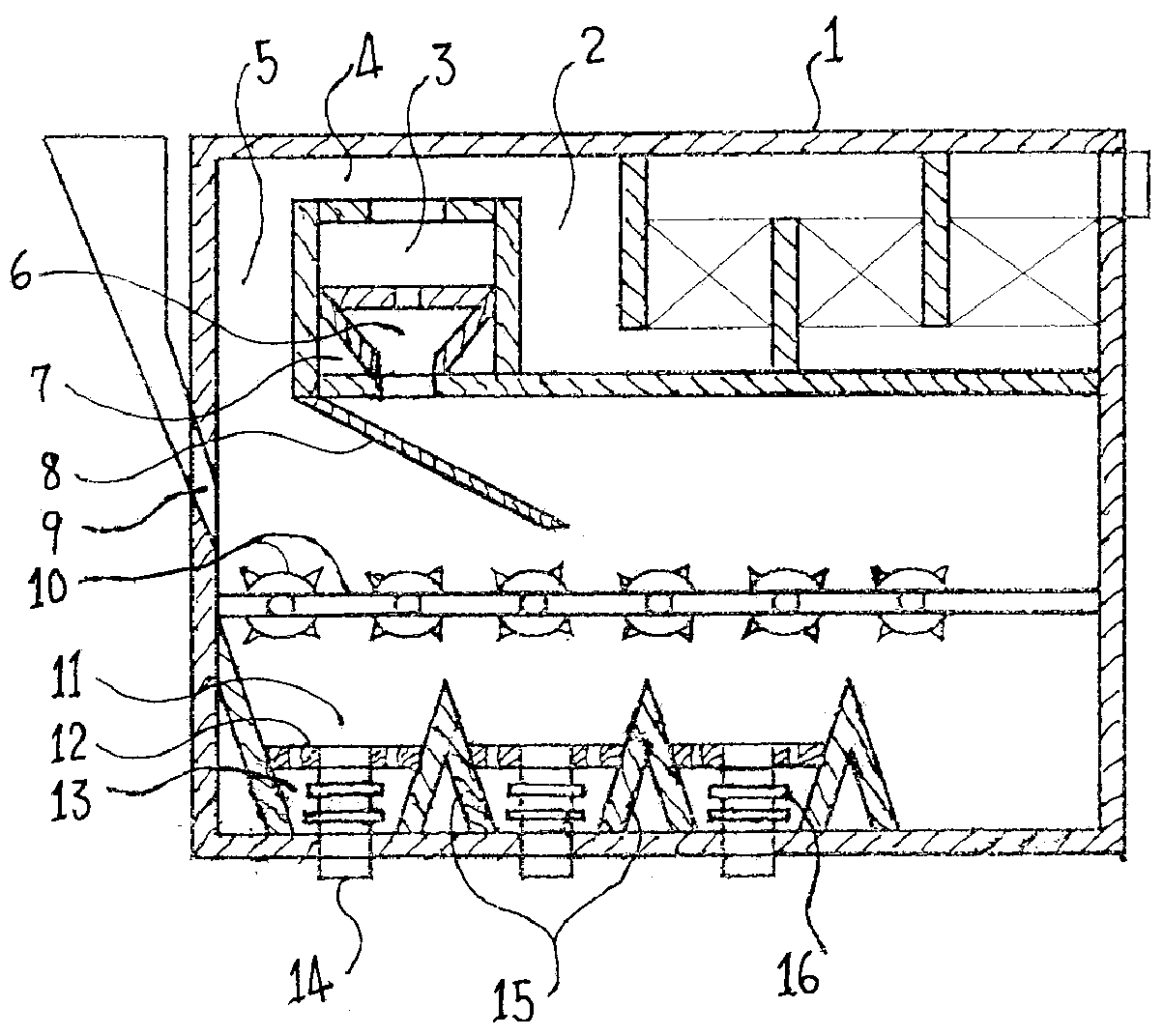

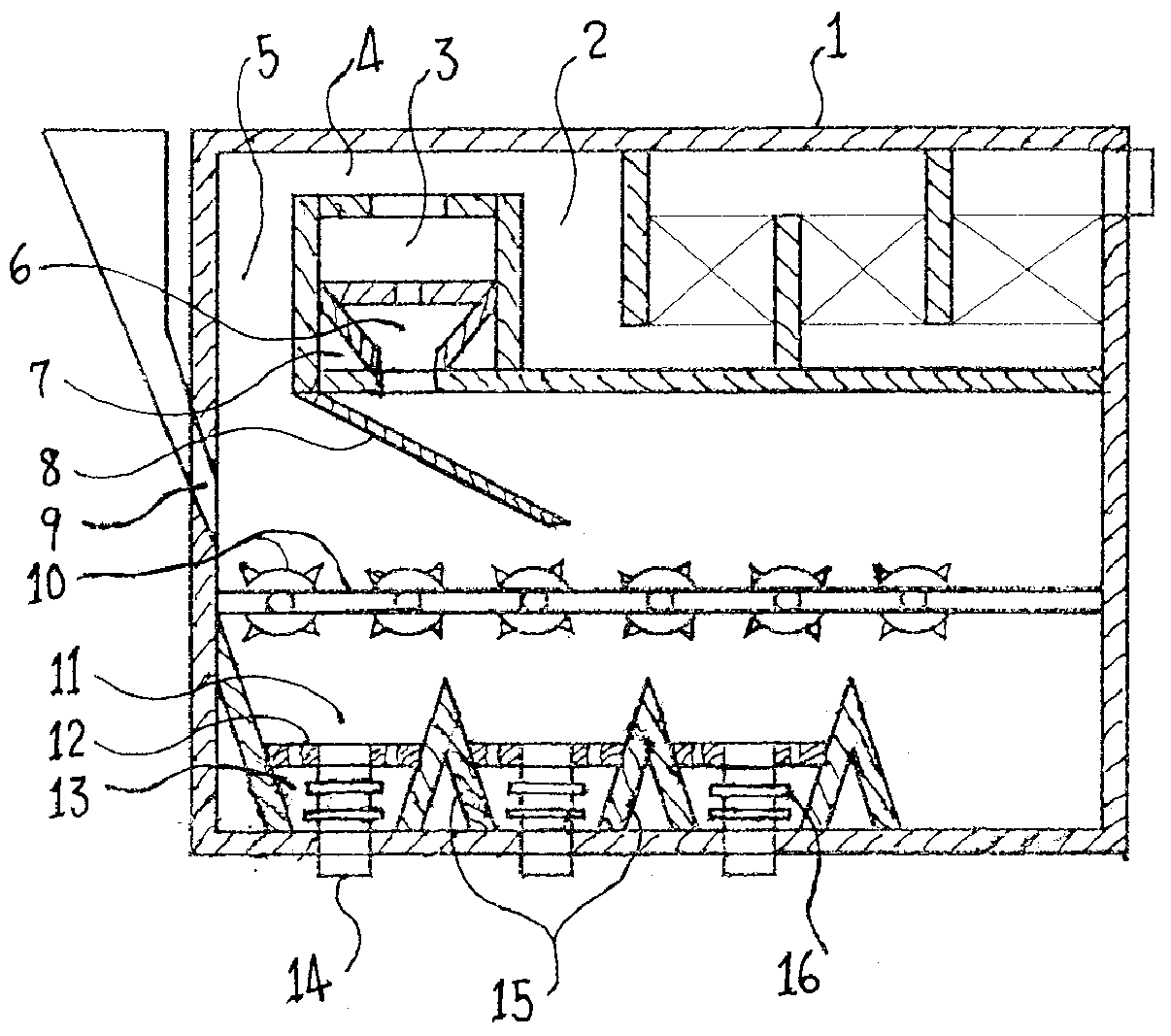

Automatic garbage screening, guiding and compartmenting pyrolysis device

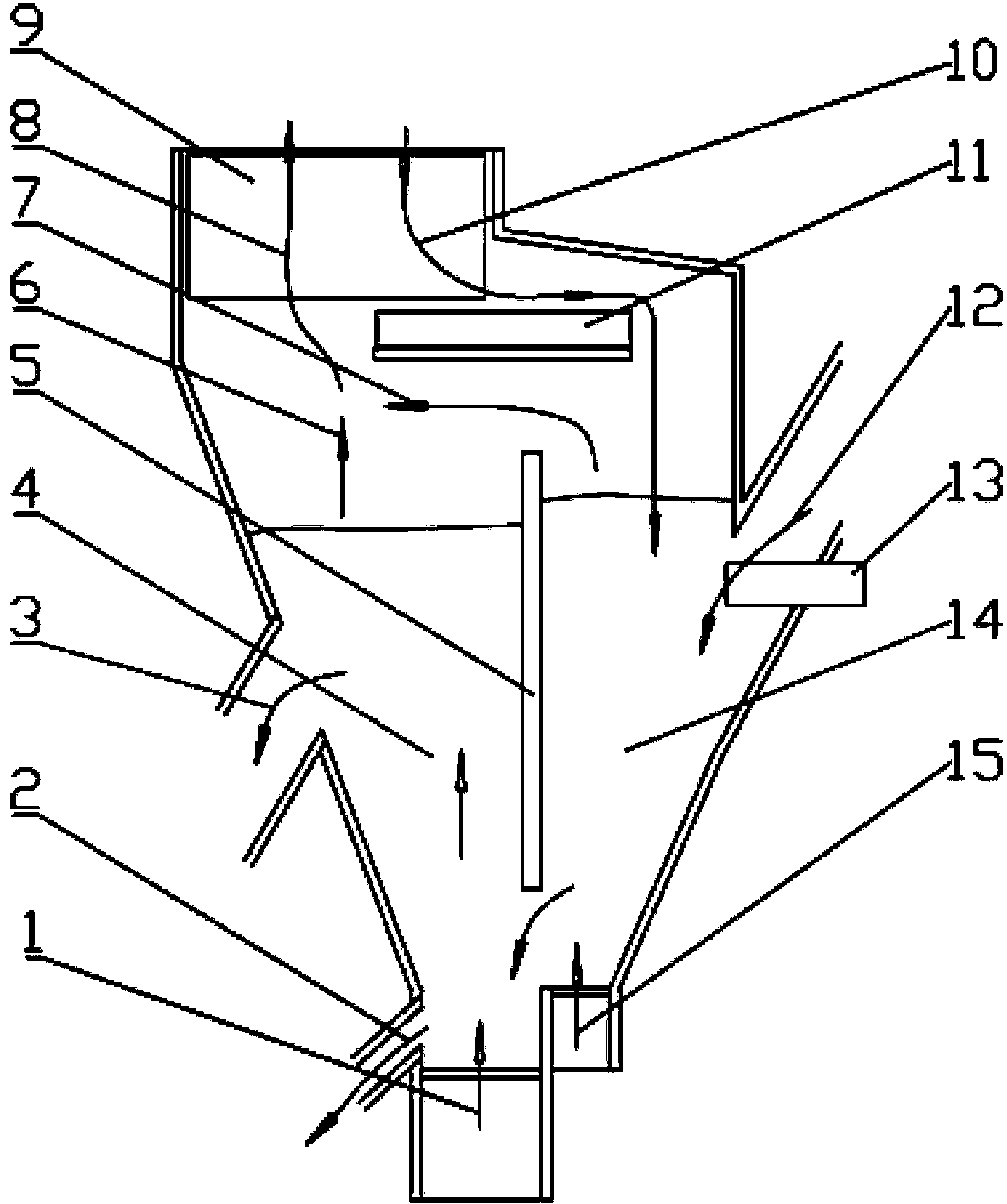

The invention discloses an automatic garbage screening, guiding and compartmenting pyrolysis device to overcome the defects that according to an existing garbage pyrolysis treatment device, blockage is likely to happen, dioxin is likely to be generated, and the maintaining and using cost is high. A screening mechanism is arranged below or under a garbage inlet. A solid phase pyrolysis compartment is arranged below the screening mechanism. A gas phase pyrolysis chamber and a wet gas channel are arranged above the screening mechanism. A guiding partition protruding downwards is arranged between the wet gas channel and the gas phase pyrolysis chamber. The automatic garbage screening, guiding and compartmenting pyrolysis device is used for garbage incineration pyrolysis treatment, garbage can be automatically screened while the incineration pyrolysis process is achieved, classifying and compartmenting gradual pyrolysis can be achieved, blockage in the pyrolysis process can be prevented, and environment-friendly pyrolysis preventing dioxin generation is better achieved. Meanwhile, the space utilization rate is high, the occupied space is small, the initial building investment can be reduced, energy consumption is low, auxiliary energy is not needed, and the running and maintaining cost is low.

Owner:周小华

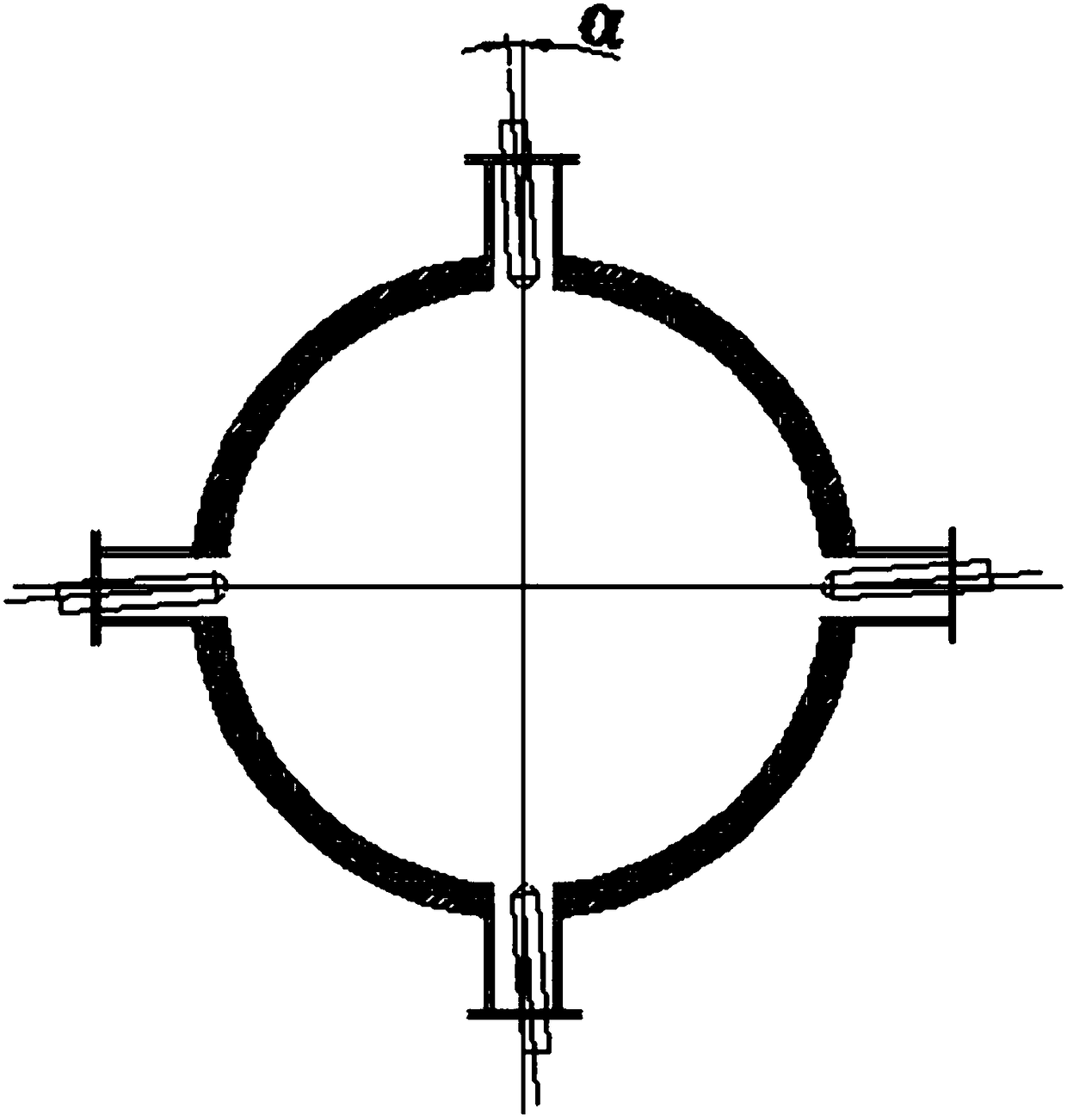

Preparation system of industrial gas and preparation method of industrial gas

