Organic garbage pyrolysis device and organic garbage pyrolysis treatment method

A technology of pyrolysis of organic waste, applied in special forms of dry distillation, petroleum industry, coke oven, etc., can solve the problems of easy coking in reactors, low pyrolysis efficiency, uneven heating, etc., and achieve reduction and harmlessness chemical, high-efficiency pyrolysis, and reduced thermal hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

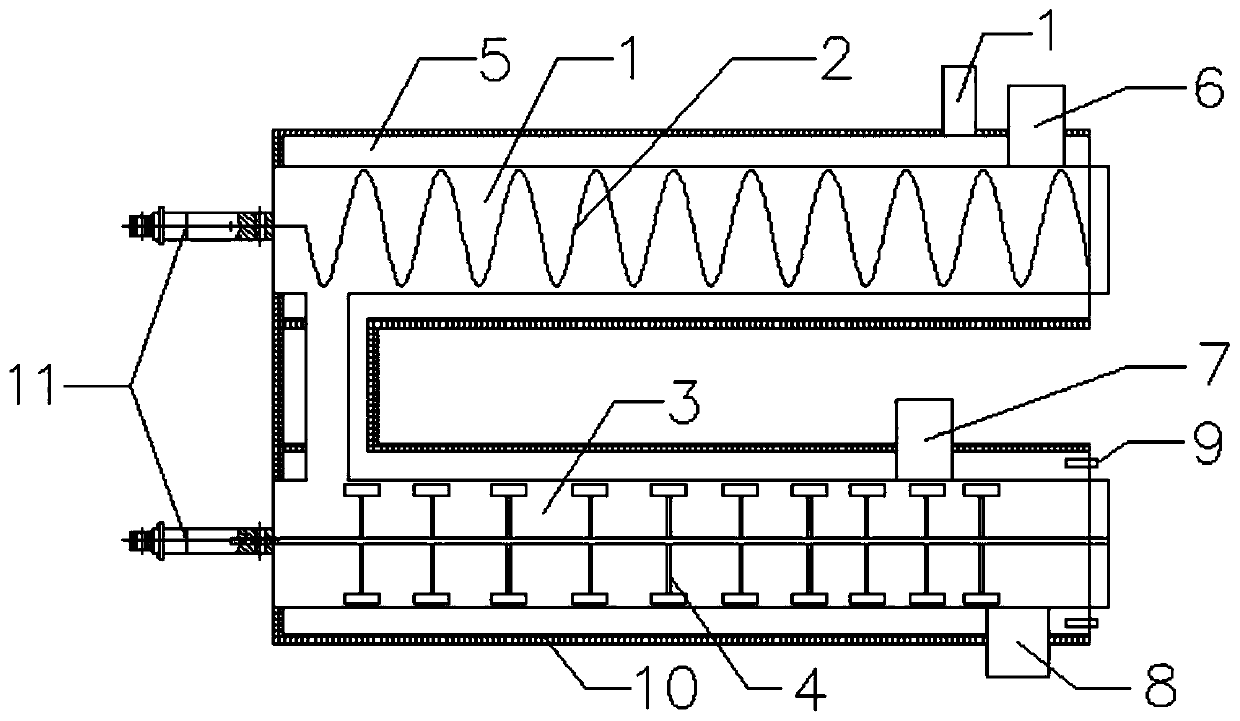

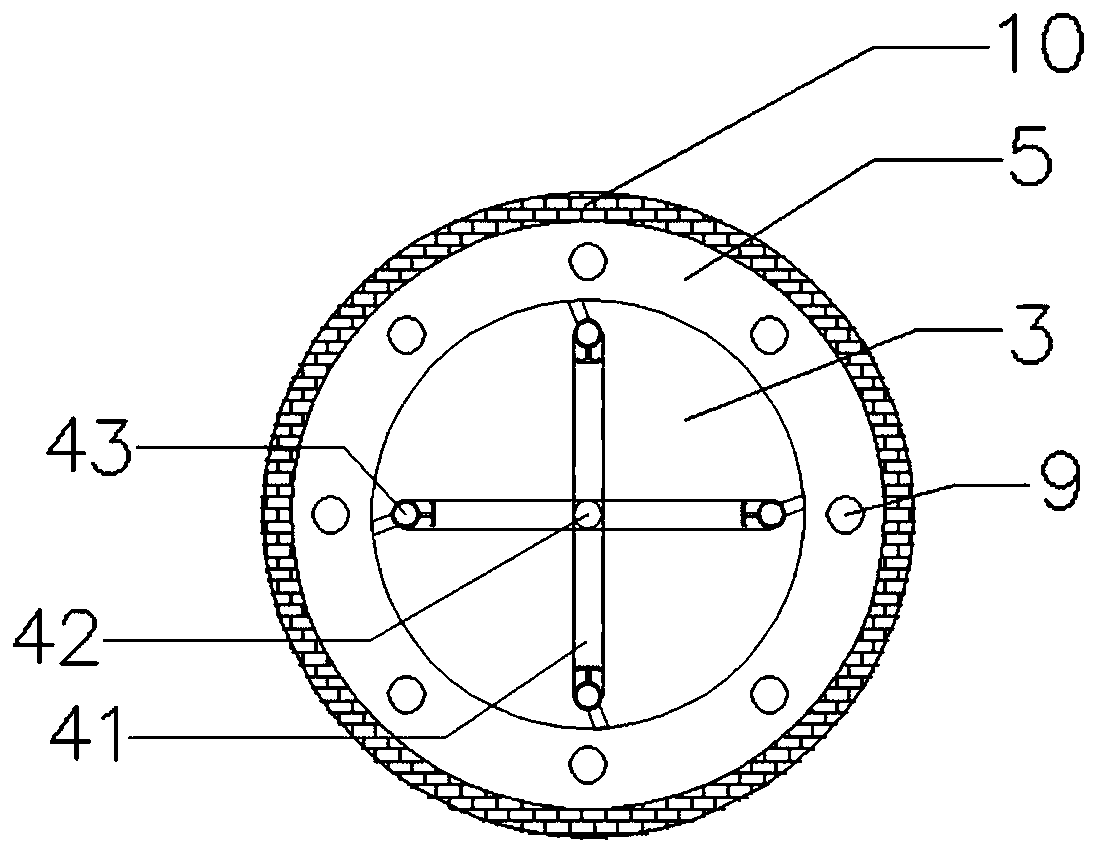

[0040] An organic waste pyrolysis device mainly includes a low-temperature pyrolysis chamber 1 , a high-temperature pyrolysis chamber 3 , a flue gas chamber 5 , an insulating layer 10 and a motor 11 .

[0041] There is a material inlet 6 on the top of one end of the low-temperature pyrolysis chamber 1, and the waste material enters the low-temperature pyrolysis chamber 1, where moisture removal, partial melting, and primary pyrolysis reactions mainly occur; The chamber 1 rotates to stir and convey the garbage materials. The distance between the spiral blade and the inner wall of the low-temperature pyrolysis chamber 1 is 2-5mm, and in this embodiment it is 2mm.

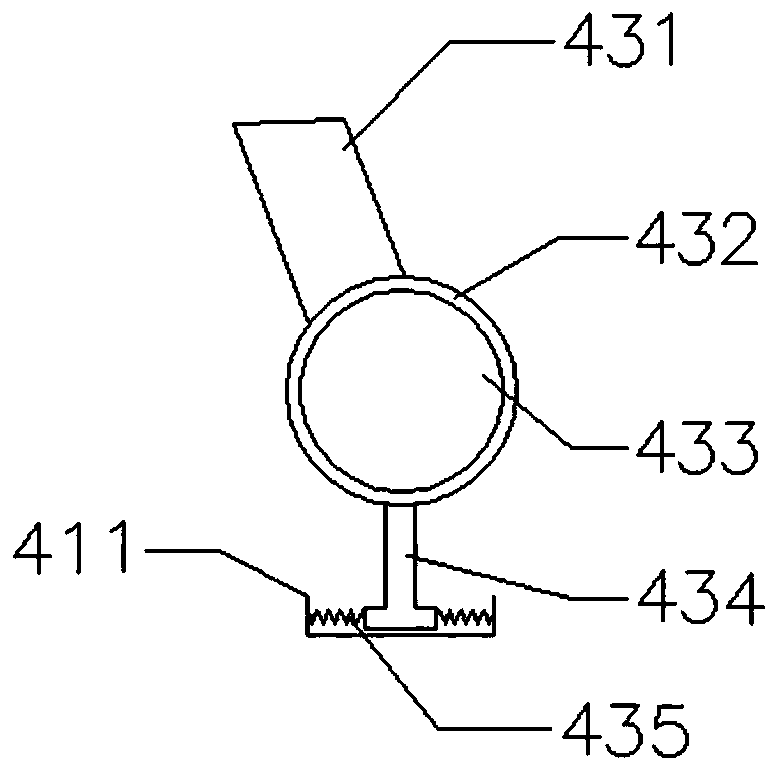

[0042] The far end of the high-temperature pyrolysis chamber 3 has a pyrolysis steam outlet 7 and a pyrolysis solid outlet 8, and there is a stirring coke scraper 4 inside. And the secondary cracking and polycondensation reaction of the primary pyrolysis product occurs; the stirring coke scraper 4 is composed of a sti...

Embodiment 2

[0052] Pyrolysis treatment process of an organic waste:

[0053] The specific components of domestic waste in a waste station are as follows:

[0054]

[0055] The process is as follows:

[0056] 1. After sorting and removing inorganic substances such as slag, broken glass, metal, etc., the garbage is crushed and sent to the low-temperature pyrolysis chamber of the pyrolysis device;

[0057] 2. In the low-temperature pyrolysis chamber, under the shaftless spiral stirring, the garbage is dehydrated, partially melted, and the primary pyrolysis reaction occurs;

[0058] 3. The pyrolysis products produced in the low-temperature pyrolysis chamber enter the high-temperature pyrolysis chamber, and under the agitation of the stirring coke scraper, further deep pyrolysis occurs, and secondary cracking and polycondensation reactions occur;

[0059] 4 The high-temperature pyrolysis steam generated by pyrolysis is exported from the pyrolysis steam outlet, and the pyrolysis solid is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com