PendingCN108517227ALow costAdaptableEnergy inputGasification processes detailsCyclonic separationSlag

The invention discloses a preparation system of industrial gas and a preparation method of industrial gas. The preparation system comprises a pulverized coal conveying unit, a entrained-flow gasifier,a convection waste heat boiler, a steam drum and a dust removing unit; the entrained-flow gasifer is provided with a gasification chamber, a cyclone separation chamber and a collection chamber; the side wall of the gasification chamber is uniformly provided with first nozzles; the top of the gasification chamber is provided with a first synthesis gas outlet, and the bottom of the gasification chamber is provided with a liquid slag outlet; the cyclone separation chamber is provided with a straight barrel section and a lower cone separation section, the first synthesis gas outlet is communicated with the straight barrel section, the top of the straight barrel section is provided with a second synthesis gas outlet, the bottom of the lower cone separation section is provided with a fly ash outlet, and the cyclone separation chamber is also provided with a cyclone riser leaded out from the straight barrel section; the side wall of the gasification chamber is uniformly provided with secondnozzles; the collection chamber is used for collecting the slag discharged from the liquid slag outlet so as to block the bottom of the gasification chamber from being communicated with the outside. The preparation system and the preparation method have lower investment, lower industrial gas cost, cleaner and stronger coal adaptability.

Owner:EAST CHINA UNIV OF SCI & TECH

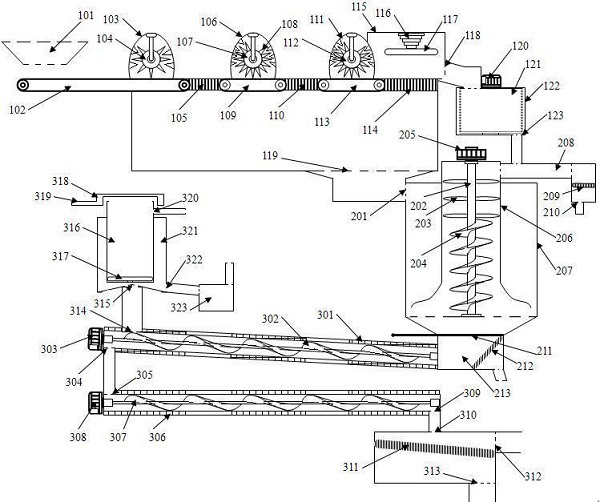

Solid waste recycling device

InactiveCN111744938AImprove screening effectRealize step by step multiple crushingTransportation and packagingSolid waste disposalOil separationEnvironmental engineering

The invention relates to a solid waste recycling device. The solid waste recycling device comprises a crushing and screening device, a back flushing and water draining device and a pyrolysis device. By specifically arranging all the components, recycling of solid waste without overall secondary pollution such as water removal, oil removal, separation, classification and recycling, and water purification is achieved.

Owner:高琦彬

A method for preparing furfural by co-pyrolysis

The invention belongs to the field of biomass energy utilization, and in particular relates to a method for preparing furfural by co-pyrolysis. The present invention uses biomass rich in xylose units as the raw material for preparing furfural, mixes the raw material with oxalic acid, conducts rapid co-pyrolysis at 200-500°C under anaerobic conditions, and condenses the pyrolysis gas to room temperature. A liquid product rich in furfural is obtained. The oxalic acid involved in the method of the present invention is common and easy to obtain, and the price is low. In the co-pyrolysis process, it plays the role of catalyzing the decomposition of raw materials to form furfural. , so the co-pyrolysis process is green, efficient and pollution-free.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

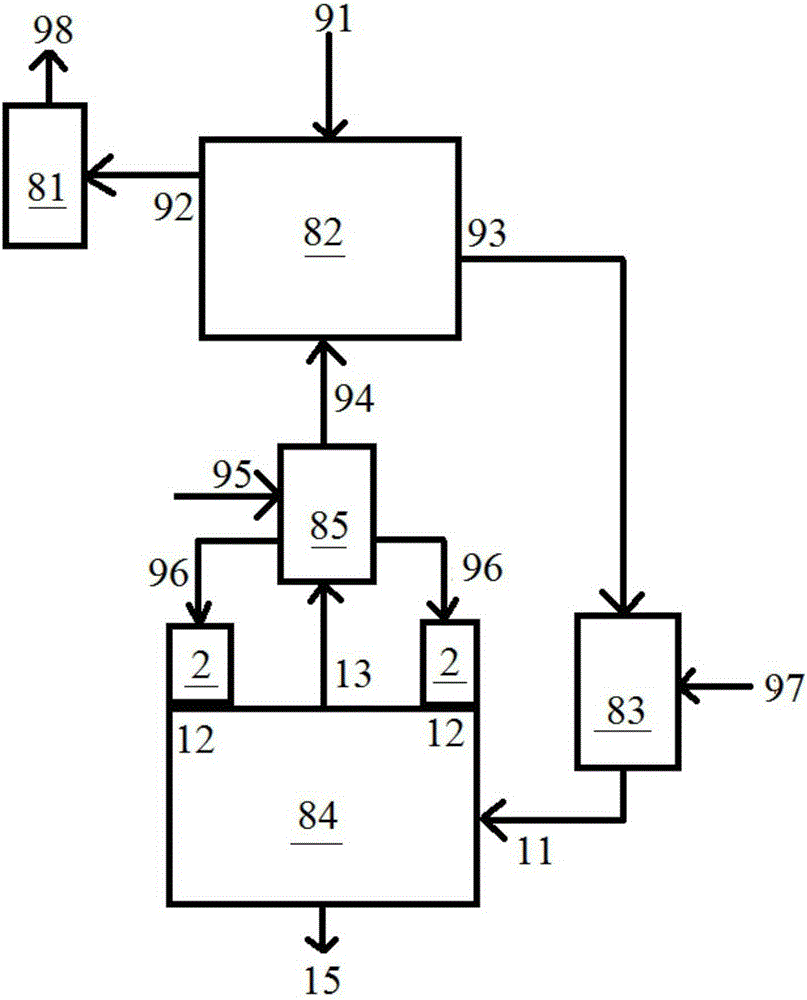

Reaction system and method for carbon-containing materials

InactiveCN106544060AEfficient pyrolysisReduce energy consumptionCombustible gas productionSolid carbonHigh carbon

The invention discloses a reaction system and method for carbon-containing materials. The reaction method comprises the steps that medium-temperature pyrolysis is conducted on the solid carbon-containing materials through medium-temperature gas; gas is collected in the medium-temperature pyrolysis process; high-temperature pyrolysis and gasification are conducted on a solid product obtained after medium-temperature pyrolysis; and a high-temperature gaseous product generated by high-temperature pyrolysis and gasification is cooled into medium-temperature gas, and medium-temperature pyrolysis is conducted on the solid carbon-containing materials through the medium-temperature gas. The reaction method is realized through the reaction system. In this way, the medium-temperature pyrolysis process and the high-temperature pyrolysis and gasification process of the carbon-containing material form a cycle; the solid product, with the high carbon content, obtained after medium-temperature pyrolysis can be used as the raw material used for high-temperature pyrolysis and gasification, and the high-temperature gaseous product generated by igh-temperature pyrolysis and gasification can be used as a heat source for medium-temperature pyrolysis after being cooled, so that heat energy of the system is sufficiently utilized while sufficient pyrolysis of the carbon-containing materials is achieved, and energy consumption of the system is low; and due to the fact that emissions are few, the environmental friendliness is good.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

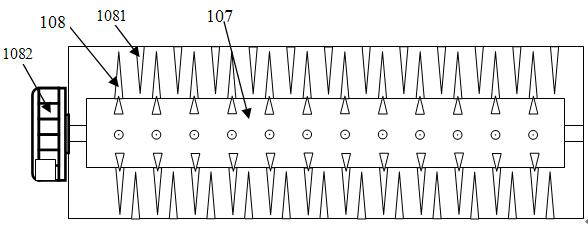

Organic solid waste rapid heating device and heating method

ActiveCN113025353AReduce generationFast pyrolysisElectrical coke oven heatingIndirect heating destructive distillationAutomatic controlControl cell

An organic solid waste rapid heating device mainly comprises infrared heaters, a heating furnace, a pyrolyzing furnace and an automatic control unit. The pyrolyzing furnace is embedded in the heating furnace, the outer wall of the pyrolyzing furnace is coated with an infrared wave-absorbing coating, the infrared heater is located on the outer side wall of the heating furnace, and rapid heating of the pyrolyzing furnace is achieved through heat radiation. According to requirements, the plurality of infrared heaters can be arranged and are used for quickly heating the pyrolyzing furnace. The inner wall of the pyrolyzing furnace is covered with a heat preservation layer, heat loss in the pyrolyzing furnace is prevented, and the material temperature is maintained, so that rapid heating and efficient heat preservation of materials are achieved, the pyrolysis heating time is shortened, the organic solid waste pyrolysis efficiency is improved, and dioxin is effectively reduced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

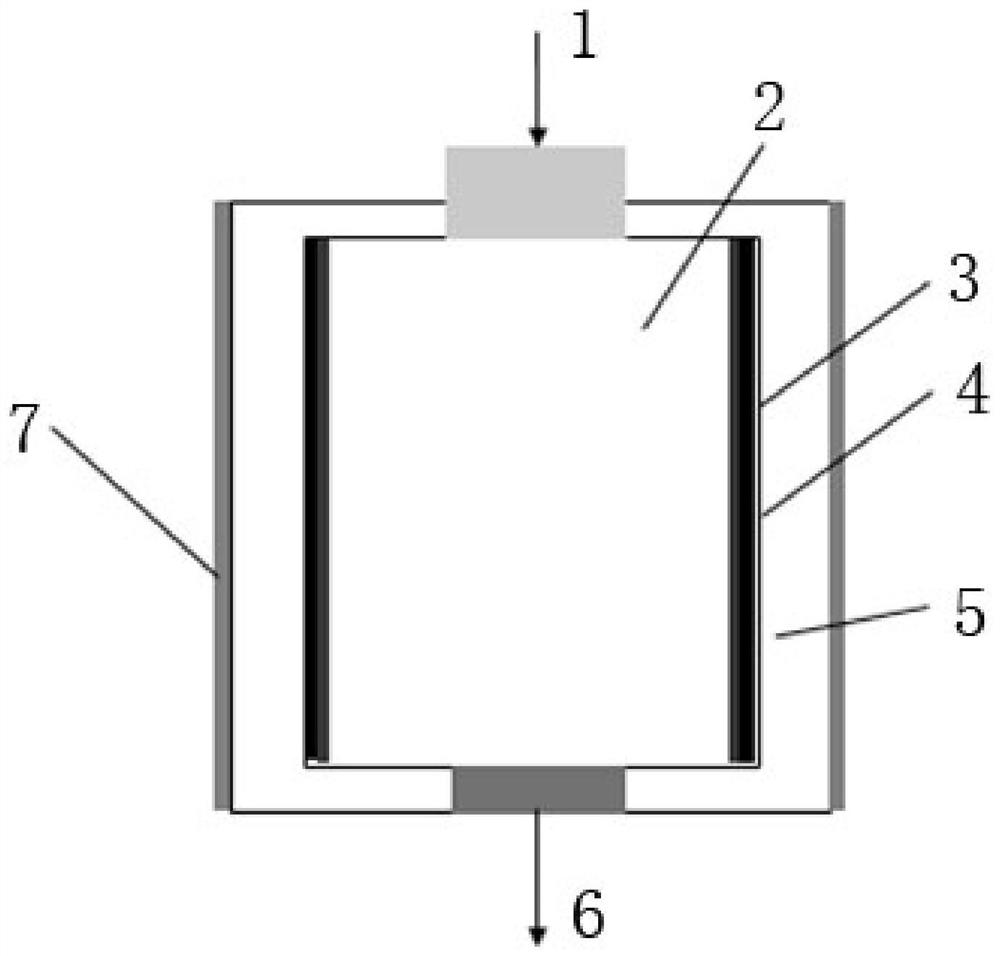

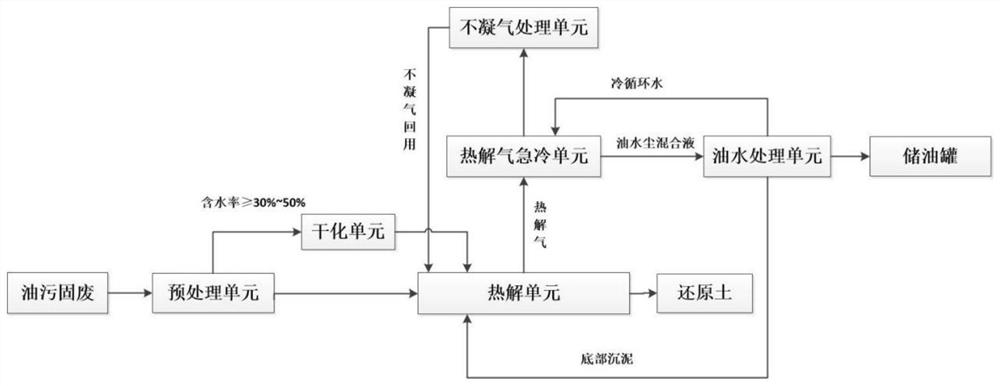

Harmless treatment method for oil stain solid waste

PendingCN113860695AAvoid pollutionHigh standard of treatmentSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesProcess engineeringOil water

The invention discloses a harmless treatment method for oil stain solid waste. The harmless treatment method is characterized by comprising a pretreatment unit, a drying unit, a pyrolysis unit, a pyrolysis gas quenching unit, a non-condensable gas purification unit and an oil-water treatment unit. The method comprises the following specific steps: step 1, pretreating the oil stain solid waste: feeding the oil stain solid waste into a pretreatment unit, crushing the oil stain solid waste by using a crusher, feeding the crushed oil dirt solid waste into a rotary screen for screening, screening out inorganic matter with the particle size of more than 8-10mm in the oil dirt solid waste, putting the oil dirt solid waste back to the crusher for continuously crushing, and remaining oil dirt solid waste smaller than 8-10 mm to enter next step. The method is easy to operate, stable and reliable in equipment operation and good in pyrolysis effect in the whole process, the oil-gas separation cost is reduced, the oil-gas quality is improved, the occupied area of the equipment is greatly reduced while continuous operation is realized under the condition of the same treatment capacity, and meanwhile, the thermal efficiency is high, and the economic benefit is obvious.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

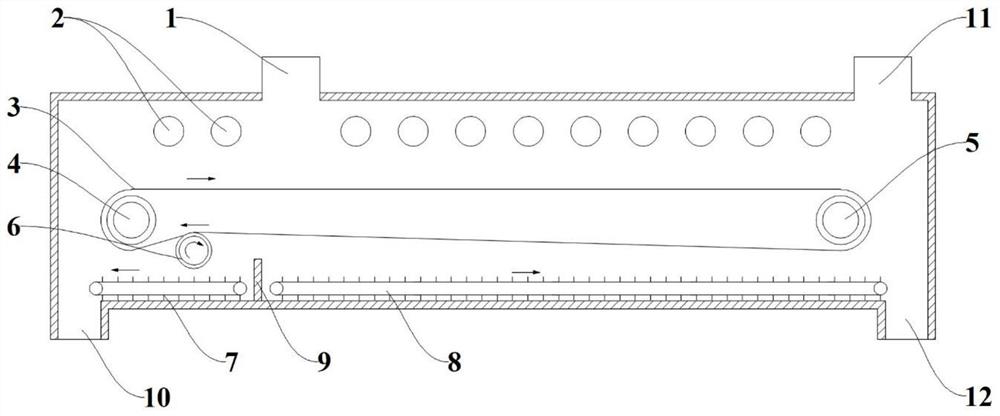

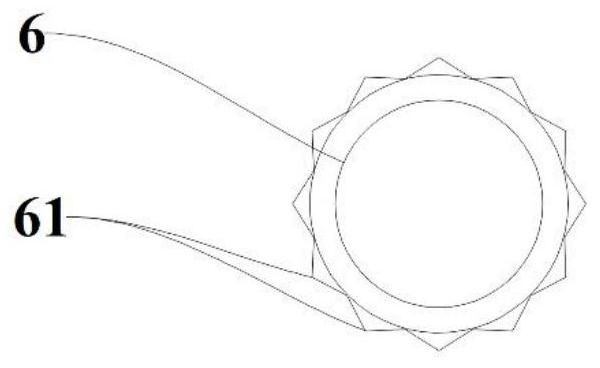

Self-cleaning static rotary pyrolysis device

ActiveCN113481022AEasy to controlHeating evenlySludge treatment by pyrolysisByproduct vaporizationDrive wheelCoke

An embodiment of the invention provides a self-cleaning type static rotary pyrolysis device. The self-cleaning type static rotary pyrolysis device comprises a feed port, a heating pipe, a chain plate, a driving wheel, a driven wheel, a coke cleaning wheel, a scraper coke extractor, a scraper tar extractor, a partition plate, a coke outlet, a pyrolysis gas outlet and a tar outlet. When the device runs, materials fall into the left side of the chain plate from the feed port, and the chain plate drives the materials to move from left to right; in a moving process, the heating pipe above the chain plate continuously heats the materials, so organic components of the materials are heated and decomposed; generated pyrolysis gas is discharged from the pyrolysis gas outlet; generated wall-adhered coke blocks are continuously cleaned by the coke cleaning wheel which is propped against the outer wall of the lower side of the chain plate, fall into the scraper coke extractor below the coke cleaning wheel and are conveyed to a coke outlet for discharging; and generated tar falls into the scraper tar extractor below the chain plate under the action of gravity and is conveyed to a tar outlet for discharging. The self-cleaning type static rotary pyrolysis device is simple and compact in structural design, simple to clean and maintain, high in automation degree, high in decoking effect, efficient and stable to use.

Owner:北京博霖环境科技有限公司

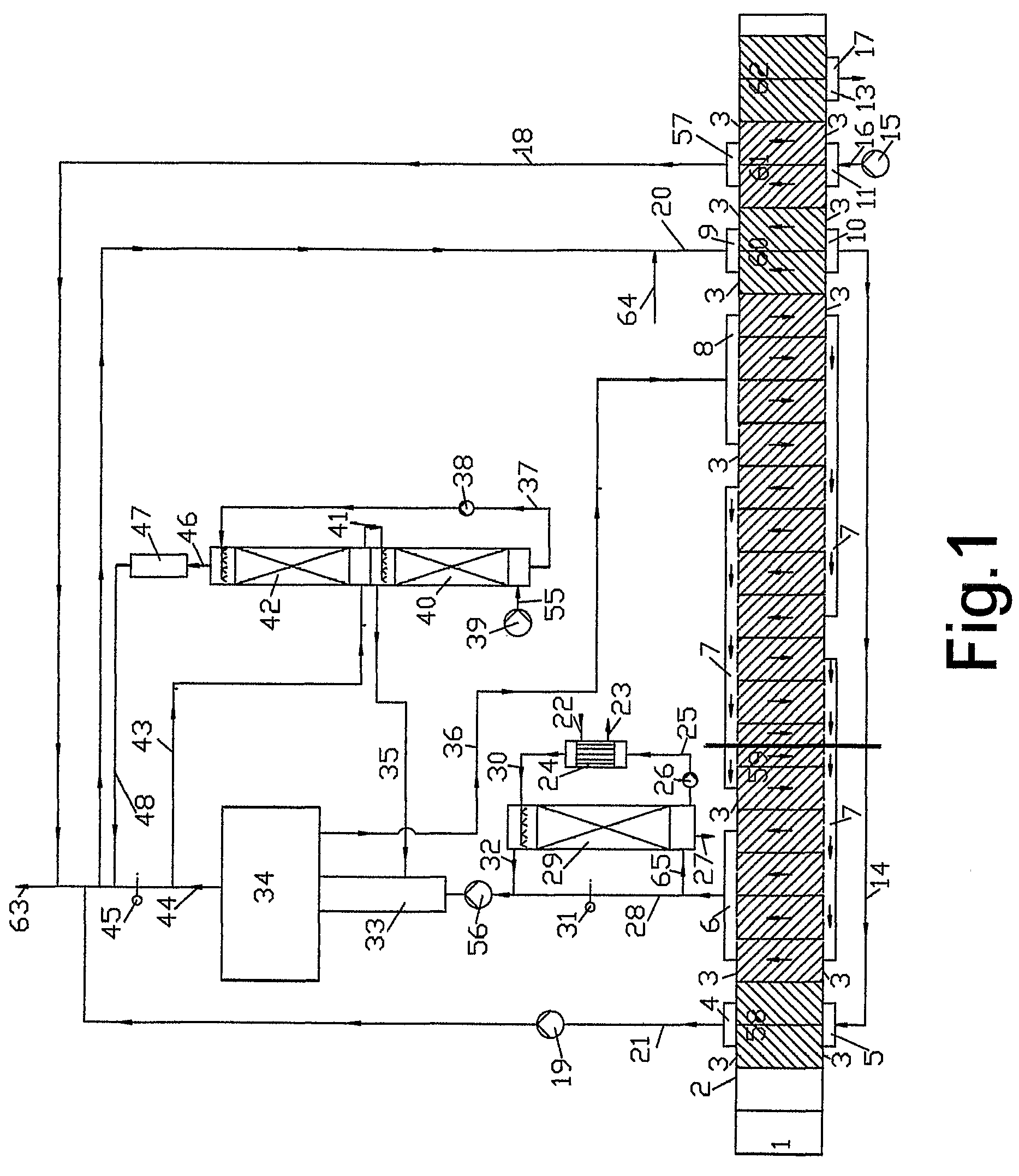

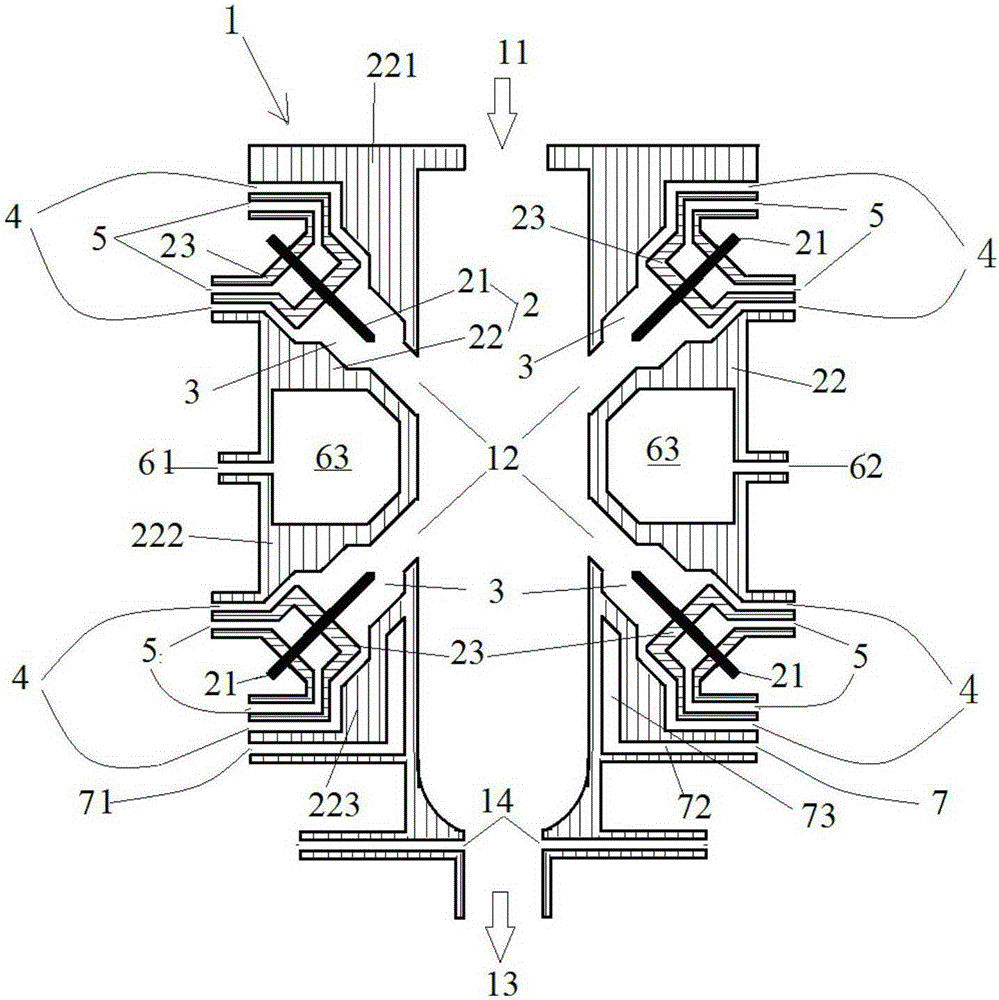

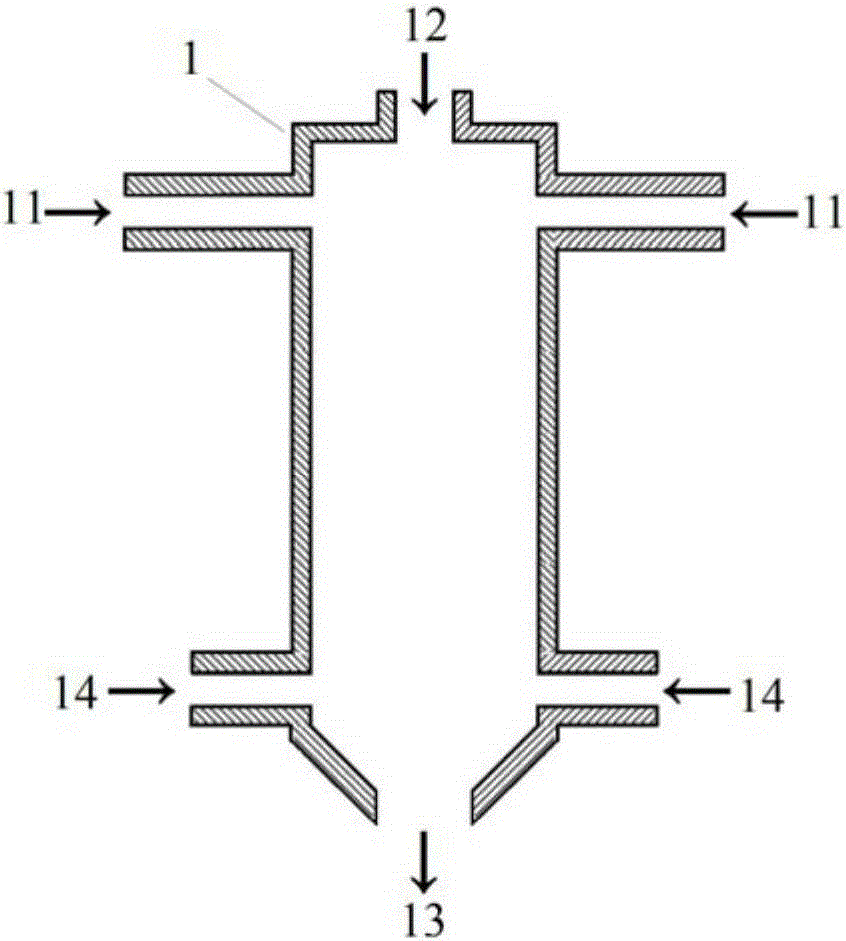

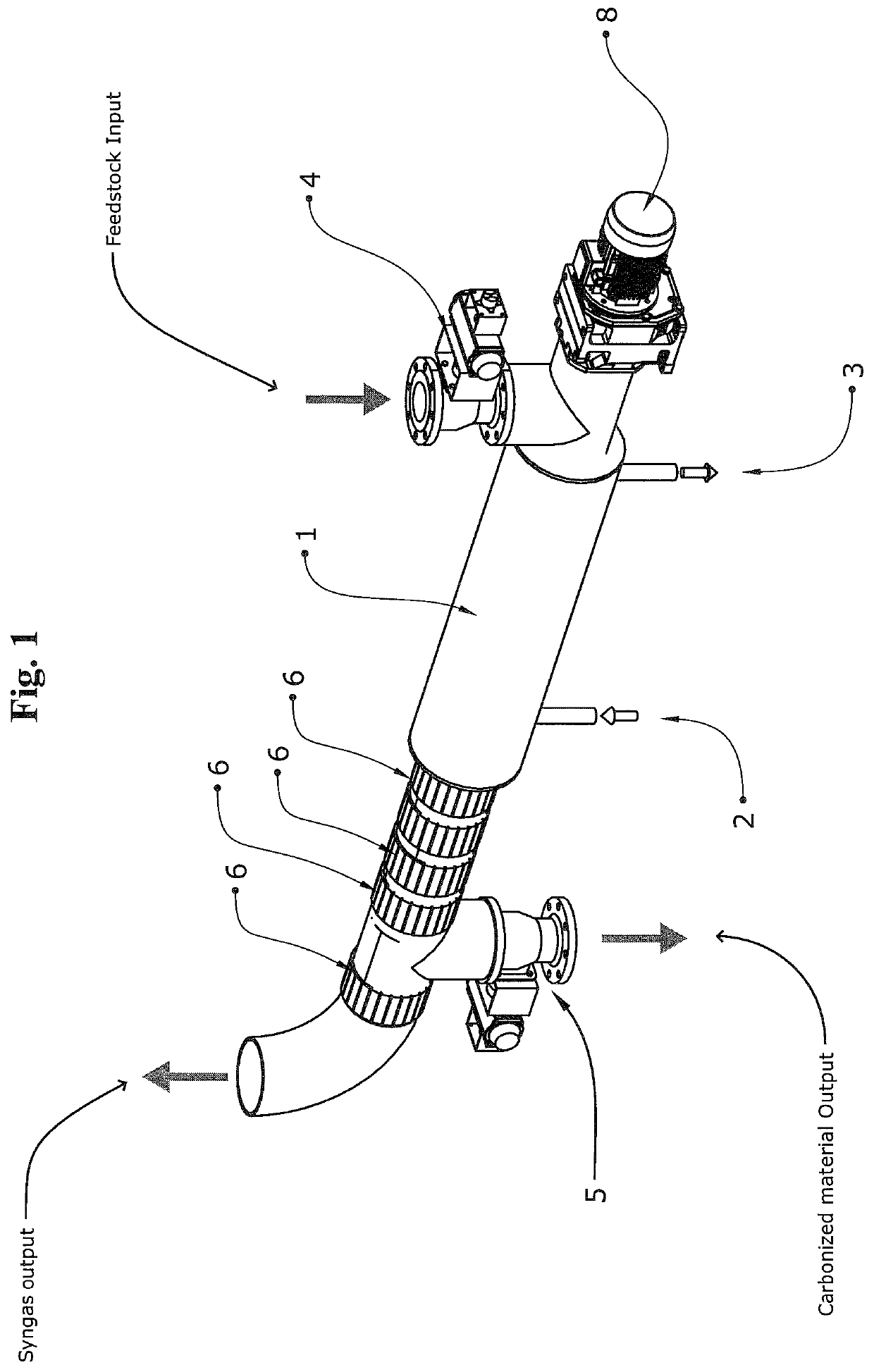

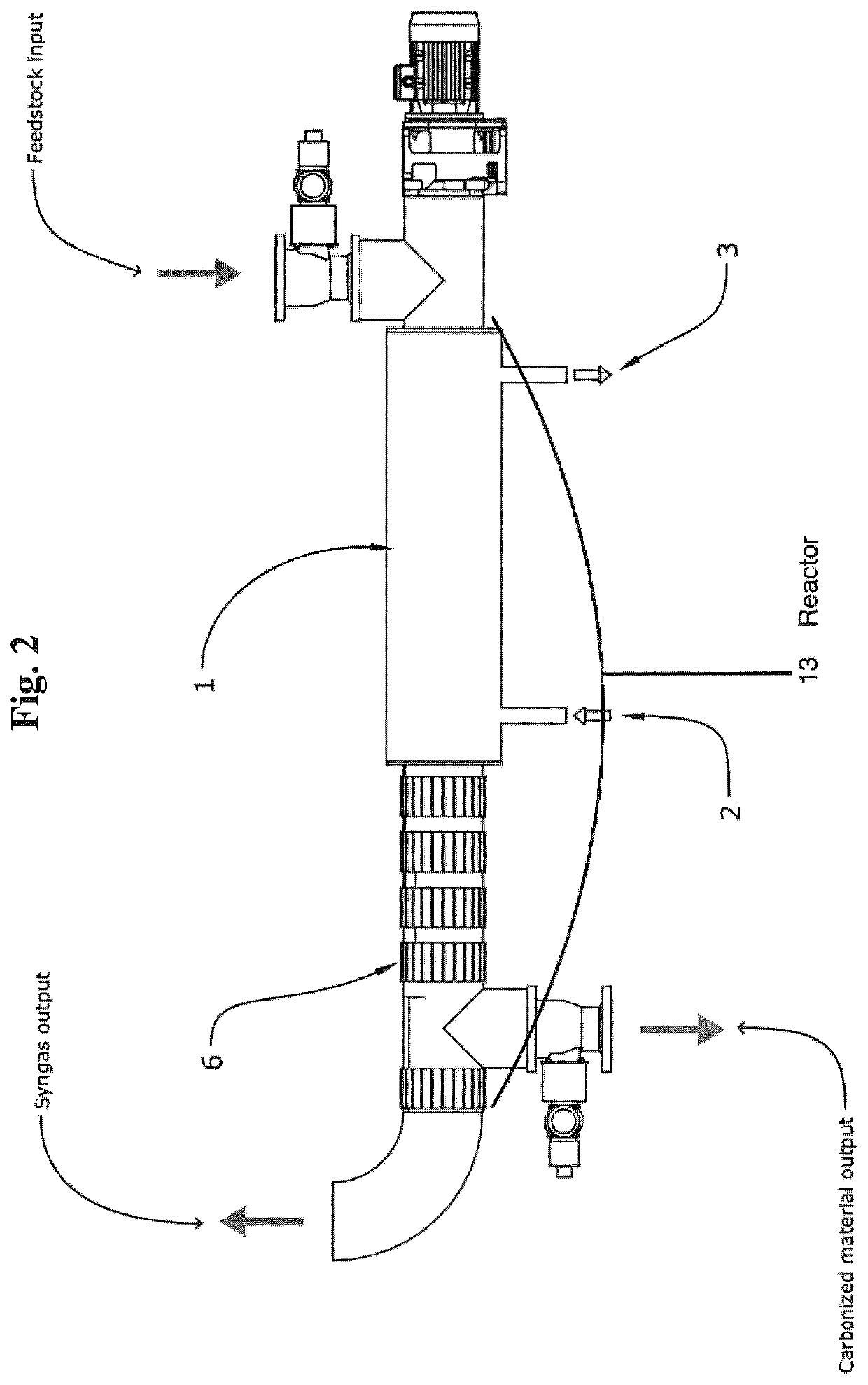

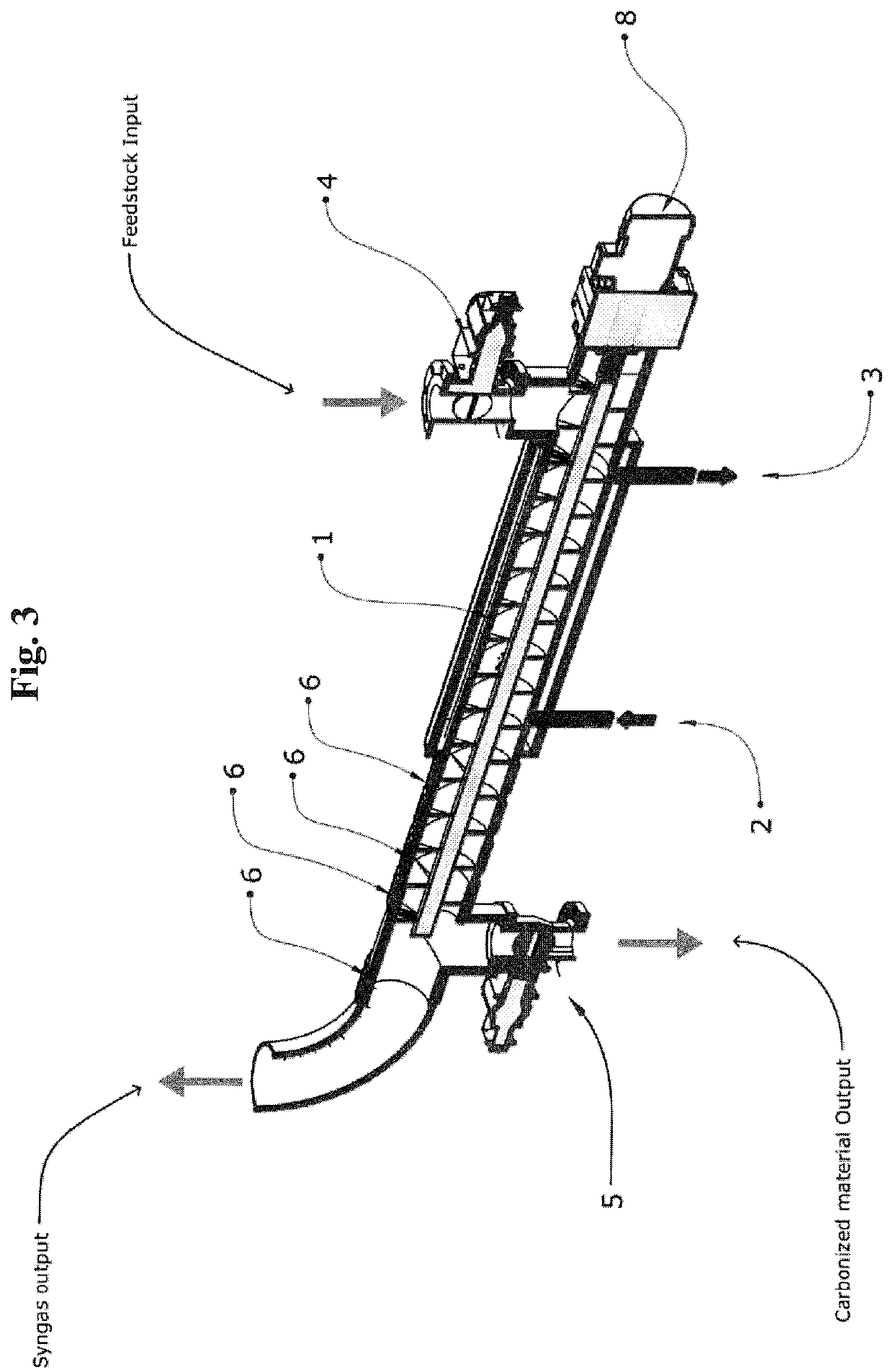

Hybrid pyrolysis system and method

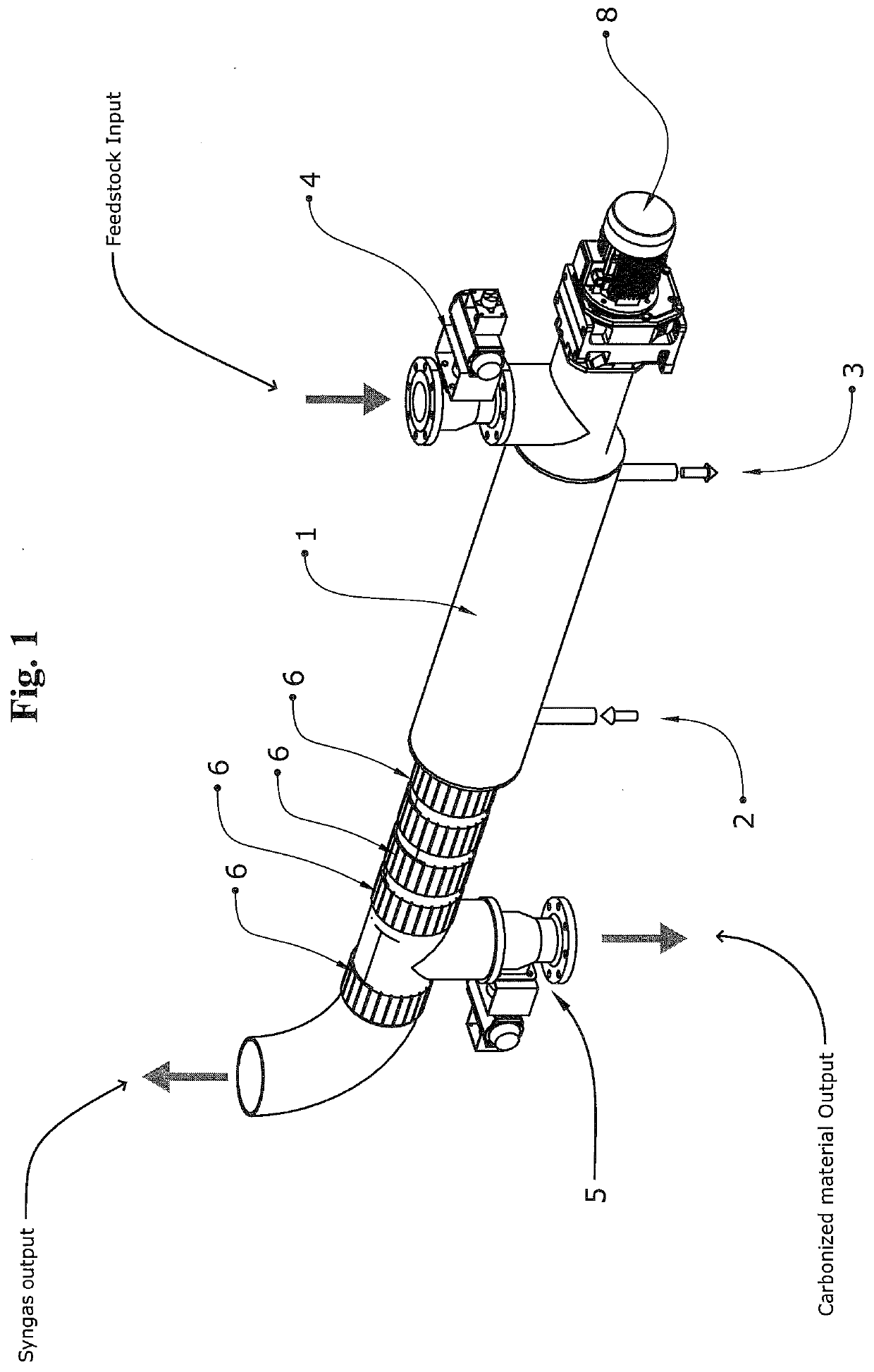

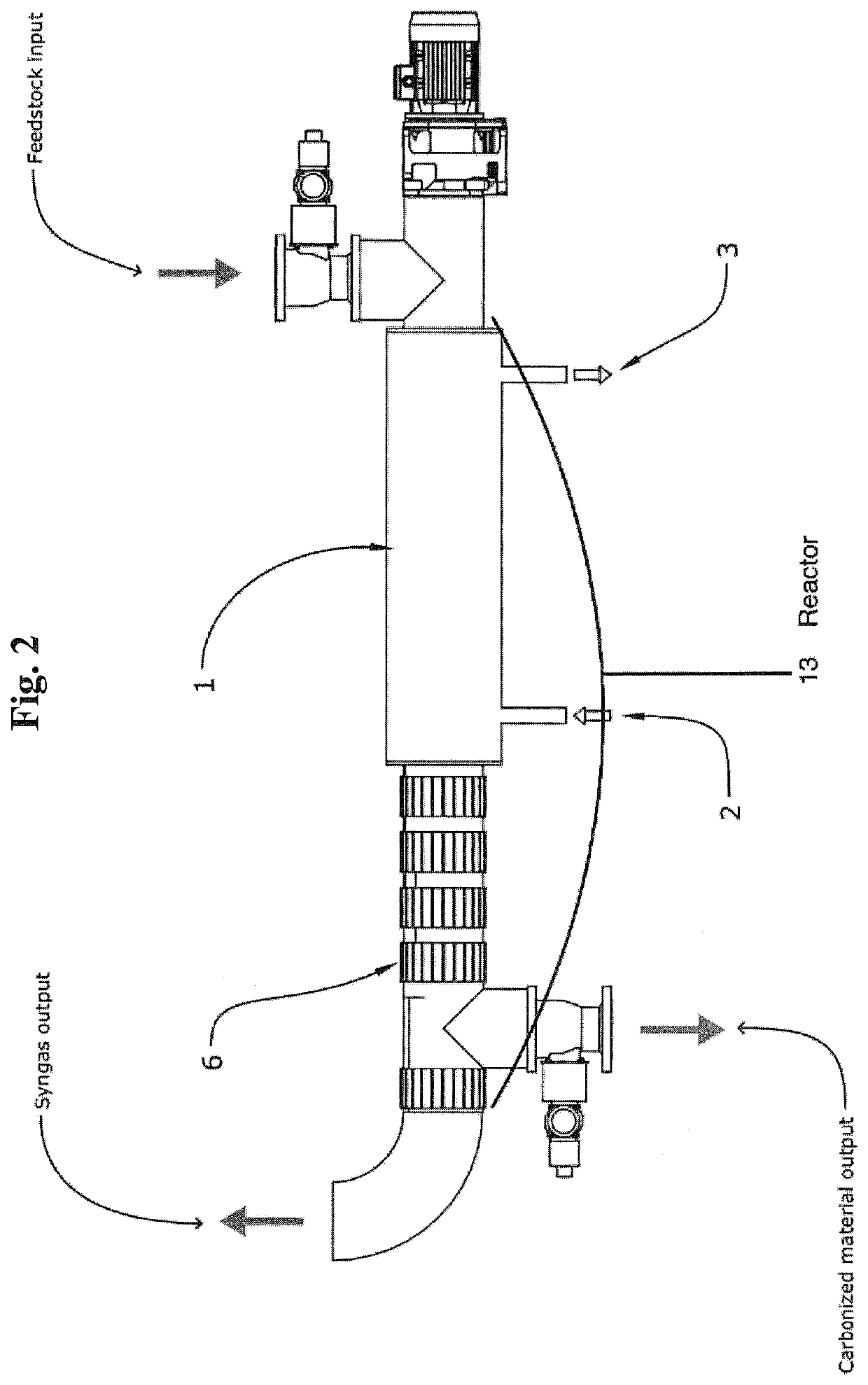

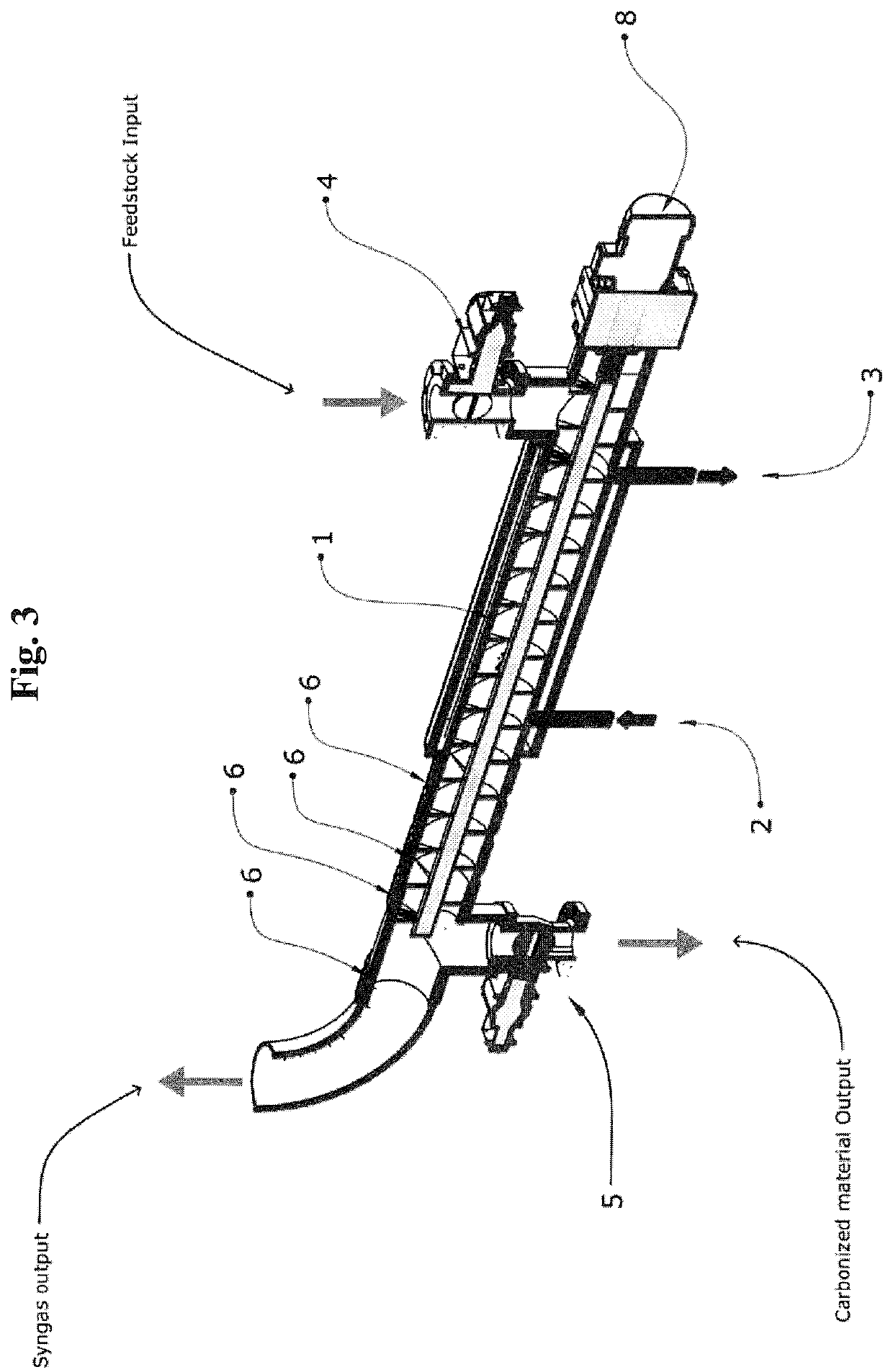

ActiveUS20210277311A1Efficient pyrolysisMechanical conveying coke ovensElectrical coke oven heatingSyngasProcess engineering

A system and method for performing pyrolysis comprises a reactor through which organic material is conveyed from an upstream end toward a downstream end and within which said pyrolysis will occur; a combustion chamber fluidically connected to the downstream end of the reactor; an output pipe fluidically connected to the downstream end of the reactor; a capsule surrounding a first part of the reactor and into an internal portion of which heated thermal fluids are disposed for heating the first part of said reactor; and a plurality of electrical resistors disposed around a second part of the reactor for heating the second part of the reactor; whereby, as a result of the pyrolysis occurring within the reactor, the syngas is conducted toward the combustion chamber while the carbonized material is conducted outwardly from the reactor through the output pipe.

Owner:BIOFORCETECH

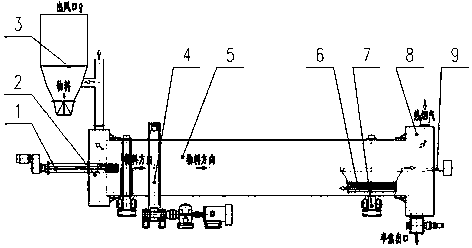

A biomass pyrolysis liquefaction polygeneration system

ActiveCN108102673BEfficient use ofImprove qualityLiquid hydrocarbon mixture productionGas purification with selectively adsorptive solidsAcetic acidPre treatment

The invention belongs to the technical field of biomass treatment, and specifically discloses a biomass pyrolysis liquefaction polygeneration system. The system comprises a biomass pre-treatment sub-system, a pyrolysis sub-system, a multi-stage condensation sub-system, a pyrolysis gas purification sub-system, and a gas adsorption upgrading sub-system that are connected in sequence, wherein the biomass pre-treatment sub-system is used for pre-treating a biomass raw material so as to obtain a biomass semi-coke product, the pyrolysis sub-system is used for pyrolyzing the biomass semi-coke productso as to obtain pyrolysis volatiles and coke, the multi-stage condensation sub-system is used for condensing the pyrolysis volatiles in multiple stages so as to obtain various biological oils and pyrolysis gases, the pyrolysis gas purification sub-system is used for spraying and condensing the pyrolysis gas so as to condense and dissolve acetic acid steam in the pyrolysis gas to obtain wood vinegar and coarse gas, and the gas adsorption upgrading sub-system is used for adsorbing the coarse gas to remove impurities, so as to obtain a clean gas product rich in methane. The biomass pyrolysis liquefaction polygeneration system has the advantages of high treatment efficiency, high heat use ratio, convenience in operation, high applicability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Waste horizontal screening fluidized pyrolysis device

The invention discloses a rubbish transverse motion screening, fluidifying and pyrolyzing device. To overcome the defects that an existing rubbish pyrolyzing device is blocked easily and generates dioxin, and the maintenance and use expense is high, a screening mechanism is arranged below the side of a rubbish inlet, a gas phase pyrolyzing chamber is arranged above the screening mechanism, at least two solid phase pyrolyzing chambers are arranged below the screening mechanism, each solid phase pyrolyzing chamber is provided with inclined walls connected with each other, each solid phase pyrolyzing chamber is provided with a burnout chamber, a wind cavity and an ash channel, each wind cavity is communicated with the corresponding burnout chamber through a wind channel of an interlayer, each ash channel is communicated with the corresponding burnout chamber and penetrates the corresponding interlayer and the corresponding wind cavity, and the wind cavities are connected with a hot air conveying mechanism. The device is used for carrying out rubbish pyrolyzing treatment and can pyrolyze and screen rubbish at the same time, the rubbish can be classified, fluidified and pyrolyzed in separated chambers, pyrolysis blocking can be prevented, environment-friendly pyrolysis without generating dioxin can be achieved better, the construction investment and pyrolysis energy consumption can be reduced, and the operation and maintenance cost is low.

Owner:长沙超梵环境科技有限公司

Fused salt-oily sludge thermochemical conversion fluidized bed reactor, system and application of molten salt-oily sludge thermochemical conversion fluidized bed reactor

ActiveCN114409213ANo lossReduce lossSludge treatment by pyrolysisLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The invention discloses a molten salt-oily sludge thermochemical conversion fluidized bed reactor which comprises a first chamber and a second chamber, the first chamber is communicated with the second chamber through a channel structure, and a reaction device and a first cooling chamber are arranged in the first chamber; a second cooling chamber and a condensation chamber are arranged in the second chamber, and the reaction device, the first cooling chamber, the second cooling chamber and the condensation chamber are sequentially communicated. According to the molten salt-oily sludge thermochemical conversion fluidized bed reactor, molten salt is used as a heat carrier for cyclic utilization, and a fluidized bed is a pyrolysis reactor. Heavy oil in the oil sludge is converted into light oil through cracking in a high-temperature environment, and then the light oil is condensed and recycled.

Owner:NORTHEAST GASOLINEEUM UNIV

Hybrid pyrolysis system and method

ActiveUS11345859B2Efficient pyrolysisMechanical conveying coke ovensElectrical coke oven heatingSyngasThermodynamics

A system and method for performing pyrolysis comprises a reactor through which organic material is conveyed from an upstream end toward a downstream end and within which said pyrolysis will occur; a combustion chamber fluidically connected to the downstream end of the reactor; an output pipe fluidically connected to the downstream end of the reactor; a capsule surrounding a first part of the reactor and into an internal portion of which heated thermal fluids are disposed for heating the first part of said reactor; and a plurality of electrical resistors disposed around a second part of the reactor for heating the second part of the reactor; whereby, as a result of the pyrolysis occurring within the reactor, the syngas is conducted toward the combustion chamber while the carbonized material is conducted outwardly from the reactor through the output pipe.

Owner:BIOFORCE TECH CORP

Biomass pyrolysis charring and tail classifying and collecting method

InactiveCN106433710AEasy to collectImprove conversion utilizationPigmenting treatmentBiofuelsExhaust gasTar

The invention discloses a biomass pyrolysis charring and tail classifying and collecting method. The method is characterized in that biomass wastes to be treated undergo staged pyrolysis, carbon block separation and collection, dedusting, tar separation and collection, pyroligneous liquor separation and collection, and combustion gas compression and collection to form multiple useful byproducts. The method has the advantages of recycling realization, energy saving, environmental protection, and reduction of discharge of exhaust gas and wastes in production.

Owner:泰州瑞沣环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com